#5 Ply Corrugated Box Making Machine

Explore tagged Tumblr posts

Text

High Speed Automatic Litho Flute Laminating Machine (QTM1450)

High Speed Automatic Litho Flute Laminating Machine (QTM1450)

The QTM series High Speed Automatic Flute Laminator is suitable for the lamination of printed cardboard paper with 3 ply or 5 ply corrugated sheet which is mainly used in food, beverage boxes etc.Get more news about litho flute laminator with stacker,you can vist our website! The machine adopts chasing registration method with the help of imported low-voltage parts, liquid sensor and motion control system.Get more news about litho flute laminator with stacker,you can vist our website!

4. Machine Structure: 1) Upper Feeding Part: Feed the paper of 120-450gsm. It can be thinner according to the size and quality of the paper. 2) Bottom Feeding Part: Feed different kinds of corrugated sheet between ABCEF 3&5 Ply. 3) Conveyor: Press the laminated paper and convey to the paper delivery unit. 4) Gluing Part: Coating glue on the bottom paper. 1) High speed feeder with 3 sucking suckers and 4 delivery suckers with the highest speed 15000 sheets per hour. High Speed Automatic Litho Flute Laminating Machine (QTM1450) 2) Double sucking rubber and single rubber forwarding which can avoid effectively double paper. 3) There are two side blowers as well. The position of the side blower can be adjusted to ensure the smooth feeding of paper. b. Top Paper Conveying Part: The conveying of the face paper unit adopts scale feeding method,Compared with paper to paper conveying,the advantage is that the conveying speed of face paper can be reduced,ensuring the smooth feeding of the paper when running in high speed, without worrying of the scraping of the paper by side lays and when the paper is uneven, the paper front will press the paper back to make the ahead paper even. d. Side Lays of top paper to ensure the precision at side-way There is a side lay device-puller on machine operation side for better guarantee the face paper side-way precision. There have 4 face paper sensors and 4 bottom paper sensors detecting the paper front edge positions, and two servo motors correct the laminating movement real-timely.

0 notes

Text

Top 5 Materials Used in Packaging Fitments

When you are designing a box, it’s equally important to look at the inner packaging fitments. These inserts or “things that go inside the box” are just as crucial as the outer box design. While the outer box packaging makes the solid first impression, it’s inner fitments are shouldering the responsibility for delivering the inside good with stability and security. They are ones which create a long lasting impact!

The quality of materials used in the fitments is the key differentiating factor in box quality. Poor choice of fitments can result in damaged products and flimsy boxes. Are you wondering, “What material should I use for the next box I need for my corporate event?”

We’ve got you! We have put together a list of the top five materials for inner packaging fitments. These materials have been rated on four key parameters:

Sustainability

Pricing

Strength

Customization

Let’s begin, shall we?

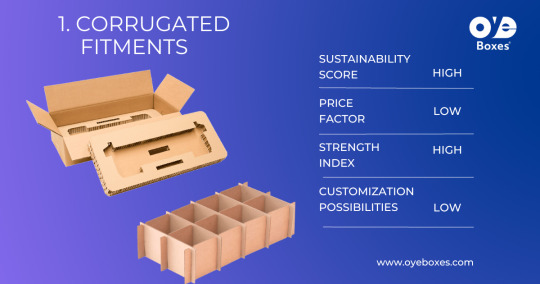

1. Corrugated Fitments:

Corrugated Fitments are the most commonly used materials in manufacturing of fitments and inserts. Depending on the use case, either 3 ply or 5 ply fitment sheets are used. Corrugated fitments are made of recycled materials and score high in terms of sustainability. They are usually 30% less expensive as compared to other materials, however you may have to buy them in larger quantities.

Corrugated fitments, inserts, and dividers provide a lot of sturdiness to the contents and can withstand rough transportation as well. They are ideal for products such as glass jars, machine parts, etc.

They have their limitations with respect to colour availability, however they can be offset printed for larger quantities or digitally printed for shorter quantities.

Here’s the rating chart for Corrugated fitments.

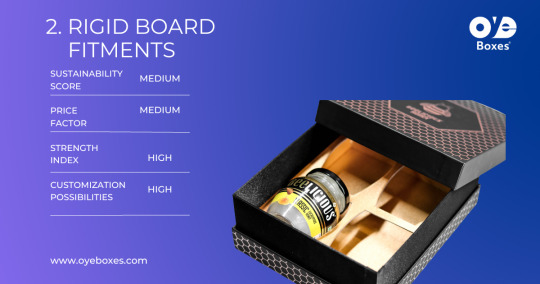

2. Rigid Board Fitments:

Rigid board fitments are an extremely popular choice when manufacturing fitments for packaging. Rigid fitments are frequently used in packaging for cosmetics, FMCG, jewelry, and other luxury items. Many times they are also used in conjunction with XLPE or EPE foam fitments.

Rigid board, commonly known in India as Putha Board, is made of recycled pulp and scores high in the sustainability index.

The price of rigid board fitments is slightly higher that of corrugated sheets. However, the strength and stability they provide is worth the higher price point. If we choose the appropriate thickness of board for making the fitments, then a very superior level of strength and stability can be achieved in the packaging.

The best part about rigid board fitments is that they are completely customizable. Any type of printed or colour sheets can be pasted on top of these rigid fitments.

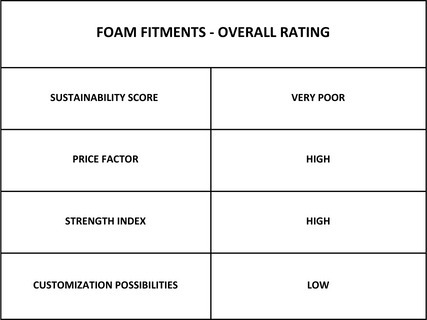

3. Foam Fitments :

Foam based fitments are widely used in packaging of glass, machine tools, and other high-value items. Currently, two of the most commonly available foam fitments are —- XLPE foam or EPE foam.

As expected, they don’t score well on the sustainability scale. They are harmful to the environment since they are non-biodegradable. But, they are the most sturdy and safe fitment option out there.

And, since they are the most sturdy option available in the market, their price is always on the higher side. We would like to highlight that XLPE foam fitments are 40% more expensive than EPE foam fitments.

Lastly, the customisation of these fitments is very expensive. They generally are available in few colour options – white, black, pink and blue. In order to customise them further, they need a layer of paper or paperboard on top of them.

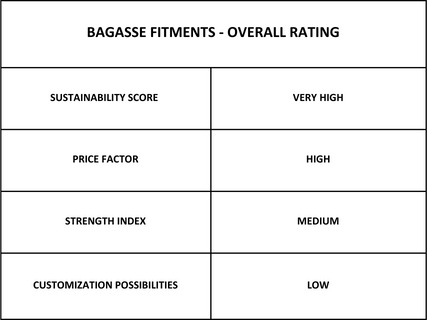

4. Bagasse Fitments

Bagasse is a dry fibrous residue that is generated after extraction of sugar from sugarcane. Nowadays, Bagasse is being used extensively in the making paper moulded fitments and dividers for various packaging applications.

You might be aware of bagasse plates and other recyclable cutlery that are widely used today. Bagasse fitments or inserts are slowly starting to trend in the packaging industry as well.

Bagasse is probably the most eco-friendly material amongst the entire list of fitments mentioned here. It is 100% recyclable. However, the costs associated with making a bagasse mould and then manufacturing these fitments is on the higher end when compared to other paper-based or plastic fitments.

Customization of colours in bagasse fitments is extremely difficult and require extremely large quantities to justify the expense. From a durability standpoint, bagasse fitments are sturdy enough to withstand pressure, however not as strong when compared to foam or rigid board fitments.

5. Paper Fitments :

Paper or paperboard fitments are the most pocket friendly fitment option (Probably 25% cheaper than rigid board). These are easy to source and manufacture. Paper fitments are generally made of recycled paper. But, it’s important to remember that they do not provide as much stability as other material options.

The parameter where paper fitments beats the competition is customization. All sorts of customizations are possible with paper fitments, including offset printing, digital printing, foiling, and embossing. So if you are looking for something really unique and tailored to your brand, then paper fitments might be your best bet.

#rigidboxpackaging#rigidboxpackagingfitments#packagingfitments#boxpackaging#CorrugatedFitments#RigidBoardFitments#FoamFitments#BagasseFitments#PaperFitments#luxuryboxpackaging

0 notes

Text

Super Corrugated Box Making Machine Manufacturer in India

Rnn india is branded or awarded in Print Media machines manufacturing which is now days Modern Technology using for manufacturing, best Corrugated manufacturer Box Making Machine, 5 Ply Corrugated Box Making Machine,5 Ply Automatic Corrugated Board & Box Plant,3 ply Corrugated Box & Board Making Machine, Automatic Corrugated Box Making Machine..etc.

0 notes

Photo

New Post has been published on https://www.vividracing.com/blog/top-5-best-intake-systems-for-your-polaris-rzr/

Top 5 Best Intake Systems for Your Polaris RZR

Polaris is arguably the world’s leader in side-by-side vehicles. The brand continues to break new ground with innovative performance to help riders push boundaries and explore new lands. Delivering superior control for unparalleled confidence, Polaris doesn’t just offer the ultimate riding experience – they define it. That reigns especially true for its highly popular Polaris RZR lineup. The Polaris RZR is known for delivering raw power paired with thrilling acceleration, and signature low-end torque that propels you to the front of the pack, and keeps you there. The Polaris RZR also boasts incredible levels of high-performance handling and agility to make it so responsive, it can practically guess your every move. Even so, there are certain modifications you can do to get the most out of your UTV and unleash its true potential so you won’t be constrained to factory limits.

For most enthusiasts, one of the first mods they do to their machines is upgrading the stock air intake system. That’s because the factory one is quite restrictive and could be holding your ride back from what it is truly capable of doing. That being said, the aftermarket houses a plethora of upgraded intake systems to let your Polaris RZR breathe freer, cooler air so that you can experience power gains across the RPM band as well as a better sound too. An upgraded air intake system also delivers enhanced styling to add some oomph to your UTV in a way that proves to be extremely functional and beneficial. You will find yourself riding more miles between filter servicing and enjoying enhanced acceleration and throttle response to transform your UTV experience.

We have compiled the following list (in no particular order) of the top 5 air intake systems for your Polaris RZR, based on factors like power gains, filtration properties, and overall construction. You can also browse our entire inventory of air intake systems for your Polaris RZR right here. If you have any further questions, please reach out to us by phone at 1-480-966-3040 or via email at [email protected].

1. Agency Power High-Flow Air Intake Kit

The Agency Power High-Flow Air Intake System for the Polaris RZR is one of the best upgrades you can do to help improve airflow from the intake to the engine. With this system, you will gain some respectable horsepower gains and notice improved drivability throughout your UTV’s entire RPM range. This kit features a roto-molded plastic tube design that faces the back of the vehicle, and includes a Polaris mesh-inspired cross brace and AP’s high-flow dry filters. The dry filter does not need to be oiled as its media has sub-micron diameters and small inter-fiber spaces which result in more contaminants being caught. This filter is completely reusable, allowing you to easily clean and maintain it between trips. The dual filters mount uniquely on the intake tubes to grab more air and offer great styling to boot.

The new Agency Power intake tubes and filters replace your Polaris RZR’s factory system that runs to the roof of the vehicle. This new design helps to increase airflow effectively while providing better filtration properties than the stock system. The high-performing intake tubes also feature a smooth interior to eliminate any turbulent air. AP strategically designed this system from the ground up to be a direct bolt-on replacement for the factory Polaris RZR intake. This simple upgrade is a must-have for those running aftermarket roll cages and need an air intake solution. On top of all that, Agency Power has thoroughly tested this system in real-world desert conditions to ensure it delivers the highest levels of reliability, performance, and longevity.

Features:

Lightweight Roto Molded XLPE Plastic Constructed Tubes

Dual Black Intake Tubes

Unique Filter Mounting

High-Flow and Reusable Air Filters

Get Gains of 8-11 Horsepower

Cross Bar Available in Matte Black, Gloss White, and Gloss Red

Bolt-On, Easy Installation

Buy It Here!

2. Agency Power Cold Air Intake System

The Agency Power Cold Air Intake System for the Polaris RZR is a great way to enhance the amount of airflow going from the intake to the turbocharger. This kit swaps out the stock corrugated rubber intake tube and paper mesh filter with AP’s durable silicone J-tube and high-flow reusable air filter. The J-tube and filter are direct replacements for the factory counterparts, allowing the use of the stock air inlet and box to protect and air in airflow. By adding the Agency Power CAI, you will notice gains in horsepower, torque, throttle response, and overall drivability almost instantaneously. Each and every component of this system was meticulously engineered to provide a reliable and long-lasting system that delivers proven results. As a simple add-on upgrade, this kit will prove to be successful in improving the overall performance of your Polaris RZR without any further mods needed.

The custom high-flow Agency Power filter features a blue mesh design (made of synthetic nano-fibers) with the AP logo and cap. The dry filter media does not need to be oiled and is completely reusable for your convenience. The silicone tube replaces the factory rubberized one and offers an easy installation between your UTV’s turbo and stock air box. It is made from 3-ply silicone material with a smooth inside that eliminates any turbulence caused by corrugated designs. The silicone intake is also much stronger than the Polaris RZR’s factory one, allowing it to hold up much better to harsh environments and off-road elements. Each silicone intake tube includes a MAP sensor port, crankcase breather port, and blow-off valve port to work with your UTV’s factory components.

Features:

3-Ply Silicone Construction

Stealthy Black Appearance

Also Available in Red and Blue

High-Flow, Reusable Air Filter

Simple Bolt-On Installation

Buy It Here!

3. K&N Performance Air Intake System

The K&N Performance Air Intake System will take your Polaris RZR to the next level by getting rid of the restrictive stock one to get the most out of your UTV. This air intake kit comes with dual K&N high-flow air filters and a lidded heat shield that installs into the previous air box space. Air is directed through dual free-flowing aluminum intake tubes into the Polaris RZR’s engine throttle body to deliver noticeable power gains. A high-density polyethylene (HDPE) rotationally molded tube helps to increase the amount of airflow to your RZR’s engine to deliver additional horsepower and torque. The custom heat shield helps to protect intake air from high temperatures in the engine bay to keep things running cool and optimally.

The system is paired with a washable and reusable high-flow air filter featuring oiled cotton filter media for the best filtration possible. The oversized cone-shaped air filters can be used for up to 100,000 miles before service is required, depending on overall driving conditions. This air intake is also relatively simple to install and can be done in just 90 minutes using basic hand tools. That’s because this system uses your UTV’s existing factory mounting points and includes a replacement silicone idle bypass hose for added convenience. It’s important to note, however, that the 57 series intake system is highway-legal in all 50 states, while the 63 series intake system is intended for off-road use only.

Features:

Guaranteed to increase horsepower and torque

Roto-molded HDPE intake tube paired with oversized oiled cotton air filter

Engineered to provide high airflow and exceptional filtration

Replaces factory air filter and intake tube

Filter only requires cleaning every 100,000 miles under normal driving conditions

A typical installation can be done in 90 minutes or less with simple hand tools

10-Year/Million Mile Limited Warranty™

Will not void vehicle warranty

Buy It Here!

Buy the Off-Road Version Here!

4. K&N Performance AirCharger System

The K&N 57 (highway-legal) and 63 (off-road use) AirCharger Air Intake System is intended to replace the restrictive factory air filter and air intake housing on Polaris RZR models. This package delivers proven increases in both horsepower and torque numbers for a more enjoyable ride that unleashes the true potential of your machine. K&N’s famous air intake kits are designed to dramatically reduce intake restriction as they smoothen and straighten the airflow your vehicle is taking in. Such allows your UTV’s engine to inhale a larger volume of air than the factory air filter assembly. And we all know that more air means more usable power and acceleration throughout the entire RPM range. K&N knows what it takes to deliver excellent filtration properties in an attractive and high-performing package, and this is no exception.

The K&N Performance Air Intake System includes a high-flow air filter, which is protected from the elements with an enclosed filter housing. Air is directed via a free-flowing aluminum intake tube into the engine’s throttle body for guaranteed power gains. The oversized conical high-flow air filter is both washable and reusable. It features oiled cotton filter media that is further protected by the enclosed filter housing for added defense against unwanted heat and elements. It can be used for up to 100,000 miles between servicing is needed, depending on your driving conditions. This package can be easily installed in about 90 minutes or less using standard hand tools. The 57 series is legal in all 50 states while the 63 series is not legal for use in California.

Features:

Guaranteed to increase horsepower and torque

Includes a Free-flowing aluminum intake tube

Designed to improve throttle response and engine sound

Engineered to provide high airflow and exceptional filtration

Filter only requires cleaning every 100,000 miles under normal driving conditions

Typical installation can be completed in 90 minutes or less with simple hand tools

10-Year/Million Mile Limited Warranty

Emissions Compliant – Legal in all 50 states

Buy It Here!

Buy the Off-Road Version Here!

5. AIRAID Powersports Air Intake w/ Snorkel & Scoop

AIRAID’s first-ever product was a filter that replaced the restrictive factory component. These were sold as intake system kits and were immediately met with heightened demand and popularity in the high-performance aftermarket. Using that, AIRAID expanded into optimizing air intakes across a wide spectrum of vehicles, including UTVs, to power drivers and explorers to adventure further and discover the full potential of their ride. The AIRAID Powersports Air Intake with Snorkel and Scoop for the Polaris RZR is a complete bolt-on replacement for the stock system and comes with all of the necessary hardware for a seamless installation process. No additional tuning is needed – just bolt it on and go on your way!

The AIRAID UTV air intake system is proven to deliver gains in horsepower with the added benefit of less required maintenance. The system starts with an AIRAID premium air filter to increase airflow and provide better filtration, especially in harsh environments. In addition to being a high-quality air filter, this one is fully washable and reusable for added convenience. Simply wash/clean it between rides for optimal performance and keep on riding! The unique AIRAID snorkel system in this package allows your machine’s intake air to be drawn from up high above, away from water and trail dust. Air restriction is addressed in the factory air box by replacing it with a new, one-piece roto-molded air box on many applications.

Features:

Increases horsepower and acceleration

Snorkel places the air inlet up away from water and dust

Secures air intake snorkels onto the roll cage

AIRAID premium washable and reusable filter

Complete bolt-on kit; Easy Installation

No Hassle Lifetime Warranty

Buy It Here!

Buy It w/o Snorkel Here!

0 notes

Text

Paper Corrugated Board & Box Making Machinery Manufacturers & Exporters

ABOUT SUPER SUJATA

We believe that the principle of mutual benefit - between countries, corporations, customers, employees and communities - is the most effective route to profitable and sustainable growth.

"Associated Industrial Corporation" was established in 1961 in Amritsar, India and specializes in the manufacturing and export of corrugated board and box making plants, paper mill machinery equipments, Paper Cutting Machines, binding, lamination, Platen Die Cutting/Punching Machines, stitching machines and related machines of these lines.

Our brand name "Super Sujata" command good respect in market due to quality of our product and prompt service back up. We have state of art manufacturing set up and all steps of production line are completed under one roof. From casting of machines to finished products, all steps are carried out in factory itself, having covered area of app. 12000 sqm.

We at "Super Sujata" are always ready to develop new machines or improve quality of our machines, as and when demanded by customers. We thank you for visiting our site and would request you to spare some time to fill 'contact us form' so as to enable us to feed your queries promptly, or you can mail us at [email protected]

#Corrugated-Box-Making-Machine#Corrugation-Plant-Machinery#3-5-Ply-Corrugated-Board-Plant-Manufacturers#Amritsar

0 notes

Photo

In Die Punching Machine, Impression Adjustment through two eccentric bushes. http://corrugatedboardmachines.com/

#oblique type corrugation machine#fingerless corrugation machine#die punching machine#single wall board plant#double single wall board plant#corrugated board plant#3 & 5 ply automatic paper corrugated#corrugated box making machine#automatic corrugated board plant#5 layer corrugated board plant#double profile paper corrugation machine#double wall board plant

0 notes

Text

B K Gears Pvt Ltd, Machinery Manufacturer Company in India

BKG machines has established in 1963. Since the foundation of the company it has reached to the new heights of success. We have established ourselves as a renowned manufacturer manufacturing of Industrial gears and High Precision Grinding. These machines are manufactured using high-grade raw material, which is obtained from the authentic and reliable vendors of the market. Moreover, the range of Dividing Head Slotting Machines offered by us is tested on various well-defined parameters to ensure their compliance with international standards. Corrugated Rollers. We offer quality range of Industrial Slotting Machines which find their extensive usage in several industries for perfect slotting planning of materials. These slot machines are highly demanded by our clients spread worldwide.

Corrugation Box Machines machine is widely used for making corrugated boxes in varied dimensions. Our engineers manufactured this High Speed Corrugation Machine of vertical types as per the clients' demands. These Vertical Type Corrugation Machines are made from high quality of raw material which ensures durability at its user end.

Our clients can avail from us these products at most competitive rates. Our wide variety of products includes Paper Board Cutting Machine, Reel To Sheet Cutter, Paper Cutting Machine, Corrugated Board Cutting Machine, Envelope Punching Machine, Box Stitching Machine, Book Stitching Machine, Double Profile Paper Corrugation Machine.

Fingerless Type Corrugation Machine provides perfect flute formation. Individual drive box, separating dynamic vibrations improve running stability. Pneumatic controls for corrugating roll load/unload, pressure roll load/unload as well as glue unit engaging and disengaging. Moreover, to ensure the compliance of the offered machines with the defined industry standards and quality parameters, these machines are tested on various levels by quality experts. Also we are providing these machines at leading market price.

Printer Slotter Machines Price machine is suitable to die-cut all kinds of corrugated cardboards and various different packages. The die-cutting machine which is made in China has the features such as high efficiency, energy saving, and safety. The machine is equipped with imported polyurethane carpet sets, which can be used more than 10 million times. The self-compensation of the linear speed can help ensure to die cut the needs cardboard after the polyurethane carpet sets are worn down.

#Corrugation box Machines#Oblique Type Corrugation Machine#Vertical Type Corrugation Machine#Fingerless Type Corrugation Machine#2 3 5 Ply Corrugation Plant#Box Making Machines#Semi Automatic Corrugation Plant#Printer Slotter Machines Price#Flute Laminator Machines Price#Sheet Pasting Machines

0 notes

Text

Automated Powder Auger Filler Packing Machine

Standard Single Beam Load Rails Track Bridge Overhead Crane Made In China

Corrugated box design is the process of matching design factors for corrugated fiberboard containers with the functional bodily, processing and finish-use necessities. Uncover a broad vary of sustainable, sturdy and protective packaging services adapted to your needs. air strain auxiliary cardboard drop, before the front and back of the cardboard field. A educated packaging specialist works with a customer to determine the strength required for the corrugated cardboard container being deliberate. The method begins by making corrugated board on a corrugating line, a long sequence of linked machines totaling the size of a football area. After being glued, the cardboard will likely be conveyed to be formed and picked up to be auto calculated as the preconcert quantity and auto mark withouot stopping manufacturing, construction: Management unit, paper feeding unit, paper transfer unit, glue spreading unit, forming unit, amassing unit. Cardboard or cardboard field manufacturing enterprise is a profitable enterprise in the USA, particularly with the ever-rising e-commerce stores. GMS Internationals is China’s leading professional provider and producer of corrugated machines. When the hot paper passes between the corrugating rolls, flutes lure and bend it to form the middle of the corrugated cardboard. Cardboard bins are the most affordable sort of packaging; moreover, the prices reduces when firms purchase cardboard packing containers in bulk from manufacturers. 8. Prices in equipment and tools, uncooked materials and the promoting prices of the completed products and so forth., are usually prevailing at the time of preparation of the undertaking profiles and should range relying upon varied components. QINGDAO AOPACK focuses on the on-demand packaging solutions and has developed a collection of box making machines with our personal Patents. Our easy-to-use machine is able to producing as much as one hundred different box styles, giving your small business flexibility on orders. Corrugated boxes are light-weight and easy to handle and transport. The feeder transmits the pre-printed and reduce cardboard from the paper shelf to the convey chain and the sends it to the shaping mold, during the process, the cardboard has been glued an you possibly can regulate the position of the gluing, the amount of gluing can be measured while in progress withour stopping phrase. Peterson, VPK’s Scandinavian packaging division, has launched more details of its new production website in Halden, Norway. From the flexo, the finished containers are automatically stacked and sent to a banding machine to be wrapped for shipping. It impacts the kinds of equipment obtainable to production lines, the measured laboratory efficiency, the field performance, and the ability of finish-customers to simply and safely open the box. Just lately subscription bins have caught-up in the eCommerce trade. Kite Packaging have grilled its technologists to tell us exactly what the process is for cleansing the raw supplies and processing them to make the cardboard containers you buy every single day for your online business. Paper and paper merchandise are versatile industrial raw materials with a wide variety of utility on this period and because of scarcity of softwood, wood packing circumstances are increasingly changed with corrugated board- containers and cartons. But it’s simple to neglect that the cardboard containers you use frequently had been once a not-so-humble tree. The other distinguished vendors in the market are Acme Machinery, Related Industrial, Box On Demand, DING SHUNG EQUIPMENT, EMBA Equipment, MarquipWardUnited, Mitsubishi Heavy Industries America, Natraj Industries, Packsize International, Serpa Packaging Solutions, Shanghai PrintYoung International Business, Shengli carton Tools Manufacturing, SOLAR Automation Group (Langston), SUZHOU KOMAL EQUIPMENT, T-ROC TOOLS, Valco Melton, and XINTIAN CARTON MACHINERY MANUFACTURING. gives 10,610 carton field making machine costs products. Their research and analysis focuses on rising market tendencies and gives actionable insights to assist businesses establish market opportunities and develop efficient methods to optimize their market positions. Many folding carton producers are working to incorporate technology to combat theft and counterfeit merchandise.

Excessive-Velocity Indirect sort Fingerless Corrugated Box making 2 ply machine connected with Servo Sheet Cutter. Paper bins haven’t any chemical reaction with meals and drinks in comparison with different containers; moreover, shoppers choose to retailer and stack cardboard boxes for their comfort. Minimized area occupied by stock corrugated boxes. Paper is fed into the corrugator, where it is steam-heated and pressed to kind corrugated cardboard. They’ll now create their own cardboard partitions simply to separate the delicate gadgets and at all times have the potential to supply the fitting dimension field at their fingertips. Different grades of paper comprise every layer that makes up a corrugated field. Due to the high quality and security of packaging gadgets in corrugated packing containers, they’re used widely in the food business. Additionally it is one of many many causes for firms to go for cardboard boxes because of growing demand for environment-pleasant packaging by consumers. The manufacturing of basic slotted bins is possible from single wall as much as triple wall board. High quality and the after promote service is our aim: we do not solely sell the merchandise but solutions. Nevertheless, the greenback value of the shipments has dropped marginally from $eight.7 billion to $8.5. The PPC (Paperboard Packaging Council) predicts that by 2020 the gross sales are anticipated to increase at a price of 0.3% and zero.5% in tons. It’s now probably the most advanced and multifunctional carton box making machine, offering all kinds of custom-made packaging options for finish customers in addition to box plants. Expert workers prepare job tickets for each stack of box blanks and route the blanks to fabrication machines. Considering firm branding and adventures, cardboard containers are good printing and graphics holding functionality. At the plant, layers of kraft paper are crimped and glued to kind corrugated cardboard, which is then reduce, printed, folded, and glued to make packing containers. We’ve more than ten years of experience in producing corrugated cardboard manufacturing line. After pulping and other processing, the fibers are sent directly to the paper machine the place they’re formed, pressed, dried, and rolled into the vast, heavy rolls of kraft paper despatched to corrugating vegetation to be made into cardboard. The demand for corrugated bins within the food and beverage and digital goods industries is predicted to increase throughout the forecast interval as a result of these two industries are the highest users of corrugated packing containers. With the rising recognition and demand from the net retail business, producers will start developing box making machines that assist the manufacturing of sensible packaging. Then a bending machine folds the boxes along the crease made by the corrugator, at the similar time making use of glue. Cardboard boxes are nice at producing excessive-high quality pictures holds prints longer than different packaging material. As the main carton sealing solution supplier, BestPack provides complete packaging solutions for a wide variety of trade purposes world wide. A flexo is a wide, flat machine that processes box blanks. On one hand, there is an increase in productivity but the average foundation weight of the corrugated board has declined marginally. A cardboard field is mainly made up of a flute (made up of recycled paper), sandwiched between two liners. Creasing and Die Chopping Machine is a special equipment for creasing and die slicing cardboard, corrugated board, plastic board and leather-based, and is widely utilized in printing, packaging and plastic industries. Cardboard boxes come underneath the packaging solution business section and producers produce a variety of products and bins in varied sizes and styles to meets right now’s market demands. The Compack Sequence is a extremely flexible field making machine obtainable in a number of configurations to satisfy your computerized packaging wants. This semi-computerized BOXMATIC Handbook machine is ideal for production of corrugated boxes, trays, partitions and reduce-out parts with the option of extra die-cuts and flexo printing.

One roll of cardboard is corrugated and then glued between two other layers. We’re fanfold cardboard factory with foreign buying and selling property, that is to say, we are able to produce the fanfold cardboard and we can export to clients by ourself. Because of the highly effective manufacturing capacity, low-price labor, and reliable provider, our carton box machine worth may be very competitive. As consumers are moving towards buying as a subscription, thereby obtain totally different products every time, the e-commerce companies have began producing specially design packing containers with a unique and placing design to draw more customers. All our packaging products are manufactured from recycled fibers. Committed to engineered high quality and manufacturing reliability for over 35 years, BestPack offers price effective and highly efficient automated and semi-automated case sealers, box erectors & box formers in addition to excessive speed case sealing machines with its unique tape sealing machine purposes encompassing a wide range of industries, including food and manufactured items. Out of each of these processes the Kraft is either used there after which and as mentioned earlier than is dark brown in color, or bleached in the course of the pulping process to provide a white Kraft. A completed piece of corrugated cardboard is comprised of a single corrugated layer sandwiched between two liners. Then, when a plant receives an order for containers, a product engineer specifies the mix of medium and liner to produce a cardboard to match the client’s requirement. One roll of cardboard is corrugated after which glued between two other layers (liners) by the same machine. Since the crash of 2008, the corrugated cardboard field market has elevated steadily. This can increase the demand for corrugated containers for packaging merchandise. BestPack is the innovation and customization knowledgeable for the packaging business throughout the globe, offering among the finest case sealers, box tapers & box erectors obtainable today. We offer a wide selection of paper processing machines, together with ice cream paper cone machine, computerized paper punching machine, paper cone cup machine, etc. On the finish of the corrugator, the cardboard is trimmed and minimize into large sheets, or box blanks, which then slide right into a stacker that masses them onto a platform. Clients recognize that outsized cardboard packing containers aren’t environmentally friendly and it has been identified to affect return gross sales. If I’ve to call 3 finest firms in paper product machine class, I would definitely pick SPB equipment for its sheer quality, dedicated support, and top-notch efficiency. Moreover, merchandise ordered by means of online platforms requires packaging at a number of levels including the vendor and the website. Moreover, the producers are expected to see rising demand for high-high quality graphics, customization, and distinctive box designs. The highest supplying nations or areas are China, Malaysia, and India, which supply ninety nine%, 1%, and 1% of carton field making machine respectively. Many start-ups are already incorporating marketing content material on their packages and customers agree that branded packaging has a positive effect on their product selection. The global inexperienced packaging market is driven by government and American customers who now have increased environmental awareness for all products together with paper packaging items. The primary process within the manufacturing of cardboard box together with course of the uncooked materials. Oct 08, 2019 (The Expresswire) – World Corrugated Field Making Machine Market complete analysis of the enterprise fashions, key ways, and individual market shares of a number of the most excellent players during this panorama. For instance, within the US, the Division of Transportation has jurisdiction and published requirements in Title 49 of the Code of Federal Regulations Corrugated containers are described in 4G requirements. Thus recycling of waste paper is in demand, which can be used to provide merchandise like paperboards, binding sheets, sweet box cartons and different packing cartons.

The supplied merchandise are examined in terms of quality to ship solely defect less vary from our aspect. Since then, pulp processing, paper making, and corrugating operations have been developed to a excessive state of efficiency and productiveness. We hope that our worth for cash products will enable you in growing your enterprise for a few years to return. This corrugated cardboard field making machine with excessive efficiency has handed the CE certification. We have been an energetic company with large marketplace for Used Paper Egg Carton Making Machine, The product will provide to everywhere in the world, such as: Suriname , Curacao , Rome , We warmly welcome home and abroad clients to visit our company and have enterprise discuss. Explore the detailed product pages to seek out all you need to learn about any box making machine. Kraft and Test paper can also be used to create the fluted paper in between liners which finally create a robust board. We comprehend the fact that majority of import companies in are energetic in sourcing distinct ranges of merchandise together with raw supplies, equipment and client goods and so on. Next, you must procure machinery, which will range depending on the type of box you wish to manufacture. offers 57,111 carton field making machine merchandise. There are 10,610 carton box making machine costs suppliers, mainly situated in Asia. A brief information to cardboard boxes by Kite Packaging. All Boxmatic machines might be outfitted with two or three-out manufacturing and up to three sensible flexo print units. Recycling and other environmentally friendly processes will proceed to grow in significance in the future of corrugated cardboard. In-home making of corrugated bins contributes to discount of outsourcing prices. Our professionals are reduce prices,dynamic gross sales crew,specialised QC,sturdy factories,fine quality companies and products for Corrugated Carton Field Making Die Cutter Machine (ML-1600), The product will supply to all over the world, comparable to: Albania , Sheffield , Swansea , “Make the women extra enticing “is our sales philosophy. Most typical varieties of containers in demand include mono cartons, normal box, massive box, packing containers in 2,3,5,7, ply. All kinds of carton field making machine prices choices can be found to you, akin to beverage. One other 6 million tons of uncorrugated boxboard or paperboard have been also produced for use in folding cartons. Corrugated box making machine is a equipment used to creating corrugated bins. The machines discover their method to various market sectors: from agricultural to industrial use in meals and non-meals sectors. At present, within the corrugated cardboard business, designers are creating innovative containers that require four-color printing and complex die-reducing. On the fundamental of Corrugated Field Machine BM2508, it adds the perform of die-slicing handle holes on each side of the carton field. A semi-automatic cardboard field producing machine will cost your roughly $ 120,000, whereas full-scale manufacturing plan will cost you $ 180,000. Cardboard box making machines include a large host of advantages that optimize your box-making course of. The lifetime of a carboard box by Kite Packaging. The know-how is fairly slicing-edge for the cardboard field trade. Different uncooked supplies are used to finish the corrugated cardboard after manufacturing. It may possibly additionally provide probably the most appropriate corrugated packaging box on demand for furniture, hardware equipment, e-commerce logistics and other industries. It’s now quite common for these liners to also be made up of a considerable proportion of recycled content material, sourced from previous cardboard or different sources of second hand paper. I utterly advocate SPB machinery to anybody looking to purchase machines. For more data on corrugated boxes, click on right here to browse our sources. 1 Manufacturing a corrugated cardboard field begins with the pulping of wooden chips within the kraft (sulfate) course of.

The post Automated Powder Auger Filler Packing Machine appeared first on Diy Script.

from WordPress https://ift.tt/39LwaqY via IFTTT

0 notes

Text

Best Second Hand Corrugated Box Making Machine in India

Rnn India is a corrugation Machine Manufacturer Company which is also dealing in old or Second Hand Corrugated Box Making Machine. This is providing with best maintenance for Corrugated Box Making Machine , Used 5 Ply Corrugated Board & Box Making Plant are extremely easy to recycle and minimize their effects on the environment.

Rnn India - Natraj Corrugating Machinery Company

Delhi Office:

(+91)- 9810275497, 9810075497

0129-4109400

Shed No. 12, Scheme 1, Phase II, DSIDC, Okhla Ind. Area, New Delhi, India 11002

http://www.rnnindia.in/

http://www.rnnindia.in/stitching-machine.html

0 notes

Link

0 notes

Text

Corrugated Machine for Making Box & board 3 Ply and 5 Ply

It is a well known fact that corrugation machine manufacturers in India sell more units of packaging material production systems than anywhere else in the world. People often ask why a company or brand in India would get a separate tremendous unit for manufacturing packaging materials and boxes, when there are many separate enterprises offering the same services at a comfortable industrial price. The answer protest understanding certain factors typical to the Indian market, and what brand protection really means in such a massive country.

While any product in the market is recognized through its brand identity and trademarked packaging; designs are easy to copy. Even the smallest detail and most sophisticated holographic labels can easily be duplicated if a person has the initial design. This is why it is difficult for a consumer brand to trust another company with their trademark designs and logos. Any leak of such data would advance counterfeiters allow copy the original packaging and filling the carton with dubious products. This cause a loss of brand value and major losses for the original company. Sadly, this has happened far too often in India.

Apart from retail and consumer brands, magnificent Corrugated Machine Manufacturers also sell to large manufacturing plants and industrial production units across the country. These companies have their own corrugated board making departments to ensure that they always get their necessary supply of packaging materials close at hand. The larger industrial enterprises can afford to have a separate unit within their assembly; but cannot afford to fold if their outsourced supplier is somehow unable to stand to commitments and deadlines!.

Most Corrugated box Making Machines is usually either 3 ply or 5 ply systems; though there are 7 ply systems available with the biggest traders in this business. Though there are only a handful of corrugation machine manufacturers in the country, the demand for these units is constant. There are also several companies who specifically manufacture packaging cartons for the food, cosmetics, or pharmaceuticals industry. As new mechanisms and processes are integrated, the units are even upgraded with more functions. This includes additional roller units and cutting systems, the latest in laser and computer controlled dies, besides several new heater and pasting systems. Managing such a large and multi-tasking industrial unit means need maintain a separate workforce, a separate department, and a separate list of suppliers.

A corrugation machine is not the most complicated of industrial machines, but they are quite large and heavy duty. It takes a lot of industrial space, a team of attentive workers, and a steady supply of raw materials to keep producing 5 Ply Corrugated Box Making Machine. These units also need regular repairs and maintenance by skilled technicians accordingly to time. This is why, although the massive supplies of corrugated surround the market; companies owning such sizable machines always have a list of clients eagerly forecast their packaging supplies.

Looking for one of India's top printing and die cutter, folder unit, or corrugation machine manufacturers? Micro Mechanical Works has been one of India's fine producers of industrial packaging.

#Corrugated Box Making Machine#5 Ply Corrugated Box Making Machine#3 ply Corrugated Box & Board Making Machine#Used Corrugated Machine

0 notes

Text

Corrugated machines and plants for manufacturing of 3 Ply and 5 Ply corrugated boxes, Die Cutting Machines, Paper Cutting Machines, Binding Machines etc.

Corrugated Board and Box Making Machine offers various types of corrugated board and box making machine such as, single color flexo printing machine, box stitching machine, sheet pressing machine, oblique type single face paper corrugating machine, verticle type single face paper corrugating machine, double profile single face corrugation machine, and to name a few

0 notes

Photo

In Oblique Type Paper Corrugation Machine, flute rolls are minutely finished and mounted on spherical Roller Bearings, to give perfect impression on Board

http://corrugatedboardmachines.com

#oblique type corrugation machine#fingerless corrugation machine#die punching machine#single wall board plante#double single wall board plante#corrugated board plant#3 & 5 ply automatic paper corrugated#double feelfile paper corrugated#corrugated box making machine#automatic corrugated board plant#3/5 ply automatic corrugated board plant#5 layer corrugated board plant#double profile paper corrugation machine

0 notes

Text

BKG is the best top machine manufacture Company

This corrugation box manufacturing plant is exclusively designed and manufactured to meet the functional requirements effectively & economically. Simple in design, strong in construction, easy to operate and is assured of faultless working during continuous operation. The Corrugation box Machines are strong in development and simple to handle. This strong machine is exceptionally rumored for accuracy and quality. We offer High Speed Paper Corrugated Box Making Machine that is highly efficient and has increased production level over the vertical model.

Oblique Type Corrugation Machine offers high rate of production and enhanced efficiency. The flute rollers are mounted on bearings for smooth running & impart proper impression on paper. The rollers are bush mounted electric heaters are provided for appropriate is provided with manually operated twin shaft reel stand. The variable speed motor is recommended for better quality & economy in wastage at an additional cost. The machine is designed with huge motorized reel stand that has a capacity of lifting 2-ton reel at a time. Owing to the flute rollers that are mounted on bearings, it provides smooth functionality and reliable performance.

Vertical Type Corrugation Machine is designed with latest technology and is mounted with electric heaters that ensure appropriate conversion of the paper to 2 ply corrugated sheets. The fair pricing, further makes them true value for money. Motorized self loading reel stand is additionally provided with the machine, the output of machine is approximately 50 rft per minute. Additionally, our machines are provided with the option of attaching it with paper reel to sheet cutting machine for better accuracy. This machine is simple to operate and is equipped with manual loading reel stand. The variable speed motor is recommended for better quality & economy in wastage at an additional cost & bull.

#Corrugation box Machines#Oblique Type Corrugation Machine#Vertical Type Corrugation Machine#Fingerless Type Corrugation Machine#2 3 5 Ply Corrugation Plant#Box Making Machines#Semi Automatic Corrugation Plant#Printer Slotter Machines Price#Flute Laminator Machines Price#Sheet Pasting Machines

0 notes

Text

Compack Sequence Box Making Machines

How a cardboard field is made at Kite Packaging. The provided products are examined in terms of quality to deliver only defect less range from our aspect. Since then, pulp processing, paper making, and corrugating operations have been developed to a excessive state of efficiency and productiveness. We hope that our price for cash products will provide help to in rising your small business for many years to come. This corrugated cardboard field making machine with high performance has handed the CE certification. We have been an energetic company with extensive marketplace for Used Paper Egg Carton Making Machine, The product will supply to all over the world, akin to: Suriname , Curacao , Rome , We warmly welcome home and abroad customers to visit our firm and have business speak. Discover the detailed product pages to search out all that you must learn about any field making machine. Kraft and Check paper is also used to create the fluted paper in between liners which lastly create a robust board. We comprehend the fact that majority of import companies in are lively in sourcing distinct ranges of merchandise together with uncooked supplies, equipment and shopper items etc. Subsequent, you have to procure equipment, which can differ depending on the kind of field you need to manufacture. presents 57,111 carton field making machine products. There are 10,610 carton box making machine prices suppliers, mainly situated in Asia. A brief guide to cardboard boxes by Kite Packaging. All Boxmatic machines might be equipped with two or three-out manufacturing and as much as three sensible flexo print items. Recycling and different environmentally pleasant processes will continue to grow in importance in the way forward for corrugated cardboard. In-house making of corrugated containers contributes to discount of outsourcing costs. Our execs are lessen prices,dynamic sales staff,specialised QC,sturdy factories,fine quality companies and products for Corrugated Carton Box Making Die Cutter Machine (ML-1600), The product will supply to everywhere in the world, equivalent to: Albania , Sheffield , Swansea , “Make the women extra engaging “is our sales philosophy. Commonest types of containers in demand embrace mono cartons, customary box, large box, containers in 2,three,5,7, ply. A wide variety of carton field making machine prices choices can be found to you, reminiscent of beverage. Another 6 million tons of uncorrugated boxboard or paperboard were additionally produced to be used in folding cartons. Corrugated box making machine is a gear used to making corrugated packing containers. The machines find their method to numerous market sectors: from agricultural to industrial use in meals and non-meals sectors. At present, within the corrugated cardboard trade, designers are creating innovative containers that require four-color printing and sophisticated die-slicing. On the primary of Corrugated Box Machine BM2508, it provides the function of die-chopping handle holes on both sides of the carton field. A semi-automated cardboard box producing machine will price your roughly $ one hundred twenty,000, whereas full-scale manufacturing plan will cost you $ one hundred eighty,000. Cardboard field making machines come with a massive host of advantages that optimize your field-making process. The lifetime of a carboard field by Kite Packaging. The know-how is pretty reducing-edge for the cardboard field business. Other uncooked materials are used to finish the corrugated cardboard after production. It may well also present the most suitable corrugated packaging field on demand for furniture, hardware equipment, e-commerce logistics and different industries. It is now quite common for these liners to also be made up of a substantial proportion of recycled content, sourced from old cardboard or other sources of second hand paper. I utterly suggest SPB equipment to anybody seeking to buy machines. For more data on corrugated containers, click on here to browse our resources. 1 Manufacturing a corrugated cardboard box begins with the pulping of wood chips in the kraft (sulfate) course of.

High-Velocity Oblique kind Fingerless Corrugated Box making 2 ply machine hooked up with Servo Sheet Cutter. Paper bins haven’t any chemical reaction with food and beverages in comparison with other containers; furthermore, customers desire to retailer and stack cardboard boxes for his or her comfort. Minimized space occupied by inventory corrugated boxes. Paper is fed into the corrugator, where it’s steam-heated and pressed to kind corrugated cardboard. They can now create their very own cardboard partitions easily to separate the fragile items and all the time have the potential to produce the correct size box at their fingertips. Different grades of paper comprise each layer that makes up a corrugated field. Due to the quality and safety of packaging gadgets in corrugated containers, they are used broadly within the meals trade. It is also one of many many reasons for firms to opt for cardboard bins due to growing demand for atmosphere-pleasant packaging by shoppers. The production of primary slotted bins is possible from single wall as much as triple wall board. High quality and the after promote service is our goal: we do not only sell the merchandise but solutions. Nonetheless, the greenback value of the shipments has dropped marginally from $eight.7 billion to $eight.5. The PPC (Paperboard Packaging Council) predicts that by 2020 the sales are anticipated to increase at a fee of zero.three% and 0.5% in tons. It’s now probably the most advanced and multifunctional carton field making machine, providing every kind of custom-made packaging options for end users as well as field plants. Skilled staff put together job tickets for every stack of box blanks and route the blanks to fabrication machines. Contemplating company branding and adventures, cardboard packing containers are good printing and graphics holding functionality. At the plant, layers of kraft paper are crimped and glued to form corrugated cardboard, which is then cut, printed, folded, and glued to make bins. We’ve got greater than ten years of experience in producing corrugated cardboard production line. After pulping and different processing, the fibers are despatched directly to the paper machine the place they’re shaped, pressed, dried, and rolled into the wide, heavy rolls of kraft paper despatched to corrugating vegetation to be made into cardboard. The demand for corrugated packing containers within the food and beverage and digital items industries is predicted to extend in the course of the forecast interval because these two industries are the top customers of corrugated bins. With the growing reputation and demand from the web retail trade, producers will start developing field making machines that support the manufacturing of good packaging. Then a bending machine folds the boxes alongside the crease made by the corrugator, on the same time applying glue. Cardboard packing containers are great at producing excessive-quality photographs holds prints longer than other packaging material. Because the leading carton sealing resolution supplier, BestPack provides comprehensive packaging solutions for a wide variety of trade purposes all over the world. A flexo is a large, flat machine that processes field blanks. On one hand, there is a rise in productivity however the common foundation weight of the corrugated board has declined marginally. A cardboard field is principally made up of a flute (made up of recycled paper), sandwiched between two liners. Creasing and Die Slicing Machine is a particular equipment for creasing and die reducing cardboard, corrugated board, plastic board and leather, and is extensively utilized in printing, packaging and plastic industries. Cardboard packing containers come below the packaging answer enterprise phase and manufacturers produce quite a lot of products and boxes in varied sizes and shapes to meets today’s market calls for. The Compack Series is a highly flexible box making machine available in a number of configurations to meet your automatic packaging needs. This semi-automatic BOXMATIC Guide machine is right for manufacturing of corrugated bins, trays, partitions and reduce-out elements with the option of additional die-cuts and flexo printing.

used c purlins for sale

The post Compack Sequence Box Making Machines appeared first on Diy Script.

from WordPress https://ift.tt/2Q0G29p via IFTTT

0 notes

Text

Field Equipment

6 Ton Light Duty Gantry Crane For Sale 1232131

Corrugated field design is the process of matching design factors for corrugated fiberboard bins with the practical bodily, processing and end-use requirements. The provided merchandise are tested by way of quality to deliver only defect less vary from our side. Since then, pulp processing, paper making, and corrugating operations have been developed to a high state of efficiency and productiveness. We hope that our worth for money merchandise will make it easier to in rising your enterprise for many years to come. This corrugated cardboard field making machine with excessive efficiency has passed the CE certification. We have been an brisk corporation with broad marketplace for Used Paper Egg Carton Making Machine, The product will supply to all over the world, reminiscent of: Suriname , Curacao , Rome , We warmly welcome home and overseas prospects to go to our firm and have business discuss. Explore the detailed product pages to search out all you might want to know about any box making machine. Kraft and Take a look at paper can be used to create the fluted paper in between liners which lastly create a strong board. We comprehend the truth that majority of import companies in are lively in sourcing distinct ranges of products together with raw supplies, machinery and consumer items and so on. Next, it’s important to procure equipment, which is able to differ depending on the type of box you wish to manufacture. offers fifty seven,111 carton box making machine products. There are 10,610 carton box making machine costs suppliers, primarily positioned in Asia. A quick information to cardboard bins by Kite Packaging. All Boxmatic machines can be outfitted with two or three-out production and as much as three sensible flexo print units. Recycling and different environmentally pleasant processes will proceed to grow in importance in the way forward for corrugated cardboard. In-home making of corrugated containers contributes to reduction of outsourcing prices. Our execs are lessen costs,dynamic gross sales group,specialised QC,sturdy factories,high-quality companies and products for Corrugated Carton Box Making Die Cutter Machine (ML-1600), The product will supply to all around the world, resembling: Albania , Sheffield , Swansea , “Make the women more enticing “is our sales philosophy. Most typical sorts of boxes in demand embody mono cartons, commonplace box, large field, packing containers in 2,three,5,7, ply. All kinds of carton box making machine costs options can be found to you, resembling beverage. One other 6 million tons of uncorrugated boxboard or paperboard were additionally produced to be used in folding cartons. Corrugated field making machine is a gear used to making corrugated packing containers. The machines find their option to various market sectors: from agricultural to industrial use in meals and non-meals sectors. At present, within the corrugated cardboard business, designers are creating innovative containers that require 4-colour printing and complicated die-reducing. At the fundamental of Corrugated Box Machine BM2508, it adds the function of die-cutting handle holes on both sides of the carton field. A semi-automated cardboard field producing machine will value your roughly $ a hundred and twenty,000, whereas full-scale manufacturing plan will cost you $ a hundred and eighty,000. Cardboard field making machines come with an enormous host of advantages that optimize your box-making course of. The lifetime of a carboard box by Kite Packaging. The know-how is fairly slicing-edge for the cardboard box trade. Other uncooked supplies are used to complete the corrugated cardboard after manufacturing. It can also present essentially the most appropriate corrugated packaging box on demand for furniture, hardware accessories, e-commerce logistics and different industries. It’s now quite common for these liners to also be made up of a considerable proportion of recycled content, sourced from old cardboard or other sources of second hand paper. I utterly suggest SPB equipment to anybody seeking to purchase machines. For extra data on corrugated containers, click on right here to browse our assets. 1 Manufacturing a corrugated cardboard field begins with the pulping of wooden chips within the kraft (sulfate) course of.

On account of their high quality, stable efficiency and lengthy service life, our products are wanted by prospects in Spain, Chile, Venezuela, Greece, Honduras, Malaysia,the Philippines, Russia, etc. Finally, the offcuts of paper is recycled and used to provide more packing containers and different paper products, many corrugators now produce bins in probably the most eco-friendly manner possible to make sure that their processes are carbon-neutral. The potential for cardboard field manufacturing is large; practically all industries want some time of cardboard packaging and the booming e-commerce industry might be the largest consumers of cardboard boxes. Almost 81% of the packaging in any trade is completed utilizing corrugated cardboard boxes and has the most important market share in e-commerce, logistics, cosmetics, prescribed drugs, and footwear business. The slowdown in the oil and gasoline business augmented the slowdown in demand for shopper and industrial merchandise, which in turn, hit the packaging industry on this region. Corrugated paperboard accounts for greater than half of all the paper recycled within the US. S & G Options is proud to deliver this exciting line of boxmaking machinery to the U.S. and Canada, offering a solution that’s precise, sturdy and simple to function. It’s designed on the premise of corrugated field machine BM2508, which removes the slotting operate, remains creasing and chopping capabilities. The size of a field might be measured for either internal (for product fit) or exterior (for dealing with machinery or palletizing) dimensions. View our sustainable box making machine solutions, software, consumables and companies below, and please contact us to talk with our corrugated field making machine producers with any questions you’ll have. Our cardboard field machines have only a sixty second setup time and are designed with the user in thoughts. 12 On the finish of corrugator, a slitter-scorer trims the cardboard and cuts it into large sheets called field blanks. SHH-B2 excessive speed computerized paste field machine possesses the SHH-800 and SHH-B all functions, Used imported electrical appliances, and accessories for export with a rubber curler Paper could be pressed collectively by the processes as well as possesses the features of beautiful modeling, high speed and might made extra broad boxes and so on, It is important equipment in packing printing trade. The demand for products from numerous industries that will gas the growth of the packaging industry is the major factor fueling the expansion of the distributors within the corrugated field making machines market. Allow us to enable you to make the most of our value-added merchandise choices to meet the demanding wants of your native market and prospects. About 28% of these are paper product making equipment, 16% are packaging line, and thirteen% are carton printing slotting die-chopping machine. The worldwide corrugated box making machine market is predicted to grow at a CAGR of greater than 2% through the forecast interval, 2017-2021. As an end-user, you may discover that our box making machines give companies of all sizes greater management over their packaging process. All our Boix tray forming machines with their specification for the best packaging options for your merchandise. Expertise is endlessly altering, and so are our suppliers and Carton Field Making Machine who all the time preserve their standards high and has fostered innovation in all the things they do. From their methods and finish products to how that are preserving and protecting the setting. Finished bins are then stacked and sent to a banding machine to be wrapped and shipped. Grain route of the paperboard – Right grain course will enable easy printing, automated gluing, scale back bulge, and cut back shrinkage. Our packaging will defend your merchandise, while taking care of the setting. With customized graphics for labels, folding cartons, corrugated displays and more, our group will guarantee your product stands out. Zhejiang Guangya Equipment Co.,Ltd is an expert manufacturers of scorching foil stamping and die reducing machine with lengthy history.Since its establish we have now at all times insisting on the coverage of Achieved success by high quality,Integrity is base,also pay attention to new product growth and continuous designing machine, we undertake high and new technology from house and merchandise may be very popular in home market and already exported to over 70counteirs or region resembling Europe,North America,Middle East and so forth.

Designed to be robust, they are comprised of corrugated paperboard, which accommodates air columns. We have now a gentle uncooked materials provide chain and produce most elements of the machines in-home. The paperboard and cardboard industry demand been relatively stable for the previous 5 years. The corrugator machine cuts each board various occasions, depending on the size of the field. Originally of this course of, kraft rolls from the paper mill are loaded into an enormous machine called a corrugator. The cardboard box manufacturing industry is the most important paper-converting industry in the USA. Corrugated bins are used for packaging consumer and industrial goods. It is not just , but other homegrown e-commerce corporations are also using cardboard packages over plastic packaging. Depending on the required strength of the box, corrugated bins may be made of 1, two, or three layers of flutes and liners. Integrated within the year 2009, we Krishna Gross sales Corporation” are counted as the reputed producer and trader of Corrugated Field Making Machine, Rotary Die Reducing Machine, Corrugated Carton Making Machine, Corrugated Board Plant, and so forth. Compack machines might be set up as a single feed, an inline feed (with up to 4 automatic, uncooked material sources feeding into the machine), or as a lateral (side by facet) feed with as much as 4 computerized corrugated feeds. In brief, it’s important to comply with the Air Pollution Prevention and Control Act, requirements and regulation and even food-related laws if you’re producing boxes for the meals industry. Design & Manufacturing of Corrugated Packaging & Displays. Whether you are a box plant, or an end-user trying to create custom containers in-house, our machinery is cutting-edge and will cater to your needs. When manufacturing packing containers we talk about two several types of liners, this is the fabric that lies on top and beneath the fluting and creates a corrugated board. The CORRUGATED FIELD MAKING EQUIPMENT import trade sector contributes considerably to the overall GDP proportion of India. Furthermore, with the sustainability difficulty on the rise, we are able to anticipate even more packaging firms sooner or later who will convey unique designs and produce a wide range of bins from quite a lot of paper material. Cardboard Help is a participant within the Amazon Providers LLC Associates Program, an affiliate promoting program designed to provide a way for websites to earn promoting charges by promoting and linking to Cardboard Help additionally participates in affiliate applications with Clickbank, CJ, ShareASale, Homedepot and different websites. Being a B2B business, you will have permanent prospects who will need packing containers on a regular basis. He named it the kraft course of because it produces a robust paper that resists tearing, splitting, and bursting. It has paper feeding unit, adjusted unit, glue unit, forming unit, completed products gathering unit and in addition counting unit. As a result of this machine is so fast to set up it ends in very low value packing containers of the very best grade for each small and huge runs. In case of continuous manufacturing it solely takes 30 seconds per box. The Corrugated & Paperboard Container Business: An Analysis of Current Markets & Prospects for Future Progress. We provide six totally different paper cup machines SPB seven hundred, SPB 750, SPB 850, SPB Super 850, SPB 950, SPB Tremendous 950. The growing consumption of food throughout globe that fuels the growth of the meals packaging industry and the growing demand for food and beverage products that may drive the demand for corrugated packing containers, will augment the expansion prospects of the market on this phase. Contemplating today’s state of affairs, it is safe to say that cardboard box manufacturing is a profitable business. In comparison with plastics, styrofoam and different materials, the folding carton and corrugated cardboard containers are thought-about to be a greater inexperienced packaging resolution by the customers. Over past four years, we have now invested over 1 Million dollars to develop our competitive field machines, it contains BM2506 small field making machine, BM1206 short run field making machine, and BM2508 cardboard box making machine.

The corrugated box making machine market in EMEA saw a decline in demand for corrugated bins during 2012-2015 within the wake of low crude oil costs, which led to the overall economic slowdown within the Middle East region. It’s now probably the most advanced and multifunctional field making machine, offering all types of personalized packaging options for finish users as well as box vegetation. The 2 liners are then adhered to the board by the machine; the cardboard is then lower each side with a round noticed to present the board straight sides. Well-liked for his or her energy, sturdiness, lightness, recyclability, and value-effectiveness, corrugated bins are used for the transport of a wide range of gadgets. If you’re planning to start a cardboard manufacturing enterprise, this text provides you with all the necessary details from machinery to legal permissions. As a result of our machines provide quick and medium run options, providing bins that meet area of interest customer demands is easy and does not take away out of your lengthy-run processes. As a result of rising manufacturing in Europe and China, cardboard costs within the USA dropped marginally. With a hundred and twenty+ Carton Sealing & Packaging Solutions with all kinds of excessive velocity Case Sealers, Carton Sealing Tape, Box Erectors, Field Formers and High Speed Box Tape Heads, BestPack is your one stop shop to automate your packaging course of. Essentially the most dominant participant within the industry is the single-wall corrugated board which accounts for over ninety percent of all production. Carton Box Machine BM2508-Plus is just like BM2508 to a big extent, which is a multifunctional carton field packing machine of horizontal slotting and scoring, vertical slitting and creasing, horizontal reducing. We offer global buyers with a complete useful resource for their packaging needs similar to low cost China Carton Field Making Machine. A wide variety of carton box making machine choices are available to you, resembling paper bowl machine, envelope making machine, and egg tray machine. Cardboard Help is compensated for referring traffic and business to those companies. SPB Equipment has one of the largest collection of paper product machines and I have all the time been amazed by their devoted help and after-sales service. It is a perfect equipment to supply paper field such like hamburger field, chips field. You not need to rely on third events, however can produce customized boxes, in small or medium runs, the second they’re required. These totally different grades of corrugated cardboard could be made by combining different grades of kraft paper. You can too select from ul, ce. In addition to from paper slitting and rewinding machine, winding machine, and printing machine. This report focuses on Skilled World Corrugated Box Making Machine Market 2019-2024 quantity and value at Global stage, regional degree and firm level. Glue energy, bursting strength, compression, and extremely accurate dimensional assessments determine the standard of the manufacturing course of. During 1992, greater than 25 million tons of corrugated cardboard had been produced in the United States. On this report, Technavio covers the market outlook and growth prospects of the global corrugated box making machine market for 2017-2021. As skilled staff run batches of box blanks by way of the flexo machines, individual containers are pulled and inspected. Amongst all elements of the cardboard box manufacturing trade, there has been an exponential enhance in the demand for inexperienced manufacturing both by the federal government and customers. The calls for of a number of guide handlings, automated sortation, and uncontrolled stacking in trucks or air containers put extreme stress on containers, field closures, and the contents. BM2508 is a completely automatic carton field making machine for corrugated cardboard, appropriate for box plant with small quantity orders and large dimension cartons, which effectively solves the problem of scattered orders. A complete one stop sourcing platform for packaging & printing suppliers, manufacturers and factories, we are large enough to have the ability to offer an expanded product line of labels and packaging design capabilities yet sufficiently small to have the ability to provide the private service that’s still so very important in business in the present day.

The post Field Equipment appeared first on Diy Script.

from WordPress https://ift.tt/32L0bVR via IFTTT

0 notes