#5 Axis Machining Manufacturer

Explore tagged Tumblr posts

Text

Top Boons of 5-axis CNC Machining

5 axis machining is now the most feasible choice for all types of machining jobs, not only the most difficult ones that require longer tool reach. 5-axis CNC machining is widely utilized for the most complex and precise jobs. This manufacturing approach is expected to provide significantly improved precision.

5-axis custom machining services provide a variety of advantages

Higher speed

5-axis machining allows the use of shorter cutting tools since the head may be lowered and the cutter is directed to the surface. You might expect better outcomes by increasing cutting speed and tool vibration.

Increased productivity

One of the most time-consuming parts of 3-axis machining is setting up a workpiece many times because it needs to be reoriented. This is required if an item needs to be machined on all or multiple sides, as the cutting tool remains at a fixed angle. A machinist must be physically present to rotate the component once machining on one side is completed for these 3-axis operations, and this human need can be a significant bottleneck in production.

5-axis machining by 5 axis machining manufacturer significantly minimizes the need for repeated setups since the movement of the table or spindle allows the cutting tool to approach the workpiece from various angles without removing it from the machine and resetting it. This leads to higher productivity throughout the whole process.

Hiring a dependable 5-axis machining services

Make sure your production team has been in operation for a significant amount of time. They should be highly experienced and qualified to ensure the quality of the job and timely completion. A corporation should be dependable and trustworthy.

Before selecting a firm, do not be afraid to ask questions regarding their 5-axis machining capabilities. A machine must also be of superior quality and capable of doing this task within a certain timeframe.

Inquire about the pricing of their services. Make sure you pay for what you get, and that the price matches the quality of the goods. Also, be informed of the materials they will be employing.

Main Source: https://bolesolutions.mystrikingly.com/

#5 axis machining manufacturer#5 Axis Machining Supplier#5 axis machining services China#5 Axis Machining Center

2 notes

·

View notes

Text

Maintenance Tips for Your CNC Turning Machine by MechPlus China

As a leading CNC turning machine manufacturing, MechPlus China understands the importance of proper maintenance to ensure precision and efficiency. Regular upkeep not only extends the machine's lifespan but also maximizes productivity and quality. Here are essential maintenance tips from MechPlus China to keep your CNC turning machine running smoothly and efficiently.

Keeping your CNC turning machine in top condition is crucial for optimal performance. Regular maintenance not only extends the machine's lifespan but also ensures precision and efficiency in your operations. Here are essential maintenance tips to keep your CNC turning machine running smoothly.

Daily Inspection and Cleaning

Start each day with a thorough inspection of your CNC turning machine. Check for any signs of wear and tear, and ensure all components are in good working order. Clean the machine daily to remove any debris, chips, and coolant residue. This prevents buildup that can affect performance and accuracy.

Lubrication

Proper lubrication is vital for the smooth operation of your CNC turning machine. Lubricate all moving parts as recommended by the manufacturer. This includes the spindle, guideways, and ball screws. Regular lubrication reduces friction, prevents wear, and extends the machine’s life.

Coolant Maintenance

Maintaining the coolant system is essential for the longevity of your CNC machine. Regularly check the coolant level and concentration. Replace or refill the coolant as needed. Also, clean the coolant tank and filters to avoid contamination that can damage the machine and workpieces.

Alignment and Calibration

Ensure that your CNC turning machine is properly aligned and calibrated. Misalignment can lead to inaccuracies in your machining processes. Regularly check and adjust the machine’s alignment and calibration according to the manufacturer’s guidelines. This ensures precision in your operations.

Check Electrical Components

Inspect the electrical components of your CNC turning machine regularly. Look for any loose connections, worn-out wires, or faulty switches. Address any electrical issues immediately to prevent machine downtime and potential safety hazards.

Monitor Machine Vibration

Excessive vibration can lead to poor machining quality and damage to your CNC turning machine. Monitor the machine for any unusual vibrations or noises during operation. Identify and address the source of the vibration to maintain optimal performance.

Regular Software Updates

Keep your CNC machine’s software up to date. Manufacturers often release updates that improve functionality and fix bugs. Regularly updating the software ensures your machine operates efficiently and takes advantage of the latest technological advancements.

Tool Maintenance

Regularly inspect and maintain the cutting tools used in your CNC turning machine. Sharp and well-maintained tools are crucial for high-quality machining. Replace worn or damaged tools promptly to ensure precise and efficient operation.

Preventive Maintenance Schedule

Implement a preventive maintenance schedule for your quick response machining tool. Follow the manufacturer’s recommended maintenance intervals for all components. Regular preventive maintenance helps identify potential issues before they become major problems, reducing downtime and repair costs.

Training and Safety

Ensure that all operators are properly trained in the maintenance and operation of the CNC turning machine. Regular training updates and adherence to safety protocols are crucial for preventing accidents and ensuring smooth operations.

Document Maintenance Activities

Keep detailed records of all maintenance activities performed on your CNC turning machine. Documenting maintenance helps track the machine’s condition over time and provides valuable information for troubleshooting and repairs with all types of customized machining parts.

In conclusion, regular maintenance of your CNC turning machine is essential for its longevity and performance. By following these tips, you can ensure your machine operates efficiently, reducing downtime and improving the quality of your machining processes. Implement these maintenance practices to keep your CNC turning machine in optimal condition.

#Prototyping solutions#SLA Rapid Prototyping manufacturing#SLS Rapid machining manufacturing#5 Axis CNC machining manufacturing#3D metal printing manufacturing

2 notes

·

View notes

Text

Precision Engineering with 5 Axis Machining in India Trusted Manufacturers & Suppliers

In the era of advanced manufacturing, 5 Axis Machining India is transforming industries with its precision, efficiency, and ability to create complex components. As leading 5 Axis Machining Manufacturers, Sinnar Ureplas specializes in high-quality machining solutions, catering to aerospace, automotive, medical, and industrial sectors. Our state-of-the-art CNC technology ensures superior accuracy, reduced production time, and cost-effective solutions.

As trusted 5 Axis Machining Suppliers, we provide intricate 5 Axis Machining India, ensuring durability and performance. Read on to learn about the benefits, applications, and why Sinnar Ureplas is the preferred partner for precision machining.

Precision Engineering with 5 Axis Machining in India – Trusted Manufacturers & Suppliers

Manufacturing industries are evolving rapidly, demanding higher precision, faster production, and cost-effective solutions. 5 Axis Machining in India has emerged as a game-changer, allowing manufacturers to produce highly intricate parts with exceptional accuracy. Sinnar Ureplas, a trusted name among 5 Axis Machining Manufacturers, offers advanced machining solutions that cater to industries requiring high-quality precision components.

What is 5 Axis Machining?

5 Axis Machining refers to CNC (Computer Numerical Control) machining that operates along five different axes simultaneously. Unlike traditional 3-axis machines, which move only along the X, Y, and Z axes, 5 Axis Machines offer two additional rotational movements, allowing for intricate shaping and detailing. This multi-directional capability enhances flexibility, precision, and efficiency in the production of complex components.

Key Benefits of 5 Axis Machining

✅ Higher Precision & AccuracyWith advanced movement control, 5 Axis Machining ensures extreme precision, reducing errors and eliminating the need for multiple setups.

✅ Enhanced Production SpeedUnlike traditional machining, 5 Axis Machining Manufacturers reduce processing time by cutting materials from multiple angles in a single operation.

✅ Complex Component ManufacturingIndustries such as aerospace, medical, and automotive rely on 5 Axis Machining Suppliers for creating intricate parts that require detailed contouring.

✅ Cost-Effective SolutionsBy minimizing material waste and reducing manual intervention, 5 Axis Machining lowers production costs while improving efficiency.

✅ Superior Surface FinishWith fewer tool changes and seamless movement, the final product has a smoother surface finish, eliminating the need for additional polishing.

Process of 5 Axis Machining at Sinnar Ureplas

1️⃣ Client Consultation & Design Analysis – Understanding project requirements and optimizing designs. 2️⃣ Material Selection & Preparation – Choosing the right materials for durability and performance. 3️⃣ CNC Programming & Machine Setup – Ensuring precision cutting and minimal waste. 4️⃣ Machining & Quality Inspection – High-precision manufacturing with rigorous quality checks. 5️⃣ Final Product Delivery – On-time delivery of customized 5 Axis Parts in India.

If you are looking for precision-driven 5 Axis Machining in India, Sinnar Ureplas is your ideal partner. With advanced CNC technology, skilled engineers, and a commitment to quality, we provide machining solutions that exceed industry expectations.

Contact us today to learn more about our 5 Axis Machining Services and get a custom quote!Visit: https://sinnar-ureplas.com/5-axis-machining-manufacturers-suppliers-india.php

Contact: +91 89753 22242

0 notes

Text

Revolutionize Your Manufacturing: A Comprehensive Guide to 5 Axis Machining in India.

Explore the transformative power of 5 Axis Machining India! This article delves into the technology, its benefits, finding top manufacturers, and how Deccanew simplifies the process

The landscape of manufacturing is constantly evolving, driven by the demand for increasingly complex designs and faster turnaround times. In this dynamic environment, 5 Axis Machining has emerged as a game-changer, pushing the boundaries of what's possible.

This advanced technology allows for the machining of complex 3D geometries in a single setup, eliminating the need for multiple setups and significantly improving efficiency. Here in India, 5 Axis Machining is rapidly gaining traction, offering exciting possibilities for various industries.

Demystifying 5 Axis Machining: How Does it Work?

Traditional CNC machining typically utilizes 3-axis systems – X, Y, and Z. These axes control the movement of the cutting tool along a linear path. While effective for simpler designs, 3-axis machining can become cumbersome for complex geometries requiring intricate angles and curves.

5 Axis Machining Manufacturers overcomes these limitations by adding two additional rotational axes – A and B. These axes allow the cutting tool to tilt and rotate on multiple planes, effectively mimicking the movement of a human hand manipulating a part. This enables machining of all five sides of a workpiece in a single setup, streamlining production and minimizing errors.

Unleashing the Benefits of 5 Axis Machining: Why Choose This Technology?

Here's a glimpse of the significant advantages that 5 Axis Machining offers:

Design Freedom: This technology unlocks the potential for creating intricate and previously impossible designs. Complex shapes, curved surfaces, and intricate angles are easily achievable, pushing the boundaries of product development.

Enhanced Efficiency: By eliminating the need for multiple setups and tool changes, 5 Axis Machining significantly reduces production time and improves overall efficiency. This translates to faster turnaround times and increased production capacity.

Superior Accuracy: The precise control offered by 5 Axis Machining ensures exceptional accuracy and repeatability. This is crucial for parts with tight tolerances and complex features.

Reduced Costs: While the initial investment in a 5 Axis CNC machine might be higher, the long-term benefits through reduced production time, scrap rates, and labor costs lead to significant cost savings.

Improved Quality: The ability to machine complex geometries in a single setup minimizes the risk of errors and inconsistencies associated with multiple setups. This translates to consistently high-quality parts.

Versatility: 5 Axis Machining caters to a wide range of materials, from soft plastics to hardened steel. This versatility makes it a valuable asset across various industries.

Finding the Perfect Fit: Top 5 Axis Machining Manufacturers in India

The Indian manufacturing landscape boasts a growing network of highly skilled 5 Axis Machining manufacturers. However, identifying the right manufacturer for your specific needs can be a challenge.

This is where Deccanew steps in. We act as a bridge between you and the leading 5 Axis Machining manufacturers in India. We understand the intricacies of this technology and can connect you with the perfect partner based on your project requirements, material needs, and desired turnaround time.

Deccanew: Your Gateway to 5 Axis Machining Success

At Deccanew, we offer a comprehensive platform that simplifies the process of finding high-quality 5 Axis Machining solutions in India. Here's how we can assist you:

Extensive Network: We have established relationships with leading 5 Axis Machining manufacturers across various regions of India.

Custom-Tailored Solutions: We understand that every project has unique needs. We work closely with you to identify the ideal manufacturer equipped to fulfill your specific requirements.

Streamlined Communication: Deccanew facilitates seamless communication between you and potential manufacturers, ensuring a smooth and efficient process.

Competitive Quotes: We leverage our network to help you access competitive quotes from various manufacturers, allowing you to optimize your budget.

Quality Assurance: We prioritize quality and maintain high standards within our network of manufacturers.

Embracing the Future of Manufacturing:

5 Axis Machining represents a transformative leap in the world of manufacturing. By offering design freedom, unmatched efficiency, and superior quality, this technology paves the way for innovative products and streamlined production processes.

Deccanew empowers you to harness the power of 5 Axis Machining in India. Contact us today at 9657039991 to unlock a world of possibilities and elevate your manufacturing capabilities.

Visit:- https://www.deccanew.com/5-axis-machining-parts-manufacturers-suppliers-india.php

Contact: 9657039991

0 notes

Text

Different Types of Brush Making Machines

Nowadays, there is a booming demand for brush-making machines. With their growing popularity among various industries, looking for the best machines is of utmost importance. Your search for the best manufacturing team for these machines now comes to an end, thanks to our team from Sharma & Sons. We are offering the best brush solution you have ever laid your eyes on.

Being a leading professional company for all brush machines, we have been engaged in research and development for so many years now. Our main goal is to develop the best product machines that come in handy with the latest technology.

Major technical database:

We have a growing technical database, which has been around since the inception of our company. That makes us one of the leading names in the manufacturing field. We have an in-house team, comprising technical professionals and engineers to offer our clients premium ranges of brush machines.

We will develop the entire design range within our factories and will sell the final results to the international and domestic markets.

There is also an experienced marketing and sales team working with us to check out various aspects of customer feedback and sales regarding each consignment.

The types we follow:

Being associated with brush-making machines for such a long time, we have generated and created multiple types of brush-making machines. The differences will help in covering the maximum crowd at the same time and focus on their flexible needs. So, before you proceed further, we would like you to get the detailed information regarding the types of machines we have in store.

2 Axis Brush Tufting Machine:

Available in brand new condition and with the automatic grade, our 2 Axis Brush Tufting Machine is one to watch out for. It has the capability to produce around 2500 pieces in one go.

This machine is able to produce various kinds of brooms and brushes, which will have multiple filling angles by just changing the specified platforms.

It can be easily installed with just one tufting motor head to offer higher speed and cost-effective results in the end.

There are Touch panels and PLC control systems available from this machine with an English display on the top for better understanding.

There are different procedures performed by a single machine, which will reduce hair mechanic technology dependency.

3 Axis Brush Tufting Machine:

If you are planning to create brushed with curved surfaces, then 3 Axis Brush Tufting Machine might be the right option to get from our side. There are plastic brush pieces, which are to be moulded in advance within the available holes. These holes are now vertical to the surface at around 90 degrees and they cannot be tilted at any other angle. The generic brush size is around 350mmx 180mmx 360 degrees. However, we can customize some of the other sizes as per the requirement through our 3 Axis Brush Tufting Machine models.

There are mainly two grippers available holding two brushes on the work table. Under its automatic mode, it has the power to tuff brushes continuously in a non-stop manner.

4 Axis Brush Tufting Machine:

Another interesting choice of the machine while looking for brush making category from our side has to be 4 Axis Brush Tufting Machine.

All the wearing parts and the spare parts of this machine are designed in a standard manner.

It helps in reducing hair mechanic technology dependency.

Our machines have the power to create one, two, or three colored brushes in one go.

Once proficiently installed by our team members, these machines are subject to last the longest with a little bit of maintenance from your side.

5 Axis Brush Tufting Machine:

We have specially designed 5 Axis Brush Tufting Machine for you, which is used to tuff brushes with the help of stainless steel wires. It is always recommended that the plastic brush pieces need to be molded with holes before getting into the machine. On the other hand, the wooden brushes also need to be pre-drilled with holes in them.

Here, the working table is quite flexible and the nylon filaments or the SS wires can be tufted at different angles, which in turn, will look radial.

This machine helps in processing filaments in two different colours, with a maximum length is around 120mm in 5 Axis Brush Tufting Machine.

A hand controller is widely used here to manually enter the hole positions within the program, with one hole at a time.

The best Drilling and Tufting Brush Machine at your service:

We have the best Drilling and Tufting Brush Machine in store for you, which has been a result of years of research from our side. The machine consists of a main motor, which is sprightly procured from Italy and known for its high working head speed. Then you have a premium quality precision filament box, known to offer reliable and stable performance throughout. So, next time you are looking for one such brush-making machine, focusing on us at Sharma & Sons will be a great note to consider.

#5 axis brush tufting machine#brush tufting machine from india#brush making machine#brush making machine in india#brush tufting machine exporter#brush tufting machine supplier & exporter#brush making machine at best price in india#brush making machine manufacturers & suppliers#brush tufting machine#brush broom tufting machine#2 axis brush tufting machine#3 axis brush tufting machine#4 axis brush tufting machine

0 notes

Text

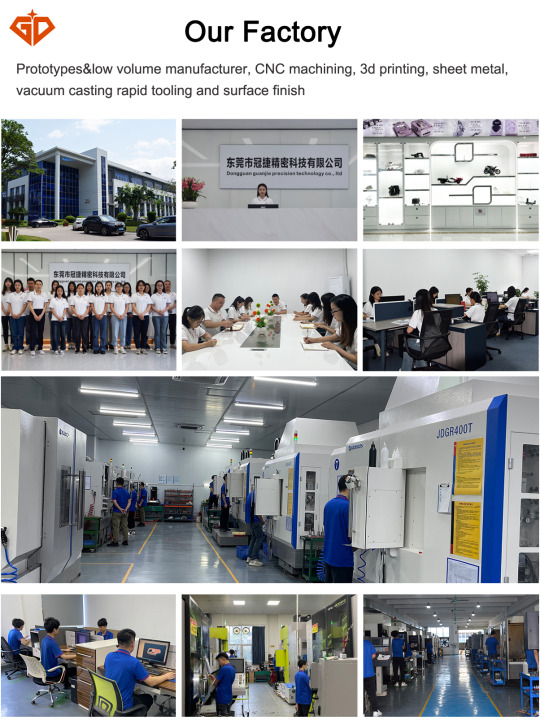

We are a Prototypes&low volume manufacturer, provide CNC machining, 3d printing, sheet metal, vacuum casting rapid tooling and Injection Molding.If you need it for your recent projects, please contact me:[email protected]

#prototyping#cncmachining#5 axis machining#cnc milling services#sheet metal#sheet metal fabrication#sheet metal manufacturing

0 notes

Text

Are you looking for a reliable and precise low-volume manufacturing service?

Look no further! 🌟

At ProtoTech Machining, we are not just a manufacturer; we innovate with precision.🛠️

Our company specializes in top-notch low-volume manufacturing services that are tailored to various industry needs such as aerospace, medical, automotive, robotics, and many other sectors. From CNC machining to Rapid prototyping and Sheet Metal Fabrication, our expert team can leverage cutting-edge technologies to turn complex designs into reality. 🚀

Plus, whether you need 3D printing, 5-axis, or Swiss CNC machining, we have the best capabilities to provide innovative and cost-effective solutions without compromising quality. ✨

So don’t wait any longer! Contact us now and let us be your partner in all your manufacturing needs. 📞

Browse https://prototech-machining.com/low-volume-manufacturing/ to learn more.

#prototechmachining#3dprinting#cncmachining#technologies#swisscncmachining#manufacturing#innovative#metalfabrication#aerospace#medical#automative#robotics

2 notes

·

View notes

Text

5 axis cnc milling machining services

#prototyping#prototype#rapid prototyping#prototype machining#cnc machining#precision machining#machining parts#5 axis cnc milling#5 axis milling#5 axis cnc machining#5 axis cnc#cnc machining service#cnc machining parts#cnc machining prototype#cnc precision machining#precision manufacturing#cnc precision milling#cnc milling#precision cnc milling

1 note

·

View note

Photo

This book is essential reading for researchers and practitioners in computer science, technical managers and software specialists This book provides a comprehensive treatment of the subject of sculptured surface machining in terms of user needs, CAM software solutions and theoretical research results and issues. State-of-the-art capabilities of the best commercial CAM systems are compared to user needs, and advanced academic research is presented. Among the topics covered are the following: Generative NC for dies and molds; 5-axis machining of impellers; Cutting simulation and NC verification; Virtual machining; CAPP for die and mold machining; NURBS-based CNC interpolators

Cutting Molds/Dies from Scan data

Experiences from a Quantum Leap Improvement in Turbine Manufacturing

A Generative Approach for Die Pattern Machining

Geometric Contributions to 3-Axis Milling of Sculptured Surfaces

Efficiency of Multi-Axis NC Machining of Sculptured Part Surfaces

Best-Fit of Sculptured Surfaces

Point-based Geometric Modelling

Virtual Machining and the Manufacturing Model

Virtual CNC with Performance Error Modeling

Fast Simulation of Sculptured Surface Milling with 3-Axis NC Machine

Simulation of Ball-nose End Milling Operations — Selection of Geometric Resolution Parameters

Machining Process Modeling for Intelligent Rough Machining of Sculptured Parts

Bridging the Gap Between Tool Path Generation for Sculptured Surface Machining and Computer Aided Process Modelling Techniques

Automatic Five-Axis CNC Feedrate Selection via Discrete Mechanistic, Geometric, and Machine Model Integration

Milling Simulation with an adaptive Strategy

Deformed Swept Volume Analysis to NC Machining Simulation with Cutter Deflection

Segmentation and Surface Fitting in Reverse Engineering

Surface Reconstruction from Point Clouds

Reverse Engineering Employing a Wrap-Around SurfaceTriangle Set

Manufacturability of Reverse Engineered CAD-models : a case study

https://archive.org/details/springer_10.1007-978-0-387-35392-0

3 notes

·

View notes

Text

⚡In a flash, the laser moves like a paintbrush! Watch the metal take shape in an instant under the beam, the magic of technology that is accurate to the millimeter - it turns out that manufacturing can be so cool! ✨ #IndustrialAesthetics #HardcoreTechnology

SheetMetalProcessing #LaserCutting #SmartManufacturing #IndustrialTechnology #PrecisionManufacturing #MetalArt #ManufacturingBlackTechnology #Flash #TechAesthetics #ProductionMoment

0 notes

Text

#5 axis brush tufting machine manufacturer#5 axis tufting machines india#brush tufting equipment india#advanced brush tufting equipment india#precision tufting machines india#5 axis brush manufacturing machinery#tufting machine suppliers india

0 notes

Text

GD prototyping CNC milling and turning are the mostly common used processing technique that can manufacture complex and multi-structure plastic and metal parts.

#cnc machining services#cnc milling services#cncmachining#cnc machining parts#cnc machining manufacturer#cnc machining china#5 axis machining

1 note

·

View note

Text

Maximizing Efficiency With Laser-Cutting Machines: Melbourne’s Best Solutions

Laser-cutting technology has revolutionized manufacturing and fabrication across various industries. From precision cutting in metal fabrication to intricate designs in signage and jewelry, laser cutting machines in Melbourne are transforming production processes. Whether you're a small business, startup, or large enterprise, choosing the right laser cutter is essential for efficiency and profitability.

This guide explores the features, benefits, and costs of laser-cutting machines while highlighting why SLTL Group is the go-to provider for advanced laser solutions in Melbourne.

Key Features of Laser Cutting Machines

1. High-Precision Cutting

Modern fiber laser cutting machines offer unmatched precision, making them ideal for industries requiring accuracy in metal and non-metal applications. These machines utilize advanced beam technology, ensuring sharp edges and minimal burrs on cut materials.

2. Speed and Efficiency

With advanced CNC technology, laser cutters provide high-speed cutting, reducing production time and increasing output. This efficiency is particularly beneficial in mass-production industries such as automotive and aerospace manufacturing.

3. Versatility Across Materials

Laser machines can cut a wide range of materials, including:

Stainless steel

Aluminum

Carbon steel

Copper and brass

Acrylic

Wood

Plastics

Composites

4. Automation and Smart Integration

SLTL Group offers automated laser cutting solutions integrated with AI-driven systems, improving workflow and reducing manual labor costs. Features like real-time monitoring, remote control, and predictive maintenance make these machines highly efficient.

5. Energy-Efficient Technology

Modern fiber laser systems consume less power while delivering high-performance cutting, reducing operational expenses. Compared to traditional CO2 laser machines, fiber lasers are more energy-efficient, contributing to sustainable manufacturing practices.

Benefits of Using Laser Cutting Machines

1. Improved Productivity and Output

With high-speed laser cutters, businesses can meet tight deadlines without compromising on quality. Automated feeding systems and multi-axis cutting capabilities further enhance production efficiency.

2. Cost-Effective Operations

Laser cutting reduces material wastage, minimizes labor requirements, and enhances overall cost-efficiency. Traditional cutting methods, such as mechanical or plasma cutting, often result in higher maintenance and operational costs.

3. Enhanced Design Flexibility

Laser technology allows for intricate and complex cuts that traditional methods cannot achieve. This is particularly useful in custom fabrication, where precision and customization are essential.

4. Minimal Maintenance Requirements

Compared to traditional cutting machines, fiber laser cutters require minimal upkeep, leading to lower maintenance costs. The absence of mechanical contact with the material also reduces wear and tear.

5. Safe and Eco-Friendly Processing

SLTL Group’s laser cutting solutions adhere to global safety standards while ensuring eco-friendly operations with minimal emissions. With features such as fume extraction systems and protective enclosures, workplace safety is enhanced.

Understanding Laser Cutting Machine Costs

The cost of laser-cutting machines in Melbourne depends on several factors, including:

1. Type of Laser Cutter

CO2 Laser Cutters: Ideal for non-metal materials like wood and acrylic, generally lower in cost.

Fiber Laser Cutters: Best for metal applications, offering high efficiency but at a higher initial investment.

Hybrid Laser Cutters: Combining fiber and CO2 technology for multi-material applications, often priced at a premium.

2. Power and Cutting Capabilities

Higher-wattage machines provide faster cutting speeds and deeper penetration but come at a premium price. Entry-level laser machines start at around AUD 20,000, while industrial-grade models can exceed AUD 500,000.

3. Automation and Software Integration

Advanced CNC systems with automation features increase machine costs but improve long-term efficiency. Integrated ERP and CAD software compatibility adds to the overall investment.

4. Brand and Warranty

Trusted brands like SLTL Group offer high-quality, reliable laser machines backed by comprehensive warranties and excellent customer support. Investing in a reputable brand ensures long-term reliability and reduced downtime.

Case Study: How SLTL Group Helped a Melbourne Manufacturer Scale Production

A leading sheet metal fabrication company in Melbourne struggled with inefficiencies in its cutting processes, leading to high material wastage and production delays. After integrating an SLTL Group fiber laser cutting machine, the company achieved:

40% faster production times

30% reduction in material wastage

Enhanced precision, eliminating the need for secondary processing

By choosing SLTL Group, the company not only improved operational efficiency but also increased its competitive edge in the market.

Why Choose SLTL Group for Laser Cutting Machines in Melbourne?

SLTL Group is a global leader in fiber laser cutting technology, providing innovative and customized laser solutions to businesses in Melbourne and beyond.

1. Cutting-Edge Laser Solutions

SLTL Group offers state-of-the-art laser cutting machines designed for high-speed, precision cutting across industries. Their machines incorporate AI-driven automation and cloud-based monitoring for optimal performance.

2. Customization Options

Tailored solutions to meet specific industry needs, from small-scale startups to large industrial enterprises. SLTL Group provides customizable laser power options, automation levels, and additional attachments like tube-cutting modules.

3. Comprehensive After-Sales Support

Customers benefit from training programs, maintenance services, and 24/7 support for uninterrupted operations. SLTL Group ensures that businesses maximize the value of their investment.

4. Industry-Leading Experience

With decades of expertise in laser technology, SLTL Group remains at the forefront of innovation. Their ongoing research and development efforts ensure that customers receive cutting-edge solutions tailored to their needs.

Industries Benefiting from SLTL Group’s Laser Cutting Machines

1. Metal Fabrication

High-precision metal cutting for industrial and commercial applications. SLTL Group’s fiber laser cutters are widely used in steel processing plants, HVAC manufacturing, and heavy machinery production.

2. Automotive and Aerospace

Production of lightweight, high-strength components for advanced manufacturing. Aerospace manufacturers rely on laser cutting for producing intricate airframe components with minimal material distortion.

3. Signage and Advertising

Custom signage and branding materials with intricate laser-cut designs. The ability to create precise lettering, logos, and detailed engravings makes laser cutting a preferred choice for the advertising industry.

4. Jewelry and Creative Arts

Fine detailing and engraving for bespoke jewelry and artistic creations. Laser cutting enables jewelry makers to work with precious metals, creating intricate patterns with extreme precision.

Future Trends in Laser Cutting Technology

AI-Powered Automation: Enhancing efficiency with intelligent laser systems that optimize cutting parameters in real time.

Eco-Friendly Processing: Reducing emissions with sustainable laser technology, including energy-efficient fiber lasers.

Smart Manufacturing Integration: Seamless ERP and CAD software integration for optimized production, reducing material waste, and improving workflow automation.

Conclusion

Investing in a high-quality laser cutting machine in Melbourne can transform your business operations, enhancing productivity, precision, and cost-effectiveness. SLTL Group stands as a trusted provider of innovative fiber laser cutting solutions, offering superior performance and unmatched customer support.

Looking for the best laser-cutting machine in Melbourne? Explore SLTL Group’s Laser Solutions today and elevate your production capabilities!

0 notes

Text

Maximizing Efficiency With Laser-Cutting Machines: Melbourne’s Best Solutions

Laser-cutting technology has revolutionized manufacturing and fabrication across various industries. From precision cutting in metal fabrication to intricate designs in signage and jewelry, laser cutting machines in Melbourne are transforming production processes. Whether you're a small business, startup, or large enterprise, choosing the right laser cutter is essential for efficiency and profitability.

This guide explores the features, benefits, and costs of laser-cutting machines while highlighting why SLTL Group is the go-to provider for advanced laser solutions in Melbourne.

Key Features of Laser Cutting Machines

1. High-Precision Cutting

Modern fiber laser cutting machines offer unmatched precision, making them ideal for industries requiring accuracy in metal and non-metal applications. These machines utilize advanced beam technology, ensuring sharp edges and minimal burrs on cut materials.

2. Speed and Efficiency

With advanced CNC technology, laser cutters provide high-speed cutting, reducing production time and increasing output. This efficiency is particularly beneficial in mass-production industries such as automotive and aerospace manufacturing.

3. Versatility Across Materials

Laser machines can cut a wide range of materials, including:

Stainless steel

Aluminum

Carbon steel

Copper and brass

Acrylic

Wood

Plastics

Composites

4. Automation and Smart Integration

SLTL Group offers automated laser cutting solutions integrated with AI-driven systems, improving workflow and reducing manual labor costs. Features like real-time monitoring, remote control, and predictive maintenance make these machines highly efficient.

5. Energy-Efficient Technology

Modern fiber laser systems consume less power while delivering high-performance cutting, reducing operational expenses. Compared to traditional CO2 laser machines, fiber lasers are more energy-efficient, contributing to sustainable manufacturing practices.

Benefits of Using Laser Cutting Machines

1. Improved Productivity and Output

With high-speed laser cutters, businesses can meet tight deadlines without compromising on quality. Automated feeding systems and multi-axis cutting capabilities further enhance production efficiency.

2. Cost-Effective Operations

Laser cutting reduces material wastage, minimizes labor requirements, and enhances overall cost-efficiency. Traditional cutting methods, such as mechanical or plasma cutting, often result in higher maintenance and operational costs.

3. Enhanced Design Flexibility

Laser technology allows for intricate and complex cuts that traditional methods cannot achieve. This is particularly useful in custom fabrication, where precision and customization are essential.

4. Minimal Maintenance Requirements

Compared to traditional cutting machines, fiber laser cutters require minimal upkeep, leading to lower maintenance costs. The absence of mechanical contact with the material also reduces wear and tear.

5. Safe and Eco-Friendly Processing

SLTL Group’s laser cutting solutions adhere to global safety standards while ensuring eco-friendly operations with minimal emissions. With features such as fume extraction systems and protective enclosures, workplace safety is enhanced.

Understanding Laser Cutting Machine Costs

The cost of laser-cutting machines in Melbourne depends on several factors, including:

1. Type of Laser Cutter

CO2 Laser Cutters: Ideal for non-metal materials like wood and acrylic, generally lower in cost.

Fiber Laser Cutters: Best for metal applications, offering high efficiency but at a higher initial investment.

Hybrid Laser Cutters: Combining fiber and CO2 technology for multi-material applications, often priced at a premium.

2. Power and Cutting Capabilities

Higher-wattage machines provide faster cutting speeds and deeper penetration but come at a premium price. Entry-level laser machines start at around AUD 20,000, while industrial-grade models can exceed AUD 500,000.

3. Automation and Software Integration

Advanced CNC systems with automation features increase machine costs but improve long-term efficiency. Integrated ERP and CAD software compatibility adds to the overall investment.

4. Brand and Warranty

Trusted brands like SLTL Group offer high-quality, reliable laser machines backed by comprehensive warranties and excellent customer support. Investing in a reputable brand ensures long-term reliability and reduced downtime.

Case Study: How SLTL Group Helped a Melbourne Manufacturer Scale Production

A leading sheet metal fabrication company in Melbourne struggled with inefficiencies in its cutting processes, leading to high material wastage and production delays. After integrating an SLTL Group fiber laser cutting machine, the company achieved:

40% faster production times

30% reduction in material wastage

Enhanced precision, eliminating the need for secondary processing

By choosing SLTL Group, the company not only improved operational efficiency but also increased its competitive edge in the market.

Why Choose SLTL Group for Laser Cutting Machines in Melbourne?

SLTL Group is a global leader in fiber laser cutting technology, providing innovative and customized laser solutions to businesses in Melbourne and beyond.

1. Cutting-Edge Laser Solutions

SLTL Group offers state-of-the-art laser cutting machines designed for high-speed, precision cutting across industries. Their machines incorporate AI-driven automation and cloud-based monitoring for optimal performance.

2. Customization Options

Tailored solutions to meet specific industry needs, from small-scale startups to large industrial enterprises. SLTL Group provides customizable laser power options, automation levels, and additional attachments like tube-cutting modules.

3. Comprehensive After-Sales Support

Customers benefit from training programs, maintenance services, and 24/7 support for uninterrupted operations. SLTL Group ensures that businesses maximize the value of their investment.

4. Industry-Leading Experience

With decades of expertise in laser technology, SLTL Group remains at the forefront of innovation. Their ongoing research and development efforts ensure that customers receive cutting-edge solutions tailored to their needs.

Industries Benefiting from SLTL Group’s Laser Cutting Machines

1. Metal Fabrication

High-precision metal cutting for industrial and commercial applications. SLTL Group’s fiber laser cutters are widely used in steel processing plants, HVAC manufacturing, and heavy machinery production.

2. Automotive and Aerospace

Production of lightweight, high-strength components for advanced manufacturing. Aerospace manufacturers rely on laser cutting for producing intricate airframe components with minimal material distortion.

3. Signage and Advertising

Custom signage and branding materials with intricate laser-cut designs. The ability to create precise lettering, logos, and detailed engravings makes laser cutting a preferred choice for the advertising industry.

4. Jewelry and Creative Arts

Fine detailing and engraving for bespoke jewelry and artistic creations. Laser cutting enables jewelry makers to work with precious metals, creating intricate patterns with extreme precision.

Future Trends in Laser Cutting Technology

AI-Powered Automation: Enhancing efficiency with intelligent laser systems that optimize cutting parameters in real time.

Eco-Friendly Processing: Reducing emissions with sustainable laser technology, including energy-efficient fiber lasers.

Smart Manufacturing Integration: Seamless ERP and CAD software integration for optimized production, reducing material waste, and improving workflow automation.

Conclusion

Investing in a high-quality laser cutting machine in Melbourne can transform your business operations, enhancing productivity, precision, and cost-effectiveness. SLTL Group stands as a trusted provider of innovative fiber laser cutting solutions, offering superior performance and unmatched customer support.

Looking for the best laser-cutting machine in Melbourne? Explore SLTL Group’s Laser Solutions today and elevate your production capabilities!

#artificial intelligence#machine learning#business#lasercutting#precision machining#writers on tumblr#blog

0 notes

Text

CNC Gear Hobbing Manufacturer: Precision, Efficiency, and Innovation

Gears are an essential component of modern machinery, playing a crucial role in industries such as automotive, aerospace, industrial equipment, and renewable energy. As technology advances, manufacturers demand highly precise, durable, and efficient gears. This is where CNC gear hobbing manufacturers come into play, providing state-of-the-art solutions for high-quality gear production. If you are looking for a trusted CNC gear hobbing manufacturer, this guide will help you understand why choosing the right partner is essential for your business.

What is CNC Gear Hobbing?

CNC gear hobbing is a highly efficient gear-cutting process that utilizes Computer Numerical Control (CNC) technology to automate and optimize the machining of gear teeth. This method ensures high accuracy, consistency, and repeatability in gear production, making it the preferred choice for industries that require precision-engineered gears.

The key steps involved in CNC gear hobbing include:

Mounting the gear blank on a CNC hobbing machine.

Programming the CNC system with the exact gear specifications.

Rotating the hob and workpiece in synchronization to cut the gear teeth accurately.

Performing quality control checks to ensure compliance with industry standards.

Why CNC Gear Hobbing is the Best Choice

Industries around the world are shifting towards CNC gear hobbing due to its numerous advantages. Here are some key reasons why manufacturers prefer this method:

1. Exceptional Precision

CNC gear hobbing machines operate with high accuracy, ensuring that each gear meets exact specifications. This precision is crucial for applications that require tight tolerances and flawless performance.

2. Consistent Quality

Once programmed, CNC gear hobbing machines can produce identical gears repeatedly with minimal variation, ensuring consistent quality across production batches.

3. Higher Production Efficiency

Automation significantly reduces manual intervention, speeds up the manufacturing process, and minimizes material waste, making CNC gear hobbing a cost-effective and time-efficient solution.

4. Versatile Gear Production

CNC gear hobbing machines can produce various types of gears, including:

Spur gears

Helical gears

Worm gears

Sprockets

Splines

5. Cost-Effective Manufacturing

Despite the initial investment in CNC gear hobbing machines, manufacturers benefit from long-term cost savings through reduced labor costs, faster production times, and lower defect rates.

Industries That Rely on CNC Gear Hobbing

CNC gear hobbing manufacturers serve a wide range of industries, including:

Automotive: Producing gears for transmissions, differentials, and powertrains.

Aerospace: Manufacturing high-precision gears for aircraft engines and navigation systems.

Industrial Machinery: Creating gears for pumps, compressors, and heavy equipment.

Renewable Energy: Producing gears for wind turbines and solar tracking systems.

Robotics: Manufacturing small, intricate gears for robotic applications.

These industries demand high-performance gears, and CNC gear hobbing manufacturers ensure that every component meets the highest quality standards.

How CNC Gear Hobbing Works

The CNC gear hobbing process consists of the following steps:

Workpiece Setup: The gear blank is mounted securely onto the hobbing machine.

CNC Programming: The machine is programmed with precise gear specifications.

Gear Cutting: The rotating hob cuts the gear teeth into the workpiece with extreme precision.

Quality Control: Each gear undergoes rigorous inspection to ensure it meets industry standards.

Finishing and Delivery: Additional finishing processes, such as grinding or heat treatment, may be applied before the gears are shipped to customers.

Features of Modern CNC Gear Hobbing Machines

Advanced CNC gear hobbing machines come with innovative features to enhance production efficiency and gear quality, including:

Multi-Axis Control: Enables complex gear designs with high precision.

High-Speed Spindles: Increases production speed while maintaining accuracy.

Automated Tool Changes: Minimizes downtime and enhances efficiency.

Integrated Cooling Systems: Prevents overheating and prolongs tool life.

User-Friendly Interfaces: Simplifies programming and machine operation.

Benefits of Choosing a CNC Gear Hobbing Manufacturer

Partnering with a trusted CNC gear hobbing manufacturer brings several advantages:

1. Improved Gear Quality

Precision manufacturing ensures that gears perform reliably under demanding conditions.

2. Higher Production Output

Automated processes enable manufacturers to meet high demand efficiently.

3. Competitive Market Position

Manufacturers using CNC gear hobbing can offer high-quality gears, giving them an edge over competitors.

4. Reduced Manufacturing Costs

Efficiency gains lead to lower operational costs and improved profitability.

5. Custom Gear Solutions

Manufacturers can provide tailored solutions to meet specific customer requirements.

Why Choose Gear Hobbing Solutions for CNC Gear Hobbing?

At Gear Hobbing Solutions, we take pride in being a leading CNC gear hobbing manufacturer, offering cutting-edge technology, expertise, and exceptional customer service. Here’s what sets us apart:

Expertise and Experience

With years of experience in the industry, we understand the complexities of gear manufacturing and deliver solutions that exceed expectations.

State-of-the-Art Technology

Our CNC gear hobbing machines are equipped with advanced features to ensure precision, efficiency, and consistency.

Customization Options

We work closely with our clients to develop custom gears tailored to their specific applications.

Commitment to Quality

We adhere to stringent quality control measures and are ISO-certified to ensure our gears meet international standards.

Comprehensive Support

From consultation and design to production and delivery, we provide end-to-end support to ensure your project’s success.

The Future of CNC Gear Hobbing

The future of CNC gear hobbing manufacturers looks promising, with advancements in technology shaping the industry. Key trends include:

AI Integration: Leveraging machine learning for predictive maintenance and optimized production.

IoT Connectivity: Enabling real-time monitoring and remote control of CNC machines.

Sustainable Manufacturing: Developing energy-efficient and eco-friendly gear production methods.

These innovations will further enhance the precision, efficiency, and cost-effectiveness of CNC gear hobbing.

Conclusion

CNC gear hobbing is revolutionizing gear manufacturing by delivering high-precision, efficient, and cost-effective solutions. As a leading CNC gear hobbing manufacturer, Gear Hobbing Solutions is committed to providing top-quality gears that meet the needs of various industries.

If you are looking for a trusted CNC gear hobbing manufacturer, contact us today. Let us help you enhance your gear production capabilities and achieve new levels of efficiency and reliability.

0 notes