#4roll bending machine

Explore tagged Tumblr posts

Text

Discover the world of plate bending/rolling and how it shapes industries like shipbuilding, metal fabrication, and more. Learn the process, machine types, and why Himalaya Machinery is your ultimate solution. Dive in now!

For more information visit: https://www.himalayamachine.com/post/what-is-plate-bending-rolling-everything-you-need-to-know-is-here

0 notes

Text

5 Undeniable Advantages of Variable Geometry Plate Rolling Machine

Do you remember the first time when mankind was surprised? The wheel was a revolutionary invention.

The second time people were amazed was when they built a tubeless tire.

Variable Geometry plate rolling machines did the same thing. The precision and accuracy are undeniably the best in these machines. It's fascinating how productivity is not compromised.

Great for medium to large thickness range, a Variable Geometry plate bending machine has increased rolling capacity and cost savings. (Getting interesting, isn't it?)

We will explore how these machines optimize pre-bending and elevate the efficiency and performance of metal fabrication processes. Let's unlock the potential of Variable Geometry plate rolling machines together!

Are you a workshop owner? We know you can't wait to find out how these machines can help you optimize pre-bending and elevate the efficiency of your workshop's metal fabrication processes. Let's take a quick look at what a Variable Geometry plate rolling machine is first.

Variable Geometry Plate Rolling Machine: Why Industry Needs It?

Plate rolling machines are great for simple round metal structures. On the other hand, a Variable Geometry plate bending machine brings the same precision and accuracy to the complex metal structure forming that normal machines do.

The difference between the two is, Variable Geometry plate rolling machines do it for complex metal structures. On top of it, these machines complete normal metal plate bending machines comparatively faster.

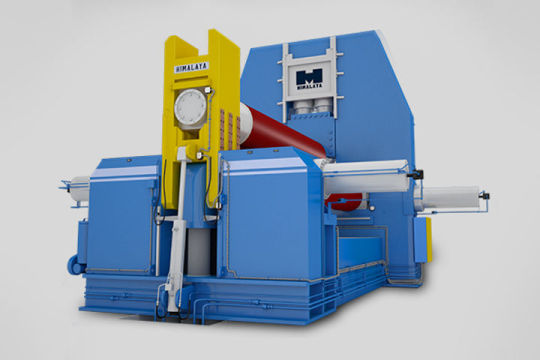

Himalaya Variable Geometry Plate Rolling Machine

5 Major Upsides of Variable Geometry Plate Rolling Machines

What is one thing that every workshop expects in terms of productivity? Speed, right? It directly relates to productivity.

Versatility, productivity, efficiency and other generic benefits are undoubtedly present in Variable Geometry plate bending machines. But what makes them superlative are the five most important points listed below. Don’t worry! We will discuss all of it.

Enhanced forming control and consistency

Roll tighter diameter forms

Roll cones without overloading your machine

Increased roll capacity

Less stress re-rolling

Let’s learn about all 5 advantages of variable geometry plate rolling machines in detail.

1) Enhanced Forming Control and Consistency

Variable Geometry Plate Rolling Machines provide superior control and consistency in the forming process. You get the facility to adjust the roll geometry, operators can precisely manipulate the plate deformation and achieve desired shapes without excessive stress.

This feature minimizes material distortion, reduces the risk of defects, and ensures consistent quality throughout the rolled plates.

Improved forming control and consistency leads to enhanced product performance, reduced rework, and improved customer satisfaction.

2) Roll Tight Diameter Forms

Rolling diameters close to the top roll can be 1.15 times the diameter or even smaller, thanks to the significant interference between the top roll and bottom rolls.

Comparatively, the minimum diameter of the four-roll plate rolling technology is 1.2 times that of the top roll.

The left bottom roll of a three-roll plate roller's adjustability reduces the flat portion during pre-bending. Is there a more versatile machine?

Variable Geometry plate rollers can handle plates of varied thicknesses by modifying the bottom rolls' interaxis distance. This is similar to employing multiple V dies and bending forces in a press brake.

3) Rolling Cones Without Overloading Your Machine

To facilitate cone rolling, Variable Geometry plate rollers can tilt the bottom rollers. It allows the machine to operate at full capacity while rolling conical shapes.

The Variable Geometry plate rolling machine's bottom rolls are not motorized. Therefore there is no braking or gearbox wear. Because of this, typical four-roll plate rollers are less efficient and expensive than Variable Geometry plate rollers.

4) Increased Roll Capacity

Variable Geometry Plate Rolling Machines offer a higher roll capacity in comparison to three or four-roll machines with the same roll diameter. The adjustable geometry of the rolls allows for the effective utilization of the entire roll surface, maximizing the contact area with the plate being rolled.

Increased roll capacity enables the machine to handle thicker and wider plates, accommodating larger workpieces with ease. By providing a higher roll capacity, Variable Geometry Plate Rolling Machines enhance the versatility and flexibility of the rolling process, allowing for the fabrication of a broader range of plate sizes and thicknesses.

5) Re-Rolling With Less Tension

When re-rolling a newly welded form, Variable Geometry plate roll technology does not allow the welded joint to come into contact with the top roller and the bottom rollers simultaneously.

Also, the top roll in a Variable Geometry plate roller can be used as a press brake ram to re-roll the welded seam of the cylinder.

Generally, as a workshop owner, one would think such a machine is only ideal and might not exist. But it does and has enormous potential to multifold your workshop’s productivity.

Conclusion

The variable geometry plate rolling machine is a truly revolutionary machine in the metal fabrication industry. End of story.

Its unique design and functionality offer a range of advantages, from enhanced precision and efficiency to effortless plate straightening. It rolls tighter diameter forms, handles conical shapes, minimizes flat end sections, and re-rolls with less tension. This machine is an invaluable asset for workshops and manufacturing facilities.

Contact us for your plate rolling machine requirements. With over 44 years of experience, Himalaya Machinery has established itself as a trusted manufacturer and seller of high-quality metal fabrication and plate rolling/bending/straightening machines.

#3 roller plate rolling machines#plate bending machine price#3 roll plate bending machine#3 roll bending machine#banding machine#plate bending machine#3 roll plate rolling machine#roll bending machine#4roll bending machine#4 roll plate bending machine

0 notes

Text

3-Roll Plate Bending/Rolling Machine: Working Principle & the Rolling Process

Ever wondered how the metal around you is getting its shape? Be it an automobile part, a ship or a large metal container. It's not magic, but a machine breathing life into metal and turning it into breathtaking art.

Plate rolling is an incredibly essential part of any metal industry. The task of these rolling machines is simple: shaping metal plates into cones, cylinders, and curved shapes.

The definition looks simple, but the plate bending/rolling machines deliver sophisticated, cutting-edge, unique products. Different types of plate rolling/bending machines are available in the market. This blog will have a detailed view of a 3-roll plate rolling/ bending machine's working principle and rolling process.

What is Roll Plate Bending/Rolling Machine?

A Plate Rolling machine, also known as a roller machine, is a metal rolling equipment. Its main purpose is to shape metals into conical, cylindrical or curved shapes. Industries worldwide require different machines according to their needs.

Plate rolling is a complex process but crucial for expanding the bending options available to your customers. Moreover, it depends on the precision levels and skill set of operators.

What Are the Types of Roll Plate Bending Machines?

There are three types of plate rolling/bending machines that individual industries need:

2-roll Plate Bending/Rolling machine

3-roll Plate Bending/Rolling machine

4-roll Plate Bending/Rolling machine

As mentioned above, each machine has its individual use, but here we will have a look at the 3-roll Plate Bending/Rolling machine.

What is the Working Principle of a 3-Roll Plate Rolling/Bending Machine?

Before understanding the working, let's have a brief look at a 3-Roll Plate Rolling/Bending Machine.

Industries of all sizes, from shipping to metal fabrication, need 3-roll plate bending/rolling machines. The process/task of the machine remains the same: bending metal sheets into the desired shape.

Images 1, 2, and 3 show how a 3-roll plate bending machine uses rollers A, B, and C to shape metal plates. This is a pre-pinching/pre-bending process in plate bending.

The manufacturer can control the amount and speed of the rollers to achieve the desired shape. As you can see, the plate smoothly and uniformly bends/rolls using the three rollers. The engineer can also bend or roll the desired location to achieve the required shape during the pre-bending process.

Let’s have a look at the mechanism in detailed steps.

Step 1: Placing the Plate

The first step for rolling a plate needs placing the plate between the upper (I) and lower rollers (II and III). This process bends the plate into an arc or closed circle. As the metal sheet passes through the three cutting points created by the rollers, the plate will mold into the desired shape.

(Have a look at Diagram 1 of the working principle of a 3-roll rotating/ bending machine.)

Step 2: Plastic Bending Deformation

After the insertion of the metal plate, the top roller applies downward pressure on the plate. As a result, the plate undergoes a plastic bending deformation process due to compression.

Plastic bending deformation of metals occurs when an object's shape and size change due to applied force. Deformation happens when the shape of a material or object changes due to pressure. Plastic deformation occurs when the applied force is enough to cause a permanent deformation.

Step 3: Rotation & Friction

Due to the friction between the rollers and the plates, the lower rollers begin rotating, causing the plate to move back and forth along its longitudinal direction.

The plate moves back and forth as the lower roller alternatively does a forward and reverse rotation. At the same time, the upper roller continuously exerts vertical pressure or downward pressure on the plate.

Key Factors of a 3-Roll Plate Bending/ Rolling Machine

To bend the plate to a radius no longer than the upper roller, you can modify the relative position of the upper and lower rollers.

A motor and a reducer power the lower roller (II and III), making them rotate in a similar momentum and in the same or opposite direction.

To vary the curvature of the desired plates, you can adjust the position of the upper rollers.

You can change the position of the upper rollers to vary the curvature of the desired plates. Moreover, you can readjust the upper roller if you do not receive the desired curvature after a single rolling process. Then, you can redo the process until you achieve the desired shape.

There is one disadvantage of this machine. When you look at the above diagram, you can notice that the three rolls of the 3-roll bending/rotating machine form an isosceles triangle.

During the process, this triangle-forming shape forces the two ends of the machine to leave a straight part. The straight part of the machine is half the distance between the centers of the two lower rollers. This is the part where the rollers cannot roll.

Despite this one disadvantage, there are several benefits and features of a 3-roll plate bending machine. The main benefits of this plate rolling machine are structure, ease of operation, and low cost.

Wrapping Up!

3-roll plate bending machines have played an important role in history and continue to do so. You can rely on our plate-bending machines across various industries, including shipping, oil tanks, metal structures, tubes, and pipes. Be it 2-roll bending, 3-roll bending or 4-roll bending machines.

We hope this blog helped you understand the working principle of our 3-roll bending machine. Feel free to contact us for all your plate-bending machinery needs. Our team at Himalaya Machinery would love to help you.

original source:- https://www.himalayamachine.com/post/3-roll-plate-bending-rolling-machine-working-principle-the-rolling-process

#3 roller plate rolling machines#3 roll plate bending machine#roll bending machine#4roll bending machine#plate bending machine price#3 roll bending machine#4 roll plate bending machine

0 notes

Text

Metal Plate Straightening Machine: Making It Work in Your Best Interest

Are you a workshop owner? If you are, you’d agree that achieving perfectly flat and undulated metal plates is of utmost importance. It’s the exact reason for the emergence of metal plate straightening machines. From mining to ship and rocket building, plate straightening machines serve their purpose globally. These machines are used to rectify any distortions or deformations during manufacturing.

Operators worldwide put a distorted, deformed, or coiled-up metal plate into a straightener and get good results. Plate straightening is only one of the processes of metal forming or manufacturing. And just like any other process or metal forming, every workshop can perform at its best if all procedures are done correctly.

In this article, we will discuss the importance of a plate straightening machine and then share the benefits of it. This way, it will help you to make the most out of your plate straightening machine.

Plate Straightening Machine: Why Do You Need One?

There are two sides you need to consider when answering this question. There are some economical and characteristic reasons why you need a plate straightening machine.

Let’s start with economic reasons:

Economic Reason 1: Growing Demand for Paced-Up Manufacturing

The world population crossed 8 billion on 15th November 2022. 40 million more people have come to life since that day. (Get what we are saying?) With the increase in population, the demand is set to increase no matter what.

Here are some sectors with heavy demand for plate straightening machines:

Space travel: Rocketbuilding, launchpads, and other equipment.

Sailing: Luxury boats, yachts, and ships.

Renewable Energy Sector: Windmills, wind turbines and energy storage systems.

Electrical Vehicles: Chassis and other parts.

Defense and Military Equipment: Tanks, missiles, and missile systems.

These sectors are growing rapidly, and the gain in demand in the future is undeniable. No wonder many companies from these sectors prefer Himalaya plate straightening machines for their workshops.

Economic Reason 2: Highly Productive and Versatile

Would you save time or money? It’s not a hard task to answer this question. But not having a plate straightening machine and using a third-party workshop’s plate straightening machine is.

Having a plate straightening machine in your workshop reduces your dependability. This way, your in-house machine operator can straighten metal plates as and when required.

These machines are highly productive and straighten as thick as 2mm to 40mm and 4000mm wide metal plates. Every machine straightens metal plates of different thicknesses within this range. Now you know why they are called ever-versatile machines.

Economic Reason 3: Get One, Save Thousands

Let’s look at it this way.

You have a workshop and a plate straightening machine. There are two possibilities:

Scenario 1: You already have clients that require plate straightening done for them, so you outsource the work, send the metal plates there, pay the machine owner and driver and then bring the plates back.

Scenario 2: In the workshop, you don’t require this machine as there’s no work for it. But you know there is high demand for plate straightening in the market.

Why lose money that you can save?

If you have a metal plate bending machine that costs more than these machines, investing in one of these will only be beneficial for your workshop. Metal plate straightening machines are even easier to operate. You don’t have to worry about the machine operator not understanding the work.

That’s all for economic reasons. Moving ahead, these technical reasons will help you understand how a plate straightening machine can help you grow your workshop.

Technical Reason 1: High-Quality Assurance

When it comes to quality, plate straightening machines are highly precise and productive at the same time. The uniform straightening is achieved with the help of clamps that keep the machine in place and rollers that have uniform texture on the circumference. It’s exactly why these machines are an integral part of metal plate fabrication.

You want your machine to do exactly as stated above. Why waste your time when you can have a machine that provides uniform straightening at a faster speed? These machines eliminate waviness, camber, and other shape irregularities, ensuring that the final product meets the requirements.

Himalaya plate straightening machines are made with attention to detail. There are heat treatment facilities and machine testing laboratories that collaborate with the Quality Assurance system to manufacture machines that deliver quality at a constant speed.

Technical Reason 2: Residual Stress Relief

When the plate is straightened, it alleviates residual stresses that accumulate later during the rolling process. It enhances the mechanical properties of the metal plates.

The key point is the straightening of the metal plate makes it less prone to deformation. The metal plate is now better suited for subsequent fabrication processes.

What is your end goal with your product? It’s obviously a metal structure with structural integrity. The straightened metal plates are also easy to polish, reliable, and durable.

Characteristic Reason 3: Improves Efficiency of Overall Process

After straightening your metal plate, the plate rolling process becomes faster. Since there is no need for shape correction, your processes are streamlined.

With less manual labor required, the possibility of human errors is lowered. On top of it, your process becomes quicker, and you don’t have to do manual straightening or shape correction after the plate rolling process.

Conclusion

Metal plate fabrication will go on as long as we use metals. Metal plate straightening machines are ideal solutions for a uniform, flat surface. Flatter the metal plates, the easier the plate rolling process.

Be it productivity, efficiency, or versatility, these machines have everything you need. Let us know if you have any questions regarding plate straightener machines. We, Himalaya Machinery, would love to cater to your metal fabrication machinery needs. original source:- https://www.himalayamachine.com/post/metal-plate-straightening-machine-making-it-work-in-your-best-interest

#3 roll plate bending machine#3 roll bending machine#roll bending machine#4roll bending machine#plate bending machine

0 notes

Text

Metal Plate Rolling Machines: Working, Intricacies & Functionalities

Have you ever wondered how these huge tanks and machines are built? In childhood, I thought they just melted iron or metal and let it dry. Little did I know about the concept of metal plate rolling machines.

Metal plate rolling machines give the conical and cylindrical shapes or bend the metal plates at required angles. This is how workshops worldwide utilize metal plate rolling machines for manufacturing.

We know what you are thinking. “How does that happen? Sheets are fine, but how do you roll or bend a metal plate?” It’s due to the malleability and ductile strength of metal plates.

Malleability is a metal’s ability to be formed into sheets. Ductile strength is how much pressure a metal plate can take to be rolled and not break.

But how does it work?

How does the machine roll these thick and hard metal plates?

We will answer all the questions making circles in your mind. However, to understand how a plate rolling machine works, let’s first understand what functions different parts of a plate rolling machine serve.

In-Depth Look at Different Parts of a Plate Rolling Machine

These machines are extremely heavy-duty, and their build is as solid. Every part of these machines plays an important role in plate rolling.

Let’s explore what these 20 parts of a plate rolling machine do:

1) Frame — It is the body of a plate rolling machine. Provides stability and structural support.

2) Upper Roll — Upper roll is mostly an idler. It rotates at its place and doesn’t move up, down or toward sides.

3) Bottom Rolls — They move up, down, and sideways to adjust the metal plate and roll it at a desired angle to form a cylinder, cone, or arc.

4) Side Rolls — Side rolls support metal plates to maintain uniform rolling.

5) Support Rolls — Same as side rolls, they provide support for metal plates.

6) Drive System — Transfers power from the hydraulic system to rolls for rotation and movement.

7) Control Panel — All the rotational, pressure and other machine controls are housed here.

8) Hydraulic System — Powers roll movements and control precision in plate rolling.

9) Guide Rolls — Makes sure the alignment of a metal plate is accurate while passing through rolls

10) Pinch Rolls — Their dedicated function is to feed the plate into the machine.

11) Pre-Bending Rolls — Utilized for pre-bending on the plate edges.

12) Anti-Deflection System — Negates powers causing plate deflection and minimizes deflection during the rolling process.

13) Lateral Guide System — Ensures proper alignment of the metal plate

14) Clamping System — It holds the metal plate firm while the rolling job is underway.

15) Digital Display — DRO (Digital Readout) displays measurements and settings of different pressure and motor systems. Also helps in repeating a job if the reading are pre-recorder.

16) Lubrication System — To reduce wear and tear, the lubrication system keeps rolls, motors, and other parts prone to depreciation lubricated.

17) Cooling System — Cools down hydraulic oil, which is getting circulated between the hydraulic power pack and all hydraulic cylinders/hydro motors.

18) Material Handling System — Makes it easier to load and unload metal plates to and from the machine.

19) Tilting Table — Helps feed metal plates at a fixed angle. Largely used for heavy/thick metal plates.

20) Conveyors — Makes it easier to feed longer metal plates to the plate rolling machines.

For some parts of these machines, you would think they do the same thing. However, the case is this machine does only one work, i.e., rolling metal plates. So many parts only coordinate and perform this function to achieve near-perfect accuracy for rolled metal plates.

Moving forward to how a plate-bending machine works.

Working Mechanism of a Plate Rolling Machine: Explained!

The number of rolls in a plate rolling machine varies depending on the requirements of a workshop. Generally, there are either 3 or 4 rolls in plate rolling machines. It is because these machines roll metal plates of thicknesses that are required in most applications.

There have also been 5, 6, 7, and even 8 rolls in a single plate rolling machine! It is to be noted that the requirement for these types of machines is scarce. They are only custom-made due to a lack of buyers. 3 and 4 roll plate rolling machines are the most commonly used machines. Therefore, today we will understand the working of 3 and 4-roll plate rolling machines.

Part 1 — How Does a 3-Roll Plate Rolling Machine Work?

A 3-roll plate rolling machine is your go-to choice for rolling thin metal plates up to 3–4 inches. It provides precision and is more cost-effective than a 4-roll plate rolling machine. The only thing to remember is the thickness of the plate you want to roll.

You need to perform three steps while rolling a metal plate on a 3-roll plate rolling machine.

Pre-bending

Center alignment

Roundness correction.

An operator will obtain the metal plates and check for defects. It is important to do so to steer clear of failed rolling attempts in the future. They will also check for material quality and specifications to be at par with national or international standards.

The operator will turn on the machine after checking the lubrication system. They will derive the machine’s status by observing the rolls and the pressure by looking at a Digital Readout. The machine is now ready for pre-bending.

Step 1: Pre-Bending on 3-Roll Plate Rolling Machine

The side rolls are placed closer, and a metal plate is fed to the machine to receive the initial bend. Now the machine is turned on to commence the metal plate rolling process.

The top roll exerts pressure on the plate, while the side rolls apply pressure to the sides. To achieve the desired curvature, the operator adjusts the angle and placement of the metal plate.

Here’s an image to understand how pre-bending shapes the tail and edge of a metal plate.

Step 2: Center Alignment on a 3-Roll Plate Rolling Machine

Upon the completion of pre-bending, it is now time to align the metal plate in the center so that the power is distributed uniformly throughout the surface.

The operator will now adjust the side rolls to put the plate firmly. Next, they will check alignment and fine-tune adjustments.

Once the operator is satisfied with the center-aligning of the plate, they will secure it in place using the clamp system.

Step 3: The Real Rolling Process

Pressure and rotation parameters are now set, and the plate is in place. Next, the operator lets the plate pass through the rolls.

Step 4: After-Rolling Roundness Correction

The metal plate might have some deflection. They check if a perfect cylindrical or an arc is forming. If it isn’t, there is a need for roundness correction. The operator now asks the laborers to make sure both ends meet correctly.

Let’s move to the working of the 4-roll plate bending machine.

Part 2 — How Does a 4-Roll Plate Rolling Machine Work?

The most beneficial thing about 4-roll plate rolling machines is that they give desired results within a single feed. It means that a workshop can get its rolling job done in half the time compared to a 3-roll plate rolling machine, which has to be fed twice for pre and post-bending and rolling.

There are three bottom rolls and a top roll. More bottom rolls result in better accuracy and precision throughout the rolling procedure.

Once the operator has obtained the metal plate, they will check for the material, its ductile strength, and malleability. After confirming that the metal plate meets national or international standards (according to where the machine will be used), they will set the diameter, pressure, and rotational parameters for the metal plate.

The Single-Step Rolling Process

Pre-bending, rolling, and post-bending are all done in a single feed. The operator inserts the metal plate between the top and bottom rollers.

Pre-pinching is done upon the metal plate entering the machine. Then it rolls into a desired cylindrical or conical shape.

Once the rolling process is complete, the metal plate gets post-bent, ending the process of rolling.

It is necessary to understand that both these machines can roll the same thickness of metal plates (a 4-roll plate rolling machine can also roll thicker ones with better precision), but 4-roll cousins are beneficial as they save half the time.

A 3-roll plate rolling machine would be a good choice if one is tight on their budget. Otherwise, there is no better investment than a 4-roll plate rolling machine. Talking about investments. It is necessary to perform maintenance of your machine. The machine manual will have the directions for maintenance. But we have some tips for you to keep your plate rolling machine’s efficiency at its best.

Quick Maintenance Tips for Plate Rolling Machines

Follow these 6 essential tips for machine maintenance.

1) Inspecting the plate rolling machine — Check the bearings, gears, rollers, frame, hydraulic systems, and other parts of the machine.

2) Take precautionary protocols for machine maintenance — Don’t use solvents or inflammable materials, and make sure grease doesn’t disperse in the air.

3) Perform detailed inspection before rolling the metal plate — Check if external parts, indicator lights, and the pressure gauge are working properly. Also, check for leakage in tubes and pipes.

4) Perform weekly maintenance of the plate rolling machine.

5) Perform monthly maintenance of the machine.

6) Annual maintenance is extremely important as you need to check if any part needs replacement.

You can also read our informative article “A Complete 6-Step Guide to Maintenance of Plate Rolling Machine” to learn more about machine maintenance.

To Conclude

Plate rolling machine is a highly mechanical equipment. You must know which machine your workshop requires to make the most out of it. While a 3-roll machine is cheaper, a 4-roll plate rolling machine will double the productivity. Your choice can always depend on your priority needs.

We hope this article has helped you with questions in your mind. Feel free to ask any questions and contact us, Himalaya Machinery, if you have a plate rolling machine requirement. original source :https://www.himalayamachine.com/post/metal-plate-rolling-machines-working-intricacies-functionalities

#3 roll bending machine#3 roller plate rolling machines#plate bending machine price#3 roll plate rolling machine#banding machine#plate bending machine#3 roll plate bending machine#4roll bending machine#roll bending machine#4 roll plate bending machine

0 notes

Text

Types of Plate Rolling Machines: Applications, Advantages & Disadvantages

Plate rolling machines play a crucial role in the metal-forming industry, allowing workshops worldwide to shape metal plates into cones, cylinders, and curved shapes. In this article, we will explore the different types of plate rolling machines and delve into their working mechanisms, advantages, and drawbacks. Whether you belong to the construction, manufacturing, or aerospace industry, understanding these machines can be beneficial. So, let’s get started!

Plate Rolling Machines: Applications and Importance:

The metal-forming industry heavily relies on plate rolling machines for their versatile capabilities. These machines find applications in a wide range of industries, including construction, manufacturing, shipbuilding, oil and gas, aerospace (rocket shell building), automotive, oil tank manufacturing, medical equipment, defense, and renewable energy. The following examples highlight the significance of plate rolling machines in these industries.

Types of Plate Rolling Machines: Working Mechanism, Advantages, and Drawbacks: 2-Roll Plate Rolling Machines:

The 2-roll plate rolling machine represents the basic form of this technology. It consists of one idler roll that remains stationary and another roll that can be adjusted vertically.

This machine applies force and pressure to shape metal plates into the desired radius. Industries such as manufacturing, construction, and automotive utilize 2-roll plate rolling machines to create body shells, equipment components, chassis, frames, and body panels. While these machines offer high production efficiency and minimal warping, they may lack precision due to the fewer number of rolls.

Advantages of 2-Roll Plate Rolling Machines:

High production efficiency (350–1000 pieces/h)

Minimal or zero warping and cracks

Straight section of thin plates remains within material thickness

Drawbacks of 2-Roll Plate Rolling Machines:

Requires a new guide roll for each production batch, which is time-consuming and expensive

Lacks precision compared to machines with more rolls

3-Roll Linear Guideway Plate Rolling Machines:

Advantages of 3-Roll Linear Guideway Plate Rolling Machines:

Requires less floor space for on-site usage

Interchangeable top roll

Provides high precision and smallest possible flat end

Suitable for cone bending, hot rolling, and non-circular bending

Drawbacks of 3-Roll Linear Guideway Plate Rolling Machines:

Higher initial cost and foundation requirements

Changing the roll can be time-consuming

4-Roll Linear Guideway Plate Rolling Machines:

Renowned for their high precision and efficiency, 4-roll linear guideway plate rolling machines offer excellent productivity. These machines feature one top roll and three bottom rolls, providing increased versatility. They can roll metal plates as thin as 2mm up to 100mm, and even thin plates below 10mm in a single pass. Their applications align with those of 3-roll linear guideway machines, but they also excel in mass production scenarios.

Advantages of 4-Roll Linear Guideway Plate Rolling Machines:

Allows feeding from either direction

Performs pre-bend, roll, and post-bend in a single insertion

Capable of cone bending, non-circular bending, and hot rolling

Provides simple operation and does not require highly skilled operators

Drawbacks of 4-Roll Linear Guideway Plate Rolling Machines:

Higher initial cost compared to 2 or 3-roll machines

No interchangeable top roll available

Difficult to re-roll a welded cylinder

3 and 4-Roll Swing Arm Plate Rolling Machines:

Swing arm plate rolling machines come in 3-roll and 4-roll configurations. These machines utilize the lateral movement of swing arms to roll metal plates. The 3-roll swing arm machines have two bottom rolls and an interchangeable top roll, while the 4-roll swing arm machines have three bottom rolls and an interchangeable top roll.

They offer a rolling range of 2mm to 100mm and provide efficient handling of heavy workloads.

Advantages of Swing Arm Plate Rolling Machines:

Interchangeable top roll for enhanced versatility

Great efficiency and ability to handle heavy workloads

Suitable for moderate operator skills

Long life expectancy under favorable workloads

Drawbacks of Swing Arm Plate Rolling Machines:

Higher flat end received upon completion of rolling compared to linear guideway machines

Changing the top roll can be time-consuming

Equipment cost and maintenance are comparatively higher

Conclusion

Plate rolling machines are indispensable tools in various industries, enabling the formation of complex shapes from metal plates. In this article, we explored the different types of plate rolling machines, their working mechanisms, and their applications in various industries.

By understanding the advantages and drawbacks of each type, you can make informed decisions when choosing a plate rolling machine for your specific requirements. If you have any questions or need assistance with plate rolling machines, feel free to contact us. We are here to help.”

Original Source: https://www.himalayamachine.com/post/types-of-plate-rolling-machines-applications-advantages-disadvantages

#plate bending machine price#3 roll plate bending machine#3 roll plate rolling machine#4roll bending machine#roll bending machine#4 roll plate bending machine#banding machine#3 roll bending machine#3 roller plate rolling machines#plate bending machine#plate roll

0 notes

Text

A Complete 6-Step Guide to Maintenance of Plate Rolling Machine

Do you have a plate rolling machine at your workshop? If yes, you may already know how crucial the maintenance of such a machine is. Maintaining your machine doesn’t only benefit its life expectancy but also maintains the quality of work. A thing to keep in mind is that you should hire a machine operator who knows the plate rolling machine inside out. The workshops put their machines through heavy workloads and, ignoring the maintenance, learn in a difficult way why maintenance of a plate rolling machine is vital.

If you own a business, you would already know how costly plate rolling machines are and how crucial it is to maintain their maximum workload capacity. If you’re wondering how to perform maintenance of a plate rolling machine, take a diary and pen, and jot down these 6 steps of machine maintenance.

Step 1: Inspecting the Plate Rolling Machine

The plate bending process involves using lubricants, residue post-rolling, and cut-down or broken parts of the steel plate that you would have rolled earlier.

Let us tell you about the different parts of a plate rolling machine first.

Parts of a Plate Rolling Machine

Bearings: Support moving parts of the machine. Decrease friction.

Gears and Shafts: They transmit power and motion to different areas of the machine.

Rollers: Form and shape metal plates as they are fed to the machine.

Frame: It is the body of the machine.

Hydraulic Systems: They control the rotation of rollers at varying speeds and pressure to obtain required angles through the rolling job.

Electronics and Electrical Systems: Transmits power and allows the operator to control the machine using the console.

Plate Feeding and Handling System: Component that loads and feeds the metal plates to the rolls of the machine.

Lubrication system: Lubricates the machine for minimum friction and a smooth work process.

Before you commence the work during your shift, you must clean the machine and look for residue or broken parts. Also, check the state of the rolls of the machine. Follow these sub-steps to perform your daily inspection.

Turn off the plate rolling machine before the inspection.

Inspect the machine and look for the residue from the previous shift or day.

Check for abnormalities on different parts of the machine

Make sure the tightening screw is, well, tight.

Inspect the brakes and ensure they are set at normal to be reliable.

You must have realized that you should do this basic inspection every day before starting the work shift. It sounds like a very basic daily cleanliness routine, and it is. However, when you have bigger fish to fry, it is necessary to make sure the basic cleaning procedures are followed. Now you can move on to precautions that you must take to maintain your plate rolling machine.

Step 2: Precautionary Protocols for Maintenance of Plate Rolling Machine

We all put aside the manuals that come with the machine, or the first operator would have read it. What’s necessary is to notice that the new operator must have learned things from the old one. They might not know about tiny details and the warnings and advice about cleaning the machine.

Efficient cleaning requires you to strictly follow the guidelines from the machine manual. Here are the five instructions you should know and follow during the maintenance of the plate roller machine.

I) Don’t use solvents or inflammable materials. They may cause direct harm to the machine.

II) Make sure the grease doesn’t disperse in the air.

III) Restore guards after cleaning them with metal cleaner or polish. Do not forget to fit the guards again. Deactivated guards increase the chances of injuries.

By far, what we have discussed are routine and basic cleaning and maintenance procedures. Next up, how to perform a detailed inspection before starting the work.

Step 3: Detailed Inspection Before Rolling the Plate

Check for all the parts to be in working order. Note if there are any deformities or refrain from using if any critical parts are missing, broken, or deformed.

I) Inspect external parts of the machine for deformity or damage.

II) Set indicator lights to normal and check operation switch, limit position and console.

III) Check pipes and tubes for leaks. It includes checking oil pumps and cylinders and

IV) Ensure the rollers are working properly and the brakes are in shape.

V) Ensure the pressure gauge is working properly.

VI) Lubricate parts that require manual lubrication.

Step 3: Daily After-Work Maintenance

Leave the machine in better condition than you found it while starting your shift. This will automatically inspire the next shift operator to perform regular maintenance as you do every day.

I) Check the normal operation of the safety device

II) Ensure proper working of braking mechanisms

Step 4: Weekly Maintenance of the Plate Rolling Machine

This inspection is crucial as the filters might or might not get filled after a week. So here’s what you need to do.

I) Check for the proper functioning of the emergency stop mechanism

II) Inspect side protectors

III) Check for the proper functioning of the rear protector

IV) Filter has an indicator that tells you whether it is clogged. Unfortunately, the yellow indicator light on the vacuum switch means you must replace the filter immediately.

Step 5: Monthly Maintenance of the Plate Rolling Machine

You don’t want the machine to have leakages and month-old residue in the finer areas where it is impossible to reach every day because it takes time. Performing monthly maintenance keeps your machine in check for the standard.

I) Clean all pipes, tubes, and hydraulic components:

Cylinders, valves, motor/pump units, and other pipe and tubular systems.

It helps you make sure there are no leaks

This way, the contaminants cannot get into the machine while removing and replacing components

II) Check all the internal and external fittings and ensure no leaks or loose fittings.

III) Have flexible tubing that connects the pump and system. Upon swelling, replace right away.

IV) Check the oil level, for it is necessary to maintain energy transmission, conversion and control over the machine.

V) Tank air filter should be cleaned with compressed air.

Step 6: Annual Maintenance of the Plate Rolling Machine

Machine parts that take time to wear down or some filters that get filled slowly over time must be checked annually.

I) Upon the pressure drop reaching 1 bar, you should change the oil separator microfilter. Or, do it anyway after a year. It is a beneficial measure to take.

II) Re-fill oil in the hydraulic circuit

III) Replace the oil filter element with a new one.

Final Touch

A plate rolling machine is a heavy investment for any size of business. It is not a miscellaneous expense. Even after knowing this, some workshops continue overloading their plate rolling machines and neglect regular, weekly, monthly or annual inspections. Take a pen, not these steps and start working with due diligence. We at Himalaya Machinery provide the best plate rolling and straightening solutions. Contact us through the mail and share your requirements with us.

#3 roller plate rolling machines#3 roll bending machine#4roll bending machine#roll bending machine#plate bending machine price

0 notes

Text

What is Plate Bending/Rolling? Everything You Need to Know is here

You must have seen ships, rockets, oil tanks, windmills, and several other large structures around you or on trips. If you are as curious as I am, you may have always thought about how these large structures are made. For such large metal structures to be made in the desired shapes, metal Plate Bending/Rollings are installed at the workshops and factories.

Plate Bending/Rolling machine operators put the metal plates between the rollers in the machine and set the bending force, which results in bending the sheet in the desired manner. Therefore, if you are planning to enter the metal Plate Bending/Rolling industry, it is necessary to learn what it is, why it is performed and how one can perform Plate Bending/Rolling.

Let’s understand Plate Bending/Rolling in detail and also discuss how it is performed using different types of machines.

What is Metal Plate Bending/Rolling?

As you can see in the above image, the metal plate is between the top and bottom roller. Both rolls rotate at different RPMs and put force on the metal plate to bend/roll it. Yet, this is not the whole process. Let us tell you more about how a metal Plate Bending/Rolling/rolling machine works.

How Does a Metal Plate Bending/Rolling/Rolling Machine Work?

There are 4 crucial steps one must follow in order to achieve desired metal plate shape through a metal Plate Bending/Rolling/rolling machine.

Setting bending force according to the desired radius

Placing the metal plate on the table to maintain uniform bending/rolling

Pre-Pinching/Pre-Bending the tails of the metal plate

Passing the metal plate through the Plate Bending/Rolling/rolling machine

Step 1: Setting Bending Force on the Plate Bending/Rolling Machine

A bending operator will first assess the workload of the Plate Bending/Rolling/rolling machine. Once they are through the assessment, they decide on the bending force to be applied on the metal plate to bend/roll the machine at desired ID or OD (Inside Diameter or Outside Diameter).

A decision on ID or OD is necessary since that is the result.

Step 2: Placing the Metal Plate on the Table to Restrict Unwanted Movement

When the operator puts the metal plate on the table, it limits the movement of the plate in an unwanted direction. This is necessary since a moving metal plate would be mis-bent during the process.

Step 3: Pre-Pinching / Pre-Bending before Commencing the Bending Process

Pre-pinching or Pre-bending is the process of bending both the tails of the metal plate at the initial stage to achieve the desired radius at tails during the bending. It also helps the operator do minimal process post-bending.

Step 4: Bending the Workpiece through the Metal Plate Bending/Rolling Machine

Now that the metal plate is on the stand with pre-pinching or pre-bending successfully achieved, the operator can place the metal plate between the top roll and the bottom roll(s). The bending process is crucial, and having an experienced operator is helpful for the workshops since Plate Bending/Rolling/rolling machines are a major investment.

Types of Machines used for Performing Plate Bending/Rolling Operations

All around the world, several industries such as shipbuilding, metal fabrication, wind energy, earth moving, metal structures, rocket shell making, oil tanks, tubes and pipes, and thousands of others utilize metal Plate Bending/Rolling machines to make varying sizes of equipment and metal structures.

These are the types of Plate Bending/Rolling/rolling machines that these industries use for performing their Plate Bending/Rolling/rolling operations:

2-roll Plate Bending/Rolling machine

3-roll Plate Bending/Rolling machine

4-roll Plate Bending/Rolling machine

All above types of machines can be classified into two types based on their guideway type:

Linear Guideway Plate Bending/Rolling machine

Swing Guideway Plate Bending/Rolling machine

Different industries require different machines according to the workload they want the machine to handle. The choice of the machine also depends on the precision levels and majorly on the skillset of the operators.

Wrapping Up

The plate-bending industry is larger than we can imagine, and we hope this article has helped you with your questions regarding the same. If you are in the Plate Bending/Rolling industry or a manufacturer who requires a metal Plate Bending/Rolling machine at their workshop, stop thinking and contact Himalaya Machinery to inquire about matching your needs. We would love to help you with your needs and improve your experience of buying a plate-bending machine.

0 notes

Text

10 Features that make Himalaya 3-Roll Plate Bending/Rolling Machine an Ultimate Choice

Quality has no substitute when it comes to customer satisfaction. Himalaya Machinery has been providing metal forming solutions for 40+ years now. From the large set of machines that we supply, 3-roll plate bending/rolling machines are a top choice for our customers. As experienced as we are, we have always stayed in touch with our customers to keep bettering.

3-roll plate bending/rolling is a process of bending metal sheets into desired shapes. These machines are an integral part of the manufacturing process. Building large customized machines requires businesses to bend/roll metal sheets in large quantities, and you need machines that have features even you wouldn’t know your businesses needed all this time.

Let us tell you a bit about what 3-roll plate bending/rolling machines are and which industries utilize them.

Understanding 3-Roll Bending/Rolling Machine

When the industrial revolution started, there was a need for machines that would efficiently deliver quality within the workspace. 3-roll bending machines have played an important role in history and continue to do so.

Of the three rolls in Himalaya Machinery’s 3-roll bending/rolling machine, two side rolls are movable, which induces linear movement, while the top roll rotates idly at its position. This top roll is interchangeable so you can roll smaller and larger diameter shells as required. The process of changing the roll takes no more than 30 minutes.

Finally, as shown below, the bending and the rolling process ends successfully.

Let’s move on to the features of the Himalayan Machinery 3-roll bending/rolling machine.

What Features make Himalaya 3-Roll Plate Bending/Rolling Machines the First Choice of Manufacturers?

Bending/rolling is majorly mechanical work. However, technological advancement has enabled us to provide our customers with machines that provide the accuracy they need in their work.

We have delivered over 2500 machines throughout the country and overseas. With a good idea of what the customers need, we provide them with the best features available in the market.

Here are the features that make the Himalaya 3-roll plate bending/rolling machine the best choice for you as a manufacturer.

1. Thickness Range — 2mm to 160mmThe machine comes with the ability to bend/roll metal sheets as thin as 2mm to thick as 100mm. When it comes to varying workload handling, it is one of the most versatile machines.

2. Pre-Pinching and Pre-BendingThe 3-roll plate bending/rolling machine provides the smallest possible flat end for the metal sheet you have placed to bend/roll. This signifies a well-built machine since the result is what the manufacturer wants.

3. Interchangeable Top RollIf you want to change the top roll, you can do it easily in your workspace; the process only takes 30 minutes. With this, you can insert another roll if your requirement changes or there is heavy wear and tear in the old top roll.

4. Surface Hardened RollsThe rolls are hardened with an induction process, and the hardness of these rolls is between 42–55 HRC. This amount of hardness elongates the durability and longevity of the machine.

5. Tilting TableA tilting table becomes a necessary piece of equipment when handling a lengthier metal sheet. This table helps you set the sheets at a specific angle while feeding them to the machine, and they turn out extremely useful while bending sheets of larger lengths.

6. ConveyorsIt is harder to feed larger-length metal sheets by yourself. To feed these metal sheets, the conveyors prove to be helpful. Himalaya provides this feature to address the needs of many manufacturers.

7. Central & Side Shell ProtectsIn the manufacturing industry, the safety of workers is a top priority. No worker wants to work in a company that doesn’t pay heed to safety. Therefore, the 3-roll plate bending/rolling machine comes with central and side shell protection for the workers’ safety.

8. Hard Chrome Plated RollsSelective industries require some regulations fulfilled, and we provide these Hard Chrome Plated rolls for the pharmaceutical and dairy industries.

9. PLC Control & CNC CapabilitiesUpon investing, you need the return to be optimized. Meaning you will require the machine to work for a longer time. The 3-roll machine from Himalaya comes with precision and comparatively easier operation with PLC control and CNC capabilities.

10. Automation (Industry 4.0) ReadyAutomation has helped in lowering the error rate in manufacturing units. In addition, when you switch to automation, you don’t have to worry about investing money in brand-new machines because all Himalaya Machinery machines are future-ready.

These are the top 10 features we provide to generate great value for our customers and stakeholders.

Why Choose Himalaya?

Just like our name, our journey has been a grand one. As said earlier, we have installed more than 2500 machines worldwide and some machines sold 40 years ago are still running to date. We’ve got repeat orders from more than 400 customers across the globe due to the support we provide to our clients. Himalaya believes in efficient machines, excellent customer support, and an ever-lasting bond with customers.

Original Source:- https://www.himalayamachine.com/post/himalaya-3-roll-plate-bending-rolling-machine-10-features-you-need-to-know

#3roll bending machine#3 roll plate bending machine#plate bending machine price#banding machine#3 roll bending machine#4roll bending machine#4 roll plate bending machine#3 roll plate rolling machine#roll bending machine#3 roller plate rolling machines#bending roller machine

0 notes

Text

How does Himalaya Ensure Optimum Manufacturing Quality?

Excellence is a seller. And we tell you this from our 40+ years of experience in the manufacturing industry. Since our inception, we, Himalaya Machinery, have had satisfied customers and happy stakeholders as our mission. Be it metal cutting, bending, welding, rolling, or CNC machining. We have always thrived for excellence.

#Roll Bending Machine#Plate Bending Machine Price#3 Roll Bending Machine#3 Roll Plate Bending Machine#3 roller plate rolling machines#3 roll plate rolling machine#3 roll bending machine#banding machine#heavy machine#4roll bending machine#heavy machinery#machine#heavy metal

0 notes

Text

How does Himalaya Ensure Optimum Manufacturing Quality?

How does Himalaya Ensure Optimum Manufacturing Quality? Excellence is a seller. And we tell you this from our 40+ years of experience in the manufacturing industry. Since our inception, we, Himalaya Machinery, have had satisfied customers and happy stakeholders as our mission. Be it metal cutting, bending, welding, rolling, or CNC machining. We have always thrived for excellence.

We are a state-of-the-art manufacturing unit and help customers become leading manufacturers in their respective fields. Realizing this thought commences by wielding a passionate workforce. As a result, our expertise is acknowledged by overseas customers from several countries.

How do we make it possible? The idea of satisfactory manufacturing excellence? Marching forward needs a set of discipline and values. Here are some values Himalaya Machinery has garnered as a pioneer of optimum manufacturing quality providers

The Himalayan Core Values As a leading manufacturer, we realized from the beginning that a strong core of values is necessary, which will shape the future of our metal-bending/rolling brand.

Focus on Customers’ Success

A good doctor is one whom you don’t have to visit again. And when it comes to machine building, we, as a unit, focus on making end-to-end solutions for our customers so that they can run their businesses seamlessly.

If need be, we are present with our customer support and service engineers. But, we make all our efforts in the direction of the clients not needing help again.

Be Result Oriented

In the end, what matters is the results. Therefore, keeping the desired results in mind while making heavy machinery for our customers is necessary. This focus helps to proactively analyze and solve any difficulties the customers may face.

Taking Ownership

Himalaya Machinery has never looked the other way when it comes to standing for the consequences or solving existing or predictable critical problems. Taking responsibility needs nurturing, and Himalaya has well-nurtured this quality since the beginning.

Improve Continuously and Apply Creativity

They say perfection is a myth. It is more like a motivation to strive to improve at something. So we have kept improving, which led to exporting the first 3-roll plate bending/rolling machine to Kenya in 2016.

Getting creative helps provide more features in the machines for the customers and be in the same age the world wants to be. Adaptability is simplified with creativity at Himalaya Machinery.

Work As a Team

Working as a team is a necessity while manufacturing such large machinery. There is no margin for error, and as a team, it is made sure that the process has less erring or stays error-free.

Deliver Quality

No one wants to pay more and get less. Therefore, qualitative work is a primary focus and will stay that way when Himalaya Machinery delivers the work to customers.

All the work without the customers feeling satisfied is of no work. Thus, customer satisfaction tops our checklist of goals to be met.

Customer Satisfaction Comes First

Satisfying the customer is one point that proves that manufacturing excellence is met at the point of deal completion.

Himalaya Machinery builds user-friendly metal-forming solutions for manufacturers worldwide. And a reputation like this, as a brand that provides optimum manufacturing quality, is built on years of perseverance, experience, and excellence.

Two important points in the initial phase of customer acquisition.

On-hand stock

Skilled workforce

Always On-Hand Stock

Advanced planning helps make the customers know that we are the ones they can trust to get their work done. If you are in need, you need the machine as early as you can get. What else would be better than a solution provider who has on-hand stock?

This is an example of how much on-hand stock you can expect Himalaya to have when you contact us to fulfil your requirements.

Skilled Workforce

We are grateful to the entire workforce that has worked with the company since 1978 and joined later. Skillful individuals need to be cared for, and we have worked on it throughout our journey collectively as a brand.

Here are some stats to let you know how skilled the Himalayan workforce is.

2500+ installations in India and abroad.

400+ repeat orders from trusted customers.

40+ years in the industry

Throughout the years, the manufacturing setup has grown into a vast world spread over 16,000 square meters.

Our Manufacturing Setup We want to do so much as a manufacturing company in sheet metal, metal bending/forming, Shipyard and other leading industries. Our manufacturing arsenal line-up has the following sections.

1) Assembly Line Three assembly lines that can handle 25, 50, and 100 tons of components for small, medium, and large machines are set up in Himalaya Machinery spread in 16,000 square meters.

2) Heavy and Light Machine Shop Turning, threading, boring, cross boring, milling, profile threading, drilling, facing, and tapping are handled in these shops. These shops can handle up to 40 tons of components and machinery.

3) CNC Machine Shop Two Vertical Machining Centers (VMCs), two CNC turning centers, and two heavy-duty CNC lathes are placed in the CNC shop to get the components processed with cutting-edge technology.

4) Heat Treatment Facility To complement and benefit the work life of components we deliver to our customers, we take them to a heat treatment facility, impart benefiting properties and alter their microstructure.

5) Material Testing Laboratory We test and check the physical, chemical, and mechanical properties of the materials we use to deliver the best quality machines to our customers.

6) Quality Assurance System We leave no page unturned regarding the QA process of manufactured machines. The QA sector is independent, and only after the machines have been tested mechanically, physically, and chemically do they pass this quality assurance test.

7) Testing facilities of Assemblies and Sub Assemblies We also assemble machines for our customers and have independent testing facilities for assembled and sub-assembled machines in Himalaya Machinery.

This is all that Himalaya does as a unit to satisfy not just our customers and stakeholders but also ourselves as a passionate workforce.

Some Last Words As sophisticated and revolutionary as the setup of Himalaya Machinery looks, it has been only through around four decades of sweat-breaking hard work. Machine quality, customer satisfaction, and longer work life for machines are the three core goals that we aim to meet. Have machinery requirements? Here’s the list of all our products.

#Roll Bending Machine#Plate Bending Machine Price#3 Roll Bending Machine#3 Roll Plate Bending Machine#3 roller plate rolling machines#3 roll plate rolling machine#3 roll bending machine#banding machine#4roll bending machine

0 notes

Text

Difference Between 3 Roll plate Bending/Rolling Machines & 4 Roll Plate Bending/Rolling Machines

When it comes to workshop machines, one of the versatile machines is a Plate Bending/Rolling machine. It can do various jobs over and above circular shells when used suitably. Its ability to bend any workpiece makes it important in sheet metal and other industries. You can produce Circular shells and other shapes like Conical l, Multi radius and Elliptical with a good quality Plate Bending (Rolling) machine. Compared to other machine tools, it exhibits quite an extended working life.

Primarily, there are three different types of bending machines:

2-roll plate bending (rolling) machine

3-roll plate bending (rolling) machine

4-roll plate bending (rolling) machine

Choosing the right bending machine for your machine shop or metal fabrication company demands understanding the differences between each and their unique features, application, advantages and disadvantages. It is crucial to understand which machine gives what type of output and which machine will be best for one’s rolling jobs/application.. However, this article will discuss 3-roll plate bending (rolling) machines and 4-roll bending machines.

3 Roll Plate Bending/Rolling Machines (Linear Guideway Type)

The bottom rolls in linear guideway geometry machines are positively guided in the machine frames. The axis of the bottom rolls is closer to the top roll. The close spacing between the top and bottom rolls enhances the circularity of the rolled shell. Therefore, the precision/circularity of the final resultant rolling workpiece is better when compared to swing guide or variable geometry machines.

The design is such that the bending forces are directly transferred from cylinders to rolls, as no linkages are involved. Due to this, no wear and tear are caused and the guideways and roll parallelism is maintained. An ideal machine’s front and back frames are cut and machined to achieve an extremely precise alignment of the guideways in which the bottom rolls move. Thus, the users can get excellent accuracy in terms of roll movement and superlative Bending / Rolling quality.

Here’s a video showing the bending/rolling capabilities of Himalaya’s 3 Roll Plate Bending/Rolling machines:

Himalaya’s Plate Bending (Rolling) machines are designed for hassle-free usage and energy-saving features; to ensure peace of mind and operational convenience for plate bending work. The general components of the machine go something like this:

Rolls — three or four — depending upon the model

Two frames ( Head and Tail Side frame)

Swing Arm for the removal of the rolled shell

Coaxial planetary gearboxes

Hydraulic system with an energy-saving feature

Comprehensive overload protection

Easy centralized controls, PLC & CNC version

Roll parallelism mechanism

The 3-roll machines have linear guideways for the two bottom rolls. There is a minimum distance between the bending points to achieve higher precision of rolling jobs.

Advantages of Three Roll Plate Bending (Rolling) Machine

Compact construction: Demands less floor space and is thus useful for site conditions.

Offers easy Re-rolling of a welded shell: Since no rolls are pressed against each other, the welded seam can jump over the rolls.

Cost-effective: You can buy a larger and better machine for a given investment compared to the same rolling capacity of a four-roll or variable geometry plate bending machine.

Operator-friendly machine: Ease of operation for bending/rolling of Cylinders, Cone bending attachment is also provided to make this operation easy. The main three basic operations can be easily learned: Rolling, Pre-Bending and Removal of the shell.

All the functions performed by a 3-roll bending machine are the same as a 4-roll bending machine. However, the key difference is that with a 3-roll bending machine, you have greater control over the desired output.

Four Roll Plate Bending (Rolling) machine

As the name suggests, the four-roll plate bending (rolling) machine has four rollers. In this machine, the top roll remains stationary, the bottom roll moves vertically, and the two side rolls move in a linear guide way to form the shell.

In this arrangement, the workpiece is held between the top and bottom roll while the side rolls create the bend by moving vertically. For holding the plate surface, the bottom moves up securely against the top roll while the side roll rises to create a precise bend.

Here’s how it looks:

The planetary gearboxes and hydraulic motor power drive the top and bottom rolls.

The location of the bottom roll directly below the top will ensure a good grip while bending plates/sheets.

Thin plates demand closely spaced rolls to eliminate driving slippage.

Due to the high productivity of low-thickness shells, the four-roll machines are a good investment for the mass production of pipes and shells.

Over and above the cones, other non-circular shapes like oil tankers & elliptical shells can be made.

The 4-roll configuration also allows CNC operation.

Out of the four rollers, the upper roller is a drive roller, and the lower inside is an enslaved person-driven ruler; the former is fixed while the letter can be lifted and moved. With the help of a hydraulic motor, you can drive the upper roller; however, with the lower and side roller rotation, you have to use only the friction in the steel plate and the roller to drive it.

One of the biggest benefits of using this machine is that it is simple and convenient. These machines also perform the same function as three-roll machines.

Advantages of 4 Roll Bending Machine:-

Large material- Like the 3-roll version, these bending machines can handle plate thicknesses from about half an inch to four inches or even more, based on the model.

Higher productivity — With CNC features, one can achieve higher productivity than 3 roll plate bending/rolling machines.

Suitable for mass production: Due to the high productivity of low-thickness shells, the four-roll machines are an attractive investment for producing pipes and shells.

the the the o better understand the two types, we have made a table

Parameter

3 Roll Plate Bending/Rolling Machine

4 Roll Plate Bending/Rolling Machine

Structure

The bottom rolls in our linear guideway machines, are positively guided in the machine frames. The axis of bottom rolls is closer to the top roll. The close spacing between top roll and bottom rolls improves circularity of the rolled shell. Hence accuracy of resultant job is better than swing guide or variable geometry machines.

The four-roll plate bending (rolling) machine has four rollers. In this machine, the top roll remains stationary, the bottom roll moves vertically, and the two side rolls move in a linear guide way to form the shell.

Application

Based on models, these bending machines are capable of bending plate thicknesses from about half an inch to four inches.

Based on models, these bending machines are capable of bending plate thicknesses from about half an inch to four inches.

Unloading Process

Usually, the unloading process of four rollers is controlled by push buttons, thus making the process easier.

Usually, the unloading process of four rollers is controlled by push buttons, thus making the process easier.

Before investing in any metal-forming technology, it is important to explore the priorities. Once you are sorted with your requirements, you can choose the right bending machines. An ideal piece of the bending machine should be capable enough to handle common materials, special materials, and different shapes.

So, are you looking for a good quality plate roll bending machine for your business? We have got your back. Feel free to contact Himalaya Machinery to get the best bending machine and get your work done in a jiffy. Original Source : https://www.himalayamachine.com/post/3-roll-plate-bending-vs4-roll-plate-bending-machine

0 notes