#4 Axis CNC Cutter

Explore tagged Tumblr posts

Text

Best 4 Axis CNC Router Manufacturer Company in Pune

The 4 axis CNC router is a powerful tool that is perfect for those who need to quickly and easily create detailed designs. The machine is easy to operate and install, and comes with everything you need to get started. The Mach 3 software is simple and easy to use, and the flexible coupling makes it easy to connect to a variety of different devices. The spindle motor knob is also a great feature that allows you to make small adjustments to your design. The chrome shafts are also very durable and can withstand a lot of wear and tear.

The 4 axis CNC router is perfect for anyone who wants to create detailed and intricate designs. The machine is very easy to operate, and the software is very user-friendly. The flexible coupling makes it easy to connect to a variety of different devices, and the spindle motor knob is a great feature that allows you to make small adjustments to your design. The chrome shafts are also very durable and can withstand a lot of wear and tear.

The 4 axis CNC router is a great machine for anyone who wants to create detailed and intricate designs. The machine is very easy to operate, and the software is very user-friendly. The flexible coupling makes it easy to connect to a variety of different devices, and the spindle motor knob is a great feature that allows you to make small adjustments to your design. The chrome shafts are also very durable and can withstand a lot of wear and tear.

We are leading manufacturer of 4 Axis CNC Router and we are reach requirement of all client to Supply 4 Axis CNC Router worldwide from Pune, India.

For more information about 4 axis CNC router Manufacturers company in Pune,

#4 Axis CNC Router Manufacturer in Pune#4 Axis CNC Router Supplier in Pune#Buy 4 Axis CNC Cutter#4 Axis CNC Routers manufacturing company#4 Axis CNC Cutter

0 notes

Text

EXPLORING THE 5 COOL PARTNER SELLER ELECTRONICS PRODUCTS-Part1

Exploring the 5 Cool Partner Seller Electronics Products

Prologue

Are you an electronics enthusiast looking to expand your electronics project repertoire? Want to take your skills to the next level by exploring new and exciting products? Look no further than our list of five cool electronics products from partner sellers!

Whether you’re interested in building your own smart home devices, experimenting with sensors, or creating your own robot, these products are sure to inspire you. They cover a lot of application areas, from loop detectors used to monitor vehicle count in parking garages to Arduino CNC shields used in CNC machines, from simple pulse sensors used to detect cardiovascular pulse signals from fingertip to RGB LED panel light used in smart home, these products are unique, compact, and functional. Not only are these products fun to build and use but they’re also designed to help you learn new skills and techniques along the way.

What’s more, these products all come from trusted partner sellers who are committed to developing high-quality products. They’re happy to provide technical support for customers who have questions, so you can be sure you’re getting the best in electronics.

So get ready to dive into the world of electronics and explore these five cool partner seller products. You’re sure to find something that piques your interest and takes your own electronics projects to the next level.

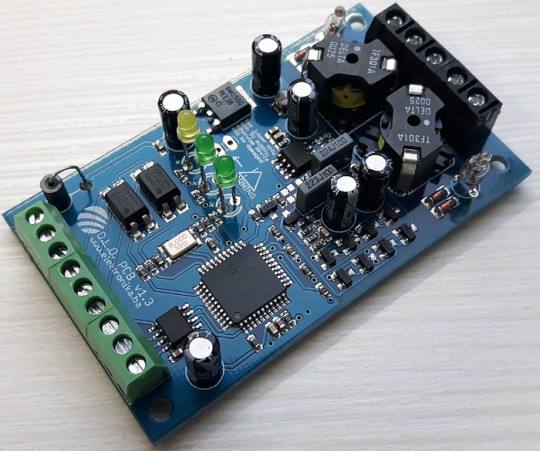

Inductive Loop Vehicle Detector by Elektronika-ba

Whether you need to monitor occupancy and count vehicles in parking garages, control vehicle access at door and barrier controls, or facilitate traffic light installations and traffic controllers, the inductive loop detector is the perfect solution. It can even detect the direction and speed of vehicle traffic, making it an invaluable tool for a variety of traffic-related applications. In addition, this device can function as a stand-alone speed trap and can be easily interfaced with Arduino.

We can also provide a pre-programmed PIC chip to meet your project requirements.

Specifications

Number of operating modes: 4

Tuning: Automatic

Detection type: Presence/Pulse

Presence time: Adjustable in 3 steps

Pulse duration: 250 ms / 500 ms

Signal filtering: Adjustable in 2 steps (NORMAL, HIGH)

Loop inductance: 20 uH — 1000 uH

Frequency range: 20 kHz — 145 kHz

Frequency selection: 2 combinations (LOW, HIGH)

Sensitivity: Maximum 0.0025% Δf/f, adjustable in 8 steps

Detection speed: 10 ms by default, adjustable

Start-up time: ~ 1 second per channel (or longer if the frequency is not stable)

Temperature range: -35°C — 120°C

Sensor protection: Galvanic isolation + gas discharge tube for lightning protection

Don’t settle for less — click here to learn more about the Inductive Loop Vehicle Detector and experience the compact, yet cool detector!

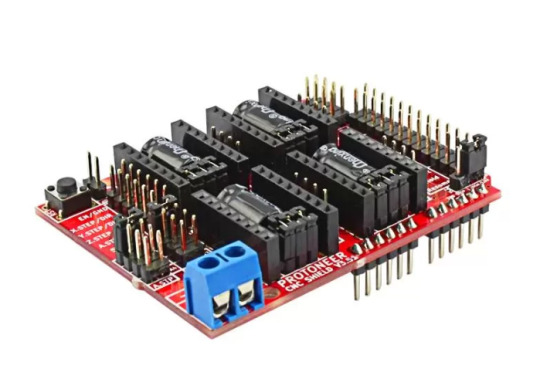

Arduino CNC Shield V3.51 by Protoneer

Designed by Protoneer, this kit is packed with features to ensure high precision control of your stepper motors, you can use it to easily build small CNC routers, DIY laser cutters, 3D printers, or any project that requires precise stepper motor control.

Our latest version 3.51 includes several enhancements to make assembly and installation even easier. We’ve added end-stop and probe signal filtering circuitry to eliminate false triggers and allow the use of unshielded cables for end-stops and probes. We’ve also increased the size of the solder pads for easier assembly and updated the probe pin labels to make installation a breeze.

With the Arduino CNC Shield Kit, you’ll have everything you need to build your own CNC router or mill with ease.

Features

Includes Noise Filers on all end stops and the probing pin. (New in V3.51)

GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

4-Axis support (X, Y, Z, A-Can duplicate X, Y, Z or do a full 4th axis with custom firmware using pins A4 and A3)

2 x End stops for each axis (6 in total)

Coolant enable

Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others)(Not Included)

Jumpers to set the Micro-Stepping for the stepper drivers. (Some drivers like the DRV8825 can do up to 1/32 micro-stepping )

Compact design.

Stepper Motors can be connected with 4-pin molex connectors or soldered in place.

Runs on 12–36V DC. (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.)

Don’t wait — click here to see more about the Arduino CNC Shield V3.51 and start your next project today!

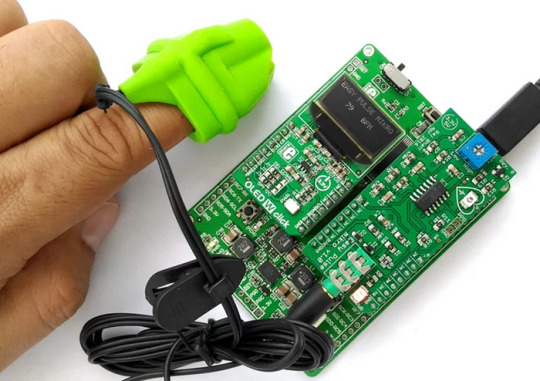

Easy Pulse Mikro by Embedded Lab

What’s more, the Easy Pulse Mikro is designed in the convenient Mikro bus form factor, making it easy to integrate with a wide range of mikroElektronika’s development boards. With all necessary instrumentation and amplification built right in, this powerful sensor provides a clean and precise analog PPG waveform output that’s routed to the AN pin of the mikroBus connector.

Whether you’re a hobbyist, student, or professional developer, the Easy Pulse mikro is the perfect tool for monitoring heart rate and other vital signs.

Click here to see more about the Easy Pulse mikro.

Features

Compatible with mikroBus socket.

Filtered and amplified analog PPG signal output

On-board potentiometer for adjusting amplifier gain, if needed (rotate clock-wise for increasing gain)

Onboard LED for indicating heartbeat. It flashes synchronously with the heartbeat on detecting the pulse from the fingertip.

2 notes

·

View notes

Text

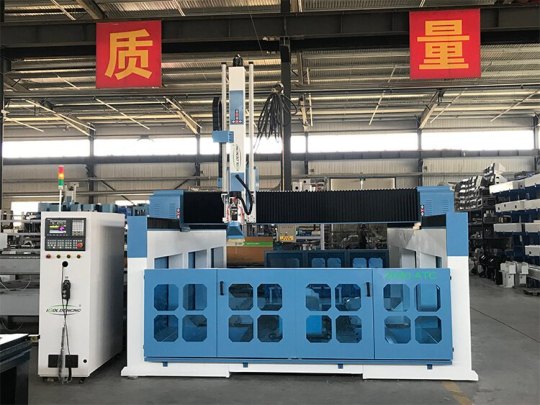

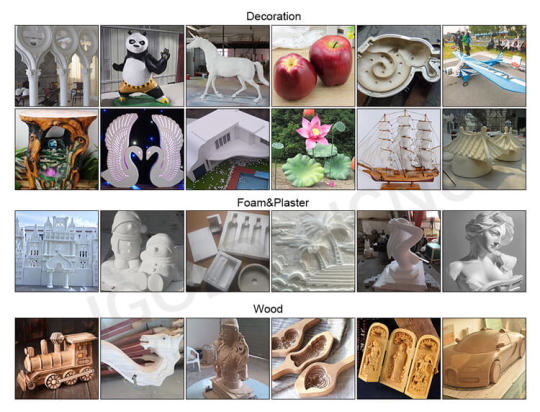

Automatic Tool Change Foam Router EPS CNC Carving Machine

CNC Router Foam Cutting Machine

Automatic Tool Change Foam Router, also known as an EPS CNC Carving Machine with Automatic Tool Change, is a specialized computer-controlled machine designed for cutting, carving, and shaping Expanded Polystyrene (EPS) foam materials. These machines are equipped with an automatic tool change system that allows for the seamless swapping of cutting tools during the CNC routing process.The 3d CNC router milling machine can be seamlessly spliced, suitable for various shapes.This CNC router foam machine also can be used in embossing, lettering, hollowing, cutting, vertical carving, round carving, etc.

This 4 axis cnc foam router is a little special when compared with the ordinary four axis machine. The conventional 4-axis construction has two types: one is that the spindle can swing ±90 degrees; the other refers to the rotary axis. Either of the two can be called the ordinary 4-axis cnc machine. What makes this machine special is that it is actually a 2 in 1 cnc foam router as it has the two types 4 axis construction stated above. Based on this design, there is no doubt that it has more possibilities than a normal 4-axis machine. The 4 axis cnc foam router here is perfect for 3D polystyrene shapes making.

4 Axis 3d CNC Router Milling Machine

EPS/foam CNC router usually comes with a big working dimension for carving and cutting large-size workpieces of wood, aluminum, and styrofoam. It can also be equipped with an ATC spindle and a rotary device for complex, heavy-duty, and long-term work. It is widely used to process and carve wood and styrofoam automotive, ship or other molds, and GRG or GRC decorations, and architecture models.

Automatic Tool Change Foam Routers are specifically designed to work with EPS foam materials. EPS foam is commonly used in various industries for insulation, packaging, and creative applications due to its lightweight and easy-to-cut properties.Like other CNC machines, EPS CNC carving machines with automatic tool change offer high precision and accuracy. The CNC technology ensures that complex designs, intricate patterns, and 3D shapes can be executed with precision.

Foam Router EPS CNC Carving Machine

Packaging: Creating custom foam inserts for protecting fragile items during shipping.

Sculpture and Art: Carving intricate sculptures and art pieces from EPS foam.

Architectural Design: Crafting decorative elements and architectural details.

Set Design: Producing props and scenery for theater, film, and events.

Sign Making: Crafting 3D signs, logos, and lettering.

This cnc router foam cutter is designed especially for custom EPS expanded polystyrene foam moldings. The molded foam is usually used for casting & founding. Three-axis construction with 1500x3000mm machining size (5×10 in English); (need 4th rotary? please check out foam milling machine with rotary axis) Dirt guard is designed on X Y Z axes particular for cnc foam machining, which keeps the precise transmission parts away from the machining debris. The table is made of aluminum profiles. It is ideal for EPS EVA foam machining as well as wood machining. CNC router foam cutter for custom EPS EVA molding for sale at a reasonable price now!

Application Scope

How Many Kinds of CNC Foam Router Are There?

Well, this need to see from which perspective. From a motion axis quantity perspective, there are 3 axis, 4 axis and 5 axis cnc foam router; from application point of view, there are cnc foam router for polystyrene, for woods and for aluminum.

0 notes

Text

TK8120 12AXES CNC SPRING COILING MACHINE

1. Controlled with twelve axes: wire feed axis (5 axes), upper cutter axis, lower cutter axis, upper variable diameter axis, lower variable diameter axis, variable diameter movable axis, pitch axis and core pulling axis.

2. The twelve axes can work single-step or synchronously.

3. Computer interface displayed in Chinese and English which makes the operation easy.

4. Equipped with right and left rotation cutter frame.

5. Cutter can perform straight cut, opposite cut and twist cut.

0 notes

Text

PRECISION CNC, VMC, Machining 4 and 5 Milling Job Work — Pitrukrupa Engineering

Pitrukrupa Engineering is country’s leading Manufacturer, Exporter and Supplier firm offering high performing CNC Milling and Turning Components since its inception in 2009.

Our CNC Job Work Services and CNC Products

CNC Job Work CNC Machining Work We are offering CNC Components to our clients. For accomplishing this work, experts bank on innovative machines and important tools.

Precision Machining Work Precision machining relies on the use of advanced, computerized machine tools

VMC Machining Work VMC Machines are chiefly used to turn raw blocks of metal like aluminum, steel and other metal components.

Milling Machining Work Milling Job Work is the machining process of using rotary cutters to remove material from a workpiece by advancing

4 Milling Components For accomplishing this work, experts bank on innovative machines and important tools. 4 Axis Milling Components

5 Axis Milling Components We are offering CNC Components 5 Axis Milling Components to our clients. For accomplishing this work, experts bank on innovative machines and important tools. We are counted amidst the trustworthy manufacturer, exporter and supplier of a wide range of 5 Milling Components.

HMC Machining Work We are engaged in manufacturing, exporting and supplying our clients a high quality range of CNC EDM Components.

CNC Turning Machining Work We are offering CNC Turn Mill Machining Work to our clients. For accomplishing this work, experts bank on innovative machines and important tools.

CNC Lathe Machining Component CNC Lathe Machining Component For accomplishing this work, experts bank on innovative machines and important tools.

CNC Turn Mill Components With the help of our deft professionals and advanced structure, integrated with latest equipment, we are offering CNC Turn Mill Components.

CNC Turn Mill Machining Parts With the help of our deft professionals and advanced structure, integrated with latest equipment, we are offering CNC Turn Mill Machining Parts.

EDM Wire Cutting Work EDM Wire Cutting Work are essential to the manufacturing industry because of their precision and speed.

CNC laser Cutting Work A CNC laser cutter features a laser head containing a laser focusing lens and a nozzle.

CNC Bending Work CNC Bending Work can bend sheet metal work from just a few mm across to sections many metres long on the largest industrial machines.

AEROSPACE AND DEFENCE MACHINING PARTS MANUFACTURINGCNC machining is commonly used to manufacture various electronics components used in aircraft systems such as control panels, connectors, sensor housing and instrument cluster components.

Aluminium And Steel Precision Welding Fabrication Aluminium And Steel Precision Welding Fabrication bimetallic transition insert is definitely the best way to weld steel to aluminum for structural applications.

Aluminium High Pressure Die Casting Aluminium High Pressure Die Casting manufacturing process that produces accurately, defined, smooth and textured-surfaced metal parts.

Aluminium Extrusion Aluminum extrusion is a process by which aluminum alloy material is forced through a die with a specific cross-sectional profile.

For More Details Click Here : https://www.pitrukrupaengineering.com/

0 notes

Text

Unlocking Precision: Understanding CNC Machine Configuration

CNC (Computer Numerical Control) machines have revolutionized manufacturing by automating and streamlining the production of intricate parts with unparalleled precision and efficiency. At the heart of every CNC machine lies its configuration – a carefully orchestrated combination of components and parameters that determine its capabilities and performance. In this blog, we'll delve into the essential elements of CNC machine configuration, shedding light on the key components that drive its functionality and versatility.

Machine Type: CNC machines come in various types, each designed for specific machining operations and applications. Common types include:

CNC Milling Machines: Used for cutting and shaping solid materials, such as metal, wood, and plastics, using rotating cutting tools.

CNC Lathes: Ideal for machining cylindrical parts by rotating the workpiece against stationary cutting tools.

CNC Routers: Employed for cutting and carving materials like wood, foam, and composites using computer-controlled routing heads.

CNC Plasma Cutters: Utilized for cutting metal sheets and plates using a high-velocity jet of ionized gas (plasma). Selecting the appropriate machine type depends on factors such as the desired machining operations, material types, part complexity, and production volume.

Axis Configuration: The axis configuration of a CNC machine refers to the number and orientation of its motion control axes. Common configurations include:

3-Axis Machines: Capable of moving along three linear axes (X, Y, Z) to perform 2D and 3D machining operations.

4-Axis Machines: Incorporate an additional rotary axis (typically A or B) for rotating the workpiece, enabling more complex machining operations and angular cuts.

5-Axis Machines: Feature two additional rotary axes (typically A and B or A and C), allowing for simultaneous movement and rotation in multiple directions, expanding the range of machining possibilities and enhancing precision.

Multi-Axis Machines: Combine three or more linear and rotary axes to achieve intricate machining capabilities, such as simultaneous milling, turning, and grinding. The axis configuration determines the machine's flexibility, precision, and suitability for specific machining tasks.

Control System: The control system is the brain of the CNC machine, responsible for interpreting the part design data (usually in the form of G-code) and translating it into precise movements and commands for the machine's motors and actuators. Key components of the control system include:

CNC Controller: The central unit that processes the G-code instructions and coordinates the motion of the machine axes.

Motor Drives: Power the machine's motors and provide precise control over their speed and position.

Feedback Systems: Include encoders and sensors that provide feedback on the position, velocity, and acceleration of the machine axes, ensuring accurate motion control.

Human-Machine Interface (HMI): Allows operators to interact with the CNC machine, input machining parameters, monitor the machining process, and troubleshoot any issues. Modern CNC machines may utilize proprietary control systems or industry-standard platforms such as Fanuc, Siemens, or Mitsubishi, each offering unique features and capabilities.

Tooling and Workholding: Tooling and workholding play a critical role in CNC machining, enabling the secure fixation of workpieces and the precise execution of machining operations. Key components include:

Cutting Tools: End mills, drills, inserts, and other cutting tools tailored to specific materials and machining operations.

Tool Changers: Automatic or manual systems for changing cutting tools during machining processes, reducing downtime and increasing productivity.

Workholding Devices: Vises, clamps, fixtures, and chucks that securely hold the workpiece in place during machining, ensuring stability and accuracy. Proper selection and setup of tooling and workholding solutions are essential for achieving optimal machining results and minimizing setup time.

CNC machine configuration encompasses a myriad of components and parameters that determine the machine's capabilities, performance, and versatility. By understanding the machine type, axis configuration, control system, and tooling/workholding options, manufacturers can select and configure CNC machines to meet their specific machining requirements and production goals. Whether producing precision parts for aerospace, automotive, or medical applications, CNC machines stand ready to unlock the potential of modern manufacturing with their unparalleled precision and efficiency.

0 notes

Text

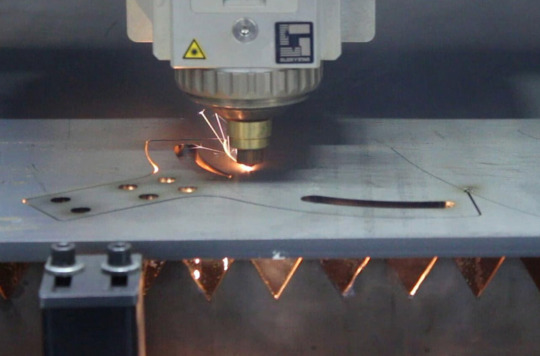

What are the Benefit of Fiber Laser Cutting Machine – Applications

Benefit of Fiber Laser Cutting Machine

We all know that fiber laser is now well accepted in the market, and also because of the excellent advantages of good beam quality and high conversion efficiency in the company, it is widely preferred in some finishing fields. A form of active choice for products in many industrial applications, fiber lasers currently make up close to 50% of the industrial field. As frequency conversion light sources, fiber lasers have many benefits over conventional gas and solid state lasers. In this post, we will discuss what is a fiber laser cutting machine, its characteristics, benefits, and uses. We will also discuss its features, advantages, and benefits.

What Is A Fiber Laser Cutting Machine?

A brand-new machine in the globe that produces high energy density laser beams is the fiber laser cutting machine. The work piece’s surface is targeted by the laser beam, which causes the area of ultra-fine focus to rapidly melt and evaporate as it moves through the CNC mechanical system. Automatic cutting through positional illumination. It has clear benefits over large volume gas lasers and solid-state lasers, and has increasingly taken on significance in industries such as high-precision laser processing, lidar systems, space technology, laser medicine, and others.

With clean and smooth edges, the optical fiber laser cutting machine can be utilised for both plane cutting and oblique cutting. It is appropriate for cutting metal plates with extreme precision. The original five axis laser can be swapped out for the manipulator at the same time for 3D cutting. It has a higher photoelectric conversion rate and uses less space and gas than a typical CO2 laser cutting machine. It is a cutting-edge technological product that also conserves energy and protects the environment.

Features Of CNC Fiber Laser Cutting Machine

1. The CNC fiber laser cutting machine has a high optical power conversion efficiency, with a conversion efficiency of above 30%. The lack of a water cooler requirement for the low power fiber laser significantly reduces operational power consumption, lowers operating expenses, and achieves the highest level of production efficiency.

2. The cost of operation and maintenance is the lowest when a laser cutting machine is in operation because it only requires electric power and does not require the production of additional laser gas.

3. The fiber laser cutting machine uses a redundancy and semiconductor modularization design. There is no start-up time and no optical lens in the resonator. Its features include adjustability, lack of maintenance, and excellent stability. They offer unmatched cost and maintenance time savings over conventional lasers.

4. The fiber laser cutter has the best cutting and welding capabilities, the best output beam quality, the highest power density, is favourable to the absorption of metal materials, and the lowest processing cost.

5. The entire machine’s optical transmission does not require a sophisticated light guide machine, such as a mirror. The optical system is easy to use, reliable, and requires little upkeep.

6. Because the cutting head has protective lenses, there is relatively little need for expensive consumables like focusing lenses.

7. Since light is produced via optical fiber, the mechanical system’s design is highly straightforward and simple to combine with robots or multi-dimensional workbenches.

8. Once the laser has been integrated into the shutter, the system can be divided into many machines, optical fiber division, multiple channels operating simultaneously, easy function expansion, simple update, and more.

9. The small volume, light weight, flexible position, and tiny area of the fiber laser cutting machine are benefits.

Applications of Fiber Laser Cutting Machines

The use of the fiber laser cutting machine includes a variety of manufacturing and processing sectors, including sheet metal processing, aviation, aerospace, electronics, electrical appliances, tube accessories, automobiles, grain machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, lifts, home appliances, crafts, tool processing, decoration, advertising, metal processing, kitchenware processing, and others.

Materials For Fiber Laser Cutting:

Cutting of metal sheets and pipes in stainless steel, carbon steel, alloy steel, silicon steel, galvanised sheet, spring steel, aluminium, copper, silver, aluminium alloy, pickling sheet, gold, and other metals.

0 notes

Video

youtube

3 axis 4 axis 5 axis cnc hot wire foam cutter pvc cutting machine cnc fo...

0 notes

Text

Some Tips On Purchasing A CNC Router

The CNC router has revolutionized woodworking, machining and precision. It is efficient and precision that is unlike any other. If you're a professional enthusiast or skilled craftsman purchasing a CNC router could help your project reach higher levels. With so many options in the marketplace and a variety of options, it is difficult to choose the best cnc wood cutting routers. In this piece we offer seven crucial suggestions to think about when shopping for a CNC router. Begin by learning about factors that will help you make the right decision.

7 Tips On Buying CNC Routers

Here are seven tips to help you decide on a CNC Router

Set out your needs

If you are looking to purchase a CNC Router, you must first determine your needs and expectations. Think about the kind of work you'll be doing and the type of material you'll work with. Determine the size and complexity of your project. Once you know what your needs are, you can narrow down your choices and focus on locating a cnc drilling machines that will meet the exact requirements of your business.

Find reputable manufacturers

It's crucial to do some investigation prior to buying a CNC Router. Find reputable companies with years of experience in the production of high-quality machines. Read customer reviews and other testimonials to assess the levels of satisfaction of customers who have purchased from them before. An established manufacturer can provide the most durable and reliable CNC router that can last for many years to come.

Consider your budget

Before you make a computer numerical control purchasing a router, establish your budget. Set a budget to help sort out options that you can't afford. CNC routers come at various price points. While it's important to find a router that fits your budget, avoid compromising on quality. Do not focus solely on cost, but instead think about the value and performance of the machine over the longer term.

Evaluate machine specifications

One of the most important aspects to consider when buying the CNC router is its specifications. The speed and power of the spindle directly affect the effectiveness as well as performance. Additionally, consider the working size and the cutter's depth, ensuring that it is able to meet your needs. By analyzing these specs, to find the CNC router that is compatible with the features you desire.

Examine the control and software system

The controls and the software of a 4 axis cnc router plays a major role in its usability and performance. Examine the interface of the program to make sure it's user-friendly and simple to use. It's crucial that the CAD/CAM software you use is compatible with the machine's software. It will enable you to easily integrate your workflow. Ask about training options and support services to help you learn.

Check for safety features

youtube

If you are buying machinery of any type, such as CNC routers, safety should always be the top priority. Security features such as safety stop button emergency or interlocks can help prevent accidents and injuries. Check if it complies to the safety rules and standards.

After-sales services and warranties are crucial

Take note of the After-sales support and warranties provided by the manufacturer. Review the warranty terms and coverage of the CNC router that you are planning to buy. An extensive warranty guarantees any potential issues will be dealt with promptly. Check out the brand's reputation in customer support to ensure your assistance is available whenever needed.

Get recommendations and help

Don't be afraid to ask for advice or suggestions from experts in the industry as well as users who have expertise. They can offer valuable advice and help you avoid potential traps. It is possible to join a group of CNC users through online forums and communities.

Go to a showroom and take the opportunity of a test run

Whenever possible, it's advisable to test drive or visit a showroom to witness the performance on the CNC router in person. Get a demo from the manufacturer, or stop by the showroom of a dealer in your area to observe the machine in action. The hands-on demonstration will provide you a better understanding of its capabilities and allow users to inquire about specific issues.

Make an informed choice through comparing alternatives

Make a list of potential CNC routers following an extensive search. In order to make an informed choice look at their capabilities, pricing, and value. Select a model that has an appropriate mix of features as well as price.

Make your purchase and then keep track of it

The time has come to purchase. In order to finalize your purchase contact the authorized dealer or the manufacturer. Keep in contact with them regularly to get information on shipping updates and the delivery process. A constant and open dialogue will guarantee the smoothest transaction possible and keep you informed about possible delays or other changes.

Prepare for installation and training

Be sure to have completed your installation prior to when the CNC router arrives. Clear the workspace and ensure it's appropriate for the dimensions and needs of the machine. Set aside time to train as well as acquainting yourself with operation that is this CNC router. A thorough understanding of its capabilities and functions will assist to maximize its capabilities and achieve the desired results.

Maintenance and ongoing support

Follow the maintenance instructions that are provided by your supplier in order to keep your CNC router in top condition. Regularly clean the machine and inspect its components for signs of wear and tear. Be in contact with the manufacturer or their support staff for customer inquiries for any technical assistance or assistance with troubleshooting issues. You can extend the life of your CNC and ensure it is running smoothly by following the correct maintenance procedure and asking for help when you need it.

Bottom Line

Buying a CNC router needs careful consideration and research to ensure that you get the most value for your woodworking and machining demands. When you have defined your needs and researching reliable manufacturer, and assessing the machine's specifications, and considering factors such as budget, software, safety features, and after-sales service making an informed choice. Seek recommendations, take the test drive before making a final decision on your purchase. Be prepared for installation and training, and maintain regular maintenance for the longevity of the CNC router. You are on the path to acquiring a CNC that will increase your creative, productivity and precision by keeping these guidelines in your head.

0 notes

Text

Laser cutting machine - a good helper for cutting pipes

youtube

1. Automatic laser cutting and blanking of metal tubes in full stroke.

According to the technical requirements of full-stroke automatic laser cutting materials for large-length metal pipes, the mechanical structure adopts a unique dual-drive pneumatic chuck rotation mechanism (driving shaft W, driven shaft W1), and the left driving shaft W-axis pneumatic chuck rotation mechanism A unique double-drive pneumatic chuck rotation mechanism is used to realize the axial movement of large-sized metal pipes.

2. CNC cutting process.

CNC cutting is a high-volume, high-efficiency, high-quality cutting production method, and its core is the CNC cutting system. The quality problems existing in the current laser pipe cutting process include: excessive cutting point of parts, high corner, deflection of cutting surface, circular deformation or inability to close, etc., which directly cause serious waste of pipe fittings and low cutting production efficiency.

CNC cutting technology refers to the advanced cutting technology and rich cutting experience provided by the cutting control software of the CNC system, so that the cutter can obtain high-quality and high-efficiency CNC cutting by skillfully using the control system.

3. A complete set of professional material technology.

Laser CNC cutting has high efficiency and complex programming materials. Improper use will waste piping and reduce cutting efficiency. On the computer, the NC cutting program is generated through professional pipe cutting software drawing, package and segment programming to realize full-stroke automatic laser cutting of large-length metal pipes. The special pipe sleeve software is the basis and premise to realize mass production, high efficiency and high quality blanking.

4. Pipe cutting process.

Because of pipe cutting (especially for small square pipes), slag adheres to the pipe wall, and most of the heat generated by cutting is absorbed by the workpiece. When the cutting density is high, the angle of the pipe is often overheated and the four angles of the square pipe are overheated, which seriously affects the cutting quality, and even cannot be cut.

To address these issues:

(1) The laser cutting head has a height sensing follow-up system, which can ensure that the height of the cutting nozzle is consistent with the surface of the workpiece during the cutting process (the focus remains unchanged), so that the cutting effect is not affected by the change of the surface of the workpiece;

(2) The method of increasing the oxygen pressure (6-8Mpa);

(3) Use software to increase the speed of sharp corner synthesis.

0 notes

Text

Kitchen Cabinet Door Making CNC Router Machine for Sale

The pneumatic 4 process nesting CNC machine is a multi-function automatic CNC nesting machine, which integrates cutting, chamfering, relief, hollowing, punching, slotting and other processes, while meeting the processing requirements of cabinet doors and cabinets, can realize automatic loading and unloading, save labor, and greatly improve the processing speed and efficiency.It has the advantages of low procurement cost, simple operation and complete functions. Four different bits can be installed to complete various processing functions, such as cutting, engraving and drilling at one time. It is equipped with auto loading and unloading tables. So it can load and unload the materials automatically. It is an ideal machine for large production enterprises, specially for making cabinet.

It can be used with edge banding machine, laminating machine, side hole machine and other machines to customize the whole house.

The CNC router for cabinet making relates to a four process double station double pusher material opening machine. The feeding machine consists of a working bench, which is equipped with a two working table along the length direction of the platform support at the top of the workbench support, and there is a Y moving mechanism above the bench bracket. The two transverse symmetrical Y to the rack in the Y moving mechanism is fixed on both sides of the platform bracket, and the transverse beam in the moving mechanism at the Y. The top is fixed with a X direction rack with a transverse setting of X to the moving mechanism, and a Z direction moving mechanism on the left side of the moving mechanism along the direction of the feeding, and the Z to the driving motor in the Z moving mechanism is fixed vertically on the X slide plate in the X to the moving mechanism, and the Z direction slide plate in the Z moving mechanism is equipped with a processing device. The opening machine can make maximum use of the working time of the opening machine, high processing efficiency, convenient feeding and unloading, and can avoid the droop of the drag chain. The cabinet making CNC router is suitable for kitchen cabinet making, cabinet door making, corner cabinet making, decorative cabinet making, home cabinet making, wall cabinet making, wood cabinet making, base cabinet making and other custom cabinet making in bathroom, garage, living room, and office.

Cabinets Making CNC Router Applications

Cabinet making:CNC router is ideally suitable for furniture decorations, musical instruments, wooden crafts, solid wood furniture, MDF door, wood composite door, cabinet making, kitchen cabinet doors, windows, tables, etc.

Decoration Industry:Art model, wall art, screen relief engraving and cutting, decoration processing, gifts wrapping, waved plate, electrical cabinets panels, sports equipment, and other industrial wood works.

Kitchen Cabinet Door Making CNC Router Machine Advanced Performance

4 kinds of process switching processing, to achieve 0 seconds tool change, greatly improve the work efficiency.

Using HQD6.0kw air cooled automatic tool change spindle, long life, low noise, reliable quality.

IGOLDENindependent electric control cabinet, humanized design, Taiwan Baoyuan system, easy to operate.

Using Taiwan silver guide rail and crescent rack, high positioning accuracy, smooth sliding, reliable quality, long life.

Professional CNC Taiwan Baoyuan control system, easy to learn and easy to operate.

Can increase the automatic loading and unloading platform, save labor costs, fast cost recovery, meet the needs of the production line, automatic intelligent operation, efficiency is greatly improved.

The 4 spindle CNC router is very easy to use.You only need to save the position of the cutters in the tool path, then the system could realize the cutter auto changing according to the cutter code.So this four-axis CNC machine kitchen cabinet machine runs very efficiently and stably.

Powerful 4 Spindle Auto-Change Of Drilling Milling Machine

The Heavy structure adopts thicken steel square which improves the stability of wood CNC 4×8. This Stronger structure is necessary for cutting solid materials such as hardwood. During the 4×8 wood CNC machine cutting and carving process, the XYZ axis remains stationary against external cutting forces.

High Efficiency Cutter Changing Of Multi Spindle CNC Router For Sale

The advantage of This 4 spindle CNC machine kitchen cabinets is that the spindle change speed is fast or we call it tool change. It only takes 2 seconds to turn on the spindle in advance for preheating. And you can use different spindles from 800w to 6.5kw, instead of using 8.5kw ATC spindle for drilling.This 4 spindle CNC router is easy to maintain and easy to replace the spindle; there is no tool change problem, and it will not stop work due to the tool change problem. It is beneficial to the mass production line.

Stable Working Sturcture Of CNC Machine Kitchen Cabinets

As a drilling milling machine,a strong and stable structure is very important,because this machine has 4 spindle,it need to process many material in a very stable environment.So the gantry and base frame of our 4 spindle CNC router is made of tubular steel.and the entire length of the column is welded with reinforcing ribs to achieve a stable beam Components.The Gantry uprights of this machine are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, belts, and wiring harnesses.Moreover the base frame has a long service life after precision welding.

0 notes

Text

TK-680 6AXIS CNC SPRING COILING MACHINE

web:https://www.wnjspringmachine.com/product/tk-680-6axis-cnc-spring-coiling-machine.html

1. Controlled with six axis:wire teed axis, slider or upper variable diameter,slider or down variablediameter,up-cut blade axis, down-cut blade axis and pitch axis. 2. The six axis can work single-step or synchronously. 3. Computer interface displayed in Chinese and English which makes the operation easy. 4. Equipped with right or left-handed winding blade rest. 5. The cutter can perform straight cut, twist cut and swing cut. 6. The computer has software functions of automatic programming.

0 notes

Text

Common Faults And Solutions of Duct CNC Plasma Cutting Machine

https://www.blkma.com/support/common-faults-and-solutions-of-duct-cnc-plasma-cutting-machine.html

1. When the machine stops working, the system works, the cutting gun moves in one direction or not, and pressing any key (especially the pause button) doesn't work, it maybe the machine is jammed.

Remove interference, especially notices that the plasma power is grounded with the machine tool.

Add spacer to the motor(old system)

When the flame is fired, notice if the cutting oxygen switch is in an arc.

2. When the machine stops working, the system runs normally, and the cutter stops or is just an axis:

The walking motor is blocked.

Motor failure (check whether the machine tool is stuck and keep the machine stable)

3. Motor is abnormally working.

Drive alarm, broken/ plasma machine with high-frequency interference grounding.

Bearing is broken.

The motor is broken.

Whether the drive code is correct. Whether the driver's green light is bright, the AC wiring of the drive is strong, or whether there is 380V output.

220V missing items

4. CNC plasma cutting machine is not working.

The system soft limit is in place.

Cutting machine bump limit (it is possible to hit 2 limit switches)

A motor line is lost

Drive alarm (plasma power interference, need grounding)

Urgent stop shuts down (need to open before starting up)

5. Drive alarm

Whether the polarity of dc power supply is wrong.

Whether the supply voltage is too high.

Whether there is a short circuit between the winding wires of the motor or whether the power supply and winding are short-circuited.

Whether the current value, subdivision and half - flow function of the drive are reasonable.

Whether the plug is charged.

The use environment of the drive.

Whether the control signal level is high.

Machine interference

6. The size of the CNC plasma cutting machine is not accurate.

Whether the drive alarm/dial code is wrong.

Plugging (interference)

Whether the bearing is damaged

System gear numerator/denominator.

7. Programs cannot be stored or scrambled.

Under the main menu, press G G 3 key, select file format, shut down after operation, then reboot.

0 notes

Text

Rapid CNC Machining Services

Rapid CNC Machining Services

Hord offers customers with varieties of precision CNC machining services, including CNC milling, CNC turning, EDM, wire cutting and surface grinding. With the advanced 3-axis, 4-axis and 5-axis CNC machining center and an experienced team, we can make any custom design, simple or complex. If you have any CNC parts need to manufacturing.Get more news about Prototype Cnc Machining,you can vist our website!

What is CNC Machining? Rapid CNC machining is a fast and economical method for manufacturing a few precision prototype from plastic and metal materials. It is widely used in the development and design of new products. Of course, it is also a common method to make volume manufacturing for some parts with limited molding. Such as high-quality mobile phone case, laptop case, lampshades, etc. But the cost is slightly higher than extrusion, pressure die casting and other processes. CNC Milling CNC milling is just one of the CNC machining processes available. Milling is a particular form of precision CNC machining. Milling uses a cutter that removes material by moving into the work-piece at an angle. The movement of the cutter is controlled by computer instructions, allowing for extreme precision and repeatability. CNC Turning CNC turning is a particular form of precision machining in which a cutter removes material by making contact with the spinning work-piece. The movement of the machinery is controlled by computer instructions, allowing for extreme precision and repeatability. Turning is different to CNC milling, in which the cutting tool rotates and is directed from multiple angles at the work-piece, which is usually stationary. Because CNC turning involves rotating the work-piece in a chuck, it is generally used to create round or tubular shapes, achieving far more accurate rounded surfaces than would be possible with CNC milling or other processes. The tooling that is used with a CNC lathe machine is mounted to a turret. This component is programmed to make certain movements and remove material from raw materials until the desired 3D model is formed. Like CNC milling, CNC turning can be used for the rapid manufacture of either prototypes or end-use parts. We work with a wide range of plastic and metal materials, including magnesium, mild and stainless steel, aluminum, brass and titanium as well as rigid engineering grade plastic resins. These materials are parts of our standard stock and can be sourced from reliable suppliers that have been thoroughly reviewed and approved by us for immediate access. In addition, we can also provide specialty materials, such as super hard alloys – just talk to our engineers to learn how we can meet your needs. Most importantly, in order to ensure that your parts meet all regulatory requirements, we have an incoming materials inspection lab where we use sophisticated analytic testing instruments using Raman spectroscopy to confirm the exact chemical and physical properties of all raw materials. We leave nothing to chance for your peace of mind.

0 notes

Text

The 7 Most Common Types of CNC Machines

CNC machines are used in a variety of industries for a number of purposes. Chances are, if you have ever been in a factory or seen one in a movie, you’ve seen a CNC machine in action. They’re intricate machines with a variety of options that each specialize in a specific market.

Here are seven of the most common types of CNC machines:

Machining Centers

Machining centers are probably the most common type of CNC machine. They typically have 3 or 4 axes and can do things like drill, bore, tap, and ream. Some machining centers even have fifth axes, which gives them even greater flexibility.

Lathes

Lathes are another common type of CNC machine. They’re used to create parts that have cylindrical symmetry, like screws, shafts, and pipes. Unlike machining centers, lathes only have two axes (X and Z). However, some lathes come with additional features like Y-axis capability or live tooling that allow them to perform functions similar to those of a machining center.

Grinders

Grinders are used to remove material from workpieces to create a desired shape or finish. Like machining centers and lathes, grinders can be operated manually or with CNC controls. The most common type of grinder is the surface grinder, which is used to create or clean up flat surfaces.

Routers

Routers are similar to grinders in that they remove material from workpieces to create a desired shape or finish. However, routers are more often used on softer materials like wood or plastic. Routers can be operated manually or with CNC controls, and the most common type is the handheld router. While routers are less expensive than some other types of CNC machines, they require more maintenance because the bits need to be replaced more frequently due to wear and tear.

Plasma Cutters

Plasma cutters are unlike any other type of CNC machine because they use plasma—an ionized gas—to cut through metal workpieces. Plasma cutters are typically used for applications where speed and precision are paramount, such as in the automotive industry. Because plasma cutters can operate at very high speeds, they require special care when it comes to maintenance and upkeep.

Laser Cutters:

Laser cutters use a high-powered laser beam to cut material. They are often used for cutting intricate shapes or making very precise cuts.

Waterjet Cutters:

Waterjet cutters use a high-pressure stream of water to cut material. This type of cutter can be used on almost any type of material, making it very versatile.

CNC machines are an essential part of modern manufacturing, and there are a wide variety available to suit any need. Machining centers, lathes, grinders, routers, and plasma cutters are just some of the most common types of CNC machines—each with their own unique capabilities and benefits. Do you have a need for a specific type of CNC machine?

Conclusion

If you need a CNC machine for your business, it’s important to choose the right type. The seven types of machines we’ve outlined are some of the most common, so they should give you a good starting point. If you still have any doubt don’t hesitate to call and talk to an expert for cnc turning in Canada to learn more about which machine is best for your needs.

0 notes

Text

How do milling parts process planar parts?

1. Parts whose machining surface is parallel or perpendicular to the horizontal plane, or whose included angle is fixed are plane parts. At present, the vast majority of parts processed on CNC milling machines belong to planar parts. The characteristic of planar parts is that each machining surface is planar or can be expanded into a plane.

2. Variable bevel parts: parts with a continuous change in the angle between the machining surface and the horizontal plane are called variable bevel parts.

Such parts are mostly aircraft parts, such as integral beams, frames, edge strips and ribs on aircraft; In addition, there are inspection fixtures and assembly frames, which also belong to variable angle parts.

3. Surface parts: parts whose machining surface is a spatial surface are called surface parts. The machining surface of surface parts cannot be expanded into a plane.

During machining, themachinedsurface and the milling cutter are always in point contact. Generally, three methods are used for machining curved surface parts. When the curved surface is complex and the passage is narrow, which will damage the temporary surface and require the tool to swing, four axis or five axis machining centers should be used.

What are the processing materials?

3. Surface parts: parts whose machining surface is a spatial surface are called surface parts. The machining surface of surface parts cannot be expanded into a plane.

During machining, the machined surface and the milling cutter are always in point contact. Generally, three methods are used for machining curved surface parts. When the curved surface is complex and the passage is narrow, which will damage the temporary surface and require the tool to swing, four axis or five axis machining centers should be used.

1、 Steel milling

The machinability of steel varies with alloy elements, heat treatment and manufacturing processes.When processing soft low carbon steel, the main problem is that chip buildup and burr will be formed on the workpiece. When machining harder steel, in order to avoid edge collapse, the relative position between the milling cutter and the workpiece will become more important.

2、 Stainless steel milling

Stainless steel can be classified into ferrite or martensitic stainless steel, austenitic stainless steel and duplex stainless steel, and each type has its own milling suggestions.

3、 Cast iron milling

The main wear standards of gray cast iron milling are abrasive grain or flank wear and hot crack. For parts, workpiece edge collapse and surface quality are the main problems.

4、 Non ferrous material milling

Nonferrous metal materials include not only aluminum alloys, but also magnesium, copper and zinc based alloys. Machinability is mainly different due to different silicon content. Hypoeutectic Al Si alloy is the most common type, with silicon content less than 13%.

5、 Superalloys and titanium alloys

Milling superalloys and titanium usually requires a machine tool with high rigidity, high power and high torque to operate at low speed. Groove wear and cutting edge collapse are the most common wear types. The high heat generated limits the cutting speed.

0 notes