#3E-Economics

Explore tagged Tumblr posts

Text

realities, maximalism,and the need for big book™️

some gubat banwa design thoughts vomit: since the beginning of its development i've kind of been enraptured with trying to really go for "fiction-first" storytelling because PbtA games really are peak roleplaying for me, but as i wrote and realized that a lot of "fiction first" doesn't work without a proper sort of fictional foundation that everyone agrees on. this is good: this is why there are grounding principles, genre pillars, and other such things in many PbtA games--to guide that.

broken worlds is one of my favs bc of sheer vibes

Gubat Banwa didn't have much in that sense: sure, I use wuxia and xianxia as kind of guideposts, but they're not foundational, they're not pillars of the kind of fiction Gubat Banwa wants to raise up. there wasn't a lot in the sense of genre emulation or in the sense of grounding principles because so much of Gubat Banwa is built on stuff most TTRPG players haven't heard about. hell, it's stuff squirreled away in still being researched academic and anthropological circles, and thanks to the violence of colonialism, even fellow filipinos and seasians don't know about them

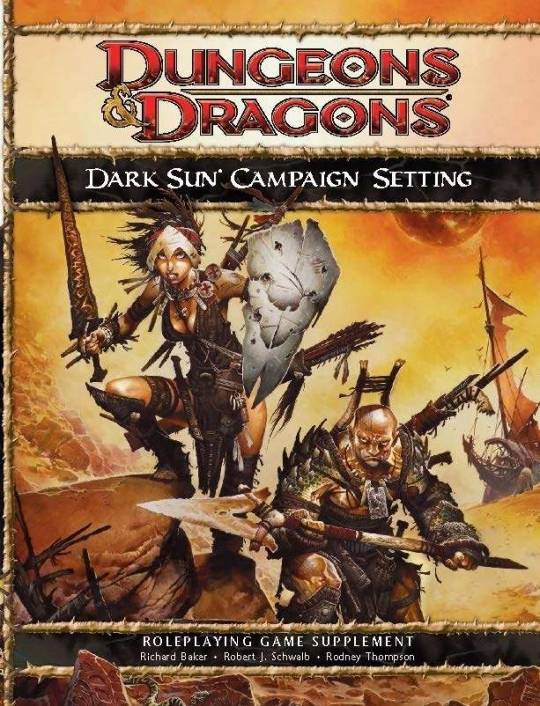

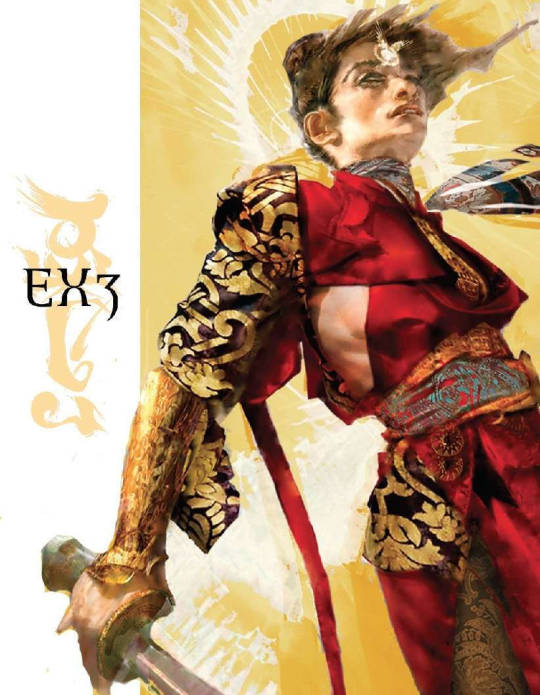

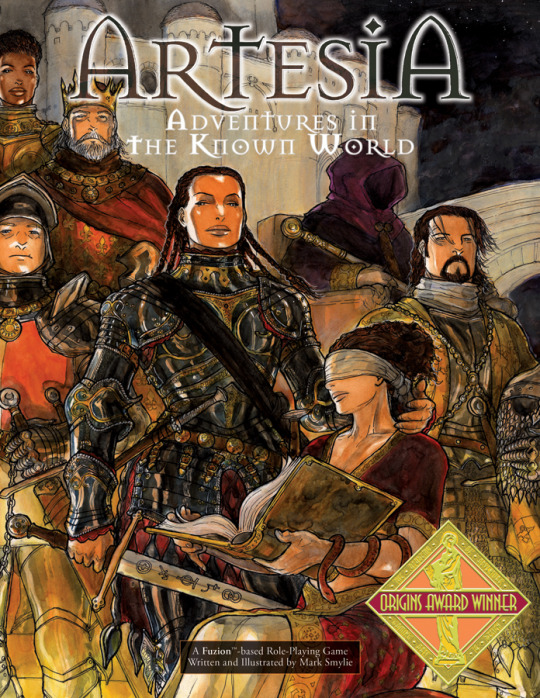

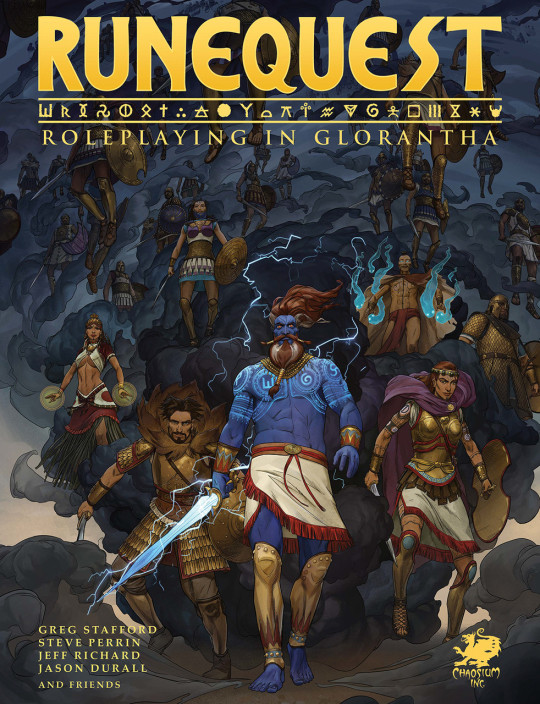

this is what brought me back to my ancient hyperfixations, the worlds of Exalted, Glorantha, Artesia, Fading Suns... all of them have these huge tomes of books that existed to put down this vast sprawling fantasy world, right? on top of that are the D&D campaign settings, the Dark Suns and the Eberrons. they were preoccupied in putting down setting, giving ways for people to interact with the world, and making the world alive as much as possible.

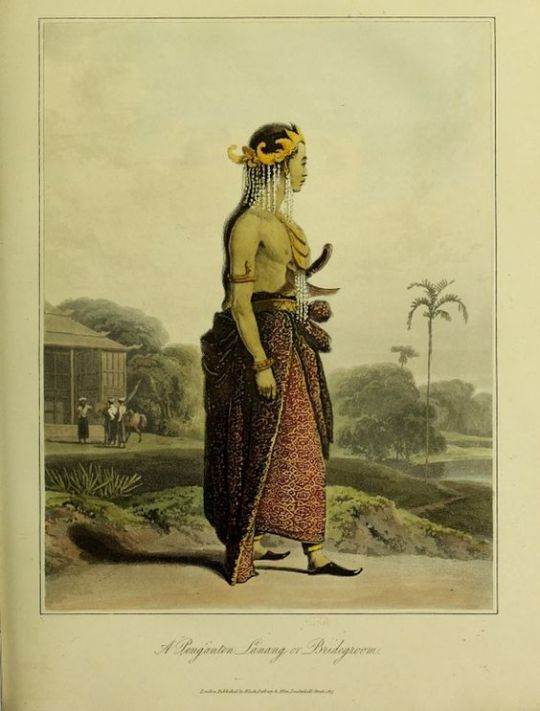

one of my main problems with gubat banwa was trying to convey this world that i've seen, glimpsed, dreamed of. this martial fantasy world of rajas and lakans, sailendras and tuns, satariyas and senapatis and panglimas and laksamanas and pandai... its a world that didn't really exist yet, and most references are steeped in either nationalism or lack of resources (slowly changing, now)

i didn't want to fall back into the whole gazeteer tourist kind of shit when it came to writing GB, but it necessitated that the primary guidelines of Gubat Banwa were set down. my approach to it was trying to instill every aspect of the text, from the systems to the fluff text to the way i wrote to the way things were phrased, with the essence of this world i'm trying to put forward. while i wrote GB mainly for me and fellow SEAsian people, economically my main market were those in the first world countries that could afford to buy the book. grokking the book was always going to be severely difficult for someone that didn't have similar cultures, or are uninterested in the complexities of human culture. thus why GB had to be a big book.

in contemporary indie ttrpg spaces (where I mostly float in, though i must admit i pay more attention to SEAsia spaces than the usual US spaces) the common opinion is that big books like Exalted 3e are old hat, or are somewhat inferior to games that can cram their text into short books. i used to be part of that camp--in capitalism, i never have enough time, after all. however, the books that do go big, that have no choice to go big, like Lancer RPG, Runequest, Mage, Exalted are usually the ones that have something really big it needs to tell you, and they might be able to perform the same amount of text-efficient bursting at the seams flavor writing but its still not enough.

thats what happened to GB, which I wanted to be, essentially, a PbtA+4e kind of experience, mechanically speaking. i very soon abandoned those titles when i delved deeper into research, incorporated actual 15th century divination tools in the mechanics, injected everything with Martial Arts flavor as we found our niche

all of this preamble to say that no matter how light i wanted to go with the game, i couldnt go too light or else people won't get it, or i might end up writing 1000 page long tome books explaining every detail of the setting so people get it right. this is why i went heavy on the vibes: its a ttrpg after all. its never gonna be finished.

i couldnt go too light because Gubat Banwa inherently exists on a different reality. think: to many 3 meals a day is the norm and the reality. you have to eat 3 meals a day to function properly. but this might just be a cultural norm of the majority culture, eventually co opted by capitalism to make it so that it can keep selling you things that are "breakfast food" or "dinner food" and whatnot. so its reality to some, while its not reality to others. of course, a lot of this reality-talk pertains mostly to social--there is often a singular shared physical reality we can usually experience*

Gubat Banwa has a different fabric of reality. it inherently has a different flow of things. water doesn't go down because of gravity, but because of the gods that make it move, for example. bad things happen to you because you weren't pious or you didn't do your rituals enough and now your whole community has to suffer. atoms aren't a thing in gb, thermodynamics isn't a real thing. the Laws of Gubat Banwa aren't these physical empirical things but these karmic consequent things

much of the fiction-first movement has a sort of "follow your common sense" mood to it. common sense (something also debatable among philosophers but i dont want to get into that) is mostly however tied to our physical and social realities. but GB is a fantasy world that inherently doesn't center those realities, it centers realities found in myth epics and folk tales and the margins of colonized "civilization", where lightnings can be summoned by oils and you will always get lost in the woods because you don't belong there.

so Gubat Banwa does almost triple duty: it must establish the world, it must establish the intended fiction that arises from that world, and then it must grant ways to enforce that fiction to retain immersion--these three are important to GB's game design because I believe that that game--if it is to not be a settler tourist bonanza--must force the player to contend with it and play with it within its own terms and its own rules. for SEAsians, there's not a lot of friction: we lived these terms and rules forever. don't whistle at night on a thursday, don't eat meat on Good Friday, clap your hands thrice after lighting an incense stick, don't make loud noise in the forests. we're born into that [social] reality

this is why fantasy is so important to me, it allows us to imagine a different reality. the reality (most of us) know right now (i say most of us because the reality in the provinces, the mountains, they're kinda different) is inherently informed by capitalist structures. many people that are angry at capitalist structures cannot fathom a world outside capitalist structures, there are even some leftists and communists that approach leftism and revolution through capitalism, which is inherently destructive (its what leads to reactionaries and liberalism after all). fantasy requires that you imagine something outside of right now. in essence read Ursula K Le Guin

i tweeted out recently that you could pretty easily play 15-16th century Luzon or Visayas with an OSR mechanic setting and William Henry Scott's BARANGAY: SIXTEENTH CENTURY PHILIPPINE CULTURE AND SOCIETY, and I think that's purely because barebones OSR mechanics stuff fits well with the raiding and adventuring that many did in 15-16th century Luzon/Visayas, but a lot of the mechanics wont be comign from OSR, but from Barangay, where you learn about the complicated marriage customs, the debt mechanics, the social classes and stratum...

so thats why GB needs to be a (relatively) big book, and why I can contend that some books need to be big as well--even if their mechanics are relatively easy and dont need more than that, the book, the game, might be trying to relay something even more, might be trying to convey something even more than that. artesia, for example, has its advancements inherently tied to its Tarot Cards, enforcing that the Arcana guides your destiny. runquest has its runes magic, mythras (which is kinda generic) has pretty specific kinds of magic systems that immediately inform the setting. this is why everything is informed by something (this is a common Buddhist principle, dependent arising). even the most generic D&D OSR game will have the trappings of the culture and norms of the one that wrote and worked on it. its written from their reality which might not necessarily be the one others experience. that's what lived experience is, after all

*live in the provinces for a while and you'll doubt this too!

390 notes

·

View notes

Text

[ID. A screenshot from Reddit reading:

“THEY ARE TRYING TO KILL YOU

and they’re doing it one program at a time

MEDICAID SLASHED

cut: $880 BILLION

MILLIONs will lose access to any kind of healthcare

FDA GUTTED

thousands fired. new, life-saving drugs will be delayed indefinitely

WORK OR DIE

new medicaid rules require employment. Can’t work? Can’t have any healthcare

CDC SLASHED

cut: $4 BILLION

exclusively from disease prevention, antibiotics, and violence programs

FOOD AID GUTTED

cut: $300 BILLION

MILLIONS of our most vulnerable families will lose their SNAP benefits

MENTAL HEALTH PROGRAMS GONE

Over a thousand mental health and public health grants CANCELED eliminating crucial support

ENDING COVID VACCINE

RFK Jr (not a doctor) says pregnant women and kids don’t need the NOVAX COVID-19 vaccine. CDC recommendations are being erased

NO MORE FLUORIDE

Proven to help children’s dental health, this will have so many negative consequences.

NIH FUNDING GUTTED

cut: $18 BILLION

cut from research studies to find cures for cancer, Alzheimer’s, etc

OSHA DISMANTLED

who needs safe workplaces? Not you!

REPRODUCTIVE HEALTH

remember when they said they weren’t going to go after Roe v Wade and then immediately did that? Women have died and will continue to die from lack of access to abortions

GLOBAL INITIATIVES ELIMINATED

efforts to combat global diseases like measles are gone

THEY WANT YOU TOO TIRED TO FIGHT!”

End ID 1]

[ID 2. Another Reddit screenshot reading:

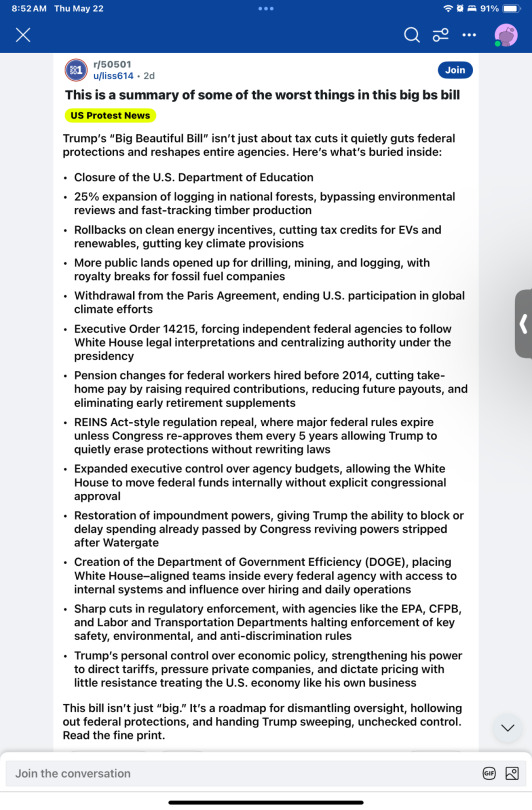

“This is a summary of some of the worst things in big bs bill

US Protest News

Trump’s “Big Beautiful Bill” isn’t just about tax cuts it quietly guts federal protections and reshapes entire agencies. Here’s what’s buried inside:

Closure of the U.S. Department of Education

25% expansion of logging in national forests, bypassing environmental reviews and fast-tracking timber production

Rollbacks on clean energy incentives, cutting tax credits for EVs and renewable, gutting key climate provisions

More public lands opened up for drilling, mining, and logging, with royalty breaks for fossil fuel companies

Withdrawal from the Paris Agreement, ending the U.S. participation in global climate efforts

Executive Order 14215, forcing independent federal agencies to follow White House legal interpretations and centralizing authority under the presidency

Pension changes for federal workers hired before 2014, cutting take-home pay by raising required contributions, reducing future payouts, and eliminating early retirement supplements

REINS Act-style regulation repeal, where major federal rules expire unless Congress re-approves them every 5 years allowing Trump to quietly erase protections without rewriting laws

Expanded executive control over agency budgets, allowing the White House to move federal funds internally without explicit congressional approval

Restoration of impoundment powers, giving Trump the ability to block or delay spending already passed by Congress reviving powers stripped after Watergate

Creation of the Department of Government Efficiency (DOGE), placing White House-aligned teams inside every federal agency with access to internal systems and influence over hiring and daily operations

Sharp cuts in regulatory enforcement, with agencies like the EPA, CFPB, and Labor and Transportation Departments halting enforcement of key safety, environmental, and anti-discrimination rules

Trump’s personal control over economic policy, strengthening his power to direct tariffs, pressure private companies, and dictate pricing with little resistance treating the U.S. economy like his own business

This bill isn’t just “big.” It’s a roadmap for dismantling oversight, hollowing out federal protections, and handing Trump sweeping, unchecked control. Read the fine print.”

End ID 2]

[ID 3. Another Reddit screenshot reading:

“EMERGENCY 3E PROTEST

#3E #STOPTHEBILLIONAIREBAILOUT

Capitol building in Washington, D.C.

A bill that strips people of food and health care is not a tax policy, it is autogenocide.

Washington DC and every state capitol, city hall, and town hall

Thursday, May 22, 9AM

They are stealing from the bottom 10% and transferring it to the top 10%

END IMPUNITY

END AUTOGENOCIDE

END OLIGARCHY”

End ID 3]

https://5calls.org , find and call your Reps and Senators!

the fucking budget bill of hell passed the house that removes HRT from medicare, general medicare spending cuts, student financial aid cuts, and oh yeah lets the teump regime ignore court orders even harder and lets for even harder executive overreach. they did this shit at motherfucking 2 am so people wouldn’t notice too

it passed house like i said but still needs to pass senate.

tell your senators to invoke byrd rule which is a goddamn real thing apparently

call your goddamn senators i swear to god

and if you’re in DC there’s a protest going on as we speak

go do your civic duty you piece of shit

29K notes

·

View notes

Text

Skilling Bharat: How Inspire India Now is Bridging the Skill Divide

By Team Inspire India | Rural Development | Skill & Livelihood

🎯 The Real Challenge Behind Bharat’s Unemployment

While India boasts one of the youngest populations in the world, the paradox lies in the lack of employable skills among its youth. The skill divide—between urban and rural, male and female, and educated and employable—has long restricted India’s rise as a truly inclusive economic powerhouse.

Recognizing this gap not just as a labor issue but as a strategic national challenge, Inspire India Now has launched a targeted, data-backed, and community-led approach to bridge this skill chasm—right from the panchayat to the policy level.

🌐 The Inspire India Skill Model: Beyond Training, Towards Transformation

Under the strategic guidance of Mr. Rajesh Shukla, Inspire India Now has developed a multi-tiered skilling model focused on the “3E” framework:

Education—foundational learning aligned with NEP and local dialect

Employment—direct linkages with rural enterprises, MSMEs, and SHGs

Entrepreneurship—converting skill training into self-sustaining ventures

This is not just about short-term job readiness. It’s about building a resilient, adaptable, and entrepreneurial workforce from Bharat’s heartland.

🏫 Skill Incubators: Rural India's New Learning Hubs

The flagship Skill Incubators set up under Inspire India Now are not ordinary vocational centers. These hubs serve as

Digital learning zones with AI-powered content in regional languages

On-ground workshop spaces with mentorship from local artisans and professionals

Access points for micro-credit, raw material aggregation, and market linkages

Special Modules Offered:

Solar technician training for tribal belts

Bamboo product design and export in the Northeast

AgriTech + Drone handling for farmers' children

Textile and tailoring for rural women

Retail & digital literacy for unemployed youth

👩🌾 Women at the Center: Skilling for Empowerment

Through its collaboration with Jaggo Nari Federation, Inspire India ensures that over 60% of its skill trainees are women. These women aren’t just workers—they’re becoming micro-entrepreneurs, SHG leaders, and mentors for others.

Success stories include:

Laxmi Devi, a widow from Bihar who started a tailoring unit employing 9 women

Sapna Kumari, a digital literacy trainer now leading workshops in 4 villages

SHG 2.0 models producing solar-powered lamps, herbal products, and eco-bags

📊 Data-Driven Outcomes That Matter

Inspire India Now measures success not by certificates issued, but by livelihoods created and income levels improved. Some key metrics:

15,000+ youth trained across 7 districts in 2024

4,200 women-led nano-enterprises launched

600+ rural artisans connected to global e-commerce platforms

32% average income growth within 6 months of course completion

🌍 Partnerships That Power Progress

To scale sustainably, Inspire India Now collaborates with

CSR-backed industry partners for hiring and funding labs

Gram Panchayats for on-ground mobilization and infrastructure

Tech companies for AI-based skilling assessments and gamified learning

NABARD & SIDBI for microfinance tie-ups post-training

These strategic tie-ups ensure that skilling is not a dead-end course but a pipeline to productivity and dignity.

🚀 Next Frontier: Skill 3.0 & Bharatpreneurship

Under Mr. Shukla’s direction, the next phase—Skill 3.0—focuses on:

Integrating green skills (sustainable agriculture, EV repairs, waste management)

Promoting Bharatpreneurship—village-based startups led by youth and women

Enabling virtual mentorship from India’s top professionals to rural learners

🙌 Conclusion: The Time to Skill Bharat is Now

Inspire India Now it isn’t merely skilling individuals—it’s rebuilding the confidence of rural India. When a young girl in Jharkhand learns how to code, or when a weaver from Kutch connects with a buyer in Germany—that is not just success, it's a silent revolution.

India’s demographic dividend can become its biggest strength—but only if we invest in skill with strategy, scale, and soul.

Let us Skill Bharat, Inspire India—one learner, one village, one vision at a time.

#rajesh shukla#rajesh shukla chief strategist#rajesh#mr rajesh shukla#rajesh shukla mumbai#rajesh shukla bjp#mr tajesh shukla mumbai

0 notes

Text

Energy/exergy, economic, and environment (3E) analysis of the hydrogen energy production process

Aji Nugroho, R. A., Hsu, H.-W., Wang, W.-C., Utomo, V. L., Saputro, H., Sittijunda, S., Kuo, J.-K., & Surjasatyo, A. (2025). Energy/exergy, economic, and environment (3E) analysis of the hydrogen energy production process. International Journal of Hydrogen Energy, 103, 467–479. https://doi.org/10.1016/j.ijhydene.2025.01.200 Abstract Recently, hydrogen has been shown to play an important role in…

0 notes

Text

3E Accounting Limited: Your Trusted Partner for Business Success in Hong Kong

Introduction

3E Accounting Limited, Hong Kong, is a premier accounting firm committed to providing tailored financial solutions to businesses of all sizes. As a company incorporation specialist in Hong Kong, we have become a trusted name for seamless company formation, SME support, and professional accounting services. Our mission is to empower businesses with financial clarity and compliance, fostering growth and success in the dynamic Hong Kong business landscape.

Your Trusted Accounting Firm in Hong Kong

At 3E Accounting Limited, we pride ourselves on being a one-stop solution for all accounting needs. Whether you are searching for an accounting firm near me or require specialized guidance, our experienced professionals are equipped to deliver excellence.

Comprehensive Accounting Services

Our services include bookkeeping, financial reporting, tax compliance, payroll management, and more. We utilize state-of-the-art technology to ensure precision, efficiency, and confidentiality in all financial processes.

Why Choose Us?

Expertise: Our team comprises certified accountants with extensive experience.

Personalized Solutions: We tailor our services to match the unique requirements of each client.

Cost-Effectiveness: High-quality services at competitive rates.

Commitment to Compliance: We stay abreast of Hong Kong’s regulatory requirements, ensuring that your business remains compliant.

Hong Kong Company Formation Made Simple

Establishing a business in Hong Kong is a strategic decision due to its robust economy, favorable tax policies, and global connectivity. At 3E Accounting Limited, we simplify this process, making us the go-to company incorporation specialist in Hong Kong.

Our Company Incorporation Services

Company Name Search and Registration We assist in selecting and registering your company name, ensuring adherence to Hong Kong’s regulations.

Documentation Preparation We handle all required documents, including the Articles of Association and business registration forms.

Bank Account Setup We facilitate smooth and hassle-free bank account opening for your new business.

Post-Incorporation Compliance Our team ensures that your company complies with statutory requirements such as annual returns and tax filings.

Empowering SMEs in Hong Kong

As a recognized Hong Kong SME support specialist, 3E Accounting Limited understands the challenges small and medium enterprises face. We provide bespoke solutions to help SMEs thrive in a competitive environment.

Tailored Support for SMEs

Financial Planning and Analysis: We help SMEs create sustainable financial strategies.

Tax Optimization: Our tax experts guide SMEs in leveraging Hong Kong’s tax benefits.

Corporate Secretarial Services: Ensuring regulatory compliance while letting you focus on core operations.

Grants and Funding Assistance: We assist SMEs in identifying and applying for government grants and subsidies.

Why SMEs Choose Us?

Our comprehensive approach, combined with our deep understanding of SME challenges, makes us an indispensable partner for growing businesses.

The Role of a Hong Kong Company Formation Specialist

Selecting the right partner for company formation is crucial for long-term success. As a leading Hong Kong company formation specialist, we provide unmatched expertise, making the process efficient and worry-free.

Our Edge in Company Formation

Local Expertise: Profound knowledge of Hong Kong’s legal and economic framework.

Streamlined Processes: End-to-end support, minimizing delays and errors.

Support Beyond Formation: From compliance to financial planning, we are with you every step of the way.

Accounting Solutions for Every Business Need

From startups to established corporations, 3E Accounting Limited caters to diverse industries and business types.

Customized Services for Various Sectors

E-commerce Businesses: Inventory management, tax compliance, and financial reporting.

Professional Services: Expense tracking, payroll solutions, and regulatory compliance.

Retail and Hospitality: Cash flow management, financial forecasting, and bookkeeping.

Our tailored approach ensures that each business gets the financial support it needs to succeed.

Why Location Matters: "Accounting Firm Near Me"

Finding an accounting firm near me is crucial for personalized and prompt service. With a central location in Hong Kong, 3E Accounting Limited offers accessibility and efficiency to local businesses.

Benefits of Choosing a Local Accounting Firm

Face-to-Face Consultations: Personalized discussions to better understand your needs.

Quick Response Times: Immediate support when you need it.

Local Market Insights: Expertise in navigating Hong Kong’s unique business environment.

Our Commitment to Excellence

At 3E Accounting Limited, we believe that our success lies in the success of our clients. Our commitment to quality and innovation drives us to continually refine our services.

Technology-Driven Solutions

We leverage the latest accounting software and tools to deliver real-time insights and streamline processes.

Professional Development

Our team undergoes continuous training to stay updated with industry trends and regulatory changes.

Transparent Communication

We prioritize clear and open communication, ensuring that our clients are always informed.

Partnering with 3E Accounting Limited

As your trusted partner, we are dedicated to providing reliable, efficient, and innovative solutions. Whether you need a dependable accounting firm or a specialist for Hong Kong SME support, we are here to guide you at every step.

#accounting firm#accounting firm near me#company incorporation specialist hong kong#hong kong company formation specialist

0 notes

Text

New Member Spotlight: Universal Business School

Universal Business School is the first green business school in India which is endorsed by 60 Global CEOs. Founded by CEOs of billion-dollar global businesses, Universal Business School is a truly global business school dedicated to International education and business, relevant to the global economy, industry, and society. UBS offers national (AICTE approved, Accredited by NBA & AIU) and internationally accredited BBA, MBA & MSc Programs in collaboration with Cardiff Metropolitan University (Wales, UK), University of Economics (Varna, Bulgaria), Swiss School of Management (Italy), Northeastern Illinois University (Chicago, USA), University of Dallas (Texas, USA) and Lincoln University (California, USA). Universal Business School follows the unique 3E (Ethics, Experiential learning and Environment) model in imparting world class education. UBS is committed to creating responsible business professionals by promoting the ideology of ethical business and environmental sustenance.

#universal business school#universal business school faculty feedback#universal business school faculty reviews#universal business school feedback#universal business school karjat#universal business school maharashtra#universal business school mumbai#universal business school news#universal business school placement feedback#universal business school placement review

0 notes

Text

Bike Transportation Services Noida

Noida Home Packers Movers bike transport services Noida is one of the oldest pillars of this business. With our head workplace in Noida and a nationwide network of branches all over India, we've gained the arrogance and conviction of all our clients by establishing and conducting our business with honesty, integrity, and humanity. We've got complete additionally reliable and cost-efficient solutions to any or all your transportation needs. Bike courier service in Noida list of self-satisfied purchasers has given the impression to be growing in today's date that gets pleasure from a special advantage of checking the standing of their cargo online through our on-line Vehicle pursuit feature visible on our website. We hope to supply the most effective services to our valued consumer base throughout India on the premise of 3E's, particularly Effectual, Economic and Economical, which makes us a proud and growing company within the name of Bike courier service in Delhi. We tend to welcome every valuable suggestion forwarded by our precious customers and provide a depot of knowledge to the clients in terms of Bike parcel service Delhi. To know more you can call us at: +91 9717677583.

#biketransportationservicesnoida#biketransportation#biketransportationservices#noidabiketransportationservices

0 notes

Text

Microwave 2T XMC-80D Wins iF Design Award 2024 & Red Dot

Huawei Microwave 2T E-band XMC-80D Takes Home the 2024 iF and Red Dot Design Awards.

iF Design Award Vs Red Dot

Because of its innovative technology and cutting-edge product design, the Huawei XMC-80D, a next-generation 2T E-band outdoor unit (ODU), was honored with the if Design Award and the Red Dot Design Award. After the XMC-3E in 2021, this is the second time Huawei’s microwave equipment have won these two esteemed prizes.

Modern optimization algorithms on the XMC-80D significantly increase coding efficiency for greater spectrum utilization, and with dual-channel and dual-polarized transmission, a single box can supply up to 25 Gbps of bandwidth. Up to 50 Gbps of speed can be achieved with a single E-band link, nearly decreasing the amount of gear needed and providing an amazing 150% increase in capacity over existing E-band solutions. To fulfil the ultra-large bandwidth requirements of 5G and 5.5G, this capability more than suffices.

XMC

Because it allows service switching via the backplane, service traffic can pass through all of its primary control service interfaces. Furthermore, the product’s unified IDU design allows for flexible scaling up and seamless evolution in an incredibly economical manner. The device has ergonomic handles for convenient travel and installation, and a double-sided heatsink to maximize heat dissipation.

James Zeng, President of Huawei Microwave Product Line, said of the honors: “They show how competitive we are in the microwave industry. We’ll keep coming up with innovative, straightforward backhaul technologies that offer incredibly high bandwidth in all situations where massive backhaul is required for 5G and 5.5G.”

Red Dot Design Award 2024

iF Design Award 2024

The latest Huawei microwave, the 2T E-band XMC-80D, earned the iF Design Award and Red Dot Design Award for 2024. This two-fold award shows the product’s excellent performance, design, and telecom industry impact.

XMC-80D Huawei Microwave 2T E-band

Modern telecom equipment like the Huawei Microwave 2T E-band XMC-80D boosts network capacity. This device uses cutting-edge technology in the E-band spectrum, known for its high-frequency range and large bandwidths. It is crucial to today’s network infrastructure because to its innovative functionality and design.

Important Elements

The XMC-80D’s 10Gbps transmission bandwidth ensures quick data transfer and efficient network operation.

Advanced Modulation: 256QAM modulation boosts data rates and spectrum efficiency.

Robust Design: The XMC-80D can tolerate harsh environments with its IP65 dust and water protective casing.

Energy Efficiency: The XMC-80D reduces power usage and running costs using sustainable energy-saving technologies.

The Value of Red Dot and iF Design Awards

The iF Design Award and Red Dot Design Award recognize the XMC-80D’s innovative design. These awards honour products with superior design, functionality, and user experience.

iF Design Award

The iF Design Award, one of the world’s most prominent design contests, rewards creative, usable, and beautiful products. This prestigious prize was granted to the XMC-80D for its advanced technology and exquisite design.

What is Red Dot Design Award

Another prestigious award that honours exceptional product design and innovation is the Red Dot Design Award. The XMC-80D’s strong and effective design, together with its excellent performance, guaranteed its position as one of the best in the sector.

Effects on the Industry of Telecommunications

iF Communication Design Award

In the telecom industry, the Huawei Microwave 2T E-band XMC-80D’s release represents a critical turning point. Its cutting-edge features and superb design support the development of network infrastructure, facilitating quicker and more dependable communication.

Improved Network Efficiency

The XMC generates high-frequency transmissions that support huge bandwidths by functioning in the E-band spectrum, which is necessary for contemporary data-intensive applications. This feature is perfect for both urban and rural installations since it guarantees uninterrupted connectivity and improved user experiences.

Cost-effectiveness and Sustainability

The energy-efficient design of the XMC-80D not only lowers operating expenses but also complies with international environmental standards. Huawei supports the shift to more sustainable practices and helps the telecoms industry become greener by reducing power consumption.

Infrastructure Fit for the Future

The durable design and state-of-the-art technology of the XMC-80D prepare networks for future needs. There is a rising need for dependable, high-capacity infrastructure as data usage rises. These requirements are met by the XMC-80D, which guarantees that networks are ready to take on new challenges.

Client References

The Huawei Microwave 2T E-band XMC-80D has received high marks for performance and dependability from several customers and industry experts. Testimonials emphasize its strong design, simplicity of installation, and notable improvement in network efficiency.

Adoption and Global Reach

The XMC-80D has been embraced by telecommunications firms globally, as they have realized its potential to improve network performance. Its widespread deployment highlights its adaptability and efficiency in a range of settings and scenarios.

In summary

In the telecom sector, the Huawei Microwave 2T E-band XMC-80D is a ground-breaking device that has raised the bar. Its quality in design and usefulness is shown by its recognition with both the Red Dot Design Award and the iF Design Award. The XMC-80D stands out as a crucial component, promoting efficiency, sustainability, and excellent performance as networks adapt to meet increasing data needs.

Read more on govindhtech.com

#Microwave2T#XMC80D#WinsiFDesign#Award2024#HuaweiMicrowave#Huawei#5g#xmc#networkoperation#network#GlobalReach#80D#Costeffectiveness#Sustainability#Telecommunications#technology#technews#news#govindhtech

0 notes

Text

3e: Objection to Formula

When I started on this article, the plan was to talk to you about the magic item system in D&D 3rd edition, and let’s put a pin in the word ‘system’ there. But engaging with it meant looking at a place in history and a realisation of how I’m not just talking about stuff from an earlier edition of D&D I’m talking to you about an earlier version of myself.

As long as there has been an online, it seems, I have wanted to make things and put them on there.

In 3rd edition D&D, the game presented magical items as a major way your characters got better. This was so important that a level 20 character buck naked and a level 10 character fully and properly geared could be reasonably comparable threats and capable of handling similar things. Even a wizard, one of the more powerful buck-ass naked characters could benefit immensely from their budget being spent on stuff, like good and convenient spellbooks and more spells and the time to scribe them into your spellbook. Gear was so important to the game’s math that many early character options were just embarrassing ‘armour, but a little bit better’ and ‘weapons, but a little bit better.’

This presents us with Gear Complaint #1: Gear is too powerful and important.

Hold on, this gets weird.

Now I am somewhat poisoned by 4th edition and its wildly different gear system, but 3e’s items had some real problems. For a start, the typical item was only to be imagined as something looted from an opponent, which meant any given enemy had to have items comparable to yours. This created a lot of economic inflation pretty fast – when you were at a level when you could swing +3 swords, most enemies would have +1 swords to keep up with you, and that meant that every mook was holding a few grand in just their gear, which meant it was worth your time to strip them down for parts but also, because the items were just +1 swords, they weren’t interesting, they were never going to do anything or be better than your +3 sword, which in turn just meant you wound up travelling between encounters with a sack full of unused, bloodstained equipment from whatever you fought last.

Okay, that means complaint #2: Gear is boring.

And then in the hatrick triplicate of this, because everything has gear, magic items that did interesting things had a pricing structure, in the rulebook, with formulas, so that if you wanted to, you could create custom magical items that, provided they followed very specific rules, could achieve weird and seemingly overpowered effects, because this entirely unseeing system worked by looking at the spell system. You could have permanent, ongoing magical effects of spells, if you paid the right price for them. You could have items that cast a spell a certain number of times a day, if you paid the right price for them. You could have items that represented a host of small, minor, niche application spells, if you paid the price for them.

Which means we get to complaint #3: Gear is so complex it rewards character calculus.

I’ve talked about character calculus before. It’s not actually calculus, it’s much more like citations, where you take all the ‘legal’ books and crossreference all the referential material to make a case to your DM that this feat and this feat and this feat and this spell all interact with the same part of the system and therefore I can do this thing that’s probably broken. After all, you’re not doing anything as powerful as the Wizard is, so what’s the harm? It’s one of the most rewarding things you can do in 3e D&D, of finding the way all these puzzlebox pieces can slot together, where no level is wasted or inferior to another, better chosen level of class or prestige class, where no feat is being used where a niche improved variation works, and where every piece of gear is spending the character budget down to the last few gold coins.

Where the spell’s effect was directly comparable to some other combat effect – bonus damage or bonus to hit or bonus armour class – that could be priced per those effects. Thing is there were a lot of things you could do with a spell that were hard to price like that. Even just some annoying things were really powerful to have on things like an on-hit weapon attack. A level 1 Command spell only added 2,000 GP to the price of a sword, but if you’re attacking with it three times, that’s three chances for your enemy to roll a natural 1 and hit the deck. Some spells designed to resist specific negative effects like mind control were very low level, and therefore could just be jammed on magical items for a small increase in budget.

I can’t get over this; There were tables. There were tables for doing math on this stuff. You could reduce prices by adding ‘curse’ effects, by percentages. A use-activated 3/day stick of Knock costs something like 1,800 GP, which is to say, a pittance for a mid-level adventurer, and it completely makes a joke out of any lockpicking skill any given rogue has developed. It isn’t just that wizards displace Rogues, they can displace rogues in parties they don’t even join.

Anyway, fun system to dick around with. Lots of numbers. If you bother to read every spellbook and look for every unique magical effect or every possible use of a summon you could have a lot of fun just… making things.

And I did.

Back in the day on USENET, which was kind of like a forum with very little central control or moderation but which was also mostly only for text-only gigadorks who liked to argue about which Babylon 5 episode was the second best, and that included the showrunner, I posted for … a while? A weekly set of magic items. I would come up with a central theme, I would do the math on how they should exist, I would write a little blurb and I posted them on to Usenet.

I got told by people – many people older than me – that these items were good.

I went to look for these articles. The articles that I drew pictures for, and included links to the pictures, in the USENET posts. The articles that were written before I had a blog, and for an audience thrown out into a general space for anyone who wanted them to see.

It’s very strange to see a website timestamp a post you know you read, at the time, with ’20 years ago.’

D&D 5e is being rolled up and updated. There is a new edition war looming on the horizon; either this edition revision just becomes an accepted blip or the game fractures again, as it did around 3.0, 3.5, 4, and 5. And there are signs throughout our literal history of the places I have been, in the strata of this hobby like tree rings.

I miss USENET a lot. I miss knowing there was a place I could put anything I wanted and maybe someone would see it, and, probably, call me an idiot if it wasn’t very good. But that newsgroup, the D&D newsgroup, was a shockingly civil, pro-creative place that didn’t tell me to stop bothering or yell at me about my magic items with their lore. Some recommendations were made about power level, some arguments about whether I was justifying my math right.

But I-

I’ve always been doing this.

I have never not been posting, I guess.

Check it out on PRESS.exe to see it with images and links!

1 note

·

View note

Text

Test Bank For Macroeconomics 3e By Karlan

Test Bank For Macroeconomics 3e By Karlan

Macroeconomics 3e by Karlan is a comprehensive textbook that explores the principles and theories of macroeconomics. It provides an in-depth examination of various macroeconomic concepts, including national income, unemployment, inflation, monetary policy, fiscal policy, economic growth, and international trade. With clear explanations and real-world examples, the book helps students understand the complexities of macroeconomic theory and its applications in today's global economy. It is designed to be accessible to students while offering rigorous analysis and insights into macroeconomic phenomena. Table of Contents Chapter 1: Economics and Life Chapter 2: Specialization and Exchange Chapter 3: Markets Chapter 4: Elasticity Chapter 5: Efficiency Chapter 6: Government Intervention Chapter 7: Measuring GDP Chapter 8: The Cost of Living Chapter 9: Unemployment and the Labor Market Chapter 10: Economic Growth Chapter 11: Aggregate Expenditures Chapter 12: Aggregate Demand and Aggregate Supply Chapter 13: Fiscal Policy Chapter 14: The Basics of Finance Chapter 15: Money and the Monetary System Chapter 16: Inflation Chapter 17: Financial Crisis Chapter 18: Open-Market Macroeconomics Chapter 19: Development Economics

Test Bank For Macroeconomics 3e By Karlan

Read the full article

0 notes

Text

Regulation (EU) 2017/746 (IVDR): MDR IVDR Amendment Jan. 2023

Introduction

Recent amendments to Regulation (EU) 2017/745, also known as the Medical Devices Regulation (MDR), have introduced significant changes to the timelines and conditions for placing certain medical devices on the market or putting them into service. This comprehensive analysis explores the key points of these amendments, focusing on the intricate timeline considerations.

Paragraph 3 Amendments

Paragraph 3 has undergone crucial revisions, introducing new provisions (3a to 3g) that outline conditions and timelines for the placement of medical devices on the market or into service.

Let’s delve into the details of these Regulation (EU) 2017/746 amendments:

3a. Derogation and Conditions

By derogation from Article 5, devices falling under paragraphs 3b and 3c may be placed on the market or put into service, subject to the fulfilment of conditions specified in paragraph 3d.

3b. Placing Devices with Certificates

Devices with certificates issued under Directive 90/385/EEC or Directive 93/42/EEC, valid by virtue of paragraph 2, can be placed on the market until specific dates:

– Until 31 December 2027 for class III devices and class IIb implantable devices (excluding specific items).

– Until 31 December 2028 for class IIb devices (excluding those covered by the previous point), class IIa devices, and class I devices in sterile condition or with a measuring function.

3c. Conformity Assessment Procedure

Devices with conformity assessment procedures under Directive 93/42/EEC, not involving a notified body, may be placed on the market or put into service until 31 December 2028, provided certain conditions are met.

3d. Conditions for Placement

Devices can be placed on the market until the specified dates (3b and 3c) if the following conditions are met by 26 May 2024:

– Continued compliance with relevant directives.

– No significant changes in design and intended purpose.

– No unacceptable risk to health or safety.

– Implementation of a quality management system by the manufacturer.

– Lodgement of a formal application for conformity assessment by 26 May 2024 and a written agreement signed with a notified body by 26 September 2024.

3e. Application of MDR Requirements

In derogation from paragraph 3a, devices in paragraphs 3b and 3c are subject to MDR requirements for post-market surveillance, market surveillance, vigilance, and registration of economic operators and devices.

3f. Responsibilities of Notified Bodies

The notified body issuing the certificate in paragraph 3b remains responsible for surveillance unless agreed otherwise. A transition of surveillance responsibilities is outlined in agreements between manufacturers and notified bodies.

3g. Derogation for Class III Custom-made Implantable Devices

Class III custom-made implantable devices can be placed on the market until 26 May 2026 without a certificate, provided a formal application is lodged by 26 May 2024, and a written agreement with a notified body is signed by 26 September 2024.

Paragraph 4 Replacement

Paragraph 4 stipulates that device lawfully placed on the market before 26 May 2021, and those placed afterward under paragraphs 3a, 3b, 3c, and 3g, may continue to be made available or put into service.

Article 122 Amendments

Article 122 outlines amendments related to the repeal of Directives 90/385/EEC and 93/42/EEC, effective from 26 May 2021. Noteworthy points include the continuation of Directives’ application for devices in specific paragraphs of Article 120(3a) to (3f) and (4).

Article 123 Amendments

In Article 123(3), point (d), the amendment includes a reference to Article 120(3e), further emphasizing the continued application of certain requirements from the repealed Directives.

Regulation (EU) 2017/746 Amendments

The amendments to Regulation (EU) 2017/746, also known as the In Vitro Diagnostic Devices Regulation (IVDR), focus on Articles 110 and 112.

Article 110 Amendment

Devices lawfully placed on the market under Directive 98/79/EC before 26 May 2022, and those placed afterward under paragraph 3 of this Article, may continue to be made available or put into service.

Article 112 Amendment

For devices referred to in Article 110(3) and (4) of the IVDR, Directive 98/79/EC shall continue to apply to the extent necessary for the application of those paragraphs.

Conclusion

The recent amendments to MDR and IVDR introduce a complex framework of conditions and timelines for the placement of medical devices on the market. Stakeholders, including manufacturers and notified bodies, must carefully navigate these provisions to ensure compliance and a smooth transition to the new regulatory landscape.

Originally Published at: https://omcmedical.com/regulation-eu-mdr-ivdr-amendment/

0 notes

Text

L'Antai College of Economics and Management se classe au 25e rang mondial

L'ACEM de l'Université Jiao Tong de Shanghai (SJTU) se classe au 25e rang mondial et au 3e rang en Chine, pour la 3ème année consécutive

Communiqué Antai College of Economics & Management, Shanghai Jiao Tong University – Le classement mondial des universités 2024 par matière : commerce et économie, a été publié le 26 octobre. L’Antai College of Economics and Management (ACEM) de l’Université Jiao Tong de Shanghai (SJTU) se classe au 25e rang mondial et au 3e rang en Chine, figurant dans le top 3 de la Chine continentale depuis…

View On WordPress

#Antai College of Economics and Management#Chine#chine-magazine#éducation chinoise#Shanghai#université chine

0 notes

Text

Top 7 best CNC machining manufactures

Top 7 best CNC machining manufactures

When it comes to the CNC machining manufacturing industry, finding reliable top-tier manufacturers is of utmost importance.

CNC (Computer Numerical Control) machining technology plays a vital role in modern manufacturing, providing designers and

engineers with highly precise and dependable production solutions. Globally, there are numerous renowned CNC machining

manufacturers, known for their excellent technology, high-quality finished products, and outstanding customer service.

In this article, we will focus on the top 7 CNC machining manufacturers that stand out in the field, showcasing their expertise and

innovative solutions that bring exceptional value to customers across various industries. Whether it's prototyping or low-volume

production, these CNC machining manufacturers excel with their performance and relentless pursuit of excellence in the industry.

Let's delve into these outstanding manufacturers, exploring their technical prowess and commitment to meeting customer needs.

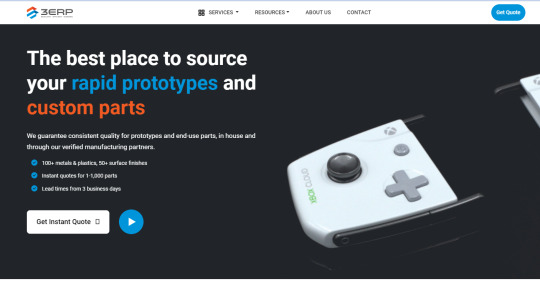

1. 3ERPmold (3E Rapid Prototyping)

A 3ERP (3E Rapid Prototyping) mold is a type of mold used in rapid prototyping and low-volume production processes. It is a

cost-effective and time-efficient solution for creating parts and products that require limited quantities. The term "3ERP" stands for

"3E Rapid Prototyping," representing the three main aspects of the service: "Economical," "Efficient," and "Excellent."

Here's an introduction to 3ERP molds:

Economical: 3ERP molds are designed to be cost-effective, especially for low-volume production runs. Traditional injection molds

can be expensive and time-consuming to produce, making them less suitable for small quantities. In contrast, 3ERP molds can

significantly reduce tooling costs and allow for more affordable production of prototypes or limited batches.

Efficient: As the name suggests, 3ERP molds offer rapid prototyping capabilities, enabling quick turnaround times. This speed is

achieved through various manufacturing technologies, such as 3D printing, CNC machining, and vacuum casting. These methods

enable the creation of molds faster than conventional mold-making processes.

Excellent: Despite their rapid production, 3ERP molds maintain a high level of quality. The materials used in the process are carefully

selected to ensure the durability and accuracy of the molds, resulting in precise parts and prototypes.

Common applications of 3ERP molds include:

Prototype Development: Engineers and designers often use 3ERP molds to create prototypes for testing and validation before moving

on to mass production.

Low-Volume Production: When only a small quantity of parts is needed, 3ERP molds can be a cost-efficient solution compared to

traditional tooling methods.

Bridge Tooling: 3ERP molds can serve as bridge tooling, providing a temporary production solution while awaiting the development

of final production molds.

Custom Parts: Manufacturers can use 3ERP molds to produce custom parts that are not feasible or economical using other

manufacturing methods.

It's important to note that while 3ERP molds offer advantages in terms of speed and cost for low-volume production, they may not be

suitable for high-volume manufacturing due to their limited lifespan and potential limitations in material selection. For larger

production runs, traditional injection molding or other mass production methods are generally more appropriate.

As technology advances, the capabilities and applications of 3ERP molds may expand, providing an even more versatile solution

for rapid prototyping and low-volume production needs.

2. REGO MOULD

REGO MOULD is a professional Rapid prototyping companies that has been serving customers since 2008. Our focus is on providing

top-quality services such as mold design, mold fabrication, plastic injection molding, CNC machining, rapid prototyping, and much more.

specialize in the mould manufacturing for aerospace, automotive, robots & automation, telecommunications, consumer electronics,

home appliance, and other industries.Our factory is over 5000 square meters in size and is closed to convenient transportation.

At present, Rego has over 100 employees, Equipment is mostly imported from Switzerland and Taiwan.We have 5 sets of 5-axis CNC

milling, 30 CNC machines, 15 EDM machine, We have the capacity to produce 50-60 injection moulds per month.

If you are looking for information on Rego Mould or mold-making companies, I can provide you with a generic introduction to Rego Mould:

Rego Mould specialize in the design, fabrication, and production of molds used in various manufacturing processes, such as injection

molding, blow molding, die casting, and more. Molds are crucial tools that shape and form raw materials into specific shapes or products

during the manufacturing process.

Here are some key points about Rego Mould:

Expertise: Rego Mould typically have a team of skilled engineers and designers with expertise in mold design and fabrication. They use

specialized software and equipment to create precise and customized molds based on client requirements.

Materials: Molds can be made from different materials, depending on the manufacturing process and the material being molded.

Common materials used for mold fabrication include steel, aluminum, and various alloys.

Prototyping: Rego Mould often provide prototyping services to help clients validate their designs and ensure that the molds meet the

required specifications before full-scale production.

Customization: Rego Mould can create molds tailored to the specific needs of their clients. They can produce molds for a wide range

of products, from simple components to complex and intricate parts.

Quality Control: Quality is critical in Rego to ensure the accuracy and consistency of the molded products. Reputable mold manufacturers

have stringent quality control processes in place to deliver high-quality molds.

Lead Times: The time required to manufacture a mold can vary depending on its complexity and the manufacturing company's workload.

Some companies may offer expedited services for faster mold production.

Additional Services: In addition to mold manufacturing, some companies may offer related services, such as mold maintenance, repair,

and modification, to ensure the longevity and efficiency of the molds.

Remember, if you are specifically interested in "REGO MOULD," I recommend verifying the information through their official channels or

contacting them directly for accurate and up-to-date details about their services and capabilities.

https://jnrorwxhnlnlln5p.ldycdn.com/cloud/jpBpqKjkloSRrkiqqkoiio/weixintupian_202307271917232.png

3. Star Rapid

Star Rapid is a global rapid prototyping, rapid tooling, and low-volume manufacturing company that offers a wide range of services to

support product development and production needs. Headquartered in China, Star Rapid serves clients from various industries worldwide,

providing them with high-quality and cost-effective solutions for bringing their ideas to life.

Here's an introduction to Star Rapid and its services:

Rapid Prototyping: Star Rapid specializes in rapid prototyping services, which allow clients to quickly and iteratively create physical

prototypes of their designs. They offer various prototyping technologies, including 3D printing (SLA, SLS, FDM, etc.), CNC machining,

vacuum casting, and more. Rapid prototyping enables designers and engineers to validate their concepts, test product functionality,

and make design improvements before moving to production.

Rapid Tooling: The company also provides rapid tooling services, which bridge the gap between prototyping and full-scale production.

Rapid tooling techniques, such as aluminum tooling or soft tooling, enable faster and more cost-efficient production of low to medium

volumes of parts compared to traditional steel injection molds.

Low-Volume Manufacturing: Star Rapid specializes in low-volume manufacturing, catering to customers who need small to medium

quantities of parts. Their expertise in rapid prototyping and rapid tooling allows them to deliver production-grade parts in quantities

that may not be feasible or economical with mass production methods.

Materials and Finishing Options: Star Rapid offers a wide selection of materials to choose from, including various plastics, metals, and

elastomers. Additionally, they provide a range of finishing options, such as painting, plating, anodizing, and more, to meet specific product

requirements.

Design for Manufacturability (DFM) Support: The company's team of experienced engineers provides Design for Manufacturability (DFM)

support to optimize product designs for better manufacturability and cost-effectiveness. They work closely with clients to address potential

design issues and ensure smooth production processes.

Global Reach: While headquartered in China, Star Rapid has a global presence and serves customers from all over the world. They offer

international shipping and support, making it convenient for clients regardless of their location.

Quality Control: Star Rapid is committed to maintaining high-quality standards throughout their processes. They have a robust quality

control system in place to ensure that the parts they produce meet the required specifications and expectations.

As a company, Star Rapid focuses on customer satisfaction, providing fast turnaround times, competitive pricing, and excellent customer

service. They cater to a wide range of industries, including automotive, aerospace, medical, consumer electronics, and more, helping businesses

of all sizes turn their ideas into reality efficiently and effectively.

4. HLH Prototypes Co. Ltd

HLH Prototypes Co. Ltd is a prominent and well-established manufacturing company based in China that specializes in providing rapid

prototyping, rapid tooling, and low-volume manufacturing services. With extensive experience and a global client base, HLH Prototypes

is recognized for delivering high-quality products, quick turnaround times, and excellent customer service.

Here's an introduction to HLH Prototypes Co. Ltd:

Company Overview: HLH Prototypes was founded in 2001 and is headquartered in Shenzhen, China. Over the years, the company has

grown to become one of the leading rapid prototyping and manufacturing service providers in the industry.

Rapid Prototyping Services: HLH Prototypes offers a wide range of rapid prototyping technologies, including 3D printing (SLA, SLS,

FDM, etc.), CNC machining, vacuum casting, and more. These capabilities allow clients to quickly create physical prototypes for design

validation, testing, and evaluation purposes.

Rapid Tooling Services: In addition to prototyping, HLH Prototypes provides rapid tooling solutions. These methods, such as aluminum

tooling or soft tooling, enable the production of low to medium volumes of parts without the high costs associated with traditional steel

injection molds.

Low-Volume Manufacturing: HLH Prototypes specializes in low-volume manufacturing, catering to clients who require small to medium

quantities of parts. This service is ideal for bridging the gap between prototyping and full-scale production.

Material Selection: The company offers a wide range of materials to choose from, including various plastics, metals, resins, and composites.

This diversity allows clients to select the most suitable materials for their specific project requirements.

Design for Manufacturability (DFM) Support: HLH Prototypes has a team of experienced engineers who provide Design for Manufacturability

(DFM) assistance. They work closely with clients to optimize product designs for better manufacturability, cost-effectiveness, and overall

product quality.

Quality Assurance: HLH Prototypes places a strong emphasis on maintaining high-quality standards throughout their manufacturing

processes. They have a rigorous quality control system in place to ensure that the produced parts meet the required specifications and

quality requirements.

Global Reach: While based in China, HLH Prototypes serves clients from around the world. They offer international shipping and support,

making their services accessible to businesses and individuals regardless of their location.

Overall, HLH Prototypes Co. Ltd has built a reputation as a reliable and trusted partner for rapid prototyping and manufacturing needs.

Their commitment to excellence and customer satisfaction has made them a go-to choice for a wide range of industries, including

automotive, aerospace, medical, consumer electronics, and more.

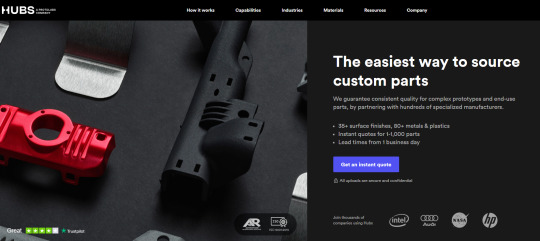

5. 3D Hubs B.V.

3D Hubs B.V. was a well-known online platform that provided on-demand manufacturing services, including 3D printing, CNC machining,

injection molding, and sheet metal fabrication. It facilitated the connection between customers seeking to manufacture custom parts and

a network of manufacturing partners worldwide.

Here's an introduction to 3D Hubs B.V. based on the information available:

Company Overview: 3D Hubs B.V. was founded in 2013 and was headquartered in Amsterdam, Netherlands. It was one of the early

pioneers in the online manufacturing platform space, offering a streamlined and user-friendly process for customers to access various

manufacturing services.

Online Manufacturing Platform: 3D Hubs operated as an online manufacturing platform where customers could upload their 3D models

or CAD designs and receive instant quotes for the production of their parts. The platform provided a wide range of manufacturing

technologies, allowing customers to choose the most suitable method for their specific project requirements.

Manufacturing Technologies: The services offered by 3D Hubs included 3D printing, CNC machining (milling and turning), injection

molding, and sheet metal fabrication. This allowed customers to access a comprehensive range of manufacturing options for different

materials and part complexities.

Global Network of Manufacturing Partners: 3D Hubs had a vast network of manufacturing partners worldwide. These partners were

carefully vetted to ensure they met quality standards and could offer competitive pricing. When customers placed orders,

the manufacturing was handled by the most suitable partner within the network.

Fast Turnaround Times: The platform was known for providing relatively quick turnaround times for prototype and low-volume

production orders. This enabled customers to receive their parts promptly, facilitating faster product development cycles.

Materials and Finishing Options: 3D Hubs offered a variety of materials for 3D printing and machining processes. Additionally, they

provided finishing options such as painting, anodizing, and surface treatments to meet specific part requirements.

Quality Control: The platform had measures in place to ensure the quality of the manufactured parts. Customers could leave reviews

and ratings after receiving their orders, contributing to the platform's quality assurance process.

6. Quickparts

"Quickparts" was a division of 3D Systems, a leading provider of 3D printing and additive manufacturing solutions. While Quickparts

is primarily known for its rapid prototyping and low-volume production services, they also offer mold-making services as part of their

broader manufacturing capabilities.

Here's an introduction to Quickparts MOULD:

Mold-Making Services: Quickparts MOULD is a division of Quickparts that specializes in providing mold-making services. They design

and fabricate molds used in various manufacturing processes, such as injection molding, which is a widely used method for producing

plastic parts in large volumes.

Expertise in Mold Design: Quickparts MOULD has a team of skilled engineers and designers with expertise in mold design. They use

advanced software and tools to create precise and efficient molds that meet the specific requirements of their clients.

Materials for Molds: Molds can be made from various materials, with steel and aluminum being common choices. The material selection

depends on factors such as the type of manufacturing process, the expected production volume, and the properties of the molded material.

Customization: Quickparts MOULD offers customized mold solutions to cater to the specific needs of their clients. They work closely with

customers to understand their requirements and design molds that align with their product specifications.

Quality Control: As with all manufacturing processes, quality control is paramount in mold-making. Quickparts MOULD has stringent

quality assurance measures in place to ensure the accuracy, durability, and functionality of the molds they produce.

Rapid Prototyping and Low-Volume Production: In addition to mold-making services, Quickparts specializes in rapid prototyping and

low-volume production using various manufacturing technologies, including 3D printing and CNC machining. This comprehensive approach

allows clients to benefit from a wide range of manufacturing solutions under one roof.

Global Reach: Quickparts MOULD, being part of 3D Systems, has a global presence and serves clients from various industries worldwide.

Their international reach and manufacturing capabilities make them a preferred choice for businesses seeking rapid prototyping,

low-volume production, and mold-making services.

For the most current and detailed information, I recommend visiting their official website or contacting them directly to inquire about their

mold-making services and capabilities.

7. Xcentric Mold

Xcentric Mold & Engineering, commonly known as Xcentric, is a leading rapid manufacturing company based in the United States.

With over 25 years of experience, Xcentric specializes in providing rapid injection molding and CNC machining services, offering

high-quality, low-volume production solutions to a diverse range of industries.

Here's an introduction to Xcentric Mold & Engineering:

Expertise in Rapid Manufacturing: Xcentric is a pioneer in the field of rapid manufacturing. They are known for their expertise in rapid

injection molding and CNC machining, which enables them to produce functional prototypes and low-volume production parts quickly

and efficiently.

Injection Molding Services: Xcentric offers rapid injection molding services, which is a cost-effective method for producing plastic parts

in low volumes. They utilize advanced injection molding technology and materials to create high-quality parts that closely resemble the

final product.

CNC Machining Services: In addition to injection molding, Xcentric provides CNC machining services. They use state-of-the-art CNC

milling and turning equipment to produce precision parts from a wide range of materials, including metals and plastics.

Material Selection: Xcentric offers a comprehensive selection of materials for both injection molding and CNC machining processes.

This allows customers to choose the most suitable materials for their specific applications and requirements.

Design for Manufacturability (DFM) Support: Xcentric has a team of experienced engineers who provide Design for Manufacturability

(DFM) support. They work closely with clients to optimize their designs for better manufacturability, cost-effectiveness, and overall part quality.

Fast Turnaround Times: The company is known for its quick turnaround times, allowing customers to receive their prototypes or

low-volume production parts within days. This speed is achieved through streamlined processes and efficient manufacturing techniques.

Quality Assurance: Xcentric maintains a strong focus on quality control throughout their manufacturing processes. They have quality

inspection measures in place to ensure that the produced parts meet the required specifications and adhere to strict quality standards.

Online Quoting and Ordering: Xcentric operates an easy-to-use online platform where customers can upload their 3D models, receive

instant quotes, and place orders for their prototypes or production parts. This streamlined process simplifies and expedites the ordering process.

Global Reach: While based in the United States, Xcentric serves clients from around the world. They offer international shipping and

support, making their services accessible to businesses and individuals worldwide.

As an established and reputable rapid manufacturing company, Xcentric Mold & Engineering continues to be a reliable partner for

businesses seeking high-quality, rapid prototyping, and low-volume production solutions.

0 notes

Text

ugh, as someone who was, mistakenly, part of the 4e backlash back when it came out, i am chafing at all the misinformation in here. so, let's take a look.

first, quick timeline:

2000: D&D 3e comes out, then a revised edition comes out in 2003 because haste was broken af (comedic exaggeration, this was not the only reason).

2002: Paizo is founded as a separate company to take over the publishing of Dragon and Dungeon magazines. Paizo also start publishing their own periodicals, including a resurrection of the pulp sci-fi magazine Amazing Stories, and started republishing a lot of old pulp novels that had gone out of print. this isn't, strictly speaking, relevant to the rest of this, but it is a fun bit of trivia that gives a solid insight into why early Pathfinder was like it was in a lot of ways, in terms of worldbuilding and plots.

2003: Paizo starts publishing the series of articles that will become The Shackled City, Paizo's debut "adventure path" in Dungeon magazine. based on its success, they continue this "adventure path" model a couple more times throughout Paizo's run of Dungeon. the original "Defense of the Ancients" map for Warcraft III is published.

2004: World of Warcraft launches, introducing millions to the "MMO" and codifying many elements of the genre in the minds of its players in a way very similar to how the elements of TTRPGs were codified in the minds of first-time 5e players in the late 2010s.

2006: Dungeons & Dragons Online launches. it is, of course, based on a modified version of the 3.5e ruleset.

2007: WotC ends the contract with Paizo to publish Dragon and Dungeon in order to start publishing them in-house as digital magazines. in response, Paizo starts publishing the Pathfinder Adventure Path product line for D&D 3.5e, essentially spinning off the Dungeon adventure path model into its own stand-alone publications, in order to fill in the gap of losing their flagship publications. WotC announces 4e, and Paizo starts planning what to do when the edition rolls over.

2008: 4e launches, the GSL for it goes through several revisions ultimately leading Paizo to decide that they can't effectively carry their PFAP line over into it, and as they finish up the APs already in the pipeline, prepare to launch their own Pathfinder Roleplaying Game the next year.

2009: League of Legends launches, leading to the popularization of the MOBA genre. Pathfinder 1e also launches, leading to the ever-present D&D edition wars developing into an outright schism.

2013: Neverwinter launches, an MMO loosely adapted from the 4e ruleset.

okay. lots of shit, some of it probably seems barely related to anything here.

first off, the founding of Paizo was a business decision primarily driven by the economics and logistics of magazine publication versus book publication. in the early days of D&D under WotC's leadership, WotC actually planned to run things fairly light and tight, originally planning to only focus on the popular Forgotten Realms campaign setting, and either licensing the rights to publish compatible products that adapted other settings to 3e to other companies like Sovereign Press (Dragonlance) and White Wolf Publishing (Ravenloft). a curious semi-example of this was WotC's decision to have 3e's version of Oriental Adventures, a book title previously used in 1e AD&D to introduce the setting of Kara-Tur, use The Legend of the Five Rings' Rokugan as its template setting (while also adapting a few elements from Kara-Tur that explicitly did not exist in Rokugan), but then leaving Alderac Entertainment Group to publish any further 3e-compatible Rokugan material. so, no, Paizo was not formed from disgruntled former WotC employees over game design disagreements, and the decision to create a separate company to handle the Dragon and Dungeon magazines is not all that uncharacteristic of WotC in this era.

next, as pointed out in the timeline, DDO launched well before 4e and its mechanics are distinctly 3.5e-based. obviously heavily modified to suit a MMO framework, but undeniably far more similar to 3e than 4e. in fact, even Tome of Battle which launched for 3e in the same year bears a greater similarity to 4e than DDO does in many respects, and feels much more like a testing ground for mechanics that would be utilized in 4e.

as said, Pathfinder's creation was more due to the nature of the GSL which also caused many other 3rd-party publishers to turn away from 4e as well due to how restrictive the license was making it exceedingly difficult to use 3pp 4e products as a successful business model. since Paizo had lost their flagship product, their attempts at republishing pulp fiction weren't picking up steam, and they had just started developing this whole setting for their adventure paths, nabbing the remains of 3e to keep the OGL alive was kind of their best option to stay afloat as a company. while i do think they genuinely strove to make the best of it, rather than using it as a mere cash grab, i also think it was undoubtedly a business decision first and foremost, and not born out of ideological disagreements over game design.

now, as for the 4e slander. first off, 4e is now my favourite version of D&D, certainly from a gameplay standpoint. certainly if we aren't counting Pathfinder as D&D. but at the time, yeah i kinda hated it, and at least in my case, when i first browsed a copy of the Player's Handbook in my local bookstore (R.I.P. Borders), i hadn't read anything substantial about it online yet, and MMO was still the first thing that came to mind. while now i can probably agree with you that MOBA is perhaps more accurate, when looking at this timeline, i think you'll understand why people went to comparing it to MMOs first, considering a single MMO was larger than the entire genre of MOBAs at the time 4e launched. but that's a digression.

the main features i would point to as why 4e can be described as "MMO-like" are: the overtly mechanic-focused rules text, especially in contrast to earlier editions.

4e also drastically simplified skills, 3e's main non-combat mechanics, and completely lacked anything like 2e's strongholds or followers, resulting in very little mechanical support for characters to do much of anything outside of combat, and virtually nothing outside of dungeon delving. this all culminated in the kind of experience someone playing World of Warcraft may have where they have very little ability within the framework of the game itself to actually interact with the world outside of killing monsters. even crafting magical items was reduced to picking up a couple of rituals that let you turn any magic item into "residuum" that could then be reconstituted into a magical item of effectively your choice using a second ritual, very much resembling mechanics like WoW's own Enchantment profession.

additionally, to anyone familiar with running dungeons in WoW, the general rhythm of how powers had a "cool-down" in 4e was also familiar. you've got your at-will powers which simply link to the GC, your encounter powers that you need to try and use at the right point in a boss fight, but can rely on for every boss fight in a dungeon, and your daily powers, which you typically save for the final boss, or for situations that particularly call for it.

again, even though the exact mechanics of marking may derive more intentionally from basketball, they aren't dissimilar to tank mechanics in an MMO, and anyone who's got experience as an MMO tank will be able to intuit how to use them fairly well. given that many of the people checking out 4e were much more the sort to had played WoW more than even watching let alone playing basketball... it's perhaps understandable why they'd spot that similarity rather than the other.

all of this was also a pretty hard turn from 3e's much more "immersive sim" design, imo best exemplified by how, on a fundamental level, NPCs, monsters, and PCs are all built off the exact same set of mechanics, allowing the three to be losslessly transferred between each other, lending a certain verisimilitude. the fact that the rules are equally capable of modeling a PC, an NPC, and a monster forging a sword, casting a spell, or attacking an ogre using the exact same set of rules can subtly emphasize the idea of "this is a real, breathing world".

but that's not the only way to make a TTRPG, and again, i like 4e. a lot. for adrenaline-pumping dungeon delving, it is perhaps peak game design, even. and the ways that it resembles MMOs are, i think, a big part of that, both in what it focuses on and supports and what it glosses over.