#3D Printing Extrusion Materials Market Share

Explore tagged Tumblr posts

Text

3D Printing Extrusion Materials Market: Exploring UV-Curable Resins for Rapid Prototyping

3D Printing Extrusion Materials is Booming on the Back of Growing Adoption of Additive Manufacturing

The global 3D printing extrusion materials market is experiencing significant growth driven by rapid developments in additive manufacturing technology. 3D printing extrusion materials such as photopolymers, filaments, and pellets offer advantages including high dimensional accuracy, lightweight and durable designs, and cost-effective production of complex geometries. The ability of 3D printing extrusion materials to produce intricate functional parts without tooling or fixtures has boosted their use across various end-use industries including aerospace, automotive, healthcare, consumer goods, and construction. The Global 3D Printing Extrusion Materials Market is estimated to be valued at US$ 12.77 Billion in 2024 and is expected to exhibit a CAGR of 19% over the forecast period from 2023 to 2030.

3D printing extrusion materials enable mass customization and on-demand manufacturing, which has increased their demand for prototyping and production applications. Continuous technological advancements focused on developing enhanced material properties such as strength, durability, and temperature resistance are further driving the market. Key Takeaways Key players operating in the 3D printing extrusion materials are 3D Systems Corporation, Stratasys Ltd., Materialise NV, EOS GmbH, Arkema S.A., SABIC, Evonik Industries AG, DuPont de Nemours Inc., BASF SE, Dow Chemical Company, HP Inc., Royal DSM N.V., EnvisionTEC GmbH, CRP Group., Carbon, Inc. These companies are focusing on new product launches and capacity expansion strategies to strengthen their market position. The growing demand for 3D printed parts and components across various industries is a major factor propelling the 3D printing extrusion materials market. Industries are increasingly adopting 3D printing for rapid prototyping, tooling, and production applications due to advantages such as low costs and reduced turnaround times. The market is also witnessing increased global expansion as players are enhancing their distribution networks across emerging economies. The rising investments in additive manufacturing technologies and growing R&D activities globally present significant growth opportunities for 3D printing extrusion materials over the forecast period. Market Key Trends Particle size reduction and new material formulations are notable trends being observed in the 3D printing extrusion materials market. Market players are focusing on further miniaturization of particle sizes to enable the production of micro-scale features and complex geometries. Continuous innovation in specialty polymer materials including carbon-reinforced, flame-retardant, and biocompatible varieties are expanding the application horizons for 3D printing extrusion materials. The market is also witnessing new opportunities through the development of hybrid and composite materials with blended properties. With the rising popularity of additive manufacturing, the demand for high-performance 3D printing extrusion materials is expected to exhibit strong growth over the next decade.

Porter's Analysis Threat of new entrants: New companies find it difficult to enter the market due to the significant capital investments required for manufacturing 3D printing extrusion materials.

Bargaining power of buyers: Buyers have moderate bargaining power due to the availability of alternatives and substitutes.

Bargaining power of suppliers: Suppliers have moderate bargaining power due to the availability of options for buyers and dominance of few players.

Threat of new substitutes: threat of substitutes is moderate with emerging new alternative 3D printing technologies.

Competitive rivalry: The market is dominated by few major players and there is intense competition. Over the years, North America has been dominating the 3D printing extrusion materials market owing to increasing demand from industries such as aerospace & defense and healthcare. USA holds a significant share in North America. The aerospace & defense industry in USA is increasingly utilizing 3D printing for lightweight components and complex parts for aircraft. The region has witnessed high investments in R&D and new product launches by key players such as 3D Systems Corporation and Stratasys, Ltd. Asia Pacific region is expected to grow at the highest CAGR during the forecast period owing to growing demand from application industries such as consumer goods and foundry in countries such as China and India. Foundry application offers vast opportunities for 3D printing extrusion materials market in Asia Pacific. Expanding manufacturing sector, easy availability of skilled labor force, and government initiatives are promoting adoption of advanced technologies including 3D printing.

#3D Printing Extrusion Materials Market gowth#3D Printing Extrusion Materials Market share#3D Printing Extrusion Materials Market Trend

0 notes

Text

Sustainability at the Core: Eco-friendly Initiatives in the 3D Printing Extrusion Materials Market

3D printing extrusion materials, also known as filaments, are the basis for additive manufacturing through fused filament fabrication. The 3D printing extrusion materials are designed to be fed into a 3D printer liquefier head, which melts the materials and lays down successive layers in a predetermined pattern to construct complex geometries and parts. Advanced materials such as thermoplastics, photopolymers, bio-derived polymers and composites and others are used as 3D printing extrusion materials. The global 3D printing extrusion materials market is estimated to be valued at US$ 3 Bn in 2023 and is expected to exhibit a CAGR of 19.% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Dynamics: Rising Application in Medical Industry (mentioned as driver in the heading) is one of the major factors driving growth of the 3D printing extrusion materials market. 3D printing offers several advantages for medical applications including ability to produce customized implants and prosthetics, manufacturing of anatomical models for pre-surgery practice and tissue engineering. This has increased the demand for high-performance materials that can seamlessly integrate into biological systems. Moreover, biocompatible and bioabsorbable materials are being developed specifically for medical 3D printing applications. The growing adoption of 3D printing extrusion materials across various industries such as automotive, aerospace, consumer goods and electronics is also fueling market growth. Lightweight and high strength materials are enabling complex designs that were previously impossible to manufacture using traditional methods. This has increased the applications of 3D printing in prototyping as well as production of end-use parts. SWOT Analysis Strength: 3D printing extrusion materials have strong mechanical properties that enable the creation of complex geometries. Their thermoplastic nature allows for high strength and durability in final parts. Molten extrusion materials can precisely bond layer upon layer, resulting in smooth surfaces without supports. Weakness: Extrusion-based 3D printing has limitations regarding material choices and is best suited for functional prototypes rather than highly refined parts. Additional processing may be required to achieve visual aesthetics on par with injection molded plastics. Opportunity: Advancements in material chemistry are expanding the range of properties achievable with extrusion feedstock. High-performance engineering resins with unique mechanical specifications continue to enter the market. New applications are being developed across industries like aerospace and automotive that leverage 3D printing for low-volume parts. Threats: Availability of competitive additive manufacturing processes poses a threat as many can achieve better surface quality and resolution compared to fused filament fabrication. Low barriers to entry in 3D printer manufacturing have led to market saturation and price declines. Key Takeaways The global 3D Printing Extrusion Materials Market is expected to witness high growth over the forecast period of 2023 to 2030.

Regional analysis shows that North America currently dominates usage and is expected to remain the largest market through 2030 due to extensive adoption across various application areas. Europe and Asia Pacific show strong growth potential as 3D printing technology proliferates in important verticals like automotive, industrial machinery, and consumer products manufacturing. Key players operating in the 3D Printing Extrusion Materials Market are Stratasys, 3D Systems, DSM, 3D Hubs, Arkema, Evonik AG, BASF SE, SABIC, LG Chem, Arevo Labs. The market demonstrates steady consolidation as larger firms acquire startups to expand material portfolios. Stratasys and 3D Systems have become dominant suppliers renowned for delivering reliable extrusion equipment and quality build materials to both individual makers and production environments worldwide.

#3D Printing Extrusion Materials Market Share#3D Printing Extrusion Materials Market Growth#3D Printing Extrusion Materials Market Demand#3D Printing Extrusion Materials Market Trend

0 notes

Text

0 notes

Text

3D Printing Metal Market Competitive Landscape and Leading Players

3D Printing Metal Market Growth Strategic Market Overview and Growth Projections

The global 3D printing metal market size was valued at USD 475 million in 2021. It is expected to reach USD 3.61 billion by 2030, growing at a CAGR of 25.3% during the forecast period (2022–2030).

The latest Global 3D Printing Metal Market by straits research provides an in-depth analysis of the 3D Printing Metal Market, including its future growth potential and key factors influencing its trajectory. This comprehensive report explores crucial elements driving market expansion, current challenges, competitive landscapes, and emerging opportunities. It delves into significant trends, competitive strategies, and the role of key industry players shaping the global 3D Printing Metal Market. Additionally, it provides insight into the regulatory environment, market dynamics, and regional performance, offering a holistic view of the global market’s landscape through 2032.

Competitive Landscape

Some of the prominent key players operating in the 3D Printing Metal Market are

3D Systems

Autodesk Inc.

Stratasys Ltd

Arcam AB

The ExOne Company

Hoganas AB

Optomec Inc.

Organovo Holdings Inc.

Ponoko Limited

Voxeljet AG.

Get Free Request Sample Report @ https://straitsresearch.com/report/3d-printing-metal-market/request-sample

The 3D Printing Metal Market Research report delivers comprehensive annual revenue forecasts alongside detailed analysis of sales growth within the market. These projections, developed by seasoned analysts, are grounded in a deep exploration of the latest industry trends. The forecasts offer valuable insights for investors, highlighting key growth opportunities and industry potential. Additionally, the report provides a concise dashboard overview of leading organizations, showcasing their effective marketing strategies, market share, and the most recent advancements in both historical and current market landscapes.Global 3D Printing Metal Market: Segmentation

The 3D Printing Metal Market segmentation divides the market into multiple sub-segments based on product type, application, and geographical region. This segmentation approach enables more precise regional and country-level forecasts, providing deeper insights into market dynamics and potential growth opportunities within each segment.

By Type

Steel

Titanium

Aluminum

Nickel

Others

By technology

Directed Energy Deposition

Binder Jetting

Powder Bed Fusion

Metal Extrusion

Others (Digital Light Projector, Multi-jet Fusion, and Material Jetting)

By Form

Powder

Filament

By End Use

Consumer Products

Aerospace & Defense

Automotive & Transportation

Healthcare

Others

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/3d-printing-metal-market

Market Highlights:

A company's revenue and the applications market are used by market analysts, data analysts, and others in connected industries to assess product values and regional markets.

But not limited to: reports from corporations, international Organization, and governments; market surveys; relevant industry news.

Examining historical market patterns, making predictions for the year 2022, as well as looking forward to 2032, using CAGRs (compound annual growth rates)

Historical and anticipated data on demand, application, pricing, and market share by country are all included in the study, which focuses on major markets such the United States, Europe, and China.

Apart from that, it sheds light on the primary market forces at work as well as the obstacles, opportunities, and threats that suppliers face. In addition, the worldwide market's leading players are profiled, together with their respective market shares.

Goals of the Study

What is the overall size and scope of the 3D Printing Metal Market market?

What are the key trends currently influencing the market landscape?

Who are the primary competitors operating within the 3D Printing Metal Market market?

What are the potential growth opportunities for companies in this market?

What are the major challenges or obstacles the market is currently facing?

What demographic segments are primarily targeted in the 3D Printing Metal Market market?

What are the prevailing consumer preferences and behaviors within this market?

What are the key market segments, and how do they contribute to the overall market share?

What are the future growth projections for the 3D Printing Metal Market market over the next several years?

How do regulatory and legal frameworks influence the market?

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

0 notes

Text

Medical Polymer Market worth $60.5 billion by 2029

The report "Medical Polymer Market by type (Medical plastics, Medical elastomers), Application (Medical Disposables, Medical Instruments And Devices, Prosthetics, Diagnostics Instruments And Tools), Manufacturing Technology, and Region - Global Forecast to 2029", is expected to grow at a CAGR of 8.0% during the forecast period, from an estimated USD 41.1 billion in 2024 to USD 60.5 billion by 2029. The growth of the medical polymer market is fueled by several key factors. Technological advancements, especially in areas like 3D printing and nanotechnology, have expanded the possibilities for medical polymer applications. Increasing awareness about infection control and patient safety has led to the development of antimicrobial and biocompatible polymers. Moreover, the trend towards personalized medicine and minimally invasive procedures drives the demand for specialized polymers that offer precise properties. Additionally, environmental concerns are pushing the industry towards bio-based and sustainable polymers, further driving market growth.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=211635984

Medical Plastics, by type, is expected to be the most significant medical polymer market segment during the forecast period.

Medical plastics are poised to maintain the most significant market share in the medical polymer market due to their unparalleled versatility and suitability for a wide range of medical applications. The demand for medical plastics is driven by their exceptional properties such as biocompatibility, durability, and ease of sterilization, which are crucial for medical device manufacturing. Additionally, the ongoing advancements in polymer engineering continue to enhance the performance and functionality of medical plastics, making them indispensable in modern healthcare settings. Moreover, the shift towards disposable medical products and the rising demand for minimally invasive procedures further propel the adoption of medical plastics, solidifying their position as the dominant type in the medical polymer market.

Medical Instruments & devices is anticipated to be the most significant medical polymer market segment, by application, during the forecast period.

The medical instruments and devices application segment is poised to capture the most significant market share in the medical polymer market due to several compelling factors. Firstly, the increasing demand for advanced medical technologies and the growing prevalence of chronic diseases are driving the need for innovative medical devices and instruments. These devices require materials with specific properties like biocompatibility, stabilizability, and chemical resistance, all of which medical polymers can provide. Additionally, the trend towards minimally invasive procedures is driving the development of lightweight and durable medical devices, further boosting the demand for medical polymers in this segment. Furthermore, ongoing technological advancements in medical polymer formulations and manufacturing processes are enhancing the performance and reliability of medical instruments and devices, reinforcing their dominance in the market.

Extrusion tubing is anticipated to be the most significant medical polymer market segment, by manufacturing technology, during the forecast period.

Extrusion tubing manufacturing technology is poised to maintain the most significant market share in the manufacturing technology segment of the medical polymer market due to its efficiency, versatility, and cost-effectiveness. This technology enables the production of precise and uniform medical tubing with a wide range of properties such as flexibility, transparency, and biocompatibility, meeting the diverse needs of medical applications. The customizable nature of extrusion processes allows for tailored tubing dimensions, wall thickness, and material compositions, ensuring compatibility with various medical devices and procedures. Additionally, the scalability and mass production capabilities of extrusion technology make it highly favorable for manufacturers seeking efficient solutions for medical polymer components. These factors collectively contribute to the dominance of extrusion tubing manufacturing technology in the medical polymer market's manufacturing technology segment.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=211635984

Asia Pacific is expected to be the fastest-growing region in the global medical polymer market, by region, during the forecast period.

The Asia Pacific region is experiencing rapid growth in the global medical polymer market due to several key factors. Firstly, the region's burgeoning population and rising middle-class income levels are driving increased healthcare spending, leading to higher demand for medical devices and equipment that rely on medical polymers. Additionally, the region benefits from a robust manufacturing infrastructure and a skilled workforce, allowing for cost-effective production of medical polymers and related products. Moreover, favorable government policies, investments in healthcare infrastructure, and technological advancements are further propelling market growth in the Asia Pacific. The region's dynamic economies, coupled with a growing focus on healthcare modernization and innovation, position it as the fastest-growing region in the global medical polymer market.

To enable an in-depth understanding of the competitive landscape, the report includes the profiles of some of the top players in the medical polymer market. These are BASF SE (Germany), SABIC (Saudi Arabia), Covestro AG (Germany), Celanese Corporation (US), and Evonik Industries (Germany).

#MedicalPolymers#HealthcareMaterials#BiocompatiblePolymers#MedicalGradePolymers#MedicalDeviceMaterials#BiomedicalPolymers#PolymerInnovation#HealthcareIndustry#MedicalTechnology#HealthcareInnovation#MedTech#AdvancedMaterials#PolymerScience#MedicalPlastics#SustainableMaterials

0 notes

Text

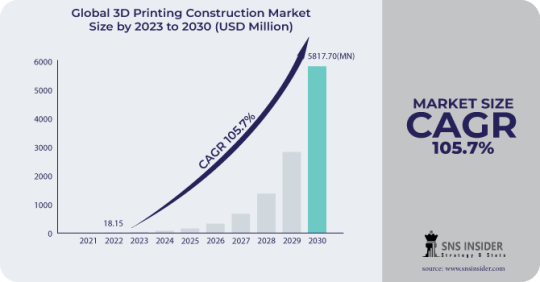

3D Printing Construction Market Analysis and Forecast 2031: Navigating Trends and Scope

3D Printing Construction market research is a valuable source of advice and information as it contains important information about global business. The research report includes a quantitative analysis of various aspects that have influenced the growth of the industry, such as country, supplier, market shape and size, and market characteristics. This study analyzes historical and forecast data to calculate the total market size based on global conditions. Tables and diagrams containing important data about the state of the industry are included in the overall business overview, along with tips and analysis for companies and consumers interested in the market.

Ask For Sample Report Here @ https://www.snsinsider.com/sample-request/1095

Primary and secondary procedures, approved research methods and services are crucial for 3D Printing Construction market research. The report covers all key market drivers and prospects, market constraints and their main competitors, company profile and general strategies to gain presence in the local and global level. This study looks at several countries to provide a qualitative and quantitative assessment of the world economy over the forecast period.

Segmentation View

By Construction Method

Extrusion

Powder Bonding

Others

By Material Type

Concrete

Metal

Composite

Others

By End-User

Building

Infrastructure

By Company

Apis Cor

COBOD International A/S, CyBe Construction

D-shape, Heidelberg Cement AG (Italcementi SpA)

LafargeHolcim

Sika AG

Skanska

Yingchuang Building Technique (Shanghai) Co., Ltd. (Winsun)

XtreeE

This Testing as a Service (TaaS) market research includes a detailed survey of vendors in the global market, along with an accurate analysis of the vendor market to determine the size of the market. The survey provides an overview of the market segments of the target sector and the many growth prospects that the sector faces. Buyers looking to increase their market share in recent and future business situations can benefit significantly from 3D Printing Construction market research.

Regional Developments

This study looks at current trends in these areas and the different options available to service providers worldwide. In a highly competitive environment, a global survey of the 3D Printing Construction market identifies all the key players operating in the automotive hose market and ranks them based on company strengths and products. The regions covered in this research report include Europe, North America, South America, Asia Pacific and others.

Competitive Outlook

This study examines the importance and predictive evidence of the field and its aspects. The report also includes information on the major global industry players in the 3D Printing Constructionmarket including company profile, specifications, product image, capacity, price, cost, and revenue. Market size, major methods of business performance, and company exposure in the region are all covered by market Research. It also includes expert opinions, information about the business environment, and marketing plans.

Buy This Report Here @ https://www.snsinsider.com/checkout/1095

This 3D Printing Construction market research evaluates the results of internal expert interviews, detailed secondary research, and primary interviews. Each service provider is evaluated using financial analysis, fundamental data, region participation, sales performance, and segment contribution. Upstream industry differences, market segments, business environments, demand developments, and cost and pricing structures are all included in the global study.

0 notes

Text

Plastics Market Trends, Share, industry Growth 2024-2032

IMARC Group, a leading market research company, has recently releases report titled “Plastics Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032” offers a comprehensive analysis of the industry, which comprises insights on the global plastics market trends. The global market size US$ 634.8 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 829.7 Billion by 2032, exhibiting a growth rate (CAGR) of 2.93% during 2024-2032.

Request For Sample Copy of Report: https://www.imarcgroup.com/plastics-market/requestsample

Factors Affecting the Growth of the Plastics Industry:

Increasing Demand in the Packaging Industry:

The expansion of the packaging industry represents one of the primary factors propelling the market growth. Additionally, the rising reliance of individuals on online shopping channels is driving the demand for convenient and efficient packaging solutions. Plastics offer a versatile and cost-effective means of packaging, providing durability and flexibility for various applications. Moreover, advancements in plastic technologies, such as barrier coatings and modified atmospheres, enhance the protective qualities of plastic packaging, making it an indispensable choice for many industries.

Rapid Urbanization and Changing Lifestyles:

Rapid urbanization and evolving lifestyles of individuals are contributing substantially to the growth of the market. The increasing rate of urbanization is driving the need for products that align with the fast-paced urban lifestyle, where convenience and efficiency are paramount. Plastics, being lightweight, durable, and easily moldable, are widely used the manufacturing of numerous consumer goods, ranging from electronics to automotive components. The rising demand for plastic-based products beyond necessities to encompass a wide array of lifestyle products, including fashion accessories, home goods, and recreational items is favoring the market growth. This shift in consumer preferences, coupled with the adaptability of plastics in design and functionality, propelling the market growth.

Technological Innovations and Material Advancements:

Continuous innovations in plastic materials and manufacturing processes are strengthening the growth of the market. Researchers and industry leaders are investing in developing sustainable and eco-friendly alternatives to traditional plastics, addressing concerns related to environmental impact. Additionally, the increasing use of biodegradable plastics, recycled materials, and bio-based polymers to meet stringent environmental regulations and consumer demands for greener alternatives is offering a favorable market outlook. Furthermore, technological advancements, such as three-dimensional (3D) printing and nanotechnology, are opening new frontiers in plastic applications, enabling the production of complex and customized products across various sectors. These innovations enhance the performance characteristics of plastics and attract a wider consumer base.

Leading Companies Operating in the Global Plastics Industry:

Arkema S.A

BASF SE

Celanese Corporation

Chevron Phillips Chemical Co. LLC

Chimei Corporation

Covestro AG

Dow Inc.

Eastman Chemical Company

Evonik Industries AG

Exxon Mobil Corporation

Sumitomo Chemical Co. Ltd.

Toray Industries Inc.

Plastics Market Report Segmentation:

By Type:

Polyethylene

Polypropylene

Polyvinyl Chloride

Others

Polyethylene represents the largest market segment as it offers customization and can be easily molded, extruded, and fabricated into various shapes and sizes.

By Application:

Injection Molding

Blow Molding

Roto Molding

Compression Molding

Casting

Thermoforming

Extrusion

Calendering

Others

Injection molding holds the largest market share as it allows high-volume production with a short cycle time.

By End User:

Packaging

Automotive

Infrastructure and Construction

Consumer Goods

Others

Packaging accounts for the majority of the market share as plastic packaging can resist breaking and shattering and ensure safe transportation of products.

Regional Insights:

North America (United States, Canada)

Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

Asia Pacific's dominance in the plastics market is attributed to the expansion of several industries in the region.

Global Plastics Market Trends:

The increasing emphasis on sustainable and circular economy initiatives is creating a positive outlook for the market. Along with this, manufacturers are investing in research and innovation to create biodegradable plastics, recycled materials, and bio-based polymers. These alternatives help reduce the environmental impact of traditional plastics by promoting recyclability, minimizing waste, and lowering carbon footprints. Furthermore, governing authorities and regulatory bodies worldwide are also implementing policies to encourage the adoption of sustainable practices within the plastic industry.

Other Key Points Covered in the Report:

COVID-19 Impact

Porters Five Forces Analysis

Value Chain Analysis

Strategic Recommendations

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact US

IMARC Group 134 N 4th St. Brooklyn, NY 11249, USA Email: [email protected] Tel No:(D) +91 120 433 0800 United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

0 notes

Text

The global defense 3D printing market is split into segments based on processes: material extrusion, powder bed fusion, vat photopolymerization, binder jetting, direct energy deposition, material jetting, and sheet lamination. The need for printing extremely complex, small-to-medium-sized, efficient parts of defense equipment is predicted to drive the quickest growth rate of any method in the market for direct energy deposition. The most market share was also held by the powder bed fusion segment. The benefits of powder metal 3D printing include a variety of material selections and suitability for prototyping.

0 notes

Text

0 notes

Text

3D Printed Metal Market Analysis and Forecast For Next 5 Years

Latest Study on Industrial Growth of Global 3D Printed Metal Market 2023-2028. A detailed study accumulated to offer Latest insights about acute features of the 3D Printed Metal market. The report contains different market predictions related to market size, revenue, production, CAGR, Consumption, gross margin, price, and other substantial factors. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the future trends and developments of the market. It also examines the role of the leading market players involved in the industry including their corporate overview, financial summary and SWOT analysis.

The Major Players Covered in this Report: 3D Systems Corporation (United States), General Electric Company (United States), Stratasys Ltd. (United States), Renishaw plc (United Kingdom), Sandvik AB (Sweden), Carpenter Technology Corporation (United States), Materialise NV (Belgium), Voxeljet AG (Germany), EOS GmbH Electro Optical Systems (Germany).

3D Printed Metal Market Study guarantees you to remain / stay advised higher than your competition. With Structured tables and figures examining the 3D Printed Metal, the research document provides you a leading product, submarkets, revenue size and forecast to 2028. Comparatively is also classifies emerging as well as leaders in the industry. Click To get SAMPLE PDF (Including Full TOC, Table & Figures) @ https://www.advancemarketanalytics.com/sample-report/128033-global-3d-printed-metal-market 3D Printed Metal Market Overview: 3D printing is the process of creating a 3-dimensional object by adding successive layers of a particular material one on top of each other until the overall object has been formed. 3D printing metal is also referred to as metal additive manufacturing. The common metals used in 3D printing include titanium, nickel, stainless steel, aluminum, among others.

Challenges:

A Large Amount of Energy is Required During the Process and It is Labor-Intensive

Specific Material Requirements

Longer Built Times

Opportunities:

Increasing Demand for 3D Printing in Emerging Countries

Emerging Applications of 3D Printing Metals

Market Growth Drivers:

Growing Demand From the Aerospace & Defense and Automotive Industries

Huge Investments in Research & Development (R&D) Activities have been Facilitating Manufacturing of Components

Mass Customization of Products With Complex Design and Structure

This study also covers company profiling, specifications and product picture, sales, market share and contact information of various regional, international and local vendors of Global 3D Printed Metal Market. The market opposition is frequently developing greater with the rise in scientific innovation and M&A activities in the industry. Additionally, many local and regional vendors are offering specific application products for varied end-users. The new merchant applicants in the market are finding it hard to compete with the international vendors based on reliability, quality and modernism in technology.

Read Detailed Index of full Research Study at @ https://www.advancemarketanalytics.com/reports/128033-global-3d-printed-metal-market

The titled segments and sub-section of the market are illuminated below:

In-depth analysis of Global 3D Printed Metal market segments by Types: Type I, Type II

Detailed analysis of Global 3D Printed Metal market segments by Applications: Application I, Application II

Additional Segments: by End User Industry (Aerospace & Defense, Automotive, Medical & Dental), Metal Type (Stainless Steel, Aluminum, Titanium, Nickel, Others (Cobalt-chrome, Copper, Silver, Gold, and Bronze)), Form (Powder, Filament), Technology (Powder Bed Fusion, Metal Extrusion, Binder Jetting, Directed Energy Deposition, Others (Digital Light Projector, Multi-jet Fusion, and Material Jetting))

Regional Analysis for Global 3D Printed Metal Market: • APAC (Japan, China, South Korea, Australia, India, and Rest of APAC; Rest of APAC is further segmented into Malaysia, Singapore, Indonesia, Thailand, New Zealand, Vietnam, and Sri Lanka) • Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe; Rest of Europe is further segmented into Belgium, Denmark, Austria, Norway, Sweden, The Netherlands, Poland, Czech Republic, Slovakia, Hungary, and Romania) • North America (U.S., Canada, and Mexico) • South America (Brazil, Chile, Argentina, Rest of South America) • MEA (Saudi Arabia, UAE, South Africa)

Furthermore, the years considered for the study are as follows: Historical year – 2018-2022 Base year – 2023 Forecast period** – 2023 to 2028 [** unless otherwise stated]

**Moreover, it will also include the opportunities available in micro markets for stakeholders to invest, detailed analysis of competitive landscape and product services of key players.

Buy Latest Study of Global 3D Printed Metal Market @ https://www.advancemarketanalytics.com/buy-now?format=1&report=128033

Guidance of the Global 3D Printed Metal market report:

– Detailed considerate of 3D Printed Metal market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets. – Comprehensive valuation of all prospects and threat in the Global 3D Printed Metal market. – In depth study of industry strategies for growth of the 3D Printed Metal market-leading players. – 3D Printed Metal market latest innovations and major procedures. – Favourable dip inside Vigorous high-tech and market latest trends remarkable the Market. – Conclusive study about the growth conspiracy of 3D Printed Metal market for forthcoming years.

What to Expect from this Report On 3D Printed Metal Market:

1. A comprehensive summary of several area distributions and the summary types of popular products in the 3D Printed Metal Market. 2. You can fix up the growing databases for your industry when you have info on the cost of the production, cost of the products, and cost of the production for the next future years. 3. Thorough Evaluation the break-in for new companies who want to enter the 3D Printed Metal Market. 4. Exactly how do the most important companies and mid-level companies make income within the Market? 5. Complete research on the overall development within the 3D Printed Metal Market that helps you elect the product launch and overhaul growths.

Enquire for customization in Report @ https://www.advancemarketanalytics.com/enquiry-before-buy/128033-global-3d-printed-metal-market

Detailed TOC of 3D Printed Metal Market Research Report-

– 3D Printed Metal Introduction and Market Overview – 3D Printed Metal Industry Chain Analysis – 3D Printed Metal Market, by by End User Industry (Aerospace & Defense, Automotive, Medical & Dental), Metal Type (Stainless Steel, Aluminum, Titanium, Nickel, Others (Cobalt-chrome, Copper, Silver, Gold, and Bronze)), Form (Powder, Filament), Technology (Powder Bed Fusion, Metal Extrusion, Binder Jetting, Directed Energy Deposition, Others (Digital Light Projector, Multi-jet Fusion, and Material Jetting))

– Industry Manufacture, Consumption, Export, Import by Regions (2014-2019) – Industry Value ($) by Region (2014-2019)

– 3D Printed Metal Market Status and SWOT Analysis by Regions

– Major Region of 3D Printed Metal Market i) Global 3D Printed Metal Sales ii) Global 3D Printed Metal Revenue & market share – Major Companies List – Conclusion Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Asia. Contact US : Craig Francis (PR & Marketing Manager) AMA Research & Media LLP Unit No. 429, Parsonage Road Edison, NJ New Jersey USA – 08837 Phone: +1 201 565 3262, +44 161 818 8166 [email protected]

#Global 3D Printed Metal Market#3D Printed Metal Market Demand#3D Printed Metal Market Trends#3D Printed Metal Market Analysis#3D Printed Metal Market Growth#3D Printed Metal Market Share#3D Printed Metal Market Forecast#3D Printed Metal Market Challenges

1 note

·

View note

Text

Market Resilience: Adapting to Global Changes in 3D Printing Extrusion Materials

The 3D printing extrusion materials market is estimated to be valued at US$ 12.77 Bn in 2023 and is expected to exhibit a CAGR of 19.% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview: 3D printing extrusion materials are polymers that are used as filaments or pellets to produce parts and prototypes through extrusion-based 3D printing processes. Some common extrusion materials used are acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), high impact polystyrene (HIPS), polyethylene terephthalate glycol-modified (PETG), and many others. These materials find applications in various industries including aerospace, automotive, consumer products and industrial goods for producing functional prototypes and end-use parts.

Market Dynamics: The 3D printing extrusion materials market is driven by rising demand from automobiles industry for prototyping components. Several automakers are adopting 3D printing technology for manufacturing vehicle parts owing to its ability to produce complex designs that are lightweight and durable. ABS and PLA are widely used 3D printing materials for automotive applications. Another driver is the growing applications of 3D printing in healthcare industry. Materials such as PLA, polyvinyl alcohol (PVA) and polyethylene glycol (PEG) are used to produce medical implants, surgical guides and prototypes of human organs through 3D printing. This is positively impacting the demand for specialty healthcare extrusion materials. However, high capital investment requirement for 3D printing equipment and technology is a major challenge for widespread adoption.

SWOT Analysis

Strength: The 3D Printing Extrusion Materials Market provides enhanced product customization which helps in producing lightweight and complex design parts. It reduces manufacturing expenses by eliminating tooling costs and lowering waste. It offers greater design flexibility to produce prototypes and finished goods with fewer design limitations.

Weakness: High initial investment required for printers and material development limit the adoption of 3D printing technology. Lack of standardized processes and performance issues related to mechanical properties restrict the use of 3D printing.

Opportunity: Growing demand from healthcare and aerospace industries for producing customized medical implants and aircraft components offer significant opportunities. Increasing research on developing sustainable biodegradable materials will expand the application scope.

Threats: Availability of substitute technologies like CNC milling and injection molding poses threat to 3D printing adoption. Stringent regulations over material formulations and recyclability cause compliance challenges.

Key Takeaways:

The global 3D Printing Extrusion Materials Market is expected to witness high growth, exhibiting CAGR of 19.% over the forecast period, due to increasing demand from end-use industries like automotive, aerospace, and healthcare. Advances in material science for developing high-performance plastics and composites tailored for specific 3D printing processes fuel the market growth.

Regional analysis North America dominates the global market, owing to presence of major manufacturers, availability of advanced 3D printing technologies and government funding for additive manufacturing based R&D activities in the region. Asia Pacific exhibits the fastest growth in the coming years on account of rising industrial automation, low production cost and increasing foreign investments in the region.

Key players operating in the 3D Printing Extrusion Materials Market are 3D Systems Corporation, Stratasys Ltd., Materialise NV, EOS GmbH, Arkema S.A., SABIC, Evonik Industries AG, DuPont de Nemours Inc., BASF SE, Dow Chemical Company, HP Inc., Royal DSM N.V., EnvisionTEC GmbH, CRP Group., Carbon, Inc. The players focus on new product launches, expansions, partnerships and mergers & acquisitions to gain competitive edge in the market.

#3D Printing Extrusion Materials Market Share#3D Printing Extrusion Materials Market Growth#3D Printing Extrusion Materials Market Demand#3D Printing Extrusion Materials Market Trend

0 notes

Text

Metal Additive Manufacturing In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

Metal Additive Manufacturing Market Research, 2031

The global metal additive manufacturing market size was valued at $2.6 billion in 2021, and is projected to reach $14.1 billion by 2031, growing at a CAGR of 18.1% from 2022 to 2031. Metal additive manufacturing, commonly known as 3D metal printing, is a specialized process for manufacturing metal components by using metal powder, wire, or metal sheet. Machineries use a laser or an electron beam to heat metal in powder or wire form to consolidates it into the form of an object.

Metal additive manufacturing offers various advantageous features over the traditional methods of component or object manufacturing. However, metal additive manufacturing does not replace the traditional methods of manufacturing which is highly effective in mass manufacturing. The metal additive manufacturing is highly suitable for manufacturing customized products, products with fine details, complex products, and most importantly, it can manufacture working metal prototypes. In addition, its various advantages, such as less waste generation, fast-paced production, and recreation of legacy parts, are expected to positively influence the metal additive manufacturing market growth.

The metal additive manufacturing market is segmented into Type, Component and End User Industry. By type, the market is categorized into powder bed fusion, binder jetting, direct energy deposition, bound powder extrusion, and others. On the basis of components, it is categorized into systems, materials, and service & parts. And on the basis of end-user industry, the market is categorized into aerospace, automotive, healthcare, and others. Region-wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. North America held the largest metal additive manufacturing market share in 2021, accounting for the highest share in revenue, and Asia-Pacific is anticipated to grow at the highest CAGR during the forecast period. This is attributed to increased investments in industrial sectors such as automotives, electronics, and healthcare.

Competition Analysis

Key companies profiled in the metal additive manufacturing market forecast report include BeAM Machines, DMG Mori Seiki Co., Ltd., EOS GmbH, Farsoon Technologies, GE Additive, Renishaw Plc, Sisma SpA, SLM Solutions, Trumpf, and Xi‘an Bright Laser Technologies Co., Ltd.

Full Report With TOC:-https://www.alliedmarketresearch.com/metal-additive-manufacturing-market-A25776

0 notes

Text

Polyether ether ketone (PEEK) Market to 2035 | Regional Analysis and Forecast | ChemAnalyst

According to ChemAnalyst report, “Global Polyether ether ketone (PEEK) Market Analysis: Plant Capacity, Production, Technology, Operating Efficiency, Demand & Supply, End-Use, Foreign Trade, Sales Channel, Regional Demand, Company Share, 2015-2035”, The Polyether ether ketone (PEEK) market has grown remarkably in the historic period of 2015-21 and is estimated to further grow at a steady CAGR of 3.67% in the forecast period.

PEEK is a high-performance engineering thermoplastic and a polyaromatic semi-crystalline that belongs to polyaryletherketone family. PEEK polymer is derived from step-growth polymerization by the dialkylation of bisphenolate salts. It can be integrated by using nucleophilic substitution of 4,4’-difluorobenzophenone or 1,4-bis(4-fluorobenzoyl) benzene with hydroquinone in the presence of alkali carbonate under microwave irradiation to obtain high yield. Injection moulding, extrusion and compression monofilament are most of the conventional method that are used for processing PEEK but now this polymer is being processed by using advance 3D printing technology that extends possible applications such as from patient-specific hearing aids to surgical aids or instruments.

In comparison to other polymers, PEEK exhibits outstanding properties for instance it is resistant to chemicals and high temperature, chemically inert and insoluble in all solvents, lightweight, creep-resistant, biocompatible, bioresorbable, etc. Since, PEEK molecule is very stable in nature, therefore it can be reprocessed and re-melted again and again without losing its properties. This reduces the environmental impact and ensures that waste material from manufacturing processes can be re-used economically. PEEK polymers are well suited for harsh and demanding environments. This light thermoplastic polymer can support numerous requirements at once to address material limitations in applications, frequently replacing metals, as well as to meet cost-efficiency and sustainability needs.

Read Full Report Here: https://www.chemanalyst.com/industry-report/polyether-ether-ketone-peek-market-678

The Polyether ether ketone (PEEK) market is segmented based on end-use, sales channel, and region. Based on the end-user industry, the Polyether ether ketone (PEEK) market is segmented into Aerospace, Automotive, Medical Implants, Electronics and Electricals, and Others. Among these, the Aerospace Industry is the leading segment and held approximately 42% of the market in 2022 and is anticipated to dominate the market even in the forecast period. PEEK is also heavily employed in the medical sector. Almost everywhere in the body, PEEK provides optimum flexibility of movement for patients over an extended period. Evonik and Samplast recently launched VESTAPEEK Fusion, an osteoconductive PEEK biomaterial, achieved by using a functional additive called biphasic calcium phosphate that allows attachment of bone cells to implants more efficiently, thus, accelerating bone fusion and convalescence. Companies like Victrex and Solvay are leading companies for manufacturing PEEK biomaterials in medical grade that are well suited for medical devices application such as dental abutments, blood management, surgical instruments, spinal fusion, trauma facture fixation, etc. With this increased use of non-implantable and implantable devices, the PEEK demand is anticipated to further increase in the forecast period.

Based on demand, Europe is dominating the Polyether ether ketone (PEEK) market among all other regions. The region held a market share of around 45% of the world's Polyether ether ketone (PEEK) market in the year 2022. In Europe, the key market drivers being the application of PEEK in the aerospace, automotive and medical sectors in major countries such as Belgium and Germany. Meanwhile, APAC is the second largest consumer of PEEK but leads in terms of producing PEEK, with China being the biggest shareholder.

Request Sample Report: Polyether ether ketone (PEEK) Market Analysis Report

“Global Polyether ether ketone (PEEK) Market Analysis: Plant Capacity, Production, Technology, Operating Efficiency, Demand & Supply, End-Use, Foreign Trade, Sales Channel, Regional Demand, Company Share, 2015-2035”, the significant players in the Polyether ether ketone (PEEK) market are Victrex plc., Jida Evonik High Performance Polymers, Panjin Zhongrun High Performance Polymers Co. Ltd., Jilin Joinature Polymer Co., Ltd., Daicel-Evonik Ltd., Oxford Polymers, Victrex JV, and Others.

“Consistently growing demand for Polyether ether ketone (PEEK) in the demanding end-user industries such as Aerospace, Automotive, Electrical and Electronics, and medical industries is anticipated to fuel the Polyether ether ketone (PEEK) market in the forecast period till 2035. Due to the properties of PEEK such as biocompatibility, bioresorbable, light weight, high-heat resistivity and other exceptional properties, a rise in its demand is projected to drive its market growth over the forecast period. “Said Mr. Karan Chechi, Research Director with TechSci Research, a research-based management consulting firm promoting ChemAnalyst worldwide.

About Us:

ChemAnalyst is a subsidiary of Techsci Research, which was established in 2008, and has been providing exceptional management consulting to its clients across the globe for over a decade now. For the past four years, ChemAnalyst has been a prominent provider of Chemical commodity prices in more than 15 countries. We are a team of more than 100 Chemical Analysts who are committed to provide in-depth market insights and real-time price movement for 300+ chemical and petrochemical products. ChemAnalyst has reverberated as a preferred pricing supplier among Procurement managers and Strategy professionals worldwide. On our platform, we provide an algorithm-based subscription where users can track and compare years of historical data and prices based on grades and incoterms (CIF, CFR, FOB, & EX-Works) in just one go.

The ChemAnalyst team also assists clients with Market Analysis for over 1200 chemicals including assessing demand & supply gaps, locating verified suppliers, choosing whether to trade or manufacture, developing Procurement Strategies, monitoring imports and exports of Chemicals, and much more. The users will not only be able to analyze historical data for past years but will also get to inspect detailed forecasts for the upcoming years. With access to local field teams, the company provides high-quality, reliable market analysis data for more than 40 countries.

ChemAnalyst is your one-stop solution for all data-related needs. We at ChemAnalyst are dedicated to accommodate all of our world-class clients with their data and insights needs via our comprehensive online platform.

Contact Us:

ChemAnalyst

B-44 Sector-57 Noida,

National Capital Region

Tel: 0120-4523990

Mob: +91-8882805349

Email: [email protected]

Website: https://www.chemanalyst.com/

0 notes

Text

3D Printing Market Size, Share & Industry Growth Analysis Report by Offering (Printer, Material, Software, Service), Process (Binder Jetting, Direct Energy Deposition, Material Extrusion, Material Jetting, Powder Bed Fusion), Application, Vertical, Technology and Region - Global Growth Driver and Industry Forecast to 2028

1 note

·

View note

Text

3D Food Printing Market Projected to Garner Significant Revenues by 2027

According to a research report "3D Food Printing Market by Vertical (Government, Commercial, and Residential), Technique (Extrusion based printing, Selective laser sintering, Binder jetting and Inkjet printing), Ingredient and Geography - Global Forecast to 2027" published by MarketsandMarkets, the 3D food printing market is estimated to account for nearly USD 201 million in 2022 and is projected to reach a value of nearly USD 1,941 million by 2027, growing at a CAGR of 57.3% from 2022. Large-scale manufacturing of food in commercial kitchens has exacerbated the problem of food waste. 3D food printing is a distinguished approach to reducing waste throughout consumption by utilizing food products such as meat off-cuts, leftover fruits and vegetables, and seafood by-products. Thus, with increasing awareness among consumers about food wastage and environmental issues, more consumers and food suppliers are anticipated to adopt 3D food printers. This is projected to drive the 3D food printing market.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=267692011

By ingredient type, the carbohydrate segment is estimated to account for the largest share in the 3D food printing market in 2022.

On the basis of ingredient type, the carbohydrate segment is estimated to dominate the 3D food printing market in 2022. Carbohydrate is the most widely used ingredient type used in 3D food printing because of the gelatinization property of carbohydrates. Increasing demand of carbohydrate-based food such as bakery products, confectionaries, driving the demand of carbohydrate type.

By vertical, commercial segment is projected to be the fastest-growing segment during the forecast period in the 3D food printing market.

During the forecast period, the commercial segment is projected to grow at the highest CAGR in the bakery processing equipment market, in terms of value. Most of the companies working toward the development of the 3D food printers are focusing on the commercial vertical. 3D food printers are more popularly used as chocolate, candy, and bread printing machines as the ingredients required to make these products are easily available. However, the companies such as Nestlé (Switzerland), Barilla (Italy), and Modern Meadow are also working to develop ingredients for other foods, including meat.

Extrusion based printing sub-segment is estimated to account for the largest market share and the fastest growth in the global 3D food printing market.

Extrusion technology pushes materials into holes at high temperatures and pressures, one layer at a time, and stacks them. Naturally soft materials include puree, jelly, frosting, cheese, and mashed potatoes. Extrusion-based 3Dfood printing is one of the most extensively used and adopted processes among the available options. It is the most affordable 3D printing technology, and because of its low cost, it is also the most popular among small enterprises and households. Thus, their usage is rising rapidly in the 3D food printing sector.

Make an Inquiry @ https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=267692011

The North American market is estimated to dominate the 3D food printing market in 2022

The North America is estimated to account for the largest market share in the 3D food printing market in 2022. The presence and growth of the companies offering the 3D food printing technology in this region are boosting the market in this region. This region is projected to be the largest market during the forecast period.

The US is known as one of the early adopters of the new technologies in the world. The busy and fast-moving life of common people makes it hard for them to get the proper nutritious diet. The 3D food printing technology could provide an option to have customized nutritious food. Also, the US government spends the highest amount of budget on healthcare, and the benefits of 3D food printers to provide food rich in specific nutrients and with the ease of chewing and swallowing would provide a suitable option for feeding the aged patients.

This report includes a study of marketing and development strategies, along with the product portfolios of the leading companies in the 3D food printing market. It includes the profiles of leading companies such as 3D systems (US), TNO (Netherlands), NATURAL MACHINES (Spain), Choc edge (UK), Systems & Materials Research Corporation (US), byFlow B.V. (Netherlands), beehex (US), CandyFab (US), ZMORPH S.A (Poland) and Wiiboox (China).

0 notes