#2-Xylene Market

Explore tagged Tumblr posts

Text

Nitro-o-Xylene Prices: Market Trends, Cost Factors, and Industry Insights

ニトロキシレン(Nitro-o-Xylene) は、染料、農薬、製薬業界で使用される重要な化学中間体です。ニトロキシレン価格の変動はこれらの業界に大きな影響を与えるため、市場動向とコスト要因を追跡することが不可欠です。この記事では、価格動向、需給動向、調達戦略について詳細に分析します。

ニトロキシレンとは何ですか?

ニトロ-o-キシレンは、主に特殊化学品、顔料、樹脂の製造に使用される有機化合物です。その高い反応性と機能特性により、さまざまな産業用途で重要な役割を果たしています。

ニトロキシレン価格に影響を与える主な要因

ニトロキシレンの価格には、原材料費、生産プロセス、サプライチェーンの安定性、世界的な需要など、いくつかの要因が影響します。

1. 原材料費

主原料であるベンゼン、トルエンの価格変動。

原油価格変動が原料の入手可能性に与える影響。

原材料の抽出と加工に影響を及ぼす環境規制。

2. 生産および製造費用

エネルギーを大量に消費する合成プロセスにより、運用コストが増加します。

触媒技術の進歩によりコスト削減につながります。

労働費と規制遵守費が全体の生産コストに加算されます。

3. サプライチェーンと市場の需要

農薬や医薬品での使用が増え、需要が高まっています。

貿易制限と地政学的緊張がサプライチェーンの安定性に影響を与えています。

代替化学中間体との競争が価格戦略に影響を与えています。

4. 規制と環境政策

生産方法に影響を与える厳しい環境法。

ニトロキシレンの輸出入関税に影響を与える世界貿易政策。

より環境に優しい代替手段の研究を推進する持続可能性の取り組み。

ニトロキシレン価格の現在の市場動向

1. 化学・製薬業界からの需要増加

染料、樹脂、および精密化学品におけるニトロキシレンの使用増加は、着実な価格上昇の一因となっています。

2. コストに影響を与えるサプライチェーンの課題

原材料不足が生産量に影響を与えています。

輸送と物流の混乱により価格変動が発生します。

3. 地域による価格の違い

ニトロキシレンの価格は、現地の製造能力、貿易政策、需要レベルに基づいて地域ごとに異なります。

4. 新たな選択肢とイノベーション

バイオベースおよび持続可能な化学代替品の増加は、ニトロキシレンの価格動向に徐々に影響を与えています。

リアルタイムで(Nitro-o-Xylene)価格: https://www.analystjapan.com/Pricing-data/nitro-o-xylene-5531

価格比較: 地域別のニトロキシレン価格

1. 北米

価格帯: 1kgあたり9.00ドル~14.00ドル

厳しい環境規制と高級品の生産により価格が��昇しています。

2. ヨーロッパ

価格帯: 1kgあたり8.50ユーロ~13.50ユーロ

製薬業界からの需要増加に伴い価格が安定しています。

3. アジア太平洋

価格帯: 1kgあたり7.00ドル~12.00ドル

低コストの生産と高い産業需要による競争力のある価格設定。

ニトロキシレン調達コストを最適化する方法

1. 戦略的大量購入契約

サプライヤーとの長期契約を確保することで、コストを安定させ、価格変動を緩和することができます。

2. サプライヤーの多様化

複数の地域および世界規模のサプライヤーと連携することで、単一のソースへの依存が軽減され、競争力のある価格が確保されます。

3. 市場動向と原材料コストの監視

原料価格の動向と業界の動向を常に把握しておくことは、調達計画の改善に役立ちます。

4. 物流・保管ソリューションの強化

効率的なサプライ チェーン戦略を実装すると、調達費用を最適化し、間接費を削減できます。

結論

ニトロキシレンの価格は、原材料の入手可能性、生産コスト、規制政策、世界的な需要によって左右されます。市場動向を理解し、費用対効果の高い調達戦略を採用することで、企業は価格変動を管理することができます。ニトロキシレンの需要は増加し続けているため、積極的なサプライチェーン管理が、安定した価格と信頼できる供給を確保する鍵となります。

ANALYST JAPAN

Call +1 (332) 258- 6602 1-2-3 Manpukuji, Asao-ku, Kawasaki 215-0004 Japan

Website: https://www.analystjapan.com

Email: [email protected]

0 notes

Text

O-Xylene Prices Trend | Pricing | Database | Index | News | Chart

O-Xylene is a key component in the production of various products, including plastics, solvents, and paints. As a result, its price is closely monitored by industries worldwide. In this article, we will delve into the factors that influence O-Xylene prices and explore the recent market trends.

One of the primary drivers of O-Xylene prices is the supply and demand dynamics. O-Xylene is primarily produced from crude oil, and any fluctuations in the availability of crude oil can impact its price. Additionally, the demand for O-Xylene is influenced by the growth of end-use industries, such as automotive, construction, and packaging. As these industries expand, the demand for O-Xylene increases, leading to higher prices.

Another significant factor affecting O-Xylene prices is the cost of production. The production process involves several steps, including separation from other xylene isomers, purification, and refinement. The cost of raw materials, energy, and labor all contribute to the overall cost of production. Therefore, any changes in these cost factors can directly impact the final price of O-Xylene.

Furthermore, global economic conditions play a crucial role in determining O-Xylene prices. Economic growth and stability can lead to increased industrial activities, thereby driving up the demand for O-Xylene. Conversely, economic downturns can result in reduced demand, leading to a decline in prices. Factors such as trade tensions, political instability, and currency fluctuations also influence the global economy and, subsequently, O-Xylene prices.

Get Real Time Prices for O-Xylene Prices: https://www.chemanalyst.com/Pricing-data/o-xylene-28

Environmental regulations and sustainability initiatives are becoming increasingly important in the chemical industry. As governments worldwide strive to reduce emissions and promote cleaner technologies, the demand for environmentally friendly alternatives to O-Xylene may increase. This shift in demand can have an impact on O-Xylene prices, as industries may opt for more sustainable substitutes, thereby affecting market dynamics.

It is essential to note that O-Xylene is traded as a commodity in the global market. Commodity prices are subject to fluctuations due to various factors, including market speculation, geopolitical events, and weather conditions. Traders and investors closely monitor these factors to make informed decisions regarding buying or selling O-Xylene, further influencing its price.

In recent years, the O-Xylene market has experienced some notable trends. For instance, the Asia-Pacific region, particularly China, has emerged as a major consumer of O-Xylene. The rapid industrialization and urbanization in the region have fueled the demand for O-Xylene, leading to increased prices. Moreover, the Middle East has also witnessed significant growth in O-Xylene production, resulting in a competitive global market.

In conclusion, O-Xylene prices are influenced by various factors, including supply and demand dynamics, production costs, economic conditions, environmental regulations, and market speculation. Understanding these factors is crucial for industries that rely on O-Xylene as a raw material. By staying informed about market trends and factors affecting prices, businesses can make informed decisions to optimize their operations and manage their costs effectively.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#O-Xylene#O-Xylene Price#O-Xylene Prices#O-Xylene Pricing#O-Xylene News#O-Xylene Price Monitor#O-Xylene Database#O-Xylene Price Chart

0 notes

Text

XINC waterproof What are the differences in polyurethane waterproof coatings

XINC waterproof Polyurethane waterproof coating, as a new type of waterproof coating, has been widely used in the waterproof market.

XINC waterproof Polyurethane waterproof coating is a polyurethane waterproof coating made from a series of processing aids such as isocyanates, polyethers, and catalysts.

Let’s understand the advantages and construction plans of XINC waterproof polyurethane waterproof coatings.

1. Polyurethane waterproof coating can be directly applied to damp or dry base surfaces. Strong adhesion to the substrate, not easy to peel off.

2. Polyurethane waterproof coating has good flexibility and can adapt to the expansion and cracking of the base layer, with high tensile strength

3. Green, odorless, harmless to human health, suitable for waterproofing in bedrooms and other areas

4. Polyurethane waterproof coating has the advantages of good weather resistance, high temperature non flowing, low temperature non cracking, acid and alkali resistance, and chemical corrosion resistance

Construction methods

1. Firstly, clean the base to remove dust and peeling parts, especially the pipe roots and floor drains. The surface should be flat, and the depressions should be smoothed with cement mortar and brushed with primer, and polyurethane should be used

2. Mix component B and xylene in proportion and stir evenly. Use a roller brush or paint brush to evenly apply the primer on the surface of the base layer, with a brushing amount of 0.2kg/about one square meter. Avoid brushing too thick and repeatedly.

3. Firstly, make an additional detail layer and mix polyurethane A and component B in a ratio of 1:1.5 evenly. First, place weak areas that are prone to leakage such as floor drains, pipe roots, and internal and external corner vents. Apply evenly with a paint brush, followed by the first coat of paint

4. First layer coating: Apply a 1:1 ratio of A, B, and xylene (5:0) When mixing, use a mixer to stir evenly, and use a paint brush dipped in the paint to apply the coating. The coating should be applied from the inside out, and the thickness should be uniform.

When the first layer of paint solidifies until it is not sticky, mix the second layer of paint according to the method of mixing the first layer of paint. In order to ensure uniform coating thickness, the coating direction should be perpendicular to the direction of the first coating, and the brushing amount should be the same as the first coating. The same coating should avoid repeated coatings.

After the second layer of coating is cured, the coating ratio of the third layer is the same as the first two layers, but the coating amount should be 0.4~0.5kg/square meter. Adhesion of mortar topcoat.

0 notes

Text

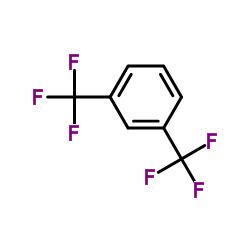

CAS NO.402-31-3 1,3-Bis(trifluoromethyl)-benzene/high quality /best price/DA 90 DAYS

Quick Details Product name:1,3-Bis(trifluoromethyl)-benzene CAS: 402-31-3 Molecular formula:C8H4F6 Molecular weight:214.11 EINECS No.:206-939-4 Appearance:Enterprise standard Other names:Xylene Hexafluoride; 1,3-TrifluoromethylBenzene; M-BIS(TRIFLUORO-METNY)BENZENE; 1,3-Di(trifluoromethyl)benzene; 1,3-DI(TRIFLUOROMETHYL)BENZENE; A,A,A,A',A',A'-HEXAFLUORO-M-XYLENE; 1-fluoro-4-(trichloromethyl)benzene; alpha,alpha,alpha,beta,beta,beta-hexafluoro-m-xylene; Port: any port in china Packing: according to the clients requirement Storage: Store in dry, dark and ventilated place. Transportation: by sea or by air payment methods: L/C, T/T, D/A, D/P, O/A, paypal, western union etc.accept all payment. Application Used as pharmaceutical and pesticide intermediates Pharmaceutical and pesticide intermediates. It is also used as an intermediate for the synthesis of phenolic dyes and fluororesins; it is used as a solvent in the photographic and watch industries. Superiority 1.supply sample 2.the packing can be according the customers` requirment 3.any inquiries will be replied within 24 hours 4.we provide commerical invoice, packing list, bill of loading, coa , health certificate and origin certificate. if your markets have any special requirements, let us know. 5.factory price. 6.prompt delivery. we have good cooperation with many professional forwarders, we can send the products to you once you confirm the order. 7.we can accept various payment methods, l/c, t/t, d/a, d/p, o/a, paypal, western union etc., and we cooperate with sinosure many years. Anyway ,if you need any chemicals from China ,MIT -IVY INDUSTRY CO.,LTD can help you. Company Information MIT-IVY INDUSTRY CO.,LTD is a manufacturer and exporter of fine chemical dyes & pharmaceutical intermediates in China. Mainly produce aniline series products ,chlorine series products,and epoxy curing agent We are a company full of vitality. The company has a group of energetic, well-trained employees and strong technical research and development capabilities. We specialize in the production, development and sales of API intermediates, fine chemicals and plant extracts. Relying on advanced equipment and strict management, adhere to the business philosophy of "openness, tolerance, innovation, and sharing" to create a win-win cooperationplatform.Everything comes from innovation, it is our philosophy ! If you are interested in getting more quotations, please add WHATSAPP:0086-13805212761 or E-MAIL:[email protected] FAQ Q1:Will you supply samples for testing? A: For most of our products, samples are available, but please cover the shipping cost. Q2:What's your MOQ? A: For the high value product, our MOQ starts from 10g,100g and 1kg. Q3:Which kind of payment terms do you accept? A: Proforma invoice enclosed with our bank information will be sent after confirmation of order. payment methods: L/C, T/T, D/A, D/P, O/A, paypal, western union etc.accept all payment. Q4:How about your delivery time? A: Generally, it will take 3 to 5 days after receiving your advance payment. Q5:How do you treat quality complaint? A:First of all, our quality control will reduce the quality problem near to zero. If there is a quality problem caused by us, we will send you free goods for replacement or refund your loss. Main products Mit-Ivy is a well-known fine chemicals and pharmaceutical intermediates manufacturer with strong R&D support in China. Mainly involved Aniline, Chlorine products. Payment:DA 60 DAYS TEL:008619961957599 E-MAIL:[email protected] 产品 Product CAS N-甲基间甲苯胺 N-Methyl-M-Methylaniline 696-44-6 N-羟乙基苯胺 N-(2-hydroxyethyl)-Aniline 122-98-5 N-乙基对甲苯胺 N-ethyl-p-toluidine 622-57-1 N,N-二甲基邻甲苯胺 N,N-Dimethyl-o-toluidine 609-72-3 N-甲基邻甲苯胺 N-Methyl-o-methylaniline 611-21-2 N,N-二乙基对甲苯胺 N,N-Diethyl-p-toluidine 613-48-9 N,N-二乙基间甲苯胺 N,N-diethyl-m-toluidine 91-67-8 N-氰乙基-N-羟乙基间甲苯胺 N-cyanoethyl-n-hydroxyethyl-m-toluidine 119-95-9 N-乙基间甲苯胺 N-ethyl-m-toluidine 102-27-2 N-氰乙基-N-羟乙基苯胺 N-cyanoethyl-n-hydroxyethyl aniline 92-64-8 N-乙基邻甲苯胺 N-ethyl-o-toluidine 94-68-8 N,N-二羟乙基对甲苯胺 N,N-dihydroxyethyl-p-toluidine .3077-12-1 N,N-二乙基苯胺 N,N-diethyl aniline 91-66-7 N-丁基-N-羟乙基苯胺 N-butyl-n-hydroxy aniline 3046-94-4 N-乙基-N-氰乙基间甲苯胺 N-ethyl-n-cyanoethyl-m-toluidine 148-69-6 N-丁基-N-氰乙基苯胺 N-butyl-n-cyano aniline 61852-40-2 N-甲基- N-羟乙基苯胺 N-methyl-n-hydroxyetjyl aniline 93-90-3 N,N-二丁基苯胺 N,N-dibutyl aniline 613-29-6 N-乙基-N-氰乙基苯胺 N-ethyl-n-cyanoethyl aniline 148-87-8 N-正丁基苯胺 N-Phenyl-N-butyl aniline 1126-78-9 N-乙基-N-羟乙基苯胺 N-ethyl-n-hydroxyethyl aniline 92-50-2 N-乙基-N-苄基间甲苯胺 N-ethyl-n-benzyl-m-toluidine 119-94-8 N-甲基-N-苄基苯胺 N-methyl-n-benzyl aniline 614-30-2 N-异丙基苯胺 N-isopropy aniline 768-52-5 N-乙基-N-苄基苯胺 N-ethyl-n-benzyl aniline 92-59-1 N-环已基苯胺 N-Cyclohexylaniline 1821-36-9 N,N-二甲基间甲苯胺 N,N,3-trimethyl- Dimethyl-m-toluidine 121-72-2 N-甲基甲酰苯胺 N-Methylformanilide 93-61-8 N-甲基-N-羟乙基对甲苯胺 N-(2-HYDROXYETHYL)-N-METHYL-4-TOLUIDINE 2842-44-6 N,N-二甲基对甲苯胺 N,N,4-trimethyl-;dimethyl-4-toluidine; Dimethyl-p-toluidine 99-97-8 N-甲基对甲苯胺 N-Methyl-p-toluidine 623-08-5 N,N-二甲基苯胺 N,N-dimethyl aniline 121-69-7 N,N-二羟乙基苯胺 N,N-dihydroxyethyl aniline 120-07-0 N-乙基-N-羟乙基间甲苯胺 N-Ethyl-N-Hydroxyethyl-M-Toluidine 91-88-3 N,N-二羟乙基间甲苯胺 N,N-dihydroxyethyl-m-toluidine 91-99-6 N-乙基苯胺 N-ethyl aniline 103-69-5 N-甲基苯胺 N-methyl aniline 100-61-8 N-甲基对甲苯胺 4-Methyl-N-methylaniline 623-08-5 N-甲基-N-羟乙基苯胺 2-(N-Methylanilino)ethanol 93-90-3 N,N-二甲基对苯二胺 N,N-DIMETHYL-P-PHENYLENEDIAMINE 99-98-9 3-(甲氨基)甲苯 3-(Methylamino)toluene 696-44-6 N,N-二异丙醇对甲苯胺 DIPROPOXY-P-TOLUIDINE 38668-48-3 N,N-二乙基邻甲苯胺 N,N-DIETHYL-O-TOLUIDINE 606-46-2 N-甲基对硝基苯胺 N-Methyl-4-nitroaniline 100-15-2 N,N-二苄基苯胺 N,N-DIBENZYLANILINE 91-73-6 N-苯基乙醇胺 2-Anilinoethanol 122-98-5 N-苄基苯胺 N-Phenylbenzylamine 103-32-2 N-羟乙基间甲苯胺 N-2-HYDROXYETHYL-M-TOLUIDINE 102-41-0 N-乙基N氯乙基间甲苯胺 N-ETHYL-N-CHLOROETHYL-M-TOLUIDINE 22564-43-8 N,N-二乙基-4-氨基-2-甲基苯甲醛 4-Diethylamino-2-methylbenzaldehyde 92-14-8 间甲苯胺 M-Toluidine MT 108-44-1 1,4-二溴-2,5-二碘苯 1,4-DIBROMO-2,5-DIIODOBENZENE 63262-06-6 N,N-二羟乙基对苯二胺硫酸盐 N,N-Bis(2-hydroxyethyl)-p-phenylenediamine sulphate 54381-16-7 N-乙基-N-苄基-4-氨基苯甲醛 4-(N-Ethyl-N-benzyl)amino-benzoaldehyde 67676-47-5 N,N-二乙基-4-氨基苯甲醛 4-Diethylaminobenzaldehyde 120-21-8 对二甲胺基苯甲醛 p-Dimethylaminobenzaldehyde 100-10-7 2-氨基噻唑 2-Aminothiazole 96-50-4 对甲苯胺 P-Toluidine PT 106-49-0 N,N-双(2-羟基丙基)苯胺 N,N-BIS(2-HYDROXYPROPYL)ANILINE 3077-13-2 N-乙基-N-氰乙基苯胺 3-Ethylanilinopropiononitrile 148-87-8 N-乙基-N-(3'-磺酸苄基)苯胺 N-Ethyl-N-benzylaniline-3'-sulfonic acid 101-11-1 邻苯甲酰苯甲酸甲酯 Methyl 2-benzoylbenzoate 606-28-0 对羟基苯甲酸甲酯 Methylparaben 99-76-3 十四酸异丙酯 Isopropyl myristate 110-27-0 棕榈酸异丙酯 Isopropyl palmitate 142-91-6 邻甲苯胺 O-Toluidine OT 95-53-4 4-甲基-N-苯基苯胺 N-PHENYL-P-TOLUIDINE 620-84-8 N,N-二甲基苄胺 N,N-Dimethylbenzylamine BDMA 103-83-3 N,N-二甲基甲酰胺 N,N-Dimethylformamide DMF .68-12-2 N-甲基甲酰胺 N,N-Dimethylformamidedimethyl acetal (DMF-DMA) 4637-24-5 N,N-二甲基乙酰胺 N,N-Dimethylacetamide DMAC 127-19-5 N,N-二乙基间甲苯甲酰胺 避蚊胺 N,N-diethyl-m-toluamide DEET 134-62-3 N,N-二乙基羟胺 N,N-Diethylhydroxylamine DEHA 3710-84-7 N,N-二甲基-间甲基苯胺 N,N-DIMETHYL-M-TOLUIDINE 121-72-2 N-甲基二苯胺 N-Methyldiphenylamine 552-82-9 N,N-二氰乙基苯胺 N,N-Dicyanoethylaniline 1555-66-4 N-乙基-2-硝基苯胺 N-Ethyl-2-Nitro-Benzenamine 10112-15-9 N-(2-羟乙基)乙二胺 AEEA 111-41-1 二乙烯三胺(DETA) Diethylenetriamine DETA 111-40-0 三乙烯二胺 Triethylenediamine 280-57-9 三乙烯四胺 TriethylenetetramineTETA 112-24-3 四乙烯五胺 TEPA 112-57-2 间二氯苯 1,3-Dichlorobenzene MDCB 541-73-1 间二三氟甲苯 1,3-Bis(trifluoromethyl)-benzene 402-31-3 粉末丁腈橡胶 MITIVY33-1(POLYMER/ADHESIVE COMPOUNDING) 9003-18-3 十六烷基氯化吡啶 Cetylpyridinium chloride monohydrate 6004-24-6 对氯甲苯 4-Chlorotoluene 106-43-4 无水硫酸钠 SODIUM SULFATE 7757-82-6 /15124-09-1 碱性嫩黄 Auramine O 2465-27-2 偶氮二异丁腈 2,2'-Azobis(2-methylpropionitrile) 78-67-1 N-甲基-N-氰乙基苯胺 N-Cyanoethyl-N-methylaniline 94-34-8 N-甲基-N-羟乙基间甲苯胺 N-Methyl-N-hydroxyethyl-m-methylaniline N-甲基-N-苄基间甲苯胺 N-Methyl-N-hydroxyethyl-m-methylanilin CB91170851 N-甲基-N-氰乙基间甲苯胺 N-Methyl-N-cyanoethyl-m-methylaniline CB91139498 N-羟乙基间甲苯胺 N-Hydroxyethyl-m-toluidine CB71167929 N,N-二羟乙基间氯苯胺 NN-dihydroxyethyl m-chloroaniline CB2546593 N,N-二乙基邻甲苯胺 N,N-DIETHYL-O-TOLUIDINE 606-46-2 Read the full article

#13-Bis(trifluoromethyl)benzene#13-Bis(trifluoromethyl)benzenefactorysupplier#13-Di(trifluoromethyl)benzene#13-TrifluoromethylBenzene#1-fluoro-4-(trichloromethyl)benzene#1.3-Bis(trifluoromethyl)-benzene#402-31-3#AAAA'A#A'-HEXAFLUORO-M-XYLENE#alphaalphaalphabetabetabeta-hexafluoro-m-xylene#API#Bestpriceof13-Bis(trifluoromethyl)benzene#BuyHighpurityof13-Bis(trifluoromethyl)benzene#C8H4F6#CASNO.402-31-3#Chemicals#Dyeintermediates#Finechemicals#goodsupplierof13-Bis(trifluoromethyl)benzene#inorganicrawmaterials#intermediates#M-BIS(TRIFLUORO-METNY)BENZENE#Organicrawmaterials#PharmaceuticalIntermediate#pharmaceuticalintermediates#polyesterresin#XyleneHexafluoride

0 notes

Text

4 Factors To Check To Get To The Best Cannabis Seeds

When under stress, the adrenal gland in the produces cortisol, a hormone that increases our blood sugar level and levels of insulin and slows down the burning of overweight. Stress increases inflammation which causes weight gain around the waist. Need to fight stress by attempting to keep our mind free from negatives.

youtube

A therapeutic aromatherapy soap is built from natural ingredients so it gentle onto the skin and excellent for reducing bad spots. It's also excellent for dry skin care. In fact harsh soaps can be the regarding dry weed. Aromatherapy soap is also an excellent choice for sensitive skin cells. Try lavender. Many of you may read about yesterdays 4/20 protest at Civic Center Village green. Perhaps, some people were as an element of the over 3000 audience. Whether you are for or against Cannabis reform within state, you are able to still make the most of of the plants' numerous benefits consuming it. Yes, that's fantastic. I said eating it. And no, Now i am not referring to pot-brownies. Before we start by getting exercising details flab, we should find the actual root associated with the problem so that most of us can win the battle of the bulge. The excess flab possibly be due to poor burning up. Our appetite is controlled by hormones produced by our body and certain chemicals given by our thinking ability. We should strive to balance our hormones and consume omegas, pumpkin oil, Golden Acres CBD Oil Oil Benefits, flaxseed oil after they help reduce fat. Forget tablets 8 glasses a business day. That's not a bad start but let's double it. A person vegetable-soup in the market for lean? Then drink a minimum of a gallon of water a month. While dieting for competition, bodybuilders will drink just about 2 gallons of water per day. Why do you think that is? Due to the association calyx-leaf, this plant is simple manicure. Saving money leaves with heavy growth structure almost look wide because of your height. Recognized for its mordant character, the Cotton Candy has a huge drying result and it is suggested a glass of water or juice should attend hand while medicating. Although major paint new features producing more environmentally friendly paints, a good quality majority professionals can still contain hazardous substances. VOC's (Volatile Organic Compounds) are owned by a group of Cannabis Study chemicals that evaporate quickly and leave an undesirable odor, regarding example toluene, xylene and formaldehyde, and Golden Acres CBD are main things in modern day paint. They toxic to humans, particularly children would be to elderly, and also toxic on the environment. Anxiety can be an extreme step to a situation you regard as anxious. It is not necessarily bad. Particularly is following you to produce dark alley with an iron pipe in their hand, it's normal to feel tense and determined. It may save your life. This can be a 'fight or flight' syndrome in project.

1 note

·

View note

Text

Direction to Silicone Sealant

Ⅰ. What is natural cure silicone sealant

Silicone sealant, is a kind of adhesive common-used in construction and daily life. It can be divided into single component and double component, according to its curing mechanism reaction characteristics. Single component silicone sealant achieves curing through contacting with the moisture in the air, absorbing heat and producing a crosslinking reaction. Natural cure silicone sealant is a common product on market. It is widely used in household decoration, adhesion in kitchen and bathroom, sunshine plate glass pasting, fish tank pasting, glass curtain wall, aluminum plastic plate pasting and other common civil projects, such as silicone sealant for aluminium windows.

Ⅱ. Direction to natural cure silicone sealant

(1) Usage

Single component silicone sealant is ready for use. You can easily peel it out of the bottle with a glue gun and smooth the surface with a spatula or wood chip.

(2) Curing process

The curing process of natural cure silicone sealant is developed from the surface inward. Silica gel with different characteristics has different surface dry time and curing time, so surface repair work must be carried out before the sealant surface dry. If a certain place is covered by color separation paper, the paper must be taken away before the surface forms after gluing.

(3) Cure time

The curing time of natural cure silicone sealant is increased with the increase of bonding thickness. For an example, 12mm acid glass glue may take 3-4 days to solidify, but within 24 hours, 3mm outer layer has been solidified. When using it to bond glass, metal, or most wood, it has a peel resistance of 20 pounds/inch after 72 hours at room temperature.

If the place of the silicone sealant is partially or completely closed, then the curing time is determined by the tightness of the sealing. In an absolutely sealed place, it is possible to remain permanently unsolidified. if the temperature is increased, it will make the glass glue soft. The gap between metal-metal bonding surface should not exceed 25mm. In all kinds of bonding occasions, including closed conditions, the bonding effect should be thoroughly checked before the use of bonded equipment.

Acid sealant will produce a smell in the curing process due to the volatilization of acetic acid. This smell will disappear during curing process, and finally there will be no smell after curing.

(4) Sealing

If silicone sealant is used for sealing, the usage is the same with the above steps. squeeze the glass glue into the joint surface or gap, so that the sealant and the surface are fully in contact.

(5) Clean

Before curing, silicone sealant can be wiped off with cloth or paper towels. After curing, it must be scraped with a scraper or be cleaned with solvents such as xylene or acetone.

https://www.zteastsilicone.com/direction-to-silicone-sealant.html

0 notes

Text

Methoxy propyl Acetate Prices, Price Trend, News, Analysis & Forecast

Methoxy Propyl Acetate Prices: For the Quarter Ending March 2024

Methoxy propyl acetate, also known as PMA, is a versatile chemical compound widely used in various industries such as paints and coatings, cleaners, and cosmetics. Its demand and pricing are influenced by several factors, including raw material costs, market demand, and regulatory changes. Understanding the dynamics behind methoxy propyl acetate prices is crucial for businesses operating in these sectors.

One significant determinant of methoxy propyl acetate prices is the availability and cost of raw materials. As with many chemical compounds, the prices of key raw materials used in the production of PMA can fluctuate due to factors such as supply chain disruptions, changes in global oil prices, and shifts in demand for related chemicals. For instance, the cost of methanol and acetic acid, which are essential precursors in the synthesis of PMA, can impact the overall production cost and, consequently, the selling price of methoxy propyl acetate.

Get Real Time Prices of Methoxy Propyl Acetate: https://www.chemanalyst.com/Pricing-data/methoxy-propyl-acetate-1574

Market demand plays a pivotal role in influencing methoxy propyl acetate prices. Industries such as paints and coatings rely heavily on PMA as a solvent due to its low volatility and strong solvency power. Similarly, the electronics industry utilizes PMA as a solvent in the production of electronic components. Fluctuations in demand from these key sectors can lead to changes in pricing. Additionally, emerging applications for PMA in sectors like pharmaceuticals and agrochemicals can further impact its demand and, consequently, its price.

Regulatory factors also contribute to the pricing dynamics of methoxy propyl acetate. Environmental regulations, such as restrictions on volatile organic compound (VOC) emissions, can influence the choice of solvents used in various applications. Methoxy propyl acetate, with its low VOC content and favorable environmental profile, is often preferred over conventional solvents like xylene or toluene. Changes in regulations regarding the use of certain solvents or the imposition of stricter emissions standards can drive demand for PMA and affect its pricing.

Global economic conditions and geopolitical factors can also affect methoxy propyl acetate prices. Economic downturns may lead to reduced industrial activity and lower demand for PMA, putting downward pressure on prices. Conversely, periods of economic growth and increased industrial production can boost demand for PMA and support higher prices. Geopolitical events such as trade disputes or disruptions in key manufacturing regions can disrupt supply chains and affect the availability and pricing of methoxy propyl acetate and its raw materials.

In conclusion, methoxy propyl acetate prices are subject to various factors including raw material costs, market demand, regulatory changes, and geopolitical developments. Businesses involved in the production, distribution, or use of PMA must closely monitor these factors to anticipate price fluctuations and make informed decisions. By understanding the dynamics driving methoxy propyl acetate prices, stakeholders can better navigate the challenges and opportunities in this essential chemical market.

Get Real Time Prices of Methoxy Propyl Acetate: https://www.chemanalyst.com/Pricing-data/methoxy-propyl-acetate-1574

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

What You Need to Know About Industrial Coatings

It is an industrial coating that one will need to have especially if they want to achieve protection of substrates like steel and concrete. It is this material that is being applied to the material to ensure that it will not be affected by rust or corrosion. It is also the industrial coating that is being applied to maintain the shimmer and spark that the material has which can decreases over time due to corrosion. Once an industrial coating is applied that it can help protect the material from any dust and debris. This is widely used to protect steel and concrete from corrosion.

When you will take a look at industrial coating that it can be a mixture of different substances. It is a result of mixing different materials together. When taking a look at most industrial coatings that they will have a substance known as Xylan. A composite of fluoropolymers which includes PTFE and PFA and FEP is what this substance is all about. A dry film lubricant is what this substance is all about. In order to make the mixture strong that it will be mixed with thermoset polyimide and polyamide binder resins. The resins that are used in the mixture can also include Ethyl Acetate, Xylene, N-Methyl, 2-, and Dimethylformamide. It is with the help of these substances mixed all together that it can result in one of the strongest coatings available in the market. Learn more info about Industrial paints.

The application of an industrial coating is wide. Most of the time these coatings are used in industrial outfits and facilities. There are also coatings that are used to retard fire and some are also fire resistant. There are various polymers that are used in order to create industrial coating and they can be polyurethane, epoxy, and moisture cure urethane. It is also an industrial coating that will be applied to warehouses especially for the ones that are made from steel.

It is the industrial coatings that are also being sued in many different ways. Zinc, Phosphate, Xylan, PVD Coating and many re are just a few of the examples. It is a stronger coating that one will also get once these materials will be mixed together which is done by some people. Industrial coatings are also being applied in areas where foot traffic is heavy. Hospitals, factories, kitchens are just a few of the areas where industrial coatings are usually applied. Preventing workers from slipping and getting hurt is what the industrial coatings will help avoid once applied. It is also with the help of an industrial coating that the area that you have will be easier to clean. Withstanding pressure, as well as wear and tear, is what n industrial coating will also be able to do and that is why many industries choose to use them. Find out more here the uses of Liquid Greenhouse Shading Concentrate.

Check out also this related article - https://www.huffingtonpost.com/2015/02/19/painting-tips_n_6678306.html

1 note

·

View note

Text

CAS NO.402-31-3 1,3-Bis(trifluoromethyl)-benzene/high quality /best price/DA 90 DAYS

Quick Details Product name:1,3-Bis(trifluoromethyl)-benzene CAS: 402-31-3 Molecular formula:C8H4F6 Molecular weight:214.11 EINECS No.:206-939-4 Appearance:Enterprise standard Other names:Xylene Hexafluoride; 1,3-TrifluoromethylBenzene; M-BIS(TRIFLUORO-METNY)BENZENE; 1,3-Di(trifluoromethyl)benzene; 1,3-DI(TRIFLUOROMETHYL)BENZENE; A,A,A,A',A',A'-HEXAFLUORO-M-XYLENE; 1-fluoro-4-(trichloromethyl)benzene; alpha,alpha,alpha,beta,beta,beta-hexafluoro-m-xylene; Port: any port in china Packing: according to the clients requirement Storage: Store in dry, dark and ventilated place. Transportation: by sea or by air payment methods: L/C, T/T, D/A, D/P, O/A, paypal, western union etc.accept all payment. Application Used as pharmaceutical and pesticide intermediates Pharmaceutical and pesticide intermediates. It is also used as an intermediate for the synthesis of phenolic dyes and fluororesins; it is used as a solvent in the photographic and watch industries. Superiority 1.supply sample 2.the packing can be according the customers` requirment 3.any inquiries will be replied within 24 hours 4.we provide commerical invoice, packing list, bill of loading, coa , health certificate and origin certificate. if your markets have any special requirements, let us know. 5.factory price. 6.prompt delivery. we have good cooperation with many professional forwarders, we can send the products to you once you confirm the order. 7.we can accept various payment methods, l/c, t/t, d/a, d/p, o/a, paypal, western union etc., and we cooperate with sinosure many years. Anyway ,if you need any chemicals from China ,MIT -IVY INDUSTRY CO.,LTD can help you. Company Information MIT-IVY INDUSTRY CO.,LTD is a manufacturer and exporter of fine chemical dyes & pharmaceutical intermediates in China. Mainly produce aniline series products ,chlorine series products,and epoxy curing agent We are a company full of vitality. The company has a group of energetic, well-trained employees and strong technical research and development capabilities. We specialize in the production, development and sales of API intermediates, fine chemicals and plant extracts. Relying on advanced equipment and strict management, adhere to the business philosophy of "openness, tolerance, innovation, and sharing" to create a win-win cooperationplatform.Everything comes from innovation, it is our philosophy ! If you are interested in getting more quotations, please add WHATSAPP:0086-13805212761 or E-MAIL:[email protected] FAQ Q1:Will you supply samples for testing? A: For most of our products, samples are available, but please cover the shipping cost. Q2:What's your MOQ? A: For the high value product, our MOQ starts from 10g,100g and 1kg. Q3:Which kind of payment terms do you accept? A: Proforma invoice enclosed with our bank information will be sent after confirmation of order. payment methods: L/C, T/T, D/A, D/P, O/A, paypal, western union etc.accept all payment. Q4:How about your delivery time? A: Generally, it will take 3 to 5 days after receiving your advance payment. Q5:How do you treat quality complaint? A:First of all, our quality control will reduce the quality problem near to zero. If there is a quality problem caused by us, we will send you free goods for replacement or refund your loss. Main products Mit-Ivy is a well-known fine chemicals and pharmaceutical intermediates manufacturer with strong R&D support in China. Mainly involved Aniline, Chlorine products. Payment:DA 60 DAYS TEL:008619961957599 E-MAIL:[email protected] 产品 Product CAS N-甲基间甲苯胺 N-Methyl-M-Methylaniline 696-44-6 N-羟乙基苯胺 N-(2-hydroxyethyl)-Aniline 122-98-5 N-乙基对甲苯胺 N-ethyl-p-toluidine 622-57-1 N,N-二甲基邻甲苯胺 N,N-Dimethyl-o-toluidine 609-72-3 N-甲基邻甲苯胺 N-Methyl-o-methylaniline 611-21-2 N,N-二乙基对甲苯胺 N,N-Diethyl-p-toluidine 613-48-9 N,N-二乙基间甲苯胺 N,N-diethyl-m-toluidine 91-67-8 N-氰乙基-N-羟乙基间甲苯胺 N-cyanoethyl-n-hydroxyethyl-m-toluidine 119-95-9 N-乙基间甲苯胺 N-ethyl-m-toluidine 102-27-2 N-氰乙基-N-羟乙基苯胺 N-cyanoethyl-n-hydroxyethyl aniline 92-64-8 N-乙基邻甲苯胺 N-ethyl-o-toluidine 94-68-8 N,N-二羟乙基对甲苯胺 N,N-dihydroxyethyl-p-toluidine .3077-12-1 N,N-二乙基苯胺 N,N-diethyl aniline 91-66-7 N-丁基-N-羟乙基苯胺 N-butyl-n-hydroxy aniline 3046-94-4 N-乙基-N-氰乙基间甲苯胺 N-ethyl-n-cyanoethyl-m-toluidine 148-69-6 N-丁基-N-氰乙基苯胺 N-butyl-n-cyano aniline 61852-40-2 N-甲基- N-羟乙基苯胺 N-methyl-n-hydroxyetjyl aniline 93-90-3 N,N-二丁基苯胺 N,N-dibutyl aniline 613-29-6 N-乙基-N-氰乙基苯胺 N-ethyl-n-cyanoethyl aniline 148-87-8 N-正丁基苯胺 N-Phenyl-N-butyl aniline 1126-78-9 N-乙基-N-羟乙基苯胺 N-ethyl-n-hydroxyethyl aniline 92-50-2 N-乙基-N-苄基间甲苯胺 N-ethyl-n-benzyl-m-toluidine 119-94-8 N-甲基-N-苄基苯胺 N-methyl-n-benzyl aniline 614-30-2 N-异丙基苯胺 N-isopropy aniline 768-52-5 N-乙基-N-苄基苯胺 N-ethyl-n-benzyl aniline 92-59-1 N-环已基苯胺 N-Cyclohexylaniline 1821-36-9 N,N-二甲基间甲苯胺 N,N,3-trimethyl- Dimethyl-m-toluidine 121-72-2 N-甲基甲酰苯胺 N-Methylformanilide 93-61-8 N-甲基-N-羟乙基对甲苯胺 N-(2-HYDROXYETHYL)-N-METHYL-4-TOLUIDINE 2842-44-6 N,N-二甲基对甲苯胺 N,N,4-trimethyl-;dimethyl-4-toluidine; Dimethyl-p-toluidine 99-97-8 N-甲基对甲苯胺 N-Methyl-p-toluidine 623-08-5 N,N-二甲基苯胺 N,N-dimethyl aniline 121-69-7 N,N-二羟乙基苯胺 N,N-dihydroxyethyl aniline 120-07-0 N-乙基-N-羟乙基间甲苯胺 N-Ethyl-N-Hydroxyethyl-M-Toluidine 91-88-3 N,N-二羟乙基间甲苯胺 N,N-dihydroxyethyl-m-toluidine 91-99-6 N-乙基苯胺 N-ethyl aniline 103-69-5 N-甲基苯胺 N-methyl aniline 100-61-8 N-甲基对甲苯胺 4-Methyl-N-methylaniline 623-08-5 N-甲基-N-羟乙基苯胺 2-(N-Methylanilino)ethanol 93-90-3 N,N-二甲基对苯二胺 N,N-DIMETHYL-P-PHENYLENEDIAMINE 99-98-9 3-(甲氨基)甲苯 3-(Methylamino)toluene 696-44-6 N,N-二异丙醇对甲苯胺 DIPROPOXY-P-TOLUIDINE 38668-48-3 N,N-二乙基邻甲苯胺 N,N-DIETHYL-O-TOLUIDINE 606-46-2 N-甲基对硝基苯胺 N-Methyl-4-nitroaniline 100-15-2 N,N-二苄基苯胺 N,N-DIBENZYLANILINE 91-73-6 N-苯基乙醇胺 2-Anilinoethanol 122-98-5 N-苄基苯胺 N-Phenylbenzylamine 103-32-2 N-羟乙基间甲苯胺 N-2-HYDROXYETHYL-M-TOLUIDINE 102-41-0 N-乙基N氯乙基间甲苯胺 N-ETHYL-N-CHLOROETHYL-M-TOLUIDINE 22564-43-8 N,N-二乙基-4-氨基-2-甲基苯甲醛 4-Diethylamino-2-methylbenzaldehyde 92-14-8 间甲苯胺 M-Toluidine MT 108-44-1 1,4-二溴-2,5-二碘苯 1,4-DIBROMO-2,5-DIIODOBENZENE 63262-06-6 N,N-二羟乙基对苯二胺硫酸盐 N,N-Bis(2-hydroxyethyl)-p-phenylenediamine sulphate 54381-16-7 N-乙基-N-苄基-4-氨基苯甲醛 4-(N-Ethyl-N-benzyl)amino-benzoaldehyde 67676-47-5 N,N-二乙基-4-氨基苯甲醛 4-Diethylaminobenzaldehyde 120-21-8 对二甲胺基苯甲醛 p-Dimethylaminobenzaldehyde 100-10-7 2-氨基噻唑 2-Aminothiazole 96-50-4 对甲苯胺 P-Toluidine PT 106-49-0 N,N-双(2-羟基丙基)苯胺 N,N-BIS(2-HYDROXYPROPYL)ANILINE 3077-13-2 N-乙基-N-氰乙基苯胺 3-Ethylanilinopropiononitrile 148-87-8 N-乙基-N-(3'-磺酸苄基)苯胺 N-Ethyl-N-benzylaniline-3'-sulfonic acid 101-11-1 邻苯甲酰苯甲酸甲酯 Methyl 2-benzoylbenzoate 606-28-0 对羟基苯甲酸甲酯 Methylparaben 99-76-3 十四酸异丙酯 Isopropyl myristate 110-27-0 棕榈酸异丙酯 Isopropyl palmitate 142-91-6 邻甲苯胺 O-Toluidine OT 95-53-4 4-甲基-N-苯基苯胺 N-PHENYL-P-TOLUIDINE 620-84-8 N,N-二甲基苄胺 N,N-Dimethylbenzylamine BDMA 103-83-3 N,N-二甲基甲酰胺 N,N-Dimethylformamide DMF .68-12-2 N-甲基甲酰胺 N,N-Dimethylformamidedimethyl acetal (DMF-DMA) 4637-24-5 N,N-二甲基乙酰胺 N,N-Dimethylacetamide DMAC 127-19-5 N,N-二乙基间甲苯甲酰胺 避蚊胺 N,N-diethyl-m-toluamide DEET 134-62-3 N,N-二乙基羟胺 N,N-Diethylhydroxylamine DEHA 3710-84-7 N,N-二甲基-间甲基苯胺 N,N-DIMETHYL-M-TOLUIDINE 121-72-2 N-甲基二苯胺 N-Methyldiphenylamine 552-82-9 N,N-二氰乙基苯胺 N,N-Dicyanoethylaniline 1555-66-4 N-乙基-2-硝基苯胺 N-Ethyl-2-Nitro-Benzenamine 10112-15-9 N-(2-羟乙基)乙二胺 AEEA 111-41-1 二乙烯三胺(DETA) Diethylenetriamine DETA 111-40-0 三乙烯二胺 Triethylenediamine 280-57-9 三乙烯四胺 TriethylenetetramineTETA 112-24-3 四乙烯五胺 TEPA 112-57-2 间二氯苯 1,3-Dichlorobenzene MDCB 541-73-1 间二三氟甲苯 1,3-Bis(trifluoromethyl)-benzene 402-31-3 粉末丁腈橡胶 MITIVY33-1(POLYMER/ADHESIVE COMPOUNDING) 9003-18-3 十六烷基氯化吡啶 Cetylpyridinium chloride monohydrate 6004-24-6 对氯甲苯 4-Chlorotoluene 106-43-4 无水硫酸钠 SODIUM SULFATE 7757-82-6 /15124-09-1 碱性嫩黄 Auramine O 2465-27-2 偶氮二异丁腈 2,2'-Azobis(2-methylpropionitrile) 78-67-1 N-甲基-N-氰乙基苯胺 N-Cyanoethyl-N-methylaniline 94-34-8 N-甲基-N-羟乙基间甲苯胺 N-Methyl-N-hydroxyethyl-m-methylaniline N-甲基-N-苄基间甲苯胺 N-Methyl-N-hydroxyethyl-m-methylanilin CB91170851 N-甲基-N-氰乙基间甲苯胺 N-Methyl-N-cyanoethyl-m-methylaniline CB91139498 N-羟乙基间甲苯胺 N-Hydroxyethyl-m-toluidine CB71167929 N,N-二羟乙基间氯苯胺 NN-dihydroxyethyl m-chloroaniline CB2546593 N,N-二乙基邻甲苯胺 N,N-DIETHYL-O-TOLUIDINE 606-46-2 Read the full article

#13-Di(trifluoromethyl)benzene#13-TrifluoromethylBenzene#1-fluoro-4-(trichloromethyl)benzene#1.3-Bis(trifluoromethyl)-benzene#402-31-3#AAAA'A#A'-HEXAFLUORO-M-XYLENE#alphaalphaalphabetabetabeta-hexafluoro-m-xylene#API#C8H4F6#CASNO.402-31-3#Chemicals#Dyeintermediates#Finechemicals#inorganicrawmaterials#intermediates#M-BIS(TRIFLUORO-METNY)BENZENE#Organicrawmaterials#pharmaceuticalintermediates#polyesterresin#XyleneHexafluoride

0 notes

Text

Brine Concentration Technology Market is anticipated to expand at a CAGR of more than 4.0% from 2018 to 2026

The global brine concentration technology market was valued at nearly US$ 12 Bn in 2017 and is anticipated to expand at a CAGR of more than 4.0% from 2018 to 2026, according to a new report titled ‘Brine Concentration Technology Market – Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2017-2026’ by Transparency Market Research (TMR) Growth of brine concentration technology is highly dependent on oil & gas activities. The shift toward clean energy is expected to drive the demand for brine concentration technology in the near future. Brine is a salt water solution, which may contain different salts such as calcium sulfate, silica, calcium chloride, and sodium. Brine needs to be treated before discharging it into the environment. Brine concentration technology involves treating the produced brine to remove harmful salts from the water.

Increase in demand from oil & gas industry

Oil & gas exploration is a major source of energy in many countries. Its production has been described as one of the most important industrial activities of the 21st century.

Are you a start-up willing to make it big in the business? Grab an exclusive PDF Brochure of this report : https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=44285

Water is a complex mixture of organic and inorganic compounds and the largest volume of by-product generated during oil and gas recovery operations. The oilfield produced water can be a source of fresh water for water-stressed oil-producing countries. Extraction and production of oil & gas leads to reduction in reservoir pressure. Additional water is usually injected into the reservoir water layer to maintain hydraulic pressure and enhance oil recovery.

Rise in concern about environmental pollution

Increase in concern about the environment has played a major role in the adoption of brine concentration technology. Various projects, including several para-xylene chemical plants in China and a wastewater discharge pipeline for a paper mill, have been suspended or canceled as a result of public protests. Growth in concern about the environment is likely to compel industries to adopt brine treatment as a necessary solution in order to gain public acceptance. High installation cost of brine concentration technology can be a restraining factor, specifically for small industries that have lower capital investment.

REQUEST FOR COVID19 IMPACT ANALYSIS – https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=44285

Currently, Vertical Tube Falling Film (VTFF) technology segment is anticipated to expand significantly

In terms of technology, the vertical tube falling film (VTFF) segment currently holds the major share of the market due to the technology’s application in achieving zero liquid discharge in industries. Development of offshore oil & gas industry in North America and Middle East has propelled the demand for HERO technology. The HERO segment is likely to expand at a CAGR of 6.39% during the forecast period, followed by the VTFF segment (CAGR of 5.57%). MVC and CCD segments are also anticipated to expand during the forecast period.

Innovation, quality improvement, and recent development in brine concentration technology

In 2015, Desalitech and C2HM together emphasized on developing the Closed Circuit Desalination (CCD) technology. The CCD technology improves the efficiency and productivity. It helps in passing concentrated brine through the system continuously and leaving the salt precipitate behind through salt extraction gate. The new technology helps tackle issues arising due to depleting amount of freshwater for domestic and industrial purposes. Installation of brine concentration plants enables industries to reuse the recovered water and thus lower their operating costs.

More Trending Reports by Transparency Market Research –

https://www.prnewswire.com/news-releases/district-heating-market-to-exceed-valuation-of-us-2-9-trn-by-2031–notes-study-by-tmr-301459107.html

Countries in Asia Pacific to lead brine concentration technology market

Asia Pacific is estimated to emerge as one of the prominent regions of the brine concentration technology market. Highly environment-conscious Europe and North America are projected to lead the global brine concentration technology market in the near future. The brine concentration technology market is projected to witness a large number of collaborations among manufacturers and technology developers during the next few years. Over the years, China has become a strategic center for brine concentration technology. This is projected to boost the demand for brine concentration technology systems in Asia Pacific in the near future.

Buy Now : https://www.transparencymarketresearch.com/checkout.php?rep_id=44285<ype=S

Highly competitive market with domination of top players

The global brine concentration technology market is a highly competitive. In order to acquire higher market share, companies operating in North America, Middle East & Africa, and Asia Pacific are rapidly expanding their production facilities of brine concentration technology. Leading players dominate the market.

Key players operating in the brine concentration technology market are Advent Envirocare Technology Pvt. Ltd., Modern Water plc. Memsys Water Technologies GmbH, Enviro Water Minerals Company Inc., Oasys Water, TETRA Technologies, Inc., Fluid Technology Solutions, Inc., Osmo Membrane Systems GmbH, Saltworks Technologies Inc., Duraflow LLC., Veolia, and Synder Filtration, Inc.

About Us:

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather, and analyse information. Now avail flexible Research Subscriptions, and access Research multi-format through downloadable databooks, infographics, charts, interactive playbook for data visualization and full reports through MarketNgage, the unified market intelligence engine. Sign Up for a 7 day free trial!

Contact

Rohit Bhisey Transparency Market Research, 90 State Street, Suite 700, Albany, NY 12207 Tel: +1-518-618-1030 USA – Canada Toll Free: 866-552-3453 Email: [email protected] Website: https://www.transparencymarketresearch.com

0 notes

Text

Aprotic Solvents Market 2025 Size, Share | Revenue, Business Growth, Demand and Applications

28th December 2021 – Global Aprotic Solvents Market is estimated to grow significantly in the forecast period owing to the increase in demand from several end use industries and growing use of bio-based items. Aprotic solvents are the solvents, which are not capable of hydrogen bonding, for which they cannot be hydrogen bonds. Aprotic solvents usually have intermediate polarity and dielectric constants.

Rising consumption of aprotic solvents among several other end use industries like oil & gas, petrochemicals, enhanced recycling technology, and growing demand for eco-friendly solution are majorly driving the growth of aprotic solvents market. Furthermore, improved features like low reactivity, high relative permittivity, thermal stability with the use of aprotic solvents in production of gas and oil refining are other boosting factors of aprotic solvents. However, increase in demand for non-toxic alternates to aprotic solvents, strict government regulations, flexible raw material cost and growing environmental concern are expected to hamper the growth of aprotic solvents market in the coming years.

Access Aprotic Solvents Market Report with TOC @ https://www.millioninsights.com/industry-reports/aprotic-solvents-market

Increase in demand for aprotic solvents is predicted to expand impressively in the pharmaceutical segment in the years to come owing to the innovations in the segment, which introduces new drugs. Over the years, the demand for toluene is also on the rise. The raw material is used to produce other chemicals like benzene, xylene, and trinitrotoluene (TNT). Hence, the demand is expected to remain strong in future as well. Besides, N-Methyl-2-pyrrolidone (NMP) potentially dissolves numerous metals due to which its demand is expected to resister significant growth especially in oil & gas and plastic segment.

Aprotic solvents industry is categorized on the basis of solvent type, application and geography. On the basis of solvent type, the market is divided into N-Methyl-2-pyrrolidone, benzene, toluene, acetone, chloroform, and others. In terms of application, aprotic solvents market is divided into pharmaceutical, oil & gas, personal care, electronics, adhesives, paints & coatings, and others. Oil & gas segment is expected to register significant growth since it extensively uses aprotic solvents. They are used as fracking fluids while oil drilling operations since it increases the quantity of hydrocarbons.

Geographically, aprotic solvents industry is segmented as North America, Latin America, Europe, Asia Pacific, and Middle East & Africa. Asia Pacific is expected to hold larger market share of aprotic solvents owing to the steady growth observed in industries like electronics and electrical, pharmaceutical, and paints & coatings. North America is projected to lead aprotic solvents industry after Asia Pacific due to growing pharmaceuticals and oil & gas industry.

The prominent players in aprotic solvents industry include AlzChem AG, Ashland, Asahi Kasei, BASF SE, CNPC Jilin Chemical Group, Eastman Chemical Company, Imperial Chemical Corporation, Celanese Corporation, Ineos Chemicals Company, Shell Chemicals, DuPont Conglomerate Company, Mitsubishi Chemicals, and Nanjing Jinlong.

Request a Sample Copy of Aprotic Solvents Market Report @ https://www.millioninsights.com/industry-reports/aprotic-solvents-market/request-sample

0 notes

Text

Aprotic Solvents Market 2025 Demand, Outlook | Regions, Size Estimation and Upcoming Trend

28th December 2021 – Global Aprotic Solvents Market is estimated to grow significantly in the forecast period owing to the increase in demand from several end use industries and growing use of bio-based items. Aprotic solvents are the solvents, which are not capable of hydrogen bonding, for which they cannot be hydrogen bonds. Aprotic solvents usually have intermediate polarity and dielectric constants.

Rising consumption of aprotic solvents among several other end use industries like oil & gas, petrochemicals, enhanced recycling technology, and growing demand for eco-friendly solution are majorly driving the growth of aprotic solvents market. Furthermore, improved features like low reactivity, high relative permittivity, thermal stability with the use of aprotic solvents in production of gas and oil refining are other boosting factors of aprotic solvents. However, increase in demand for non-toxic alternates to aprotic solvents, strict government regulations, flexible raw material cost and growing environmental concern are expected to hamper the growth of aprotic solvents market in the coming years.

Access Aprotic Solvents Market Report with TOC @ https://www.millioninsights.com/industry-reports/aprotic-solvents-market

Increase in demand for aprotic solvents is predicted to expand impressively in the pharmaceutical segment in the years to come owing to the innovations in the segment, which introduces new drugs. Over the years, the demand for toluene is also on the rise. The raw material is used to produce other chemicals like benzene, xylene, and trinitrotoluene (TNT). Hence, the demand is expected to remain strong in future as well. Besides, N-Methyl-2-pyrrolidone (NMP) potentially dissolves numerous metals due to which its demand is expected to resister significant growth especially in oil & gas and plastic segment.

Aprotic solvents industry is categorized on the basis of solvent type, application and geography. On the basis of solvent type, the market is divided into N-Methyl-2-pyrrolidone, benzene, toluene, acetone, chloroform, and others. In terms of application, aprotic solvents market is divided into pharmaceutical, oil & gas, personal care, electronics, adhesives, paints & coatings, and others. Oil & gas segment is expected to register significant growth since it extensively uses aprotic solvents. They are used as fracking fluids while oil drilling operations since it increases the quantity of hydrocarbons.

Geographically, aprotic solvents industry is segmented as North America, Latin America, Europe, Asia Pacific, and Middle East & Africa. Asia Pacific is expected to hold larger market share of aprotic solvents owing to the steady growth observed in industries like electronics and electrical, pharmaceutical, and paints & coatings. North America is projected to lead aprotic solvents industry after Asia Pacific due to growing pharmaceuticals and oil & gas industry.

The prominent players in aprotic solvents industry include AlzChem AG, Ashland, Asahi Kasei, BASF SE, CNPC Jilin Chemical Group, Eastman Chemical Company, Imperial Chemical Corporation, Celanese Corporation, Ineos Chemicals Company, Shell Chemicals, DuPont Conglomerate Company, Mitsubishi Chemicals, and Nanjing Jinlong.

Request a Sample Copy of Aprotic Solvents Market Report @ https://www.millioninsights.com/industry-reports/aprotic-solvents-market/request-sample

0 notes

Text

Xylene Market: Top Manufacturers, Consumption, Sales, Revenue & Trends 2021-2026

Xylene Market 2021-2026 The Global Xylene Market involves an ideal combination of primary and secondary research with the help of which the experts’ inferences and calculations are derived. Our reports are revised at regular intervals to be able to give recent information to our clients and help them make efficient business decisions. The information provided in the reports is verified in terms of quality and reliability.

The Major Players Covered in this Report: PTT Global Chemical Public Company Limited, Merck KGaA, Braskem, Formosa Chemicals & Fibre Corp, Reliance Industries Limited, Exxon Mobil Corporation, Flint Hills Resources, SK global chemical CoLtd., BASF, DUpont, LOTTE Chemical CORPORATION, MP Biomedicals, Nutan Chemicals, Honeywell International Inc., Puritan Products, Tokyo Chemical Industry Co., Ltd., Doe & Ingalls, Gadiv Petrochemical Industries Ltd, Cepsa

Get a Sample PDF Report: https://straitsresearch.com/report/Xylene-market/request-sample

By Type , Ortho-Xylene , Meta-Xylene , Para-Xylene , By Application, Paints and Coatings, Plastics & Polymers, Aviation fuel, Textiles, Pesticides, Others ,

The report specifically highlights the Xylene market share, company profiles, regional outlook, product portfolio, a record of the recent developments, strategic analysis, key players in the market, sales, distribution chain, manufacturing, production, new market entrants as well as existing market players, advertising, brand value, popular products, demand and supply, and other important factors related to the Xylene market to help the new entrants understand the market scenario better.

Important factors like strategic developments, government regulations, Xylene market analysis, end-users, target audience, distribution network, branding, product portfolio, market share, threats and barriers, growth drivers, latest trends in the industry are also mentioned.

Regional Analysis For Xylene Market:

North America (United States, Canada, and Mexico) Europe (Germany, France, UK, Russia, and Italy) Asia-Pacific (China, Japan, Korea, India, and Southeast Asia) South America (Brazil, Argentina, Colombia, etc.) Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, and South Africa)

In this study, the years considered to estimate the market size of the Xylene are as follows:

• History Year: 2014-2019 • Base Year: 2019 • Estimated Year: 2020 • Forecast Year 2021 to 2026 The main steps in the investigation process are:

1) The first step in market research is to obtain raw market information from industry experts and direct research analysts using primary and secondary sources.

2) Extracts raw data from these sources to extract valuable insights and analyze them for research purposes.

3) Classify the knowledge gained by qualitative and quantitative data and place it accordingly to make final conclusions.

Key Questions Answered in the Report:

• What is the current scenario of the Global Xylene Market? How is the market going to prosper throughout the next 6 years? • What is the impact of COVID-19 on the market? What are the major steps undertaken by the leading players to mitigate the damage caused by COVID-19? • What are the emerging technologies that are going to profit the market? • What are the historical and the current sizes of the Global Xylene Market? • Which segments are the fastest growing and the largest in the market? What is their market potential? • What are the driving factors contributing to the market growth during the short, medium, and long term? What are the major challenges and shortcomings that the market is likely to face? How can the market solve the challenges? • What are the lucrative opportunities for the key players in the Xylene market? • Which are the key geographies from the investment perspective? • What are the major strategies adopted by the leading players to expand their market shares? • Who are the distributors, traders, and dealers of the Global Xylene market? • What are sales, revenue, and price analysis by types and applications of the market? For More Details On this Report: https://straitsresearch.com/report/Xylene-market

About Us:

Regardless of whether you're looking at business sectors in the next town or crosswise over continents, we understand the significance of being acquainted with what customers purchase. We overcome the issues of our customers by recognizing and deciphering just the target group, while simultaneously generating leads with the highest precision. We seek to collaborate with our customers to deliver a broad spectrum of results through a blend of market and business research approaches. This approach of using various research and analysis strategies enables us to determine greater insights by eliminating the research costs. Moreover, we're continually developing, not only with regards to where we measure, or who we measure but in how our visions can enable you to drive cost-effective growth.

Contact Us:

Company Name: Straits Research Email: [email protected] Phone: +1 646 480 7505 (U.S.) +91 8087085354 (India) +44 208 068 9665 (U.K.)

0 notes