Don't wanna be here? Send us removal request.

Link

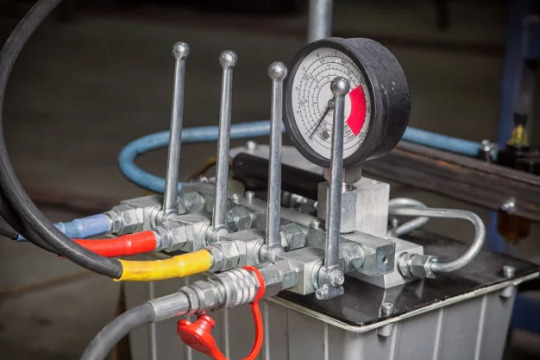

Go Hydraulics can help you with all of your hydraulic pump repairs. If you need a hydraulic repair service, GO Hydraulics can help. Whether you need hydraulic cylinder or pump repairs, we do it all, so contact us today!

0 notes

Text

Repair Or Change: What Is The Optimal Option For My Hydraulic Valve?

Hydraulic valves can break, no matter how reliable or well-made they are. A damaged valve is problematic because it can prevent a hydraulic system from operating, so if you ever encounter this problem, you need to find a suitable location immediately. If you are not sure whether you should repair or replace your hydraulic valve, the following guide will help you find which option is best.

Repairing the valve is usually more cost-effective as the cost is lower than buying a new valve in repair. If you notice that only part of your valve is defective, then you should focus on repair as it will be more affordable and take less time than replacement. Hydraulic valves can sometimes experience premature failure due to minor causes, and if most of the other parts are fine, the valve can survive and continue to function if you complete the necessary repairs. Can. . In these instances, repairing it would be your best option, so weigh the situation and assess the extent and type of damage.

Remember that valves can fail for various reasons and can be as small as a faulty screw, so the issue is not always serious.

Technicians can disassemble your valve and clean it so that it can be inspected thoroughly. This will allow them to see what the problem is and the problem can be something simple such as replacing a soft seal.

If your hydraulic valve is badly damaged and has experienced a lot of wear and tear, replacing it will be the best option. If several parts of the valve are damaged, repairing each of them individually will be more expensive, and replacing the whole will reduce costs. Additionally, if some unused parts of the valve are too expensive to be manufactured individually, it may be cheaper to replace the entire valve, so you need to consider the entire situation. Older valves and those that have been used extensively may fail and if this continues to happen, it would be best to seek a replacement.

Essentially, you need to assess the situation as both repairs and replacements can be costly.

If the valve can be repaired, you will not want to spend money on a new one, but you may not even want to pay for the repair as these can add cost and in some cases, eliminate more costs than replacement. . . Complete valve.

If you need hydraulic repair service, GO Hydraulics can help. Whether you need a cylinder or pump repair, we do it all, so contact us today!

#hydraulic equipment supplier#hydraulic cylinder repair#hydraulic pump repair#hydraulic hose repair#hydraulic repair service

0 notes

Text

Reasons Behind Hydraulic Cylinder Failure

Hydraulic cylinders are a crucial component in machinery used in various industries. They have many uses in the construction and manufacturing industries, for example, and any breakdown can slow down or lead to significant costs to operations. Proper use, maintenance and inspection are crucial to keep them in good condition.

When a hydraulic cylinder fails to work, it can prevent the system from operating effectively, slow or stall down operations, waste electricity, and damage components.Some of the reasons behind hydraulic cylinder failure are a misalignment, overheating, leaking seal, corroded barrel, damaged eye bearing or piston rods. To resolve malfunctioning cylinders, it is important to first understand the nature of the failure, inspect the causes, and then address it accordingly.

Hydraulic Cylinder Components

The components of a hydraulic cylinder need to be understood to identify faults and resolve them. Primarily, there are some important hydraulic cylinder parts that work in the joint and any failure can affect the entire system.

Visible piston rods

Piston which transfers energy to the piston rod

Cylinder cap

Cylinder head

Seals and bearings

Corrosion Caused by Chemicals

Hydraulic cylinders operate in all types of environments, some of which involve exposure to chemicals. Happily, abrasive chemicals sometimes damage weak materials, such as cylinder seals. If the seal is not compatible with the seal material, it may corrugate. Ensure that the new components of the hydraulic cylinder are compatible with the environment in which they are used. Contact the manufacturer to select the informant.

Contaminated Hydraulic Fluid

The hydraulic liquid can be contaminated by air, water or rough particles that can get trapped between the piston bar and its seal, moving presentation, causing leaks and affecting the load it carries. Even during maintenance and repairs, if proper cleaning procedures are not followed, seals can be damaged. This is the reason why you need to have certified professionals for maintenance and inspection.

Corroded Barrel

When water enters the hydraulic cylinder, the barrel can be corroded. Since this is an interior, the repair is not easy. The cylinder should be compatible with the environment in which it operates. Sealed water must be kept effectively to prevent leakage into the barrel.

Damaged Eye and Rod Bearings

If the cylinder is forced to carry more load, the eye bearing may be affected. Similarly, improper alignment between the cylinder and the load it carries can damage excessive loads, denting or rod bearings. Never use cylinders with dented rods or barrels as it will damage the bearings and seals. Replace it with a new one immediately.

Extreme Heat or Cold

Both hot and cold, extreme operating temperatures can affect the seal. Breaking the seal causes critical fluids, such as ub, to leak out of the cylinder, allowing water, air, and debris particles to enter, causing cylinder failure. Deformed seals must be replaced before they can be damaged. Timely inspection is very important to prevent most of these failures.

Go Hydraulics

We have over 30 years of experience in all makes and models of hydraulic components in manufacturing, agriculture, marine, lumber, and automotive industries. Contact Go Hydraulics for timely maintenance, repairs, and reconstruction of hydraulic components.

0 notes

Text

Importance of Hydraulic Equipment Maintenance

Some believe that hydraulics don’t really require maintenance and are built to function perfectly for long periods of your time . GO Hydraulics is here to inform you, sadly, that's not the case and hydraulic equipment does require maintenance to make sure longevity and avoid expensive issues and headaches.

Without the right care, hydraulic equipment would require fixing which is certain to place a dent in your wallet. With the advanced technology and mechanics available and incorporated into the equipment lately , fixing any kind of problem, regardless of how minor can find yourself costing a fortune and this is often something every mechanic and maintenance operator wants to avoid.

Hydraulic equipment maintenance isn't always easy and requires time and energy but within the end of the day , it's extremely worthwhile . you're not only helping to supply a extended lifespan, but you're also lowering on unexpected and unnecessary costs also .

Should you run into any problems with any of your hydraulic equipment, GO Hydraulics is that the company you want! Specializing within the hydraulic repair of any kind, including hydraulic cylinder repair, they're going to confirm you get the simplest service possible.

0 notes

Text

Hydraulic System Overheating? Here’s How to Fix it

After leaks, overheating is that the second commonest problem that happens with hydraulic equipment. Inefficiencies are what causes the heating of hydraulic fluid while operational , which can end in losses of input power, which is then converted to heat. If you’re experiencing overheating problems in your hydraulic systems, there are two solutions which will assist you with this problem. you'll prefer to either decrease the warmth load or increase the warmth dissipation. Start by checking the reservoir fluid level and fill it to the right level if you see that it’s low because hydraulic systems dissipate heat through the reservoir.

0 notes

Photo

Hydraulics has made a big impact on variety of industries, especially the development industry. Its development and implementation into construction have powered the industry, with most machines being powered by hydraulics. Hydraulics are keeping the development industry propelling forward. Making impossible, innovative feats in both architecture and engineering, hydraulics make many things within the housing industry possible.

Here are some samples of how hydraulics are transforming the development industry in equipment and heavy hydraulic machinery.

1. Hydraulic Cylinders 2. Cylinder Barrels, Pistons & Heads 3. Hydraulic Hoses 4. Hydraulic Pumps 5. Hydraulic Filters

GO Hydraulics may be a full hydraulic repair service center committed to hydraulic cylinder repair and hydraulic ram repair within the GTA. With over 30 years of experience, we are the experts in hydraulics within the agricultural, construction, marine, and lumber industries. In need of a hydraulic repair? Contact us for a quote and and we’ll revisit to you as soon as possible.

1 note

·

View note