Don't wanna be here? Send us removal request.

Text

How a vacuum cleaner works and what to look for when purchasing one.

Okay. Before we go on about this, I will like to tell you something. I will like to tell you a little secret on vacuum cleaner technology and design, so that, rather than focus on specific products, like the powersmith ash vacuum cleaner, I can help you to understand what makes a good vacuum cleaner. I think that the knowledge that I can provide to you will result in you being able to select the proper product. Firstly I want to say that you get what you pay for. I think if you buy properly, you buy right. You buy once you'll be completely satisfied.

Not too long ago in this business of vacuum cleaners, it was possible to buy a machine for $100, like Hoover upright and use it for 15 or 20 years. However, today, that's impossible. The vacuum industry is broken essentially into two types of machines, either quality or something that's far less than that. And we find that the best equipment pays because it lasts longer. It's the old adage, you get what you pay for.

So the biggest selling machines in the quality end of the spectrum are the Italian and German vacuums. However, the preponderant number of vacuums today are made in China. The average life being a year or two. So that would serve as a little backdrop to what I'm going to say next, which is, you need to understand the way the vacuum works and cleans and what is involved in a quality vacuum.

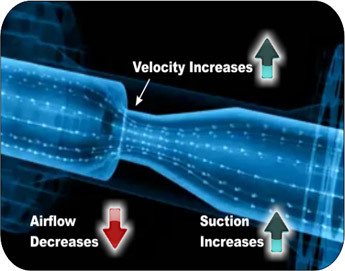

There are two or three functions in a vacuum that will affect cleaning. Air flow assumption are one function they're tied together and the last is agitation. If you take a dust brush and you dust a tabletop, you have a certain specified amount of airflow and suction, and the dusting action, the bristles are supplying agitation. when you clean other surfaces, specific tools provide the agitate.

When you clean a carpet, which is typically the most difficult area of the house to clean properly, you are using agitation airflow and suction to arrive at a finished result. It's important also to understand that in this process of vacuuming you are removing immense numbers of very small particles in the hundreds of millions per minute. The dust mite allergens, the bacteria, the pollens, the molds, the spores are being removed from the house.

The intent is to remove them effectively and keep them in the machine and the only way to keep them in the machine is if the housings, the component parts of the vacuum are engineered to airtight levels. If they're not, the pressure in the machine when its operating, will force the small particles out. You cannot see these particles but they will be coming out so in the vacuum industry there's an apprehension generally that most vacuums are very much the same.

That, there's perhaps small differences. But that's not true. The quality of vacuums varies tremendously. The most important end result of a good vacuum cleaner, for example, like an ash vacuum cleaner, is not only to remove particles out of the house allergens but to also retain them inside the machine. The only way that can be accomplished is if the vacuum cleaner itself, in its design and construction, has airtight housings and passageways to prevent leakage from the vacuum. So the very best machines in that regard are made in Italy and in Germany.

Today most vacuums, the old-fashioned American machines, Hoover's Eureka, Bessel's dirt devils and so on are made in China and those airtight levels are not achieved.

So an important backdrop to selecting a vacuum is to understand that the particle containment is probably the biggest part of the immediate result needed. The other things are;

1. How well the machine cleans.

2. How easy is it to use.

3. How long will it last.

4. The noise level and so on

Without saying much more I'd like to give you a little detail here on the way vacuums work to help you understand and then you can intelligently make a selection as to the machine that you think is best for you.

When a vacuum is functioning, there are three elements involved in the cleaning process. Airflow and suction which are tied together and agitation. The airflow and the suction is provided by the motor fan or fans. There's a couple of different types of motors used in this business in residential vacuums and I'll explain that, and then the agitation is provided by the tool that's used at that point.

For example, If you're dusting a table top the dust brush bristles are providing agitation. If you're cleaning a bare floor the bristles on that nozzle are helping to provide agitation.

The hardest section of the house to be cleaned would be the carpet, in most instances, and a carpet is cleaned with three different types of nozzles today. Either a traditional, if you use old fashioned rug nozzle there are no revolving bristles at all. The tool is moved back and forth over the carpeted surface and the airflow and the suction do the majority of the cleaning. There are generally some sort of Pickers or device on the bottom of the nozzle to help remove, break the surface friction and remove material. Then we have tools where the brush revolves and those come in two types. Turbo tools which work off the airflow that enters the tool and then motorized or electric brushes which is the preferred way to clean for residential use.

The average hose is approximately an inch or an inch and a quarter in diameter. That allows the main motor to provide the necessary suction and air flow to whatever the cleaning process that you need to achieve.

In the commercial field vacuum, hoses will go up to three inch some even bigger but the average is an inch and a half. The problem with that for residential use is the hose gets a little bulky. The advantage is it helps enhance the air flow and the cleaning ability.

So when you spin a brush in a machine, there are a couple of standardized brushes that would be used in products in this industry. It's important to understand that the action of the brush is to surface comb the tips of the carpet.

Many people, even in this industry, think that bristles reach down in and comb deeply embedded dirt up to the surface. They never do that under any circumstances. They are combing the tips and if you look at the bristle on a brush you'll see it's relatively short and once the brush is set into a housing that bristle is just meeting or exceeding the bottom of the intake of the housing. So it's a surface grooming tool. It's an assist to the process but the key to deep cleaning or carpet is to have plenty of airflow and suction. Now some believe that air flow is the most important part of the equation but there's a link between the airflow and the suction and both are needed. A very good example is, if one is trying to clean powdered sugar off a table, that product, that material is extremely lightweight. The surface has very little tension. Airflow really would be all that's needed to remove that powdered sugar and bring it back to the container.

If we were trying to dig sludge out of a production pit in a manufacturing facility, we would need lots and lots of suction to lift it and then the air flow is necessary to help carry it back to the container, whichever container it is. So it's the melding of those two processes that achieves proper vacuuming.

So a brush is combing the tips while the airflow and the suction is deep cleaning the carpet. So the apertures I mentioned before are important because we want to maximize that type of airflow. For a turbine brush, it's used typically for upholstery. The industry makes turbine brushes for cleaning rugs. Many manufacturers will offer them as options in their cleaning equipment.

If you use a turbine brush on an average carpet especially if it's thicker or longer you are not going to effectively deep clean that carpet. In contrast, if you look at an electrified brush, the intake on the brush is huge coming all the way across and back and keeping that inch or inch and a quarter opening so that the airflow can have its effect. There's a motor in the tool which spins the brush.

So it's a surface cleaning tool. So that high airflow is very important. we don't recommend that you use turbine brushes. Once the particles are in the vacuum, as highlighted before, you need to keep them in the machine. You need those air tight seals. The air has to leave at some point so you need to contain as many particles as they come into the machine as possible and that's accomplished in two or three different ways.

The first is the bagging mechanism that's in the machine. The vacuum is assailed with fine particles and you cannot properly empty the machine with any degree of being sanitary. The particles are flying all over the place so a bag is a necessity. An average industry standard bag are traditional bags they will contain only the larger particles. Then we march through bag design we might say when you hit a properly designed bag. Like a bag from a Miele which is a German vacuum cleaner.

There are nine layers of filtration in this bag. Its function is to capture particles well and to keep as many as possible in the bag but yet allow the airflow to come properly through so you can continue to clean. So the design of a bag is extremely important.

After the bag, there's typically a secondary filter. The final filter on the vacuum is what determines the final air quality in connection with this airtight design. So that final filter is very important. The vacuum cleaner industry uses the term HEPA or HEPA like in an extremely casual manner.

When you see a high-grade filter, like the Miele filter, it is completely sealed. If you tried to take this apart with a screwdriver, it would probably take you ten or fifteen minutes.

It's a certified S Class HEPA filter and it has a gasket and when it fits into the compartment in which it resides there's no air bypass. Everything has to go through the filter. This means everything, bacteria size is removed. This is extremely important.

To recap we need to be able to vacuum effectively when we have agitation. Also if your product is using a spinning brush, there are two types of belts typically. Stretch rubber belts which needs replacement and then a cog belt, or a timing belt if you will. It has teeth, it doesn't stretch. The brushes always spun at a proper speed. And if you typically Jam the product, like picking up a t-shirt under a bed, most of those designs involve the tool shutting down, the brush shutting down. It protects the belt. You may never replace the belt.

So agitation design is important. Looking at a power brush motor you can see it's small. Its function is simply to spin the brush, as we get into suction motors they vary this is a small compact but very high efficiency suction motor this again can be seen on a Miele vacuum, a German machine. This is a standard twin fan suction motor made by the Ametek lam people. This type of motor would be used in many different vacuums in this industry. It is larger and heavier motors come with one fan 2 fans and 3 fans. The more fans the more cleaning efficiency. When we get into commercial products the motors get bigger because the larger the fan chamber the more air is brought through the machine. In a domestic pull around vacuum, this type of motor would be too big and too heavy. So the standard size motors and vacuums in canister and upright machines are in this range.

This is a standard size for a power tool. These are the types of brushes, the belts the airflow. I've discussed the filtration. All these result in a machine that will give you the proper cleaning efficiency and keep the particles inside the vacuum. So when you choose a vacuum cleaner, these are the things that need to be in the forefront of your mind. I think that if you buy right you buy once, you'll be totally pleased with the product

0 notes

Text

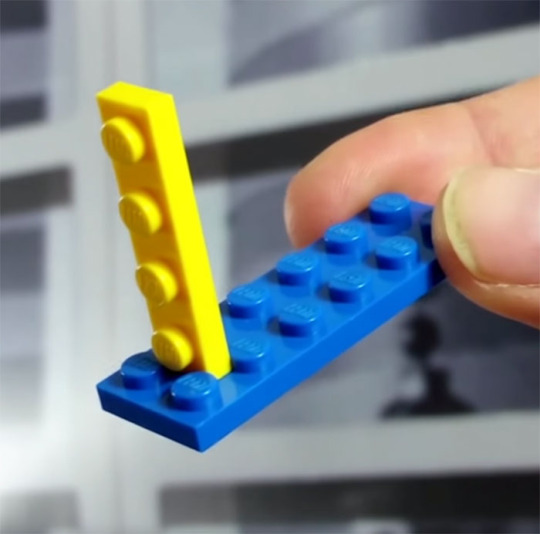

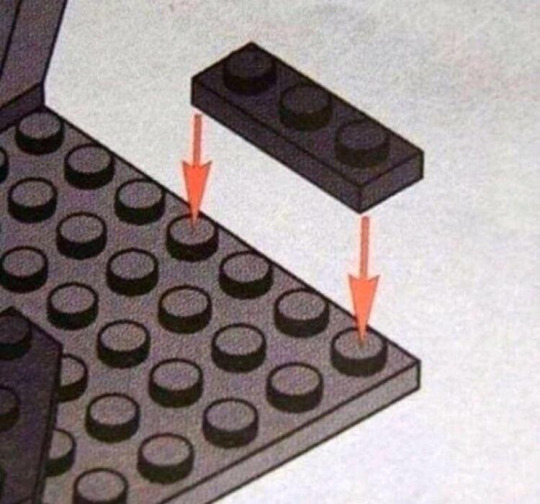

Nothing Illegal here. is there?

mods are asleep post illegal lego building techniques

108K notes

·

View notes