Explore Spray Contec Inc. for MSA safety equipment and industrial solutions. We proudly serve USA and the Middle East with top-quality products service.

Don't wanna be here? Send us removal request.

Text

0 notes

Text

MSA Safety: The Importance of MSA Safety in Protecting Workers – A Comprehensive Guide

In these days’s international, the protection and nicely-being of humans is paramount. Whether they'll be working in excessive-risk industries which includes production, mining, or oil and fuel, or in business company settings like manufacturing, protective humans from place of work risks is crucial. This is wherein MSA Safety steps in, presenting cutting-edge-day and reliable answers designed to make certain worker protection in numerous environments. In this guide, we’ll find out the significance of MSA Safety and why it’s crucial in protective employees on the assignment.

What is MSA Safety?

MSA Safety is a international leader in supplying modern-day protection merchandise and answers. Founded in 1914, the economic organization agency makes a speciality of developing and production personal protective device (PPE) and safety merchandise that protect employees from a big type of risks. These merchandises are essential for industries wherein employees are uncovered to risks together with toxic gases, fires, falls, and extra.

The Importance of MSA Safety in Protecting Workers

Worker safety is a essential scenario for groups and companies the world over. MSA Safety plays a critical function in protective personnel with the beneficial useful resource of providing first-rate, dependable, and advanced protection device. Here are some key motives why MSA Safety is so crucial:

1. Protecting Against Workplace Hazards

One of the primary reasons MSA Safety is so important is its functionality to defend employees from functionality workplace dangers. Whether it’s protecting in opposition to respiratory dangers, exposure to poisonous chemical materials, or falling from heights, MSA Safety gives products in particular designed to mitigate dangers. For instance, their fuel detection machine is used to reveal the air amazing in volatile environments, ensuring humans are not uncovered to volatile gases. Similarly, their fall safety systems save you injuries with the aid of providing reliable beneficial useful resource to employees going for walks at heights.

2. Ensuring Compliance with Safety Regulations

Employers are required via law to conform with protection requirements and suggestions, which incorporates folks that relate to worker safety. MSA Safety products are designed to fulfill or exceed the protection rules cited thru occupational health and safety authorities which encompass OSHA (Occupational Safety and Health Administration) and the National Institute for Occupational Safety and Health (NIOSH). By the use of MSA Safety merchandise, employers can make sure that their places of work meet those protection necessities and keep away from the crook and economic results of non-compliance.

3. Minimizing Workplace Injuries

Accidents inside the place of business can bring about intense injuries, extended healing times, or perhaps fatalities. Using MSA Safety merchandise, which includes head safety (difficult hats), taking note of protection, and respiratory device, permits reduce the hazard of accidents because of falls, flying debris, loud noises, and perilous airborne debris. MSA Safety constantly improves its merchandise to lower workplace injuries, offering superior generation and brilliant materials that stand the take a look at of time.

4. Enhancing Worker Productivity and Confidence

When human beings enjoy comfortable and protected, they'll be more confident and centered on their obligations. MSA Safety products no longer best defend personnel however moreover assist growth their productiveness. With exquisite gadget designed for comfort and simplicity of use, people are a top notch deal less probably to be distracted or fatigued, fundamental to advanced standard performance and higher huge venture substantial regular overall performance. This is in particular vital in annoying and immoderate-pressure environments.

5. Wide Range of Safety Solutions

MSA Safety offers a severa variety of protection solutions that cater to numerous industries and their specific goals. Whether it’s commercial enterprise corporation people requiring paying attention to protection or oil and fuel humans searching gas detection structures, MSA Safety has the right solution. The enterprise enterprise’s large product line includes fall protection machine, breathing protection, head protection, eye and face protection, and hundreds extra.

Key Products Offered with the aid of the usage of using using MSA Safety

Let’s take a better test a number of the important products provided via MSA Safety:

Gas Detectors: These devices come across risky gases collectively with carbon monoxide, methane, and hydrogen sulfide. MSA Safety gives portable and stuck gasoline detectors to expose air incredible in volatile environments, ensuring personnel' protection from poisonous publicity.

Fall Protection Equipment: MSA Safety designs and manufactures harnesses, lanyards, and exceptional fall protection tools to keep employees comfortable whilst walking at heights. These systems are critical in industries like manufacturing, roofing, and energy.

Respirators and Masks: For people exposed to airborne debris and contaminants, MSA Safety offers breathing protection answers that ensure clean air and save you inhalation of unstable materials.

Hard Hats and Head Protection: Protection from head injuries is vital in masses of workplaces. MSA Safety manufactures durable, reliable difficult hats that offer advanced safety from influences and falling items.

Hearing Protection: Prolonged exposure to loud environments can bring about everlasting taking note of damage. MSA Safety gives paying attention to protection solutions, along side earplugs and earmuffs, to help lessen noise exposure.

Why Choose MSA Safety?

Choosing MSA Safety manner selecting a business business enterprise with over a century of experience in the protection enterprise enterprise. MSA Safety is idea for its willpower to innovation, amazing, and worker safety. The business enterprise invests in studies and development to make certain its merchandise meet the modern-day safety necessities and technological enhancements.

Moreover, MSA Safety has a worldwide presence, presenting safety answers to a big range of industries global. Their products are relied on through personnel and corporations alike to maintain them cozy in volatile environments.

Conclusion

MSA Safety plays an crucial function in protecting personnel from the severa risks they face every day in diverse industries. From gasoline detection to fall safety, the corporation offers a big type of products designed to guard people and ensure compliance with protection regulations. By selecting MSA Safety, corporations can foster a manner of lifestyles of safety, lessen place of business injuries, and enhance worker self belief, all of which make contributions to a powerful and green frame of workers.

0 notes

Text

MSA Safety Products: Ensuring Worker Protection with Advanced Technology

In industries in which unstable environments are a steady threat, the protection of people is a top priority. MSA Safety Products is a major agency in providing splendid protection tool designed to shield people from potential dangers. With a reputation for innovation and reliability, MSA's style of merchandise offers essential safety in places of work, from manufacturing websites to chemical plant life and oil rigs. Their willpower to protection is contemplated in their use of advanced generation and non-forestall product development to satisfy the ever-changing needs of severa industries.

Why MSA Safety Products Are Crucial

Safety inside the place of work is more than just a compliance issue; it's far a moral obligation. Every employee merits to transport returned home successfully after an afternoon’s artwork. MSA Safety Products gives a big sort of private defensive device (PPE) designed to shield personnel from falling, publicity to harmful materials, and unique place of business dangers. These merchandises aren't exceptional engineered to fulfill company requirements however exceed them, presenting stronger safety and peace of mind for all humans and employers.

MSA has been a pioneer within the protection products industry, imparting solutions that assist prevent accidents, ailments, and fatalities. Their tool is utilized in a ramification of sectors, which includes advent, mining, firefighting, manufacturing, and electricity production. Whether it's far a fall protection gadget, respiration safety equipment, or gas detection device, MSA Safety Products is at the vanguard of defensive employees.

Range of MSA Safety Products

Fall Protection Systems

One of the maximum common dangers in industries like advent and utilities is falling from heights. MSA Safety Products offers a complete line of fall safety tool, consisting of harnesses, lanyards, and anchor factors. These products are designed to provide humans with the vital manual and safety while running at expanded heights. Whether it's far for maintenance on excessive-upward push homes or production of huge infrastructure, MSA's fall safety gear ensures that personnel live comfy.

Respiratory Protection

Respiratory dangers are a big assignment in industries like mining, chemical production, and healthcare. MSA Safety Products provides a big choice of respiration protection tools, in conjunction with respirators and air-purifying structures. These products defend personnel from inhaling poisonous fumes, dirt, and vapors that might reason serious breathing issues. MSA’s respiration products integrate consolation with modern-day technology, making it a whole lot less tough for personnel to breathe efficiently while acting their obligations.

Gas Detection Systems

In industries in which unstable gases and vapors are commonplace, detecting and tracking air exceptional is essential. MSA Safety Products gives innovative fuel detection structures that assist recognize hazardous gases in real-time. With transportable and glued gasoline detectors, those systems can warn personnel of the presence of volatile materials, stopping volatile publicity. MSA’s gasoline detection era is depended on with the useful resource of masses of specialists international for its accuracy and reliability.

Head Protection

Head injuries can be existence-threatening, making the need for terrific head safety critical. MSA Safety Products manufactures durable helmets and difficult hats which is probably designed to resist impact, offering maximum safety in opposition to falling objects and head trauma. These helmets are extensively applied in production, mining, and manufacturing settings, in which the hazard of head damage is immoderate. MSA’s head safety solutions additionally include accessories like face shields and ear safety, making sure whole safety for employees.

Hearing Protection

In noisy environments, listening to protection is vital for long-time period worker fitness. MSA Safety Products offers paying attention to protection answers, which incorporates earmuffs and earplugs. These merchandise are designed to reduce noise publicity, preventing listening to loss and associated situations. MSA’s taking note of protection tool is relaxed and adjustable, making sure that personnel can placed on them for prolonged durations without ache.

Advanced Technology in MSA Safety Products

What devices MSA Safety Products apart from unique protection equipment producers is their determination to integrating advanced era into their merchandise. By the use of present day materials and enhancements, MSA creates tool that isn't simplest durable but additionally notably effective in shielding people.

For instance, MSA Safety Products includes real-time monitoring generation in an entire lot of their gadgets. Gas detectors and monitoring structures can now connect to cloud-based totally absolutely systems, permitting safety managers to show employee protection remotely. This technological development permits in proactive preference-making, ensuring that people are continuously blanketed.

Moreover, MSA keeps to invest in studies and improvement to beautify the efficiency, consolation, and usability of their products. They take into account that the more secure and intuitive the system is, the more likely personnel will adhere to protection protocols.

Commitment to Worker Safety

MSA Safety Products is extra than just a industrial agency company; it's miles a associate in ensuring that people skip domestic comfortable. By making an investment in the present day generation, MSA offers protection solutions which can be each realistic and modern. They keep in mind that protection isn't always a one-size-suits-all solution, this is why their merchandise are customizable to meet the precise dreams of various industries and art work environments.

As place of work protection regulations hold to conform, MSA stays in advance of the curve, adapting its merchandise to satisfy the ones adjustments. Their ongoing commitment to worker protection has made them a trusted call inside the safety merchandise agency, and they hold to play a wonderful feature in decreasing place of business injuries and fatalities.

Conclusion

MSA Safety Products has constructed a legacy of be given as real with, reliability, and innovation. By imparting a entire sort of advanced era merchandise, they make certain that humans in all industries are well-included. From fall safety to gas detection, MSA offers the tool that allows save you injuries and accidents, growing more at ease running environments for all. Investing in MSA Safety Products is an funding inside the nicely-being of personnel, making it an crucial choice for corporations committed to providing a relaxed place of work.

In a international in which employee safety need to in no manner be compromised, MSA Safety Products is main the manner in making sure that workers are covered thru innovation, technology, and strength of mind to brilliant.

0 notes

Text

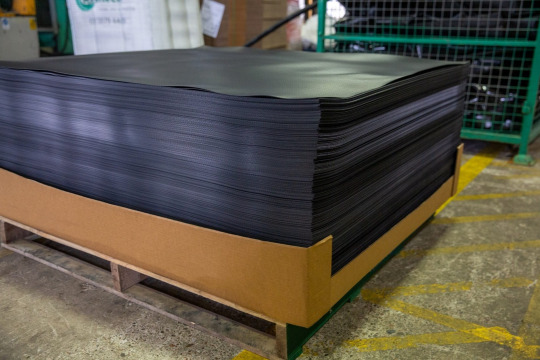

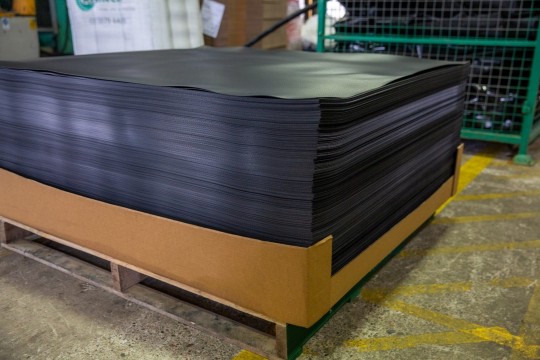

Why Plastic Slip Sheets Are the Best Alternative to Wooden Pallets in Logistics

In the modern-day-day logistics company, agencies are continuously looking for techniques to optimize their deliver chain, reduce expenses, and enhance desired common overall performance. One of the amazing solutions which have gained recognition in modern-day years is Plastic Slip Sheets. These sheets function a mild-weight and price-powerful opportunity to conventional wood pallets, making them a top notch desire for masses industries.

What Are Plastic Slip Sheets?

Plastic Slip Sheets are skinny, durable sheets crafted from excessive-density polyethylene (HDPE) or polypropylene (PP). They are designed to replace wood pallets in delivery and warehousing operations. These sheets permit for easy loading and unloading of merchandise using specialised push-pull attachments on forklifts.

Advantages of Using Plastic Slip Sheets Over Wooden Pallets

1. Cost-Effective Solution

One of the most critical reasons corporations are switching to Plastic Slip Sheets is their affordability. Unlike wood pallets, which require sizeable investments, slip sheets are plenty less expensive to manufacture and purchase. Businesses can preserve as an awful lot as eighty% on cloth costs via manner of changing traditional pallets with plastic alternatives.

2. Lightweight and Space-Saving

Plastic Slip Sheets are quite mild-weight in assessment to wood pallets. A relatively-current-day wooden pallet weighs around 30-50 kilos, on the same time as a slip sheet weighs a top notch deal plenty lots much less than 5 pounds. This drastic good buy in weight translates to lower transport costs and extended load functionality. Additionally, they soak up considerably an lousy lot a superb deal loads a lot less vicinity, permitting corporations to hold extra merchandise within the identical location.

3. Eco-Friendly and Sustainable

Many groups are specializing in sustainability, and Plastic Slip Sheets are an extraordinary way to lessen environmental impact. Unlike timber pallets that require decreasing down timber, plastic sheets are frequently made from recycled materials. They also are recyclable, contributing to a round economic gadget and reducing waste.

4. Increased Durability and Hygiene

Unlike timber pallets, that would soak up moisture and harbor bacteria, Plastic Slip Sheets are proof in opposition to water, chemical materials, and contaminants. This makes them excellent for industries like food, pharmaceuticals, and chemical materials, in which hygiene and safety are top priorities.

5. Easy Handling and Efficiency

Using Plastic Slip Sheets improves warehouse common average overall performance. Since they'll be moderate-weight, people can deal with them more without trouble than wooden pallets. Additionally, agencies the usage of slip sheets remove the want for pallet preservation, decreasing tough paintings costs and downtime.

6. Reduced Risk of Pests and Infestation

Wooden pallets are susceptible to pests like termites and fungi, that could contaminate shipments. Plastic Slip Sheets are pest-resistant, making sure that products live cozy in some unspecified time in the future of transportation.

7. Compliance with International Shipping Standards

Many international locations have strict hints on wood pallets, requiring fumigation and treatment earlier than use. With Plastic Slip Sheets, agencies can avoid the ones regulations, making sure smoother global shipments and decreasing compliance fees.

How to Implement Plastic Slip Sheets in Your Supply Chain

Switching to Plastic Slip Sheets requires minimal funding in new device. Businesses need a forklift with a push-pull attachment to deal with slip sheets correctly. These attachments are quite honestly to be had and may be set up on maximum famous forklifts.

Industries That Benefit from Plastic Slip Sheets

Several industries are already leveraging Plastic Slip Sheets for his or her logistics operations:

Food and Beverage: Ensuring hygiene and preventing infection.

Pharmaceuticals: Maintaining immoderate sanitary requirements.

Automotive: Reducing transportation charges for additives and components.

Retail and E-alternate: Maximizing warehouse garage and delivery regular regular overall performance.

Conclusion

As agencies are looking for charge-effective, sustainable, and green logistics answers, Plastic Slip Sheets become the great opportunity to wooden pallets. They offer numerous blessings, which embody decreased fees, extended common well-known performance, sustainability, and compliance with international delivery guidelines. By adopting Plastic Slip Sheets, groups can improve their supply chain on the same time as contributing to a greener planet.

0 notes

Text

Why Stainless-Steel Gate Valves Are Essential for Industrial Applications

In the arena of business employer methods, the significance of dependable and robust valves can't be overstated. Among the numerous forms of valves used, stainless steel gate valves stand out due to their severa advantages, making them an crucial problem in plenty of industries. These valves are generally hired in structures that require precise go with the flow control, sturdiness, and resistance to corrosion. This article will find out the importance of stainless-steel gate valves in company applications and highlight their key benefits.

What Are Stainless Steel Gate Valves?

A stainless steel gate valve is a type of valve that controls the go along with the glide of drinks and gases via manner of using lifting or reducing a gate (or wedge) into or out of the go with the flow path. These valves are typically implemented in pipelines wherein the go with the flow desires to be every simply open or really closed, presenting extraordinary sealing and minimal resistance. Made from notable stainless-steel, those valves are engineered to stand up to excessive situations, making them perfect for industries that require advanced standard overall performance.

Key Features of Stainless Steel Gate Valves

The versatility of stainless-steel gate valves lies in their layout and introduction. These valves are built with a gate that is raised or reduced via the motion of a stem, which can be operated manually or automatically. The stainless-steel material ensures sturdiness and reliability, especially in corrosive and immoderate-temperature environments. Some of the important aspect skills include:

Corrosion Resistance: Stainless metallic gate valves are alternatively evidence in competition to corrosion, making them appropriate to be used in aggressive environments, together with chemical materials, water, and steam.

Durability: The excessive-energy nature of chrome steel gives outstanding sturdiness, ensuring the valve can withstand immoderate pressures, temperatures, and terrific stressors in business company settings.

Minimal Flow Resistance: These valves offer little or no resistance to the go with the go together with the glide of fluids whilst fully open, which allows enhance device overall performance.

Reliable Sealing: The gate mechanism ensures that once the valve is definitely closed, it gives a amazing seal, stopping leaks and maintaining the integrity of the pipeline.

Applications of Stainless-Steel Gate Valves

The massive form of stainless-steel gate valve packages in the course of industries is a testament to their versatility and effectiveness. Here are a few key industries wherein the ones valves play a vital feature:

Oil and Gas Industry: In the oil and gasoline region, chrome steel gate valves are used to control the go with the flow of crude oil, herbal gas, and sensitive products. The valves are perfect for excessive-strain and excessive-temperature environments, wherein durability and protection are paramount.

Water Treatment Plants: Stainless metal gate valves are generally utilized in water remedy facilities to manipulate the go together with the float of water and wastewater. Their corrosion resistance is especially beneficial in environments in which publicity to water and chemical substances is not unusual.

Chemical and Petrochemical Industries: Due to their functionality to get up to corrosive materials, stainless steel gate valves are drastically used within the chemical and petrochemical industries. These valves make certain the relaxed and inexperienced operation of plants that cope with aggressive chemical substances.

Power Generation: In electricity flowers, stainless steel gate valves are critical for controlling steam and water go together with the glide in severa stages of electricity generation. Their sturdy construction guarantees they carry out reliably under immoderate conditions.

Food and Beverage: The food and beverage commercial enterprise agency is based totally totally on stainless steel gate valves due to their sanitary residences and the convenience with which they will be wiped easy. They are commonly utilized in pipelines that supply liquids which encompass milk, juices, and beer.

Pharmaceuticals: In pharmaceutical production, the want for clean, uncontaminated product go with the flow is important. Stainless metallic gate valves make certain a sanitary, leak-evidence seal, that is vital for retaining product purity.

Why Choose Stainless Steel Gate Valves?

Cost-Effectiveness: While chrome steel gate valves can also to start with seem more expensive than other materials, their sturdiness and resistance to corrosion purpose them to a cost-effective choice in the long run. With a lot less want for common replacements or upkeep, the ones valves offer high-quality value through the years.

Maintenance Benefits: The robust manufacturing and immoderate resistance to region on and tear imply that stainless steel gate valves require minimal protection. This consequences in a bargain a good deal a good deal less downtime and stepped forward typical performance for industrial operations.

Versatility: Stainless metallic gate valves can be applied in a considerable shape of applications, from controlling water go together with the glide to managing enormously corrosive substances. Their potential to feature beneath excessive pressure and temperature situations similarly offers to their versatility.

Safety and Compliance: Stainless steel gate valves meet rigorous protection and outstanding necessities, making sure that industries stay compliant with environmental and protection regulations. Their reliability lets in save you injuries and highly-priced breakdowns.

Conclusion

In prevent, stainless-steel gate valves are an essential a part of contemporary-day-day company applications. Their functionality to cope with immoderate situations, face up to corrosion, and provide dependable sealing makes them the proper preference for industries which consist of oil and gas, water treatment, prescription drugs, and additional. Whether you need to manipulate the go with the go with the go with the flow of water, chemical compounds, steam, or oil, those valves offer the durability and favored overall performance critical to ensure clean and inexperienced operation. Their low protection needs, lengthy company existence, and rate-effectiveness motive them to a top preference for industries looking to optimize overall performance at the same time as reducing downtime.

0 notes

Text

How Custom Flanges Improve Efficiency in Piping Systems

In the sector of commercial piping, performance and precision are key elements that decide the general overall performance of a gadget. One important issue that complements the overall performance of piping structures is Custom Flanges. Unlike big flanges, Custom Flanges are especially designed to healthful the precise requirements of a undertaking, making sure better overall performance, protection, and charge-effectiveness.

What Are Custom Flanges?

Custom Flanges are specialized flanges which might be manufactured based totally absolutely at the particular goals of a piping machine. They are tailor-made to house precise design parameters, fabric requirements, and operational conditions. Whether you need flanges for high-stress packages, severe temperatures, or corrosive environments, Custom Flanges offer an great solution.

Benefits of Custom Flanges in Piping Systems

1. Enhanced Performance and Precision

Standard flanges might not usually healthy perfectly inside a piping gadget, predominant to leaks, stress drops, and inefficiencies. Custom Flanges are designed with precise specifications, making sure a awesome fit and decreasing the dangers of operational disasters.

2. Increased Durability

Industries consisting of oil and fuel, chemical processing, and energy generation require flanges that could withstand harsh situations. Custom Flanges can be crafted from excessive-grade materials which include stainless-steel, carbon metal, and alloy substances, making sure longer existence and better resistance to put on and tear.

3. Cost Savings on Maintenance

Using Custom Flanges can extensively lessen maintenance expenses. Since they're designed to healthy precisely, they limit the opportunities of leaks, that can lead to high priced upkeep and downtime. Additionally, their stronger durability manner fewer replacements over time.

4. Adaptability to Unique System Requirements

Not all piping systems are constructed the equal. Some require flanges with specific dimensions, special coatings, or more appropriate sealing homes. Custom Flanges offer flexibility in layout, taking into account adjustments that preferred flanges cannot accommodate.

5. Improved Safety and Reliability

A poorly ready flange can be a excessive safety danger, important to leaks, bursts, or tool screw ups. Custom Flanges ensure a comfortable connection, decreasing the hazard of injuries and making sure compliance with industry safety requirements.

Applications of Custom Flanges

Custom Flanges are widely utilized in numerous industries in which famous flanges are not enough. Some of the essential issue packages encompass:

Oil and Gas Industry: High-stress and high-temperature environments require specialised flanges for secure operations.

Chemical Processing Plants: Corrosive chemicals name for flanges crafted from resistant materials.

Power Generation: Steam and thermal structures need robust and heat-resistant flanges.

Pharmaceutical Industry: Precision piping is crucial for preserving hygiene and compliance.

Water Treatment Plants: Custom designs assist in optimizing go with the flow and decreasing leakage risks.

Types of Custom Flanges

Slip-On Custom Flanges – Easy to put in and best for low-stress applications.

Weld Neck Custom Flanges – Provide higher reinforcement and are appropriate for excessive-stress structures.

Blind Custom Flanges – Used to seal off pipe ends for preservation or modifications.

Socket Weld Custom Flanges – Ideal for small-diameter and excessive-pressure programs.

Threaded Custom Flanges – Suitable for piping systems in which welding isn't always feasible.

Lap Joint Custom Flanges – Provide flexibility and simplicity of disassembly.

Factors to Consider When Choosing Custom Flanges

When deciding on Custom Flanges on your system, do not forget the following factors:

Material Compatibility: Choose substances that suit the operational surroundings.

Pressure and Temperature Ratings: Ensure the flange can resist the required pressure and temperature ranges.

Size and Dimensions: Accurate measurements are critical for a proper in shape.

Coating and Finishing: Corrosion-resistant coatings enhance the lifespan of flanges.

Compliance with Standards: Ensure the flanges meet industry necessities along with ANSI, ASME, or DIN.

Conclusion

Investing in Custom Flanges is a smart desire for industries that require performance, sturdiness, and precision of their piping systems. These tailored additives decorate overall performance, beautify safety, and reduce lengthy-time period prices. Whether you are operating in the oil and fuel area, electricity vegetation, or chemical processing, Custom Flanges offer a dependable and fee-powerful solution for optimizing your operations. By selecting the proper substances, layout specs, and manufacturing requirements, you can make sure a seamless and efficient piping machine for future years.

0 notes

Text

How Plastic Slip Sheets Reduce Shipping Costs and Improve Efficiency

In these days’s fast-paced logistics company, companies are constantly looking for techniques to reduce expenses and decorate efficiency. One of the brilliant answers is the use of Plastic Slip Sheets. These mild-weight however long lasting sheets replace traditional wooden pallets, imparting a couple of benefits, which consist of rate monetary economic financial savings, area optimization, and more wonderful environmental sustainability.

What Are Plastic Slip Sheets?

Plastic Slip Sheets are skinny, flexible sheets made from excessive-density polyethylene (HDPE) or polypropylene. They function a base for unitized masses, removing the need for bulky wooden pallets. These sheets allow forklifts prepared with a push-pull attachment to move devices successfully.

Benefits of Using Plastic Slip Sheets

1. Cost Reduction

One of the most critical advantages of Plastic Slip Sheets is their capacity to lower transport fees. Since they may be appreciably lighter than wooden pallets, they assist lessen freight costs. Additionally, their charge in keeping with unit is a lot decrease than timber pallets, making them a budget-first-rate preference for corporations.

2. Space Optimization

Unlike wood pallets that soak up massive space, Plastic Slip Sheets are pretty-thin and stackable. This approach greater products can be stored in warehouses and transported in boxes, maximizing garage overall overall performance.

3. Eco-Friendly Solution

Using Plastic Slip Sheets lets in lessen deforestation through doing away with the need for timber pallets. Moreover, they'll be recyclable and reusable, contributing to a sustainable deliver chain.

4. Improved Handling Efficiency

With the proper forklift attachments, Plastic Slip Sheets allow for quicker and smoother cloth managing. They lessen loading and unloading times, improving common warehouse productiveness.

5. Durability and Hygiene

Unlike timber pallets that may smash, splinter, or harbor pests, Plastic Slip Sheets are proof closer to moisture, chemical substances, and pests. This makes them ideal for industries like prescription drugs and food logistics.

How to Implement Plastic Slip Sheets in Your Business

To begin the use of Plastic Slip Sheets, groups want to spend money on a push-pull forklift attachment. These attachments allow operators to slide sheets results, making product coping with seamless. Training frame of people at the contemporary machine guarantees a easy transition from traditional pallets to Plastic Slip Sheets.

Conclusion

The adoption of Plastic Slip Sheets is a endeavor-changer for agencies seeking to optimize costs and overall performance in logistics. Their slight-weight, long lasting, and green nature makes them a superior alternative to traditional pallets. If your industrial agency dreams to reduce charges and beautify operational overall performance, it’s time to undergo in mind switching to Plastic Slip Sheets.

0 notes

Text

How Custom Flanges Improve Efficiency in Piping Systems

In the sector of commercial piping, performance and precision are key elements that decide the general overall performance of a gadget. One important issue that complements the overall performance of piping structures is Custom Flanges. Unlike big flanges, Custom Flanges are especially designed to healthful the precise requirements of a undertaking, making sure better overall performance, protection, and charge-effectiveness.

What Are Custom Flanges?

Custom Flanges are specialized flanges which might be manufactured based totally absolutely at the particular goals of a piping machine. They are tailor-made to house precise design parameters, fabric requirements, and operational conditions. Whether you need flanges for high-stress packages, severe temperatures, or corrosive environments, Custom Flanges offer an great solution.

Benefits of Custom Flanges in Piping Systems

1. Enhanced Performance and Precision

Standard flanges might not usually healthy perfectly inside a piping gadget, predominant to leaks, stress drops, and inefficiencies. Custom Flanges are designed with precise specifications, making sure a awesome fit and decreasing the dangers of operational disasters.

2. Increased Durability

Industries consisting of oil and fuel, chemical processing, and energy generation require flanges that could withstand harsh situations. Custom Flanges can be crafted from excessive-grade materials which include stainless-steel, carbon metal, and alloy substances, making sure longer existence and better resistance to put on and tear.

3. Cost Savings on Maintenance

Using Custom Flanges can extensively lessen maintenance expenses. Since they're designed to healthy precisely, they limit the opportunities of leaks, that can lead to high priced upkeep and downtime. Additionally, their stronger durability manner fewer replacements over time.

4. Adaptability to Unique System Requirements

Not all piping systems are constructed the equal. Some require flanges with specific dimensions, special coatings, or more appropriate sealing homes. Custom Flanges offer flexibility in layout, taking into account adjustments that preferred flanges cannot accommodate.

5. Improved Safety and Reliability

A poorly ready flange can be a excessive safety danger, important to leaks, bursts, or tool screw ups. Custom Flanges ensure a comfortable connection, decreasing the hazard of injuries and making sure compliance with industry safety requirements.

Applications of Custom Flanges

Custom Flanges are widely utilized in numerous industries in which famous flanges are not enough. Some of the essential issue packages encompass:

Oil and Gas Industry: High-stress and high-temperature environments require specialised flanges for secure operations.

Chemical Processing Plants: Corrosive chemicals name for flanges crafted from resistant materials.

Power Generation: Steam and thermal structures need robust and heat-resistant flanges.

Pharmaceutical Industry: Precision piping is crucial for preserving hygiene and compliance.

Water Treatment Plants: Custom designs assist in optimizing go with the flow and decreasing leakage risks.

Types of Custom Flanges

Slip-On Custom Flanges – Easy to put in and best for low-stress applications.

Weld Neck Custom Flanges – Provide higher reinforcement and are appropriate for excessive-stress structures.

Blind Custom Flanges – Used to seal off pipe ends for preservation or modifications.

Socket Weld Custom Flanges – Ideal for small-diameter and excessive-pressure programs.

Threaded Custom Flanges – Suitable for piping systems in which welding isn't always feasible.

Lap Joint Custom Flanges – Provide flexibility and simplicity of disassembly.

Factors to Consider When Choosing Custom Flanges

When deciding on Custom Flanges on your system, do not forget the following factors:

Material Compatibility: Choose substances that suit the operational surroundings.

Pressure and Temperature Ratings: Ensure the flange can resist the required pressure and temperature ranges.

Size and Dimensions: Accurate measurements are critical for a proper in shape.

Coating and Finishing: Corrosion-resistant coatings enhance the lifespan of flanges.

Compliance with Standards: Ensure the flanges meet industry necessities along with ANSI, ASME, or DIN.

Conclusion

Investing in Custom Flanges is a smart desire for industries that require performance, sturdiness, and precision of their piping systems. These tailored additives decorate overall performance, beautify safety, and reduce lengthy-time period prices. Whether you are operating in the oil and fuel area, electricity vegetation, or chemical processing, Custom Flanges offer a dependable and fee-powerful solution for optimizing your operations. By selecting the proper substances, layout specs, and manufacturing requirements, you can make sure a seamless and efficient piping machine for future years.

0 notes

Text

Premium Stainless Steel Gate Valves – Durable & Reliable | Spray Contec Inc.

Looking for excellent stainless-steel gate valves? Spray Contec Inc. Gives durable, corrosion-resistant valves on your business desires. Our stainless steel gate valves ensure reliable performance in even the maximum stressful packages. Browse our range of pinnacle-quality valves designed for lengthy-time period use. Perfect for water, gas, and different fluid systems. Explore our collection and find the great valve solutions today!

0 notes

Text

Customizable Plastic Slip Sheets | Spray Contec Inc.

Discover superb, customizable plastic slip sheets at Spray Contec Inc. Our reliable and value-powerful answers are designed to enhance your delivery and storage efficiency. Whether you need a single sheet or bulk orders, our durable slip sheets are engineered to withstand the rigors of transportation and warehouse operations. With easy customization options to fulfill your specific desires, Spray Contec Inc. Ensures you get the right solution to your commercial enterprise. Enhance your logistics procedures with our premium plastic slip sheets these days. Order now for a smoother, greater green workflow!

0 notes

Text

Safety Masks - Protect Against Dust, Chemicals & More | Spray Contec Inc.

Shop for safety masks at Spray Contec Inc. Designed to protect in opposition to dust, chemicals, and different airborne risks. Our mask provide advanced safety, ensuring your safety in environments with harmful debris. Whether you’re in creation, chemical compounds, or healthcare, our masks provide comfort and reliability. Shop now to protect your respiration fitness.

0 notes

Text

Safety Masks - Protect Against Dust, Chemicals & More | Spray Contec Inc.

Shop for safety masks at Spray Contec Inc. Designed to protect in opposition to dust, chemicals, and different airborne risks. Our mask provide advanced safety, ensuring your safety in environments with harmful debris. Whether you’re in creation, chemical compounds, or healthcare, our masks provide comfort and reliability. Shop now to protect your respiration fitness.

0 notes

Text

MSA Safety Solutions | Top Industrial Safety Equipment at Spray Contec Inc.

Explore MSA Safety solutions at Spray Contec Inc. Our company offers the highest quality industrial safety products designed to protect workers across the USA and the Middle East. With a focus on durability and reliability, MSA safety equipment is trusted worldwide. From head protection to respiratory solutions, we provide comprehensive safety measures for various industries. Discover our diverse range of MSA products and ensure a safer working environment for your team. Browse through our extensive collection and find the right solutions tailored to your needs.

0 notes

Text

Chemical Resistant Gloves - Protection for Hazardous Work | Spray Contec Inc.

Discover great chemical resistant gloves at Spray Contec Inc. Our gloves are designed to defend your arms from dangerous chemical compounds, making sure protection in laboratories, factories, and different risky environments. With superior sturdiness and flexibility, these gloves offer the protection you need. Shop now for reliable chemical resistant gloves that prioritize your protection.

0 notes

Text

MSA Safety Equipment | Premium Industrial Safety Gear at Spray Contec Inc.

Shop for pinnacle-grade MSA safety gadget at Spray Contec Inc. We specialize in delivering high-overall performance industrial protection gear to customers within the USA and the Middle East. Whether you are in need of protective helmets, fall safety structures, or breathing gadgets, our MSA safety equipment offers the excellent in nice and innovation. With a commitment to employee safety, our products are designed to meet rigorous standards and ensure dependable protection. Browse our good sized collection today to locate the correct MSA protection solutions in your industry.

0 notes

Text

0 notes

Text

Custom Plastic Slip Sheets - Spray Contec Inc.

Spray Contec Inc. Offers customizable plastic slip sheets designed to enhance shipping and storage efficiency. Our durable, value-effective slip sheets are ideal for reducing garage space and improving logistical strategies. Available in diverse sizes, our plastic slip sheets are ideal for organizations searching out dependable and environmentally friendly options to conventional wooden pallets. With a focal point on excellent and performance, we supply products that meet your precise desires. Whether you’re in manufacturing, retail, or logistics, our plastic slip sheets provide a sensible solution for optimizing your operations. Order now and streamline your shipping and storage wishes!

0 notes