Want to know more about Bricks? Let me teach you a lesson or two!

Don't wanna be here? Send us removal request.

Photo

Making the most out of bricks!

Musée Yves Saint Laurent, Marrakesh | Studio KO

206 notes

·

View notes

Photo

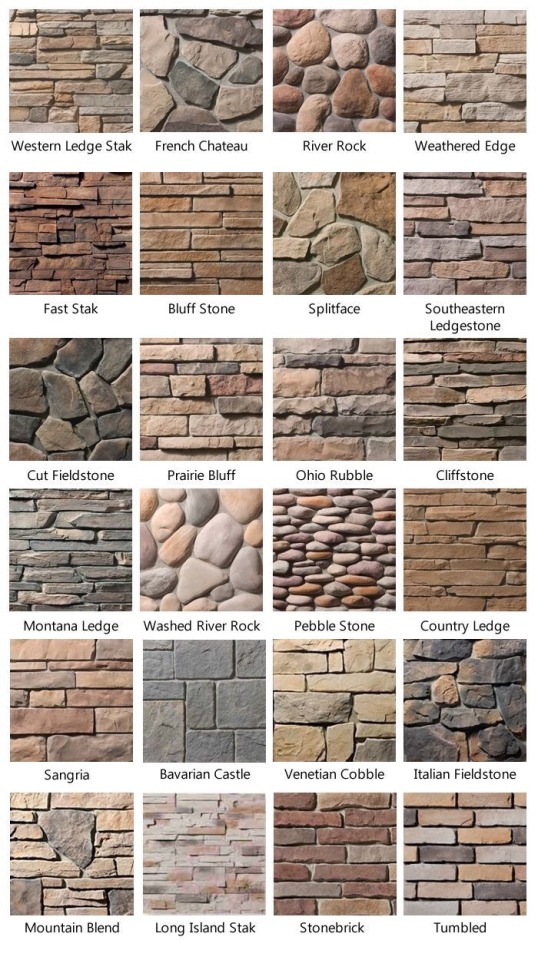

Different kind of bricks! Are you familiar with them?

Know your bricks!

81K notes

·

View notes

Text

Brick Flooring

Summary: If brick floor covering is likewise your fancy, you've come to the right page. Simply continue reading for intriguing details about brick flooring fancy.

Brick flooring has long been the dream of many homeowners in modern world homeowners like Gretchen Breuer. She had longed for those archetypal brick Romanesque or perhaps Baroque styles that feature heavily on brick and terra cotta. These gorgeous homes, though just recently fading away, are having a sluggish resurgence on remote villas and country facilities that harmonize the setting.

Really, brick houses are simply beautiful. They tie together with landscapes and yards. They stay cool even in the harshest sunshine and no other can give the exact same comfortable feel brick fireplaces can provide. And the older the bricks get the more exceptional appeal they have.

Brick floor coverings are just as stunning. Modern homes have actually opted to go for brick floor covering for foyers and anterooms. They make excellent footpaths for gardens. And they truly make charming living-room flooring especially if coupled with brick fireplaces and walls. A very country manor feel.

An undisputed leader in brick floor covering, Brick Floor Tile Inc. offers Genuine Brick Flooring in 1/2" or 15/16" in density. The brick floor covering provided at Brick Flooring Tile Inc. are unrivaled for its best mix of resilience and quality. And it is really produced too, the colors of their brick run throughout its mass that it stays the very same even when used.

When Port Stone Paver System stated that "A brick floor ..." "has a sense of permanence to it, like it's existed a long time", barely nobody could disagree. Portstone's brick flooring has the authentic rustic feel and an aged quality that is most cherished in brick tiles. Chip-off, split, and irregular formed to make them feel and look like genuine aged brick floor covering.

0 notes

Text

Pros And Cons Of Bricks And Blocks

Advantage:

BRICKS - It can hold up against heat thus offering fire security to your home or structures - It has better sound efficiency where it able to block the noise from outside. - It likewise uses lower utility cost. Energy efficient homes its intrinsic mass qualities assist keep a house cooler in the summertime and warmer in the winter season. - It reduces the nation's energy needs and produce a cleaner environment - It offers wide variety of non-fade colors. - It does not require painting for protection from being damaged like woods. - It is a load bearing material which is it likewise assist to support the structure. - It is virtually maintenance-free. It never needs painting, caulking or staining. - It will not burn or rot like other finish materials

BLOCKS As for the advantage of block, let's look at the building and construction strength. - Concrete block homes is much better in stand up to hurricane, twister and earthquake with the help of steel reinforcement. Put concrete are added in the central hollow area of the block walls. - While for the appraisal worth( forecast of future cash flows), the labor costs and material used to construct block houses are more affordable than wood frame home. - Most significantly blocks are environmentally friendly material. The blocks are made from sustainable resources that are recyclable. - Blocks are not subject to same damage as woods, therefore it require lesser repairs will decrease the effect on landfills.

BRICKS - Throughout severe weather, it may cause destruction of the surface area due to frost damage. - It includes a great deal of weight to the structure. Therefore it increases the tension of the structure which stronger structure had to support this bricks. - When the brick reveal some damage, it is not able to repair that part just however to remove the whole wall area which very costly. Plus, product used are mainly related. - Badly made bricks such as clinkers and older recycled bricks might be pitted, irregularly formed, worn or susceptible to chipping. - In humid climates, porous brick invites mold. It suffers damage as water and ice broaden and agreement in its pores. - Brick is not economical for lots of house contractors. It can be harmed by vines.

BLOCKS The drawback of block is for northern environments because the frame wall are not being insulated. For that reason, the cold air from the exterior will move into your house. Besides, block is not vulnerable to fire, mold and termites.

0 notes

Photo

Bricks can be of many use. Sometimes it could be used for it’s strength and durability, other times it can serve as an eye candy for passersby.

b r i c k

me at intstagram

206 notes

·

View notes

Photo

An example of how bricks helped shaped history! This shows that bricks are not only capable of withstanding through time, but can also give out a unique type of aesthetic.

Carlos Mijares. Capilla en Zacatecas, Mexico

735 notes

·

View notes

Text

Bricks - The Process

Background The term brick refers to little units of structure product, typically made from fired clay and secured with mortar, a bonding agent comprising of cement, sand, and water. Long a popular material, brick maintains heat, with-stands corrosion, and withstands fire. Due to the fact that each system is small-- normally 4 inches wide and two times as long, brick is a perfect product for structures in confined spaces, in addition to for curved styles. Additionally, with very little upkeep, brick structures typically last a long time.

For the above-cited practical factors and due to the fact that it is also a visually pleasing medium, brick has actually been used as a structure product for a minimum of 5,000 years. The first brick was most likely made in the Middle East, in between the Tigris and Euphrates rivers in exactly what is now Iraq. Lacking the stone their contemporaries in other regions used for permanent structures, early builders here depend on the abundant natural materials to make their sun-baked bricks. These, nevertheless, were of restricted use because they lacked durability and could not be used outdoors; exposure to the components caused them to break down. The Babylonians, who later on controlled Mesopotamia, were the very first to fire bricks, from which many of their tower-temples were built.

From the Middle East the art of brickmaking spread west to exactly what is now Egypt and east to Persia and India. Although the Greeks, having a numerous supply of stone, did not utilize much brick, evidence of brick kilns and structures remains throughout the Roman Empire. Nevertheless, with the decline and fall of Rome, brickmaking in Europe soon reduced. It did not resume until the 1200s, when the Dutch made bricks that they seem to have actually exported to England. In the Americas, individuals began to use brick during the 16th century. It was the Dutch, however, who were considered skilled craftsmen.

Prior to the mid-1800s, individuals made bricks in small batches, depending on relatively inefficient shooting methods. Among the most widely used was an open clamp, where bricks were put on a fire beneath a layer of dirt and utilized bricks. As the fire waned throughout several weeks, the bricks fired. Such approaches gradually became obsolete after 1865, when the Hoffmann kiln was invented in Germany. Better matched to the manufacture of great deals of bricks, this kiln contained a series of compartments through which stacked bricks were transferred for pre-heating, burning, and cooling.

Brickmaking enhancements have actually continued into the twentieth century. Improvements consist of rendering brick shape absolutely consistent, lessening weight, and accelerating the shooting procedure. For example, modern bricks are seldom solid. Some are pressed into shape, which leaves a frog, or anxiety, on their top surface area. Others are extruded with holes that will later speed up the firing process by exposing a bigger quantity of surface area to heat. Both techniques decrease weight without reducing strength.

However, while the production procedure has definitely enhanced, the market for brick has not. Brick does have the biggest share of the nontransparent materials market for business building, and it continues to be utilized as a siding product in the real estate industry. Nevertheless, other siding products such as wood, stucco, aluminum, plaster, and vinyl are strong competitors since they cost up to 50 percent less, and some (especially stucco and plaster) provide built-in insulation. Yet these systems can cost approximately 1.75 times that of brick, which also requires less maintenance. Other materials that take on brick despite their normally greater expense consist of precast concrete panels, glass, stone, artificial stone, concrete masonry, and mixes of these products, due to the fact that advances in manufacturing and style have made such materials more attractive to the home builder. According to the U.S. Industrial Outlook, using brick as a siding material for single-family houses dropped from 26 percent in 1984 to 17 percent in 1989.

Raw Products

Natural clay minerals, including kaolin and shale, comprise the main body of brick. Small amounts of manganese, barium, and other ingredients are combined with the clay to produce various tones, and barium carbonate is utilized to improve brick's chemical resistance to the components. Lots of other ingredients have actually been used in brick, including by-products from papermaking, ammonium compounds, wetting representatives, flocculents (which cause particles to form loose clusters) and deflocculents (which distribute such clusters). Some clays require the addition of sand or grog (pre-ground, pre-fired material such as scrap brick).

A wide range of finish materials and techniques are utilized to produce brick of a particular color or surface area texture. To create a typical covering, sand (the main part) is mechanically mixed with some type of colorant. Often a flux or frit (a glass consisting of colorants) is added to produce surface area textures. The flux decreases the melting temperature level of the sand so it can bond to the brick surface. Other materials including graded fired and unfired brick, nepheline syenite, and graded aggregate can be utilized also.

The Production

Process The preliminary step in producing brick is squashing and grinding the raw materials in a separator and a jaw crusher. Next, the mix of ingredients wanted for each specific batch is chosen and filtered before being sent on to one of three brick shaping procedures-- extrusion, molding, or pushing, the very first of which is the most adaptable and therefore the most common. Once the bricks are formed and any subsequent procedures performed, they are dried to remove excess moisture that might otherwise cause cracking during the occurring firing procedure. Next, they are fired in ovens and then cooled. Lastly, they are dehacked-- immediately stacked, covered with steel bands, and padded with plastic corner protectors.

Grinding, sizing, and integrating basic materials 1 First, each of the ingredients is conveyed to a separator that eliminates large-scale product. A jaw crusher with horizontal steel plates then squeezes the particles, rendering them still smaller sized. After the raw products for each batch of bricks have been chosen, a scalping screen is typically used to separate the different sizes of material. Material of the appropriate size is sent out to storage silos, and over-sized product goes to a hammermill, which crushes it with quickly moving steel hammers. The hammermill utilizes another screen to manage the maximum size of particle leaving the mill, and discharge goes to a number of vibrating screens that separate out product of inappropriate size before it is sent on to the next stage of production. Extrusion 2 With extrusion, the most common approach of brick forming, pulverized material and water are fed into one end of a pug mill, which uses knives on a turning shaft to cut through and fold together product in a shallow chamber. The mix is then fed into an extruder at the far end of the mill. The extruder normally includes two chambers. The first eliminates air from the ground clay with a vacuum, thus preventing splitting and other problems. The 2nd chamber, a high-pressure cylinder, condenses the material so the auger can extrude it through the die. After it is compressed, the plastic material is displaced of the chamber though a specifically shaped die orifice. The cross-section of the extruded column, called the "pug," is formed into the shape of the die. Areas of preferred length are cut to size with rotating knives or stiff wires. In molding, soft, damp clay is shaped in a mold, normally a wood box. The interior of package is frequently covered with sand, which supplies the preferred texture and helps with eliminating the formed brick from the mold. Water can also be utilized to assist release. Pressing, the third type of brick forming, needs a material with low water content. The product is placed in a die then compacted with a steel plunger set at a desired pressure. More routine fit and sharper in outline than brick made with the other 2 methods, pressed bricks likewise feature frogs.

Chamfering the brick 3 Chamfering machines were developed to produce a furrow in brick for such applications as paving. These makers use rollers to indent the brick as it is being extruded. They are often geared up with wire cutters to do the chamfering and cutting in one action. Such machines can produce as numerous as 20,000 systems per hour.

Coating 4 The choice of sand finishing, also applied as the brick is extruded, depends on how soft or difficult the extruded product is. A continuous, vibrating feeder is used to coat soft product, whereas for textured material the finish may need to be brushed or rolled on. For more difficult materials a pressure roller or compressed air is used, and, for extremely difficult materials, sand blasting is required.

Drying 5 Before the brick is fired, it should be dried to eliminate excess moisture. If this wetness is not removed, the water will burn off too quickly throughout shooting, causing cracking. 2 kinds of dryers are used. Tunnel dryers utilize cars to move the brick through humidity-controlled zones that avoid cracking. They consist of a long chamber through which the ware is gradually pressed. External sources of fan-circulated hot air are pushed into the dryer to speed the process. 6 Automatic chamber clothes dryers are likewise used, specifically in Europe. The extruded bricks are automatically positioned in rows on two parallel bars. The bricks are then fed onto special racks with finger-like gadgets that hold a number of sets of bars in several layers. These racks are then transferred by rail-mounted transfer cars or by lift trucks into the dryers.

Firing 7 After drying, the brick is filled onto automobiles (generally automatically) and fired to heats in furnaces called kilns. In general, the vehicles that moved the bricks through the drying process are also used to convey them through the tunnel kiln. These cars are pressed through the kiln's constantly maintained temperature zones at a specific rate that depends on the material. The majority of kilns in the United States use gas as a fuel source, though a third of the brick presently produced is fired utilizing strong fuels such as sawdust and coal. Tunnel kilns have changed in style from high-load, narrow-width kilns to shorter, lower-set larger kilns that can fire more brick. This type of design has actually also led to high-velocity, long-flame, and low-temperature flame burners, which have actually improved temperature harmony and reduced fuel usage. Setting and packaging 8 After the brick is fired and cooled, it is unloaded from the kiln automobile through the dehacking procedure, which has actually been automated to the point where almost all manual brickhandling is eliminated. Automated setting makers have been developed that can set brick at rates of over 18,000 per hour and can rotate the brick 180 degrees. Typically embeded in rows eleven bricks large, a stack is wrapped with steel bands and fitted with plastic strips that work as corner protectors. The packaged brick is then delivered to the job website, where it is normally unloaded utilizing boom trucks.

0 notes