PRECITOOLS presence in tumblr - Italian supplier of tube and sheet metal bending industrial solutions, tools and machinery

Don't wanna be here? Send us removal request.

Text

0 notes

Text

Tube bending mandrels

Mandrel tube bending is a technology we know very well, and tube bending tools are one of our core products.

With tube bending tools, it is quite complicated because we have a lot of requests, but we cannot cover them all because of the lack of drawings. All tube bending machines are different, connection dimensions are different, and there is no unification.

Another story about mandrels: we can supply mandrels to any machine. You can come with your sizes or requirements, or just provide us with the necessary information: parameters of the tube to be bent, length of mandrel, and thread for connection. This will be enough for our recommendations. We can provide any type of mandrel, from solid plugs to very complicated multi-ball constructions and solutions for rectangle and square tubes and special profiles.

Here is more information:

0 notes

Text

Multi-V bending dies for Promecam bending tooling system

For the Promecam tooling system, we offer 4V and 3U bending dies. These dies are the most universal product for starter sets for press brakes and have the economic possibility of working with different thicknesses. These dies could just be turned around to get other V-openings. It is also very effective for the customer who just starts to work with the press brake and has the necessity to prepare their actual parameters for die opening and tonnage to be used.

We also have a polyurethane insert for the V50 opening, so you can work to bend in polyurethane as well. And together with our 3U die, you can have the complete range of main used openings from 6 mm.

More information in our blog article about 4V / Multi-V bending dies for press brakes

In other systems, these dies could be used with adapters. Contact us if you need any additional information.

0 notes

Text

Promecam bending tools for high tonnage bending

We came today with a new, interesting text topic.

Even for the Promecam system, we are offering solutions to bend big thicknesses and special materials with tonnages bigger than 100 t/m. And if you need to perform this job, you also need to change the Promecam standard holders to HD clamps, and we can also supply them. We know how to calculate and study your requirements, to tell you the necessities of flange size and possible radius, and to warn you about the risks. Bending the thick material on the press brake is a very dedicated and special task, and you should be absolutely sure that you can do it and that it will not damage anything, including the parts and the beam of your press brake. Out of standard systems, we offer the special individual production of high-tonnage, heavy-duty reinforced tools for your needs to install big-tonnage press brakes. So contact us for the details, or you can follow our article about it as well!

0 notes

Text

Together with press brake tools, we are also able to supply panel bending tools for automatic panel bending centers and automatic folding machines and centers: Accurl, Amada, CIDAN, Durma, Erbend, LVD, Prima Power / Finn Power, Salvagnini, Schroder, Tecnoma, Trumpf, etc. Mainly these machine tools are used to make small height boxes and panels, very widely used in cooling industries and the production of refrigerators. If you will be able to provide the drawings and all necessary sizes we are able to offer the bending tools according to your specifications and lengths including the lateral horns with optimal precision and necessary grinding. We are absolutely sure that the price difference could be also the key to look for external supplier as well. We are open for your projects and inquiries. Contact us for any information.

0 notes

Text

Bending of radius shapes is a tricky thing. If it is a U-shape (or U-channel) (this means the sides should be 180 degrees) it will be a double tricky thing and it is impossible to achieve with the standard tools. The solution for bending should be to close the part more than 180 degrees to have the coefficient of return when the part is extracted. We are talking about it also in our blog. The hard story is that the radius bend makes the big spring back and it is not just a couple of angles. We study different ways of bending from offering standard tools to bumping tools with completely special complicated solutions.

Sure that each task is unique and conditions are different. For real big radiuses the U-shape bend could be achieved during 3 or 4 radius bends but if the distance of the lateral sides is small it will just make a collision with the tooling of the machine beam. Or probably it is possible to bend all in coining but it requires much more force. Anyway, we are open to your requests for radius bending so let us know if you study the tools for it.

1 note

·

View note

Text

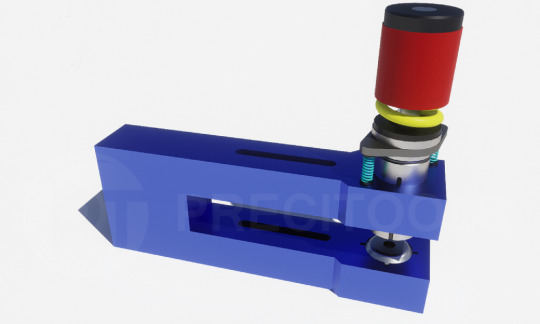

Today we will speak about punching units - small devices with big possibilities.

Mainly punching unit could be attached to any equipment with produced force - any press, hydraulic station, etc. But because we speak a lot of bending tools, for sure we will speak about the press brake.

Installation of a punching unit to the press brake could make a universal tool to punch the holes where necessary and then to make bending. Or to punch the holes, to form the holes, and then to make bending. If there is no punching press on production, with a punching unit installed on the press brake the factory now can do countersinks, embosses, dimples, lance and form shapes and any other forming necessary. And with the clever distribution of stations, it could be the ideal solution to punch and bend just between a few meters.

Punching units are available with their tooling but we also can supply punching units to use with a standard Thick Turret system with A, B, C, and D stations. In this way, tools are 100% interchangeable with punching press to divide the tasks and you are independent to find the supplier of main tooling to use. If it is possible, using several units at one time could speed also up the production process in time!

0 notes

Text

To tell the truth, bar and tube bending with the press brake - is quite a rare application that is requested if, for example, the customer needs to have simple bent bars directly at the same place and probably weld after together. With a tube it is more complicated - during the bending the tube wall could be easily deformed, so it is for applications where the ovality of the tube is not so important or necessary to make internal filler - sand for example. Anyway it is possible, used by some companies and the special bending tooling for press brake to bend tubes and bars is presented and we are ready to supply it as well. Well, as we told you before it is a special case because if you want constant production - it is more easy to purchase a simple tube bending machine. But with bar bending more force is necessary so the method to bend with press brake has its advantages. We publish it to show different possibilities for applications to be made with press brake.

0 notes

Text

By the way, we would like to note - we can supply blades for your guillotine shears as well. It should be under the drawing or sometimes if the model is well known probably the sizes are available. For sure our blades are high-quality products, Made in Italy for the long use and cutting of your sheet metal. High resistance of blade materials, precision manufacture, and verification of material thickness to be cut, including special steel like Domex, Weldox, Hardox, etc. In addition, we supply various types of blades and knives for sheet metal notching machines and punching and cutting automatic centers. We have competitive prices and good supplies already. For customers who can wait 3 months, the prices could be more competitive and better. Anyway contact us and we will find the solution.

0 notes

Text

0 notes

Text

Sometimes sellers who deal with all press brake tooling systems have additional advantages to make the right solution. It happens rarely but happens when we offer the customer to buy adapters and the tooling from another system. Why? Because it is more effective and also cheaper than planning the geometry of a special punch and die. In this case, we have more flexibility and more wide choice of solutions we are offering to our potential customers. Anyway, the customer can compare with the offers and decide what is more interesting for him to proceed.

For all the questions please visit our website about bending tooling: https://www.press-brake-tools.com/

0 notes

Text

Dear All! All our customers, partners, colleagues, friends, and everybody else who browses about us on the Internet!

How it goes?

A lot of time we are answering this question like "not bad", "could be better", "everything is ok", "better than average", "so-so" etc.

We want to salute and congratulate all for the new upcoming year, wish to have a small rest and a nice celebration, and moreover wish that in the New Year 2024, we can reply about everything like "It is perfect", "Great", "It couldn't be better", "Incredible fine", "Outstanding!" so you will have all the things wonderful and ideal.

We wish to you all the best with your businesses, your work, your families, your relations, and your daily worries. Let everything be not just good and positive but amazingly perfect and gorgeous! Let us have an idle New Year, much better than all the previous ones, and bring maximum happiness to all of us. Let us wish to you the fulfillment of all your goals, achieving all your hopes, and solving all your problems. Or better, elimination of any problems. Good luck and be happy! All the best!

0 notes

Text

Another set for supply for our customer for TW System. By the way, we also made our new catalog 2023 edition for these style press brake tools so you can download and check it here:

Download PDF catalog of press brake tools TW System Line

We can provide any solution for the hemming/flattening applications including pre-bending, final flattening with complete pressing, or "tear type" hemming (which is used typically in door profiles) and for sure any special projects and applications. For sure we can supply complete sets, punches, or dies only as well as flattening hemming bar for TW-system dies (but should be with the threaded hole). One request for all your construction engineers and parts designers - please respect the minimum necessary size for the flanges, otherwise we have a lot of doubts and troubles at the beginning.

0 notes

Text

Before we made our articles on @Medium in English and other sources for another language. But now we decided that we need to move to our main company website and to make a blog there. So here is our new blog and everybody is welcome. If you are interested in technologies for sheet metal and tube deformation, fabrication, bending, and forming as well as press brake, and tube bending machinery, or just like to read short articles about industrial machine tools - you are warmly invited to visit us. And for sure if you are interested in any of our products do not hesitate to contact us any time.

0 notes

Text

Who likes the positive feedback from the customer about our bending tools? We are))) And for sure they help us with future projects as well. But to tell the truth, we have not a lot. The reason is quite simple - a lot of times we do not deal with production people, we deal with purchase managers and then they will just send our bending tools, for example, to the shop and other people will operate with them. And people need to work and to make their tasks, they do not have time to make photos and feedback. Anyway, we know that we are doing good and hope that our customers will return to us one more time or even more than once. Also, we are flexible so we can help with other projects and requests - not directly but we know a lot about the Italian industrial market to guide you to the right people and companies.

0 notes

Text

We suppose this article will be helpful for everybody without doubts

#press brake#CNC press brake#bending technologies#sheet metal#sheet metal bending#technology#engineering

0 notes

Text

Punching tools are not our core business (there are various reasons but anyway we are happy to receive new satisfied customers) and sometimes we offer complete projects for supply bending and punching - companies like it for the possibility to purchase all from single hands. And we like not-standard projects like specials and formings. For sure we can support all main manufacturers and trademarks of CNC punching presses. And we also know the solutions, how, for example, you can take your TRUMPF-style punching tools and put it with the adaptor (that we can offer) to your press brake. Not a lot of customers know it so for somebody we also open their eyes to what possibilities they can bring to their bending machine to work with louvers, for example.

#precitools#punching tools#punching tooling#sheet metal#production#punching sheet metal#louvers punching#technology#punching press

0 notes