Tried to find inner calm in the hustle and bustle of NYC but I instead became obsessed with it; I have yet to succeed in that.

Don't wanna be here? Send us removal request.

Photo

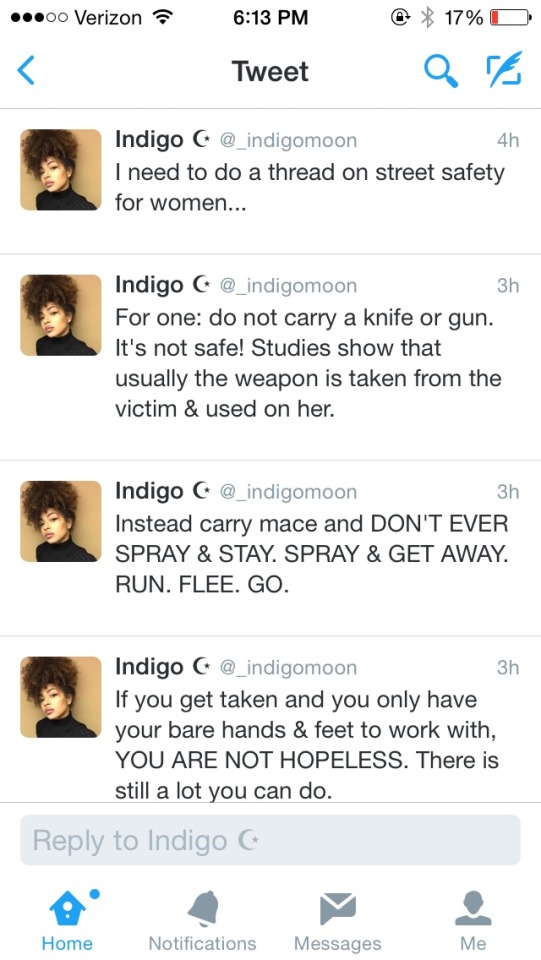

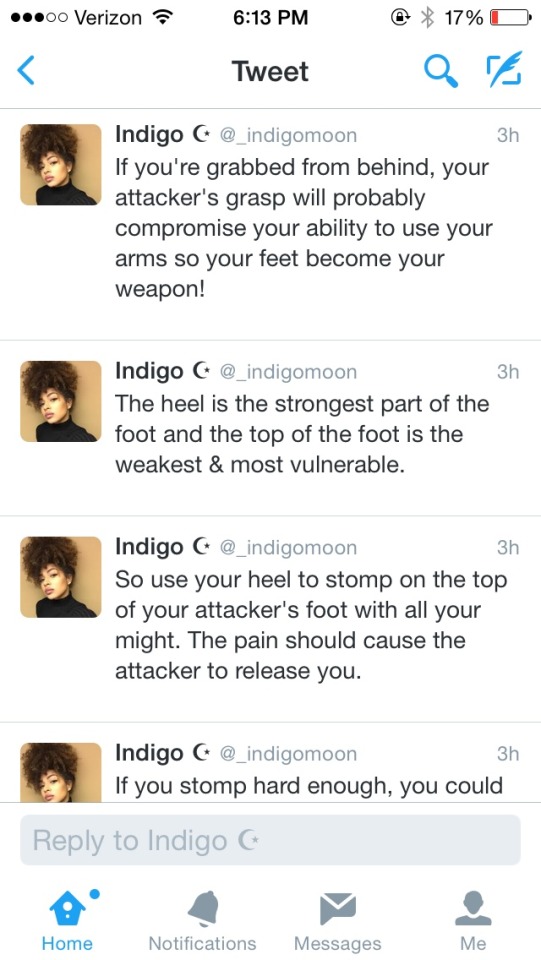

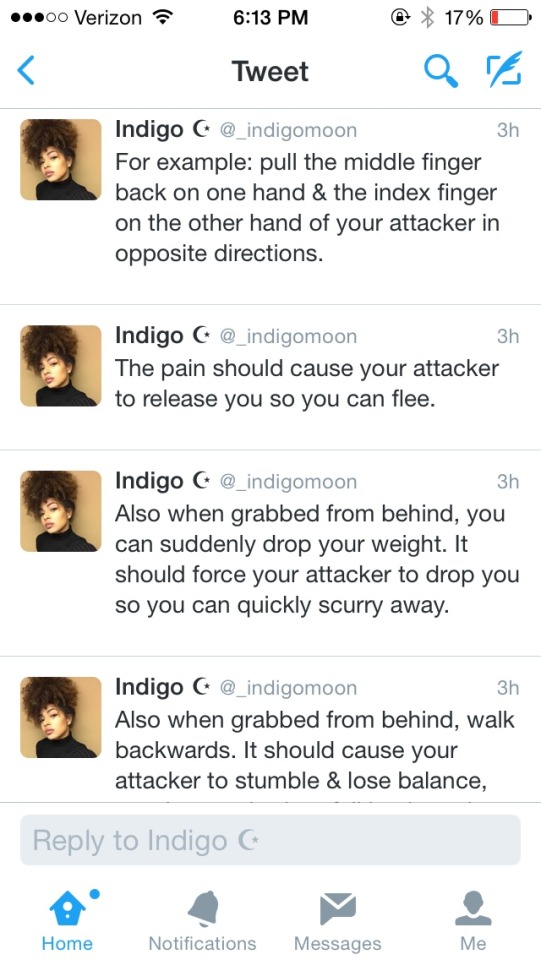

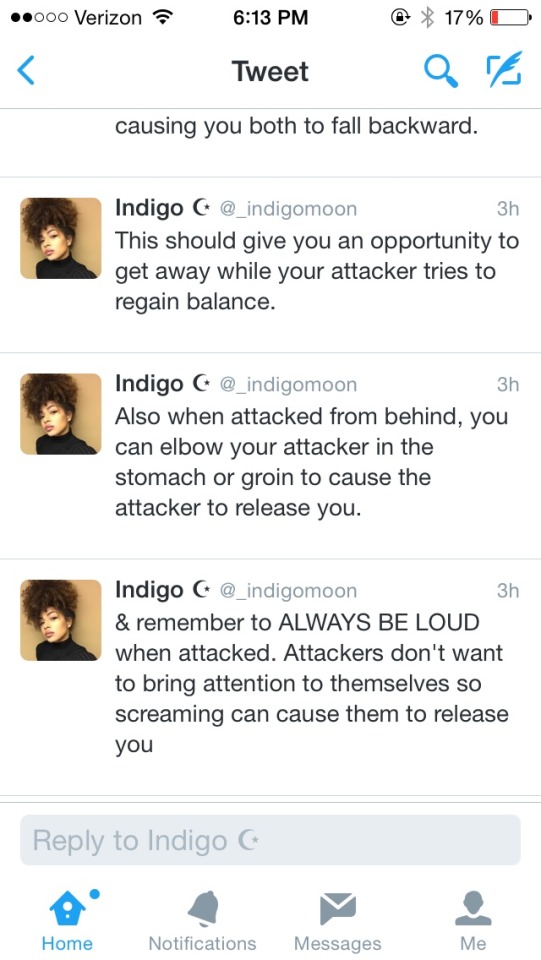

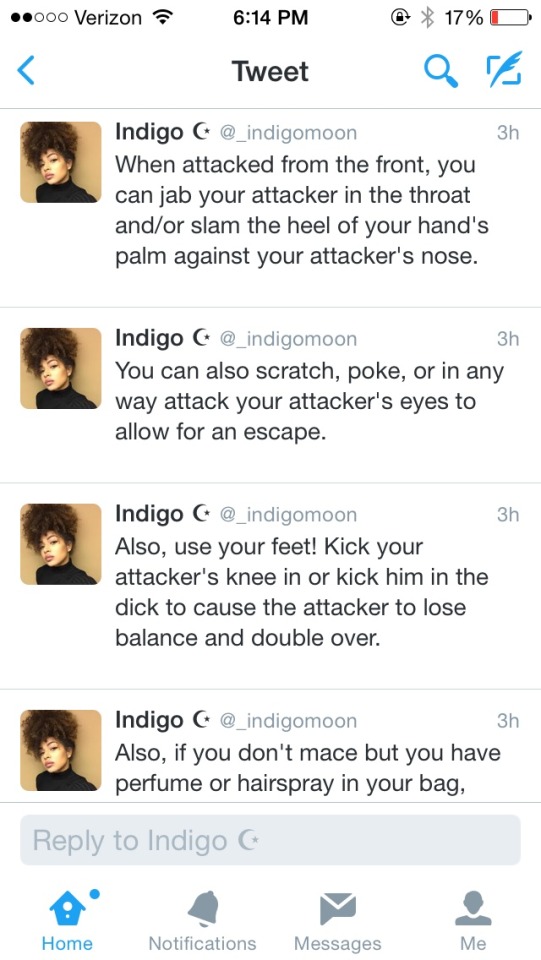

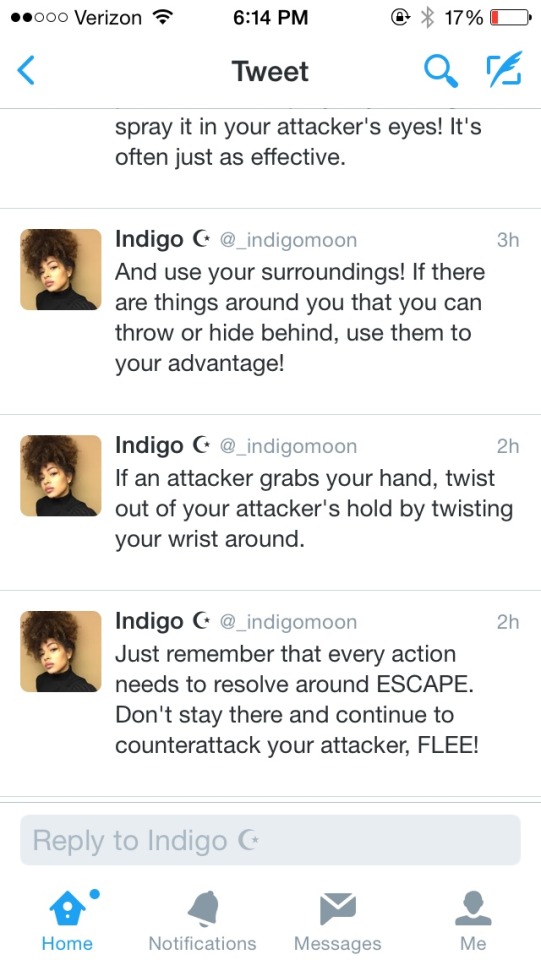

These aren’t my tweets, but I saw this and thought it could be helpful. ✨Girl Power✨

306K notes

·

View notes

Photo

32 Elegant White Bedroom Ideas

image credit: www.bellamumma.com

9 notes

·

View notes

Photo

In 2014, experienced soap business owners had a wealth of advice for those just starting out. Looking for some tips? Click through to read valuable business advice from fellow soapers!

26 notes

·

View notes

Photo

How I Make Soap - Part 7 of Many - Curing and Drying Handmade Soap

So I unmolded the my cold process and my hot process soaps.

You can see immediately, cold process produces smooth and perfectly molded soap and hot process produces a crackled “rustic” soap quality.

With hot process, all you need to do is let the soap dry out and become hard. Once it’s hard enough, maybe like a week, you can immediately use the soap. However, cold process the soap must be CURE at least 4 to 6 weeks before it can be used. This period of curing allows the remaining lye and fats become properly saponified.

I like to use a rack that optimizes air flow around the soap for the drying process. Leave the soap in a cool dry place and keep the soap out of direct sunlight, which may oxide ingredients in the soap. NOTE: I can’t remember the percentage, but obviously as the soap loses moisture the size will shrink. In most cases, you shouldn’t care, BUT if you are making soap to sell, you want to put a wrapper around the soap after the shrinkage occurs.

Well…that’s about it! I’ll make some more posts about other techniques in the future, but hope this brief tutorial on my soap making process will be helpful to some :-)

———

Part 1 - What is Soap

Part 2 - Working with Lye

Part 3 - Working with Oils and Additives

Part 4 - The Hardware

Part 5 - Cold Process Soap

Part 6 - Hot Process Soap

Part 6.5 - Handmolded Soap

Part 7 - Curing the Soap

———

Disclaimer: I am not a professional soapmaker. In fact, I am a sloppy and somewhat lazy soapmaker. I do what is most economical for my personal use and have no intention of selling at this time. I wanted to learn soapmaking as a way to reduce my carbon footprint, treat my body to a better product (not necessarily a cheaper product), and stick it to The Corporate Assholes…is what I wish I could say. But really, I’ve always wanted to make soap because Fight Club made it look so badass.

P.S. No…I have not experimented with human fat.

233 notes

·

View notes

Photo

How I Make Soap - Part 7 of Many - Curing and Drying Handmade Soap

So I unmolded the my cold process and my hot process soaps.

You can see immediately, cold process produces smooth and perfectly molded soap and hot process produces a crackled “rustic” soap quality.

With hot process, all you need to do is let the soap dry out and become hard. Once it’s hard enough, maybe like a week, you can immediately use the soap. However, cold process the soap must be CURE at least 4 to 6 weeks before it can be used. This period of curing allows the remaining lye and fats become properly saponified.

I like to use a rack that optimizes air flow around the soap for the drying process. Leave the soap in a cool dry place and keep the soap out of direct sunlight, which may oxide ingredients in the soap. NOTE: I can’t remember the percentage, but obviously as the soap loses moisture the size will shrink. In most cases, you shouldn’t care, BUT if you are making soap to sell, you want to put a wrapper around the soap after the shrinkage occurs.

Well…that’s about it! I’ll make some more posts about other techniques in the future, but hope this brief tutorial on my soap making process will be helpful to some :-)

———

Part 1 - What is Soap

Part 2 - Working with Lye

Part 3 - Working with Oils and Additives

Part 4 - The Hardware

Part 5 - Cold Process Soap

Part 6 - Hot Process Soap

Part 6.5 - Handmolded Soap

Part 7 - Curing the Soap

———

Disclaimer: I am not a professional soapmaker. In fact, I am a sloppy and somewhat lazy soapmaker. I do what is most economical for my personal use and have no intention of selling at this time. I wanted to learn soapmaking as a way to reduce my carbon footprint, treat my body to a better product (not necessarily a cheaper product), and stick it to The Corporate Assholes…is what I wish I could say. But really, I’ve always wanted to make soap because Fight Club made it look so badass.

P.S. No…I have not experimented with human fat.

233 notes

·

View notes

Quote

you know you’re fucked when those late night thoughts start hitting you in the middle of the day

(via diorky)

567K notes

·

View notes

Photo

Inspiration for my rainbow soap.

17 notes

·

View notes

Photo

Sound advice.

In 2014, experienced soap business owners had a wealth of advice for those just starting out. Looking for some tips? Click through to read valuable business advice from fellow soapers!

26 notes

·

View notes

Photo

32 Elegant White Bedroom Ideas

image credit: www.bellamumma.com

9 notes

·

View notes

Photo

Source For more posts like this, follow the Ultrafacts Blog!

35K notes

·

View notes

Link

0 notes