Don't wanna be here? Send us removal request.

Photo

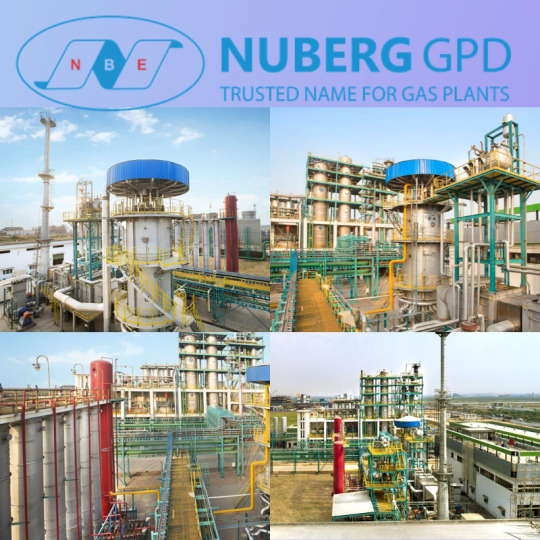

Nuberg GPD one of the trusted names for the Gas plants. Nuberg GPD offers Nitrogen Oxygen Hydrogen Gas Plants Manufacturer India and Across the world.

0 notes

Photo

SIDDHARTHA GUPTA, Director NUBERG Engineering Limited Giving Industrial Insights To Future Technocrats NUBERGGPD And Giving The Students Opportunity To Learn And Get Practical Knowledge By Sharing Hands On Experience Of ExPerts. For More Information :- http://nuberggpd.com/

0 notes

Text

Nitrogen-Copper-Dx-Oxo-Model

Another type of DE-OXO unit is used for additional cleaning using copper catalyst for removal of extra Oxygen, the moisture and Hydrogen contents and maintained upto 1PPM level.

For More details :- http://nuberggpd.com/

0 notes

Photo

PSA Oxygen Gas Plants | NUBERG GPD A Trusted Name For Gas Plants | Hydrogen, Nitrogen, Oxygen Gas Plants Manufacturer India.

0 notes

Link

0 notes

Photo

NUBERG ENGINEERING LIMITED : GAS PLANTS(GPD) A Trusted Name For Gas Plants.

Nuberg GPD one of the trusted name for gas plants. Nuberg GPD offers nitrogen gas, hydrogen gas, oxygen gas plants, and air dryer units across the world.

#hydrogengas#nitrogengas#oxygengas#nuberg#Nuberggpd#hydrogenplant#gasplants#nitrogenplants#gogreen#greentechnology

0 notes

Link

Nuberg GPD one of the trusted name for gas plants. Nuberg GPD offers nitrogen gas, hydrogen gas, oxygen gas plants, and air dryer units across the world. #Hydrogengasplants #Nitrogengasplants #Nuberggpd #Hydrogengas #Greentechnology #HydrogenPlants #NitrogenPlants #gogreen

0 notes

Photo

#Hydrogengasplants #HydrogenPlants #OxygenPlants #Greentechnology #Hydrogenpowerplants

0 notes

Text

Nitrogen Gas Plant

Pulling off an incredible feat, Nuberg Engineering Limited has commissioned its PSA Nitrogen Generator of flow rate 500 NM3/Hr, with 99.99% purity, installed in the complex of M/s Homs Refinery Ltd. In Homs City – Syria.

The unit will produce Nitrogen gas in service to ensure the need for gasoline production units. The Complete Design, Engineering, Manufacturing, Supply and Commissioning has been conducted by engineers of Nuberg Engineering Limited.

With a distinguished global expertise and continuous efforts of the Nuberg team, the production unit has been put in service to ensure the need of Nitrogen, which is a basic unit for Gasoline production where the product is obtained within half an hour of starting the operation.

The Importance of this unit lies in the generation and storage of Nitrogen. Necessary for the Gasoline production, particularly during the start-up of these units. Also, for the protection of units during pressurized suspension, which is done by Nitrogen purging. It is significant to clean up these units during the reconstruction of these compressors. This flushing of the system is performed by Nitrogen gas.

There are various stages to these units. The first one is Air Compression and the second one is Filtration of moisture and Nitrogen Adsorption by PSA technology and final stage is storage of Nitrogen.

Working in a warn torn area of Syria was a worrisome cause for the engineers on Nuberg. However commitment towards the customer and the work, engineers made sure that the unit is commissioned on time with desired outputs.

This achievement by Nuberg was also appreciated by Syrian media.

Having established more than 1000 PSA Nitrogen plants in more than 32 countries, Nuberg offers various models of Nitrogen plants based on PSA technology. Wiz:

1.Nitrogen MX Model

2.Nitrogen DX Model

3.Nitrogen COPPER-DEOXO System

Nitrogen MX Model:

This is the first and basic model for producing nitrogen gas plants which requires only compressed air in order to produce nitrogen Gas at a desired flow, Nitrogen Produced by PSA method in the TWIN TOWER CMS FILLED.

It simply works on the process called “PRESSURE SWING ADSORPTION”

Nitrogen is generated from atmospheric air “on-site” by installing a Captive PSA (Pressure Swing Adsorption) generator. Various models suitable for producing commercial nitrogen and ultra pure nitrogen are available. Gas is used in various industries for creating inert atmosphere. Gas produced by the plant is very economical as compared to cylinder / liquid nitrogen.

Nitrogen DX Model:

For Instance High Purity nitrogen DX model is introduced in the field of Nitrogen Genration Process, As DX Process leads to reduce oxygen content as low as it can i.e. below 5 ppm.

A PSA system is followed by additional purification unit using palladium as catalyst for removal of oxygen & moisture contents upto 1 PPM, Level with mostly desirable reducing constituent hydrogen (adjustable).

The Catalyst –Deoxo unit, used industrially ran with additional hydrogen feed, for exothermic reaction. O2 + 2H2 —– 2H2O

The Nitrogen, coming directly from the PSA system with the remaining oxygen, is mixed over mixer with Hydrogen before entering the catalyst reactor. At the catalyst surface the oxygen reacts with hydrogen to produce water and heat. The heat and water have to be removed by a standard water after cooler and gas dryer to required level. The remaining hydrogen concentration in the Nitrogen is around 0.5 to 1% minimum.

The high purity DX-Model finds application in chemical/electronics/metallurgical industries

Nitrogen Copper Dexo System:

This is second type of Deoxo unit is with additional after cleaning using copper for endothermic reaction for removal of extra oxygen, the moisture and hydrogen contents and maintained upto 1PPM level. This Ultra pure nitrogen gas finds application in electronic, synthetic fiber and optical fiber industries.

This De-Oxo unit needs two externally heated filled with copper as catalyst for the endothermic reaction.02 + 2Cu—-2CuO

The loaded copper bed can be regenerated by adding hydrogen during the regeneration step. For this two step process (Deoxidization and regeneration), two reactors are necessary to achieve a continuously operating De-Oxo system. The nitrogen form the PSA system with the remaining oxygen passes one of the reactors without adding hydrogen. ON passing through the reactor, the oxygen is removed by reacting with the copper surface, The advantage of the Deoxo unit based on the copper is that the high purity nitrogen leaves the unit absolutely dry & without any remaining hydrogen.

1 note

·

View note