Don't wanna be here? Send us removal request.

Text

How Fiber Laser Cutting Machines Benefit Marine Equipment Manufacturing

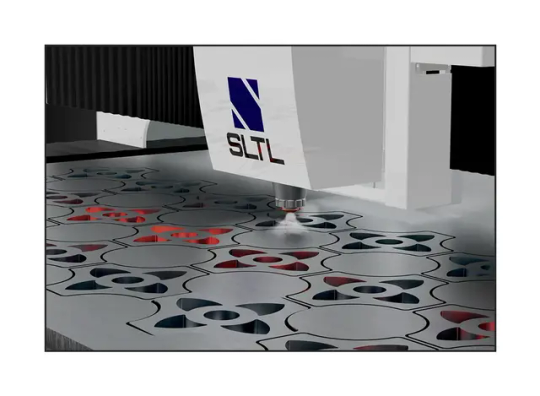

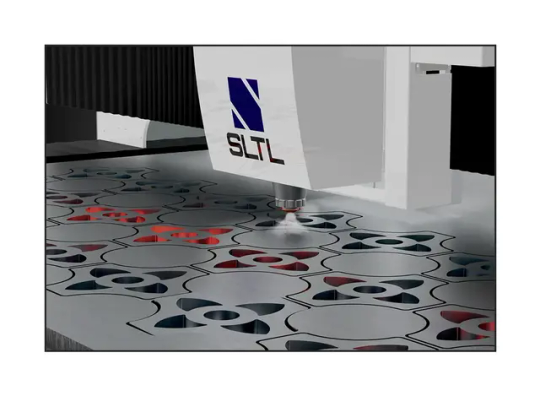

The marine industry demands precision, durability, and efficiency in manufacturing components for ships, boats, and other marine equipment. Fiber laser cutting machines have emerged as a key technology in meeting these demands. SLTL Group, a leader in laser cutting solutions, offers state-of-the-art fiber laser cutting machines that provide numerous advantages for marine equipment manufacturing.

The Importance of Precision in Marine Manufacturing

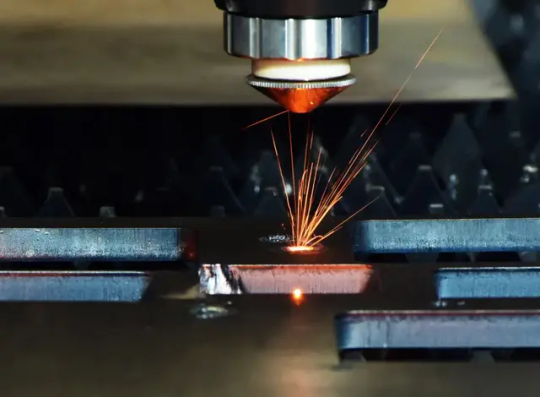

Marine equipment, such as ship hulls, propellers, and engine components, requires precise cutting and shaping to ensure proper function and longevity. Any errors in manufacturing can lead to serious consequences, such as equipment failure or reduced performance. Traditional cutting methods, like mechanical sawing or plasma cutting, often struggle to achieve the required precision and can introduce imperfections or stress into the materials.

Advantages of SLTL Group's Fiber Laser Cutting Machines

SLTL Group’s fiber laser cutting machines are designed to meet the high standards of the marine industry. Here are the key benefits:

1. Unmatched Precision

High Accuracy: Laser cutting machine can cut with incredible precision, allowing for tight tolerances and intricate designs that are essential in marine equipment manufacturing.

Smooth Edges: The clean cuts reduce the need for additional finishing processes, saving time and resources.

2. Efficiency and Speed

Faster Production: SLTL Group’s fiber laser machines cut faster than traditional methods, speeding up production timelines.

Automation Capabilities: These machines can be integrated into automated production lines, reducing labor costs and increasing throughput.

3. Material Versatility

Wide Range of Materials: Fiber lasers can cut various materials used in marine manufacturing, such as steel, aluminum, and composite materials.

Thickness Handling: The machines can handle different material thicknesses, providing flexibility in design and manufacturing.

4. Cost-Effective Operation

Low Maintenance: Fiber lasers require less maintenance compared to other cutting technologies, resulting in lower downtime and reduced operating costs.

Energy Efficiency: SLTL’s fiber lasers are energy-efficient, reducing overall energy consumption and contributing to a more sustainable manufacturing process.

5. Durability and Reliability

Robust Design: SLTL Group’s fiber laser machines are built to withstand the demanding environments of marine manufacturing facilities.

Consistent Performance: These machines deliver consistent cutting quality, ensuring every component meets the highest standards.

Best Features of SLTL Group's Laser Cutting Machines

SLTL Group's laser cutting machines are renowned for their advanced features, which make them a preferred choice in various industries. Here are the standout features:

High Precision Cutting

Ensures accurate cuts with tight tolerances.

Produces clean, burr-free edges, minimizing the need for secondary finishing.

Versatile Material Handling

Capable of cutting a wide range of materials, including metals, plastics, and composites.

Can process varying thicknesses, offering flexibility in manufacturing.

Advanced Automation

Supports integration with automated production lines for seamless operation.

Reduces manual intervention, lowering labor costs and increasing productivity.

Energy Efficiency

Utilizes fiber laser technology, which is more energy-efficient compared to traditional laser systems.

Contributes to lower operational costs and a reduced carbon footprint.

Durability and Reliability

Built with robust components designed to withstand industrial environments.

Provides consistent performance over long periods, ensuring reliability in production.

Benefits for Marine Equipment Manufacturing

Integrating SLTL Group’s fiber laser cutting machines into marine equipment manufacturing offers several key benefits:

Enhanced Quality Control: The precision and consistency of fiber lasers help maintain strict quality standards.

Reduced Waste: Accurate cutting minimizes material waste, leading to cost savings and a more sustainable operation.

Increased Production Capacity: Faster cutting speeds and automation allow for higher production volumes, meeting the growing demand in the marine industry.

Flexibility in Design: With the ability to cut complex shapes and various materials, manufacturers can innovate and create advanced designs for marine equipment.

Conclusion

SLTL Group fiber laser cutting machines provide the marine industry with a powerful tool for improving manufacturing processes. With their unmatched precision, efficiency, and versatility, these machines help marine equipment manufacturers achieve higher quality, reduce costs, and increase production capacity. As the marine industry continues to evolve, adopting advanced technologies like fiber laser cutting will be essential for staying competitive and meeting the demands of modern marine equipment.

For more information visit SLTL official website or contact at [email protected] or WhatsApp at +919925036495

0 notes

Text

Precision and Durability: Fiber Laser Cutting in the Marine Industry

SLTL Group, also known as Sahajanand Laser Technology Limited, is a pioneering leader in the laser cutting industry, renowned for its innovative and high-quality laser solutions. Established with a commitment to delivering cutting-edge technology, SLTL Group offers a comprehensive range of laser cutting machines that cater to diverse industries, including automotive, aerospace, electronics, and marine.

The marine industry is known for its stringent demands on precision, durability, and efficiency. To meet these demands, the use of advanced technologies is crucial. SLTL Group, a leader in laser cutting solutions, offers state-of-the-art fiber laser cutting machines that are revolutionizing the marine industry. Here’s a look at the advantages, benefits, and best features of SLTL Group’s laser cutting machines.

Advantages of SLTL Group’s Laser Cutting Machines

SLTL Group’s laser cutting machines offer several key advantages that make them a standout choice in the industry. They provide high precision and accuracy, ensuring intricate designs and exact measurements are met with ease. Their robust construction ensures long-term durability and minimal maintenance, making them a reliable investment.

High Precision: SLTL Group’s fiber laser cutting machines deliver exceptional precision, crucial for the intricate designs and exact measurements needed in the marine industry.

Durability: Built with robust materials and advanced technology, these machines ensure long-term performance and minimal maintenance.

Efficiency: The high-speed cutting capability of SLTL’s fiber lasers enhances productivity, allowing for quicker project completion.

Versatility: These machines can handle various materials, including steel, aluminum, and composites, making them ideal for diverse marine applications.

Benefits of Using Fiber Laser Cutting in the Marine Industry

SLTL Group’s laser cutting machines offer numerous benefits, making them an excellent choice for various industries. These machines provide unparalleled precision, enabling the creation of intricate designs with high accuracy. They are highly efficient, allowing for faster production times and reduced operational costs. With their ability to cut a wide range of materials, including metals and composites, SLTL’s laser cutters are incredibly versatile.

Enhanced Quality: Fiber laser cutting machine provides clean, precise cuts with smooth edges, reducing the need for secondary finishing processes.

Cost-Effective: The efficiency and speed of fiber laser cutting reduce production costs and waste, leading to significant savings.

Improved Safety: SLTL’s laser cutting machines come with advanced safety features, ensuring a safer working environment for operators.

Environmental Sustainability: Fiber laser cutting generates less waste and consumes less energy, supporting eco-friendly manufacturing practices.

Best Features of SLTL Group’s Fiber Laser Cutting Machines

Advanced Control Systems: These machines are equipped with intuitive control systems for easy operation and precise control over cutting parameters.

Automatic Loading and Unloading: Automated features reduce manual labor and enhance productivity, allowing for continuous operation.

Real-Time Monitoring: Integrated monitoring systems provide real-time feedback and diagnostics, ensuring optimal performance and timely maintenance.

Customizable Solutions: SLTL Group offers customizable machines tailored to meet specific needs and requirements of the marine industry.

Conclusion

The marine industry demands precision and durability, and SLTL Group fiber laser cutting machines are up to the task. With their high precision, durability, and efficiency, these machines provide numerous benefits and features that make them indispensable in the marine sector. Embracing SLTL Group’s cutting-edge technology ensures superior quality, cost savings, and enhanced safety, making it a smart choice for marine manufacturers. For more information visit SLTL official website or contact at [email protected] or WhatsApp at +919925036495

0 notes

Text

Enhancing Shipbuilding Efficiency with Fiber Laser Cutting Machines

SLTL Group, also known as Sahajanand Laser Technology Ltd., is a globally recognized leader in laser technology solutions. Established with a commitment to innovation and quality, SLTL Group designs and manufactures a wide range of laser systems, including laser cutting, welding, marking, and engraving machines. With a strong focus on research and development, the company delivers state-of-the-art products that cater to diverse industries such as automotive, aerospace, defense, and healthcare. Renowned for their reliability, precision, and advanced features, SLTL Group’s machines set industry standards and drive efficiency and productivity worldwide.

Shipbuilding is a complex industry that requires precision, speed, and reliability. The right tools and technology can significantly enhance the efficiency of the shipbuilding process. One such technology is fiber laser cutting machines, which are transforming the way ships are built. SLTL Group, a leader in laser technology, offers state-of-the-art fiber laser cutting machines that bring numerous advantages to the shipbuilding industry.

Advantages of Fiber Laser Cutting Machines in Shipbuilding

1. High Precision:

Fiber laser cutting machines from SLTL Group provide extremely accurate cuts, ensuring each component is made to exact specifications.

Precision is crucial in shipbuilding to ensure all parts fit perfectly, reducing the risk of errors and rework.

2. Increased Speed:

These machines operate at high speeds, significantly speeding up the cutting process.

Faster cutting times translate to shorter production cycles, allowing for quicker project completion.

3. Cost-Effectiveness:

Fiber laser cutting reduces material waste, which helps in cutting down costs.

Lower operational costs make these machines a cost-effective choice for shipbuilding projects.

Benefits of SLTL Group’s Fiber Laser Cutting Machines

1. Reliability:

SLTL Group’s fiber laser cutting machines are known for their reliability, ensuring consistent performance even in demanding shipbuilding environments.

Reliable machines mean fewer breakdowns and interruptions, leading to smoother operations.

2. Durability:

Constructed with high-quality materials, these machines are built to last.

Long-lasting machines reduce the need for frequent replacements, saving both time and money.

3. Versatility:

These machines can cut through a wide variety of materials, including metals and composites used in shipbuilding.

Versatility is essential for handling different components and materials required in the construction of ships.

Best Features of SLTL Group’s Fiber Laser Cutting Machines

SLTL Group’s laser cutting machines boast several outstanding features that set them apart. They utilize advanced laser technology to deliver high precision and clean cuts, ensuring top-quality results for a wide range of materials. The machines are designed with a user-friendly interface, making them easy to operate and reducing the risk of errors. They also include robust safety features to protect operators and maintain a safe working environment.

1. Advanced Technology:

SLTL Group incorporates the latest technology into their fiber laser cutting machines, ensuring top-notch performance.

Advanced features enhance the accuracy and efficiency of the cutting process, essential for high-quality shipbuilding.

2. User-Friendly Interface:

The machines come with an easy-to-use interface, making them accessible to operators with varying levels of experience.

A user-friendly interface reduces the likelihood of operational errors, ensuring a smooth workflow.

3. Enhanced Safety:

Safety is a critical concern in shipbuilding. SLTL Group’s machines are equipped with advanced safety features to protect operators.

Ensuring safe operations minimizes risks and promotes a secure working environment.

Conclusion

In the shipbuilding industry, where precision, speed, and reliability are vital, SLTL Group’s fiber laser cutting machines offer unparalleled advantages. Their high precision, increased speed, and cost-effectiveness, combined with SLTL Group’s commitment to reliability, durability, and advanced technology, make these machines an excellent choice for enhancing shipbuilding efficiency. By incorporating SLTL Group fiber laser cutting machines into your shipbuilding processes, you ensure the highest standards of quality and performance, paving the way for successful and efficient ship construction.

For more information visit SLTL official website or contact at [email protected] or WhatsApp at +919925036495

0 notes

Text

Fiber Laser Cutting in Defense Manufacturing: Ensuring Precision and Reliability

SLTL Group, a leading innovator in the laser technology industry, specializes in providing advanced solutions for a wide range of applications. Renowned for their cutting-edge laser cutting machines, particularly in the fields of metalworking and manufacturing, SLTL Group is dedicated to delivering high-quality, reliable, and efficient products. Their commitment to technological advancement and customer satisfaction makes them a trusted partner for industries seeking precision and excellence

In the fast-paced world of defense manufacturing, precision and reliability are paramount. The smallest error can have significant consequences, making it essential to use the best technology available. This is where SLTL Group’s fiber laser cutting machines come into play. They offer unmatched accuracy and efficiency, which are crucial for the defense industry.

Advantages of Fiber Laser Cutting in Defense Manufacturing

1. Unmatched Precision:

Fiber laser cutting machines deliver extremely high precision, ensuring every component is cut to exact specifications.

This precision is vital for defense equipment, where every part must fit perfectly.

2. Enhanced Speed:

These machines operate at high speeds, significantly reducing production time.

Faster production means quicker turnaround times for essential defense equipment.

3. Cost Efficiency:

Fiber laser cutting reduces material waste, which leads to cost savings.

Lower operational costs make it a cost-effective solution for defense manufacturing.

Benefits of SLTL Group’s Fiber Laser Cutting Machines

SLTL Group’s laser cutting machines offer numerous benefits, including high precision and efficiency, which ensure that every cut is accurate and clean. These machines are incredibly versatile, capable of cutting a wide range of materials with ease. They also significantly reduce material waste, making them a cost-effective solution for various industries. With their advanced technology and user-friendly interface, SLTL Group’s laser cutting machines are designed for optimal performance and reliability, ensuring smooth and uninterrupted operations.

1. Reliability:

SLTL Group’s machines are known for their reliability, operating consistently even under demanding conditions.

Reliable machines ensure uninterrupted production, which is critical in defense manufacturing.

2. Durability:

Built with high-quality materials, these machines have a long lifespan.

Durable machines reduce the need for frequent replacements, saving time and money.

3. Versatility:

Fiber laser cutting machines can cut through a variety of materials, including metals and composites.

This versatility is essential for manufacturing different types of defense equipment.

Best Features of SLTL Group’s Fiber Laser Cutting Machines

1. Advanced Technology:

SLTL Group integrates the latest technology into their machines, ensuring cutting-edge performance.

Advanced features enhance accuracy and efficiency, crucial for defense manufacturing.

2. User-Friendly Interface:

The machines come with easy-to-use interfaces, making them accessible even to operators with minimal training.

A user-friendly interface reduces the likelihood of errors, ensuring smooth operation.

3. Safety Features:

Safety is a top priority in defense manufacturing. SLTL Group’s machines include advanced safety features to protect operators.

Safe operation minimizes risks and ensures a secure working environment.

Conclusion

In defense manufacturing, where precision and reliability are non-negotiable, SLTL Group fiber laser cutting machines stand out. Their unmatched precision, speed, and cost efficiency, combined with SLTL Group’s commitment to reliability, durability, and advanced technology, make these machines the ideal choice for the defense industry. By choosing SLTL Group, you ensure that your defense manufacturing processes are equipped with the best technology available, guaranteeing the highest standards of quality and performance.

For more information visit SLTL official website or contact at [email protected] or WhatsApp at +919925036495

0 notes

Text

How Fiber Laser Cutting Machines Improve Efficiency in the Aerospace Sector

Efficiency and precision are paramount in the aerospace industry, where even the smallest error can have significant consequences. SLTL Group, a leader in laser cutting technology, offers fiber laser cutting machines that are designed to meet the rigorous demands of this sector. This blog will explore how these machines improve efficiency, highlighting their advantages, benefits, and best features.

Advantages of SLTL Group’s Fiber Laser Cutting Machines

SLTL Group laser cutting machines provide several key advantages that enhance efficiency in the aerospace sector:

High Precision: Ensures that all cuts meet the exact specifications required in aerospace manufacturing.

Speed: Operates at high speeds, significantly reducing production time and increasing throughput.

Versatility: Capable of cutting a wide range of materials, including those commonly used in aerospace, such as titanium and aluminum.

Cost-Effective: Low maintenance requirements and energy efficiency lead to reduced operational costs.

Consistency: Delivers reliable performance, ensuring uniform quality across all cuts.

Best Features of SLTL Group’s Fiber Laser Cutting Machines

The fiber laser cutting machines from SLTL Group are equipped with features that make them ideal for improving efficiency in aerospace manufacturing:

Advanced Laser Technology: Provides precise and clean cuts, minimizing the need for secondary processing and reducing waste.

User-Friendly Interface: Intuitive controls and easy-to-read displays make operation straightforward, even for operators with minimal training.

Safety Features: Includes protective enclosures, emergency stop buttons, and real-time monitoring systems to ensure a safe working environment.

Durability: Built for long operational life, reducing downtime and the frequency of repairs and replacements.

High-Speed Cutting: Capable of maintaining high speeds without compromising on quality, essential for meeting tight production schedules.

Benefits of Fiber Laser Cutting Machines in Aerospace

Fiber laser cutting machines offer numerous benefits that align with the efficiency requirements of the aerospace industry:

Minimal Maintenance: The solid-state laser source requires less maintenance, resulting in reduced downtime and consistent performance.

Material Compatibility: Can cut a wide range of materials, including those used in aerospace, ensuring versatility in applications.

Enhanced Quality: Delivers high-quality cuts with minimal thermal distortion, preserving the integrity of materials and reducing the need for rework.

Conclusion

In the aerospace sector, the need for precision, reliability, and efficiency cannot be overstated. SLTL Group fiber laser cutting machines are engineered to meet these needs, offering numerous advantages, best features, and benefits. Their high precision, energy efficiency, and robust safety measures make them an invaluable asset in aerospace manufacturing. By leveraging SLTL Group’s advanced technology, aerospace manufacturers can achieve superior quality, reduced costs, and increased productivity, ultimately improving overall efficiency and ensuring that they meet the stringent standards of the industry.

For more information visit SLTL official website or contact at [email protected] or WhatsApp at +919925036495

0 notes

Text

Meeting Aerospace Standards: The Role of Fiber Laser Cutting Machines

In the aerospace industry, adherence to stringent standards is essential. Precision, reliability, and quality are paramount, as even the smallest error can have significant consequences. SLTL Group, a leader in laser cutting technology, offers fiber laser cutting machines that are uniquely suited to meet these exacting standards. This blog will explore the advantages, best features, and benefits of SLTL Group’s fiber laser cutting machines in the context of the aerospace industry.

Advantages of SLTL Group’s Fiber Laser Cutting Machines

SLTL Group's fiber laser cutting machines provide several advantages that are crucial for aerospace applications:

High Precision: The machines deliver exceptional accuracy, ensuring that parts meet exact specifications.

Efficiency: High-speed cutting capabilities reduce production times, leading to increased productivity.

Versatility: Capable of cutting various materials, including metals and composites commonly used in aerospace.

Cost-Effective: Low maintenance requirements and energy efficiency result in reduced operational costs.

Consistency: Reliable performance ensures uniform quality in every cut.

Best Features of SLTL Group’s Fiber Laser Cutting Machines

The fiber laser cutting machines from SLTL Group are equipped with features that make them ideal for the aerospace industry:

Advanced Laser Technology: Provides clean and precise cuts, minimizing the need for secondary finishing.

User-Friendly Interface: Intuitive controls and easy-to-understand displays make operation straightforward, even for less experienced operators.

Safety Measures: Equipped with protective enclosures, emergency stop buttons, and real-time monitoring systems to ensure a safe working environment.

High-Speed Cutting: Capable of cutting at high speeds without compromising on quality, which is essential for meeting tight production schedules.

Durability: Designed for long operational life, reducing the frequency and cost of repairs and replacement

Benefits of Fiber Laser Cutting Machines in Aerospace

SLTL Group’s laser cutting machines offer significant benefits, including exceptional precision and efficiency, which ensure accurate and high-speed cutting of various materials. Their versatility allows them to handle a range of materials, such as metals and plastics, making them suitable for diverse applications. The machines’ advanced technology results in clean cuts, reducing the need for secondary processing, while their low maintenance requirements translate to cost savings and longer operational life.

Energy Efficiency: Consumes less energy compared to traditional laser systems, reducing operational costs and environmental impact.

Precision Cutting: Capable of producing intricate designs with high accuracy, essential for aerospace components.

Minimal Maintenance: Solid-state laser source requires less maintenance, leading to reduced downtime and consistent performance.

Material Compatibility: Can cut a wide range of materials, including those used in aerospace, such as titanium, aluminum, and composites.

Enhanced Quality: Ensures high-quality cuts with minimal thermal distortion, preserving the integrity of materials.

Conclusion

Meeting the stringent standards of the aerospace industry requires cutting-edge technology that guarantees precision, reliability, and efficiency. SLTL Group fiber laser cutting machines are designed to meet these needs, offering numerous advantages, best features, and benefits. Their high precision, energy efficiency, and robust safety measures make them an invaluable tool in the production of aerospace components. By leveraging SLTL Group’s advanced technology, aerospace manufacturers can achieve superior quality, reduced costs, and increased productivity, ensuring that they meet and exceed industry standards.

For more information visit SLTL official website or contact at [email protected] or WhatsApp at +919925036495

0 notes

Text

Fiber Laser Cutting: Essential for Wind Turbine Component Manufacturing

The demand for renewable energy has led to a significant rise in the production of wind turbines. Precision and efficiency are crucial in manufacturing wind turbine components, and fiber laser cutting machines have proven to be essential in this process. SLTL Group, a leader in laser technology, offers advanced fiber laser cutting machines that provide numerous advantages, benefits, and features, making them ideal for wind turbine component manufacturing.

SLTL Group, established as a pioneer in laser technology, has been at the forefront of innovation and excellence for decades. The company is renowned for its cutting-edge solutions in the field of laser cutting, marking, welding, and micromachining. With a strong commitment to quality and technological advancement, SLTL Group has continuously developed and delivered high-performance laser machines that meet the diverse needs of various industries, including automotive, aerospace, medical devices, and renewable energy.

Advantages of Fiber Laser Cutting Machines in Wind Turbine Manufacturing

Reduced Material Waste: The efficiency of fiber laser cutting machines results in minimal material waste. The precise cutting process ensures that materials are used effectively, which reduces costs and supports sustainable manufacturing practices.

Fast Production Speed: Laser cutting machines are capable of high-speed cutting, which significantly speeds up the production process. Faster production times enable manufacturers to meet the increasing demand for wind turbines more efficiently.

Consistency and Reproducibility: Once a design is programmed into the machine, it can be reproduced consistently. This feature ensures that each component is of uniform quality, which is essential for the reliability and performance of wind turbines.

Benefits of SLTL Group’s Fiber Laser Cutting Machines

Advanced Technology: SLTL Group’s fiber laser cutting machines are equipped with the latest technology, enhancing their cutting capabilities. The advanced features contribute to high-quality results and reliable performance in manufacturing wind turbine components.

User-Friendly Interface: The machines are designed with an intuitive interface, making them easy to operate. This user-friendly design reduces the learning curve for operators, increasing productivity and reducing downtime.

Customizable Options: SLTL Group offers customizable options for their fiber laser cutting machines, allowing manufacturers to tailor the equipment to their specific needs. This flexibility ensures that the machines can meet various production requirements.

Support and Service: SLTL Group provides excellent customer support and service. Users can rely on the company for assistance with machine maintenance, troubleshooting, and any other needs that may arise during production.

Cost-Effectiveness: The long-term benefits of using SLTL Group’s fiber laser cutting machines include cost savings due to reduced material waste and increased production efficiency. These machines offer a great return on investment for wind turbine manufacturers.

Best Features of SLTL Group’s Fiber Laser Cutting Machines

High Precision: The machines deliver unparalleled accuracy, ensuring that every cut is precise and meets the exact specifications required for wind turbine components.

Versatility: SLTL Group’s machines can cut a wide range of materials, making them suitable for different parts of wind turbines.

Fast Processing: The high-speed cutting capability of these machines speeds up the production process, allowing manufacturers to produce more components in less time.

Advanced Technology: Equipped with state-of-the-art features, SLTL Group’s fiber laser cutting machines offer superior performance and efficiency.

User-Friendly Design: The intuitive interface of the machines simplifies operation, reducing the learning curve for operators and enhancing productivity.

Conclusion

Fiber laser cutting machines have become essential in the manufacturing of wind turbine components due to their precision, versatility, and efficiency. SLTL Group’s machines, with their advanced technology and user-friendly features, are a valuable asset for any wind turbine manufacturer. By utilizing these machines, manufacturers can produce high-quality components while enjoying the benefits of reduced waste, fast production, and consistent results. For those in the wind energy industry, investing in fiber laser cutting technology from SLTL Group represents a significant step towards achieving excellence in production and contributing to the growth of renewable energy.

For more information visit SLTL official website or contact at [email protected] or WhatsApp at +919925036495

0 notes

Text

The Role of Fiber Laser Cutting Machines in Solar Panel Production

The production of solar panels requires precision and efficiency to meet the growing demand for renewable energy. Fiber laser cutting machines have become essential tools in this industry due to their advanced capabilities. SLTL Group offers state-of-the-art fiber laser cutting machines that provide numerous advantages and benefits, making them ideal for solar panel production. Below, we explore the role of these machines and their key features.

Advantages of Fiber Laser Cutting Machines in Solar Panel Production

High Precision Cutting: Fiber laser cutting machines are known for their exceptional accuracy. They can cut delicate and complex shapes with great precision, which is crucial for producing high-quality solar panels.

Versatile Material Handling: These machines can handle various materials used in solar panels, including metals like silicon, thin films, and other semiconductor materials. This versatility ensures that different components of solar panels can be cut efficiently.

Reduced Material Waste: The efficiency of fiber laser cutting machines leads to minimal material waste. The precise cutting process ensures that materials are utilized effectively, reducing costs and environmental impact.

Fast Production Speed: Fiber laser cutting machines are capable of high-speed cutting, which accelerates the production process. Faster production times enable manufacturers to meet increasing demands and improve overall productivity.

Consistency and Reproducibility: Once a design is programmed into the machine, it can be reproduced consistently. This feature ensures that each solar panel is of uniform quality, which is essential for reliability and performance.

Benefits of SLTL Group’s Fiber Laser Cutting Machines

Laser cutting machines by SLTL Group offer several key benefits, including high precision and versatility. These machines ensure accurate and intricate cuts, essential for various industrial applications. Their ability to handle a wide range of materials enhances production flexibility.

Customizable Options: SLTL Group offers customizable options for their fiber laser cutting machines, allowing manufacturers to tailor the equipment to their specific needs. This flexibility ensures that the machines can meet various production requirements.

Support and Service: SLTL Group provides excellent customer support and service. Users can rely on the company for assistance with machine maintenance, troubleshooting, and any other needs that may arise during production.

Cost-Effectiveness: The long-term benefits of using SLTL Group’s laser cutting machines include cost savings due to reduced material waste and increased production efficiency. These machines offer a great return on investment for solar panel manufacturers.

Best Features of SLTL Group’s Fiber Laser Cutting Machines

High Precision: The machines deliver unparalleled accuracy, ensuring that every cut is precise and meets the exact specifications required for solar panels.

Versatility: SLTL Group’s machines can cut a wide range of materials, making them suitable for different components of solar panels.

Customization: SLTL Group provides customizable solutions, allowing manufacturers to configure the machines according to their specific needs.

Durable Construction: The robust build quality of the machines ensures long-term reliability and minimal maintenance requirements.

Energy Efficiency: The machines are designed to be energy-efficient, reducing operational costs and supporting environmentally-friendly practices.

Conclusion

Fiber laser cutting machines have revolutionized the production of solar panels by providing high precision, versatility, and efficiency. SLTL Group’s machines, with their advanced technology and user-friendly features, are a valuable asset for any solar panel manufacturer. By utilizing these machines, manufacturers can produce high-quality solar panels while enjoying the benefits of reduced waste, fast production, and consistent results. For those in the solar industry, investing in fiber laser cutting technology from SLTL Group represents a significant step towards achieving excellence in production and contributing to the growth of renewable energy.

For more information visit SLTL official website or contact at [email protected] or WhatsApp at +919925036495

0 notes

Text

Powering the Future: Fiber Laser Cutting in Renewable Energy

The renewable energy sector is rapidly evolving, with a growing focus on efficiency and sustainability. Fiber laser cutting technology, such as that provided by SLTL Group, is playing a crucial role in this transformation. This advanced technology offers numerous advantages and benefits, making it an essential tool in the production of renewable energy components. Below, we explore how SLTL Group’s fiber laser cutting machines are contributing to the future of renewable energy.

Advantages of Fiber Laser Cutting in Renewable Energy

High Precision and Accuracy: Laser cutting machines from SLTL Group are known for their exceptional precision. They can cut complex shapes and intricate designs with high accuracy, which is essential for manufacturing components used in renewable energy systems, such as solar panels and wind turbines.

Material Versatility: These machines are capable of cutting a wide range of materials, including metals like stainless steel, aluminum, and copper. This versatility is vital for producing various parts required in renewable energy applications.

Efficiency and Speed: The speed at which fiber laser cutting machines operate is significantly higher than traditional cutting methods. This efficiency reduces production time, allowing for quicker manufacturing of renewable energy components and faster project completion.

Reduced Material Waste: The precision of fiber laser cutting ensures that material waste is minimized. This reduction in waste not only lowers production costs but also supports environmentally friendly manufacturing practices, aligning with the goals of the renewable energy sector.

Benefits of Using SLTL Group’s Fiber Laser Cutting Machines

Advanced Technology: SLTL Group integrates the latest technology into their fiber laser cutting machines, enhancing their performance and reliability. Features such as high-powered lasers and advanced control systems ensure superior cutting quality.

User-Friendly Operation: The machines are designed with an intuitive interface, making them easy to operate. This user-friendly design allows operators to quickly learn how to use the machines, increasing productivity and reducing downtime.

Customization Options: SLTL Group offers customizable solutions, allowing users to tailor the machines to their specific needs. This flexibility ensures that the machines can meet the unique requirements of different renewable energy projects.

Robust Construction: The fiber laser cutting machines from SLTL Group are built to last. Their durable construction ensures long-term reliability and consistent performance, even under demanding conditions.

Energy Efficiency: SLTL Group’s machines are engineered for energy efficiency, reducing power consumption and lowering operational costs. This feature is particularly important in the renewable energy sector, where sustainability is a key concern.

Best Features of SLTL Group’s Fiber Laser Cutting Machines

The laser cutting machines from SLTL Group offer numerous benefits that enhance manufacturing efficiency and precision. These machines are designed to deliver high accuracy, allowing for the creation of intricate and complex designs with minimal material waste. Their versatility in handling various materials, including metals and non-metals, makes them suitable for a wide range of applications.

Precision Cutting: The machines deliver high precision, allowing for the creation of intricate and complex components essential for renewable energy systems.

Material Flexibility: They can handle a variety of materials, making them suitable for diverse applications within the renewable energy industry.

High Cutting Speed: The rapid processing speed increases production efficiency and reduces manufacturing time.

Advanced Technology: The integration of the latest technological advancements ensures high performance and reliability.

User-Friendly Interface: The intuitive controls simplify operation and reduce the learning curve for operators.

Conclusion

Fiber laser cutting technology is revolutionizing the renewable energy sector by providing high precision, efficiency, and versatility. SLTL Group fiber laser cutting machines are at the forefront of this innovation, offering advanced features and numerous benefits that support the production of renewable energy components. By investing in SLTL Group’s fiber laser cutting machines, companies in the renewable energy sector can enhance their manufacturing processes, reduce costs, and contribute to a more sustainable future.

For more information visit SLTL official website or contact at [email protected] or WhatsApp at +919925036495

0 notes

Text

Creating Intricate Jewelry Pieces with Fiber Laser Cutting Machines

In the world of jewelry making, precision and detail are crucial. Fiber laser cutting machines have emerged as a valuable tool for creating intricate jewelry pieces. These machines, such as those offered by SLTL Group, provide numerous advantages and benefits that enhance the design and production process. Below, we explore the key features and benefits of using fiber laser cutting machines for jewelry design.

Advantages of Fiber Laser Cutting Machines

High Precision and Detail: Fiber laser cutting machines are known for their exceptional accuracy. They can cut complex designs with fine details, which is essential for creating intricate jewelry pieces. The precision of these machines ensures that every detail of the design is replicated exactly as planned.

Versatility in Materials: SLTL Group's fiber laser cutting machines can handle a variety of materials, including metals like gold, silver, and platinum. This versatility allows jewelry designers to work with different materials to achieve the desired look and feel of their creations.

Reduced Material Waste: The efficiency of fiber laser cutting machines results in minimal material waste. The precise cutting process ensures that the maximum amount of material is used, which is both cost-effective and environmentally friendly.

Benefits of SLTL Group’s Fiber Laser Cutting Machines

Advanced Technology: SLTL Group's fiber laser cutting machines are equipped with the latest technology, which enhances their cutting capabilities. The advanced features contribute to high-quality results and reliable performance.

User-Friendly Interface: The machines are designed with an intuitive interface, making them easy to operate. This user-friendly design reduces the learning curve and increases productivity.

Customizable Options: SLTL Group offers customizable options for their fiber laser cutting machines, allowing users to tailor the equipment to their specific needs. This flexibility ensures that the machines can meet various design requirements and production demands.

Support and Service: SLTL Group provides excellent customer support and service. Users can rely on the company for assistance with machine maintenance, troubleshooting, and any other needs that may arise.

Best Features of SLTL Group’s Fiber Laser Cutting Machines

SLTL Group is renowned for its advanced fiber laser cutting machines, which are designed to meet the needs of modern industries. Here are some of the best features that set SLTL Group’s machines apart:

· High Precision Cutting: SLTL Group’s laser cutting machines deliver unparalleled precision, capable of executing intricate designs with meticulous detail. This high accuracy is essential for applications requiring fine, complex cuts.

· Versatile Material Handling: These machines can efficiently cut various materials, including metals like stainless steel, aluminum, brass, and precious metals. This versatility makes them suitable for diverse applications across different industries.

· Superior Cutting Speed: The cutting speed of SLTL Group’s machines is optimized for rapid production. This speed reduces manufacturing time and enhances overall productivity without compromising on quality.

· Advanced Technology Integration: SLTL Group incorporates the latest technology into their machines, such as high-performance laser sources and advanced control systems. These features improve cutting efficiency and ensure top-notch performance.

Conclusion

Fiber laser cutting machines have revolutionized the jewelry industry by providing high precision, versatility, and efficiency. SLTL Group machines, with their advanced technology and user-friendly features, are a valuable asset for any jewelry designer. By utilizing these machines, designers can create intricate and beautiful jewelry pieces while enjoying the benefits of reduced waste, fast production, and consistent results. For those in the jewelry industry, investing in fiber laser cutting technology from SLTL Group represents a significant step towards achieving excellence in design and production.

For more information visit SLTL official website or contact at [email protected] or WhatsApp at +919925036495

0 notes

Text

How Fiber Laser Cutting Technology is shaping the Fashion Industry

The fashion industry is constantly evolving, and new technologies are being integrated to enhance design precision and production efficiency. Among these innovations, fiber laser cutting technology stands out for its remarkable impact. SLTL Group, a leading name in laser cutting solutions, has been at the forefront of this transformation, offering cutting-edge machines that bring numerous benefits to the fashion sector.

Advantages of Fiber Laser Cutting Technology

Fiber laser cutting technology has revolutionized the way fabrics and materials are cut in the fashion industry. This technology offers several advantages:

High Precision: The use of fiber laser cutting machines ensures that even the most intricate designs are executed with unparalleled accuracy, allowing for the creation of complex patterns and detailed artwork.

Speed and Efficiency: Fiber lasers operate at high speeds, significantly reducing the time required to cut materials. This leads to faster production cycles and increased output.

Versatility: Fiber laser cutting machines can handle a wide range of materials, including fabrics, leather, and synthetic materials, making them highly adaptable to various fashion applications.

Minimal Material Waste: The precision of fiber laser cutting minimizes material wastage, leading to cost savings and more sustainable production practices.

Reduced Post-Processing: The clean cuts produced by fiber lasers often eliminate the need for additional finishing processes, streamlining the manufacturing workflow.

Benefits of SLTL Group's Fiber Laser Cutting Machines

SLTL Group’s fiber laser cutting machines offer unique benefits that cater specifically to the needs of the fashion industry:

User-Friendly Interface: The machines are designed with an intuitive interface, making them easy to operate for both skilled and novice users.

Customizable Solutions: SLTL Group provides tailor-made solutions to meet the specific requirements of fashion designers and manufacturers, ensuring that each machine is optimized for its intended use.

High Reliability and Durability: Built with robust components, SLTL’s machines offer long-term reliability, reducing downtime and maintenance costs.

Energy Efficiency: The fiber lasers used in these machines are highly energy-efficient, contributing to lower operational costs and a smaller carbon footprint.

Best Features of SLTL Group’s Laser Cutting Machines

SLTL Group laser cutting machines incorporate several best-in-class features that enhance their performance:

Advanced Software Integration: The machines come with advanced software that allows for precise control over cutting parameters, enabling designers to achieve their desired results effortlessly.

High Cutting Speed: With the ability to cut materials at high speeds, these machines ensure that production deadlines are met without compromising on quality.

Automated Systems: Many of SLTL’s machines are equipped with automation features, such as automatic material loading and unloading, which further boost productivity.

Compact Design: The compact design of the machines ensures that they can be easily integrated into existing production lines without requiring excessive space.

Conclusion

Fiber laser cutting technology is undeniably shaping the future of the fashion industry, offering unparalleled precision, efficiency, and versatility. SLTL Group fiber laser cutting machines exemplify these advantages, providing fashion designers and manufacturers with the tools they need to stay ahead in a competitive market. By investing in SLTL’s innovative solutions, the fashion industry can continue to push the boundaries of creativity and efficiency.

0 notes

Text

Innovative Jewelry Designs Made Easy with Fiber Laser Cutting Machines

In the ever-evolving world of jewelry design, precision and creativity are crucial. SLTL Group, a leading name in laser cutting technology, offers fiber laser cutting machines that simplify the design process and enhance the capabilities of jewelry makers. This article will discuss how SLTL Group's laser cutting machine facilitate the creation of innovative jewelry designs, highlighting their advantages, benefits, and key features.

Advantages of SLTL Group’s Fiber Laser Cutting Machines

SLTL Group’s fiber laser cutting machines are recognized for their significant advantages, which include:

Superior Precision: The fiber laser cutting machines from SLTL Group provide exceptional accuracy, allowing for the creation of intricate and detailed designs. This precision is essential for achieving fine details and complex patterns in jewelry.

High-Speed Cutting: The advanced technology employed in SLTL Group’s machines enables rapid cutting speeds. This efficiency accelerates the production process and helps meet tight deadlines.

Material Versatility: These machines are capable of cutting a wide range of materials, including various metals and alloys used in jewelry making. This versatility supports creativity and allows for experimentation with different materials.

Minimal Waste: SLTL Group’s machines are designed to reduce material waste. This not only lowers costs but also promotes environmentally friendly manufacturing practices.

Benefits of Using SLTL Group’s Fiber Laser Cutting Machines

SLTL Group's fiber laser cutting machines offer numerous benefits, including unparalleled precision, speed, and versatility. Their advanced technology ensures meticulous detail in every cut, significantly reducing material waste and production costs. Designed to handle various materials with minimal maintenance, these machines enhance efficiency and consistency, enabling designers to bring intricate and innovative jewelry creations to life quickly and reliably.

Enhanced Design Flexibility: The ability to cut intricate and delicate patterns with high precision allows designers to explore new and innovative designs. This flexibility supports creative expression and design uniqueness.

Consistent Quality: SLTL Group’s machines ensure that each piece of jewelry is cut with the same high level of precision. This consistency is vital for maintaining product quality and customer satisfaction.

Cost Efficiency: The efficiency of the machines, combined with reduced material waste, leads to lower production costs. This cost-effectiveness helps in managing budgets and maximizing profits.

Faster Production: The high-speed capabilities of SLTL Group’s machines result in quicker production times. This allows for rapid response to market trends and customer demands

Best Features of SLTL Group’s Fiber Laser Cutting Machines

SLTL Group’s fiber laser cutting machines are equipped with several outstanding features:

Advanced Control Systems: The machines feature sophisticated control systems that allow for precise adjustments and programming. This ensures accurate execution of even the most complex designs.

User-Friendly Interface: With an intuitive interface, SLTL Group’s machines are easy to operate, even for those who are not experts in laser cutting technology. This simplicity facilitates a smoother workflow.

Durability and Reliability: Built with high-quality materials, SLTL Group’s machines are designed for long-term durability and reliable performance. This robustness ensures consistent output over time.

Customizable Options: SLTL Group provides customization options to tailor the machines to specific needs. This adaptability is particularly beneficial for creating bespoke jewelry pieces.

Conclusion

SLTL Group’s fiber laser cutting machines have significantly advanced the jewelry design industry by providing tools that enhance precision, efficiency, and creativity. The advanced features of these machines facilitate the creation of detailed and innovative designs while minimizing waste and reducing costs. For designers aiming to push the boundaries of jewelry creation, SLTL Group offers the ideal solutions to achieve exceptional results.

For more information visit SLTL official website or contact at [email protected] or WhatsApp at +919925036495

0 notes

Text

Maßgefertigte Metallarbeiten für das Bauwesen: Die Vorteile des Faserlaserschneidens

Im Bereich des modernen Bauwesens spielen maßgefertigte Metallarbeiten eine immer wichtigere Rolle bei der Herstellung unverwechselbarer architektonischer Merkmale und funktionaler Komponenten. Die Faserlaserschneidtechnologie ist in diesem Bereich zu einem unverzichtbaren Werkzeug geworden und bietet eine Kombination aus Präzision, Geschwindigkeit und Effizienz, die die Herangehensweise an Metallarbeiten verändert. Die SLTL Group, ein führendes Unternehmen für Laserschneidlösungen, bietet hochmoderne Faserlaserschneidmaschinen, die maßgefertigte Metallarbeiten im Bauwesen neu definieren. In diesem Blog werden die Vorteile, Nutzen und herausragenden Merkmale der Faserlaserschneidmaschinen der SLTL Group untersucht und wie sie die Baubranche revolutionieren.

SLTL Group: Ein führendes Unternehmen für Laserschneid-Innovation

Die SLTL Group ist für ihre fortschrittliche Laserschneidtechnologie bekannt, insbesondere für ihre Faserlaserschneidmaschinen. Mit einem Engagement für Qualität und Innovation liefert die SLTL Group Lösungen, die den vielfältigen Anforderungen der Baubranche gerecht werden, vom Präzisionsschneiden bis zur gesteigerten Produktivität. Ihre Faserlaserschneidmaschinen sind auf überlegene Leistung, Zuverlässigkeit und Vielseitigkeit ausgelegt.

Vorteile des Faserlaserschneidens bei kundenspezifischen Metallarbeiten

Die Faserlaserschneidtechnologie bietet mehrere deutliche Vorteile für kundenspezifische Metallarbeiten im Bauwesen:

• Hohe Präzision:

Faserlaser sind für ihre außergewöhnliche Genauigkeit bekannt und ermöglichen komplizierte und komplexe Designs mit engen Toleranzen. Diese Präzision stellt sicher, dass kundenspezifische Metallkomponenten genaue Spezifikationen erfüllen und nahtlos in Bauprojekte passen.

• Schnelle Schneidgeschwindigkeit:

Die Hochgeschwindigkeitsfunktionen von Faserlasern ermöglichen eine schnelle Verarbeitung von Metallmaterialien, was entscheidend ist, um Projektfristen einzuhalten und groß angelegte Metallarbeiten effizient zu bewältigen.

• Energieeffizienz

Faserlaser verbrauchen im Vergleich zu herkömmlichen CO2-Lasern weniger Strom, was zu geringeren Energiekosten bei gleichzeitig hoher Schneidleistung führt. Diese Energieeffizienz macht sie zu einer kostengünstigen Wahl für kleine und große Projekte.

Vorteile des Faserlaserschneidens für das Bauwesen

Die Integration der Faserlaserschneidtechnologie in Bauprojekte bietet mehrere bemerkenswerte Vorteile:

• Verbesserte Designflexibilität:

Die Präzision und Vielseitigkeit von Faserlasern ermöglichen es Architekten und Bauherren, innovative Designs und Anpassungen zu erkunden, die die Ästhetik und Funktionalität von Strukturen verbessern.

• Weniger Materialabfall:

Die Genauigkeit von Faserlasern gewährleistet präzise Schnitte, was den Materialabfall reduziert und zu Kosteneinsparungen und Nachhaltigkeit beiträgt.

• Schnellere Durchlaufzeiten:

Die hohe Schneidgeschwindigkeit von Faserlasern beschleunigt den Produktionsprozess und ermöglicht eine schnellere Herstellung und Installation von kundenspezifischen Metallkomponenten.

Beste Eigenschaften der Faserlaser-Schneidemaschinen der SLTL Group

Die Faserlaser-Schneidemaschinen der SLTL Group sind mit fortschrittlichen Funktionen ausgestattet, die Leistung und Effizienz maximieren sollen:

• Hochmoderne Faserlasertechnologie:

Die SLTL Group nutzt die neueste Faserlasertechnologie, um außergewöhnliche Schneidpräzision, Geschwindigkeit und Zuverlässigkeit zu bieten.

• Robuste Konstruktion:

Ihre Maschinen sind auf Langlebigkeit ausgelegt und halten den Anforderungen des Dauerbetriebs in verschiedenen Bauumgebungen stand.

• Benutzerfreundliche Steuerungssysteme:

Die intuitive Software und die Steuerungsschnittstellen erleichtern den Bedienern die Verwaltung von Schneidvorgängen und die Anpassung der Einstellungen an spezifische Projektanforderungen.

Fazit

Die Faserlaserschneidtechnologie, insbesondere von der SLTL Group, hat die kundenspezifische Metallverarbeitung im Bauwesen revolutioniert, indem sie beispiellose Präzision, Geschwindigkeit und Effizienz bietet. Die Vorteile von Faserlasern, darunter verbesserte Designflexibilität, weniger Materialabfall und niedrigere Betriebskosten, machen sie zu einem unschätzbaren Werkzeug für moderne Bauprojekte. Die fortschrittlichen Faserlaserschneidmaschinen der SLTL Group setzen mit ihren robusten Funktionen und ihrer innovativen Technologie neue Maßstäbe in der Branche und ermöglichen es Architekten und Bauherren, bemerkenswerte Ergebnisse bei kundenspezifischen Metallarbeiten zu erzielen.

0 notes

Text

Faserlaser-Schneidemaschinen: Architektonische Wunderwerke schaffen

In der Welt der modernen Architektur sind Präzision, Kreativität und Effizienz von größter Bedeutung. Die Faserlaser-Schneidetechnologie hat sich als bahnbrechende Neuerung erwiesen und ermöglicht es Architekten und Bauherren, neue Höhen in Design und Konstruktion zu erreichen. Die SLTL Group, ein Vorreiter bei Laserschneidlösungen, bietet fortschrittliche Faserlaser-Schneidemaschinen an, die bei der Schaffung architektonischer Wunderwerke eine entscheidende Rolle spielen. In diesem Blog werden wir uns mit den Vorteilen, Nutzen und Hauptmerkmalen der Faserlaser-Schneidemaschinen der SLTL Group befassen und untersuchen, wie sie die Landschaft der Architektur neu gestalten.

SLTL Group: Innovatoren in der Laserschneidtechnologie

Die SLTL Group ist ein führender Name in der Laserschneidbranche und bekannt für ihre innovativen Lösungen und ihr Engagement für Qualität. Ihre Faserlaser-Schneidemaschinen sind darauf ausgelegt, den sich entwickelnden Anforderungen der Architektur- und Baubranche gerecht zu werden. Mit einem Fokus auf Präzision, Zuverlässigkeit und fortschrittlicher Technologie hat die SLTL Group einen neuen Maßstab im Bereich des Laserschneidens gesetzt.

Vorteile von Faserlaser-Schneidemaschinen

Faserlaser-Schneidemaschinen bieten mehrere eindeutige Vorteile, die sie in der Architektur unverzichtbar machen:

• Unübertroffene Präzision:

Faserlaser liefern außergewöhnliche Genauigkeit, sodass Architekten komplizierte Designs mit engen Toleranzen erstellen können. Diese Präzision stellt sicher, dass jedes Detail eines Projekts fehlerfrei ausgeführt wird.

• Hohe Schneidgeschwindigkeit:

Diese Maschinen bieten schnelle Schneidgeschwindigkeiten, was dazu beiträgt, den Herstellungsprozess zu beschleunigen und enge Projektfristen einzuhalten, ohne Kompromisse bei der Qualität einzugehen.

• Energieeffizienz:

Faserlaser sind im Vergleich zu herkömmlichen CO2-Lasern energieeffizienter. Sie verbrauchen weniger Strom bei gleichbleibend hoher Leistung, was zu niedrigeren Betriebskosten beiträgt.

Vorteile für Architekturdesign und Bauwesen

Die Laserschneidmaschinen der SLTL Group, insbesondere ihre Faserlasermodelle, bieten eine Reihe bedeutender Vorteile, die sowohl die Effizienz als auch die Präzision in verschiedenen Branchen erheblich verbessern. Faserlaserschneidmaschinen bieten außergewöhnliche Genauigkeit und Hochgeschwindigkeitsleistung und ermöglichen die Erstellung komplizierter Designs und komplexer Muster mit engen Toleranzen. Ihre Energieeffizienz senkt die Betriebskosten, während ihr geringer Wartungsaufwand minimale Ausfallzeiten gewährleistet, was sie ideal für den groß angelegten und kontinuierlichen Betrieb macht.

• Verbesserte Designmöglichkeiten:

Die Präzision und Vielseitigkeit von Faserlasern ermöglichen es Architekten, die Grenzen des Designs zu erweitern und komplexe und innovative Strukturen zu schaffen, die zuvor nur schwer zu erreichen waren.

• Weniger Materialabfall:

Die Genauigkeit von Faserlasern minimiert den Materialabfall durch präzise Schnitte, was sowohl kostengünstig als auch umweltfreundlich ist.

• Schnellere Projektabwicklung:

Die hohen Schnittgeschwindigkeiten von Faserlasern führen zu schnelleren Fertigungszeiten, beschleunigen die Projektzeitpläne und ermöglichen eine schnellere Fertigstellung von Architekturarbeiten.

• Kosteneffizienz:

Geringerer Energieverbrauch und reduzierter Wartungsaufwand tragen zu allgemeinen Kosteneinsparungen bei und machen die Faserlasertechnologie zu einer finanziell tragfähigen Option für große und komplexe Projekte.

Fazit

Faserlaserschneidmaschinen, insbesondere die der SLTL Group, verändern die Architekturlandschaft, indem sie die Präzision, Geschwindigkeit und Vielseitigkeit bieten, die zum Erstellen außergewöhnlicher Strukturen erforderlich sind. Von der Verbesserung der Designmöglichkeiten bis zur Verbesserung der Kosteneffizienz liegen die Vorteile der Faserlasertechnologie auf der Hand. Durch den Einsatz dieser fortschrittlichen Schneidlösungen können Architekten und Bauherren bemerkenswerte architektonische Meisterleistungen erzielen und die Grenzen der Kreativität und Funktionalität erweitern.

0 notes

Text

Transformation des Bauwesens mit Faserlaserschneidtechnologie

In der sich ständig weiterentwickelnden Welt des Bauwesens sind Präzision und Effizienz die Schlüsselfaktoren für den Erfolg. Die Einführung fortschrittlicher Technologien hat die Art und Weise, wie Projekte ausgeführt werden, revolutioniert, und unter diesen Innovationen sticht die Faserlaserschneidtechnologie hervor. Die SLTL Group, ein führender Anbieter von Laserschneidlösungen, hat bei dieser Transformation eine bedeutende Rolle gespielt. In diesem Blog untersuchen wir die Vorteile, Nutzen und herausragenden Merkmale der Laserschneidmaschinen der SLTL Group, mit besonderem Schwerpunkt auf der Faserlaserschneidtechnologie und wie sie die Bauindustrie transformieren.

SLTL Group: Pioniere der Laserschneidtechnologie

Die SLTL Group ist bekannt für ihre Spitzentechnologie und ihr Engagement für Innovationen im Bereich des Laserschneidens. Mit dem Schwerpunkt auf der Bereitstellung hochwertiger, effizienter und präziser Schneidlösungen hat sich die SLTL Group als Branchenführer etabliert. Ihre Laserschneidmaschinen sind darauf ausgelegt, die anspruchsvollen Anforderungen verschiedener Branchen, einschließlich der Baubranche, zu erfüllen.

Vorteile der Faserlaserschneidtechnologie

Die Faserlaserschneidtechnologie bietet zahlreiche Vorteile, die insbesondere für die Baubranche von Vorteil sind. Hier ein Blick auf einige der wichtigsten Vorteile:

• Überlegene Präzision:

Faserlaser bieten beispiellose Präzision und ermöglichen komplizierte Designs und enge Toleranzen, die für komplexe Bauprojekte von entscheidender Bedeutung sind.

• Hohe Geschwindigkeit:

Die Technologie bietet im Vergleich zu herkömmlichen Methoden höhere Schneidgeschwindigkeiten, was zu höherer Produktivität und kürzeren Projektlaufzeiten führt.

• Energieeffizienz:

Faserlaser sind energieeffizienter als CO2-Laser. Sie verbrauchen weniger Strom und bieten gleichzeitig eine hohe Leistung, was zu niedrigeren Betriebskosten führen kann.

• Minimaler Wartungsaufwand:

Faserlaser erfordern aufgrund ihres Festkörperdesigns weniger Wartung. Dies reduziert Ausfallzeiten und gewährleistet einen kontinuierlichen Betrieb, der für große Bauprojekte von entscheidender Bedeutung ist.

Vorteile für die Bauindustrie

Die Integration der Faserlaserschneidtechnologie in die Bauindustrie bringt mehrere bemerkenswerte Vorteile mit sich:

• Verbesserte Genauigkeit und Qualität:

Präzisionsschneiden stellt sicher, dass die Materialien perfekt passen, was den Abfall reduziert und die Gesamtqualität von Bauprojekten verbessert.

• Reduzierter Materialabfall:

Die Genauigkeit von Faserlasern minimiert den Materialabfall durch hochpräzises Schneiden, was sowohl kostengünstig als auch umweltfreundlich ist.

• Schnellere Produktionszeiten:

Die Hochgeschwindigkeitsschneidfähigkeiten von Faserlasern führen zu schnelleren Durchlaufzeiten für Fertigung und Montage und beschleunigen so die Projektzeitpläne.

Beste Eigenschaften der Laserschneidmaschinen der SLTL Group

Die Laserschneidmaschinen der SLTL Group sind mit fortschrittlichen Funktionen ausgestattet, die Leistung und Effizienz verbessern. Hier sind einige der herausragenden Funktionen:

• Fortschrittliche Faserlasertechnologie:

Die SLTL Group verwendet hochmoderne Faserlasertechnologie, die hohe Präzision und Schnittgeschwindigkeit gewährleistet.

• Robuste Verarbeitungsqualität:

Die Maschinen sind so gebaut, dass sie dem harten Einsatz in anspruchsvollen Umgebungen standhalten und so Haltbarkeit und Zuverlässigkeit gewährleisten.

• Benutzerfreundliche Schnittstelle:

Die intuitive Software und die Steuerungssysteme erleichtern den Bedienern das Einrichten und Verwalten von Schneidvorgängen.

Fazit

Die Faserlaserschneidtechnologie, wie sie von der SLTL Group angeboten wird, verändert die Baubranche, indem sie Präzision, Effizienz und Vielseitigkeit bietet. Die Vorteile und Nutzen dieser Technologie liegen auf der Hand: von verbesserter Genauigkeit und reduziertem Materialabfall bis hin zu schnelleren Produktionszeiten und niedrigeren Betriebskosten. Da Bauprojekte immer komplexer und anspruchsvoller werden, bieten die hochmodernen Laserschneidmaschinen der SLTL Group die notwendigen Werkzeuge, um diese Herausforderungen direkt anzugehen. Der Einsatz dieser Technologie verbessert nicht nur die Projektergebnisse, sondern setzt auch einen neuen Standard für Spitzenleistungen im Bauwesen.

0 notes

Text

Warum Faserlaserschneiden für die Herstellung elektrischer Komponenten unverzichtbar ist

In der sich schnell entwickelnden Welt der Herstellung elektrischer Komponenten sind Präzision, Effizienz und Innovation entscheidend. Die SLTL Group, ein Pionier der Laserschneidtechnologie, bietet mit ihren hochmodernen Faserlaserschneidmaschinen beispiellose Lösungen. Diese Maschinen haben die Branche revolutioniert und bieten zahlreiche Vorteile und Nutzen, die sie für moderne Fertigungsanforderungen unverzichtbar machen.

Vorteile des Faserlaserschneidens für die Herstellung elektrischer Komponenten

1. Präzision und Genauigkeit

• Hochpräzises Schneiden: Laser-Schneide-Maschine bieten außergewöhnliche Genauigkeit und stellen sicher, dass selbst die kompliziertesten Designs perfekt ausgeführt werden.

• Gleichbleibende Qualität: Die Präzision von Faserlasern garantiert eine gleichmäßige Qualität aller Komponenten und reduziert so den Bedarf an Nacharbeit und Abfall.

2. Geschwindigkeit und Effizienz

• Schnelle Verarbeitung: Faserlaser schneiden schneller als herkömmliche Methoden und steigern die Produktionsgeschwindigkeit erheblich.

• Reduzierte Ausfallzeiten: Bei minimalem Wartungsaufwand bieten Faserlaser eine höhere Betriebszeit und konstante Produktivität.

3. Vielseitigkeit

• Breite Materialkompatibilität: Faserlaser können eine Vielzahl von Materialien schneiden, darunter Metalle, Kunststoffe und Verbundwerkstoffe, wodurch sie vielseitig für verschiedene elektrische Komponenten einsetzbar sind.

• Flexible Designmöglichkeiten: Die Technologie ermöglicht komplexe und benutzerdefinierte Formen und erfüllt unterschiedliche Fertigungsanforderungen.

Vorteile der Verwendung der Faserlaser-Schneidemaschinen der SLTL Group

1. Verbesserte Leistung

• Überlegene Schnittqualität: Die Faserlaser von SLTL bieten saubere und glatte Schnitte und reduzieren so den Bedarf an zusätzlichen Endbearbeitungsprozessen.

• Hochgeschwindigkeitsbetrieb: Die Maschinen arbeiten mit hoher Geschwindigkeit, sodass große Mengen an Komponenten schnell produziert werden können.

2. Kosteneffizienz

• Energieeffizienz: Faserlaser verbrauchen im Vergleich zu herkömmlichen Schneidmethoden weniger Energie, was zu erheblichen Kosteneinsparungen führt.

• Niedrigere Betriebskosten: Durch weniger Verbrauchsmaterialien und reduzierten Wartungsaufwand werden die Betriebskosten minimiert.

3. Innovation und Technologie

• Fortschrittliche Funktionen: Die Faserlasermaschinen der SLTL Group sind mit der neuesten Technologie ausgestattet, einschließlich automatisierter Steuerung und Echtzeitüberwachung.

• Intelligente Fertigung: Die Integration mit Industrie 4.0-Lösungen ermöglicht nahtlose Konnektivität und datengesteuerte Entscheidungsfindung.

Beste Funktionen der Faserlaserschneidmaschinen der SLTL Group

1. Spitzentechnologie

• Automatisierte Systeme: Die Maschinen von SLTL verfügen über fortschrittliche Automatisierungsfunktionen, die die Produktivität steigern und manuelle Eingriffe reduzieren.

• Echtzeitüberwachung: Die Live-Verfolgung des Schneidprozesses gewährleistet optimale Leistung und sofortige Fehlerbehebung.

2. Benutzerfreundliche Schnittstelle

• Intuitive Steuerung: Die Maschinen verfügen über benutzerfreundliche Schnittstellen, die sie für Bediener aller Fähigkeitsstufen zugänglich machen.

• Anpassbare Einstellungen: Bediener können Einstellungen anpassen, um spezifische Fertigungsanforderungen zu erfüllen, was Flexibilität und Präzision bietet.

3. Haltbarkeit und Zuverlässigkeit

• Robuste Bauweise: Die Faserlasermaschinen von SLTL Group sind auf Langlebigkeit ausgelegt und verfügen über langlebige Komponenten, die langfristige Zuverlässigkeit gewährleisten.

• Konstante Leistung: Die Maschinen liefern eine konstante Leistung und gewährleisten über längere Zeiträume eine qualitativ hochwertige Leistung.

Fazit

Das Faserlaserschneiden ist aufgrund seiner Präzision, Geschwindigkeit, Vielseitigkeit und Kosteneffizienz für die Herstellung elektrischer Komponenten unverzichtbar. Die SLTL Group steht an der Spitze dieser Technologie und bietet fortschrittliche Faserlaserschneidmaschinen an, die den höchsten Qualitäts- und Leistungsstandards entsprechen. Durch die Integration der Faserlaser von SLTL in Ihren Herstellungsprozess können Sie hervorragende Ergebnisse erzielen, die Effizienz optimieren und im Wettbewerbsumfeld der Herstellung elektrischer Komponenten die Nase vorn behalten.

0 notes

Text

Präzisionsschneiden von Leiterplatten: Der Vorteil des Faserlasers

Im dynamischen Bereich der Elektronik ist die Nachfrage nach präzisen, effizienten und zuverlässigen Herstellungsprozessen von größter Bedeutung. Ein entscheidender Aspekt dabei ist das Schneiden von Leiterplatten, bei dem Präzision und Genauigkeit die Leistung des Endprodukts erheblich beeinflussen können. Faserlaserschneidmaschinen sind in diesem Bereich unverzichtbar geworden und bieten unübertroffene Präzision und Effizienz. Die SLTL Group, ein führendes Unternehmen in der Laserschneidtechnologie, bietet hochmoderne Faserlaserschneidmaschinen, die auf die spezifischen Anforderungen der Leiterplattenherstellung zugeschnitten sind. In diesem Blog werden wir uns mit den Vorteilen, Nutzen und herausragenden Merkmalen der Faserlaserschneidmaschinen der SLTL Group für Leiterplatten befassen.

Vorteile von Faserlaser-Schneidemaschinen

1. Außergewöhnliche Präzision

o Mikrometergenaue Präzision: Die Laser-Schneide-Maschine der SLTL Group liefern Mikrometergenaue Präzision, die für die komplizierten Muster und winzigen Komponenten auf Leiterplatten unerlässlich ist.

o Gleichbleibende Qualität: Die hohe Präzision gewährleistet eine gleichbleibende Schnittqualität auf allen Leiterplatten und minimiert Defekte und Nacharbeit.

2. Verbesserte Geschwindigkeit und Effizienz

o Schnelle Schneidgeschwindigkeiten: Faserlaser arbeiten mit hoher Geschwindigkeit, wodurch die Schneidzeiten drastisch reduziert und die Produktionseffizienz erhöht werden.

o Optimierte Produktion: Höhere Schneidgeschwindigkeiten führen zu schnelleren Produktionszyklen, sodass Hersteller große Mengen effizient nachliefern können.

3. Vielseitigkeit bei der Materialhandhabung

o Kompatibilität mit unterschiedlichen Materialien: Die Maschinen der SLTL Group können eine Vielzahl von Materialien verarbeiten, die in Leiterplatten verwendet werden, darunter FR4, Kupfer und Aluminium.

o Anpassbar an komplexe Designs: Die Vielseitigkeit von Faserlasern ermöglicht das einfache Schneiden komplexer Designs und komplizierter Geometrien.

4. Kostengünstiger Betrieb

o Geringere Wartungskosten: Faserlaser erfordern nur minimale Wartung, wodurch Ausfallzeiten und damit verbundene Kosten reduziert werden.

o Energieeffizienz: Diese Maschinen verbrauchen weniger Strom, was zu erheblichen Einsparungen bei den Energiekosten führt.

Vorteile der Faserlaser-Schneidemaschinen der SLTL Group

Die Laserschneidmaschinen der SLTL Group bieten eine Vielzahl von Vorteilen, die sie zu einer hervorragenden Wahl für Hersteller machen. Diese Maschinen bieten außergewöhnliche Präzision und Genauigkeit, die für die Herstellung komplizierter Designs und detaillierter Komponenten unerlässlich sind. Ihre Hochgeschwindigkeitsschneidfunktionen steigern die Produktivität, sodass Hersteller enge Fristen einhalten und die Gesamtleistung steigern können. Darüber hinaus sind die Maschinen der SLTL Group äußerst vielseitig und können eine breite Palette von Materialien schneiden, was für vielfältige Fertigungsanforderungen von entscheidender Bedeutung ist.

1. Integration fortschrittlicher Technologien

o Laserquellen der neuesten Generation: Die SLTL Group verwendet fortschrittliche Laserquellen, die überragende Leistung und Langlebigkeit bieten.

o Automatisierte Funktionen: Ihre Maschinen sind mit Automatisierungsfunktionen ausgestattet, die die Effizienz steigern und manuelle Eingriffe reduzieren.

2. Kundenspezifische Lösungen

o Auf spezifische Anforderungen zugeschnitten: Die SLTL Group bietet maßgeschneiderte Lösungen, die sicherstellen, dass ihre Maschinen die einzigartigen Anforderungen der Leiterplattenhersteller erfüllen.

o Skalierbare Optionen: Ihre Maschinen können ohne erhebliche zusätzliche Investitionen skaliert werden, um wachsenden Produktionsanforderungen gerecht zu werden.

3. Benutzerfreundliches Design

o Intuitive Schnittstellen: Die benutzerfreundlichen Steuerungsschnittstellen vereinfachen die Bedienung und verkürzen die Lernkurve für die Bediener.

o Umfassende Schulung: Die SLTL Group bietet detaillierte Schulungsprogramme, um sicherzustellen, dass die Bediener die Funktionen der Maschinen voll ausschöpfen können.

4. Robuster Support und Wartung

o Eigenes Supportteam: Die SLTL Group bietet umfassenden After-Sales-Support und stellt sicher, dass alle Probleme umgehend gelöst werden.

o Regelmäßige Wartungsdienste: Sie bieten regelmäßige Wartungsdienste an, um die Maschinen auf optimalem Leistungsniveau laufen zu lassen.

Fazit Präzisionsschneiden ist bei der Herstellung von Leiterplatten von entscheidender Bedeutung, da selbst der kleinste Fehler zu erheblichen Problemen beim Endprodukt führen kann. Die Faserlaserschneidmaschinen der SLTL Group bieten die Präzision, Effizienz und Zuverlässigkeit, die erforderlich sind, um in diesem anspruchsvollen Bereich herausragende Leistungen zu erbringen. Mit fortschrittlicher Technologie, anpassbaren Lösungen, benutzerfreundlichen Schnittstellen und robustem Support ist die SLTL Group die beste Wahl für Hersteller, die ihre Leiterplattenproduktionsprozesse verbessern möchten. Durch die Nutzung der Vorteile der Faserlaserschneidmaschinen der SLTL Group können Hersteller eine höhere Qualität, gesteigerte Produktivität und mehr Innovation in ihren Betrieben erreichen

0 notes