Don't wanna be here? Send us removal request.

Text

How Vibration Damping Increases The Performance Of Golf Clubs

In golf, precision and control play a vital role, and the golfer's performance is significantly influenced by their choice of equipment.The performance and feel of a golf club are greatly influenced by vibration damping, making it an important element in club design. Here's how vibration damping technology can elevate the performance of golf clubs.

• Golf clubs are now more comfortable

• Golfers now can make more accurate and controlled shots

• Golf clubs now can transfer energy more efficiently

• Golfers are now suffering from fatigue and injury risk

• Golf clubs are now giving back better feedback and confidence

Improved comfort and feel

Golfers often look for a club that provides a solid and comfortable feel upon impact with the ball. Vibration damping material technology helps reduce the vibrations transmitted through the club, resulting in a more pleasant and controlled feel. This enhanced comfort allows golfers to focus on their swing and achieve more consistent shots.

Enhanced accuracy and control

Excessive vibrations can negatively impact the accuracy and control of a golf shot. When a golfer strikes the ball, vibrations can cause the club head to twist or rotate slightly, leading to off-center hits and less precise shots. Vibration damping technology minimizes these vibrations, providing a more stable clubhead and allowing golfers to maintain better control over their shots.

Increased energy transfer

Vibration damping materials can optimize the energy transfer from the golfer's swing to the golf ball. When vibrations are reduced, more of the energy generated by the swing is efficiently transferred to the ball at impact. This leads to increased ball speed, greater distance, and improved overall performance.

Reduced fatigue and injury risk

Golfers often experience fatigue and discomfort during long rounds of play or practice sessions. Excessive vibrations transmitted through the club can contribute to this fatigue, leading to decreased performance and an increased risk of injury. By absorbing and dispersing vibrations, vibration damping technology lessens the stress on the golfer's hands, wrists, and arms.This helps minimize fatigue and lowers the potential for repetitive stress injuries.

Enhanced feedback and confidence

Vibration damping technology allows golfers to receive valuable feedback from their shots. By reducing excessive vibrations, golfers can better perceive the quality of their strikes and identify any inconsistencies or mishits. Golfers utilize this feedback to fine-tune their technique, implement necessary adjustments, and build unwavering confidence in their swing, resulting in enhanced performance on the course.

Engineered thermoplastics play a vital role in enhancing the performance of golf clubs. By reducing vibrations and improving comfort, it provides golfers with a solid and controlled feel. The technology increases accuracy, control, and energy transfer, resulting in improved distance and overall performance.

Moreover, vibration damping helps reduce fatigue and the risk of injury, allowing golfers to play longer and maintain optimal performance. With the enhanced feedback provided by vibration damping, golfers can make necessary adjustments and build confidence in their swing. As golfers strive for excellence in their game, the integration of vibration damping technology in golf clubs becomes an essential factor in achieving superior performance on the course.

1 note

·

View note

Text

Why Tungsten Polymer Has Become The Best Material For Frangible Ammunition

With evolving time, everything is changing including the bullets we use in our guns. You would be surprised to know that instead of bullets modern bullets use tungsten polymer.In recent years, tungsten polymer has emerged as the best material for manufacturing frangible ammunition. Here's why tungsten polymer has gained popularity and become the preferred choice for frangible ammunition.

• Density and hardness are comparable to lead

Renowned for its exceptional strength-to-weight ratio, tungsten polymer stands as a remarkably dense and tough substance. When used in frangible ammunition, it creates a composite material that is both lightweight and durable. This unique combination allows frangible bullets made from tungsten polymer to fragment upon impact with a target, while maintaining sufficient structural integrity for reliable penetration.

• Reduced ricochet and over-penetration make this type of bullet safe

The natural brittleness of tungsten polymer causes the bullet to disintegrate into smaller fragments upon hitting a hard surface, reducing the likelihood of ricochet. Additionally, the controlled fragmentation ensures that the bullet does not penetrate beyond the intended target, making it safer for use in close quarters and urban environments.

• Enhanced safety during indoor training exercises

Tungsten polymer frangible ammunition offers enhanced safety during training exercises, particularly in indoor shooting ranges. The lower probability of bullet ricochet and excessive penetration leads to a safer scenario where shooters and bystanders are at a reduced risk of injuries caused by stray bullets. This makes tungsten polymer frangible ammunition an ideal choice for military, law enforcement, and civilian training purposes.

• Environmental friendliness compared to traditional lead-based ammunition

Frangible ammunition made from tungsten polymer is considered more environmentally friendly compared to traditional lead-based ammunition. In terms of health and environmental concerns, tungsten polymer differs from lead as it is non-toxic and does not pose comparable hazards. By using tungsten polymer, shooters can reduce their exposure to lead and contribute to the preservation of the environment.

• Consistent performance in any type of weather condition

Tungsten polymer frangible bullets offer consistent performance, allowing shooters to maintain accuracy and reliability. The controlled fragmentation and reliable terminal ballistics ensure that the bullets perform predictably upon impact. This predictability is crucial for shooters who rely on consistent performance for self-defense or competitive shooting scenarios.

• Versatility for various calibers and configurations

With its diverse range of calibers and configurations, tungsten polymer frangible ammunition is adaptable and suitable for various firearms and applications. Whether for handguns, rifles, or shotguns, tungsten polymer frangible ammunition can be tailored to meet specific needs and performance requirements.

A modern material for modern ammunition

Tungsten polymer has become the material of choice for frangible ammunition due to its density, hardness, reduced ricochet and over-penetration, enhanced safety, environmental friendliness, consistent performance, and versatility.

The unique properties of tungsten polymer enable frangible bullets to disintegrate upon impact, making them safer and more effective for use in close-quarters situations. As the demand for safer ammunition options continues to grow, tungsten polymer frangible ammunition is increasingly recognized as the best choice for professionals and enthusiasts alike.

1 note

·

View note

Text

Why Achieving Sustainable Goals Is ASlow Process Not An Overnight Event?

Sustainability must not exist on the idea and perception levels only.It must find its true place on the execution level. All government plans, corporate promises, and agendas would be futile without pragmatic execution. That would mean companies and organizations should start to think more objectively to achieve the desired sustainability goals.

It is important to beat the challenges that come along when companies and organizations are introducing sustainable ideas and plans of action. Let’s take a quick look at the methods and ways to find the right approach toward the implementation of sustainability.

Achieving sustainability goals is a process, not an event:

One must be aware of the fact that everything substantial would take time, humans need to get out of event desired mindsets, it is a process. The process can be slow or fast depending upon how you execute, it is the fundamental concept of life and the world. Sustainability goals can be started by understanding the importance of it or by finding a good alternative such as high density plastics.

Knowing what can replace lethal materials is something that could open many new opportunities and sustainable options, heavy plastic in the context fits the bill perfectly. Everything in the universe is the manifestation of a process, it is important to know the fact that the world has been slowly subject to degradation and it would take time to undo everything that is not desired.

Where heavy plastic can be used?

Once one knows the features of heavy plastic, one would be excited to use it in many ways, the crux of the matter is that this substance can be used in a plethora of ways and in a range of applications. You can use these materials as Frangible bullets in law enforcement agencies, you can replace lead by using these materials in the automotive industry.

The application of heavy plastic can be dynamic and can be used in many different industries, one needs to know how to implement a sustainable strategy and what to do to get the maximum result out of the action plan.

How to implement the sustainable strategy?

It demands a clear-cut plan, without a good plan, you are likely to miss certain important aspects which can cost you later. You would need to know where you can start to use heavy plastic and how much you can use. A good sustainable plan for implementation would help get better results in the long run

You would need a good manufacturer for High density materials because that is something that can get you high-quality outputs, you would need to find out how smart the manufacturer is and what they can do for you. The better and smarter manufacturers can help you in planning, they can make bespoke components for your applications and more.

It is of utmost importance to think about sustainability and going for heavy plastic is a great idea provided you know how to execute it, all you have to do is to find the manufacturers and start the implementation.

1 note

·

View note

Text

Why Thermoplastic Polymer Material Is Considered As Unique?

Thermoplastic polymer is a material that is the best combination of rubber and plastic. For any application, thermoplastic polymer is the best-performing material. It is widely used to replace rubber, lead and plastic. The material has some unique properties and is considered a high-density type.

• Industrial-grade thermoplastic composite materials can withstand extreme heat and pressure conditions

• The material is also more flexible and resistant as compared to lead or rubber

• It has special properties of absorbing shock vibrations when used for industrial applications

Abrasion resistant

Abrasion can affect the performance of any machine part. Metals tend to get rusted when oxidized. Even the hardest metal like lead may get rusted after a certain time. this means that the metal will have to be replaced so the machine keeps performing.

For best output, the material used should be super resistant to abrasion. This is one unique property of thermoplastic polymer material. The material can be used to manufacture machine parts that are in direct contact with liquids or acids.

Heat resistant

Friction can produce heat in any machine part. Vibration also produces a lot of heat in movable machine parts. Metal or rubber tends to withstand heat to certain degrees. This is where manufacturers find thermoplastic polymer more helpful.

The special property of this polymer makes it completely withstand heat. So vibrations may not damage the machine parts made up of this polymer. The material also has hardness equivalent to lead metal. It does not get damaged even when exposed to extreme heat or pressure.

Dust-free

Lead and rubber produce a lot of dust when you grind them. The dust can easily pollute your surrounding environment. Your health may get affected if this dust enters your body. The thermoplastic polymer is not the same.

If the material is used as raw material for manufacturing units, it does not produce any dust. Thus, when working with thermoplastic, your health is also safe. The material is considered dust free even at high temperature or pressure conditions.

Hardness

If the material is hard, it is more durable. Rubber and lead are commonly used as shock-absorbing pads. These materials can withstand vibrations of low or medium intensity. If the vibrations exceed a certain frequency, the rubber and lead pads may get destroyed.

This means that the pads have to be replaced very often. High density polymers can be ideal solution. The material is hard as compared to rubber and lead. It is also highly flexible and elastic. The material does not get damaged easily. You may not have to keep replacing the shock-absorbing pads very often.

Vibration dampening

Vibrations in machines can cause a lot of damage. If the intensity of vibration is greater then, the machine parts may also get damaged very often. You have to keep investing more money in maintenance. The parts have to be changed regularly.

This is one benefit if you are using thermoplastic to kill the vibrations. This material can act as a perfect barrier between movable and immovable machine parts. This simple technique helps kill any intensity vibrations. Thermoplastic material is used for many industrial applications.

0 notes

Text

What You Need To Know About Sustainability Transition?

If you look at the world,you would see that you are living in a world that is going downward because of irresponsible actions.Industrial revolution and rapid technological development have brought many good things but it has also brought environmental issues.

Here at this juncture,it is important that as a corporate house and business establishment you should and must consider meeting sustainable goals,here are the things that you should know and understand in order to achieve the desired results.

Safeguarding the environment must be a collegial effort:

The first and most important thing to understand is that there must be a collective approach toward sustainability.You should find the right alternative such as tungsten polymer to ensure that you replace potentially harmful materials such as Lead that are harmful to the environment.

Every business should consider the use of heavy plastic when and where it is applicable.When you choose a sustainable approach, you are attracting more customers who are conscious of environmental safety,this means more business and a better brand image.This can be a part of the business model that had future growth potential. However,you need to know how you should approach the whole transition of sustainability.

How to approach the transition?

The fact of the matter is that having the right idea is the first step but getting the ideas materialized is the real thing to achieve. That means you should have a good execution plan for transition.

Here at this juncture, it would be wise to find the right heavy plastic manufacturer that can help you understand your needs and the feasibility of the ideas. Thecan helpyou know where you can use the materials such as in the medical device industry, in the automotive industry, and more.

More ideas for better execution;

• If you want to use high density polymers,then the first thing you need to make sure that you are working with the best manufacturers. That would mean you have to find a good one through industry references or you can simply find good ones by searching on the web, the trick here is to verify the credibility of the manufactures

• You would need to make sure that you are looking at the kind of products and components that they can make, they should be able to get you bespoke designs for your component needs.They should help you get better quality products and heavy plastic components

• Here at this juncture, it is vital that you look at the time you would need for the transition, you should be ready for a slow process because it is always slow for migration from one system to another system.You should also try to find out whether the manufacturer is capable of getting you heavy plastic solutions or not

Choose sustainability as a way of growth:

You can truly grow only when you take a look at the broader picture,sustainability should be part of your growth strategy as that would assist the growth since all government and corporate efforts are directed toward sustainability.

0 notes

Text

Ecomass Material Proves For Industrial Uses

Vibration production is a common issue with any industrial-grade types of equipment. Manufacturers often try and look around for the best methods to kill vibrations. In most cases, it certainly is not easy to kill vibrations completely.

For More details: Phone: 512-306-0020 Business email id - [email protected] Website: https://www.ecomass.com/vibration-damping/

0 notes

Text

5 Industries Where Engineered Thermoplastics Are Commonly Employed

Looking for a safer alternative to traditional lead bullets? Frangible ammunition could be the best choice. In this article, individuals will discover the benefits of using frangible bullets.

Hunting and shooting enthusiasts have long preferred lead bullets, but they pose a serious threat to both human health and the environment. A safer option is frangible ammunition, which offers advantages including less ricochet and lead-free construction.

What is Frangible Ammunition?

A Frangible bullet is one that is designed to shatter upon collisions with a hard surface, such as a steel target or concrete wall. Unlike traditional Lead substitute, which can ricochet and cause harm to people or the environment, frangible bullets are made from materials such as copper, tin, or tungsten powder that are compressed into a solid form.

When the bullet strikes a hard surface, it splits into little bits, lowering the danger of injury or damage. It is also lead-free, making it a more secure and ecologically responsible choice.

Safety Benefits of Frangible Ammunition

● Frangible Ammunition offers several safety benefits because frangible bullets break apart upon impact, they reduce the risk of ricochets and unintended harm to people or property.

● This makes them a popular choice for use in indoor shooting ranges and other environments where safety is a top priority.

● Also, since frangible ammunition is lead-free, it presents less of a threat to the environment and people who handle it.

● In training exercises, frangible bullets offer a realistic shooting experience without harm or damage.

Accuracy and Performance of Frangible Ammunition

This results in a more effective and humane kill, as well as reduced risk of ricochets and over-penetration. Additionally, frangible bullets are less likely to damage shooting ranges and equipment, making them a popular choice for indoor and outdoor shooting facilities.

Environmental Benefits of Frangible Ammunition

It is not only safer for people, but it is also better for the environment. Traditional lead bullets can contaminate soil and water sources, leading to negative impacts on wildlife and human health. Frangible bullets, on the other hand, are made from materials like copper and tin that are non-toxic and biodegradable.

This means that they do not pose a risk to the environment and can be safely used in areas where lead ammunition is prohibited. By choosing frangible ammunition, shooters can help protect the environment while still enjoying their favourite sport or activity.

Cost-Effectiveness of Frangible Ammunition

While frangible ammunition may initially seem more expensive than traditional lead bullets, it can be more cost-effective in the long run. Because frangible bullets break apart upon impact, they do not cause damage to shooting ranges and equipment, which can save range owners and operators money on repairs and maintenance.

Also, frangible bullets can reduce the risk of ricochets and over-penetration, which can lead to costly lawsuits and legal fees. Overall, the benefits of using frangible ammunition outweigh the initial cost difference.

0 notes

Text

5 Industries Where Engineered Thermoplastics Are Commonly Employed

Engineered thermoplastic is a wonder material, which has revolutionized many industries. Due to this reason, we can see its use across various industries due to its excellent combination of mechanical, thermal, and chemical properties. Here are five industries where engineered thermoplastics are commonly employed:

1. Automotive Industry: You would be surprised to know that engineered thermoplastics are extensively used in the automotive sector for various applications. In most cars, they are utilized in interior components like dashboards, door panels, and seating systems due to their lightweight nature, durability, and design flexibility. Additionally, thermoplastics are also used for under-the-hood applications such as engine covers, intake manifolds, and cooling system components. Resistance to high temperatures, corrosion, and chemicals make engineered Thermoplastics so popular in the automotive industry.

2. Aerospace Industry: On the other hand, the aerospace industry relies on engineered thermoplastics for their lightweight properties, high strength-to-weight ratio, and resistance to harsh environments. In the aerospace industry, these materials are used in aircraft interiors for components like seating, overhead bins, and cabin panels. In some structural applications, thermoplastics can be found in winglets, fairings, and interior structural components. Low weight properties of the Aerospace Industry contribute a lot to weight reduction and fuel efficiency.

3. Electronics and Electrical Industry: Just like the automobile and aerospace industry, engineered thermoplastics play a vital role in the electronics and electrical industry due to their excellent insulating properties, flame resistance, and chemical resistance. In the electronics and electrical industry, they are used in components such as connectors, sockets, housings, and insulators. Thermoplastics like polycarbonate, ABS, and PEEK are commonly employed in manufacturing consumer electronics, electrical enclosures, and circuit boards.

4. Medical and Healthcare Industry: Engineered thermoplastics are widely used in the medical and healthcare sector due to their biocompatibility, stabilizability, radiation blockage, and chemical resistance. These materials are employed in medical device manufacturing, including surgical instruments, drug delivery systems, prosthetics, orthopedic implants, and diagnostic equipment. They offer advantages such as lightweight construction, design flexibility, and resistance to bodily fluids and cleaning agents. They are used as radiation shields for X-ray operators in hospitals.

5. Packaging Industry: Engineered thermoplastics are utilized extensively in the packaging industry due to their versatility, durability, and barrier properties. They are commonly used for food and beverage packaging, pharmaceutical packaging, and industrial packaging. Thermoplastics like polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) offer excellent barrier properties against moisture, gases, and chemicals, ensuring the quality and safety of packaged goods.

These are just a few examples of industries where engineered thermoplastics are widely used. Their properties and advantages make them suitable for applications in numerous other sectors, such as construction, renewable energy, consumer goods, and more.

If you want to use high density plastics in your industry, then you can give engineered thermoplastics a try. The best part of engineered thermoplastics is that they are affordable for small industries. You can easily mold this material with heat and use this material to make any part at a large scale. Engineered thermoplastics give many advantages that you may not like to ignore.

1 note

·

View note

Text

The Advantages Of Using Frangible Ammunition Over Traditional Lead Bullets

Looking for a safer alternative to traditional lead bullets? Frangible ammunition could be the best choice. In this article, individuals will discover the benefits of using frangible bullets.

Hunting and shooting enthusiasts have long preferred lead bullets, but they pose a serious threat to both human health and the environment. A safer option is frangible ammunition, which offers advantages including less ricochet and lead-free construction.

What is Frangible Ammunition?

A Frangible bullet is one that is designed to shatter upon collisions with a hard surface, such as a steel target or concrete wall. Unlike traditional Lead substitute, which can ricochet and cause harm to people or the environment, frangible bullets are made from materials such as copper, tin, or tungsten powder that are compressed into a solid form.

When the bullet strikes a hard surface, it splits into little bits, lowering the danger of injury or damage. It is also lead-free, making it a more secure and ecologically responsible choice.

Safety Benefits of Frangible Ammunition

● Frangible Ammunition offers several safety benefits because frangible bullets break apart upon impact, they reduce the risk of ricochets and unintended harm to people or property.

● This makes them a popular choice for use in indoor shooting ranges and other environments where safety is a top priority.

● Also, since frangible ammunition is lead-free, it presents less of a threat to the environment and people who handle it.

● In training exercises, frangible bullets offer a realistic shooting experience without harm or damage.

Accuracy and Performance of Frangible Ammunition

This results in a more effective and humane kill, as well as reduced risk of ricochets and over-penetration. Additionally, frangible bullets are less likely to damage shooting ranges and equipment, making them a popular choice for indoor and outdoor shooting facilities.

Environmental Benefits of Frangible Ammunition

It is not only safer for people, but it is also better for the environment. Traditional lead bullets can contaminate soil and water sources, leading to negative impacts on wildlife and human health. Frangible bullets, on the other hand, are made from materials like copper and tin that are non-toxic and biodegradable.

This means that they do not pose a risk to the environment and can be safely used in areas where lead ammunition is prohibited. By choosing frangible ammunition, shooters can help protect the environment while still enjoying their favourite sport or activity.

Cost-Effectiveness of Frangible Ammunition

While frangible ammunition may initially seem more expensive than traditional lead bullets, it can be more cost-effective in the long run. Because frangible bullets break apart upon impact, they do not cause damage to shooting ranges and equipment, which can save range owners and operators money on repairs and maintenance.

Also, frangible bullets can reduce the risk of ricochets and over-penetration, which can lead to costly lawsuits and legal fees. Overall, the benefits of using frangible ammunition outweigh the initial cost difference.

1 note

·

View note

Text

Common Methods To Kill Vibration In Machines

Any machine will produce some level of vibration. In most cases, movable parts are the main cause of vibration. If vibration is eliminated, then the efficiency of the machine can be improved. Making use of thermoplastic pads can help in cutting down vibrations to a greater extent.

• Machine vibrations can be produced by part oscillation in common

• Movable components of the machine should be perfectly insulated

• Vibrations can be seen in all types of machines like pumps and generators

In such machines, manufacturers may want to use the best vibration dampening techniques and solutions. Vibrations can be killed using the right technique in any mechanical or electrical system. Vibration-killing material and solutions must be effective in regulating the periodic motion of the movable machine parts.

Force identification

Before any vibration-killing methods can be put into place, it is important to identify the force that causes the vibration. Force is an important element in creating vibrations in machines. The force tends to rotate, move or rub two surfaces of the machine together.

These actions can produce a lot of heat and vibration. One of the best solutions is to try and reduce the effect of the force. The thermoplastic material can be used to make the movable parts of the machine. The same material can also be used as a pad in between two layers.

Mass addition

It is natural that if more mass is added, the vibration effect can be reduced to a greater extent. Even if the force input is the same, just by increasing the mass of the system, the vibration can be reduced or regulated.

This theory is true as per the second law stated by Newton. The same technique is used by the manufacturers of diesel engines and generator machines, which are created heavier in weight. This certainly is one of the most effective ways to control vibration.

Tuning

Tuning is the method of cancelling out the vibration by regulating the amplitude of the vibration. You can also look around for thermoplastic composite material that is being used to cancel out the vibration frequency.

When tuning a machine, the technical person might try to adjust its vibration amplitude. This simple technique will help in regulating the resonance or oscillation of the machine. Pads made up of thermoplastic materials can also help in killing the resonance effects.

Isolation technique

Certainly, a specific part of the machine is always responsible for producing vibration. Once this part has been identified, it can be isolated to regulate vibration. If it is a rotating part of the machine, then pads act as a protective layer in isolating it from the main machine.

Springs and hydraulic systems also perform the same function. The thermoplastic material

can be used as padding material to eliminate friction in rubbing machine parts. Many other techniques help in controlling vibrations in a machine.

It is important to use the right technique that will help in controlling the vibration. If you manage to control and kill vibration effectively, then you can improve the performance of the machine as well. It also improves the life span of the machine.

0 notes

Text

Why High-Density Engineered Thermoplastic Is An Ideal Material For Vibration Control?

You would be surprised to know that controlling vibration is a big challenge in the industrial world. Most mechanical machines generate vibration, which can increase wear and tear in these machines. Along with that, vibration in these machines also creates a lot of noise, which also causes determent to the environment.

For this reason, vibration control becomes essential in different industries. You would be happy to know that High-density engineered thermoplastics can be an ideal material for vibration control. High-density engineered thermoplastics offer several key properties that make them an excellent option for vibration dampening:

• Damping Properties

First and foremost, high-density engineered thermoplastics have inherent vibration damping properties that effectively absorb and dissipate vibrations. When subjected to mechanical stress, these materials can absorb and convert the vibrational energy into low-level thermal energy, reducing the amplitude and intensity of the vibrations of the machine. As a result, it has become the number one Vibration damping material in different industries.

• Lightweight

Another crucial factor is that compared to traditional damping materials, high-density Engineered Thermoplastic are a lot lighter in weight. This weight characteristic of engineered thermoplastics is beneficial for applications where weight reduction is crucial. Due to this reason, high-density engineered thermoplastics are often used in the aerospace, automotive, and electronics industries. The use of high-density engineered thermoplastics helps to minimize the overall weight of the structure without compromising its vibration-dampening capabilities.

• Design Flexibility

At the same time, engineered thermoplastics offer design flexibility due to their moldability and formability that you won’t get from any other material. Engineered thermoplastics can be easily molded into complex shapes and geometries according to the industrial requirement. This property becomes helpful when you need to integrate the damping features directly into the components or structures. This capability of high-density engineered thermoplastics enhances the overall vibration damping efficiency by ensuring optimal contact and coverage to the machine.

• Chemical Resistance

Many people don’t know another property of high-density engineered thermoplastic is that it exhibits excellent chemical resistance. Engineered thermoplastic can easily withstand exposure to various chemicals, oils, and solvents, which is advantageous in extreme industrial environments where exposure to harsh substances is a very common occurrence. The resistance to chemical degradation ensures the long-term stability and durability of the damping material.

• Corrosion Resistance

Unlike ferrous metals, which can corrode when exposed to moisture or aggressive PH environments, engineered thermoplastics are generally corrosion-resistant. This characteristic makes them suitable for applications where exposure to moisture, humidity, or corrosive substances may occur. The absence of corrosion ensures the consistent performance and lifespan of vibration-dampening High density materials.

• Cost-Effectiveness

At the same time, high-density engineered thermoplastics can often offer significant cost advantages over other damping materials, such as elastomers or specialized composites. The manufacturing processes of engineered thermoplastic, such as injection molding, can be efficient and cost-effective, especially for high-volume production. Additionally, the lightweight nature of engineered thermoplastic can contribute to cost savings in transportation, installation, and overall system weight.

These are some of the main factors which make high-density engineered thermoplastics so popular in many industries. From bullet tips to aerospace, you will see the application of high-density engineered thermoplastics everywhere.

0 notes

Text

Why High-Density Polymer And Frangible Bullets Are The Future Of Shooting

Looking for a shooting alternative that is more sustainable and safe? The solution is high-density polymer and frangible bullets. In this helpful article, learn why.

High density polymer and frangible bullets may be the answer you've been looking for if you're a gun owner seeking a safer and more ecologically responsible shooting choice. Compared to conventional lead bullets, these cutting-edge materials provide a number of advantages, such as less ricochet and increased accuracy.

The dangers of traditional lead bullets

Traditional lead bullets have long been the norm for shooting, but they pose several risks. Lead is a poisonous chemical that threatens human health and environmental contamination. Lead particles that can be breathed or consumed by humans and animals are produced when lead bullets are discharged.

Lead bullets may also ricochet off of solid objects, inflicting harm or causing property damage. Due to this, a lot of shooting ranges and hunting grounds now call for alternate components like High-Density Polymer and frangible bullets.

The advantages of frangible bullets and high-density polymer

They offer a range of benefits over traditional lead bullets.

● They are considerably better for the environment and human health. Unlike lead, these materials do not pollute the land or water and do not endanger wildlife or humans who come into touch with them.

● They are much safer in shooting ranges and hunting areas as they do not ricochet off hard surfaces.

● They are more sustainable as they can be recycled and reused, reducing waste generated by shooting activities.

● These are the future of shooting and offer a safer and more sustainable option for all.

Shooting's Impact Environmental

Shooting activities have a big impact on the environment, especially when conventional lead bullets are used. Lead is a poisonous chemical that may pollute soil and water, endangering both animals and people's health.

Lead bullets can also bounce off of solid objects, increasing the possibility of mishaps and injury. Given that they don't contain lead and don't endanger the environment or people's health, flangible bullets represent a safer and more environmentally friendly option. Shooters may lessen their environmental effect and have a safer, more sustainable shooting experience by switching to these materials.

The cost-effectiveness of switching to alternative bullets

In the long term, they may be more cost-effective even if they may initially cost more than conventional lead bullets. This is due to the fact that they are made to shatter upon impact, lowering the possibility of ricochets and preventing the need for costly repairs to shooting ranges and equipment.

Therefore, using other bullets can aid shooters in avoiding hefty fines and penalties for lead contamination. For shooters, switching to these bullets may be a more economical and environmentally friendly choice.

The future of shooting and the role of alternative bullets

The shooting business is searching for methods to lessen its environmental effect as people grow more ecologically aware. Due to its advantages over traditional lead bullets, including safety, durability, and convenience, they are becoming more and more popular.

These bullets are made to fragment upon contact, lowering the possibility of lead contamination and ricochets. These alternative bullets will change how shooting is done when more shooting ranges and organizations start using them.

0 notes

Text

Why It Sustainability Is Fundamental To The Evolution Process

The world is in the process of evolution and it is a process that will never end. Evolution has brought many breakthroughs and developments. With the development, that has also been many downsides because, in the very process of development, humans have forgotten about the world and its wellbeing.

Environmental problems are mounting and it has become a pressing problem that needs to be addressed as quickly as possible. From corporations to governments, everyone is looking for ways of sustainability. Without the right approach to sustainability, the world is going toward a dangerous future. Let's find out why sustainability is important and how you must go about it.

The environmental problem is fundamental:

It is a fact that if we do not safeguard the world, it might cease to exist in the future. The weather conditions are changing and it is bringing devastating effects to the world and affecting lives around us. As a business house, it gets imperative that you start to think about sustainability. Ignoring environmental issues that are so fundamental is simply suicidal,the awareness is growing.

People around the world are slowly coming to the very understanding that sustainability is not just an idea,it is imperative and the need of the hour. This means EV sales are growing and people are replacing lead with thermoplastic composite materials. Heavy plastic or thermoplastic composite materials is the best alternatives, let's find out how.

How thermoplastic is a great alternative?

The fact of the matter is that thermoplastic is heavy and it can replace Lead which has adverse effects on the environment and lives around us. Heavy plastic can be used as radiation shielding components in the medical device industry such as x-ray shielding, the automotive industry can use heavy plastic instead of metals, and the use of heavy plastic looks promising for valid reasons.

You as a company and a business house should know how you should go about getting the best thermoplastic solutions, here are a few ideas to help you.

How to integrate thermoplastic as a sustainable alternative?

• The first thing is that you would need to take a strategic approach, which means you need to plan the transition from old materials to thermoplastic. A good manufacturer of heavy plastic can help you with a plan so that you can go through a smooth transition.A smart approach to sustainability is something that can bring a radical change

• You would need to make certain that you are talking to the manufacturers and find out whether they can get you the exact components that you need. For instance, if you have a need for vibration dampening, they must meet your demands, they should also get you customized manufacturing solutions for automotive components, a more objective approach is what you can expect from good manufacturers of thermoplastic

Take meaningful steps:

It is important for the world to get into a sustainable mode d heavy plastic can be used in many industries, you simply need to find the best manufacturers and start the transition process todayand it would be an intelligent and responsible decision.

0 notes

Text

Why Vibration-Dampening Techniques Are Important To Kill Vibrations?

If you are used to working with machines, you know how damaging can vibrations be. Vibrations of high magnitudes can also damage any movable or fixed part of the machines. As compared to inertial force and elastic force, vibrations are smaller in magnitude.

In general, vibrations are more damaging. This is why engineers always ensure that they make use of advanced techniques to kill vibrations. In specialized circumstances, vibrations can cause a lot of damage. This is why there is always a huge demand for vibration damping material at present.

• Specialized thermoplastic fibres can be used as pads to kill vibrations

• Thermoplastic material tends to cancel vibration before machine parts can be damaged

• The movable parts of the machine can easily get damaged if vibrations are not controlled

Why is vibration dampening?

Vibration cannot be beneficial in most cases. Thus it is important to reduce and lower the vibration generated. One of the most common techniques used to reduce vibration is by placing vibration-dampening material like a pad in between two layers.

The material that is used to manufacture the pad is made up of quality thermoplastic. The material acts like a layer that can absorb the vibrations. Thus the damaging effects of vibrations can be reduced or lowered. The material that is placed in between two layers can change the frequency of the vibration.

Why use thermoplastic material?

To kill vibration the material needs to have properties very much similar to rubber material. This property is very much common in thermoplastic materials. Such materials are also termed anti-vibration materials.

The vibrations that are generated on account of friction can easily be absorbed by thermoplastic material that is placed in between two layers as a pad. This technique is widely used in manufacturing industries and commercial places where vibrations can cause severe damage.

How Thermoplastic is more applicable?

Earlier it has been told that thermoplastic may have properties very much similar to rubber material. There is yet another reason why thermoplastic is better. If you are using engineered thermoplastics then it is obvious that you are aware of its durability as well.

Compared to normal rubber material, the thermoplastic material is more durable and tough. The material does not get damaged and so it can withstand heavy vibration. Due to this property, the material is also used to manufacture machine parts.

Ability to withstand heat

The vibration of any level will always produce heat. The heat that is produced on account of vibration, may be more damaging. The heat can burn moving parts of the machine because of friction force. It is important to kill vibration if excess heat is produced.

The thermoplastic material can easily absorb heat. The main property of this material is that it does not get burned. The thermoplastic material can withstand high heat and is thus useful. The material reflects vibration-dampening coefficient properties even at high temperatures.

If you are looking forward to kill vibrations, then you need to check out the unique properties of thermoplastic materials. You can check out the properties of Ecomass material. It can be used to replace rubber and offer durability as well.

0 notes

Text

The Advent Of High Density Polymers In The World Of Sustainability

The world is in pretty bad shape,pollution levels are going high causing global warming and climate issues. It is time to think about sustainability because, without a clear-cut sustainable strategy, there is less hope for the future.

From corporate boardrooms to the Davos summit, the United Nations' COP to the EU's sustainable agenda,it is the crux of the matter everywhere. All these things point to one direction every action must lead to sustainability. The approach could be different for different organizations,you can use high density polymers as sustainable materials.Here are the places where you can use heavy plastic.

Where high-density polymers can be used?

Heavy plastic can be used in many industries, it can be used in law enforcement agencies as green ammo or frangible bullets which can be used for training purposes, in that way, lethal substance lead can be eliminated.

These materials can also be used in the medical device industry as radiation shielding materials,you can also use heavy plastic in the automotive industry too. The fact is that it can replace lead and meet all the functional requirements that your product needs. One should know how to go about getting heavy plastic and what should be the approach.

The right approach for heavy plastic as a sustainable option:

• The first thing that you need to understand the fact is that you must take a strategic route,which means you need to know the fact that the transition can be slow and a little daunting. For this, you need to talk to the best producers of heavy plastic and find out how they can help you with the transition

• You would need to talk to the manufacturer and find out how they can make components for you, most of the producers that are reputed can customize heavy plastic components for your exact needs. You need to also verify the compliance factor too because X-ray shielding must meet certain quality standards that the best manufacturers can do for you

• You should man sure that you talk to the manufacturer and find out what could be possible challenges. You also need to make sure that you are talking to them about how these materials are useful and his they can help you meet environmental goals

It is a smart idea to choose heavy plastic:

Companies can greatly benefit from sustainable efforts, new age consumers are looking for products that meet sustainable goals. In this way, you can make a better brand or is also your responsibility to do for the planet and community for sustainability.

Talk to the best heavy plastic manufacturer today:

Whether you are looking for X-ray shielding or you are going for green ammo or is important that you need to work with the best heavy plastic manufacturers. Youwould need to take a look at the clients they served for heavy plastic needs.

You would need to visit their production facility to learn more about their capability so that you know how good they are andhow they can serve you, talk to the best manufacturers today for all you needs.

0 notes

Text

How Do Different Industries Use High Density Plastics For Different Purposes?

The use of thermoplastic composites has gained popularity in recent years. These materials combine fiber strength with thermoplastic properties to produce a final product that is strong and lightweight. At the same time, the affordable price of these composites makes them perfect for mass adoption in different industries.

Depending on your needs and budget, they can be used in a variety of industries and applications. From sports to defense, various industries around the world are using this material for different applications. Let’s check out a few industries where we can see wide use of High Density Plastics

1) Automobile industry

We can see the wide use of thermoplastic composite materials in the modern automobile industry. Here, different automobile high-performance parts are made from this material. Low-weight and flexible modules have made this material so popular in the automobile industry.

2) Defense industry

Many ammunition manufacturers are also using this material for bullet tips. Compared to conventional bullets, these bullets have more benefits. The first benefit of making bullets from high density plastics is a significant increment in range and accuracy. Due to this reason, the shooter can hit a target farther away with more accuracy.

3) Healthcare sector

In the healthcare sector, we see the use of this material for radiation shielding. Modern radiation shields made from this material are lightweight. Due to this reason, people in the healthcare sector feel more comfortable when they work long hours wearing these radiation shields. Many modern hospitals have already accepted the use of radiation shields made from this material.

4) Electronic industry

Radiation shielding properties also make them suitable for sensitive electronics. We can see wide of this plastic as a sensitive electronic equipment covering. This covering protects sensitive electronic equipment from powerful radiation and increases the lifespan of electronic equipment. Due to this reason, these plastics are so popular in the electronic industry also.

5) Sports industry

You would be happy to know that the sports industry has accepted this material as an alternative to steel. These days, many golf club manufacturers are using thermoplastic composite material

for making the next generation golf clubs. Apart from golf clubs, various other sports equipment manufacturers are also using this material to make the next generation sports equipment.

Misconceptions about thermoplastic composites

One of the most widespread misconceptions about thermoplastic composites is that they are weaker than materials like steel. However, thermoplastic composite materials are some of the strongest materials for their weight. You can achieve high strength-to-weight ratios with these materials and even increase reinforcement to further strengthen the material, making it suitable for critical structural components in vehicles.

Another misconception about thermoplastic composites is that they are expensive. This myth about the price of this material is completely false. Many people don't know that thermoplastic composites can be turned into any shape by using a mold. Due to this reason, making any component at a large scale is possible with this material. Compared to aluminum or steel, thermoplastic composite materials cost way less and are ready for mass adoption in different industries.

0 notes

Text

Why Thermoplastic Materials Are The Best For X-Ray And Gamma-Ray Shielding?

Radiation is an unavoidable part of life for those people who work in the healthcare sector. Here, these people are constantly exposed to radiation from various sources like X-ray machines and medical procedures.

While low-level exposure from these machines is generally harmless, regular exposure to high-level of radiation can have harmful effects on our bodies. Therefore, these people need to protect themselves from unnecessary exposure to radiation. One effective way to do this is through the use of radiation-shielding materials.

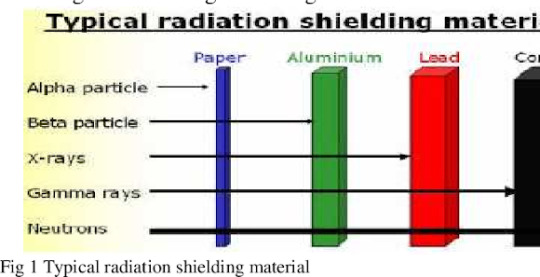

You would be happy to know that radiation shielding materials are designed to absorb or deflect radiation, reducing its effects on the human body. While there are various types of materials that can be used for this purpose, thermoplastic materials are the best for X-ray shielding.

• High-density

One of the most crucial factors that play a vital role in radiation shielding is density. The denser the material, the more effective it is at absorbing and deflecting harmful radiations. Thermoplastic materials like high-density polyethylene (HDPE) and polyvinyl chloride (PVC) have a higher density than many other materials commonly used for radiation shielding, such as concrete or lead. This makes thermoplastic materials more effective at blocking X-rays and gamma-rays.

• Lightweight

While density is important, weight is also a consideration in radiation shielding. Heavy materials like lead can be difficult to handle every day. Thermoplastic materials are lightweight, making them easier to handle and install. This also means that thermoplastic materials can be used in a wider range of applications, including medical settings where mobility is important.

• Customizable

The best part of thermoplastic materials is that they can be easily molded into a variety of shapes and sizes, making them highly customizable. This is especially important in medical settings, where radiation shielding materials need to be tailored to the specific needs of individual patients. Customizable shielding materials ensure that patients receive the maximum amount of protection while minimizing unnecessary radiation exposure.

• Durable

You would be happy to know that thermoplastic materials are highly durable and resistant to corrosion, making them ideal for use in harsh environments. The thermoplastic materials are also resistant to UV radiation, ensuring that they will maintain their effectiveness over time. At the same time, these shields also give full protection from high-level gamma radiation. You will see a wide of gamma ray shielding in different science labs.

• Cost-effective

Just a few decades ago, lead was a common material used for radiation shielding, but was expensive and difficult to work with. Thermoplastic materials, on the other hand, are cost-effective and easy to manufacture. This makes them an attractive option for a wide range of applications, from medical settings to industrial applications.

In conclusion, thermoplastic materials are the best choice for X-ray and gamma-ray shielding. They offer a range of benefits over other materials, including high-density, lightweight, customizability, durability, and cost-effectiveness. By using these materials, people in the healthcare sector can protect themselves from unnecessary exposure to radiation and ensure that we live healthy, radiation-free lives.

0 notes