Leddy Power is one of the leading electric power generation service provider located in Moorpark, CA. We are proud to provide our clients with comprehensive and reliable power solutions to cater to their needs. Our products are top of the class and can provide uninterrupted power to commercial buildings, industries, healthcare facilities, surgical centers, military, marine, agriculture, oil & gas, data centers, telecom, local, state and federal government entities. We provide our services to the Western United States including California, Nevada, and Arizona.

Don't wanna be here? Send us removal request.

Text

Why Generator Voltage Drops Under Load and How to Fix It

Generators are synonymous with ‘reliable power’…

They help our critical infrastructures, like hospitals, financial institutions, and businesses, keep functioning during a power crisis. Now, imagine the inconvenience they might cause should their power output drop. Some of the leading reasons why voltage drop occurs in generators under load have been discussed in detail here.

Common Reasons for Voltage Drop Under Load

Reason #1- Insufficient excitation (Field current)

The term ‘excitation’ simply refers to the process of supplying current to the field windings (the rotor) of the generator. Uniform magnetic field produced due to this process allows the generator to operate efficiently and engender constant voltage. In simple words... for the generator’s power output to remain stable under varying loads, balanced excitation is important.

If = Excitation current

E= Induced voltage

ᶲ = Magnetic flux

N= Number of turns in the stator windings

The generator's output voltage will fluctuate erratically if the components responsible for maintaining optimal excitation, such as the exciter or voltage regulator, fail.

How to fix insufficient excitation?

- Carefully inspect the excitation system components and rotor windings for any damage.

- Adjust excitation settings according to voltage requirement of the load.

Reason #2- Overloading the generator

Not selecting the right generator size may contribute to voltage instability among other performance issues. There is a limit to how much voltage a generator may produce. Overloading may cause the generator to work hard to meet the power demand of the connected loads… this may hinder the generator’s ability to perform smoothly and maintain consistent voltage.

So, what’s the solution?

- Select the right generator size… The following example can help you in this regard.

- Let’s imagine you have to power three loads: Device 1: 20kW, Device 2: 15kW, and Device 3: 10 kW.

Total load demand: 20 kW+ 15kW+ 10kW= 45kW

- Maintain a safety margin of 20% of the total load (20% of 45kW= 9kW) and take ‘starting surge’ into account. To calculate starting surge, multiply the motor’s rated power by 3. If the motor’s rated power is 1.5 kW, then the starting surge would be… 1.5 * 3= 4.5 kW. Add all these things up… and you have your generator size.

Generator size: 45kW + 9kW + 4.5 kW= 58.5 kW ≈ 60kW

Reason #3- Poor or loose connections

Wires and connectors linking the generator to the load may wear down or become corroded over time… which can introduce more resistance in the circuit. Added resistance will reduce the amount of current flowing through the system― impacting the generator’s output voltage. Heat buildup because of increased friction may introduce unwanted resistance to the circuit, contributing to voltage instability.

What’s the fix?

- Check wires and connections for any visible signs of corrosion, wear, or looseness.

- Properly tighten the bolts, screws, and nuts.

- Clean corroded terminals and apply a protective coating.

- Replace defective terminals and connections with high-quality substitutes.

Reason #4- Prime mover issues

How efficiently a generator will produce power depends greatly on the functionality of its prime mover… the engine or turbine. It is the central component of any generator unit, responsible for turning the generator’s rotor and inducing electric current in the stator. If it starts operating inefficiently, the generator’s voltage output will fluctuate erratically.

What’s the fix?

- Find out the culprit that has hindered the prime mover’s ability to operate smoothly and efficiently.

- Start by checking the fuel delivery, air intake, and cooling system components.

Reason #5- Load imbalance

Load imbalance is a leading reason for voltage drop in three-phase generators. Such generators work by providing three separate alternating currents in a cyclic manner… each phase offset by 120 degrees. Load imbalance resulted from uneven load distribution, improper wiring, and faulty equipment can lead to significant voltage drop, among other issues.

What’s the fix?

- There are a few things that you can do to balance the load across all three phrases.

- You can reconfigure the system wiring.

- Consider investing in load management systems or automatic phase selectors.

Wrapping Up

Some of the prominent reasons why your generator voltage might drop under load include improper excitation, overloading, loose connections, prime mover malfunction, and load imbalance (in three-phase generators). Using undersized cables, a weak voltage regulator, issues with the commutator and brushes may also result in voltage drop in generators.

#generator#generator voltage#generator maintenance#generator services#generator voltage drop#generator mechanic#diesel generator

0 notes

Text

Fuel quality is crucial for your generator's performance and longevity. Common fuel issues include stale fuel, contamination, water, and incorrect fuel types, which can lead to engine failure. Regular maintenance, proper fuel storage, and using the right fuel type can prevent these problems, ensuring your generator runs smoothly and efficiently.

#generator#generator fuel system#generator maintenance#generator services#generator mechanic#generator repair

0 notes

Text

If your Automatic Transfer Switch (ATS) isn’t starting the generator, it could be due to power supply issues, configuration errors, faulty wiring, or problems with the generator’s starting mechanism. Diagnose the problem by checking connections, testing ATS functionality, and inspecting the generator.

0 notes

Text

If your generator battery keeps dying, it could be due to issues like a defective voltage regulator, malfunctioning alternator, an old battery, infrequent use, improper charging, loose connections, or environmental factors. Regular maintenance and addressing these causes can help extend battery life and ensure reliable generator performance.

0 notes

Text

Ensure reliable power for your marine adventures by maximizing generator efficiency with essential maintenance services. This guide covers key tasks like fuel system cleaning, cooling checks, and regular oil changes, all critical to preventing breakdowns and extending generator life. Keep your power supply steady and efficient, enabling smooth sailing and peace of mind wherever your journey takes you.

0 notes

Text

To optimize diesel generator performance, invest in a robust monitoring system with key features: an intuitive dashboard, real-time data updates, remote access, customizable alerts, strong data security, automatic backup, and reliable support. These features enhance efficiency, prevent failures, and ensure reliable power management.

#generator#generator maintenance#generator mechanic#generator installation#generator services#generator engine service

0 notes

Text

Generators are crucial for backup power, but unusual noises signal potential issues. Common sounds include whining from belt or alternator problems, rattling from loose parts or debris, knocking due to engine issues or improper mounting, and hissing from fuel or exhaust system faults. Addressing these promptly ensures safety and efficiency.

#generator#generator maintenance#generator services#types of generator#generator installation#generator mechanic#diesel generator#generator engine service

0 notes

Text

What Are Some Common Mistakes to Guard Against During Generator Installation

Lately, a lot of homeowners and businesses have been opting for generators as ensuring proper power backup is very necessary. However, installing a generator is not at all an easy task and there are a lot of mistakes made by millennials when setting up their generators which can cost them dearly in the long run.

If you are thinking about installing a generator in your house or workplace then it is imperative for you to avoid these blunders. Here in this article, we will discuss the common mistakes you need to guard against during generator installation.

Opting For Improper Size

One of the top mistakes made by most people opting for generators is related to the size of the generator. Most of the time it is seen that people opt for a generator that is either too small or too big for their intended usage. Now, if a generator is too small then you won’t be getting enough power output to keep the important systems running during a power outage.

Moreover, if you are opting for a large generator then it can lead to inefficient functioning and increased consumption of fuel that could have been avoided. That is why it is necessary to take into account your load consumption including the critical appliances and items while choosing a generator for your usage.

If you have the details of your load consumption then it is going to help you in choosing the generator that serves you efficiently by handling peak load requirements without any fuss. Besides that, it is also important to factor in the duration of your appliance usage when selecting a generator for your home.

Unsuitable Placement

Not only choosing the generator with appropriate load output is necessary but placing the generator in the correct location also plays a vital role in its optimal running. Furthermore, unsuitable placement of the generator can create a lot of troubles for you including posing as safety risks for you as well.

It is pertinent for you to ensure that the generator is installed at a distance from your windows, doors, and vents so that the exhaust gases from the generators when it is running doesn’t enter your home. In addition to that, you must avoid keeping the generator near any combustible materials as it can lead to overheating & fire hazards.

That is why placing the generator in an area where there is adequate room for ventilation is very important for its optimal functioning. Besides that, when choosing a place for your generator make sure that the place is elevated from the ground so that during the rainy season the risk of water getting into the generator is minimized to a great extent.

Foresaking Locals Laws & Regulations

At times, it is witnessed that home & business owners are not at all aware of the local laws and regulations governing the use of generators and this can land you in trouble. There are a lot of instances of people having to cough up costly fines because they failed to obtain the necessary permits required to operate generators.

The laws governing the usage of generators are very broad and they take into consideration everything from the placement of the generator to its noise levels and fuel storage everything is governed by the laws. These laws and regulations not only ensure your safety but also make sure that there is minimum impact on the environment due to the operation of the generator.

Furthermore, before going forward with your plan of installing the generator, you must consult the local authorities or get in touch with a licensed contractor who is well acquainted with all the local and regulations and can help in installing your generator.

Going For DIY Methods

The majority of people take to the internet and watch some DIY videos of generator installation and try to replicate that with their own generators and this is a big mistake they are committing on their part. They end up causing problems for themselves as installing a generator isn’t an easy job.

That is why it makes sense to get in touch with a professional contractor who can assist you in installing the generator safely without any risks.

Finally

The above-discussed factors are some of the common mistakes committed by people when installing generators in their homes or businesses. Installation of a generator shouldn’t be taken lightly and following all the rules & regulations in place is the need of the hour.

#generator#generator installation#generator maintenance#generator mechanic#generator services#generator service

0 notes

Text

Discover why your generator shuts off under load in this infographic. Learn common issues like fuel problems, overloading, overheating, and mechanical faults. Explore actionable steps such as checking fuel levels, managing load capacity, ensuring ventilation, and performing maintenance. Ensure reliable generator operation with expert tips for troubleshooting and proactive maintenance.

#generator#generator maintenance#generator services#generator service#generator mechanic#generator engine service

0 notes

Text

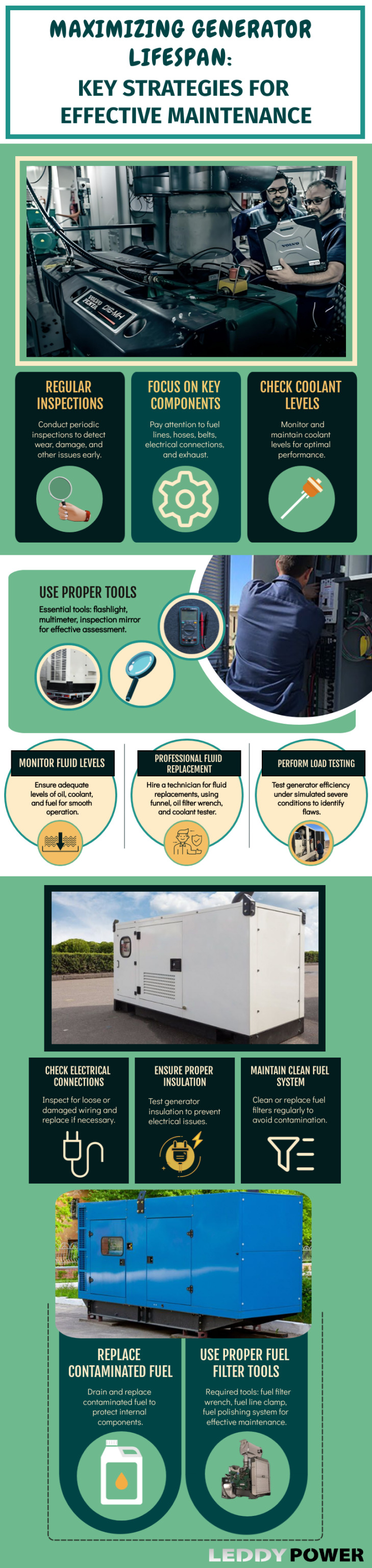

Ensuring the longevity of your generator requires regular inspections, fluid system maintenance, load testing, and clean fuel management. Focus on key components like fuel lines, belts, and electrical connections. Use proper tools and seek professional help for fluid replacements. Regularly clean or replace fuel filters and monitor coolant levels to keep your generator running efficiently and reliably.

#generator#generator maintenance#generator services#generator mechanic#generator engine service#diesel generator#commercial generator

0 notes

Text

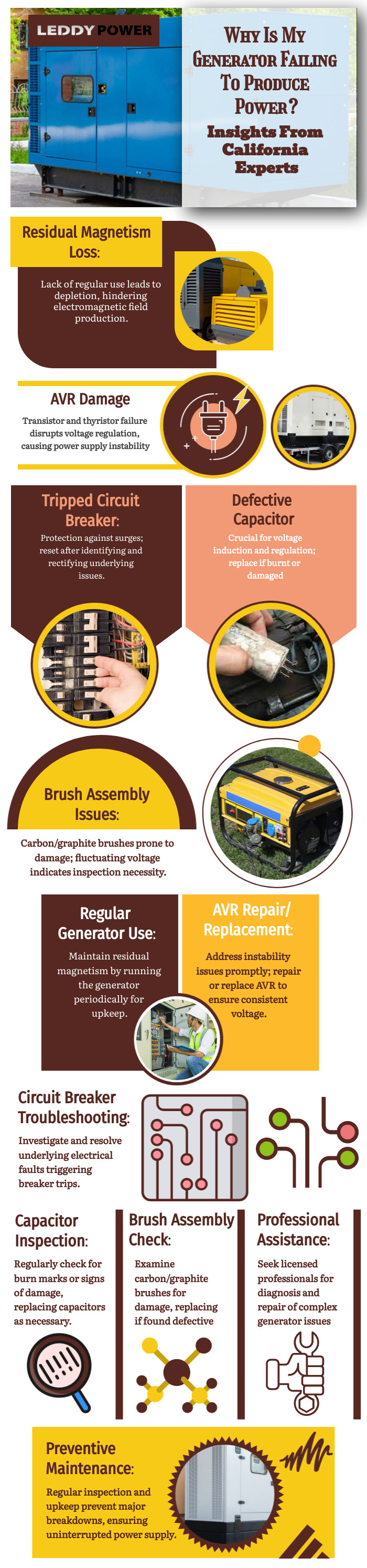

Discover insights from California experts on why your generator may fail to produce power. Learn about common issues like residual magnetism loss, damaged AVR, tripped circuit breakers, defective capacitors, and faulty brush assemblies. Find solutions to ensure uninterrupted power supply for your needs.

0 notes

Text

Why Is My Generator Failing To Produce Power? Insights From California Experts

So, your generator has given up its power generation capability. In an attempt to figure out what went wrong with your generator system, you did what any wise person would do- you Googled it and found this article. Before you read this blog post all the way through, you must understand what this post is all about… Topics covered in this article are as follows;

#1- Reasons why a generator may stop producing power

#2- Proven solutions (quick fix)

Generator Runs but No Power: Discussing the Reasons

The generator you have in your backyard is a very complex machine designed to do a very simple task- which is to fulfill your electricity requirement when the grid power is down. But being a machine your generator is susceptible to different technical glitches- some of which may impair its power generation capability.

#1- Residual magnetism- It’s lost

Electromagnetic induction; the fundamental principle on which all electric generators work. As you can guess, making of magnetic field is crucial for a generator to produce electricity. But you won’t find any magnet in your generator… Because an electric generator use something known as ‘electromagnet’. Residual magnetism is the reason why a generator get to contrive electromagnetic field required for electricity generation. Loss of residual magnetism will hinder your generator’s electricity generation ability.

So, what’s The Fix?

Not using the generator on a regular basis is what contributes to residual magnetism loss. So, if you don’t want your generator’s residual magnetism level to deplete, run it regularly and ensure its upkeep.

#2- AVR- It’s damaged

Made of transistors and thyristors, an AVR or Automatic Voltage Regulator, essentially regulates the generator’s output voltage. In other words, it is because of this component- the generator installed in your backyard provides you with constant and steady power supply. If there is something off with a part of such significance, your generator won’t delivery any electricity. Additionally, voltage spike caused by a defective AVR can result in expensive electrical repairs.

So, What’s The Fix?

A defective AVR can contribute to all sorts of performance issues in a generator including unstable terminal voltage. If you are suspecting an AVR-related issue in your generator, get it repaired or replaced as the situation demands.

#3- Circuit breaker- It’s tripped

Circuit breakers, as you are probably aware, essentially provide protection against power surges and other form of electrical anomalies. If one of circuit breakers your generator come equipped with gets tripped because of an electric short circuit or overloading, it will have an adverse impact on the generator’s power output. And yes… the generator may even cease to function because of a tripped circuit breaker.

So, What’s The Fix?

To fix the tripped circuit breaker, you must find out the reason that prompted such an action in the first place. If you lack the skill and equipment required to get the job done, contact a licensed professional who can.

#4- The capacitor- It’s broken

One reason why your generator may stop producing electricity is a defective capacitor. The capacitor is entrusted with the task of inducing voltage in the rotor. It also plays a crucial role in regulating the output voltage of the generator. So, obviously… if it gives up, the power output of your generator will fluctuate erratically and it may even cease producing electricity. Fortunately, there are signs you can look for if you suspect a capacitor issue in your generator.

So, What’s The Fix?

Check your generator’s capacitor from time to time… If you notice burn marks on the capacitor or something like that, get it replaced right away.

#5- Defective Brushes

Your generator won’t produce any electricity if its brushes are damaged. Made of carbon and graphite- generator brushes are vulnerable to all sorts of issues. If your generator’s voltage output has been fluctuating a lot lately, the very first thing that you should do is to have its brush assembly checked by certified professionals.

So, What’s The Fix?

If defective brush assembly is the reason why your generator has stopped producing electricity, consider replacing it.

Concluding Remarks

So, there you have it…

- A list of reasons why a generator may stop generating electricity.

- And, things that you can do to get the issues fixed.

We hope this helps.

0 notes

Text

Discover why your generator stalls shortly after starting. Explore fuel supply issues, air intake obstructions, engine malfunctions, and potential overloading problems. Regular maintenance, including checking fuel delivery, air filters, and engine components, is crucial for a generator's continuous operation. Addressing these issues ensures reliable and sustained power during outages.

0 notes

Text

Load bank testing is a crucial diagnostic tool that can uncover hidden problems in generator systems. By simulating real-life conditions and evaluating factors like engine health, alternator efficiency, and fuel system integrity, it ensures early detection of issues, preventing unexpected failures and ensuring the reliability of the generator during power outages.

#generator service#generator maintenance#generator#generator services#diesel generator#generator mechanic#commercial generator

0 notes

Text

Regular analysis of generator fluids is pivotal for its reliability. Evaluating fuel, coolant, and oil ensures early detection of potential issues, averting breakdowns during crucial moments. Periodic analysis prolongs the generator's life, enhances performance, and prevents costly repairs, ensuring uninterrupted power during emergencies.

0 notes

Text

These summarized points provide an overview of the key advantages and disadvantages of air-cooled and liquid-cooled generators, aiding in the decision-making process for acquiring a suitable generator for residential or commercial use.

0 notes

Text

So, there you have it; some of the prominent reasons and signs of AVR malfunction in a generator. Automatic voltage regulator is an important part of the generator's excitation system and needs adequate care to operate smoothly and efficiently.

0 notes