Don't wanna be here? Send us removal request.

Photo

Technology Market

0 notes

Text

Everything with a beginning has an and

Dear readers,

With this blog we want to announce the end of our research.

It was a very instructive week in which a lot of information about our own technology was obtained, but also a lot of informative information about other technologies on the technology market.

Here are some pictures of the market on which our stand can be seen.

The presentations went well and there was a lot of interest in our technology, the Cobot.

We have experienced this week as very educational. In the beginning the idea was created that the market was going to be like the culture shower in the first week of our education, but afterwards it turned out to be a false bias. It was a very interesting afternoon, all kinds of technologies were exhibited and every group became a specialist on a certain technology.

The research on our technology also yielded many surprising results. An example of this was that the cobot was not as difficult to program as previously thought. We also did not expect employability to be so flexible, but nothing was less true.

Furthermore, the prejudice that when cobots are used to replace people was not always true. Cobots can also be used to help people!

We also learnt that the part about the vision of the cobot was more important than we expected. The vision compares two pictures and the cobot performs an action when the two pictures match. The vision technology on the cobot was an extra addition, but it was very similar to the AI (Artificial Intelligence) technology that also appeared on the market.

We want to thank you as a reader for the interests!

And now it’s time for us to start a new challenge.

Group D:

Ivo Coolen

Justine Hoeksel

Evi Saat

Jordi Straatman

0 notes

Text

A Cobot with six axes, what does that mean?

The six axes of the cobot ensure that the cobot can do the movements that are required. The direction of the movement is determined by these axes. The first three axes are the linear movements, the X, the Y and the Z. The fourth axis is a rotating shaft, with which the workpiece can be rotated. The fifth and sixth axes are in the spindle head. Shaft five turns the spindle head to the left and right and the sixth shaft tilts the spindle head from front to back.

These movements can be performed by the cobot with any type of tool in the head. There are already many types of tools on the market that can be used in the head. There are also companies that can make special tools. In this way the cobots can be used very flexibly. In many companies, there is still a fear of cooperating with cobots. Often there is the idea that jobs will be replaced by the robots/cobots. However, this does not have to be the case at all. The cobot can also serve to illuminate an employee’s duties. This way more attention can be paid to the working conditions of the employee and this makes the work of the staff even more pleasant.

It is therefore very important that the employees of the companies are involved in the purchasing process. This also has advantages for the company itself because influences can come from the production floor. This way, the tools can be chosen correctly and no additional tools need to be purchased later. Absenteeism can also be reduced with the purchase of a cobot. Employees receive complaints from (heavy) repetitive work. A cobot can perform this work without experiencing these symptoms or having emotions.

2 notes

·

View notes

Text

What you didn’t know about the Cobot

Welcome to a new blog about the Cobot. In this blog we are telling you about the benefits versus the costs of the Cobot, about which influences the Cobot has on the Process, Control, Organisation and Information (PCOI) of a company and what strategic impact this entails.

Benefits versus Costs

A number of advantages the Cobot brings with it is flexibility and versatility. He can fulfill various functions within a company. A company can also purchase various attachments (screwdriver, welder etc.).

Example: A company has a filling machine that runs one month per year due to the average demand. The remaining eleven months the machine is basically 'doing nothing'. When the company purchases a Cobot, it can take over the function of the filling machine for one month. The gain can be achieved with the flexibility and versatility of the Cobot. For the remaining eleven months, the Cobot can be used at another factory in the factory.

Because of these advantages, a company saves a lot of costs on the use of the filling machine. It no longer work for one month, so that the available space and time can be spent more effectively. A filling machine also has a high payback time, which is considerably lower for the Cobot. And last but not least a Cobot can take over the work of a normal employee, which reduses the wage costs.

PCOI

The Cobot had a big influence on the process. The Cobot can replace a human and work a lot faster because the Cobot is able to work 24/7 without breaks. Beside this the Cobot makes less mistakes. It depends how the market is developing and growing if employees are laid off or if the Cobot is deployed to expend the production capacity. In this case the organisation will change without firing employees.

The Cobot needs to be controlled by an employee. The responsibilities within the company will be changing by adding the Cobot. These changes won’t be drastic. In the information flow there also won’t be drastic changes, the company will only add one information flow. In the beginning the management will need to check this information to see if the implementation from the Cobot is going as planned. After a few months the management only needs to check the information around the Cobot once in a period.

Strategy

There are no new PMC’s created by using the Cobot. It stimulates to competition a little, because the purchase of the Cobot reduces wage costs. The efficiency also rises because the Cobot can produce 24/7. The quality increase because the Cobot works more accurately that a regular employee. As explained earlier, the Cobot is very flexible.

0 notes

Photo

Even faster, cheaper, stronger, which impovements can be realised for the Cobot?

De Cobot has already been through some improvements, however, there are still some points for improvement for the Cobot, such as the vision, speed and other specifications.

The Cobot has a built-in vision system. This system integrates both the hardware and software perfectly. In combination with many standard vision functions, such as pattern matching, object localization, color recognition, bar code reading etc., the Cobot can for example detect if there is a product in the right place. If there isn’t a product he can take another product and place it in the right place. However, there still can be made some improvements concerning the vision. It still takes a lot of time for the software to localize the product.

The user interface has also improved a lot since the first Cobot came into the market. Nowadays everyone can program a Cobot, even employees without coding experience. A future development for the programming of the Cobot can be a video. For example an employee does the job first one time so the Cobot can see what he needs to do.

The last future development has to do with the force that the Cobot uses to pick something up. It’s a sort of feeling the Cobot has so it can do more accurate work. The developers are already busy with developing this feature.

Ofcourse there are some aspects that can always be improved, such as the costs, the speed of the proceedings and the power of the Cobot.

0 notes

Text

The one with the companyvisit

Today was the day. We visited De Wit in Helmond too see the cobot in action!

After some issues with the public transport we finally managed to get there. We had to walk 35 minutes, but at the end it was definitely worth it! First we had an interview with the operations manager. He gave us a lot of information about the Cobot and the company itself. He also gave us a tour through factory. During this tour we saw how a nail was made out of raw material. In a lot of company they outsource a lot of things like maintenance, but within De Wit this is not the case. The operations manager also showed us which tasks could possibly be replaced by the Cobot. These were often monotonous tasks. The employees were happy that they didn’t have to do these kind of tasks anymore.

De Wit is a company that listens to what the customers wants. They follow the needs of the market. They also think about the employees when they invest in more Cobots. For example the retirement age, the older employees can control the Cobot so they don’t have to do the heavy duties. Also they only invest in more Cobots if they know for sure that they don’t have to fire some employees. Ofcourse they also looked at the financial benefits. This is necessary because the competition is killing. Many competitors are based in China and Asia, which means that labor costs are already lower.

This was the short overview of today and further information will follow soon!

0 notes

Text

I’m not a ro-bot

What a news! Tomorrow the company “De Wit” will get a Cobot. The Cobot TM12.

A Cobot is a collaborative robot. This means that the robot assist the employee in successfully finishing his work. The Cobot can't be moved after it has been installed. The robot is surrounded by fences to ensure the safety of the employees. The robot can be found in the semiconductor-, panel-, CNC industry and others.

Later on, company “De Wit” will also get a robot. It only is too early to give any information about this robot because “De Wit” is still in the process of orientation for the robot. What is known is that the robot is expected to have a larger working area and a higher lifting weight of the robot.

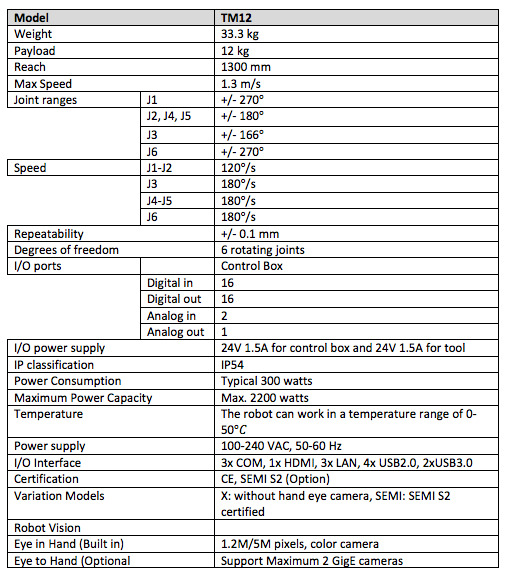

Above you can see a picture of all the specifications (product-matrix) of the Cobot TM12.

The next step for us is preparing some questions for the company visit on Monday.

0 notes

Text

Let’s get started!

Yesterday we have chosen a very nice and fascinating technology, called robotic surgery. However, we as a group found out that a visit to a hospital wasn’t realistic in such a small period of time. Since we don’t have much time anymore, we decided to search for companies with a cool technology where some of us has any connections.

A few e-mails and phone calls later we found an interesting production company located in Helmond. The company "de Wit B.V." provides high-quality fastening products for their partners. Last month they purchased a new packaging machine, named Cobot TM12. Within this company we will investigate the pros and cons entail the purchase of this machine.

Tomorrow we will contact the employee who is responsible for the Cobot TM12 machine, to get to know the machine. And last but not least, to make arrangements about the company visit.

We’re looking forward to it!

0 notes

Photo

Welcome to our blog,

We would like to introduce our self before we start talking about serious school stuff. We are a group of four students studying Industrial Engineering at Fontys University in Eindhoven. The group members are Jordi, Justine, Evi and Ivo (in order of the photo above this blog). All the four of us are in our last year, year 4, of our study. We are a group of enthusiastic that have an eager to learn.

During this assignment we need to pick an interesting technology that is used in company. After we chose the technology we will be contacting a company. This company will tell us more about why they chose this technology and what measure needed to be taking to implement this technology in the company.

In this blog you will be able to read which steps we will take as a group to successfully complete this assignment. The final product will be a market on Friday the 14th of September where we will present our technology and the impacts of this technology. You are all invited to come see our presentation on the 14th of September.

1 note

·

View note