Text

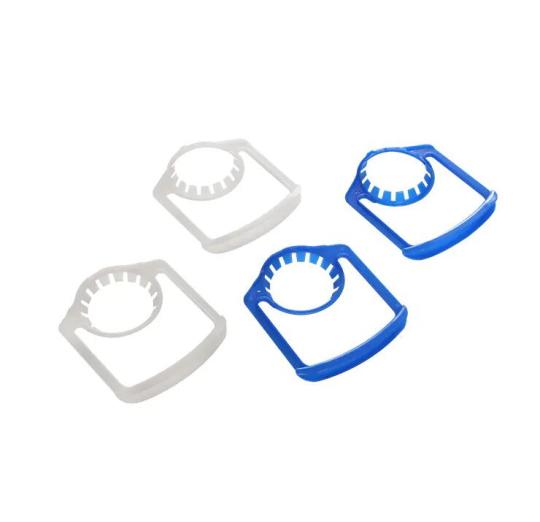

Plastic Bottle neck holder and handle

. it is not fragile and deformation. .easy to carry. .Environmental protection

0 notes

Text

The Design Of 5 Gallon PET Preforms

The existing weight ranges from 350g-800g, and the pet preform is widely used in 3-gallon and 5-gallon mineral water drums of 10L-20L and super large capacity. In terms of production technology, we adopt new raw materials, and reduce dust and magazines generated during heating through centralized drying and feeding mode.

0 notes

Text

Advantages of PET Preforms

1. Environmental Benefits PET is a type of plastic known for its recyclability. PET preforms play a crucial role in this by ensuring that the final products are made from materials that can be recycled and repurposed. The recycling process for PET can significantly reduce the environmental impact of plastic packaging. By choosing PET preforms, manufacturers contribute to a circular economy, where materials are continually reused rather than discarded. 2. Energy Efficiency The production of PET preforms is energy-efficient compared to manufacturing full bottles. Preforms are produced in a compact and uniform shape, which reduce the energy required for molding and heating. Additionally, the transportation of preforms is more efficient due to their smaller size and reduced weight compared to finished bottles. This efficiency contributes to lower carbon emissions throughout the production and distribution process. 3. Cost-Effectiveness Purchasing PET preforms wholesale offers several cost advantages. Wholesale suppliers typically offer bulk pricing, which reduces the cost per unit. This is especially beneficial for companies that require large quantities of preforms for their packaging needs. Furthermore, wholesale purchasing helps streamline procurement processes, saving time and resources for businesses.

0 notes

Text

The Role Of Wide Mouth PET Preforms

The advantages of using wide mouth PET preforms wholesale are numerous and diverse. One of the primary benefits is their ability to simplify the packaging process. The wide mouth design facilitates easy and efficient filling, which is particularly advantageous for products that need to be added in bulk or require frequent refilling. Additionally, the wide opening allows for easy access to the contents, enhancing the user experience.

0 notes

Text

Sustainable Solutions: Eco-Friendly PET Preforms

The adoption of eco-friendly PET preforms offers several significant environmental advantages:

Reduction in Carbon Footprint:

By utilizing recycled PET or bio-based PET resin, eco-friendly PET preforms help reduce greenhouse gas emissions and energy consumption compared to the production of virgin plastics. This contributes to mitigating climate change and promoting sustainable manufacturing practices.

Recycling and Circular Economy:

PET preforms made from recycled PET support closed-loop recycling systems, where post-consumer PET bottles are collected, processed, and transformed into new preforms and products. This circular economy approach promotes resource efficiency and plastic waste in landfills and oceans.

0 notes

Text

An Introduction To PET Preform Wholesale

PET preforms play a crucial role in the packaging industry, particularly in the production of plastic bottles for beverages, personal care products, household cleaners, and more. Their versatility, durability, and lightweight nature make them an ideal choice for packaging applications where strength, flexibility, and cost-effectiveness are essential. PET (Polyethylene terephthalate) preforms are small, tubular-shaped plastic components that serve as the building blocks for plastic bottles. They are typically made through a process called injection molding, where molten PET resin is injected into a mold cavity and then cooled and solidified to form the desired shape. PET preforms are designed to have a specific weight and thickness, ensuring consistent performance and quality in the final product.

0 notes

Text

Durability and Flexibility:PET Bottle Caps

PET bottle caps manufacturers are known for their durability and flexibility, making them ideal for the rigors of beverage production and distribution. These caps can withstand the pressures of bottling machinery, transportation, and handling without breaking or deforming. The flexibility of PET allows manufacturers to design bottle caps in various shapes and sizes, accommodating different bottle designs and branding needs. This adaptability is a significant advantage for the beverage industry, which often requires unique packaging solutions.

0 notes

Text

Features of PET Preform

PET Preform Wholesale offer durability and performance compared to traditional packaging materials such as glass or metal. PET bottles and containers made from PET Preform Wholesale are lightweight yet strong, providing excellent protection for the contents while minimizing the risk of breakage or damage during handling and transportation. This durability not only ensures product integrity but also reduces the risk of waste and spoilage, making PET Preform Wholesale an environmentally friendly choice for packaging.

0 notes

Text

What Are The Uses of PET Preforms?

In the personal care industry, 30mm PET preforms find applications in the packaging of cosmetics, toiletries, and household products such as shampoos, conditioners, lotions, and detergents. The transparent and glossy appearance of PET enhances the visual appeal of these products, allowing consumers to see the contents inside. PET containers are also lightweight and unbreakable, making them suitable for use in bathrooms, gyms, and travel settings where durability and portability are essential. 30mm PET preforms are utilized in the pharmaceutical industry for packaging oral medications, vitamins, supplements, and over-the-counter drugs. PET containers offer excellent barrier properties, protecting sensitive pharmaceutical formulations from moisture, light, and oxygen, which can degrade the efficacy and stability of medications. The tamper-evident neck finish of PET bottles assures consumers of product safety and integrity.

0 notes

Text

Key Elements in PET Plastic Preform Design

Material Selection:

The quality of the PET resin is paramount in PET plastic preform design. High-quality resin ensures the final product's durability, transparency, and resistance to external factors such as UV light. The careful selection of PET resin contributes to the preform's ability to maintain the integrity of the packaged contents and withstand the rigors of transportation and handling.

Preform Geometry:

PET plastic preforms are precision-engineered with specific geometries that influence the final bottle's shape and characteristics. The design of the preform includes considerations for the neck finish, body diameter, and base thickness, all of which contribute to the overall structural stability and appearance of the final container.

0 notes

Text

The Development Of Preform Molds In Recent Years

In the realm of plastic packaging, precision and efficiency are paramount, and the evolution of preform molds has played a pivotal role in meeting these demands. Preform molds are critical components in the production of plastic bottles, serving as the initial shaping stage for the containers we encounter in our daily lives. In recent years, the development of preform molds has undergone significant advancements, embracing innovations in design, materials, and manufacturing processes.

The evolution of preform molds has seen a significant emphasis on precision engineering and advanced design techniques. Computer-aided design (CAD) software has become an integral tool in the mold design process, allowing for intricate detailing and accurate simulations. This precision ensures that the molds can produce preforms with consistent dimensions and quality, meeting the stringent requirements of modern packaging standards.

0 notes

Text

The Emergence of The 5-gallon PET Preform

Polyethylene terephthalate (PET) has long been a favored material in the packaging industry due to its versatility, transparency, and recyclability. PET preforms are semi-finished products that serve as the starting point for the production of PET containers, such as bottles and jars. Traditionally, PET preforms have been associated with smaller-sized containers, but the emergence of the 5-gallon PET preform marks a notable expansion into larger packaging applications.

0 notes

Text

The Backbone Of Plastic Bottles: The Art Of PET Preform Molds

Before we explore the craftsmanship process, let's understand what PET preform molds are and why they are indispensable in the plastic bottle manufacturing industry.

Composition: PET preform molds are precision-engineered tools typically made of high-quality steel, aluminum, or other durable materials. They feature cavities and cores designed to shape molten PET (Polyethylene Terephthalate) into preforms, which are the initial forms of plastic bottles.

Function: The primary function of PET preform molds is to shape the PET material into the desired preform shape, which resembles a small test tube-like structure. These preforms are then heated and stretched to form the final bottle shape during the blow molding process.

0 notes