Updates of my experience with a low speed wind tunnel in my Experimental Aerodynamics Course at California Polytechnic State University San Luis Obispo.

Don't wanna be here? Send us removal request.

Text

Week 10: June 8th, 2017

Today is the last day of the AERO 307! Throughout the luge project, the team focused on two major components of the luge: manufacturing a new adapter plate and understanding the boundary layer growth across the ground plane. After a couple of lab days preparing and manufacturing the new adapter, the new adapter was put into practice so useable pressure data could be collected under the luge. By collecting pressure data, a little more information is gathered under the luge. As a point of validation, the boundary layer thickness increases as the pressure rake moved farther away from the leading edge of plane. Hopefully in the future of the Luge project, the Luge Team can start to collect more data under the luge to validate CFD data.

Now that the team has achieved the goals of this short term project, the team has been working effortlessly on the technical report. A few figures were added to the documents to show the difference between the new and old adapter plate on the ground plane.

Figure 1: Schematic drawing of the ground plate with the new and old adapter plate (Viviana Martinez)

The Luge model is modeled by the vertical rectangular box at the center of the ground plane. Number 1 shows the old adapter plate and number 2 shows the new adapter plate. It is evident that the bolt on the end of the new adapter is no longer in the way of the luge model. At the end of class today, the group was able to complete the technical memo so we will upload it when the submission portal is up!

As we come to an end of this class, this class was by far one of my most favorite class because I was able to apply a lot of the knowledge I learned in my classes to real life applications. This class along with AERO 304 gave me an opportunity to experience and understand more about the field of wind tunnel testing in the aerospace industry. In the aerospace industry, more practical applications such as testing a rocket or commercial aircraft in the wind tunnel would be more interesting but also a lot more complex analysis. I am excited to be joining the Tesla Team this summer and assist them in their project.

0 notes

Text

Week 10: June 6, 2017

The adaptor is almost completed! Cody was able to cut the aluminum plate to size and also drill/countersink holes to connect the sensor blank to the adaptor.

Figure 1: Adaptor cut to size by Cody

Now, to complete the adaptor, the team worked effortlessly to drill holes on the adaptor but also the ground plate. Before drilling the holes, the location of holes were decided on the diameter of the bolts. Cody said a rule of thumb is to drill holes that are three times the diameter of the bolt from both sides of the adaptor. Based on Cody’s advice, we decided to drill holes accordingly. To drill the holes on the adaptor, we use a drill press in Cody’s shop. Due to the size constraint on a drill press, we had to use a hand drill to drill the holes on the ground plane but we were able to drill the holes. This took longer than expected because the ground plane was a lot stronger than expected. After determining the location of holes and drilling for the entire class, the adaptor is finally completed!

Figure 2: Completed adaptor secured onto ground plate

Now that the adaptor is finally completed, we hope this helps the Luge Team collect more accurate data!

Over the weekend, one of the group members were able to go into the wind tunnel to collect some data with the Luge team. Boundary layers were collected using the pressure rake at a speed of 20 m/s. The pressure rake was placed at distances 0, 15, 30, 45, 60, and 75 cm away from the beginning of the ground plane. Based on the data collected, the following graph was generated by a team member, Joseph Bundros:

Figure 3: Boundary Layer at 0, 30 and 60 cm from the front of the ground plane

As expected, the boundary layer thickness increases with an increase in distance from the front of the ground plane because the boundary layer increases across a surface. However, one thing I noticed looking at this graph is the variation in boundary layer thickness between 0 and 5 mm. Although I am not sure why this is the case, I plan to research why the boundary layer behaves this way. Also note that a 99% velocity vertical line is placed on the graph. This is used to show how the boundary layer behaves as it reaches free stream velocity. Recalling from AERO 303, the boundary layer is fully developed after it reaches 99% of free stream velocity.

As the quarter wraps up, the team is working collectively to complete the technical report so the team will focus on this goal on Thursday.

0 notes

Text

Week 9: June 1, 2017

The aluminum plate for the adaptor has finally arrived! With the large plate of aluminum, the group created a drawing in order give it to Cody to cut the plate to size. The main thing we needed Cody to do is to cut the plate to 20 inches by 3.25 inches and drill/chamber holes to connect the sensor blank to the adaptor. Now that the holes have been drilled, we are one step closer to help the Luge Team collect more accurate data.

While waiting for Cody to cut the plate down, we decided to go to the wind tunnel to measure the placement of the pressure rake. To determine the change in boundary layer at the bottom of the luge, the team chose 6 distances from the leading edge of the ground plane. The 6 locations are 0, 15, 30, 45, 60, and 75 cm from the leading edge. Theoretical boundary layer thickness were calculated at each location to create a comparison with experimental results.

To safely secure the rake during the experiment, the pressure rake will be taped onto the ground plane with aluminum tape. As tested a last week, we assured Brandon that the aluminum tape will be able to safely secure the rake at a high velocity. Similar to the old setup of the luge, the pressure ports will be fed through the hole on the ground plane.

We are excited to receive the sized down adaptor from Cody so that we can drill holes to safely secure the adaptor to the ground plate!

0 notes

Text

Week 9: May 29, 2017

Today, the group was hoping to get some useful data from the luge but things did not go as planned. In the morning, the 568/569 Luge Team placed the luge in the wind tunnel with an attempt to collect data. Due to a failure in the model, large cracks formed on the luge (leg and body). As a result, the team could not conduct tests in the wind tunnel so we assisted the Luge Team with the repairing of the luge.

To the repair the luge, the leam used Epoxy and bondo. The Epoxy was placed in between the cracks to make sure the cracks were sealed. When the epoxy dried, bondo was placed around the cracks. After the bondo dried, it was sanded down to ensure a smooth finish. By sanding the bondo, it reduced the magnitude of the error that may have occurred in the pressure readings on the body. The bondo itself resulted in a lot of bumps which can disrupt the airflow, resulting in inaccurate pressure readings. If the values are inaccurate, it makes it more difficult to validate CFD data with experimental data.

Figure 1: The luge after the repairs

The Luge Team will repaint the luge for aesthetic purposes after sanding took some paint off. Although repairing the luge took the entire class, it will be ready for the Luge Team to conduct more testing later in the evening.

The team expected the aluminum plate to arrive today but since it didn’t, the team will work on creating an in-depth schematic drawing for Cody to cut the plate down to size and drill necessary holes for the screws during next class. Hopefully after next class, we will have the adaptor ready to go in order to conduct some testing!

0 notes

Text

Week 8 : May 25, 2017

Today was the day to finally present the flow viz project! After a long week of preparation, I was ready to present. This project really gave me the opportunity to analyze the performance of common wings on transport aircrafts. Concepts such as elliptical lift distribution, span wise flow, and wing geometry helps determine the performance of wing.

As other students presented, it was very interesting to learn about some of the experiments other groups conducted. One experiment that stood out to me the most is the actuator wing. By activating the actuators with 500 Hertz, it can really affect the airflow over the wing. Without the actuators on, flow separation was present at at high angles of attack. With the actuators on at high angles of attack, the air flow would wrap back onto the surface of the wing and little flow separation was present. To know about some of the common applications that the actuators are used for such as a VTall, Submarines, and the Boeing 777x which was recently implemented into the tail wing design. Hopefully in the future I can work on something as cool as this for a real world application!

After the presentations, my group and I talked to Brandon about the Luge project. He wanted us to find a way to mount a new adaptor on the plate because nuts/bolts were hanging from the other end of the plate which affects the air flow and boundary layer. After discussing with Dr.Doig, he recommended that we extend the adaptor so that the bolt/nut would be far enough from the bottom of the sled to not disrupt the flow. Below is a figure of what the adaptor currently looks like.

Figure 1: Adaptor for the plate

Currently, the team has decided to increase the length of the adaptor to 20 inches, decrease the length to 3.25 inches, and keep the thickness at 0.475 inches. Given the dimensions, a team member looked up aluminum plates on McMaster to request an order from Dr.Doig to complete this task.

Next class, we hope to have the aluminum so we can start cutting down the plate to appropriate dimensions, drilling holes in for the screw, and collect some boundary layer data to start comparing experimental data to CFD data.

0 notes

Text

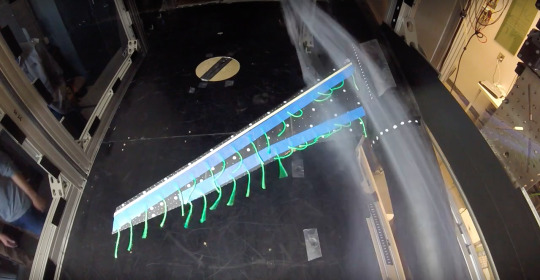

Week 8 : May 23, 2017

Now that the flow visualization experiment is over, it’s time to work on the final project of the quarter. For the final project, I am working on the Luge Project, courtesy of AERO 568/569. Normally when I think of a luge, it’s a one person luge but this project was focused on a two person luge. Below is a figure of a two person luge in practice at the winter olympics!

Figure 1: Two person luge at the Sochi Winter Olympics

Before delving into the scope of the project, the group learned that no one really knows anything under the sled on the luge. Analysis has been conducted near the head, foot, and over the body but not really under the sled.

Knowing this information, the group decided the scope of this project was to understand the boundary layer under the sled. Although this was easier said than done, the group had to deice how to fit a rake under the sled given that we only have less than 0.9 inches to work with in height. With all the rakes we have worked with in this class, they exceed the height dimensions. Luckily, we were able to find some rakes in the cabinet that met the height requirements.

Based on the looks of the rakes, they look like they were corroded and so the test decided to test if they still worked. To test the rake to see if they were clogged, the team hooked it up to the ScaniValve and blew into it to see if velocity readings were read in LabView. Thankfully, none of the ports were clogged on the rake so we plan to use this rake. Even though this rake is small, it is sufficient enough for our experiment because the boundary layer will be small under the sled.

Since we know now the rakes work, we had to decide a mounting mechanism for the rake. The team decided to stay away from nailing or drilling in the wind tunnel so we thought of aluminum tape since it successfully secured wires in other experiments conducted. The only concern the team had was that the surface area to tape the rape was very minimal. To ensure tape was effective, the team decided to tape the rake down on the wind tunnel and tested it at high speeds (44.5 m/s) to mimic the speeds that will be used in 568/569. A long piece of yarn was attached to the rake as a precaution just in case the tape was not strong enough to hold the rake down. As a result, the tape did its job!

Now that lab time was over, the group plans to meet up at the wind tunnel early Thursday morning to work with the 568/569 team. For next lab, the group plans to conduct some testing on the luge and validate some CFD data!

0 notes

Video

tumblr

Video: Airflow over the tip of an airfoil at an Angle of Attack of 10 degrees. Notice that yarn near the root curls and the yarn in the middle flutters, resembling turbulent flow

2 notes

·

View notes

Text

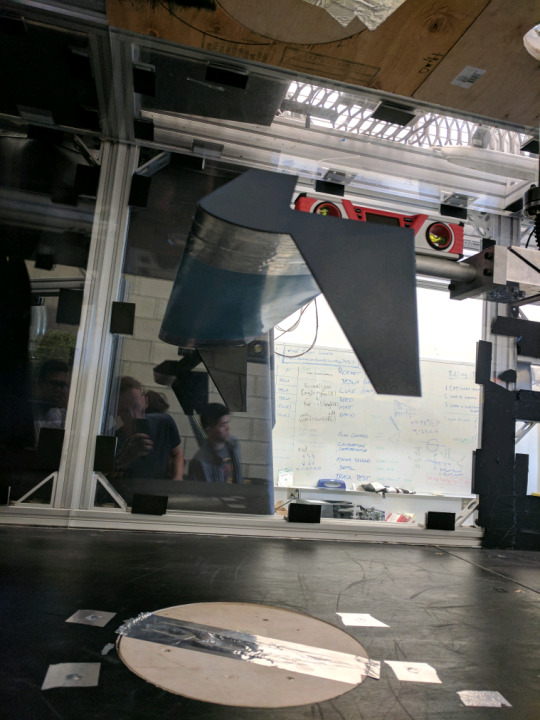

Week 7 : May 19, 2017

Given Matt’s instructions to mount the fuselage in the wind tunnel, I thought it was going to be a tedious process. However, mounting the fuselage securely in the wind tunnel took less time than expected. The plan was to operate the wind tunnel at 2 speeds (5 m/s and 25 m/s) at 3 angles of attack (0, 5, and 10 degrees). Running the wind tunnel at a low speed will allow flow visualization using the smoke to be seen.

When the team ran the wind tunnel at 5 m/s, there was not much to see. The team however did conclude that the flow separates near the root of the wing rather than the tip. This is important to note during the design process because if control surfaces are placed where the flow separates, the control surfaces would not be able to control the aircraft.

Figure 1 : Flow visualization at Angle of Attack = 0 degrees

After a couple of minutes, the team increase the wind tunnel a little bit to see if more action occurs. Due to limited action, we increased the angle of attack to 10 and 15 degrees. This was where flow separation was extremely visible!

Figure 2 : Flow visualization at Angle of Attack = 15 degrees

At high angles of attack, it is shown that flow separation becomes more visible at high angles of attack, especially at the root of the wing. Due to the washout of the wing, there is a higher angle of attack near the root than the tip. For this model, the angle of attack at the root is approximately 3-5 degrees, according to Matt. Due to a higher angle of attack at the root, it is more likely to reach stall before the tip of the wing. Theoretically, the tip of the wing should be at 0 angle of attack. Flow separation can be seen by the yarn curling to point towards the nose of the fuselage.

Another thing to note is the span wise flow. Spanwise flow always occurs due to the swept nature of the wing because it creates components parallel to the chord and outward of the fuselage (span wise flow). This can be seen due to yarn pointing towards the tip of the wing and it can be seen in Figure 2 that span wise flow is more prevalent at the tip of the airfoil compared to the root. This is because flow separation is not as dominate near the tip compared to the root.

Overall, this flow viz was cool to visualize a 3D printed wing being tested in a wind tunnel. Since the flow viz is now completed, I plan to meet up with my group this weekend to work on the powerpoint for the presentation.

0 notes

Text

Week 7 : May 16, 2017

After completing the NACA lab, it’s finally time to work on the flow viz project! With personal interest in the commercial aircraft industry, I pitched the idea of using the wing attached to a fuselage (Matt’s Thesis) for flow viz to my group. After a couple of minutes debating on what to use for Flow Viz, the team came to a consensus to use Matt’s thesis for Flow Viz. To make things a little interesting, the team decided to use flow viz paint where streamlines would be visible but Matt’s approval was required since he is planning to come back this week to conduct more test. After given the green light to use the flow viz paint, the team decided to not use it because we did not want to mess up the model prior to Matt’s testing.

Similar to past flow viz, the team decided to stick with yarn and smoke. Pieces of yarn will be cut out and attached to the surface of the wing to analyze the flow regime. If the yarn flutters a lot, then that means the flow has become turbulent. Also, the smoke will be used to determinate whether the flow separates near the root or the tip of the wing. I hypothesize that the flow will separate near the root first! Below is a model of the wing completed by Matt.

Figure 1 : Load analysis completed by Matt on the wing

The figure was provided by Matt when the wing failed at a high wind tunnel speed. Given the scale on the left side, there is a large amount of load on the wing near the root due to the airfoil. In order to prevent the wing from failing during the experiment, we will keep the wind tunnel speed under 25 m/s so this tragedy does not happen again.

To correctly mount the fuselage and the wing in the wind tunnel, Matt sent the team a step by step process on mounting it correctly. We will be very careful with the wing since it can break easily! To allocate enough time for set up and running the experiment, I booked 2 hours before the start of our testing to set up so we can be ready to run the wind tunnel at 1 pm on Thursday.

0 notes

Text

Week 6 : May 11, 2017

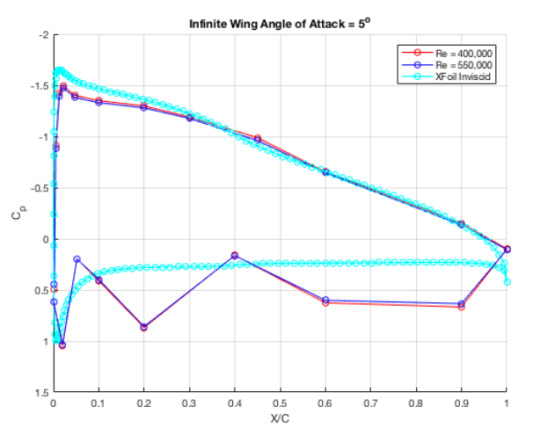

Today is the day to wrap up the NACA 4412 lab and work on the lab report. While my group members worked on the analysis for the previous experiment, I worked with another group member to analyze the pressure rake data. Because my group was personally not able to collect the data, it was hard to understand where pressure ports were located thorughout the wind tunnel. While looking through the data, I corrected port 13 because the pressure was reading a large value and the opposite signs of port 12 and 14. To correct port 13, I calculated the average between port 12 and 14.

With the help of a classmate, I learned how to export data from XFoil. Using XFoil data, I was able to plot it on the coefficient of pressure plots for the infinite wing. Below is a complete Figure for an angle of attack of 5 degrees.

Figure 1 : Coefficient of Pressure for a NACA 4412 at an angle of attack of 5 degrees

Note that the solution provided by XFoil is an inviscid solution. One thing I noticed is at low angles of attacks, the upper surface closely resembles the inviscid solution. This can be due to the fact that at low Reynold’s Number, the air flows smoothly across the upper surface. However, at higher angles of attack, the upper surface deviates from the inviscid solution. This may be caused by the fact that at low angles of attack, the flow is more attached to the upper surface. At higher angles of attack, flow begins to separation and near the stall point, there is an extremely low pressure region due to wake.

Even though my group was extremely productive today, we are planning to meet tomorrow get most of the analysis done! Over the weekend, we will meet again to complete the lab report. Even though this is the end of the NACA 4412 lab, I am very excited for the flow visualization project. As listed in the email, I am very interested in Matt’s thesis project. As someone who hopes to end in the commercial aircraft industry, placing a fuselage with wings attached will help me understand the aerodynamics of it and use it in my career!

0 notes

Text

Week 6 : May 9, 2017

The time everyone has waiting for is finally here; to test the winglet design! For this specific experiment, the group ran at two angles of attack (0 and 10 degrees) and at 2 wind tunnel speeds (10 and 20 m/s). Angles of attack and wind tunnel speeds were determined by the TAs to determine which winglet design had the highest efficiency between all the groups.

To reiterate the design of our group’s winglet design, we increased the wingspan by 60 mm on each side of the airfoil. The winglet itself was based on one of the most efficient commercial aircrafts, Boeing 737 Max. The winglet is designed to restrict the air flow from the lower surface wrapping over onto the upper surface as it would without a winglet.

The time it took to run this lab was quicker than I expected. My group was able to collect data and get out within half a hour. This allowed time for most, if not all groups to go today. Although we were not able to completely determine if our winglet design was extremely efficient, I would expect some flaws such as an increase in drag. I expect an increase in drag because the surface finish on the winglet itself was not entirely smooth. For example, the aluminum tape used to tape the airfoil sections together can cause a high surface roughness because of the small bumps on the tape. Also the winglet itself was rough from sweeping my fingers across it. From holding other group’s winglets, they sanded the surfaces to smoothen it. Because we did not 3D print our winglets, it was more difficult to use sand paper to smoothen the surfaces compared to other groups. Below is a picture of the winglet on the airfoil.

Figure 1 : Winglet on a NACA 4412

During the next lab, I will work on the MATLAB code to create more awesome graphs for the lab report!

0 notes

Text

Week 5 : May 4, 2017

Because my group ran the wind tunnel on Tuesday, it was our time to sit in the conference room and work on our lab report! Before working on the lab report, the group decided to go through all the MATLAB scripts and finalize a script to output all graphs. As the group was going through the script, we noticed minor errors and were able to correct them. One section I worked on the MATLAB code was using the panel method for the infinite wing to calculate the coefficient lift and drag of the infinite wing. The way I approached it was assuming an linear increase in in pressure forces on the panel. After calculating the pressure forces at the center of each panel, I broke it up into its components of lift and drag. At the end, I added all the lift and drag components to calculate the total lift and drag on the airfoil. Using total drag and lift forces, I calculated the coefficient of lift and drag at each angle of attack. Below are graphs obtained from the panel method:

Figure 1: Coefficient of Lift, Drag, and Cl/Cd obtained from the panel method

Looking at the data, it makes sense that lift is maximum around 15 degrees because the stall point is around 15 degrees. Also, coefficient of drag is negative because pressure drag acts in the opposite directions of fluid flow. After finalizing a MATLAB script, the group collectively created an outline of the technical memo so when it comes to writing the report, we will have an idea on what to right.

When talking to another team about using their data, they were also unable to obtain data because the data outputted was not useful. Luckily, the lab section after our’s was able to find an alternative and utilized a directional probe to obtain data. When the group posts their data on Polylearn, I will be able to use the wake momentum method to analyze the data.

During next lab, it is finally time to put our winglet into the windoff! I am excited to see how efficient our winglet design is.

0 notes

Text

Week 5 : May 2, 2017

Today was my group’s turn to run the wind tunnel today. Similar to AERO 304, we will be using the rake to collect pressure data. For the Wake Rake lab, we will be using the wake momentum method to analyze the drag on the airfoil. To create a comparision between the data obtained from the full-span pressure tapped wing and today’s lab, the group decided to run the wind tunnel at the same Reynold’s Number (400,000 and 550,000). Also, the angles of attack the group agreed to run at were 0, 5 and 10 degrees. Due to a change in temperature, we had to recalculate the velocity before the experiment to the run the wind tunnel at the same Reynold’s Number.

After calculating the velocity with new ambient conditions, it was time to start up the wind tunnel! To make this experiment the most efficient, the group decided to move the traverse across the wind tunnel before switching wind tunnel speed and angle of attack. Things were going well until we ran into a problem..... Because there is a set limit on the traverse, the group member in charge of LabView did not know what the maximum limit was until we reached it. e knew to move the traverse back when the pressure readings on the pressure ports matched up with free stream pressure. Because the pressure ports did not reach free stream pressure, that was when we reached the limit. After the traverse reached its limit, the traverse was unable to move back so my TA decided to recalibrate it. By the time we finished recalibrating the traverse, the time we had in the wind tunnel was over! Even though we were not able to finish the experiment, the group was able to obtained one set of data at 0 degree Angle of Attack at a Reynold’s Number of 400,000.

Below is a graph obtained during the experiment:

Figure 1: Coefficient of Pressure on wake rake for NACA 4412 at an Angle of Attack of 0 degrees and Reynold’s Number of 400,000.

At locations where the coefficient of pressure is approximately 1, it means that the pressure ports are reading almost free stream pressure. While other ports are reading pressures where the flow is not at free stream. When the flow is not at free stream, that may be caused when the infinite wing is directly in front of the pressure ports. Even though we were only able to obtain one set of data, my group and I are planning to get data from another group!

During next lab, my group and I are planning to work on our lab report in order to provide a draft to Dr.Doig or my TA for critique and work with a group that will be running the wind tunnel to utilize their collected data.

0 notes

Text

Week 4 : April 27, 2017

Today was my group’s turn to sit in the conference room! Similar to last week, my group and I worked on creating a MATLAB code to help analyze the data collected on Tuesday. After looking at the data from Tuesday, I noticed I was going to be dealing with a lot of data similar to the rake data collected in AERO 306. Dealing it with a large set of data from AERO 304 made it more tolerable when analyzing the data from this lab.

After completing my MATLAB code, I create 8 figures for each angle of attack with coefficient of pressure vs. a dimensionalized x distance along the airfoil. On each figure, there are two curves representing two Reynold’s Numbers (400,000 and 550,000). Below is a coefficient of pressure plot for an Angle of Attack of 10 degrees.

Figure 1: Coefficient of Pressure Plot for a NACA 4412 Infinite Wing at 10 degrees Angle of Attack .

One observation I noticed after creating these figures are that the coefficient of pressure does not vary a lot at two different Reynold’s Number. Although I am unsure why this might be, I am completing some research to understand this behavior.

Looking at the figure, it makes sense that the highest value of coefficient of pressure is 1 because it represents the stagnation point. At the stagnation point, velocity is zero so the pressure is maximum at that point, also known as the leading edge. At other angles of attack, the highest coefficient of pressure value is also 1. However, the minimum coefficient of pressure value varies according to the angle of attack. Below is the coefficient of pressure plot at 16 degrees.

Figure 2: Coefficient of Pressure Plot for a NACA 4412 Infinite Wing at 16 degrees Angle of Attack.

Since my group had extra time at the end of our experiment, we decided to collect data at the stall point. After completing a few experimental test to determine the stall point, we determined the stall point was about 16 degrees. In comparison to other angles of attacks, the maximum coefficient of pressure was 1. However, the magnitude of the minimum coefficient of pressure was the largest at the stall point. As shown in Figure 2, we can see a large difference between the minimum values of the coefficient of pressure unlike at low angles of attack, the difference between the minimum values of Cp are small.

Even though these figures will not be the final graphs I put in the technical memo, more aspects will be added such as error bars. During the next lab period, my team and I will collect data in the wind tunnel for the wake rake to analyze the different drags (total, viscous, and pressure) on the airfoil. Now that the team’s winglet design is completed and manufactured, there is one less item on the plate!

1 note

·

View note

Text

Week 4: April 25, 2017

Today was finally the time to use the infinite wing!

Before going into the lab, the team and I worked collectively to determine the speeds that we wanted to run the wind tunnel at. Originally, we wanted to run the wind tunnel at the same Reynold’s Numbers as the red/blue wing to compare the data. The suggested speed range was 20 m/s to 35 m/s. With the Reynold’s Numbers we used for the first lab, we calculated velocities around 3 m/s and 7 m/s. This was when we decided to use Reynold’s Numbers of 400,000 and 550,000. The speed at a Reynold’s Number of 400,000 was 24.16 m/s and at Reynold’s Number of 550,000 was 33.22 m/s. The Angle of Attacks the group agreed on were 0, 5, 10, 15, 20, and 25 degrees. Below is one of the coefficient of pressure plots:

Figure 1: Coefficient of Pressure plot at 16 degrees (approx stall point)

Collecting data for this lab was quicker than the previous lab because we did not have to take windoff data before and after each angle of attack and did not have to take for the vertical strut to change the angle of attack. Because we were able to finish early, we decided to collect data near the stall point which was approximately 16 degrees.

Aside from running today’s lab, our winglet design is completed!

Figure 2: Final product of winglet design for lab 4.

The winglet was based on the whitman winglet design. To increase the aspect ratio, 5 sections of an airfoil was laser cut then later combined together. After combing the sections of the winglet together, aluminum tape was used to wrap the surfaces of the sections to smoothen the surface. For the winglet piece, plexiglass was used and a laser cutter helped create the shape. As air flows on the bottom of the airfoil, the winglet traps a portion of the air so that it does not wrap to the upper surface of the airfoil. Dimensions of the winglet was based on the following figure:

Figure 3: Reference used to design the winglet to increase efficiency (Helicopters & Aircrafts : http://heli-air.net/2016/03/10/winglets-and-tip-sails-for-models/)

Due to dimension restrictions, figure 3 was used as a reference to scale dimensions down to meet requirements. Now we will wait for the day to test out the efficiency of the winglet design and hopefully it will increase the efficiency a lot!

1 note

·

View note

Text

Week 3 : April 20th, 2017

After collecting data on Tuesday, my group and I used today to analyze the data. Before analyzing the data, I polished my code from before so that it could calculate coefficient of lift and drag for the blue and red airfoil. When enhancing my MATLAB code, I ran into two dilemmas.

1. For the red wing, I was unable to account for drifting because my group only took wind off data before each angle of attack. To account for drifting, the best way to account for drifting is determining the difference before and after the experiment for each angle of attack. However, when my group ran the wind tunnel for the blue airfoil, we made sure to collect wind off data before and after each angle attack. Therefore in the graphs, the data for the blue airfoil is slightly more accurate than the red airfoil. 2. After looking at the strut data posted on Polylearn, we cannot determine the forces on the strut for our first Reynold’s Number. Our first Reynold’s Number is 55,590 and the lowest Reynold’s Number for the strut data is 150,000.

After running into the dilemmas, I talked to my TA about possibly going into the wind tunnel over the weekend to collect strut data for our Reynold’s Number and rerun the experiment for the red wing in order to collect windoff data. Due to some conflict, my group will not be able to collect data so the solution my TA proposed was:

1. Assume the drifting effect is minimal because my group was the second team to run. To prove that the drifting effect is minimal, I will show that accounting for the drift effect for the blue wing will not be a drastic change. 2. Because it would take too much work to extrapolate and interpolate Reynold’s Number and force data, it will better to ignore the strut data (even though the strut effect on the force balance is not minimal) and focus on the trend of the graphs.

After taking the TA’s suggestions into account, I created the following three graphs:

Figure 1: Coefficient of Lift for red and blue airfoil at two different Reynold’s Number.

Figure 2 : Coefficient of Drag for red and blue airfoil at two different Reynold’s Number.

Figure 3 : Ratio of Coefficient of Lift and Drag for red and blue airfoil at two different Reynold’s Number.

When analyzing the graphs, I noticed that the coefficient of lift and drag graphs do not show a stall point except for the red wing at a high Reynold’s Number. This may be due to the fact that the stall point is at a higher angle of attack. As stated before, the drifting effect was only taken into account for the blue wing. After discovering the trend, I will look more into the reason why this is occurring. Also, my group started on the introduction for the technical memo so we are on a roll!

For the next lab period, my group will be collecting data in the wind tunnel for the rake experiment.

0 notes

Video

tumblr

Flow Visualization of a NACA 4412 at an Angle of Attack of -5 degrees

1 note

·

View note