Don't wanna be here? Send us removal request.

Text

Typical mechanical seal device for various impurity media

The following describes and analyzes typical mechanical seals at home and abroad from three aspects: structure, friction pair and sealing system.

1. Seal for slurry pump and mud pump. In all areas of industrial production, the conditions of use of slurry pumps and mud pumps are very demanding. The outstanding problems encountered with seals are wear and clogging and corrosion problems. The harder the solid particles in the medium, the sharper the edges and corners, the finer the particles, the higher the temperature or pressure, and the greater the hazard. The reliability and life of the seal depend on the working environment, and the environment can be changed by the sealing system technology. Therefore, the sealing operating conditions should be improved according to local conditions. Measures include isolation, separation of solids, temperature regulation, and injection of a clean rinse into the sealing interface. The following is an example to illustrate.

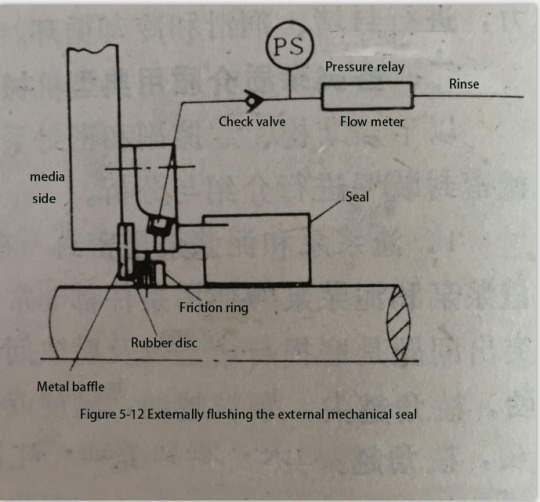

(1) Single-end seals A generally simple single-end seal has a clean rinse liquid acting on the sealed interface. The reliability and quality of the rinse is the key to the success of the seal. If the cleaning rinse is injected from the outside, the working environment of the seal can be improved, but the rinse must be lost, and the prerequisite is that the delivered liquid is allowed to be diluted by the rinse. Figure 5-12 and Figure 5-13 show the isolation and rinsing system with two basic structures. As can be seen from Figures 5-12, under normal operating conditions, when the rinsing liquid enters the sealed chamber, the rubber and metal baffles block the rinsing liquid from entering the process medium.

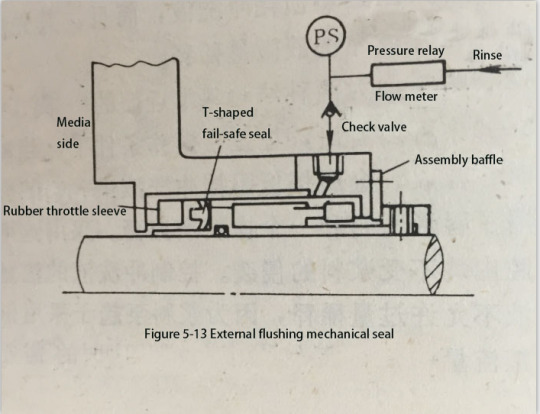

Figure 5-13 uses a lip seal and a rubber throttle sleeve. After adopting these two measures, the sealed cavity is not affected by the slurry. It is important to control the flow of the rinse fluid. The pumping fluid does not allow excessive dilution because the slurry pump tends to use low speeds, and usually the flushing fluid flow rate does not exceed 2 L/min to meet the sealing requirements. The flow meter in the figure is used to show the actual flow into the sealed chamber without excessive leakage to avoid excessive consumption of flushing fluid.

If the flushing fluid is insufficient or interrupted by chance, the check valve will automatically close. The friction ring shown in Figures 5-12 carries the load of the fluid at the end of the media, thereby cutting off the sealed medium into the sealed cavity, thus providing protection for the seal.

The sealing device shown in Figures 5-13 operates in a similar manner as described above. Under normal working conditions, the T-shaped lip seal(with spray ceramic bushing) is pressed against the side of the mechanical seal, when the inner lip wears out.

In the above two examples, the rinsing liquid is stored in the sealed chamber to prevent the medium from entering the chamber. If a pressure switch and an alarm (acoustic or optical alarm) are installed in the system, once the pressure of the flushing fluid in the sealed chamber drops, or the transported granular medium enters the sealed chamber, the operation can be stopped quickly and the mechanical seal will not be damaged.

mechanical seal face find in http://www.cdckhj.cn/news-dt.html?_l=en&article_id=49

0 notes

Text

Mechanical seal with impurity medium

One, mechanical seal design points:

For impurity-containing media, the following problems can occur with ordinary single-end mechanical seals:

(1) Early wear of the friction pair end face.

(2) The sliding compensation mechanism is blocked and cannot be axially displaced.

(3) Blocking the loading mechanism to disable the elastic member.

(4) causing abrasion of the rotating component.

In order to solve the above problems, it is necessary to know in detail the characteristics and operating conditions of the sealed medium, and to design specifically to ensure that the structure, material or sealing system can meet the requirements.

1. Structural features. When designing, structures that prevent blockage of foreign particles should be used, such as external mechanical seals; when using internal seals, the spring should be isolated from the media.

In general, a single-end mechanical seal should be preferred because of its low cost and small footprint. However, double-face machine seals must be used in the following situations:

(1) The solid content exceeds 10% by weight.

(2) Highly concentrated medium.

(3) There are dangerous and toxic media.

(4) To avoid the use of expensive materials and the like in highly corrosive media.

2. Friction pair material. When the structural design and the circulation system do not fully provide protection for the seal, the hardness of the selected friction pair material must be higher than the hardness of the abrasive particles. Usually, a pair of materials with good wear resistance and wear resistance are selected, such as cemented carbide to cemented carbide, silicon carbide to cemented carbide, and boron carbide to cemented carbide. When using a double mechanical seal, the material on the atmosphere side can be the same as that used for ordinary mechanical seals.

3. Sealing system. When using single-end mechanical seals, in order to avoid the harm of particulate impurities, measures such as washing, filtering, separating, isolating, heat-insulating and heating should be taken according to different conditions. When using double-face mechanical seals, it is required that the sealing fluid establishes pressure in the sealed chamber for sealing, lubrication and cold circulation.

0 notes

Photo

tungsten carbide seal ring

if you are interested in it, please contact me with [email protected]

0 notes

Text

The role of the main components of mechanical seals

(1) moving ring (rotating ring). The moving ring rotates together with the rotating shaft, and the end surface and the end surface of the stationary ring are attached to each other and slid relative to each other to form a sealing end surface to prevent the medium from leaking. When the compensation mechanism is designed on one side of the moving ring, the moving ring has an axial compensation capability, which is called a compensation moving ring. On the contrary, it is called a non-compensating dynamic ring. When the sealing end face is worn, the compensation moving ring can be axially moved under the action of the elastic element to compensate, and the sealing end surface is well fitted.

(2) Static ring (stationary ring). The static ring is mounted on the stationary part of the casing, gland, flange, etc. of the machine. Like the moving ring, it seals the end faces to prevent media leakage. When the compensation mechanism is designed on the side of the moving ring, the static ring cannot be compensated after the sealing end face is worn, which is called the non-compensating static ring. On the contrary, it is called compensation static ring. Compensating the static ring When the sealing end face is worn, it can also compensate by axial movement under the action of the elastic element.

(3) Static ring seals. Static ring seals are generally made of synthetic rubber or Teflon to form O-rings, V-rings and other shapes. It is used to prevent the medium from leaking between the static ring and the gland (or flange) and to make the static ring have a certain degree of floating.

(4) Dynamic ring seals. The material and shape of the moving ring seal are the same as those of the static ring seal. The moving ring seal is used to prevent leakage between the medium driven ring and the shaft (or bushing), and the moving ring has a certain floating property. Moreover, when the sealing end face is worn, it can be axially moved together with the compensating moving ring under the action of the elastic member to ensure a good fit of the end face of the moving static ring.

(5) Elastic components. The elastic element plays a very important role in the mechanical seal. Its elastic force is an important factor in making the mechanical seal end face a reasonable closing force. Only when the elastic element is properly selected can the mechanical seal be within its working pressure range, and the sealing end face will neither open nor cause serious wear. In addition, when the sealing end face is worn, the elastic member pushes the moving ring (or static ring) by the elastic force to perform automatic compensation. There are many types of elastic elements, such as springs (including cylindrical coil springs, conical springs, wave springs, etc.) and bellows (including metal bellows, Teflon bellows, rubber bellows, etc.). In general, one or several elastic elements are used in combination. In some cases, a magnetic force may be used instead of the elastic force to maintain the sealing end face.

(6) Push the ring. The push ring is the part used to transmit the spring force to the auxiliary seal and the compensation ring.

(7) Spring seat. The spring seat is mainly used to position the spring so that the spring force is evenly distributed in a direction perpendicular to the sealing end face.

(8) Anti-reduction. The anti-rotation pin is a part for preventing the static ring from rotating together with the moving ring under the action of the friction torque.

(9) Transmission components. The transmission element is used to transmit torque. Commonly used are drive pins, drive screws, transmission seats and so on.

(10) Set screws. A set screw is a part used to fasten a spring seat, drive seat or other component to a shaft (or bushing).

0 notes

Text

Group of friction pairs materials - cemented carbide

Group of friction pairs materials - cemented carbide

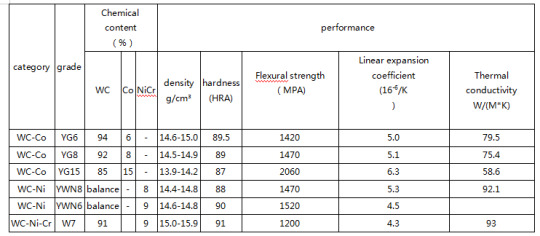

Cemented carbide has many excellent properties, such as high hardness, wear resistance, high temperature resistance, small coefficient of linear expansion, low friction coefficient and good pair performance. It is an indispensable friction accessory material for mechanical seals. The properties of commonly used cemented carbide materials are shown in Table 3-1.

1. Cobalt based cemented carbide. Tungsten-cobalt alloy is an alloy composed of tungsten carbide as the main component and cobalt as the binder phase. It is pressed and sintered by powder metallurgy. Its wear resistance is 15 to 20 times higher than the best high speed steel, and the thermal conductivity is 1 to 2 times higher. The properties of cemented carbides are related to their grain size, composition and microstructure. Since cobalt has the best wettability to tungsten carbide, cobalt is often used as the binder phase. However, metallic cobalt is easily oxidized and has poor corrosion resistance.Once the binder phase cobalt is attacked by the medium, the hard phase tungsten carbide loses its strength, and under the combined action of corrosion and mechanical stress, the seal ring sharply abrades.

2. Nickel-chromium-based cemented carbide. There are three ways to improve the chemical resistance of cemented carbides based on tungsten carbide: Lowering the content of bound metal cobalt; Selecting an abrasion resistant bonding metal or alloy to replace cobalt, such as Ni, Ni-CrNi-Cr-Co, Ni-Mo, Pt alloy, etc.; Corrosion resistant carbides such as TiC and TaC are added to improve the corrosion resistance of the hard phase.

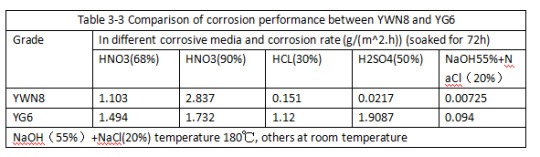

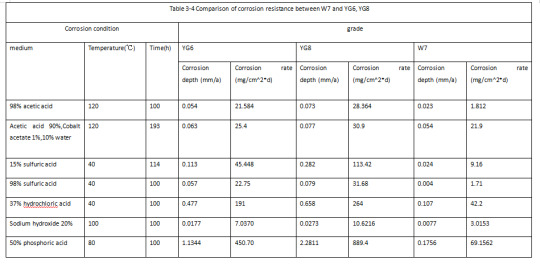

YWN8 and W7 developed in China belong to nickel-based and nickel-chromium-based hard gold, also known as corrosion-resistant hard alloy. Tables 3-3 and 3-4 show the corrosion resistance of YWN8, W7 alloy and YG6 alloy, respectively.

Many of the mechanical seal carbide rings introduced are corrosion-resistant hard composite materials. After analysis and testing, the wear-resistant cemented carbide containing low cobalt fine particles WC (Co<1%), due to the small amount of cobalt, can only be used in the hot pressing process. Hot-pressed cemented carbides are not only costly, but also difficult to shape in products with complex shapes. Ni is used instead of Co as the bonding metal. Although the corrosion resistance of the metal can be improved, the strength is only 70% to 80% of WC+Co, and the hardness is 0.5~1HRA lower than WC+Co. WC+Ni-Cr alloy has good corrosion resistance, its strength and hardness are comparable to WC+Co, and it has unique properties without magnetism. Practice has proved that when WC / Cr + Ni is 0.015% ~ 0.15% (wt), the alloy can resist acid and alkali corrosion. W7 cemented carbide is such a material.

if you need the original , please contact me with [email protected], or find it in http://www.cdckhj.cn/product.html?_l=en

1 note

·

View note