Don't wanna be here? Send us removal request.

Text

How to source fabric for your clothing line?

When sourcing fabric for your clothing line, there are a few things to keep in mind. The most important factor is the quality of the fabric. It's essential that your fabrics are durable and can withstand multiple washing.

You'll also want to choose fabrics that are in line with your target demographic. For example, if you're targeting young adults, you'll want to choose youthful and trendy fabrics.

When sourcing fabrics, it's also important to consider the cost. You'll want to find a balance between quality and affordability. You should also research the various types of fabrics available and find the one that best suits your needs.

There are a variety of fabrics to choose from, such as cotton, silk, linen, or wool.

Each has its own unique benefits and drawbacks.

For instance, cotton is affordable and versatile, but it can be prone to wrinkles.

Silk is often seen as a luxurious fabric, but it can be very expensive.

Linen is lightweight and breathable, but it can also be pricey.

Wool is durable and resilient, but it can be costly and difficult to care for.

When sourcing fabric for your clothing line, it’s important to find a supplier that you can trust.

Here are a few tips on how to find the right supplier:

Do your research. There are many suppliers out there, so it’s important to do your research and find one that meets your specific needs.

Ask around. Get recommendations from other designers or businesses in your industry.

Look for quality fabrics. Make sure the supplier offers high-quality fabrics that will stand up to wear and tear.

Check out their selection.

Make sure the supplier has a wide selection of fabrics to choose from.

5. Get samples. It’s important to order samples before you commit to a supplier. This will allow you to see the quality of their fabrics and make sure they meet your expectations.

Types of woven fabric suppliers online

When sourcing fabric, it is important to consider the many types of suppliers available. The most common types of fabric suppliers are as follows:

- Manufacturers: Manufacturers are the primary producer of a fabric. Based on the capacity of the manufacturer, each manufacturer can be either vertically integrated or a stand-alone type of manufacturer.

The vertically integrated manufacturer will have end to end facility from farming or producing fibers to spinning, weaving, and processing.

Then the other type of fabric manufacturers is the ones that buy yarns and weave or knit the fabric at their facility.

In both these cases, the price of the fabric can only differ in small variations unlike a wholesale distributor or a retail distributor.

- Wholesalers: Wholesalers are companies that purchase fabric in bulk directly from the manufacturer.

They then sell the fabric to retailers or other businesses.

Because they buy in large quantities, wholesalers typically offer lower prices than other types of fabric suppliers.

- Distributors: Distributors are companies that purchase fabric from the manufacturer and then sell it to retailers.

They do not typically carry a large selection of fabrics, but they do offer a wide variety.

Source woven fabrics online

At Dinesh Exports, we provide online sourcing services to buyers around the globe with additional support for designing, sample development, yardages, swatches, low MOQ manufacturing, and timely delivery.

In recent times, trade shows have become a tedious process with travel restrictions and other global events making it extremely difficult for buyers to meet with new suppliers.

A buyer can easily browse through our website to have a look at various products and understand the strengths easily on their system or mobile phone.

Frequently Asked Questions in Fabric Sourcing

To get you started with sourcing fabrics in the right way, please make yourself aware of these questions as they are important to get your fabric sourcing right.

What is the Fabric Reference number?

Each and every fabric will have a unique identifying number.

When a buyer approaches the seller for fabrics, they would send you a collection of fabrics that are similar to buyer requirements.

These are often called swatches or hangers.

In order properly communicate between the buyer and the supplier, each fabric should have a reference number.

2. What is the GSM?

GSM simply means grams per square meter.

It is calculated using a GSM calculator and helps determine the weight of the fabric.

Weight is an important factor while selecting fabric for apparel.

As the gsm is higher, the price and weight of the fabric increase.

Example: Heavier gsm fabrics are suitable for cold climates and bottom wear.

Whereas, lighter gsm fabrics are ideal for top-wear and hot climatic conditions.

Read more about GSM

3. What is the fabric composition?

Fabric composition refers to the type of fibers/yarns used for making the fabric.

Based on the material used, fabric compositions is like below:

Uni-blend: Uniblend fabrics have only a single material as yarns. Eg: 100% cotton fabric

Multi-blend: Multi-blend fabrics have more than one fiber content in them. Eg: 85-15 Cotton Polyester fabric (85% cotton+15% polyester)

4. What is the fabric construction?

Construction means the number of yarns in the warp and weft of the fabric.

5. What is the fabric structure?

Fabric structure represents the type of weaving style used (in woven fabrics) for making the fabric.

Read more about woven fabrics here.

6. What is the cuttable width of the fabric?

Cuttable width is the measurement across the width of the fabric roll from edge to edge.

At Dinesh Exports, we manufacture up to 61” – 63”

7. What is the Sampling price per meter/yard?

Once the buyer shows interest to manufacture fabric, they will require to receive anywhere from 2 – 100 meters of fabric to sample produce their product. The price for sampling can be higher than the bulk price because of the effort it requires to make the sample.

8. What is the MOQ (Minimum order quantity)?

The minimum order quantity is the minimum meters/yards of fabrics the buyer needs to purchase in order for the manufacturer to start production. MOQ varies depending on the manufacturer. It can vary anywhere from 200 meters to 1000 meters.

9. What is the lead time?

Lead time is the time required for the manufacturer to complete the production from order to delivery.

It can vary from 20 – 60 days.

To source woven fabrics, contact us.

1 note

·

View note

Text

Everything you need to know about the fashion week

Fashion Week is an internationally recognized event where fashion designers and brands display their latest collections.

It is a week-long event that is held twice a year, in February and September, in different locations around the world.

Fashion Week is a major event in the fashion industry and attracts a lot of attention from both the media and the public.

The week is typically packed with runway shows, parties, and other events.

It is a great opportunity for fashion designers and brands to showcase their latest collections and connect with potential buyers and investors.

There are several Fashion Weeks that take place around the world. The most notable ones are:

- New York Fashion Week: Held in February and September in New York City.

- London Fashion Week: Held in February and September in London, England.

- Milan Fashion Week: Held in February and September in Milan, Italy.

- Paris Fashion Week: Held in February and October in Paris, France.

How did fashion week get started?

Fashion shows have been around for centuries, but their modern form was born in the early 1900s.

The first fashion show took place in 1903 at the Salon des Modes in Paris.

It was organized by the magazine La Mode Pratique and featured designs by 15 different couturiers.

Fashion Show Slay GIF

from

Fashion Show GIFs

Since then, fashion shows have evolved into a hugely popular and lucrative industry.

Today, designers and brands spend millions of dollars on extravagant runway shows that are viewed by millions of people around the world.

While the first fashion show was certainly a milestone in the history of fashion, it's clear that the industry has come a long way since then.

How Paris did become the fashion capital of the world?

Paris Eifel Tower GIF

from

Paris GIFs

There are many reasons why Paris became the fashion capital of the world.

The city has always been known for its high-end fashion designers, and it has a rich history in the industry.

Additionally, Paris is a popular tourist destination, which means that fashion brands have a global audience to market to.

The city also has a strong infrastructure for the fashion industry, with many trade shows, schools, and magazines.

Finally, Paris is a center of culture and art, which contributes to the city's fashion scene.

Which brands participate in the fashion weeks?

There are many brands that participate in the fashion weeks.

Some of the most popular and well-known brands are Chanel, Dior, Prada, Louis Vuitton, and Gucci.

These brands are often considered to be the top tier of the fashion industry, and their runway shows are highly anticipated each season.

What is the future of fashion shows?

There is no one answer to this question. Fashion shows will continue to exist in some form, but they will change and evolve over time.

Some fashion shows will become more like theatrical productions, while others will focus more on the presentation of the clothes and the experience of the attendees.

Social media and technology will play a larger role in fashion shows, and the line between traditional runway shows and online presentations will continue to blur.

There will be a continued focus on sustainability in the fashion industry, and more designers will begin to use sustainable materials in their collections.

We will also see an increase in the use of recycled materials in fashion.

The popularity of athleisure will continue to grow, and more people will start wearing activewear as everyday clothing.

There will also be an increase in the number of luxury activewear brands.

Future of Fashion by Vogue

Men’s fashion will continue to become more and more gender-fluid, with more designers offering unisex collections and using gender-neutral styling in their shows.

There will be a rise in the popularity of eco-friendly fashion, with more people looking for sustainable and ethical clothing brands.

More people will start buying vintage and second-hand clothing, as they become more aware of the environmental and social impacts of fast fashion.

Conclusion

Since the first fashion show, there has been a lot of changes to how a fashion show is conducted around the world.

Every year, fashion week happens twice in Milan, New York, Paris, and London.

These extravagant parties are viewed by millions of people via social media and other technologies.

This is a clear indication of a new era in fashion shows and how it is consumed.

Several brands are focusing their product offerings to match the current sustainability trends and comfortability.

Expecting an upward trend in sustainable products and active wear.

For sustainable fabrics contact us.

0 notes

Text

Regenerative fashion in 2022

A concept which seeks to close the loop in our clothing production. In other words, one where we are creating and using resources responsibly. This is achieved by designing a garment that can be re-used, or regenerated after use, in order to make it into something new and functional again. For example, as a carpet or yarn for knitting.

Regenerative Fashion would thus imply taking responsibility for all of the environmental impacts that are involved in our products' life cycle. The choice of the raw materials, the way they are processed, and the environmental impact of manufacturing and transportation. This means that all aspects need to be addressed: water use, carbon emissions, waste generation, chemicals used in manufacturing processes, etc.

The focus on textile production has led to an interest in rethinking how clothes are made: a paradigm shift from mass-production clothing to garments that are produced locally with sustainable materials. The idea is to take a product back to its source – even if that source is a foreign country.

Relevance of regenerative fashion today?

The textile industry is the second largest polluter in the world, and the clothing industry is the fifth most polluting. The majority of this pollution comes from the dyeing and finishing process of clothing, which often uses toxic chemicals and water-intensive methods.

Regenerative fashion is a term used for fashion that is designed to minimize environmental impact. This can be done by using sustainable materials, such as bamboo, hemp, and organic cotton, or by using methods that are less water intensive, such as low-impact dyes. Some brands, such as Patagonia and H&M, have already made efforts to create sustainable clothing. But the fashion industry still has a long way to go. Fashion and sustainability are often seen as conflicting. For example, consumers often don’t like to spend money on clothing that they know will be out of style in a few months. And fashion companies prefer quick production times so that they can get their clothes into stores quickly. So it may seem like an impossible feat to have both sustainability and fast fashion. But some companies are working hard to make it happen.

The importance of regenerative fashion

There is a lot of talk about the importance of sustainability in the fashion industry, but what about regenerative fashion? Regenerative fashion is the future of sustainable fashion. It is the next step after sustainable fashion, which is focused on reducing the negative environmental impact of the industry. Regenerative fashion goes a step further and focuses on restoring and repairing the environment.

There are several ways that businesses can make their fashion lines more regenerative.

- Use sustainable materials that are environmentally friendly and biodegradable.

- Choose manufacturing processes that are less harmful to the environment.

- Work with suppliers that are also interested in sustainability.

The most important thing is to be transparent about your practices and let customers know what you’re doing.

This is where the fashion industry can really take a step forward, by using their marketing power to bring awareness to these issues and educate consumers on how they can help.

It starts with you, the consumer. We have a lot of power when we shop, and every time we spend money on something we are voting for the kind of world we want to live in. Don’t support unethical companies – they don’t deserve your money! Shop small and local whenever.

What are the limitations of regenerative fashion?

There are a few limitations to regenerative fashion. The first is that it can be difficult to create a fabric that is both durable and biodegradable. Many of the materials used in regenerative fashion, such as bamboo and banana fiber, are not as strong as traditional materials like cotton and wool. This means that they may not be able to withstand as much wear and tear.

The other limitation of regenerative fashion is that it can be expensive. The materials used are often more expensive than traditional materials, and the process of creating them is often more labor-intensive. As a result, sustainable clothing becomes inaccessible for the majority of the people.

Conclusion

Even though the majority of products made are unsustainable, there are still ways to get your hands on sustainable products. At Dinesh Exports, we manufacture certified sustainable products based on client requirements. Let’s make the world a better a place, one apparel at a time.

0 notes

Text

Slow Fashion & Minimalism in 2022

Slow fashion is a philosophy that advocates for a slower approach to consumption.

This can mean slowing down the production process, being mindful of your consumption habits, and taking steps to reduce waste in the fashion industry.

Why should I be interested in slow fashion?

The world is experiencing rapid growth in the number of consumers and their desire for more products.

This has led to an increase in overproduction, which results in mass consumerism, pollution, and the destruction of natural resources.

While there are over 6 billion people in the world, we have only 1 Earth to sustain them all.

The best way to avoid this problem is to use a circular economy, which is one that reuses materials and components of products instead of simply discarding them after they’ve been used.

A circular economy can help address issues such as pollution, waste, poverty, and global warming.

The end goal is to create a closed-loop in which waste isn’t produced.

The problem with a linear economy is that it’s unsustainable, and we’re already seeing the effects of this system.

It leads to environmental degradation, waste, and pollution as we continue to extract more resources from the earth.

There are limits to what we can do on our planet, and if we continue using resources at the rate we are now, we will run out of them eventually.

Another issue with a linear economy is that it’s not very efficient.

If we have to use resources in the same order they were created, then we will end up using them in the most inefficient way possible.

For example, if we grow food on land that requires lots of water and fertilizer, and then use more water and fertilizer to make clothing from the food we grew, it’s wasteful. We can grow food on land that doesn’t require as much water and fertilizer, then use the water and fertilizer we saved to make clothing. We can also grow food in areas that require less sunlight and use the sunlight we save to make clothes. This is a more efficient way of using resources because it minimizes our environmental impact.

In this case, economics does not work for the environment but against it: If there are economic incentives to overuse resources, people will overuse them. But if there are economic incentives to minimize resource use, people will minimize it.

Economics has a role to play in environmental protection, but it is not the only game in town.

In fact, it may be the least important of the three.

Politics and ethics matter as well — indeed, politics and ethics are necessary for sound economics to operate.

But politics and ethics do not operate on their own; they depend on people who understand them, implement them and enforce them.

The trouble is that our current approach is a little like having someone tell you that you have to have a religion, but it doesn’t matter which one.

That isn’t enough.

You need a guide who can help you choose between the options available to you and make sure that whatever you do is properly implemented and enforced.

What does it mean by Minimalistic fashion?

There are many answers to this question.

For one, it is fashion that is characterized by simplicity and comfort.

It doesn’t mean you should go out with just a pair of jeans and a T-shirt or wear a simple white shirt.

Minimalistic fashion simply means wearing only what you need and avoiding all the unnecessary items in your wardrobe.

Minimalism in Fashion Tips:

Don’t try to be someone else – This means that if you are not comfortable wearing something, then don’t wear it. It doesn’t matter if someone else wears it and looks good in it. What matters is how you feel about yourself when you wear that item.

Invest in quality – There is no point in buying a shirt for Rs. 1000 if it will be torn up after a few washes or a pair of shoes that won’t last long enough to see you through the season. If you can afford it, buy quality items that will last longer.

Think before you buy – Don’t just go out and buy something because it is on sale or you think it looks good. Before you buy anything, think about how often you will wear it and if it is worth the money. If you can’t answer these questions, don’t buy it.

Make the most of your clothes – Learn how to use your clothes effectively and don’t just throw them on the floor when you take them off. For example, hang up or fold your shirts instead of throwing them on the floor, or fold your pants and stack them neatly in a drawer. Also, get rid of old clothes that you never wear anymore – donate them to charity or sell them to a consignment shop.

Conclusion

Slow fashion and minimalistic fashion sense are somewhat similar concepts wrapped in a different cover.

The ultimate goal of each philosophy is to cut back on consumption and buy clothes that are essential.

In a world where people are expected to appear in a different dress each time they appear on social media or at any event, minimalistic fashion can definitely help decrease this pressure on people.

Minimalistic fashion alongside a slow fashion sense is only the way forward for achieving faster sustainability goals.

For minimal design fabrics that are sustainability certified, contact us

0 notes

Text

Are we ready for another hike in Cotton prices?

The Russian invasion of Ukraine has been escalating in the past few days.

The European Union and other major countries have imposed sanctions on Russia.

Due to these conditions, the world economy is in peril.

It has been a highly volatile situation for major economies including the Indian markets.

Ukraine and Russia play an important part in the production and exports of Energy and Food.

Mostly to the European Union.

With current conditions, the existing supply chains have been disrupted.

The price of essentials, commodities, and energy (including cotton and other raw materials) is expected to rise substantially.

This will have a tailspin effect on the global markets.

Impact on the Cotton prices

Cotton prices have been highly volatile in recent months.

Since the pandemic, the prices have nearly doubled.

Even though volatile, the prices of cotton are in an upward trend.

Cotton Picking GIF

from

Cotton GIFs

Southern India Mills Association (SIMA) chairman Ravi Sam said, “Due to unprecedented increase in domestic cotton price, from 135/kg to 219/kg in a year, an increase of around 65%, mills are struggling to meet export commitments.”

He also pointed out that the industry is expected to see a shortage of 30 to 40 lakh bales of cotton shortage.

SIMA has urged the government to allow duty-free import of 40 lakh bales to avoid production stoppage and job losses.

The rise in Energy & Food Prices

Many European countries are heavily dependent on Russian energy.

Particularly natural gases and crude oil.

Till now, the energy distribution has not been disrupted but the scenario is likely to take place.

Hence, the prices for energy are rising.

Pump Oil GIF

from

Pump GIFs

People are likely to come under higher prices for essential food items like bread, corn, chicken, eggs, and oil.

EU countries, Turkey, Egypt, etc will have to bear this rise in prices as the tension escalates.

An alternate scenario from Punjab

Even when cotton prices have doubled in recent months, buyers are now becoming more cautious due to the risk of loss of demand.

Prices in Punjab have crashed to Rs. 10 per kilo.

The price hike that is expected in the European region will decrease the demand for items like apparel and other cotton products.

With prices of energy, food, and other basic amenities skyrocketing, people will hesitate to spend on secondary needs like apparel and other cotton products.

“It seems as if they have bombed my cotton storage house,” said Jagjeet Singh Dhaliwall, a farmer from village Achariki in Fazilka.

Apart from this, mill owners have started visiting villages to buy directly from farmers.

But farmers are hoarding to make a good return on their hard work.

Conclusion

In recent days, global cotton prices have seen slight corrections but are still on an upward trajectory.

Indian domestic production has become challenging because of the unavailability of raw materials and the mills are requesting the government to waive off duties on cotton imports.

There is a growing fear among exporters regarding the decline of demand for cotton products like apparel and home textiles as the prices for essentials are set to increase in the EU countries.

For woven fabric manufacturing, contact us.

0 notes

Video

tumblr

We only have one home, and we need to protect it!

At Dinesh Exports, manufacturing sustainable woven fabrics is our primary priority. We also encourage brands to switch from conventional products to "sustainability certified" products that we offer.

Cotton - Linen - Modal - Tencel - Viscose - Hemp - Bamboo - Blends

We also provide services such as: - Sampling - Compliance - Testing - Customer Support

For all types of woven fabric manufacturing, reach out to us. Call/WhatsApp: +919842254924 Email: [email protected]

0 notes

Text

Will Russia-Ukraine Conflict Disrupt Indian Textile Business?

Today morning, Russian President Vladimir Putin announced that a “full-scale invasion” has started in Ukraine by the Russian military.

The conflict started looming weeks before as tensions raised between Russia and its neighboring country.

Now that the NATO-allied countries have started to implement sanctions over Russia, it is believed to disrupt economies throughout the globe.

Let’s take a closer look at these scenarios.

Putin GIF

from

Putin GIFs

Russia's dominance over the world

Russia is one of the largest crude oil producers in the world. They are a key supplier of energy globally.

Most of Europe relies on Russia for about a quarter of its oil supplies and a third of its gas.

Just as the invasion started, Brent oil prices have reached an all-time high surging above $100 per barrel.

It is expected to be in three digits for another 3-6 months.

Why does Ukraine matter?

Ukraine is the second-largest country by area in Europe and has a population of over 40 million.

It also has rich natural resource reserves.

Let’s understand Ukraine’s global ranking in exports, natural reserves, and business.

Natural Resources & Industrial Dominance

Titanium Ores – No.1 in Europe

Coal reserves – No.7 Worldwide

Iron Ores – No.2 Worldwide

Shale Gas – No.3 in Europe

Mercury Ores – No.2 Worldwide

Total Natural reserves – No. 4 Worldwide

Steel Production – No. 10 Worldwide

Ammonia production – No.1 in Europe

Defense – No. 9 Worldwide

Arable land area – No. 1 Europe

Black soil – No.3 Worldwide

Barley Production – No. 2 Worldwide

Sunflower, Sunflower oil – No. 1 Worldwide

Rye, Honey – No. 5 Worldwide

And many more.

What effects will Ukraine Russia conflict have on Indian Business?

“Even today in the FSDC meeting when we were looking at the challenges posed for financial stability, crude was one of the things.

International worrisome situations, where we actually voiced that we want diplomatic solutions for the situation developing in Ukraine, all these are headwinds”, said finance minister Nirmala Sitharaman.

India accounts for less than a 1% share of Russia’s crude oil exports. So the Indian economies are hard to get hit on this front.

But it is expected that a 15% hike in Yarns in the coming weeks.

All apparels would see an average of 30% hike in the prices.

Since the demand for products is not decreasing, there can be substantial growth in the textile industry.

Opportunities for Indian Businesses amid Russia-Ukraine conflict

The European Union is the largest importer of Indian goods.

Since the European supply chain will be disrupted, there will be a huge demand for Indian goods.

India has seen tremendous export growth in the last year and is expected to see further growth with this crisis.

More and more companies will be selecting India as their alternate supplier.

Textile Industry is also expected to benefit from this crisis as more and more countries will now be looking for India for uninterrupted materials.

Indian manufacturing won't be affected in-depth as India is not reliant on Russian energy.

Conclusion

In every crisis, there will be an opportunity.

Just like the one we are presented with.

But war is not good for the common man.

We deeply condemn the violence and the killing of innocent people.

What are your thoughts on this scenario? How do you see the Indian textile getting affected? Comment below.

For woven fabric manufacturing, contact us.

0 notes

Text

Does ‘Made in India’ Apparel have demand?

$19 billion.

This is how much apparel exports India is going to make this year.

Even though we could argue about the realistic nature of this number, we can certainly say that the real number will be around $19 billion.

AEPC Chairman Narendra Goenka told the papers that the Indian Apparel industry is on the cusp of good growth and we are trying to create a brand India image for sustainable growth. But how are we going to reach this number?

Apparel Export Opportunities from India

The Apparel Exports Promotion Council (APEC) said that the new markets for India will be Latin America, Australia, and Israel.

The current business growth is expected to grow steadily in the 2022 – 2023 time frame.

The council has taken various steps outside India in order to build good relationships with buying countries to explore opportunities together.

What will act as the fuel for growth in Exports

Production Linked Incentive (PLI) schemes announced in the union budget will help attract investments and will further push domestic manufacturing and exports.

India will execute free trade agreements with countries like UK and UAE.

India is the largest cotton yarn producer.

PM-MITRA Scheme (Mega Integrated Region and Apparel)

Building the ‘Brand India’ Image

Every country has certain qualities attached to the products it makes.

Just like an American product or a Japanese product, ‘Brand India’ is an attempt to create a certain perception towards Made in India products.

We are now in a global economy where companies are rushing to find alternative sourcing and manufacturing destinations outside China.

This is the proper time to create a good reputation and build long-term relationships with brands and retailers around the world and become one of the largest exporters of the world.

Challenges for Growth

Export of readymade garments saw an increase of 22 percent from its lows. After the COVID-19 lockdown and economic depression, the Indian apparel industry has also bounced back.

Despite the local restrictions imposed on manufacturing operations during the first and second waves of the pandemic. It is worthy to notice that the apparel industry has done exceedingly well in spite of these challenges.

As more and more orders are placed in India, there will come to a point where the infrastructure is not sufficient to fulfill all the orders. Yes, labor is not a challenge.

To put this in perspective, China has around 40% of the world's apparel trade. Since the beginning of China plus one narrative companies are withdrawing to other countries like India for alternate sourcing and manufacturing. Even if 5% of China’s production needs to be done in India, it could become a great challenge because of the infrastructural issues.

Future Trends

At present, there is a strong demand for Indian apparel. Strong demand and healthy order books are a great sign of recovery.

Orders are coming from around the globe and the exporting industry is set to see historic all-time highs in the next coming months.

MANUFACTURE WOVEN FABRICS WITH US

0 notes

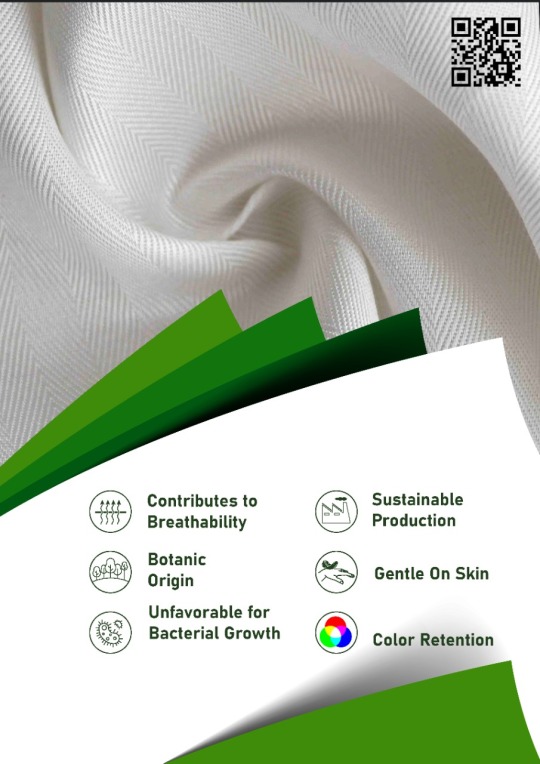

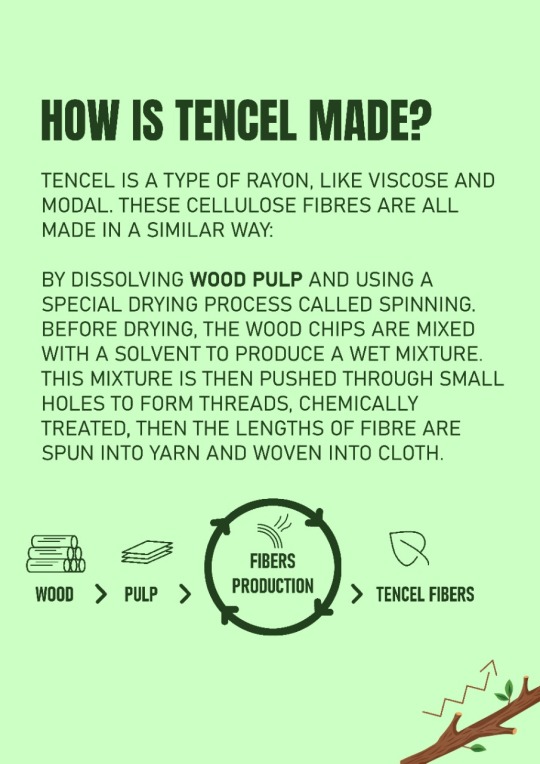

Photo

The demand for alternate fibers are on the rise. Tencel is such a fabric that has seen growing popularity among retailers and consumers alike for its novelty. It is softer than viscose but more eco-friendly. Eventually the fibers biodegrade in soil unlike other synthetic fibers. Overall Tencel fabric ranks fairly among the top fibers. At Dinesh Exports, we manufacture a whole range of Tencel fabrics with 100% and mixed blend ratios. For more details, visit: https://lnkd.in/g6ge6Qzc Call/WhatsApp: +919842254924 Email: [email protected]

0 notes

Text

The Importance of Digital Print Fabric in Fashion

Man always finds ways to optimize his efforts.

Maybe we can say that the birth of digital printers and the mass adoption of digital printing is a result of such an endeavor.

Surely, the benefits of digital printing fabrics are way higher than the traditional or any other type of printing.

Let me explain.

Table of Content:

How digital printing is revolutionizing the fashion industry

The benefits of using digital print fabrics in clothing manufacturing

The future of digital print fabrics

How Digital Printing is revolutionizing the Fashion Industry

Digital printing is a process that uses inkjet or laser technology to create real-time digital images on the spot.

The advantages of digital printing are that it is cost-effective, environmentally friendly, and can be done in smaller quantities than traditional printing.

Digital printing is a new way of printing fabric.

It is the process of transferring images from a digital file to fabric using an inkjet printer.

A heat press then transfers the ink onto the fabric, making it possible for designers to print on garments without the need for any physical production line.

Digital printing has many advantages over traditional garment production methods, including being able to produce high-quality prints with vibrant colors and no need for expensive equipment.

Additionally, it is more environmentally friendly than traditional garment production methods because there are no chemical inks or solvents used in the process.

Digital printing is a type of printing that uses digital technology to print designs onto fabric.

The process is done with the help of computers and printers.

It is a new way of printing clothes, which has revolutionized the fashion industry.

Clothes are printed digitally in order to save time.

This process also reduces the risk of errors in production, so there are more accurate designs on clothes.

Furthermore, it minimizes the need for expensive equipment and materials that are typically needed for traditional printing processes.

The fashion industry is one of the industries that has been most disrupted by the digital printing revolution.

Digital printing allows for an unlimited number of prints to be made in a short amount of time, and it has opened up opportunities for designers to create more experimental designs without worrying about the cost.

Digital printing is a process that uses digital files rather than film to create images on paper, fabric, or other materials.

It was first invented in the 1980s and has since become one of the most popular ways for designers to print their designs onto clothing.

There are many benefits to using digital printing over traditional methods, including:- The ability to print small batches of items at a time - The ability to print on different types of fabrics - The ability to print on different types of material

A post shared by Dinesh Exports (@dineshexports)

The Benefits of Using Digital Print Fabrics in Clothing Manufacturing

The digital print fabric is a new trend in the fashion world.

It is a great way to make your own clothes and accessories with your own style.

It is also a great way to make custom clothing for any occasion.

The following are some of the benefits of using digital print fabric in clothing manufacturing:

Digital print fabrics are used in the production of clothing. These fabrics are available in various materials and colors.

The benefits of using digital print fabrics in clothing manufacturing are:

- They can be used to create custom clothes online.

- They can be used to design clothes for a specific person or event.

- They can be used to design clothes with intricate patterns or designs.

- They can be used to create clothing with bold colors that would not have been possible with other fabric types.

There are many benefits to using digital print fabrics in clothing manufacturing.

With these fabrics, you can create custom clothing online and get them delivered to your doorstep.

You can also find digital print fabric near me and use it to make your own designs.

The benefits of using digital print fabrics in clothing manufacturing are too many to list, but here are some of the most important ones.

Digital printing is a lot more cost-effective than traditional printing.

It can also be done on any size or shape of the fabric, it's fast, and it's environmentally friendly.

Digital print fabrics have been around for a while now and they have been developed significantly in recent years.

They have become much more durable and they can be used for a variety of purposes - from creating custom clothing to making quilts or curtains.

The Future of Digital Print Fabrics: A Key Investment for Any Business

Digital printing is a way for businesses to set themselves apart from the competition.

Digital printing has been around for a while now, but it has never been accessible to all until recently.

The technology has finally caught up with the creative minds in fashion and apparel design.

There are many benefits that come with digital printing, including faster turnaround times, lower minimums, and more cost-effective production costs.

With these benefits in mind, it’s easy to see why the digital print fabric is the future of fashion.

The future of digital print fabrics is bright and it will continue to evolve.

It has become a key investment for any business.

Fashion companies are looking for ways to differentiate themselves from their competition and turn their products into a lifestyle statement.

Digital print fabrics allow them to do this by adding an element of exclusivity and uniqueness.

The future of digital print fabrics is in the hands of fashion designers.

They are the ones who will decide how to use this technology for their designs.

It is important to note that the future of digital print fabrics is not just about how it helps brands build their own identity and develop their own aesthetic, but also how it helps them increase their profits.

Contact Us for Digital print fabrics

0 notes

Text

What is China-plus-One Global Narrative?

The global narrative on China has been changing recently.

With the trade war going on, and with the focus on China's poor environmental record, many companies are starting to look for alternatives to Chinese manufacturing.

In this blog post, you'll discover what China-Plus-One is, and how it can help your company stay competitive in a changing landscape.

What is China-plus-one narrative?

The China-plus-one narrative persists in the U.S. and other China-dependent companies, according to the narration, which argues that China will be overtaken by India as the world’s top manufacturing hub in the future as companies have started looking for alternative sourcing destinations for their manufacturing requirements.

It is important to take note that companies are not avoiding China in any sense.

They are targeting a small percentage of the manufacturing and sourcing activities to be outside China.

This will help them to have a strategic manufacturing and sourcing partner to tackle complex supply chain issues.

On the other hand, China is experiencing a "demographic dividend" with more than 30 percent of its population under poverty and old age.

From electronics Giants like Samsung to Apple, to textile houses, hundreds of companies are setting up new manufacturing hubs in India and other neighbouring countries.

If we talk about the textile industry, the Chinese industry is going to lose up to 10% of their annual production rate.

This is a huge opportunity for countries like India to emerge as a friendly country and dominate the global market.

“India is expected to reach $65 billion in exports by 2026 if right actions from the industry majors and robust execution of government schemes”

The Rise of China as a Manufacturing Hub

China is the factory of the world. Most of the products that we use today are made in China.

At least it will have parts that were made in China.

The main reason for the rise of their power is the huge population.

China has the world’s largest population exceeding 1.4 billion out of which 700 million are working in the manufacturing sector.

On top of that, these workforces are highly trained, skillful, and productive.

With a large supply of workforce, the labor charges are naturally lower.

The workforce in China faces fierce competition which leads to low wages.

Low wages are essential in manufacturing low-cost goods.

The Chinese regulatory factors are also flexible allowing companies to decide the working hours and other conditions.

It is recorded that some people work as long as 16 hours a day, on some occasions.

Up until recently, the regulations on the environment were also negligible.

These factors are extremely suitable for growing manufacturing exponentially.

That is exactly why China became a manufacturing hub of the world.

During the early 1990s, in order to attract global investors, the Chinese government provided tax deductions and changes to its economic policies.

As a result of low tax rates and a friendly environment, they were able to attract large companies like Nike and Apple to China in the early days.

Why is China Plus One Narrative Growing?

In a post-COVID-19 pandemic world, most of the companies will try to move out of China.

But it will be extremely difficult for the companies to do so considering the huge investments in infrastructure and talent required to do so.

Rather than completely shifting out from China, companies are adopting China plus one narrative.

All the major products will now also have an alternative manufacturing hub outside of China.

They are being blamed for such a worse widespread pandemic.

The labor-intensive industries like toys, shoes, apparel, and others will see slight changes in the coming years.

The US companies especially will try to move away from China aggressively as the implementation of tariffs on China is higher due to the trade war.

Conclusions

China-plus-one means the Western world views China as the main world power, not America.

This narrative is growing in popularity, and there are many reasons for this.

It's important to remember that China is an emerging economy with many issues to address, but they're becoming more capable of doing so with each day.

The global narrative will continue to shift as time goes on, but China will always be included in it.

This will be an opportunity for countries like India, Bangladesh, Vietnam, Cambodia, etc.

Several of these countries are trying to woo companies to set up shop and move out of China with warm offers.

The technological industry, IoT and AI will move faster out of China than the others. In 5-6 years, China will not be the top manufacturer in the world.

Source high quality sustainable woven fabrics from us.

0 notes

Text

Everything you need to know about Muslin (2022 Update)

01

Muslin fabric in bulk has many uses; backdrops for productions, draperies, creating patterns for costumes and clothes, stands for patchwork quilts, batik, linings, and much more. Muslin fabric is well suited for tailors and fashion designers as it is used for rough designs. To keep costs down, some manufacturers use a blend of polyester and cotton for muslin weaving.

02

Muslin may be 100% cotton, but it is called muslin because of the plain weave and thin threads. Cotton is a highly absorbent fiber, so the more cotton a muslin fabric contains, the more absorbent it will be. In addition, it is usually 100% cotton, which means that there are no synthetic fibers intertwined with cotton in the manufacture of muslin.

03

To make muslin, cotton thread had to be spun to be as fine as possible. This unique cotton variety has established itself as the finest and softest muslin cotton in the world.

04

The work involved and the high quality of the resulting fabrics make muslin very valuable. It has survived as an important fabric due to its practicality and durability. From whimsical handmade fabrics to practical everyday fabrics, muslin does it all.

05

Muslin fabrics' versatility and unique beauty make them so easy to use for all kinds of applications and finished products. What makes muslin fabric is the combination of fiber type, thread size, and weave type. The texture as well as the fiber content is what makes a muslin fabric. The thinness of the fiber and the single-layer weave makes this fabric soft and light.

06

In muslin fabrics, the weft yarns are woven through each warp thread one at a time to give the fabric the well-known light and breathable weight. All plain weave cabling is the same size, so no matter how thick they are, the resulting fabric will have a smooth finish. The best qualities of Muslin are fine, smooth texture, woven with evenly twisted warp and weft or filler.

07

Muslin and linen are plain weave fabrics made from natural fibres. Muslin is a plain weave cotton bed linen fabric that is arguably the most common fabric in the theatre. Muslin is a woven cotton fabric believed to have originated in Dhaka (now Dhaka), Bangladesh.

08

Unbleached Muslin is a plain weave, hypoallergenic, 100% cotton fabric. Soft, breathable, durable, and flowable unbleached muslin for any craft or project. The muslin fabric is made from 100% organic cotton, soft enough, and easy to dye for any application. It is a thick fabric used for looped canvases, backgrounds, and photographs.

09

You can also use it to make pillows, embroidery, batik, and more. Some muslin muslins use silk or rayon mixed with cotton to give the fabric a larger shape. Although Bengali muslin has not yet been able to grow enough unique cotton to make a full-fledged garment, the fibers are combined with other cotton materials to create a hybrid thread.

10

Because cotton is still harvested, not created in a lab, this makes cotton fabrics (like muslin) completely natural. Although cotton is widely considered a breathable fabric, it is not as breathable as most muslins. Most people wouldn't think of this as different from the more common cotton fabrics, but it's not. Generally speaking, the nuances between regular cotton and muslin fabrics add to the overall appeal and choice of muslin over other cotton fabrics.

11

Muslin is sheer and thin so it is often paired with other fabrics, but Swiss muslin is often used as a top layer in lighter clothing. Muslin is also often used as a warp or lining for quilts and as such can often be found in the quilting section of fabric stores. Used for things like sewing warp or quilt backing, muslin is an affordable fabric for all your quilting needs. 3 regular muslin weights are light, commonly used by buyers for lining or pattern; medium weight, used for hard floors or slight slopes; heavy, used for covered soft plains and large slopes.

12

For a time, production of the fabric ceased during British rule, but the art of weaving muslin became popular in the 1990s, although very few people had effectively mastered the making of very fine muslin.

13

The culprit was Dhaka muslin, a precious fabric brought from the city of the same name in what is now Bangladesh, then in Bengal. Made using a complex 16-step process from rare cotton that grew only on the banks of the sacred river Meghna, the fabric was considered one of the greatest treasures of that era. He had truly global patronage dating back thousands of years, considered worthy of decorating the statues of the gods of ancient Greece, countless emperors from distant lands, and generations of local Mughal royalty. Muslin dakka was so light that it was called weaving of the air, so fine that those who wore it were sometimes accused of obscenity, and so complex that the knowledge of how to make it has since been lost.

14

The name, weight and structure, name, origin and specific use of the threads were the main criteria to distinguish them from each other. They were distinguished by the number of threads, the size of each woven piece and the softness of the fabric.

15

The process was so slow that it could take more than five months to weave a piece of muslin. It took 60,000 meters of cotton thread to weave 5.5 meters of fine muslin, and it took three weavers two months to complete.

For Muslin cloth manufacturing, please contact us

0 notes

Text

Impact of 2022 budget on Indian Textile Industry

The last couple of years have been a bumpy ride for the textile industry.

With pandemic stalling manufacturing, an increase in cotton prices, labor shortages, etc. it was evidently a nightmare.

But if we look at the numbers, there has been a 41% increase in textile exports from April-December 2021 against last year.

Smaller countries like Vietnam and Bangladesh have overtaken India in this segment.

The entire industry was looking forward to the 2022 Union Budget announcement with hopes to find help from the Government of India to be more competitive in the global markets and become par with its challenges.

Today the Union budget was announced.

We will look at textile industry-related announcements and their impact.

Table of Content:

Budget announcement affecting textile industry

The window of opportunity

What were the expectations before the budget announcement?

Conclusion

Budget announcement affecting Textile Industry

Finance Minister Nirmala Sitharaman today while presenting the 2022-2023 Union Budget announced that the production linked incentive in 14 sectors will create 60 lakh jobs and has the potential to generate Rs. 30 lakh crore in production over the next five years.

Based on the Economic Survey, it is estimated that this scheme will result in an additional Rs. 19000 crores of fresh investment in the textile sector.

This is expected to create a cumulative turnover of over Rs. 3 lakh crore and create over 7.5 lakh additional job opportunities in this sector.

In the previous Union Budget (2021-2022), the government has assigned an outlay of Rs. 1.97 lakh crore.

The Window of opportunity

The global companies are adopting a “China Plus One” strategy in their manufacturing practices.

This is a positive opportunity for India to take advantage and bite a bigger piece of the pie.

It is estimated that the global textile industry is around $1 trillion.

China is having a market share of 30% - 36%.

Even if India could grab 1% of this market share it will be a $10 billion market.

The Indian government has set a target of $100 billion in exports over the next five years.

These announcements are expected to prepare the Indian textile industry to propel and scale massively in this direction.

What were the expectations before the Budget announcement?

A 10% customs duty was levied on the import of cotton fiber. It was expected to be eased in order to control the yarn prices. If yarns are duty-free then the domestic supply would increase and prices would go down.

It is expected from the government that the RODTEP scheme is extended this year also. Rebate of State and Central Taxes and Levies for Garment exports and Remission of Duty and Taxes on Export Products for the yarn and fabric industry. These schemes help the industry get rebates of embedded central and state taxes.

PLI Scheme to be introduced for cotton textiles and counter the shortage of short-staple spinning capacity.

SOPs for textile parks.

Conclusion/Key Takeaways

Even though all the expectations were not met in the 2022-2023 Union Budget, the PLI scheme will make a positive impact on the textile industry.

Earlier, The Goods and Services Tax (GST) Council had decided to defer the hike in the tax rate on textiles from 5% to 12%.

For woven fabrics manufacturing, contact us

0 notes

Text

Summer & Linen: A Match made in heaven

I am about to tell you the perfect romantic story.

One that doesn’t end up in a tragedy. Like Jack and Rose from Titanic.

This is the story of Linen and Summer.

How they met and were bonded forever. So, brace yourself.

Table of content

What is Linen and how it is made? - About flax - How it is made

Why linen is popular in summer wear?

Buy flax fabrics online from Dinesh Exports India

What is linen and how it is made?

Linen used to be a precious material.

During the Egyptian empire, the pharaohs were wrapped in linen after they died.

You may have seen this in movies.

The high priests and the elites also had access to flax.

It was believed to have natural healing capacities.

About Linen

Today, linen is cultivated around the globe.

Linen is also known as flax.

The fiber is derived from the stems of the flax plant.

There is evidence that the Neolithic people in Europe were making linen textiles as long as 36000 years ago.

While this may be hard to digest, we can surely say that flax was used in ancient Mesopotamia.

The archaeologists have found evidence of domesticated flax in the remaining.

via GIPHY

This civilization existed about 10000 years ago.

With time, flax cultivation got focused in a few countries.

China is among the top manufacturers of flax today.

The popularity of flax subsided when cotton and other synthetic fibers came into existence.

The process of manufacturing flax is tedious and resource-consuming.

This was the major reason for flax to lose its popularity.

But it is still in demand.

A minority of the population still demands flax products.

A variety of products are now made with flax.

Bedsheets, fabrics, pillowcases, dish towels, bath towels, wallpaper, suits, shirts, dresses, aprons, tablecloths, diapers, napkins, bags and so on.

How linen is made?

flax manufacturing has six steps.

These steps are not the modern-day mechanized version.

Rather a medieval approach.

This will help you understand flax manufacturing better.

Step 1: Sowing the flaxseed. This is done during the month of April. Although this can be different based on country. It is important to plant the seeds during the cooler part of the year in order to avoid crop death due to heat.

Step 2: In three months, the flax plant grows to its full height. The flax stems become yellow and the seeds are turned brown during the right harvesting time.

Step 3: The flax plant is pulled out from the land and soaked in water for two weeks.

Step 4: After two weeks it is taken out and spread evenly in the sun to dry. The drying process takes about ten days.

Step 5: The dried flax plants are bundled together and kept for five days.

Step 6: It is then sent to the mill to make threads and further process to manufacture products.

Why linen is popular in summer wear?

flax has several qualities that make it an ideal material for the summer.

Linen is breathable: During the summer, it can be usual to sweat a lot. The last thing we want is our garments sticking to our skin and making us uncomfortable. Flax has a natural quick-drying property, which is higher than cotton. flax fabric appears crisper in hot weather. It is also a lightweight fiber that allows maximum breathability making it perfect for a hot summer garment.

Linen is cool and it absorbs: Linen is a heat-conducting material. The fibers have the capacity to absorb 1/5 of their weight before giving a feeling of being damp or wet. The hypoallergenic property of flax fights the breakdown of fibers due to sweating. This significantly alleviates the effect of heat and humidity.

Linen is versatile: Earth is getting warmer by the day. So linen fabrics are going to be in most demand. One of the key advantages of flax is that it lasts a long time. The color stays fresh for years. It gives the best cost-per-wear value for apparel in the market.

Buy Linen fabric online from Dinesh Exports, India

If you are a merchandiser, product developer or someone who sources fabrics for brands or factories, we can help you with high quality linen fabrics and other woven fabrics. View more linen fabrics here.

0 notes

Text

Merchandisers Guide to All over Print (AOP) Fabrics

All over print designs are repeated across the entire fabric surface.

There is always growing demand for these types of fabrics and garments around the world.

The possibilities of designs are endless here.

But there are certain things a merchandiser should know beforehand.

Let's dive into it.

History of All over print fabrics

Even though fabric printing existed many centuries ago.

A proper system for printing fabrics was invented only in the 1900s.

The sublimation printing process was invented in 1957.

In this process, a graphic is printed onto a sheet of high-release paper.

It is then transferred onto fabric or garment using high heat or pressure.

The applied heat transfers the print from the paper to the fabric.

But with time, there have been drastic advancements in the printing processes.

To read more about printed fabrics

Things to understand about all over print fabrics

It is important to have the design ready before the printing process starts.

The design is regarded as the heart of printing.

The artists who develop the designs should also have a better understanding of the step-by-step processes involved in the printing process.

A clear idea on the feasibility of printing

The qualities and characteristics of fabric are dependent on the fiber it is made up of.

So is the result from printing.

Imagine the difference between printing on cotton fabric and lycra fabric.

In order to print efficiently, we need to understand the basic difference in these fabrics and subsequently use the most efficient method of printing.

2. Print measurements and calculations in various printing methods

In rotary printing, the designs are etched on a piece of fabric using a rotor.

The limitation here is the diameter of the rotor.

It is important for the designers to understand this in order to create an optimized print.

The same goes for other types of printing.

Like flatbed screen printing.

It also comes with limitations in the size of the design it can print.

3. Understanding of repeats and colors

A repeat is a complete block of design that is used throughout the fabric.

It is crucial to set repeats properly to achieve the desired results.

4. Knowing the difference between chest print and all over print

Chest print is something that we often see on a t-shirt.

As the name indicates, the chest print design is placed over the region that comes over the chest.

It is basically a single design with more letters.

But overall prints are smaller and generic in nature.

Like dots, spirals, flowers, etc.

5. Creativity

A creative designer is flexible and understands how printing works.

He can easily tweak and make incremental changes not only to improve the design but also to increase the printing efficiency.

For example, a printing design that consists of ten or more colors may be costlier to produce.

A creative designer understands this and tries to reduce the colors from ten to six.

This cut the cost of production substantially.

6. Steps involved in the design development process

Developing a print design can be a complex process.

There are several things to consider.

Like the end consumer, price, cost of production, and so on.

A designer that has knowledge of these will be able to produce better designs.

7. Consumer behavior

Consumers are a group of people with various beliefs and perceptions.

They act differently to the same input.

Imagine what type of prints a college teen would purchase when compared with an adult that goes to work.

8. Knowledge of various seasons and trends

There are four major seasons in fashion.

Consumers expect certain prints to be available in certain seasons.

During the spring seasonal collection, floral prints are to be included as it represents the season.

9. Understanding cultures

In a society, people are formally influenced by their culture.

Religion is a great example of cultural influence over people when it comes to selecting their dresses.

Some religious culture allows wearing garments with prints of animals and people while some do not.

It is important to have an understanding of this subject to develop the appropriate prints.

10. Well versed with color matching

Print designs are always about color matching.

Prints are nothing but changes in color on certain locations of the fabric.

What is the top trending all over print fabrics?

Cotton print fabrics

Cotton is still the widely popular fabric loved by the masses. All over print cotton fabrics are at the top when it comes to demand. It is used for the production of men, women, and kid's garments.

Block print fabrics

Block printing is an ancient method of printing designs onto a piece of fabric. All over printing can also be done using block printing methods. It is used mostly for womenswear.

Digital print fabrics

Digital printing is a 10X equivalent of color printing a normal paper. A computer-generated design is printed all over onto a piece of fabric using a printer. The fabric fed into the machine in a roll form. This is a comparatively cheaper form of printing. Due to heavy mechanization, it is also the most cost-efficient. Large designs can be printed using this method because the limitation of a roller does not exist in this case.

Floral print fabrics

Floral print fabrics can be sold throughout the year. It is cyclic. The demand for all over floral print fabric increases during the spring and summer seasons.

Rayon print fabrics

All over print on rayon fabrics are a lustrous type of printed fabric due to the fiber quality.

Kalamkari print fabrics

Kalamkari print fabrics are also an ancient form of printing method. It is basically done by a group of people called the kalamkars (artists). You can read more about kalamkari fabrics here: {link}

Symmetrical pattern print fabrics

Small symmetrical patterns printed all over the fabric are another year-round favorite. This type of print design are always welcomed by the masses

Stripe print fabrics

All over print fabrics comes on stripes, zigzag, curl, and waves. It can come in a myriad of colors also. One amazing thing about stripes is that they can be used for male and female clothing. As well as casual or formal.

Camouflage print fabrics

Inspired from military uniforms, camouflage print fabrics represent variations of the military uniform that blends more than two or three colors.

Key Takeaways

All over printed fabrics are an ideal option to include in any garment collection.

Since a majority of the population welcomes all over printed fabric throughout the year, there is no question about demand.

With today's technology, it is possible to manufacture printed fabrics at the least production cost.

What are your thoughts on this view?

Do you think all over print fabrics can be sold throughout the year?

If you want us to manufacture all over printed fabrics for you, please contact us.

0 notes

Text

Historic: Indian Army Gets a New Combat Uniform

During the Indo-Sino war in 1962, the Indian army had to fight the Chinese military in the most challenging conditions.

The high peaks of Ladakh and at the North Eastern Frontier Agency, which is Arunachal Pradesh now.

The militants had a tough time battling effectively in their uniforms for several reasons.

Until this time, the military uniforms were made using cotton and cotton fiber jerseys.

This was the beginning of changes in the Indian military uniforms.

Indian Army gets a new Combat Uniform

Every year since 1949, January 15th is celebrated as Army Day.

This is to remember the occasion when General KM Cariappa took over the command of the Indian Army from General Sir FRR Bucher, the last British Commander-in-Chief in 1949, and became the first Indian Commander-in-Chief of Independent India.

During the Indian Army Day celebrations this year, on Saturday, a new combat uniform was unveiled by Army Chief Gen M M Naravane.

The new combat uniform of the Indian Army was unveiled at the 'Army Day' parade, today. pic.twitter.com/2d1u8FwV9v

— ANI (@ANI) January 15, 2022

What is new in the latest Indian army combat uniform?

The new Indian army combat uniform is designed by a team of 12 people at the National Institute of Fashion Technology.

The team includes seven professors, three students, and two alumni.

The uniform is designed with a continuous consultative process with the Army.

It was done keeping in mind the “4Cs” – comfort, climate, camouflage, and confidentiality.

What are the Key Features of the new Indian army combat Uniform?

The new uniform has an informal look, as the shirt is not tucked in.

An additional black round neck t-shirt is worn under the uniform

The uniform design is inspired by other armies, especially the US army.

It is comfortable for all-terrain combat with a 70:30 cotton-poly composition.

The design is digitally printed with four different shades.

This design was finalized after analyzing more than four types of fabrics and as many as eight designs and fifteen patterns.

A brief history on the evolution of army uniform

British East India Company instituted three different combat uniforms for three presidencies. The Bengal presidency had a partly red uniform with colored trimming and embroidery, the Bombay presidency had a grey uniform and the yellow uniform was for the Madras presidency.

A formal uniform was eventually allotted to the three presidencies after 1857 when the presidencies devolved to the British Crown.

The division of the Indian army into Indian and Pakistan armies after the Independence in 1947, the Indian army retained olive green as its base color.

Cotton uniforms and cotton fiber jerseys were replaced after the 1962 war in order to better equip for high altitude warfare.

After the Siachen glacier face-off in 1984, Indian units in the glacier were introduced to Austrian alpine clothing and climbing equipment.

In order to have a better-inbuilt element of camouflage, the Indian army replaced the old cotton olive green combat dress with a disruptive pattern battle dress.

Receives full update in 2022 January as explained.

Uniform components and style

The uniform has three components. A black round neck t-shirt, trousers, and shirt.

The shirt is not tucked in, unlike its previous versions. It has angular top pockets, lower pockets with vertical openings, knife pleats at the back, a pocket on the left sleeve, a pen holder on the left forearm, and improved-quality buttons.

The trousers have an elastic waist and buttons and a double layer at the groin.

A modified version of the uniform is also developed for the lady officers and troops of the army.

“Not all the uniforms of the military are changing.”

The uniforms will be available to personnel in a phased manner as the Army will issue tenders for private and public companies to manufacture the uniforms.

It will be distributed in a phased manner.

What do you think about this new uniform? Could it have been better to use any other material? Write down below.

For camouflage-print fabrics, contact us.

0 notes

Text

A Merchandisers Guide to Jacquard Fabric

During the 1700s, weaving a brocade fabric was an intense and laborious task.

In order to weave two square inches of finely woven fabric, it would take a weaver and a draw boy one single day.

These brocades create intricate patterns on fabric, and it was possible by lifting threads at certain points in time.

The draw boy is usually the one that does this work.

The weaving master will signal the boy to lift which threads to lift and when.

These boys are usually young as this task requires climbing on top of the loom.

It was a back-breaking task for the kids.

Maybe this was the reason Jacquard loom was invented.

Table of content:

What is Jacquard fabric?

How jacquard fabrics are made?

Preparing the yarn

Programing the jacquard loom

Weaving

Finishing

What are the different types of Jacquard fabrics?

How to care for Jacquard fabric?

Jacquard fabrics online in India

Conclusion

What is Jacquard Fabric?

Jacquard fabric is a fabric that is woven on a jacquard loom.

The jacquard loom was invented in 1804 by the French textile artisan Joseph Marie Jacquard.

Remember the young kids that worked as draw boys at the weaving mill?

Jacquard also worked as a draw boy in his early days.

Even though many great minds were working towards developing a machine to make weaving patterns easier, it took a draw boy to make it happen.

It was recorded that draw boys often became handicapped later in their lives because of the hard work they do in their prime ages.

"In 1801, Jacquard’s initial concept was appreciated by Emperor Napoleon and it is him that commissioned to make the Jacquard loom to perfection."

The number one thing that made jacquard looms possible was the ‘punch cards’.

Inspired by piano players and musical boxes, the punch card had a similar programming system which was later inspired by the invention of the world-first computer by Charles Babbage and other binary code systems.

Unlike normal printed or dyed fabric, the patterns on the jacquard fabric are deeply engraved on the fabric itself.

This is the most distinguishing characteristic of the jacquard fabric.

How Jacquard fabrics are made?

The invention of jacquard looms made it possible to weave intricate patterns and offer them for a fraction of the price at which it was sold earlier.

With time, jacquard looms also got better and more computerized.

Still, programmed looms are still called jacquard looms.

It is possible to make jacquard fabric using a variety of fibers from cotton, silk, polyester, etc.

Production of jacquard fabrics include:

Preparing the yarn

Any type of natural and synthetic fiber yarns can be used for the manufacturing of jacquard fabrics.

Yarns are also available in various sizes, spins, etc.

So depending on the client requirement or based on technical feasibility, yarns are sourced or internally produced for the production of jacquard fabric.

Programing the jacquard loom

Jacquard looms can create a variety of patterns on fabric based on their programming.

There are manufacturers that use punch cards as well as computerized programming to prepare the loom.

In both of these cases, several types of patterns can be woven.

Weaving

Once the loom is ready with the program, it is time for the weaving process.

This is an automatic process these days with little to no supervision.

The modern jacquard looms commonly feed the yarn into weaving apparatus from a central location at the top of the loom.

It then arranges this yarn into a complex web to produce the desired pattern.

Today, some jacquard looms are even capable of producing more than one piece of fabric at a time.

Finishing

The fabric is then treated with post-production finishing processes.

This adds extra functionality to the fabric in terms of smoothness, colorfastness, durability, etc.

What are the different types of Jacquard fabrics?

Jacquards fabrics have their origin in brocade fabrics.

From the 6th century, brocade was considered a luxury and most elites were able to acquire them.

These fabrics were suitable for emperors, kings, and other people with power and wealth.

Technically, any fabric that is made using the jacquard loom is called a jacquard fabric.

But based on a closer look, we can further divide jacquard fabrics as below:

Brocade:

Brocade fabric is a patterned raised cloth.

It often has multiple color yarns.

Brocade fabric is usually used for making special occasion garments that are heavy and rich.

It is a non-reversible fabric often made with metallic threads for spark.

Popular types of garments are Skirts, jackets, and coats.

Damask:

Damask fabric is a lighter version of the brocade fabric.

It has a smooth and luxurious feel to it.

It is often made using cotton, silk, linen, viscose, etc.

Damask fabrics have the colors of the background and the pattern reverse from front to back.

Popular types of garments made are dresses, skirts, blouses, tops, coats, ties.

Matelasse:

A matalasse fabric is normally a solid-colored fabric with a raised quilted effect.

It contains a wide range of floral motifs and graphics.

Outwear jackets, coats, dresses, skirts, and handbags are mostly made using this fabric.

Cloque:

Cloque fabric is a type of jacquard fabric that has a puckered or a blistered effect on the material.

It is made using cotton blends, wool, and silk.

It is used for the manufacturing of dresses, skirts, blouses, and jackets.

Tapestry:

Tapestry fabric is a heavier alternative to the brocade or damask fabric.

It is used for making coats and outerwear jackets.

Brocatelle:

Brocatelle fabric is a type of fabric that is similar to a damask fabric, but it is distinguishable due to its tightly woven, raised, and embossed patterns.

This fabric is used mostly to create Haute couture wear.

All the jacquard fabrics have a raised surface except silk.

Silk yarns are really thin and soft that these patterns are hardly felt under the fingers.

How to care for Jacquard fabric?

Jacquard fabrics are made using a variety of fabrics.

These fabrics also have various finishing treatments done.

So it is not possible to outline generic care steps, but following the below will be useful.

Useful link: Everything you need to know about care labels.

Delicate, or rich and ornate jacquard fabrics are better when dry cleaned.

Avoid using bleach on these items

If possible hand washes at 30 degrees Celsius.

While pressing, do it from the opposite side to avoid damaging the pattern.

Jacquard fabrics online in India

At Dinesh Exports, we are manufacturing a variety of jacquard fabrics. If you have any requirements, please contact us.

Conclusion

Jacquard fabrics are a piece of art. It represents beauty, art, and luxury.

Having them in your product offering can target the type of customers that are looking for such taste.

Do you have jacquard fabric products in your product offering?

0 notes