Don't wanna be here? Send us removal request.

Text

SECS/GEM, GEM300, Smart Factory & Industry 4.0

SECS (SEMI Equipment Communication Standards) and GEM (Generic Model For Communications and Control Of Manufacturing Equipment) standard is published and maintained by SEMI.org, an international organization of semiconductor manufacturers, is an organization body that governs the standard for semiconductor manufacturing.

It is the main communication protocol used in automation for (initially) semiconductor/electronics industries, however, today it has been widely adopted in photovoltaic and SMT industries too.

It provides a communication interface between equipments and host systems.

Unlike other communication protocol like PLC, it enable equipments from variety of vendors to communicate using standard and consistent protocol with various type of Host systems.

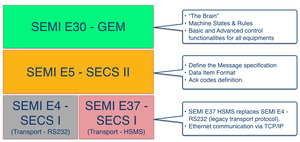

To understand the SECS/GEM standards you will need to purchase the following 3 basic standards from SEMI:

SEMI E30 GEM Standard – This is the “Brain” that defines the behaviours of equipment (Business Rules), state machine and some rules like which SECS-II messages should be used, in what situations, and what the resulting activity should be. It also defines the functionalities like Status Data Collections, Trace Data Collection, Alarms Management, Spooling, Remote Command, etc.

SEMI E5 SECS-II – Defines the details of the interpretation of messages (APIs) exchanged between equipment a host. It also defines message inputs/outputs data structure, data item format, acknowledgement codes, etc.

SEMI E37 HSMS – High Speed SECS Message Services. This is a transport layer based on TCP/IP protocol and a successor of the previous SEMI E4 SECS-I standard that is based on serial communication. This is also the layer where the SECS-II messages are encoded into HSMS message format.

0 notes

Text

SECS/GEM Data Items

SECS/GEM is an industry standard, that defines standard process of communication between equipment and fab host software for controlling and monitoring purposes. By connecting SECS/GEM equipment, fabs can immediately gain operational benefits. Factory hosts can collect data in multiple ways. Along with event reports, the fab host often requires to poll the equipment for current data values. The host can directly request Data values , or can be sampled periodically in a trace report this process is called Data Polling

There are 3 categories of Data Items defined in SECS/GEM standards:

Status Variables (SV)

Status variables are data items that identify the status of the equipment, or any of its components, such as sensors, meters, etc. Examples of status variables for process equipment are – Temperature, Pressure, Gas Flows, RF Forward Power, Spin Speed, etc. These data items are generally not attached to events such as lot start, wafer start, etc. A factory host can query the status variables to the equipment any time or can define trace data setup through which it asks the equipment of supplying status variables at regular intervals. A factory host cannot change status variables of the equipment.

Data Value Variables (DV)

Data value variables are data items that are related to a certain event, such as lot start, alarm/error occurring on the equipment, wafer processing/measurement complete, etc. Examples of data value variables are – LotID, SlotNumber, CurrentRecipe, etc. These variables change only when a certain event occurs, such as selecting a recipe, starting lot processing, etc. A factory host queries Data Value variables through defining reports and associating the reports to events.

Unlike status variables, data value variables may not have a value. For example, one of the data value variable is AlarmID, which designates the ID of the most recent alarm. However, it can be empty if there haven’t been any alarms since the equipment was turned ON. A factory host cannot change the data variables of the equipment.

Equipment Constants (EC)

Equipment constants are data items related to the configuration of the equipment – they could contain items related to the equipment hardware, software or SECS/GEM software. Unlike status variables and data value variables, a factory host can change equipment constants through SECS messages. Examples of equipment constants are – PumpDown Time Limit, Equipment Standby Time, Pins Up Wait, etc.

Data Properties:

The Data types listed above have similar properties so that it’s convenient to define the data. The equipment supplier is required to provide these properties in a SECS/GEM manual so that the fab host will be able to understand and communicate with the data. Below are some of the important data properties of the Data Types:

ID – It’s a numeric ID that must be unique in the SECS/GEM interface. These IDs can be grouped by data type and are referred to as SVIDs (Status Variable IDs), DVIDs (Data Variable IDs) and ECIDs (Collection Event IDs).

Name – It’s a name assigned to a data item so that we can identify it easily.

Format –Data type of the item.

Data formats can be simple (numeric, ASCII, Boolean) or complex (arrays, lists, structures). For example, numeric types can be I1, I2, I4, I8 (signed integer types of different byte length), U1, U2, U4, U8 (unsigned integer types) and F4 or F8 (floating point types).

Array types and List contain multiple values in the data item. For example, image data will be formatted as a Byte Array.

Structure types contain a specific type of data. For example, a variable may represent a slot map which contains carrier information and also list of slots with their wafer placement status.

Value –It’s the actual value of the data item. Data values are in an accurate, efficient, self-describing binary format so that its easy for the host to interpret the data. The data format allows collection of more data and with more efficiency.

Alarms & Collection Events (CE) also have IDs and names for their identification.

Data Polling :

The fab host often gets data on a regular intervals through event reports & trace reports and that it defines. SECS/GEM also provides a system for the fab host to poll data based on its needs.

Fab Automation services.

0 notes

Text

AUTOMATION BENEFITS in SEMI CONDUCTOR INDUSTRY AND EINNOSYS SOLUTIONS TO IT

Automation in factory is an important decision to be taken at management level.

The level of automation at any fab depends on several factors, but primarily the volume in wafer starts or outs, age of equipment, complexity of process, etc. The other main aspect to fab automation lies with the kind of experience and technological maturity of the manufacturer. Setups with longer exposure to IC manufacturing and skilled manpower are more prepared and adaptable to integrate automation solutions within their fabs and various production sites. This may include systems for Automated Material Handling, Planning , Simulation, Manufacturing Execution Systems, which include production dispatching and scheduling system and also Advanced Process Control systems and so on.

Basic automation includes preventing wrong recipe errors by the technicians by automating recipe selection through GEM/SECS. Advanced fabs have far more automation done which includes Fault Detection and Classification (FDC), Yield Management software, Recipe Management System, Automated Material Handling System (AMHS), to name a few.

Semiconductor manufacturing is undoubtedly the most complex manufacturing environments. Reasons for this being strict production processes, reentrant process flows, complex expensive equipments, variable demand, high levels of automation and an huge pull of data. Yet, despite having various challenges, semiconductor manufacturing is a key industry in many industrialized nations and contributes substantially, both directly and to the global economy. With the entry of highly automated wafer fabrication facilities (fabs), there is a industry trend to extend the traditional automation scope to integrate with advanced technologies.

Semiconductor technology grows very fast and thus there is a strong positive force to increase productivity using the existing assests . And this positive force has lead to the need of full automation to increase the existing productive. In fab automation, technological upgrades have to be taken into considerations on continuous bases.

We provide factory automation solutions, systems integration and consulting services to wafer fabs, assembly and test facilities across the globe.

We offer various products for FABS and ASSEMBLY facilities.

eInnoSys is a pure automation company for semiconductor and other related industries such as PV (solar), MEMS, Flat Panel Display (FPD), LED and other such electronics industries. We serve Equipment Manufacturers (OEMs) and factories – Fabs, ATMs (Assembly Test Manufacturing). We are a customer focused and solution oriented company, offering automation products as well as custom automation solutions for OEMs and factories.

We consider ourselves as technical partners of our customers and not just software or automation solution providers who would build systems as per customer requirements. In addition to great automation software, we provide valuable insights to our customer based on our vast experience and ensure that we create the most customer value through our services.

Here is how EINNOSYS can help to give most effective automation solutions which takes care of all the challenges in implementing Automation. In our experience, most fab automation systems have an ROI of less than 1 year, so they pay for themselves in a very short period of time.

Our Fab Automation solutions include:

Yield management software

Cycle time Improvement

Improving OEE/Throughput

Advanced Process Control (APC)

Fault Detection & Classification (FDC)

Saving Manufacturing Cost

0 notes

Link

SECS refers to Semi Conductor Equipment Communication Standard, GEM refers to Generic Equipment Model for Communications and Control of Manufacturing Equipment and SEMI stands for Semiconductor Equipment Materials Initiative.

Semiconductor Equipment Materials Initiative ( SEMI ) developed a set of standards called SECS/GEM. These standards are used to define a set of communication protocols between automated equipment and the hosts.

#SEMI#SECS#GEM#Semi Conductor Equipment Communication Standard#Generic Equipment Model#Semiconductor Equipment Materials Initiative.#SECS/GEM

0 notes

Photo

SECS/GEM, the communication interface protocol for communication between a semiconductor equipment and fab host. Fab host is a software application that is controlling and monitoring equipment processing using SECS/GEM protocol. SECS/GEM complaint equipment can communicate with the fab host using either TCP/IP (using SEMI standards E37 and E37.1 - HSMS) or RS-232 (using SEMI standard E4 – SECS-I). The SECS/GEM standard interface is used to start as well as stop equipment processing, collect measurement data, select recipes for products and change variables. With SECS (SEMI Equipment Communications Standard)/GEM (Generic Equipment Model), all this can be performed in a standard way. SECS/GEM protocol has been standardized by the non-profit association SEMI (Semiconductor Equipment and Materials International). Check www.SEMI.org to learn more about SEMI standards and SECS/GEM protocol.

0 notes

Text

Global leader in SECS/GEM, GEM300, Smart Factory & Industry 4.0.

SECS/ GEM, the communication interface protocol for communication between a semiconductor equipment and fab host. Fab host is a software application that is controlling and monitoring equipment processing using SECS/GEM protocol. SECS/GEM compliant equipment can communicate with the fab host using either TCP/IP (using SEMI standards E37 and E37.1 - HSMS) or RS-232 (using SEMI standard E4 – SECS-I). The SECS/GEM standard interface is used to start as well as stop equipment processing, collect measurement data, select recipes for products and change variables. With SECS (SEMI Equipment Communications Standard)/GEM (Generic Equipment Model), all this can be performed in a standard way. SECS/GEM protocol has been standardized by the non-profit association SEMI (Semiconductor Equipment and Materials International). Check www.SEMI.org to learn more about SEMI standards and SECS/GEM protocol.

In simple words, the SECS/GEM standard defines messages, state machines and scenarios to enable factory host applications to control as well as monitor manufacturing equipment. GEM standard is officially designated as SEMI standard E30, but frequently referred to as the GEM or SECS/GEM standard. The GEM is beneficial for both device manufacturers and equipment suppliers as it defines common set of equipment behavior and communication capabilities to provide functionality as well as flexibility to support manufacturing. Since GEM standard has only a few semiconductor-specific features, it has been adopted by other manufacturing industries as well, such as PV.

Among the capabilities offered by the SECS/GEM standard is –

For a fab host to start and stop processing

For a fab host to select, download and upload recipes from/to the equipment

For a fab host to query the equipment for values of various process parameters and equipment configuration

For a fab host to set equipment configuration parameter values

For equipment to send alarms to the fab host

For a fab host to define reports of various variables and associate them with events such as lot start or wafer complete

For equipment to send various events and associated reports to the fab host

Since SECS/GEM is a communication protocol, it is platform and technology as well as programming language independent. The host side of a connection is executing on a computer system provided by the factory, and the equipment side of a connection is running on a controller computer provided by the equipment manufacturer. This gives both – the fab as well as the equipment manufacturer interoperability, flexibility, and platform independence. Both, the fab and the OEM can develop their software application without having to worry about communication compatibility, as long as both of them are adhering to SECS/GEM standards.

EINNOSYS Inc offers software solutions for both - the FABs to integrate with FAB host as well as for the OEMs to integrate with their controller software. By integrating EIGEM – Einnosys SECS/GEM software, the equipment or fab host becomes SECS/GEM capable without having to learn the details of various SEMI standards.

SECS describe the communication between a host computer and the equipment using a single connection. In the original concept and even today in the most common scenario, the equipment provides a single SECS interface for exclusive use by a single host. The message types defined by SECS are partially asymmetric - some message types are defined only for host use, others are defined only for equipment, but also many of them are defined for the same use by either side.

However, there is a provision in the SECS standards for sharing a connection by specifying the device identification value in each message. The practice of connection sharing is not recommended for new deployments. It is a common practice that a connection is maintained for long periods of time and only interrupted if the equipment or host is rebooted. SECS connections are lightweight and don’t use much network bandwidth. It is possible to run several SECS connections on a typical desktop computer.

Products for Semiconductor Equipments:

EINEM: SECS/GEM software for equipment and fabs

Mobile Monitor: Monitoring critical equipment/recipe parameters on the mobile device

Modbus Library for Android: Modbus library for Android platform

Products for Semiconductor Fabs:

EINEM: SECS/GEM software for equipment and fabs

Recipe Server/ Stepper Job Server: Manages recipes, including versions and audit trail of recipe changes across different equipment types

Barcode Guardian: Prevents the wrong pour of chemicals and manages chemical inventory in the fab

Reticle Tracker: Manages reticle inventory across multiple locations and offers time and cost saving reports

Manual Wetbench Automation: Prevents wrong wafer dips on manual wet benches without an expensive upgrade

#Factory Automation Software#Smart Manufacturing#Factory Connectivity#Equipment Control framework#SECS/GEM

0 notes