Side blog for @dynami-tello. All about progress and updates for my Battle Shell project. Thanks for stopping by!

Don't wanna be here? Send us removal request.

Text

PROJECT BATTLE SHELL: EXPLANATION (MATERIALS)

Here's my thoughts on possible materials for this project! My goal is to make the battle shell in the most cost effective way, so I'm not going to be going out and buying custom shaped stainless steel parts, even if it would be super cool to do so.

Here's a rough overview of what this post contains, and below will have all the details.

Materials: For the flexible bits I'm planning on going with a mesh. The prototype I'll make, if it uses a mesh base will be made out of an old recycled shirt, but for the official build I want to use a tougher mesh. I'll probably go to a second hand store to find a piece of material that will work for this, as it needs to be stronger than the average shirt.

And metal vs no-metal. A big debate is picking between including metal in the Battle Shell or leaving it metal-less. I've done research into both, though I'll be going into more specific studies and balance the thoughts more.

Breakdown below

OKAY so the metal vs no-metal debate.

I'm tempted to go with metal purely because of the strength metal provides. Will it be harder to get metal for this project? Absolutely! Would it be super cool? Hell yeah!

Realistically my ideas for including metal falls more under implemented weaved metal wires into the framing of the Battle Shell rather than making it out of metal (and while I know where to get scrap metal, I don't have a sound proof area for forging and re-shaping it. Although it would be so fun to do that).

Weaved metal wires would provide a knit-like binding pattern that would help support and strengthen the individual parts of the shell. Metal could also be used for any screws, etc implemented into the build. While I do have screwdrivers of various sizes in my possession (including ones small enough to work on watches) getting the parts for that would be more difficult.

For example, in the plating system I could make each plate out of wires weaved into the correct shape, and layer two or three identical pieces together. Then wrapped in another layer of material, this would theoretically provide some of the durability of metal while still staying as flat as possible.

For the hexagonal pattern I could cut and shape groups of hexagon structures together out of weaved wire, with interwoven wire in the centre of the hexagons to boost strength. However that would take... quite a while. Unfortunately, and I'd have to buy wire to maintain size consistency.

The alternative is to go without metal! My main issue here is that unless I'm patching things together (which I'll likely still have to do in the more polished build) it will require making moulds. I've been doing research into metal alternatives, while also eliminating some from my choices.

I won't use wood or clay (or any clay-like materials). The material left that's available to me without too much hassle is plastic. However I am.. not a huge fan of plastic, and would prefer not to create more.

But that doesn't leave me without any options! I've been doing research into plastic alternatives [1][2] and have come up with a few that I'll consider for the Battle Shell.

First is, as you could likely guess, biodegradable thermoplastic. This plastic-like substances is different than the stereotypical "true plastic," the plastic made from oil, aka synthetic plastics. These are made out of materials that allow the plastic to wear down over a period of time, typically reactive to heat, while maintaining most of the same core properties as plastic.

You may wonder, how will I get these? I'd make my own plastic of course!

There's a few different approaches to making DIY "plastics". There's the more recycling-aligned strategy of melting down plastic yourself, there's a method of melting down grocery bags in heated oil and re-shaping it.

Other ways of making DIY "plastics":

Making casein "plastic" out of milk and vinegar. This method only requires heating up milk, adding vinegar, and straining and removing the casein at the end. It must be shaped/moulded before it cools, and takes over 24 hours to fully harden, depending on how thick it is. The issue with Casein "plastic" is that it's rather weak and prone to crumbling/fracturing, and therefore wouldn't work well as a battle shell (however historically it's quite good at being used for replacement buttons!). It can be strengthened with a clay additive (I believe it was "Montmorillonite" I was reading about). I need to do more research into the creation process, as it does involve curdling the milk which leaves much milk waste.

Making "plastic" out of Liquid Wood. This is an interesting option I've been researching into, and while it is a fascinating topic it's likely an option I won't pick. Liquid wood is made primarily out of honey and sap, and is biodegradable and eco-friendly. You can also buy liquid wood in stores, however it's decently expensive. Must be considered further.

Making Aliphatic Polyesters. Polyesters aren't typically known for being biodegradable, or even semi-decent for the environment in the first place. Additionally the processes of making the different types of Aliphatic Polyesters are beyond my scope, although again an interesting rabbit hole to research into.

Making "plastic" from starch. There's multiple types of starches you can use to make this bio-plastic, it can even be made out of gelatin too. Typically made with vinegar, replacements can be made to the recipe. However it's more difficult to find a balance between brittleness and durability with this bioplastic and runs the risk of creating entirely un-usable batches of plastic if the measurements are off or the heating isn't done correctly.

There's other methods too that I'm researching currently, so expect another post detailing my adventures into possible materials in the future.

If you want to read a bit about plastic alternatives here's some sites to help!

1 https://science.howstuffworks.com/environmental/green-tech/sustainable/5-plastic-substitutes.htm#pt6

2 https://www.sciencedirect.com/science/article/pii/S2666893921000189

3 https://www.sciencedirect.com/science/article/abs/pii/S1359836822004085

As a side note, do be careful when researching such topics, as I -by complete accident I must add- found many articles about creating homemade explosives. As to avoid any possible suspicious internet traffic I avoided these articles, but the presence of them alone surprised me greatly. I'm unsure if this is simply a "me" thing, as I accidentally found multiple websites for cults while researching mathematics in my grade 10 math class once as well, even when no one else seemed to be able to find such results.

#Subject: Project Battle Shell#Subject: PBS Research#Subject: PBS Thoughts#rottmnt#I will not post links to how to make homemade explosives#I did not read the articles so I do not know#...other than what I know theoretically based on knowledge I have#It's actually quite fascinating how simple it is to make plastic alternatives at home. Most of the options just need basic heating

3 notes

·

View notes

Text

PROJECT BATTLE SHELL: AN EXPLANATION

OKAY SO! Here is my more in-depth thoughts on the project. These are my earliest thoughts and ideas for it, and I'll explain more about them in future posts.

First off. Why am I not just buying a back protector? Answer: That’s boring, why would I do that if I could do this instead? Yes, I fully acknowledge that it would be easier to buy a back protector and simply modify it.

Second, what makes me qualified to take on this project? Answer: What makes me unqualified? I’ve taught myself enough semi-related skills and can teach myself further skills SO. PLUS I have the power of hyperfixation on my side and enjoy making stuff, so that’s probably all the qualifications I need. ...probably, we'll see!

Below is all the more technical speak, thanks for the interest!

NOW lets get into the nitty gritty.

I have a few plans for how to approach this project, so the skills I’ll be using and materials I’ll require will be impacted by which approach I choose. Although I have many ideas for separate little bits of how the project will come together, I have two main ideas on how to approach the base structure. Plus ideas for add-ons, fun features, etc, but that all comes later and relies on the base structure.

What I'll be referring to as the Base Structure is the structure that will hold the battle shell together. Think of it as the core, the body, or the skeleton of the shell. Everything else will be planned and built around this "skeleton", so it's important to choose a base structure that can support the rest of the build.

Structurally, regardless of which base structure I chose I have a few main features for the battle armour.

First is that I’m planning to have a mesh layer that will help hold everything together. Instead of relying solely on a solid frame to hold the battle shell together, I’ll have a mesh that has key connection points that attaches directly to the battle shell. This, hopefully, will additional support and flexibility to the shell.

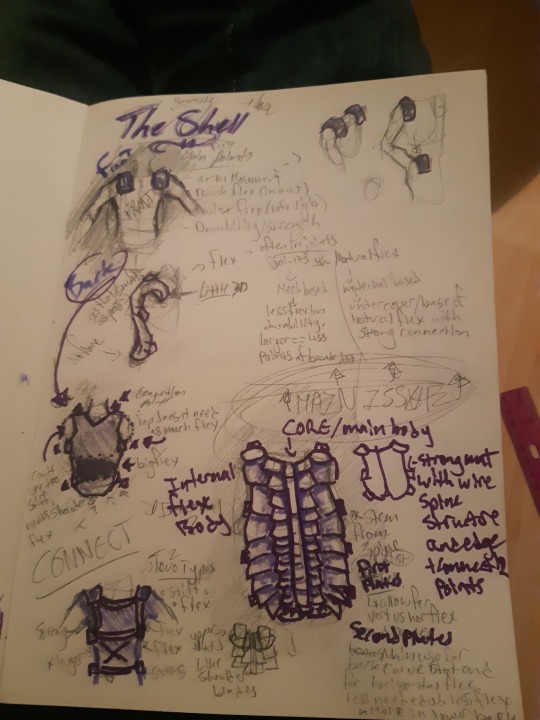

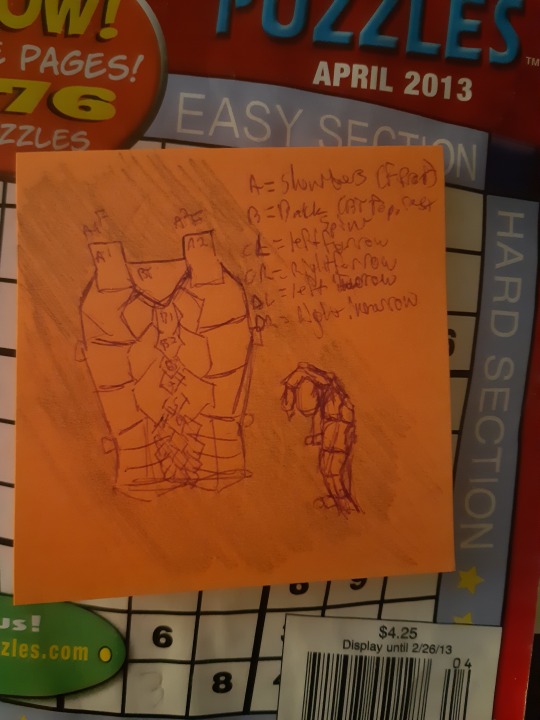

Second is how to wear it. I am creating this battle shell to be as discreet as possible. I want to be able to wear it under a sweater or a jacket without anyone really noticing. Below you can see my rough sketches on how it will connect to the user’s body and be held in place while also flexing with the user’s movements.

(apologies for my messy writing. All of it is similar to what I'll be talking to here. My note style is rather disorganized, as most of my thoughts and ideas are still within my brain and not yet on paper.)

With the main connections points being around the shoulders, chest, and lower back/waist I believe I’ll be able to have the shell connect close enough to the user’s body that it won’t stick out in awkward ways while wearing it. Though adjustments will be made once this can actually be tested. Best seen in the lowest left sketch, although future sketches will elaborate on the system.

ONTO THE BASE STRUCTURE OPTIONS

I have two main ideas for the base structure. These are based on two different construction points. Both focus on finding a balance between flexibility vs durability, something future me will likely have to consider further when it comes to finding materials. The structure needs to have enough strength that it can protect and absorb force, but cannot be too stiff as that can make it more fragile when bending forces are applied, and more obvious when wearing.

The first base structure I'm considering is a plate system. Akin to a fusion between a turtle shell and scales, the plate system will be dependent on connection points between the plates. The plates will be in different sizes depending on where on the back it is situated, and would need solid attachment to the material mesh for flexibility.

(here's the most recent sketch based on calculations I've been making for conceptualizing the plating system. Please ignore the ancient sudoku book, I am definitely not a time traveller).

Downside of this approach is the complexity. Each piece will have to sit perfectly in position, which means each piece will have to be 100% custom made and perfectly mirrored. There's also issues with the plates wearing against each other, the overlap points being particularly uncomfortable, and the plates jutting out.

Upsides of this approach is the customizability and testability. The most important point will be making the connection points between the shells, however once those are created making new plates, adjusting pre-existing plates, and more will be far easier. Additionally it'll be easier to test the plating system because I'll be able to adjust it and create new plates based on data collected.

I'll have another post explaining the plate system more later. That post will go into my ideas for material choices, which will be interesting <- lots of experiment and research.

The second base structure Idea I have is created a shaped (but still flexible) one piece structure. It would be formed out of small hexagons (similar to a beehive construct). Most similar to commercial back pieces, I believe that the beehive structure would allow for a durable material that can also take some flex and bend.

Downside of this approach is actually creating it. In a perfect world I'd have a 3D printer or a full on lap and materials that I could make a mathematically perfect mould for this, however that's not the case. Any changes in angles between the hexagonal pieces will take re-creating those pieces and possibly any they connect to, as well as many edge pieces. There's also the size factor for the individual hexagons, and how that would impact the actual strength of the project.

Upside of this approach is how solid it would be. Because it wouldn't rely on connection points (the entire piece would be connected to itself, so to speak) it would lose many of the weak spots that the plate system has. It also wouldn't have the overlap issue.

I'll make another post covering my thought process on the materials to use for this project, and soon I'll post an update on my physical progress. Thank you for reading.

#Subject: Project Battle Shell#Subject: PBS Thoughts#rottmnt#introduction#technically still an intro to the project.#There is still much to cover and research!

2 notes

·

View notes

Text

PROJECT: BATTLE SHELL

As you could probably tell from the title this project is inspired by Donnie’s battle shells in ROTTMNT. When Donnie’s shell broke in the movie my brain started thinking of ideas on how it could be theoretically possible to make something like that in real life. Of course I don’t have a lab with all sorts of tools and materials available so I’ll be making do with what I can get my hands on.

The main goal of this battle shell is to make a piece of back armour/back protector. It (sadly) won’t have any hover gear or anything else that Donnie’s battle shell has in the show and movie, although I’ve had thoughts of what fun things I could add to it, but I won’t get into that yet.

Once I've written a more extensive introduction to this project I'll link it here. It will include much of my thought process that lead me to taking it on and some of my ideas on how to tackle the project. As I mentioned I don’t have that many materials to work with, so this will be made mostly of scraps, what I can make, and affordable things I can buy.

I’ll be sharing much of my planning notes, and by the end of the project I’ll share a cost breakdown, sizing, results of durability testing, comfortability ratings, and throughout the project’s timeline I’ll be open to answering any and all questions. My ask inbox will be open and accepting anons, so feel free to leave a message!

I'll be posting (somewhat) daily updates on the status of this project on this blog. If you want check out my main blog go to @dynami-tello

Below is my tagging system

Tags:

PROJECT BATTLE SHELL -> PBS

Subject: PBS Progress Report <-(main weekly progress update)

Subject: PBS Update <-(daily updates and/or small updates)

Subject: PBS Thoughts <-(thoughts related to PBS)

Subject: PBS Research <-(research for PBS, though may be unrelated)

OTHER TAGS:

Subject: Other <-(unrelated to PBS)

Subject: Asks <-(for any asks)

Subject: Research <-(research into topics that could be related to the project)

9 notes

·

View notes