Don't wanna be here? Send us removal request.

Photo

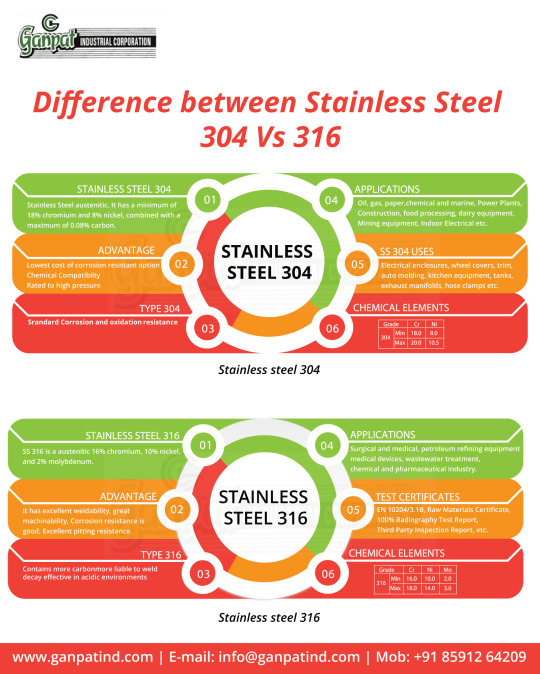

What are the Difference between Stainless Steel 304 vs 316 ?

Ganpat Industrial Corporation is one of the Top larger stainless steel 304 fitting manufacturers & exporter industry in India. This industry is famous for making high quality of Steel brands. This infographic is exactly talking about what are the difference between stainless steel 304 and Stainless Steel 316.

The steel contains both chromium between 18% & 20% and nickel between 8% and 10.5%.

The high mechanical strength of Stainless Steel 304 Welded Pipe result of the duplex micro structure and the alloy with nitrogen. Stainless Steel 304 Pipes are formed from an approximately 45 to 50 mixture of austenitic.

Ganpat Industrial Corporation is one of the pioneer trader and distributor for Alloy Stainless steel 316 / 316L Pipes, which are available in a wide range of standard and specialty stainless steel grades, including high — performance austenitic grades.

#stainlesssteelpipe304#stainlesssteelpipe316L#stainlesssteeltube#stainlesssteelpipe#stainlesssteelsquarepipe#differencebetweenstainlesssteel304and316

0 notes

Text

Applications and Benefits Inconel 601 Flanges

If you are awaiting various weld fittings for your various industrial applications and purposes, then the Inconel 601 flanges play an important role in various applications. This is nothing but the most important alternative to the flanges in the Inconel 601 model which is currently available on the market with the ASTM B564 standard. Such products can be found from the major exporter of weld fittings in your area. Everyone with industrial needs should look at the leading manufacturer website to purchase such Inconel flanges with international standards to meet your various needs.

Benefits of Inconel 601 Flanges

Flanges are now required to connect the pipes and ensure the flow of the passing material. In this case the flanges must necessarily be strong and durable as it cannot tolerate malfunctions when a liquid is passing through. The alloy here has resistance and strength properties in Inconel so overall it is a great alloy for making flanges. Among the advantages of Inconel flanges is the excellent resistance to corrosion due to the availability of nickel firstly which makes the alloy very suitable for corrosion-prone applications as the alloy can easily deal with the problem. Second Inconel flanges can be used for applications that use sulphuric and hydrochloric acid, in fact the alloys can be durable in sulphuric and hydrochloric acid environments and some other chemicals or acids.

The alloy has amazing mechanical properties and can tolerate high temperatures that are suitable for working in plants and factories. Flanges made of Inconel have a very high resistance to corrosion and along with this there is great strength in breakage which allows the alloy to be durable and consistent performance.

Applications

Off-shore oil drilling companies mostly use pipes, so they also use pipes to keep them intact to avoid spilling of gas or oil, power generation, petrochemicals, and the gas processing industry also allow chemical or gases to leak. To prevent the use of flanges, pipes in specialty, chemicals, pharmaceuticals, pharmaceutical equipment, chemical equipment, sea water equipment, heat exchangers are included, so it also includes flanges. The condenser and pulp and paper industry necessarily require an Inconel flag because of its durability, some of the many industries that use Inconel flanges. Flanges of each Inconel grade are used for their diverse properties.

1 note

·

View note