Don't wanna be here? Send us removal request.

Text

World top-quality color coating stainless steel product | DSP

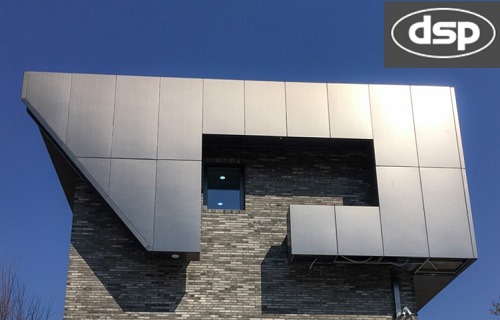

DSP Co., Ltd. is a leading manufacturer of top-quality color coating stainless steel products in the world. It is the company that pursues the leading edge rather than being a follower. Quality has always been the first priority with DSP, which is the only one company of its kind with full-fledged innovation and product development center.

DSP product wins a high reputation for its outstanding quality and diverse applications. DSP all products are popular among those who pursue elegance of the buildings. color stainless steel

Competitive strength of DSP comes not just from cutting-edge technology but also from experienced people and know-how in fabricating, installing steel structures into various applications. DSP’s production capacity is also well-enough to handle large orders. It has a global network of over thirty countries and over ten overseas agents that will enable to meet customer’s various demands on time in different physical locations.

DSP’s cutting-edge high vacuum PVD (Physical Vapor Deposition) technology enables to produce durable arc ion plating titanium finished stainless products with graceful, beautiful colors. The process provides an abrasion-resistant coating onto a stainless steel surface that is up to 10 times that of a normal stainless steel substrate. This is a superior color coating that outlasts any other existing coloring process. Semi-permanent in color and luster in addition to highly resistant to corrosion and abrasion are characteristics of the DSP arc ion plating products. It also withstands very strong acid rain and pollutants. It is far better than other exterior finishes in inflammability, resistance to chemicals, and economic effects. architectural stainless steel manufacturer

Features of DSP’s Ti-Color Coating

ü Thin-film hardness

ü Adhesion of the coating

ü Impact Resistance

ü Abrasion resistance

ü Scratch Hardness

ü Artificial Sweat Test

ü Wet Corrosion

Competitive Strength of DSP’s PVD color coating technology

ü Great resistibility against rust and scratch (Surface hardness is 10 times stronger than normal stainless steel.)

ü Various colors available – luxurious and elegant colors

ü Great longevity of coating and color (Semi-permanent)

ü Environment-friendly process

ü Cost-saving in maintenance and replacement

0 notes

Text

World‘s leading manufacturer of Embo-pattern color coil | DSP

The DSP Co., Ltd. is a worldwide top-tier color-coated metal sheet and tube manufacturer that delivers the beauty of metallic color to the world as a global leading company in PVD metallic color coating technology.

It is DSP’s corporate mission that provides its excellent quality products to worldwide customers at reasonable prices. And DSP has been making an investment in research & development for innovative products for over 30 years since its establishment in 1988.

DSP Embo-pattern color coils are available to provide various Colors. And uniform color and economical mass production is DSP’s comparative advantage that overwhelms other companies. coloured stainless steel manufacturer

Titanium color coil is manufactured using the physical deposition method where a chunk of titanium is placed into the high vacuum to produce a coating. This cutting-edge functional product is playing an important role in many areas including automotive, electrical, and electronic industries.

Embossed Pattern Roll to Roll (R2R) process efficiently uncoils the batch of stainless steel and applies the pattern and in turn recoils the steel. The advantages of this are a streamlined process and fewer initial capital investment costs. This system is very suitable for mass production and can be produced at any length a customer demands. color metal supplier

DSP Ultra-thin embossed pattern stainless steel coil provides a variety of Titanium colors with three-dimensional patterns to reach beyond the limits of stainless steel. It can be applied to different spaces such as walls and interior ceilings. Since it can be laminated to wood or steel, it is versatile and available for kitchen furniture and interior accessories. In addition, the multi-functional coating is available to make it suitable for public areas or spaces that require special functionality such as kindergartens, schools, hospitals, and more.

DSP’s various Embo-Pattern Coil colors

ü Champagne Gold

ü Gold

ü Bronze

ü Black

DSP Embo-Pattern Coil patterns

ü Brush

ü Pan

ü Micro Chess

ü Snow Flower

ü Check

ü Mesh

ü Shine Delta

ü Cube

0 notes

Text

World-top-tier Nano Color Coil Manufacturer |DSP

DSP Co., Ltd. is a world-top-tier color-coated metal sheet and tube manufacturer that delivers beauty to the world as a global leading company in metallic color coatings.

It is DSP’s corporate mission that provides its excellent quality products to consumers at reasonable prices. And DSP has been making an investment in research & development for innovative products for over 30 years since its establishment in 1988. It will continue to enable DSP to achieve customer satisfaction with assured quality and reasonable price. interior stainless steel manufacturer

Great Advantages of DSP Nano Color Coil

Through a special electro-chemical coating process, a hybrid coating of the organic-inorganic layer is put on the surface that enhances anti-bacterial, anti-pollution, and anti-fingerprint properties for minimal maintenance and cleaning work. NCC (Nano Color Coil) even makes stainless steel stronger against rust than normal stainless steel while creating aesthetically pleasing and elegant colors.

NCC-1 Matt

ü Anti-finger print

ü Diffused reflection control (Dull finished effect)

ü Anti-bacterial (99.9% inhibition of colon bacillus)

ü Minimal maintenance and cleaning

ü Stronger against rust than normal STS

ü Beautiful and elegant color

NCC-2 Gloss

ü Easy cleaning

ü Strengthening of surface (Pencil hardness test 9H and over)

ü Nice glossy finish like glass

ü Anti-bacterial (99.9% inhibition of colon bacillus)

ü Minimal maintenance and cleaning

ü Stronger against rust than normal STS

ü Beautiful and elegant color pvd coating colors

NCC-EX

ü Hybrid coating that forms a hybrid organic-inorganic layer on the surface of the coated material through an electrochemical coating process

ü Coating is always clean because of the self-cleaning ability and organic substance decomposition effect

ü Multi-Functional Coating System is OH radicals, activated oxygen disintegration (Oxidation reduction reaction), the process of pollutant disintegration and Super-hydrophilic reaction

NCC - EX Activation Evaluation Test Conditions (Fingerprints decomposition analysis)

ü NCC-EX coated and uncoated samples tested on Ti - coated Stainless steel sheet (Black, Bronze and Gold)

ü Hands were stained with the lubricant WD-40 then fingerprints were applied to demonstrate the effect of fingerprint decomposition.

ü UV intensity was set at1.43 mW/cm and after 24, 48, 72, and 100 hours pictures were taken to check the fingerprint's decomposition.

0 notes

Text

World-class leading manufacturer of Titanium Color Coating | DSP

DSP Co., Ltd. is a world top-tier color-coated metal sheet and tube manufacturer in Korea. DSP Titanium color coil is manufactured by the physical Vapor deposition method where a chunk of titanium is placed into the high vacuum to produce a perfect titanium coating. This cutting-edge ultra-functional product is widely used in many areas including automotive, electrical, and electronic industries.

What is PVD Titanium Color Coating

Physical Vapor Deposition (PVD) is a method used to deposit layers of the coating by using the condensation from the vaporized form of material and applying it to the desired target material. PVD is achieved by taking titanium Alkoxide (titanium mass) and applying a positive voltage to it while it is inside a high-temperature vacuum. This releases positively charged titanium molecules. Inside the vacuum is a material, such as stainless steel, that has a negative voltage applied to it. The negative voltage attracts the positively charge titanium molecules and results in the material being coated. Plasma cleaning and ion impact processing of materials are needed to improve the adhesion of the coating. This results in the coating having a longer lifespan. PVD technology has significantly contributed to a variety of fields including car manufacturing, electronics, and other industries.

Features and merits of DSP Titanium Color Coating

ü Thin Film Hardness: The hardness of the product film itself was measured by the Vickers hardness test and was found to be about 10 times harder than stainless steel.

ü Adhesion of the coating: The strength of the adhesion was tested by creating a 2mm wide scratch with a knife and attempting to peel off layers of the coating with cellophane tape. There was no peeling of the cellophane tape. coloured stainless steel manufacturer

ü Impact Resistance: A 1kg steel ball was dropped from a height of 50cm onto the product using a DuPont impact tester. There were no abnormalities such as discoloration or damage visual observation.

ü Abrasion Resistance: Using a SUGA abrasion tester 500g of pressure from an eraser was applied to 0.5 microns of ion plating. The applied pressure was repeated 200 times. The ion plating film was not peeled.

ü Scratch Hardness: Load of cracking point, as seen below, was tested by scratching 150mm per minute with the Kuremence Scratch Tester. The result showed Ion coating was 3 times harder than the chemical coating on scratch-resistant hardness. decorative stainless steel supplier

ü Artificial Sweat Test: The Ion-Coated frame was pre-soaked in artificial sweat of PH 4.5, JISLO 848 for 8 hours and left at room temperature for 16 hours.

Wet Corrosion:

No damage or no color change was found on Ion coating by putting it on 50G, 98% of humidity for the duration of 500 hours.

0 notes

Text

180 degree bending technology of stainless steel | DSP

DSP Co., Ltd. is a world-top-tier color-coated metal sheet and tube manufacturer that delivers the beauty to the world as a global leading company in metallic color coatings.

It is DSP’s corporation mission that provides its excellent quality products to consumers at reasonable prices. And DSP has been making an investment in Research & Development for innovative products over 30 years since its establishment in 1988. It will continue to enable DSP to achieve the customer satisfaction with quality assurance and reasonable price.

DSP has bending technology that can be designed in various ways. DSP bending technology is a state-of-the-art technology that assures the highest secure in the process. It leads to the universalization of metal materials at reasonable prices. stainless steel roofing

With such cutting-edge bending know-how, DSP are capable of various processing such as 180° bending according to the customer’s request. 180° bending is harder and more fluidly. It can be bent according to the construction method such as 180 degrees bending. DSP products do not peel off even after 180° bending.

DSP also has an expertise in cutting technology that can outperform competitors to be processed in many ways. DSP can trim its products in many ways according to the construction method such as 180 degree bending and 10mm section bending up to 7 mm bent. Such technology can make the DSP products more efficiently and more rigidly than other company’s products. color inox manufacturer

DSP color laminated stainless steel plate can significantly reduce the cost burden and improve the weakness and smoothness of stainless steel based on its unique fabrication technology that the surface is stainless steel and the structure is plated steel plate. The price burden of stainless steel plate is considerable from the perspective of customers. Therefore, in order to reduce the customer's price burden, DSP developed such laminated stainless steel plate that is a bonded plate of two different materials with improved economic efficiency.

0 notes

Text

Titanium Color Stainless Steel Coil l DSP

DSP Co., Ltd. is a world top-tier color-coated metal sheet and tube manufacturer that delivers beauty to the world as a global leading company in metallic color coatings.

And it also produces a high-level quality stainless steel color coil.

DSP Stainless Steel color coils are three types.

ü Titanium color coil

ü Nano color coil

ü Embo-Pattern color coil

DSP Stainless Steel color coils are manufactured by the Roll to Roll (R2R) process, which efficiently uncoils the batch of stainless steel applies the pattern and recoils the steel. The advantages of such methods are a streamlined process and less initial capital investment costs. This system is very suitable for mass production and can be produced at any length to fit for the customer demand. zinc roofing supplier

Great Advantages of DSP’s Roll to Roll process

ü Realization of various colors

ü Uniform colors

ü Economic mass production

DSP Titanium color coil is a high-tech functional product that has made a lot of contributions in industrial fields such as automobiles and electrical electronics as a product coated with titanium lumps in a high vacuum state by a physical vapor deposition method.

DSP Nano color coil is produced through a special electro-chemical coating process. A hybrid coating of the organic-inorganic layer is put on the surface that enhances anti-bacterial, anti-pollution, and anti-fingerprint properties for minimal maintenance and cleaning. NCC even makes stainless steel stronger against rust than normal stainless steel while creating aesthetically pleasing and elegant colors. color metal supplier

Ultra-thin Embossed Pattern STS (VERNOX) Stainless Steel that comes in a variety of Titanium Colors with three-dimensional patterns to reach beyond the limits of stainless steel. It can be applied to different spaces such as walls and interior ceilings. Since it can be laminated to wood or steel, it is versatile and available for kitchen furniture and interior accessories In addition, the multi-functional coating is available making it suitable for public areas or spaces that require special functionality such as kindergartens, schools, hospitals, and more.

0 notes

Text

Stainless steel functionality coating technology l DSP

The DSP Co., Ltd. is a world top-tier color-coated metal sheet and tube manufacturer that delivers beauty to the world as a global leading company in metallic color coatings.

It produces exterior walls, exterior roofs, internal walls, interior ceilings, interior flooring, elevator cabins, elevator doors, elevator jambs, canopies, columns. Also, it provides the colored metal sheet and tube to be used in the production of vehicles and home appliances. Outstanding features and merits of functional coating technology of DSP

DSP meets the various needs of the customers in numerous industrial fields over the world.

Its functional coating products are widely applied to the needs of non-flammability, fingerprint resistance, and non-pollution and others. architectural stainless steel manufacturer

ü Fire Resistance

ü Anti-Fingerprint

ü Noise Cancelling

ü Powerful binding force

ü Real Metal Texture

ü Non-polluting

ü Color uniformity

Fire Resistance function:

Fire resistance functional coating is the prerequisite choice of building finishes. DSP stainless steel products have greater resistance to fire resistance and resistance against chemicals than any other exterior finish materials. All the DSP stainless steel product is characterized by its color and gloss which are semi-permanent and are strong enough to withstand acid rain and contaminants.

Anti-Fingerprint function:

DSP stainless steel products have passed the fingerprint decomposition effect test. copper roofing manufacturer

ü Comparable test with a non-coated specimen coated with NCC-EX on the Ti-coated stainless steel sheet (Black, Bronze, Gold)

ü Fingerprints are applied to the specimen with the WD-40 lubricant in hand to maximize the fingerprint decomposition effect

ü Check the decomposition effect by photographing after 24, 48, 72, and 100 hours at 1.43 mW/cm for UV intensity

Real Metal Texture:

As DSP’s coating is a transparent coating enough to transmit the surface of the steel sheet, customers can feel the texture of the metal surface even in color products.

Color uniformity:

DSP is proud of its excellent functionality such as fire resistance, binding force, and noise-cancelling that meet the recent tough building standard laws. In addition, anti-fingerprint and easy-cleaning functionality ensure easy post-construction management and color uniformity for aesthetics.

0 notes

Text

World leading advanced Nano Ceramic Coating technology | DSP

The DSP Co., Ltd. is a worldwide top-tier color-coated metal sheet and tube manufacturer to produce exterior walls, exterior roofs, internal walls, interior ceilings, interior flooring, elevator cabins, elevator doors, elevator jambs, canopies, columns. Also, it provides the colored metal sheet and tube used in the production of vehicles and home appliances

DSP’s corporate vision is to deliver such beauty of metallic color to the world as a global leading company in PVD metallic color coating technology.

DSP Nano Ceramic Coating Advantages

This is an electrochemical coating method using the organic or inorganic hybrid technique.

This functional coating has self-cleaning and organic matter decomposition effects ensuring the exterior material remains clean at all times.

The surface undergoes anti-bacterial, anti-contamination, and anti-fingerprint treatment, facilitating maintenance and washing in comparison to ordinary stainless steel. This strong and elegant stainless steel is then used in construction (interior and exterior), furniture, and home appliances to great effect.

Nano Ceramic Coating Technology is Ti-Color & NCC Coating and NCC Coating.

DSP provides comparable test report of NCC -EX coating and non-coated specimen of the Ti-coated stainless steel sheet (Black, Bronze, Gold color). architectural stainless steel manufacturer

And, fingerprints are applied to the specimen with the WD-40 lubricant in hand to maximize the fingerprint decomposition effect. It is available to check the decomposition effect by photographing after 24, 48, 72 and 100 hours with UV strength at 1.43 mW/cm.

Nano Ceramic Coating Matt

ü Anti-fingerprint functionality

ü Diffuse Reflection Control (matte effect)

ü Anti-bacterial effect (99.9% inhibition rate for Escherichia coli, etc.)

ü Minimization of management and maintenance costs

ü More resistant to corrosion than ordinary STS

ü Aesthetical and elegant colors

Nano Ceramic Coating Gloss

ü Easy cleaning

ü Surface hardening (pencil hardness of 9H or higher)

ü Glass membrane-like outstanding gloss

ü Anti-bacterial effect (99.9% inhibition rate for Escherichia coli, etc.)

ü Minimization of management and maintenance costs

ü More resistant to corrosion than ordinary STS

ü Aesthetical and elegant colors

Nano Ceramic Coating – EX

ü Super-hydrophilic performance

ü Contamination resistance performance

ü Organic matter decomposition effect

ü Fingerprint decomposition effect interior stainless steel manufacturer

Multi-functional coating system NCC-EX

ü Decomposition under OH radicals, activated oxygen (oxidation-reduction reaction)

ü Decomposition of contaminants

ü Super-hydrophilic effect

0 notes

Text

Advanced PVD coating technology for metallic color |DSP

The DSP Co., Ltd. is a worldwide top-tier color-coated metal sheet and tube manufacturer that delivers such beauty of metallic color to the world as a global leading company in PVD metallic color coating technology.

DSP’s product line-ups are diverse from exterior walls, exterior roofs, internal walls, interior ceilings, interior flooring to elevator cabins, elevator doors, elevator jambs. Also, it provides the colored metal sheet and tube used in the production of vehicles and home appliances.

DSP’s leading advanced PVD coating technology

DSP operates advanced Physical Vapor Deposition (PVD) coating technology based on cutting-edge high vacuum technology to produce elegant, beautiful metallic colors and durable arc-ion plated stainless steel products.

ü This surface treatment process allows for wear-resistant coatings to be 10 times stronger than normal stainless steel products and lasts longer than any other coloring process known to date. decorative stainless steel supplier

ü The DSP stainless steel products are characterized by long-lasting color and gloss which are semi-permanent and are strong enough to withstand acid rain and contaminants.

ü What is over, DSP’s colored metal sheets have greater resistance to fire resistance and resistance against chemicals than any other exterior finish materials.

Overwhelming strength of DSP’s PVD fluorine color coating technology

ü Non-adhesion:

The surface energy is low, so dust and contaminants do not stick well and fall off easily. This feature leads to excellent cleaning so it is good for external use.

ü Corrosion resistance:

It is strongly resistant to a variety of external chemical reactions. This results in less surface change and prevents corrosion on the steel back.

ü Water repellent:

As the water repellent of the surface inhibits contact with moisture, it is easy to clean and also it leads to the automatic falling of foreign substances. zinc roofing supplier

ü Lubricity:

Low surface friction coefficient reduces the risk of surface damage due to external friction.

ü Heat resistance:

Fluoride resin has a flame retarding component and it is strong in heat change with little change at high or low temperatures.

0 notes

Text

World top-tier PVD metallic color coating technology | DSP

The DSP Co., Ltd. is a worldwide top-tier color coated metal sheet and tube manufacturer to produce exterior walls, exterior roofs, internal walls, interior ceilings, interior flooring, Elevator cabins, Elevator doors, Elevator jambs, Canopies, Columns. Also it provides the colored metal sheet and tube used in the production of vehicles and home appliances.

DSP delivers such beauty of metallic color to the world as a global leading company in PVD metallic color coating technology.

DSP’s PVD color coating technology

Physical vapor deposition or PVD is a process of producing a metal vapor that can be deposited on conductive materials as a thin, highly pure metal or alloy coating. The process is performed in a vacuum chamber at a high-degree vacuum state using a cathode arc source. Single or multiple layer coatings may be applied during the same process cycle. stainless steel building

What advantages of DSP’s PVD color coating technology

ü Large resistance to rust and scratches (Surface hardness is 10 times stronger than normal stainless steel.)

ü Various colors available, luxury and elegant colors are available

ü Excellent durability of coatings and colors (semi-permanent)

ü Eco-friendly process

ü Saving maintenance and replacement cost

What DSP’s PVD color coating machine

ü Titanium coated vacuum chamber

ü Titanium coated vacuum roll to roll machine

What process DSP’s PVD color coating work

ü Stainless steel plates are processed in sealed containers that can hold hundreds of parts at a time.

ü The air is pumped out of the container, creating a vacuum atmosphere equal to one billionth of air pressure, and blocking the pressure present in the space.

ü In the case of argon gas, it enters the container and then becomes converted into particles smaller than an atom. These particles are sprayed onto the surface for heating. interior stainless steel manufacturer

ü Particle spraying and the heat generated completely clean the surface of the plate.

ü The injected particles adhere to titanium and have extremely resistant metallic properties, which evaporate the produced titanium metal and atoms and are deposited on the surface of the object to form TiN, TiC, and TiNC films. Because of their high density and compact texture, the TiN, TiC, and TiNC films have high wear resistance.

ü Thin films covering layers further improve gloss and protect against corrosion and discoloration.

0 notes

Text

Titanium color coating with world-class PVD Technology | DSP

The DSP Co., Ltd. is a World-Wide class color coated metal sheet manufacturer that boasts its unique state-of-the-art technology accumulated for more than 30 years. DSP delivers beauty to the world as a global leading company in metallic color coatings that features long-lasting durability of various colors.

DSP’s various metallic color coatings utilizing PVD Technology

ü Champagne Gold

ü Gold

ü Bronze

ü Blonde

ü Caramel

ü Coffee Brown

ü Sepia

ü Diamond Black

ü Black

DSP’s advanced PVD Titanium coating

DSP uses advanced Physical Vapor Deposition (PVD) coating technology based on cutting-edge high vacuum technology to produce elegant, beautiful durable colors and produces arc-ion plated colored stainless steel products. copper roofing manufacturer

This surface treatment process allows for wear-resistant coatings to be 10 times stronger than normal stainless steel products and lasts longer than any other coloring process known to date.

The DSP stainless steel products are characterized by their color and gloss which are semi-permanent and strong enough to withstand acid rain and contaminants. It has also greater resistance to fire and to chemicals than any other exterior finish materials.

Ahead-of-competition features of DSP’s PVD Titanium coating

ü The Hardness of Thin Films

The hardness of the thin film of this product measured with the Micro Vickers tester is at least 10 times higher than that of stainless steel.

ü Adhesion of Films

As a result of performing the peel test by scratching the product with a knife at an interval of 2 mm and putting cellophane tape on the surface, no film peeling was observed.

ü Shock Resistance

As a result of visual assessment by observation after a 1-kg steel ball dropped on the product from the height of 50 cm by using the DuPont impact tester, there was no damage or discoloration.

ü Scratch Hardness

As usual scratches start to appear from ion plating scratched at the speed of 150 mm/min by using the Clemens type scratch hardness tester. Ion plating has 3 times higher scratch hardness than chemical plating.

Quality-guaranteed QC test of DSP’s PVD Titanium coating

ü Artificial Sweat Test

The artificial sweat liquid similar to human sweat (PH 4.5, JIS LO848) is prepared. The ion-plated frame is then submerged at room temperature for 8 hours. Afterward, it‘s removed and left to dry at room temperature for 16 hours. The table shows the results obtained when this sequence is repeated 7 times. No corrosion of ion plating from artificial sweat occurred on the metal plate. pvd coating colors

ü Wear Resistance

As a result of applying a load of 500g on an eraser by using a SUGA rotational abrasion tester on the surface with a thickness of 0.5 microns for ion plating and wearing it down for 200 repetitive cycles, the color reaction of chemical compounds were exposed but ion-plated films were not peeled off.

ü Wet Test

As a result of visually observing the change in the color of the ion-plated material after being left for 500 hours at the temperature of 50°C and the humidity of 98%, no problem was found.

0 notes

Text

Titanium color coating and Nano coating technology for metal sheet

DSP Co., Ltd. is a global leader in the technology of color coatings on metal sheet with PVD coating and NCC coating technology. Based on such two cutting-edge technologies, DSP conveys the beauty of colored stainless steel sheet and other metal sheet to the world.

DSP is specialized in producing environmentally-friendly colored stainless steel products.

Since its establishment in 1988, DSP has been continuing to develop new products and expand its product lines to be used in various applications such as wall covering, roofing, ceiling, Elevator, Door, Handrail, Fittings and custom-made remodeling.

Also, DSP has achieved remarkable developments in the area of metal sheet materials such as stainless, titanium, aluminum, and others, according to the trend and needs of customers around the world.

DSP has been ever-lastingly putting its best efforts into the development of new products with the highest priority on technological innovation, thereby providing better and beautiful colored metal sheet products up to the customer’s satisfaction.

What DSP can do

ü DSP is the company to bring the corrosion resistance and the color variation to the metal sheet.

ü DSP‘s all the products are so totally harmless to human health that may be used for a wide variety of applications including construction, interior, elevators, home appliances, cars, and others. interior stainless steel manufacturer

ü DSP produces and supplies diverse products from sheet to coil and pipe of various materials from stainless to titanium and aluminum to meet the satisfaction of customers.

ü DSP provides Color Stainless Steel with Higher Standards to be applicable from Construction to Home Appliance

How DSP can do

ü DSP's technical expertise can meet the challenges of customer’s requirement of a various materials through constant development and investment. decorative stainless steel supplier

ü DSP’s metal coating technology passes various tests that meet international standards such as American Green Guard Certification (GREENGUARD)

ü PVD coating technology (Physical Vapor Deposition) for Titanium color coating

ü NCC coating technology (Nano Ceramic Coating) for multi-functional Nano coating

0 notes

Text

World-Wide class Color Coated Metal Manufacturer

The DSP Co., Ltd. is a World-Wide class Color Coated Metal Manufacturer. DSP delivers the beauty to the world as a global leading company in metallic color coatings.

The latest interior design trend is the luxury as well as eco-friendly and edgy interior space. DSP’s eco-friendly products are harmless to humans and boast a luxurious line. Aluminum + Steel product is the DSP’s flagship line-up of aluminum laminated sheet steel for building interior and roof. stainless steel roofing

DSP stainless steel products are semi-permanent in color and luster and are highly resistant to corrosion and abrasion to withstand acid rain and pollutants. Thanks to such advantages, it is far superior to any other exterior finishing materials, such as non-flammable chemical substances.

Energy efficiency is also important in the recent construction market. For this, the technology of energy efficient elements that make up the building, such as roofing, flooring, and ceiling, is essential to building construction. DSP is providing energy efficient building materials that have acquired eco-friendliness and stability with the best technique in Korea. zinc roofing supplier

DSP’s Interior wall product line-ups Aluminum + Steel Stainless steel + PVD Stainless steel + NCC Stainless steel Plated steel sheet + NCC coating Tin plate + Tin plated steel plate Stainless steel + back material Metal panel Stainless steel + solid

DSP’s state-of-the-art Technologies

Fluorine coating: Best dry vacuum deposition coating technology Non-flammable: Strong fire resistance Real Metal Texture: Feel of the real metal surface Color uniformity: Feel of the constant color 10mm bending: Bent freely 10-year warranty: Guarantee the quality of products aiming for the world beyond Korea Cost Reduction: Benefits of stainless steel remain the same while the price is down Material: Aluminum AL3000 R2R coating: Coating stainless steel as it is on a roll

0 notes

Text

Stainless steel building materials color coating technology

The DSP Co., Ltd. is a world top class color coated metal manufacturer.

DSP delivers the beauty to the world as a global leader in metallic color coatings industry. DSP has been endeavoring to develop the color coating technology to keep the leader position in the industry of color stainless steel interior and exterior building materials.

DSP is constantly striving to reach customers with creative and innovative products, and is doing its best to become a company loved by customers.

DSP Exterior wall and roof building materials

The safety and the aesthetics as well as energy efficiency are becoming important in the recent construction market.

DSP’s exterior wall and the roof are made of high quality architectural exterior materials such as aluminum, stainless steel, and Titanium to cultivate the energy of the building and make the exterior of the building more beautiful. DSP presents the safety and beauty of buildings with the best technology in Korea. coloured stainless steel manufacturer

DSP’s exterior wall and the roof are the products that have acquired eco-friendliness and stability with the world top-class technology.

DSP Fluorine Coating Technology

DSP's fluorine coating technology is the dry vacuum deposition coating technology, which provides excellent resistance function to corrosion and abrasion

The fluorine coating products produced by DSP prevents water or oil to adhere to well and reduces the contamination by dust. Fluorine coated stainless steel is semi-permanent in color and is resistant to moisture, contaminants and lust as well. copper roofing manufacturer

In addition, DSP fluorine coating products are excellent in terms of non-combustibility and can be used as interior materials for buildings as well as exterior building materials.

Features of DSP fluorine color coating technology

· Non-adhesive

· Corrosion resistance

· Water repellency

· Lubricity

· Heat resistance

0 notes

Text

STAINLESS STEEL COLOUR COATING TECHNOLOGY TO MEET THE NEEDS OF THE WORLDWIDE CUSTOMERS

A new concept of “eco-friendly stainless” world created by the advanced technology of DSP has been unfolded.

DSP Co., Ltd., has always been pursuing customer satisfaction and impression by developing new stainless steel products since 1988, and is making ceaseless efforts to make all DSP products reborn to be the best luxury products. The company is constantly researching and striving to reach consumers with creative and innovative products, and is doing its best to become a company loved by consumers around the world.

DSP products are stainless steel plate that combines functionality and design processed through the cutting-edge high vacuum technology and organic as well as inorganic hybrid coating technology.

And 'INOXTEEL', colour stainless steel laminated plate produced by the ‘Roll to Roll' method that dramatically increases productivity and economic efficiency. architectural stainless steel manufacturer

DSP’s Colour Stainless Steel Roofing Products have not only the strong weather ability, but also the variety of design to fascinate many project owners and contractors. It has been supplied to Incheon International Airport of Korea as roofing materials, and recently, awarded the acquirement of roofing materials for Qatar’s International Airport Project.

Especially, DSP’s Colour Stainless Steel Roofing Material has passed the 4,000 hours of Accelerated Weathering Test from a Public Certification Authority of Korea. The test results were limited to 4,000 hours, because there has been no precedent with the qualification or attempts to reach 4,000 hours moreover. color inox manufacturer

DSP’s products usage arena

· Exterior wall and roof

· Interior wall, ceiling, flooring

· Home Appliances

· Car

· Elevator Kevin Door Jam

· Canopy, ceiling, pillar

· Door frame, louver, and molding

· Custom order

View more: Colour Stainless Steel Roofing

0 notes

Text

MOST INNOVATIVE COLOUR STAINLESS STEEL ROOFING PRODUCTS

The DSP Co., Ltd. is the World-wide class Colour Coated Metal Manufacturer. The colour stainless steel roofing products of DSP Co., Ltd. are most innovative products to improve conventional roofing products’ issues. The products are the first one to pass the 4,000 hours of Accelerated Weathering Test.

The DSP stainless steel roofing products need no vapour barrier. Savings in construction and maintenance costs and resistance to wind uplift and corrosion are the benefits of the DSP Stainless steel products for steel roofs.

Conventional Colour Metal Roofing Products had a chronic problem of its colour fading under the sun lights due to its vulnerability to UV lights. Conventional Zinc roofing products are susceptible to the moist that leads to perforation, thus the installation of the membranes is required to prevent this issue. stainless steel cladding

President Mr JINHYUNG KIM of the DSP Co., Ltd. states that “DSP’s Colour Stainless Steel Roofing Product has been qualified not only in the domestic market of Korea but also with the International Projects.” And he adds, “With the certification from the Accelerated Weathering Test, DSP Roofing Products has acquired the product integrity, and will bring the sensation to the Roofing Matronly in Integrity Markets, both Domestic and International.”

DSP functional coatings are applied according to the needs of customers such as non-flammable, anti-fingerprint, and non-pollution other than colour stainless steel roofing products.

View more: pvd coating colors

0 notes

Text

DSP; THE FIRST ROOFING MATERIAL TO PASS THE 4,000 HOURS OF ACCELERATED WEATHERING TEST.

The DSP Co., Ltd., whom are the World-Wide class Colour Coated Metal Manufacturer’s Colour Stainless Steel Roofing Products are an innovative product to improve conventional Roofing Products’ issues. Their innovative product is the first one to pass the 4,000 hours of Accelerated Weathering Test. Conventional Colour Metal Roofing Products had its chronic problem of its colours faded under Sun lights, due to its vulnerability to UV lights. Zinc Roofing Products are susceptible to the moist, which leads to the perforation, thus installation of the membranes is required to prevent this issue.

These materials have significant disadvantages yet were preferred by the market due to its relatively lower prices. In the meanwhile, the international market is beginning to have tendency of Copper Roofing Materials and Zinc plated Stainless Steel Roofing Materials are increasing. DSP aims to provide High performing Colour Stainless Steel Roofing products, with a reasonable price, to standout in a current market, which is bipolarized into High Price Product, and Low Cost Products. decorative stainless steel supplier DSP’s Colour Stainless Steel Roofing Products has not only the High Weatherability, but also with the variety in design, which lead to fascinate many project owners and contractors. It has been supplied to Incheon International Airport as a roofing, and recently, awarded with the acquirement of Qatar’s International Airport Project, as a roofing material. Especially, DSP’s Colour Stainless Steel Roofing Material has passed the 4,000 hours of Accelerated Weathering Test from a Public Certification Authority. The test results were limited to 4,000 hours, because there has been no precedents with the qualification or attempts to reach 4,000 hours, are moreover, it was limited to 4,000 hours because the Test Equipment’s capability is limited to only 4,000 hours. color metal supplier President Mr. JINHYUNG KIM states that, “DSP’s Color Stainless Steel Roofing Product has been qualified not only the domestic market of Korea, but also with the International Projects.” And added, “With the certification from the Accelerated Weathering Test, DSP Roofing Products has acquired the Product Integrity, and will bring sensation to the Roofing Material Markets, both Domestic and International.

0 notes