Don't wanna be here? Send us removal request.

Link

HEATING MODEL : ELECTRICALLY HEATED OR STEAM HEATED MODEL / CAPACITY IN LITERS : 60 / 100 / 150 / 200 L

TECHNICAL FEATURES

Vessel with conical shape bottom.

Vessel with material discharge cock ( 2” Size or bigger size if specified ) at centre of the conical bottom.

Vessel with top loose open-able cover and 04 nos. of legs with castor wheel ( if electrically heated ) and with fix plate ( if steam heated ).

Vessel having jacket ( Water Jacket OR Steam Jacket ) made from M.S. / SS304 as per customer need.

Jacket insulated with mineral wool & covered with M.S. or Aluminum or SS304, as per customer need.

Vessel with tank mounted stand for geared motor. Geared Motor mount on the stand and covered.

Anchor type slow speed stirrer with geared motor for mixing of the paste.

Electrical heaters with temperature controller in electrically heated model.

Operating panel provide with vessel.

Inside surface will be polished to the mirror finished and outside surfaces will be insulated with SS304.

0 notes

Link

CAPACITY AVAILABLE FROM 150 LITERS TO 1500 LITERS.

OPERATION

The Bin Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously. The unique baffle fitted on the lid ensures uniform mixing. This blender is ideally used for hormones products in pharmaceutical industry, Food, Chemical and Cosmetic products etc.

SGENERAL FEATURES

Structure made from SS304

Variable load capacity available

IBC Lock System ( can adjust for various capacity IBC)

Sensor checking lock system before machine start.

Safety Bar to cover moving part.

Rotation of tank in vertical.

Variable Speed of rotation by VFD.

PLC and Color Touch Screen Control. (Optional feature)

Timer to adjust batch time.

PLC Control color touch screen include printer and interface to network can monitor and save operation on PC computer. (Optional feature)

Maximum care has been taken to ensure safe operation of the unit.

#Pharmaceuticals Machinery#Food Industry Machinery#Cosmetic Machinery#chemical Machinery#Machinery design

0 notes

Link

GMP Model with High Capacity Mobile Hot Air Blower System

Model Available

12'', 24'', 30'', 36'', 42'', 48'', 60'' & 72''

Description

In the process of coating tablets and confectionaries, the personal skills of the coater needs to be supplemented by a correctly designed, versatile coating pan.

CHITRA Coating Pan have very heavy & sturdy structure , made from angles & channels. Complete structure covered from all sides. Two nos. of covers with hinges provided on two sides( left & right ) of the structure. Three nos. of covers are fixed with bolts.

Variable speed pulley system made out of cast iron, with motor slides are provide up to 48" size for speed variation. Motor & worm reduction gear are used of any reputed make, as per customer requirement. ( A.C. frequency drive for variable speed of coating pan will be also provided on demand )

Coating pan made from 10 SWG, SS304 or SS316 or SS316 L material and polished to the mirror finished from inside & outside.

CHITRA Coating Pans have been designed after a careful study of the needs of expert coaters such as Rotational Speed, Angle of inclination of Pan, Inside finishing of the pan , Total Volume and Temperature of the hot air.

Description

The standard pan is elliptical in shape, mounted at 30° angle. RPM of the pan is variable. with help of the variable speed pulley.( A.C. Drive provided optionally )

Inbuilt hot air blower system as a standard supply up to 48'' size ( Excluding 60'' & 72'' size ) & high capacity mobile hot air blower system also provided ( as a optional ) with temperature controller to control the temperature of air at selected temperatures between 30°C to 75°C is provided with air delivery pipe to deliver required quantity of air in the pan.

Special Features

Pan fabricated from 3 mm thick, SS Sheet of SS 304 / SS 316 quality with adequate mouth opening and depth.

Temperature controller provided for temp. controlling.

Anti vibrating unit provided for proper leveling, hence no requirement of foundation.

Compact hot air blower with inlet air damping arrangement.

General structure made out of M.S. in Standard Model & same will be covered with SS304 in GMP Model.

Easy mounting arrangement for change over from Coating Pan to Polishing Pan.

Optional

GMP models .

Contact parts ( Pan ) made out of SS 316 material.

Flameproof motor with flameproof starter for Coating Pan drive.

Steam heated hot air blower system with flameproof blower.

Polishing pan size 24', 36", 42", 48", 60" & 72", made out of mild steel or SS304 / SS316.

Buffels ( welded or detachable type ) provided inside the pan, if required.

0 notes

Link

DESCRIPTION OF SYSTEM

In the process of automatic coating of tablets the coater needs to be supplemented by a correctly designed, versatile coating system.

CHITRA’S Coating System have been designed after a careful study of the needs of expert coaters such as Rotational Speed, Efficient AHU system, inlet & exhaust air cfm & efficient solution spraying system etc.. etc...

CHITRA’S Coating System have very heavy & sturdy structure, made from SS304 pipes & sheets. Complete structure covered from outside. Processing Chamber designed with sealed from all side, in which negative pressure can be achieve. Chamber with 02 nos. of covers with hinges provided on two sides ( left & right ) of the structure to clean and remove / replace the pan.

Perforated pan with drive and mounting facility in the chamber.

Chamber with facility of wash water drain port with manually operated ball valve.

Motor with worm reduction gear unit and a bearing housing with shaft for pan drive. Variable Frequency drive for variable speed of pan.

Inlet air & exhaust air duct with b/f valve and Open – Close type pneumatic actuator, inside the chamber.

A FLP lamp at top of the chamber.

Spray nozzle mounting facility at chamber.

Perforated pan made from 10 SWG, SS316 material and polish to the mirror finish from inside & outside, with baffles & tablet unloading attachment.

AHU with pre filters, inlet air blower, cooling coil, phase & by pass system, heating coil, micro v & hepa filters with temperature sensor and Rh Sensor ( OR Dew point sensor – Optional ) & exhaust air blower.

Inlet and outlet air duct. (Non insulated – 06 meter each)

Solution preparation vessel with spraying system.

Model available 12”, 24”, 36”, 48”, 60” .

SPECIAL FEATURES : ( WHICH ARE INCLUDED IN BASIC COST OF THE M/C )

Pan fabricated from 2.5 mm thick, SS Sheet of SS 316 quality with 3.0 mm perforation at 4.5 mm triangle pitch for adequate opening area for better performance.

12” & 24” model are on wheel & 36”, 48” & 60” model with Anti vibrating unit provided for proper leveling, hence no requirement of foundation.

AHU with inside SS sheeting + Pre, Micro V & Hepa filter in SS Box + Cooling coil in copper tube and aluminum fins & Heating Coil in SS Tube & Aluminum Fins. ( if steam heated model ) and electrical heaters if electrically heated model.

Rh Sensor at air inlet line.

Differential Pressure Gauge at Hepa Filter.

Differential Pressure Gauge at Process Chamber.

Inlet air, Product Bed & Exhaust air temperature Sensor.

Variable Frequency Drive for (AC Drive) Pan Drive Motor, Inlet Air & Exhaust Air Blower.

RPM Indication facility.

FLP Lamp.

Port with Spray Ball for CIP. ( CIP system will be in customer scope )

Tablet Discharge Spout.

Inlet Air Blower.

Exhaust Air Blower.

Solution Preparation Vessel with propeller type stirrer with variable rpm facility. (Plain – Non Jacketed – Non FLP Model).

Pan Drive Motor flameproof.

Spraying Nozzle. ( Make - Spraying System – USA ).

Peristaltic Pump. ( Make – Master Flex – USA ).

Manually operated Atomizing Air Pressure Regulator & Fan Width Pressure Regulator.

Butterfly Valve at Inlet & Exhaust air duct with Actuator.

PLC & Touch Screen of Mitsubishi make (Touch Screen).

Inlet & Exhaust air duct – 5 Meter/ each.

OPTIONAL FEATURE WHICH WILL BE PROVIDE AT EXTRA COST, IF REQUIRED :

Dew Point Sensor at inlet air duct, instead of Rh sensor.

Velocity Trans-meter at inlet & exhaust air duct.

Differential Trans-meter at AHU & Process Chamber, instead of D.P.G. (02 nos.)

Jacketed Vessel instead of plain. (for Solution Preparation.).

Flameproof Model Vessel for Solution Preparation.

Flameproof Motor at inlet & Exhaust air blower.

Wet Scrubber at exhaust air.

Steam & Chilled Water Controlling Valve. (02 nos.)

Non FLP / FLP

Atomizing Air Pressure Regulator & Fan Width Pressure Regulator operating through Touch Screen.

Flameproof/Weatherproof Enclosure for Touch Screen.

Additional Duct per 1 Meter – Non insulated.

( for Inlet & Exhaust air ).

SPECIAL FEATURES WHICH COMPRISING OF FOLLOWINGS :

Horizontal, cylindrical vessel (Pan) of size 300 mm diameters, capable to coat 0.5 to 1.0 Kg. having welded on torispherical dished ends at both sides. The shell body is perforated properly (triangular pitch) to ensure optimum hot air inlet. The pan having a frontal opening for easy loading and unloading of tablets.

The pan driven by 0.5 HP flameproof motor through suitable reduction gearbox to achieve a variable rotational speed 5 – 25 RPM by means of Variable Frequency Drive (VFD).

Special type baffles with proper spacing are provided inside the pan for exposing all the tablet surfaces to get uniform coating and tablet (rolling) turning while rotating of the pan.

The coating pan is enclosed within double walled cubical, totally enclosed to ensure leak proof operation, provided with side doors for easy excess to the pan, the doors are duly insulated / properly sealed with food grade quality rubber with appropriate shore hardness. Locking device on both the doors and rounded interior corners, which helps easy cleaning and maintenance of coating pan.

A wash sink with proper drainage is provided at the lower plenum of the cabinet to conduct the washing of the perforated pan by increasing the speed of the pan in wash solution.

A luminous flameproof electric lamp is fitted on the top wall at the cubical above the coating pan to ensure sufficient effulgence to the working zone.

A peristaltic pump ( Indian make ) for precise and rapid priming facility for proper and accurate dosing of solution, supply shall be complete with solution transfer tube.

Highly sophisticated and efficient 01 No. Spray gun, ( Spraying System – USA make ) completely free from choking problem, controls both the application rate and the droplet size for all type of coating.

The guns are mounted on SS retractable header with angle adjustable arrangement.

In built type, PUF insulated double skin AHU with inside SS304 sheeting & all filters in SS304 box, comprising of Pre , Micro V & Hepa Filters, Inlet air Blower, cooling coil, Rh & inlet air temperature sensor and electric heating arrangements of 12 KW electrical load.

There are 5 micron pre filters at air inlet prior to the blower.

Centrifugal type blower fan of 100 CFM. The fan shall be dynamically balanced and with backward curved blades. Material of Construction SS304. Direct coupled 0.5 HP non flameproof electric drive motor of 415 V. Prior to inlet blower there shall be 5 micron pre filter.

The cooling section will operate if the process air entering the cooling section with high humidity at the start of the process. The cooling section will reduce the relative humidity of the air entering the air handling unit.

Shell & Tube, extended area, fixed tube sheet made with Copper tube and Aluminum Fins. ( The chilled water will be supplied by customer. )

12 KW electrical heaters made from SS tube will be at AHU for efficient & fast heating arrangement.

Micro V of 3 micron & Hepa filters 0.3 micron with attachments, viz. pressure drop / choking measurement across hepa filter by means of differential pressure gauge, DOP testing port for checking the integrity of Hepa filter, etc.

Rh sensor & inlet air temperature sensor will be provide at APU.

Phase & by pass system for precise control of inlet air temperature.

Centrifugal type blower fan of 150 CFM. The fan shall be dynamically balanced and with backward curved blades. Material of Construction MS duly painted or powder coated. Direct coupled 1.0 HP non flameproof electric drive motor of 415 V.

The quantum of exhaust air is higher than inlet air creates a negative pressure at coating zone, thus faster drying will take place. The quantum of air shall be controlled by means of variable frequency drive to both blowers.

MS power panel duly powder coated or painted comprises of contactors, relays, fuse links with base, transformers, ON-OFF switch etc. Proper ferruling and color coding will be provided for the wirings. It shall be mounted at servicing zone.

Operating panel shall be fabricated from SS304 material.

The automatic tablets coating system is operated through a user-friendly integrated control panel suitable for manual and automatic operation. The panel includes Mitsubishi make PLC & TOUCH SCREEN. The material of construction of the panel shall be of AISI 304Q. The panel having the following features :

Automatically controlled process parameters with indication and display such as :

- Inlet / Outlet Air Temperature. - Bed / cabinet temperature. - Pan RPM. - Inlet air Rh. - Spray on time. - inlet & outlet air cfm. - RPM of peristaltic pump. - Air pressure of Atomization air.

Automatic stoppage of spray in case of :

- Pan rotation stops. - Exhaust blower stops. - Hot air blower stops. - Atomization air pressure falls below set point.

All process contact parts are made of AISI 316 Q Stainless Steel. All non-process contact parts are made of AISI 304 Q Stainless Steel or heavy parts made out of mild steel and claded or covered with SS304 material.

Electric supply : 15.5 Kw. (Max.) ( In electrically heated model )

Electric supply : 3.5 Kw. (Max.) ( In steam heated model )

Steam : 30 Kgs./Hr.

Air : 20 CFM

Chilled water for AC 12” : 20 GPM : 5 DEG. C. inlet water temp.

0.5 HP FLP FOR MAIN PAN.

0.5 HP NFLP FOR INLET AIR.

1.0 HP NFLP FOR EXHAUST AIR.

0.5 HP NFLP FOR PERISTALTIC PUMP.

0.25 HP FOR STIRRER OF SOLUTION TANK

0 notes

Link

Operation

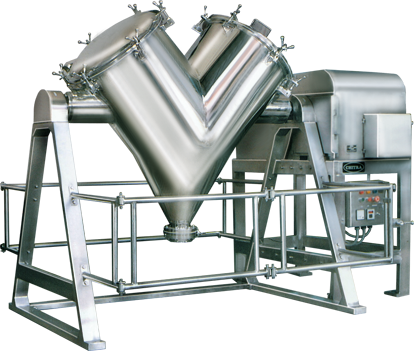

The "V" BLENDER is an efficient and versatile blending machine for mixing and lubrication process of dry powders homogeneously. Approximate two third of the volume of the Blender is filled to ensure proper mixing. The "V" Blender gives best result for powders due to suitable medium speed and "V" shape of container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc……

In V Blender the powders comes from all sides due to the "V" shape of the product container, hence requirement of RPM is medium. Suitable mainly for powder & granules type material. This type of material gets sufficient continuous movement. Due to the "V" shape of container, have only medium movement and will results in good quality of blending / lubrication of granules.

Special Features

Suitable for dry mixing of products in powder form.

Easy for loading and unloading.

Easy for cleaning.

All contact parts are made out of SS304 / SS316 or SS316 L quality material, as per customer requirement.

Simple design requires minimum maintenance.

General structure & safety guards made out of mild steel & painted in Standard Model and made out of SS304 & polished to the matt finish in GMP Model.

The "V" shape gives sufficient contineous movement to the granules, result in good quality.

Maximum care has been taken to ensure safe operation of the unit.

Manual rotating facility with hand wheel for inching.

Optional - (will be provided on extra cost on your demand)

Contact parts made out of SS316 of Ss316 L instead of SS304.

Flame proof drive motor along with flame proof starter.

Vacuum loading facility for material charging.

VFD for variable speed of cone.

0 notes

Link

Operation

The Double Cone Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously. All the contact parts made out of stainless steel of required grade by customer. Two third of the volume of the Cone Blender is filled to ensure proper mixing. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc.

Salient Features

The conical shape at both ends enables uniform mixing and easy discharge.

All contact parts are made out of stainless 304 or 316 quality material, as required by customer.

Maximum care has been taken to ensure safe operation of the unit.

Manual rotating facility with hand wheel for inching. The same will be provided with ss cover & limit switch. ( In 200 Kgs. & above model )

Two nos. of safety road will be provided at back side. ( One LH side & one RH side )

Suitable size of butter fly valve at one end of the cone provided for material discharge & hole with openable cover provided at other end of the cone for material charging & cleaning.

One shaft with 04 nos. of fixed buffels with mirror polished provided inside the cone.

Cone will be mirror polished from the inside & outside & structure will be matt polished.

All moving parts covered with SS304 covers.

Safety guards made from SS304 pipes provided in front of the m/c with limit switch.

Panel fabricated from SS304 material with facility of three phase indication, D.O.L. starter, digital timer & Amp. Meter.

As per customer requirement machine will be provided with left side drive or with right side drive.

The conical shape at both ends enables uniform mixing and easy discharge.

All contact parts are made out of SS304/316(as per customer requirement) quality material.

Maximum care has been taken to ensure safe operation of the unit.

Worm reduction gear use for speed reduction.

Food grade rubber gasket will be used on both end of cone as well as in butterfly valve.

Inside & outside of the cone will be polished to the mirror finished.

General structure made out of SS304 and Polished to the matt / mirror finish ( as required by you ) in GMP Model.

All safety guards & covers made out of SS304 in GMP Model.

Hand wheel will be provided for manual tilting of cone.

Safety guards provided with limit switch to not start the machine when safety guards are not in proper position.

0 notes

Link

Model Available :

300, 500, 600, 700 Litres & Bigger Size

Operation

The OCTAGONAL BLENDER is an efficient and versatile blending machine for mixing and lubrication process of dry granules homogeneously. Two third of the volume of the Cone Blender is filled to ensure proper mixing. The Octagonal Blender gives best result for granules due to very slow speed and octagon shape of container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc.

In Octagonal Blender the granules comes from all sides due to the octagonal shape of the product container, hence requirement of RPM is less. Suitable mainly for Crystalline & Granular type material. This type of material gets sufficient continuous movement due to their shape if container have only slow movement and will results in good quality of blending / lubrication of granules.

Special Features

Suitable for dry mixing of products in granule form.

Easy for loading and unloading of material.

Easy for cleaning.

All contact parts are made out of SS 304 / SS 316 or SS 316 L quality material, as per customer requirement.

The octagonal shape & slow speed of rotating gives sufficient continuous movement to the granules, result in good quality.

Simple design requires minimum maintenance.

General structure & safety guards made out of mild steel & coloured in Standard Model and made out of SS 304 & polished to the matt finish in GMP Model.

Maximum care has been taken to ensure safe operation of the unit.

Manual rotating facility with hand wheel for inching.

Bigger size batch at low power consumption.

Optional - (will be provided on extra cost on your demand)

Contact parts made out of SS316 instead of SS304.

Flame proof drive motor along with flame proof starter.

Vacuum Loading facility for material charging.

Cylindrical container with cone for material charging.

0 notes

Link

Operation

In recent times the most important development that took place is the replacement of the conventional reciprocating motion by the gyratory motion in the sieving and straining operation. This machine is designed to provide gyratory vibration generated by means of balance flywheel. The amplitude of vibration is adjustable to the processing needs by means of movable weight on the flywheel. This ensures that every point on the screen surface continuously transverses a circular path in horizontal plane with the elimination of the vertical motion.

This is the only movement capable of effectively presenting in turn all the faces of irregularly shaped particles to the apertures of the screen. Again due to the absence of the vertical movement, bouncing of particles does not take place and thus presenting clear screen apartus.

It is difficult to indicate specific data on the proper amplitude of gyration, for a specific product. However, it has been found that straining operation of liquid & solids calls for lower amplitude to avoid splashing unless the viscosity and tension of the liquid is high.

Special Features

Simple design allows easy dismantling, cleaning & assembling.

High speed machine with higher out put.

It is compact & portable.

Different size of sieves are available & it can be easily change to suit

the product size required.

Available in Standard & GMP Model.

No dust problem due to close sieving operation.

Castore wheel mounted structure, gives mobility of the machine.

Very low maintenance cost.

Wide range of sieves are available.

Structure covered with SS304 cover, in GMP Model.

Optional Panel

Optional

Flameproof Motor with flameproof starter.

IPC stand to put IPC at charging height.

Conact parts made out of SS316 instead of SS304.

Recommended

Sieves from 4 to 200 mesh, made out of SS304 / SS316.

Technical Specifications

Model: 20" / 30"

Drive Motor:1.5 HP. / 2.0 HP. (1440 rpm / 3Ph / 415 V / Ac)

Screen Size :550 mm / 750 mm

All contact parts are made out of SS304 quality material.

D.O.L. starter provided with the unit.

Out put :Depending upon the material properties and the screen size

Appro. Overall Dimension:900 x 900 x 1200 mm

0 notes

Link

Operation

This vibrating energy screen is unit consisting of circular pretensioned screen mounted on the frame along with vibrating motor. The vibrating motor imparts three plane vibrations to the screen due to revolving eccentric weights. Total assembly is mounted on suitable springs so that it becomes a independent body which vibrates without parting any vibrations to the foundations.

Special Features

High capacity & optimum use of space.

Process adaptability.

Low operating and maintenance cost.

Long screen life.

Easy for assembly & dis assembly for cleaning & change over of screens.

Springs amplify the vibrations leading to reduced motor HP, maintenance & operational cost.

Compact unit for easy of operations.

Available in two, three & four deck also.

Optional

Contact parts are made out of SS316 quality material instead of SS304.

Single Deck / Double Deck / Three Deck.

Recommended

Wide range of seaves available in sizes from 4 mesh to 150 mesh

Technical Specifications.

Model:12'' / 24" / 30" / 40"

Drive Motor:0.25 / 0.5 / 0.75 / 1.0 HP.

Screen diameter:300 / 600 / 750 / 990 mm ( approx.)

All contact parts are made out of SS304 quality material. ( SS316 Optional )

D.O.L. starter provided with the unit.

Out put:24" : up to 150 Kgs./ Hr.

30" : up to 200 Kgs./ Hr.

40" : up to 300 Kgs./ Hr.

(Depending upon the material properties and the screen size)

0 notes

Link

Co - Mill

CHITRA Multi Mill is a self contained portable unit useful for high speed GRANULATING, PULVERISING, MIXING, SHREDDING AND CHOPPING, etc., of a wide range of wet and dry materials without special attachments.

As compared to the four common principles of size reduction i.e. grinding, compression, impact and shearing, which often do not produce controlled size reduction, this machine utilises the principle of variable force swing hammer blades having both knife and impact edges rotating with a carefully selected screen to control size reduction.

Flow path of material in vertical rotor machine is streamlined. During comminution, material entering the chamber travels to the periphery and passes through the screen tangentially and radially, avoiding chocking and temperature rise.

Operation

MULTI MILL is designed to utilise the principle of variable force swing beaters having both knife and impact edges rotating within a selected screen to control the particle reduction. Material fed in to the processing chamber moves to the periphery and passes through the screen radially and tangentially. Finally the processed material gets collected in to the container kept below the processing chamber.

Special Features

Suitable for dry and wet granules.

All contact parts are made out of SS304 quality material.( SS316 quality is optional )

Castore wheel provided for the ease of mobility.

Seaves available in sizes of 0.5 to 12mm hole dia.

12 nos. beaters with knife edges & impact edges & 02 nos. scrapper blades.

In GMP Model complete body claded with SS304 and polished to the matt finish & in Standard Model excluding product contact parts, all other parts made out of C.I. or M.S. and coloured.

Machine rated for continuous operation.

Higher output with process uniformity.

All contact parts can easily be dismantled and cleaned for change of product.

Wide range of SS perforated screens available

Machine portable on castor wheels.

Reversible direction of blade rotation.

Different size of screen / speed / number of blade / direction of rotation of blade can be selected.

Optional - (will be provided on extra cost on your demand)

Contact parts made out of SS316 instead of SS304.

Providing flame proof drive motor along with flame proof starter and flame proof reversible switch.

Vacuum loading system fore charging the material.

Stand for IPC. (Intermediate product container) Recommended

Extra seaves available in sizes of 0.5 to 12 mm hole dia. made out of SS304 / SS316.

Application

Pharmaceuticals, Chemicals, Cosmetics, Ceramics, Colours, Dyestuff, Food Products, Pesticides, Fertilizers, Spices, Detergents, Insecticides, Plastics and Resins Industries.

Technical Specifications

Drive motor:3HP / 1440 rpm / 3 Phase / 440V / AC

D.O.L. starter provided with reversible switch.:89 mm ( approximate )

Rotor Diameter

Rotor RPM:750 / 1400 / 2200 / 2800 ( approximate )

Screen Diameter:260 mm

Blades:12 nos. With Knife & Impact Edges & 02 nos. Scraper Blades

Output:25 to 175 Kgs / Hr. (Depending upon the products and the reduction required in sizes)

Foundation not required. Castore wheel mounted base.

Appro. charging/discharging height:1445/730mm

Appro. floor space required in mm:870 X 965

Appro. net weight in Kgs.:275

Appro. gross weight in Kgs:565

Case dimensions in mm:1300 X 1080 X 1900 mm ( ht )

0 notes

Link

Lab Model

CHITRA Multi Mill is a self-contained portable unit useful for high speed GRANULATING, PULVERISING, MIXING, SHREDDING AND CHOPPING, etc., of a wide range of wet and dry materials without special attachments.

As compared to the four common principles of size reduction i.e. grinding, compression, impact and shearing, which often do not produce controlled size reduction, this machine utilises the principle of variable force swing hammer blades having both knife and impact edges rotating with a carefully selected screen to control size reduction.

Flow path of material in vertical rotor machine is streamlined. During comminution, material entering the chamber travels to the periphery and passes through the screen tangentially and radially, avoiding chocking and temperature rise.

Operation

MULTI MILL is designed to utilise the principle of variable force swing beaters having both knife and impact edges rotating within a selected screen to control the particle reduction. Material fed in to the processing chamber moves to the periphery and passes through the screen radially and tangentially. Finally the processed material gets collected in to the container kept below the processing chamber.

Special Features

Suitable for dry and wet granules.

All contact parts are made out of SS304 quality material. ( SS316 quality is optional )

Castore wheel provided for the ease of mobility.

Seaves available in sizes of 0.5 to 12mm hole dia.

12 nos. beaters with knife edges & impact edges & 02 nos. scrapper blades.

In GMP Model complete body claded with SS304 and polished to the matt finish & in Standard Model excluding product contact parts, all other parts made out of C.I. or M.S. and coloured.

Machine rated for continuous operation.

Higher output with process uniformity.

All contact parts can easily be dismantled and cleaned for change of product.

Wide range of SS perforated screens available

Machine portable on castor wheels.

Reversible direction of blade rotation.

Different size of screen / speed / number of blade / direction of rotation of blade can be selected.

Optional - (will be provided on extra cost on your demand)

Contact parts made out of SS316 instead of SS304.

Providing flame proof drive motor along with flame proof starter and flame proof reversible switch.

Vacuum loading system fore charging the material.

Stand for IPC. (Intermediate product container) Recommended

Extra seaves available in sizes of 0.5 to 12 mm hole dia. made out of SS304 / SS316.

Application

Pharmaceuticals, Chemicals, Cosmetics, Ceramics, Colours, Dyestuff, Food Products, Pesticides, Fertilizers, Spices, Detergents, Insecticides, Plastics and Resins Industries.

Technical Specifications

Drive motor: 3HP / 1440 rpm / 3 Phase / 440V / AC

D.O.L. starter provided with reversible switch.: 89 mm ( approximate )

Rotor Diameter:

Rotor RPM: 750 / 1400 / 2200 / 2800 ( approximate )

Screen Diameter: 260 mm

Blades: 12 nos. With Knife & Impact Edges & 02 nos. Scraper Blades

Out put: 25 to 175 Kgs / Hr. (Depending upon the products and the reduction required in sizes)

Foundation not required. Castore wheel mounted base.

Appro. charging/discharging height: 1445/730mm

Appro. floor space required in mm: 870 X 965

Appro. net weight in Kgs.: 275

Appro. gross weight in Kgs: 565

Case dimensions in mm: 1300 X 1080 X 1900 mm( ht )

0 notes

Link

CHITRA Oscillating Granulators is available in two models CEOG - 200 and CEOG - 400 for Pharmaceutical, Chemical, Food and Fertilizer Industries.

This machine gives high output with less percentage of fines and has the salient features like Robust Simple and Compact design, Easy installation in production line, Uniform granules, Maintenance free and can be attached with Vacuum loading and discharge arrangement or Gravity flow system. The granulating chamber and internal parts are totally washable from inside. The inner surfaces are mirror polished to prevent adherence of the product and facilitate cleaning. Sliding rails and fast fixing devices allow easy mounting and dismantling of the accessories.

Compared to other conventional models available, this machine is the best in terms of high output, minimum fines, low noise level while working, closed and compact to prevent powder leaking out, dust free operation, oscillates at low speed thus preventing excess heat generation and is designed for easy introduction in production line and continuous non-stop operation. This machine can be used for Dry and Wet granulation and have a wide field of application.

The oscillating motion of rotor gives uniform granules with less fines. Granule size varies as per the perforation of sieves. The simple design of Rotor and Sieve mounting facilitates easy cleaning and quick change over. Externally fitted bearing housings prevent the product coming into contact with bearing lubricants and hence the granules will be completely free of black particles.

Special Features

Suitable for dry & wet granulation.

Easy for loading and unloading.

Easy for cleaning.

All contact parts are made out of SS304 quality material. (SS316 will be provided on demand)

Robust, Simple & compact design requires minimum maintenance.

Easy installation in production line.

Oscillating rotor motion.

Higher output.

Uniform granules, less fines.

Maintenance free.

0 notes

Link

Tray, 48 Tray Introduction

CHITRA drying oven is specially designed for Pharmaceuticals, Food, Chemicals, Paints, Textiles & other industries. It is well accepted for economical drying of granules, powder , food material & chemicals.

Construction

"CHITRA" Drying oven is fabricated out of rigid angle iron frame with double walled panels insulated with best quality compressed fibre glass and with a rigid door fitted with strong hings and best choosen locking arrangement. A control panel is fixed in front of the oven to facilitate the operation easily. It has a large working space and is available, manufacturing from mild steel & in good finishing outside with synthetic enamel colour & inside painted with heat resistent paint to resist temperature up to 300 degree, in Standard Model. It is also manufacture completely from SS304 or SS316 ( As per customer requirement ) in GMP Model & polished to the mirror finish from inside & matt finish from outside.

Description

The Drying ovens are normally available with choice of heating mode, as electrically heated / steam heated & thermic fluid heated. In electrically heated model, digital temperature controller provided with digital timer to facilitate working day and night. In steam & thermic fluid heated model, digital temperature indicator is provided with digital timer , but the temperature controller is not supplied with the machine. Tray Dryer 12 Tray Air Circulation

A highly effective recirculating air system is provided. The heated air, is recirculated with fresh air in selected proportions for optimum drying. The system is designed so that the materials at the top & the bottom dry simultaneously.

Uniform air circulation, controlled temperature, sturdy construction and large working space are the valuables of the oven which is suitably designed to cover wide temperature range, loading and unloading is faster and simple. In higher capacities trays trolley rolls in and out of the chamber. For continuous operation a spare trolley can be had for loading while the drying cycle is taking place.

Controlled Temperature & Time Digital temperature controller with digital timer are supplied to facilitate working day and night.

Option Flame proof fittings and motor. • S.S.304 / S.S. 316 Trays.

Application Pharmaceutical, food, chemicals and other industies.

0 notes

Link

The capacity ranging from 10 / 30 / 60 / 120 / 150 / 200 / 250 / 300 / 500 Kgs., with steam heating / electrical heating & thermal heating facility.

Electrically / Steam & Thermic Fluid Heated in which general structure, made out of mild steel & painted in Standard Model & made out of S.S.304 quality material & polished to the matt finished in GMP Model, but contact parts i.e. Product Container and Retarding Chamber, are made out of S.S.304 / S.S. 316 quality material, with Non-Flameproof blower motor, (Flameproof motor provided on demand) suitable to dry wet material.

Three Piece GMP Mode

Operation

FLUID BED DRYER is designed to introduce the hot air stream at the base of the product container which is filled with the material. Induced draught is created by means of blower and fresh air is sucked in to the unit. The fresh air is heat by means of electrical heaters or steam or thermic fluid heaters. This hot air stream expands the bed of material at certain velocity & creating turbulance in the product. The phenomenon is known as fluidisation and offer conditions which are almost ideal for drying. Fluidisation produces full agitation of solid particles and since each particle gets surrounded by hot air, heat transfer is extremely high and uniform. The product is dried fast without appreciable loss of heat. Filter bags prevent particles escaping from the dryer.

Suitability

The conventional drying method of drying products in tray dryer is rather inadequate and trouble some. They occupy large floor space, have very high drying times, are labour intensive and offer uneven drying. On contrast Fluid Bed Dryer occupy comparatively lesser floor space, are very easy to operate & can dry material in least time as compared to tray dryer.

In Fluid Bed Dryer, temperature distribution through out the product is uniform and the heat transfer rate is very high. Due to the reduce drying time high production rates are achieved.

As the product is in close contact with drying air at low temperature and also for short duration, the physical and chemical properties of the products are generally not effected and therefore the dryer can effectively be used for heat sensitive products. Due to the continuous movements of product during drying lump formation, case hardening etc. are minimized.

The Fluid Bed Dryer are most suitable for drying granular, crystalline, coarse or similar material in pharmaceuticals, fine chemicals, dyes, food and allied products. The Fluid Bed Dryer is not suitable for drying liquids or pasty materials.

Special Features

Uniformity in drying and reduction in drying time.

Atmospheric inlet air is filtered by means of non woowen filter cloth. PRE /MICRO V & HEPA filters can be provided on demand on extra cost to prevent any fine dust to pass through the products.

Digital temperature indicator cum controller for inlet air & Digital temperature indicator for outlet air, are provided for electrically heated model.

Digital temperature indicator are provided for inlet & outlet air, in steam / thermic fluid heated model. (Temperature controlling valves will be in customer scope of supply)

Manually operated air dampers provided to control the inlet and outlet air flow.

An explosion safety flap of adequate capacity at the rear of dryer and an earthing point to prevent static charge in the machine.

Contact parts RETARDING CHAMBER & PRODUCT CONTAINER are made out of SS304 & polished to the mirror finished and other parts are made out of SS 304 and polished to the matt finished in Gmp model & made out of

M.S. & Painted in standard model.

Optional - (Provided on demand on extra cost)

Double wall PUF insulated AHU with PRE /MICRO V & HEPA filters and cooling coil can be provided on demand on extra cost.

Pneumatic system for Lifting of product container ( in 3 pices design ) & finger bag shaking with butter fly valve.

Flameproof motor with weather proof / flameproof enclosure for operating panel. (It is recommended in steam heated model only. Power panel should be mounted out side the flameproof area.)

Safe earthing arrangement with low voltage relay.

Solid flow sensor monitor for monitoring the leakage in the air discharge filters.

Differential pressure gauges or Differential pressure trans-meter across the air discharge bag, inlet air filter and container sieve.

"PLC" based power panel with "MMI"/ Touch Screen based operating panel with printer port facility for process automation.

Extra product container with trolley for more utilization of machine.

Online sampling port at product container for sampling of material without shut- off the machine.

Food grade silicon gasket set.

Facility of mounting of blower with motor & heating chamber with air filteration unit out side the granulation room.

Contact parts made out of SS 316 or SS316 L instead of SS304.

Pneumatically operated inlet and outlet dampers.

Silencer to reduce the noise level of exhaust air.

A.C. Frequency drive for blower motor.

Lifting and Tipling Device for Fluid Bed Dryer's Container

Operation

This equipment is most useful to transfer the material from container of FLUID BED DRYER to INTERMEDIATE PRODUCT CONTAINER. With help of this equipment dust free and very speedy material transfer from FBD bowl is possible. The equipment is equipped with one cone type container which is provided with clamping hooks to clamp the FBD bowl, rubber gasket for air tight fitting between FBD bowl and cone type container. The container is also have a butterfly valve at bottom to drain the material in required IPC or any other container. The hydraulic system (power pack unit with cylinder) is provided to lift the complete assembly with FBD bowl and tilt the pair of cone type container and FBD bowl at 180 degree.

With help of the hooks first clamp the FBD bowl with cone type container. Lift the whole assembly with FBD bowl at a desirable height. With help of hydro- mechanical system tilt the whole assembly at 180 degree. Finally all the material which was in the FBD bowl is transfer in cone container. Discharge the material in IPC or any other hopper, with help of butterfly valve which is provided at discharge of cone type container.

Special Features

GMP point of view machine provided with S.S. Cladding base & S.S. Guards / Cover. No exposed painted surface. Hydraulic power pack is also covered with SS 304 cover.

Very less material transfer time making the next operation earlier & save time and dust free system save environment of working area. The system can be operate by single operator.

Contact parts SS304 provided as a standard. SS 316 / SS 316 L can be provided on demand.

0 notes

Link

Top Spray / Dryer & Bottom Spray

Available Model 2, 10, 30, 60, 120 & 150 Kgs. 10 Kgs. model with additional set of bowl for capacity 01 to 02 Kgs.

Basic Unit

The basic machine is with two different processing insert…..

Top Spray / Dryer Insert

Wurster Insert ( Bottom Spray )

Chitra Fluid Bed Multi Technology provide processing flexibility for the production of granules & coating of powders and pellets.

Top spray / Dryer insert for granulation & drying and Wurster for particle coating & pallet coating.

The unit consists of…………………………

Inlet air handling unit. ( AHU or APU )

Inlet duct with b/f valve. ( 06 meters, standard lenth )

Inlet air plenum with pneumatic gaskets and wash water drain port and ports for nozzle inserts.

Processing inserts……… (A) Top Spray / Dryer Insert (B) Wurster Insert.

Expansions chamber..

Filter bag chamber with filter & 02 nos. side supports.

Filter cleaning system.

Outlet air duct.

Exhaust air blower assembly with motor.

Control Panel & Operating panel.

Pneumatic Panel.

Solution spray system with solution preparation vessel, Peristaltic Pump, spray nozzle & silicon tubing.

Special Features

2 bar sock resistance construction.

All contact parts made out of SS316.

All motor are of flameproof.

Inside of the all contact parts will be @ mirror finish and outside of all contact parts @ matt finish.

Rh trans-meter at AHU.

Inlet, outlet & product bed temperature sensors.

Differential pressure trans-meter for Filter bag & differential pressure gauge for Hepa filter at AHU.

A.C. Frequency drive for all motors.

Sampling port at product container.

Quick opening system for container sieve.

CIP port and nozzles.

Material charging ports , suitable for gravity and vacuum.

PLC based power panel with touch screen based operating panel for automated process controls.

Wash water drain port with valve at inlet plenum.

All rubber gaskets of silicon.

All light and sight glass with T/C clamp facility.

Pneumatic inflatable gaskets at bottom and top of the product container, top of the expansion chamber and for air discharge bag sealing.

CGMP construction.

Optional Feature Which will be provide at extra cost, If Required :

Dew Point Sensor at inlet air duct, instead of Rh sensor at AHU.

Velocity Trans-meter for CFM measurement.

Differential Trans-meter instead differential pressure gauge at AHU and

Differential Pressure Trans - Meter for container sieve.

Jacketed Vessel instead of non jacketed. (for Solution Preparation.).

Flameproof Motor & Flameproof enclosure for panel for Solution Preparation Vessel.

Wet Scrubber at exhaust air.

Steam & Chilled Water Controlling Valve.

Peristaltic Pump of Master Flex-USA make instead of Indian make.

Flow Meter at Solution Spray System. [ Emersion make ( USA ) – Coriolis Type.]

Flameproof/Weatherproof Enclosure for Touch Screen.

Additional Duct per 1 Meter – Non insulated / Insulated.

Solid flow monitoring system.

Reduce capacity bowl for top spray & bottom spray.

0 notes

Link

The capacity ranging from 10 / 30 / 60 / 120 / 150 / 200 / 250 / 300 / 500 Kgs., with steam heating / electrical heating & thermal heating facility.

Electrically / Steam & Thermic Fluid Heated in which general structure, made out of mild steel & painted in Standard Model & made out of S.S.304 quality material & polished to the matt finished in GMP Model, but contact parts i.e. Product Container and Retarding Chamber, are made out of S.S.304 / S.S. 316 quality material, with Non-Flameproof blower motor, (Flameproof motor provided on demand) suitable to dry wet material.

Three Piece GMP Mode

Operation

FLUID BED DRYER is designed to introduce the hot air stream at the base of the product container which is filled with the material. Induced draught is created by means of blower and fresh air is sucked in to the unit. The fresh air is heat by means of electrical heaters or steam or thermic fluid heaters. This hot air stream expands the bed of material at certain velocity & creating turbulance in the product. The phenomenon is known as fluidisation and offer conditions which are almost ideal for drying. Fluidisation produces full agitation of solid particles and since each particle gets surrounded by hot air, heat transfer is extremely high and uniform. The product is dried fast without appreciable loss of heat. Filter bags prevent particles escaping from the dryer.

Suitability

The conventional drying method of drying products in tray dryer is rather inadequate and trouble some. They occupy large floor space, have very high drying times, are labour intensive and offer uneven drying. On contrast Fluid Bed Dryer occupy comparatively lesser floor space, are very easy to operate & can dry material in least time as compared to tray dryer.

In Fluid Bed Dryer, temperature distribution through out the product is uniform and the heat transfer rate is very high. Due to the reduce drying time high production rates are achieved.

As the product is in close contact with drying air at low temperature and also for short duration, the physical and chemical properties of the products are generally not effected and therefore the dryer can effectively be used for heat sensitive products. Due to the continuous movements of product during drying lump formation, case hardening etc. are minimized.

The Fluid Bed Dryer are most suitable for drying granular, crystalline, coarse or similar material in pharmaceuticals, fine chemicals, dyes, food and allied products. The Fluid Bed Dryer is not suitable for drying liquids or pasty materials.

Special Features

Uniformity in drying and reduction in drying time.

Atmospheric inlet air is filtered by means of non woowen filter cloth. PRE /MICRO V & HEPA filters can be provided on demand on extra cost to prevent any fine dust to pass through the products.

Digital temperature indicator cum controller for inlet air & Digital temperature indicator for outlet air, are provided for electrically heated model.

Digital temperature indicator are provided for inlet & outlet air, in steam / thermic fluid heated model. (Temperature controlling valves will be in customer scope of supply)

Manually operated air dampers provided to control the inlet and outlet air flow.

An explosion safety flap of adequate capacity at the rear of dryer and an earthing point to prevent static charge in the machine.

Contact parts RETARDING CHAMBER & PRODUCT CONTAINER are made out of SS304 & polished to the mirror finished and other parts are made out of SS 304 and polished to the matt finished in Gmp model & made out of

M.S. & Painted in standard model.

Optional - (Provided on demand on extra cost)

Double wall PUF insulated AHU with PRE /MICRO V & HEPA filters and cooling coil can be provided on demand on extra cost.

Pneumatic system for Lifting of product container ( in 3 pices design ) & finger bag shaking with butter fly valve.

Flameproof motor with weather proof / flameproof enclosure for operating panel. (It is recommended in steam heated model only. Power panel should be mounted out side the flameproof area.)

Safe earthing arrangement with low voltage relay.

Solid flow sensor monitor for monitoring the leakage in the air discharge filters.

Differential pressure gauges or Differential pressure trans-meter across the air discharge bag, inlet air filter and container sieve.

"PLC" based power panel with "MMI"/ Touch Screen based operating panel with printer port facility for process automation.

Extra product container with trolley for more utilization of machine.

Online sampling port at product container for sampling of material without shut- off the machine.

Food grade silicon gasket set.

Facility of mounting of blower with motor & heating chamber with air filteration unit out side the granulation room.

Contact parts made out of SS 316 or SS316 L instead of SS304.

Pneumatically operated inlet and outlet dampers.

Silencer to reduce the noise level of exhaust air.

A.C. Frequency drive for blower motor.

Lifting and Tipling Device for Fluid Bed Dryer's Container

Operation

This equipment is most useful to transfer the material from container of FLUID BED DRYER to INTERMEDIATE PRODUCT CONTAINER. With help of this equipment dust free and very speedy material transfer from FBD bowl is possible. The equipment is equipped with one cone type container which is provided with clamping hooks to clamp the FBD bowl, rubber gasket for air tight fitting between FBD bowl and cone type container. The container is also have a butterfly valve at bottom to drain the material in required IPC or any other container. The hydraulic system (power pack unit with cylinder) is provided to lift the complete assembly with FBD bowl and tilt the pair of cone type container and FBD bowl at 180 degree.

With help of the hooks first clamp the FBD bowl with cone type container. Lift the whole assembly with FBD bowl at a desirable height. With help of hydro- mechanical system tilt the whole assembly at 180 degree. Finally all the material which was in the FBD bowl is transfer in cone container. Discharge the material in IPC or any other hopper, with help of butterfly valve which is provided at discharge of cone type container.

Special Features

GMP point of view machine provided with S.S. Cladding base & S.S. Guards / Cover. No exposed painted surface. Hydraulic power pack is also covered with SS 304 cover.

Very less material transfer time making the next operation earlier & save time and dust free system save environment of working area. The system can be operate by single operator.

Contact parts SS304 provided as a standard. SS 316 / SS 316 L can be provided on demand.

Fluid Bed Dryer

Two Piece GMP Model

The capacity ranging from 10 / 30 / 60 / 120 / 150 / 200 / 250 / 300 / 500 Kgs., with steam heating / electrical heating & thermal heating facility.

0 notes

Link

For Ointment - Cream - Lotion - Paste etc. Manufacturing With Double Stirrer, Scrapper & Centrally Located High Speed Emulsifier

Special Feature

• Range of models to suit gross volume 60, 100, 140, 200, 350, 600, 1000, 1500 & 2500 Liters for OINTMENT - CREAM - LOTION - PASTE - TOOTH PASTE. • All contact parts are made out of S.S.304 quality material. (SS316 provided on demand on extra cost) • Compact design requires comparatively smaller floor space. • Lowering and lifting movement achieved through motorized drive in 140 & 200 liters model & hydraulic lifting system from 350 liters to 2500 liters size models. (In 60 & 100 liters models product container moving up & down manually. Motorised system can be provided on demand on extra cost, if required.) In all other bigger size models product container remain fixed and mixing drives comes up and down by means of mechanical or hydraulic system. • Castore wheel mounted product container for the ease of mobility. (This facility available from 60 liters to 350 liters model only.) • Container with fixed legs above 350 Liters model. Hence no facility of mobility of container. • A high-speed emulsifier (Homoginizer) will be provided at the center axis, in 140 liters model and above capacity model only. (It can be interchangeable with disperser & necessary assembly provided with m/c) • In-Line Homoginizer also provided on demand, if required. • Double stirrer & SS scraper with PTFE blades for better mixing of the material. ( In 140 Liters & above model only )

• Single stirrer with scrapper in 60 & 100 Liters model. • Planetory motion of the stirrer ( beaters ) enables faster and better mixing of the material at a considerable lesser time. • As stirrer is a top driven and sealing doesn't comes in contact with product, there isn't any black particle contamination problem. • Water / steam circulation jacket for mixing bowl, to heat or cool the mix during operation in OINTMENT MIXER only. (Water jacket recommended only in 60 to 350 liters model. Steam heating recommended in 600 litres to onward all models. Jacket also made out of mild steel in Standard Model & SS304 in GMP Model.) • All non contact parts (general structure) made out of mild steel and claded with SS304 or chrome plated or made out of SS304 in GMP Model. Contact parts are polished to the mirror finished and non contact parts are polished to the matt finished in GMP Model. All safety guards & covers made out of SS304 material in GMP model & made out of mild steel & painted in standard model. • General structure & all non contact parts are made out of Mild Steel & same wil painted in Standard Model. • Fixed type product container in 600 litres and above capacity models. • Heater with temperature controller for heating facility. (For 60 / 100 / 200 / 350 litres OINTMENT MIXER only) • 100 % utilisation of machine can be possible due to facility of change of extra product container. (In 60 to 350 litres model only) • Vacuum facility provided on demand for de airation during mixing in Gel product. (For OINTMENT MIXER only) • Insulation will be provided on jacket of container. (For OINTMENT MIXER only ) as a optional facility. • Material discharge from bottom. Flush bottom valve provided for material discharge in 350 litres and above model only. (For OINTMENT MIXER only) • M/C provided with Light glass, Sight glass , material inlet, air suction valve for vacuum, CIP port facility. (For OINTMENT MIXER only) • All connection of valve, light glass, sight glass will be triclover ended. • Sampling port provided in 600 litres & above model. • Flush bottom type valve in 600 litres & above model. • All moving parts are enclosed with safety guards.

Optional

• SS316 product contact parts instead of SS304. • Vacuum system for deairation during mixing. (For gel products) • Variable speed drive for main agitators motor and emulsifier motor. • Vacuum Pump Set. • Flameproof model. • "PLC" based operating panel for automation. • Hydraulic lifting system in 60 to 200 litres model, instead of mechanical lifting system.

Application

Ideal for mixing of Pharmaceutical powders, ointments, creams, lotions, pastes, tooth paste, cosmetics, food and confectioneries, rubber and rubber compound, colours and pigments, PVC & plastic material, ceramics, pesticides, insecticides, adhesives, metal powder, resins etc. etc.

0 notes