3E Rapid Prototyping (3ERP) is an ISO9001-2015 certified manufacturer, built on the philosophy of 3Es, namely Excellent, Efficient and Economic, along with a dedicated team and the latest techniques to ensure your project runs successfully.

Don't wanna be here? Send us removal request.

Text

Learn the Primary Advantages of Plastic Injection Molding

As the name suggests, in creating desired objects plastic injection molding uses plastics and special molds.

At first, you should keep in mind that in producing tons of parts in a short period in a cost-effective manner this method is very suitable. For precision, there is the use of a special mold and a hot barrel in the process. Today, in the market you can find numerous products that are made using the same process. Here we will discuss some of the main advantages of this process.

Footwear Making

In making shoes of different sizes and shapes there is the use of this technique. So, this is one other huge industry that gets benefitted from this injection molding process.

In Making of Toys

Today, in making different types of toys, such as action figures and collector toys plastic injection molding is used.

Making of Medical Equipment

For making medical tools and equipment like jars, vials, and cups this technique is quite ideal. This technology is very much popular across the globe because of this great reason.

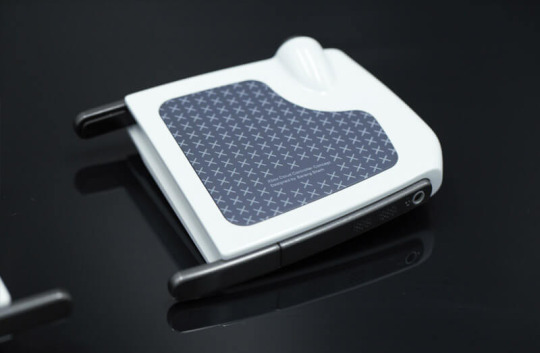

Quite Suitable for making Electronic Parts

Manufacturers have been using it to make different types of electronic components like the type of plastic used in injection molding that doesn't expand or absorb humidity. So, on the parts, the exposure to heat doesn't have any kind of negative impact.

Drinks and Food

You will find plastic utensils, such as plates, forks, and spoons almost in every food outlet and restaurant.

Skills need for Injection Molding

Strong skills are needed for injection molding China. A sample is sent to the inspection team before starting the production. It goes through the final stage for mass level production once it passes the inspection stage. After making all the units, they are packed in cartons, and details are printed on the cartons.

Experts have to use the right type of toolsets, such as pliers and blades As far as size, shape, and precision is concerned. Hence, these are some of the primary advantages of plastic injection molding. You may want to give a go to this technology if you want to enjoy these advantages.

#Injection Molding#Plastic Injection Molding#Plastic Injection Molding Services#Injection Molding Process#Plastic Injection Mold

1 note

·

View note

Text

How to Choose a Reliable CNC Shop for CNC Machining Parts

How to Choose a Reliable CNC Shop for CNC Machining Parts

In today’s modern world, every industry uses them as a crucial part. CNC machining has lots of significance in many industries. You may need a regular supply of the parts, or you may want one-off parts manufactured. To get the necessary parts you have options like opting for the best custom CNC machining, investing in your CNC turning & milling machine. Below are provided some tips on how to get…

View On WordPress

1 note

·

View note

Text

Process of Plastic Injection Molding

Plastic Injection Molding Industry

All over the world, the process of plastic injection molding is used for making plastic mold components of toys and medical equipment. Using the same process in the automobile and aerospace industry millions of components are made. If you have a look around you then you will see hundreds of things that are made with plastic molding.

Nowadays, to reduce the lead time, manufacturers work with different tooling partners.

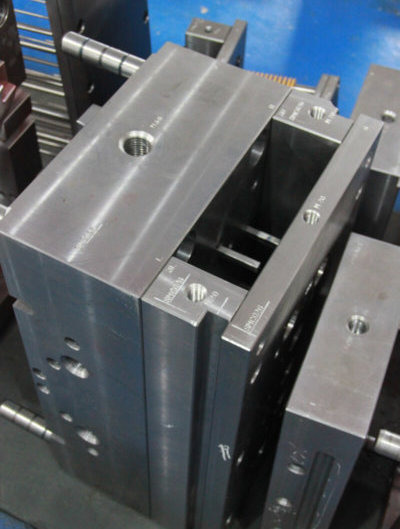

Working of the Process

The process of injection molding s involves melting plastic in the machine. Afterward, the melted plastic with high pressure is put into a mold. Then in the mold, the plastic is solidified and then released through the opening. This technique is very helpful in producing different objects.

Before the production starts, by an experienced designer or engineer, the components are carefully designed. Then an experienced professional prepares the mold in the coming phase.

After that, the plastic is put into the molding machine. Throughout the plastic injection mold making process, the machine stays closed.

Usually, in the form of pellets or granules, the plastic is injected into the mold. The machine to liquefy the plastic keeps on heating the plastic. When the process is towards the end the components are pushed through ejectors out of the mold and in the form of a finished product. This is the working of the whole process.

Reducing the Costs of Injection Molding

For better results, you need to select an automated mode change. So, as far as the production quantity goes this particular thing will reduce the changeover time and make the manufacturer more flexible.

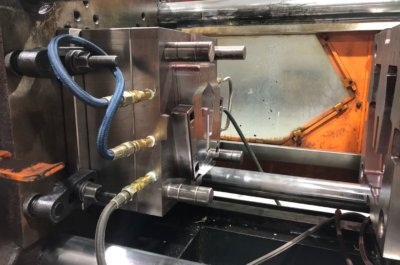

Magnetic Clamping Systems

It is very much possible to speed up the process of injection molding with the help of magnetic clamping systems.

Today from a variety of magnetic clamping solutions you can select your desired one. As one machine cannot meet the needs of mold supplier, you will find that there is a lot of variety available in the market.

Tips on Speeding up the Process

You can speed up the injection molding process by reducing the cooling time, injection time, or resetting.

2 notes

·

View notes

Text

Process of Plastic Injection Molding

Process of Plastic Injection Molding

Plastic Injection Molding Industry All over the world, the process of plastic injection molding is used for making plastic mold components of toys and medical equipment. Using the same process in the automobile and aerospace industry millions of components are made. If you have a look around you then you will see hundreds of things that are made with plastic molding. Nowadays, to reduce the…

View On WordPress

1 note

·

View note

Text

Benefits of Plastic Injection Molding

Benefits of Plastic Injection Molding

Plastic injection molding is one of the best production methods in terms of versatility. This is the particular reason why most manufacturers use it to make parts. In this article, we will learn the benefits of using plastic molding. Use of Multiple Types of Plastic One more major benefit of this technique is that at the same time it allows the use of different types of plastic. The use of…

View On WordPress

#Injection Molding China#Injection Molding Process#Plastic Injection Mold#Plastic Injection Molding#Plastic Injection Molding Services

1 note

·

View note

Text

The Bright Future of Plastic Injection Molding

Plastic injection mold making is a state-of-the-art process in which the manufacturers pour melted plastic into a specially designed mold so that they can make different types of signs, plaques, and nameplates. It is taken out of the mold as soon as the plastic cools down and it becomes solid and is used to make plastic parts based on the project needs.

The Future of the Technology

As numerous household products are made using the same technology so you can have a better idea of the future of technology. It constitutes everything that is made of plastic in our homes, such as water tanks, plastic utensils, washing machines, and computer equipment. Therefore, to get the most out of plastic injection molding down the road we can use our imagination and creativity.

Plastic injection molding focuses on the molds and their parts as time passes. Generally, high-end molds are made of strong metals, high-quality carbon fiber, and epoxy. The main purpose of using these metals is to enjoy a higher number of cycles and boost the cooling duration.

As far as we observe the future of injection molding, we can get a good idea of it by considering the 3D printers. Based on a digital model this process allows manufacturers and mold supplier to produce 3D solid objects in any shape that you can think of. The cost of component making has been significantly reduced by the combo of 3D printers and injection molding.

With corn seed makers many experts have started having conversations. Instead of conventional petroleum plastic, they want to use corn-based plastic. Today, there is the use of biodegradable material on a small scale. In the coming future, we will see many uses of the material. Therefore, using this technology we will be able to see a wide spectrum of products made.

So into the future of plastic injection molding and mold making supplies, this was an insight. Hopefully, in a few decades if not years we will be able to see the wonders of this technology. Hence we can say that this process has helped us make numerous products in a cost-effective manner.

2 notes

·

View notes

Text

The Bright Future of Plastic Injection Molding

The Bright Future of Plastic Injection Molding

Plastic injection mold making is a state-of-the-art process in which the manufacturers pour melted plastic into a specially designed mold so that they can make different types of signs, plaques, and nameplates. It is taken out of the mold as soon as the plastic cools down and it becomes solid and is used to make plastic parts based on the project needs. The Future of the Technology As numerous…

View On WordPress

2 notes

·

View notes

Text

Know Why the Use of the Injection Molding Technique is Beneficial

Know Why the Use of the Injection Molding Technique is Beneficial

Injection molding is a manufacturing process. In this particular process, in a special mold, molten material is injected. If you want to fabricate plastic parts then this technique is ideal for you. Irrespective of the size, complexity, or application of the final product you can perform the molding. This process is quite simple and in this process, the plastic is melted and then injected using…

View On WordPress

#Injection Molding China#Injection Molding Process#Plastic Injection Molding#Plastic Injection Molding Services

4 notes

·

View notes

Text

Plastic Injection Molding has been a Boon for Parts Manufacturing

For products and producing parts, Plastic injection molding is an extremely versatile method. As it has multiple benefits over other plastic injection mold making methods, it is one of the preferred methods for manufacturing parts.

Using injection molding for manufacturing plastic components and parts has four major benefits.

High Efficiency

As compared to other methods of molding, the actual molding process is very fast once the injection molds have been designed to the presses pre-programmed and the specifications of the customer. Process of Plastic injection molding allows more parts to be manufactured from a single mold and this hardly takes time. Plastic injection molding becomes more efficient and cost-effective due to the high production output rate. Typically, parts with more consistent quality are manufactured by hot-runner ejection making plastic mold systems and this is done with faster cycle times. Changing colors is not that easy. Some heat-sensitive polymers can’t be accommodated by hot runners.

Complex Geometry and Thorough Characteristics

the injection molds are applied with extremes of pressure. Against the mold compared to any other molding process, the plastic within the molds is pressed harder as a result. It is possible to add a large number of details into the design of the part because of this excessively high pressure.

Furthermore, complex and tough shapes can easily be manufactured and designed due to high pressure during the molding process. Otherwise, it would have been too expensive and complicated to manufacture.

Simultaneous Use of Multiple Plastic Types

The facility of simultaneous use of various types of plastic is one of the crucial benefits of using plastic injection molding for manufacturing parts. With the help of co-injection molding, this can be done which about using a specific type of plastic, takes away the worry.

Improved Strength

It is possible to use fillers in the injection molds in plastic injection molding. These fillers, while being molded, minimizes the plastic density and after it has been molded, it assists in adding greater strength to the part. Plastic injection with plastic mold maker has an option that other molding processes do not offer in fields where parts need to be durable and strong.

2 notes

·

View notes

Text

Have Some Details about Prototype Injection Molding on Your Plate

Ensuring that the product is pleasing aesthetically, functions efficiently, and is designed soundly is one of the major issues facing anyone who wants to get a product to market - whether they are established businesses, entrepreneurs, or inventors. A crucial step towards a final solution is prototype plastic injection molding and there are various ways to approach this issue.

Firstly, prototype production is crucial as the costs to manufacture a prototype are so much less as compared to the large-scale production costs. Simply stated, right before you produce a million copies, you want to ensure you get the product. To do this, for replacing the effect of holding a virtually identical working prototype in your hand, there is simply no way.

Injection-molded prototypes are the ideal solution

For mass production, finished products that are intended are typically manufactured in very large quantities. As a consequence, to make sure that the engineering design is sound, it is extremely prudent that the product functions as expected in its final production material and the aesthetics are satisfactory. You can’t overstate the significance of this step.

Producing a few hundred to a thousand injection molded prototypes for use in consumer research and testing before mass production is the way to execute it properly. The prototype molding services make use of this method. This requires an investment in a process for conducting research and an injection mold tool ahead of time. To safeguard your even larger investment down the road and reduce risk means making a large up-front investment. After and during mass production, executing a thorough plan at the beginning of the process will increase the product success likelihood.

As you might guess, through injection molding prototypes, engineering, and design are project-dependent on the amount of time the process takes from the introduction of the idea. Very little time as few weeks can be taken for the beginning stages through CNC cut and printed prototypes. Several months are typically taken by the injection molding procedure, but the complexity of the product decides that too.

2 notes

·

View notes

Text

Productivity is Significantly Affected by Mold Design

Productivity is Significantly Affected by Mold Design

In the design of a mold, the significance of mold design of a tool on productivity is often overlooked. Existing where the mold maker must work with the mold builder, several areas in the mold design in optimize the mold productivity. Saleable parts out of the press per hour are a good standard for mold productivity. The critical aspects of saleable parts per hour are Part quality and Cycle…

View On WordPress

2 notes

·

View notes

Text

Some Common Daily items Produced with Injection Molding

Some Common Daily items Produced with Injection Molding

You have many processes to pick from; based on the kind of part and application you want to produce while manufacturing a product needing molded plastic parts. injection molding is one of the most demanded methods to achieve cost-effective and high-quality plastic parts. For manufacturing parts in huge volumes, Injection molding is a good process of manufacturing. A hollow mold is injected with…

View On WordPress

2 notes

·

View notes

Text

Need of Using the Injection Molding Technique

Injection molding is a type of manufacturing process that is used to inject molten material. You can inject this molten material into any mold. For the fabrication purposes of plastic parts, it is widely used. The process is quite simple where the plastic is converted into the molten state and then with the help of injection it is injected into a mold. For this purpose, the raw materials required are an injection machine, a mold, and plastic raw material which help in the execution of the work.

Below are the benefits of injection molding:

Strength and efficiency: In the injection mold making the mold making machine allows the addition of fillers. This results in the reduction of plastic material density and the parts generated come out to be stronger. With time the efficiency of the system also increases as to make a mold and melt the plastic time is taken only in the beginning. After that, at the same time, the mold making supplies can produce several products as the time taken for the making of a product is very less and during a day the same mold can be used many times.

Automation: The whole process of automation allows for the making of standard quality products. In supervising and designing the product molds computer-aided design (CAD) and computer aided manufacturing (CAM) go a long way. In the formation of design not only does the automation brings suitability, but it also allows low manufacturing costs as the robots and machines carry out the whole process of processing and finishing the products.

Perfection and addition of details: With the help of plastic injection mold making more details can be added to the product as against the mold the molten plastic is subjected to high pressure. With the mold, this provides better contact and the product manufactured is close to the mold.

In comparison with other techniques in the market, the benefits of the Injection molding technique are what make it score more points, and hence for the plastic injection molding technique more and more companies opt.

2 notes

·

View notes

Text

Everything You Need To Know About the Injection Molding Process

This is the injection molding process. When it was designed in the 1930s, this process began and produces 100% American-made products; it was the base of metal dies casting designs. Today including alternative methods toward manufacturing methods the benefits of Injection molding of plastic injection mold are many. Since plastic molding scraps can be recycled and melted, Minimal losses of scrap pieces can be done. Poured, plastic resins of molten metal can be the difference between metal casting and injection molding can be but be injected by force.

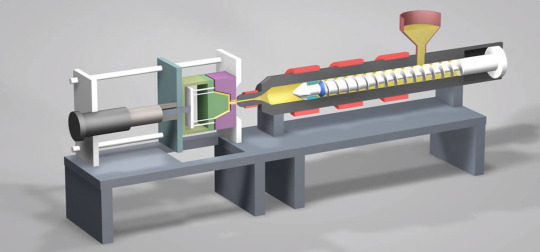

The injection molding machine consists of two basic elements, but it may be simple. The two are the clamping unit and injection unit. On to how easy this process is, it is pretty easy to catch.

With a mold, this process begins which is clamped under pressure to the cooling and injection process. Into a machine, the resins are fed and into an injection barrel, it falls where they are heated to their melting point. Then rammed or screwed into the mold by injection molding process.

Next, the dwelling phase comes something. The dwelling phase is when molten plastic is forced down to fill all cavities of the mold within the mold either by hydraulics strength or mechanically. To cool, the plastic is allowed inside the mold.

By separating the two pieces in half, the mold is opened. Out in the final step, Injection Pins force the plastic. Extraneous bits called runners are there in the product. These runners are simply recycled and trimmed. With some cycle times ranging from between 10 and 100 seconds, the whole plastic injection molding services is cyclical.

On the plastic molding company’s policy and cooling time, that all depends. This is interesting; being factored into the melting equation, every type of resin has a shrinkage value. The product will be the wrong shape or size if the equation is wrong.

That is when there is an uneven surface a temp is set too high on the plastic. Also, incomplete mold filling can be caused. With no imports, Quality injection molding is done, and can be quite expensive to have the plastic molds themselves. To cut down the cost, Buying in Bulk is away.

2 notes

·

View notes

Text

Mold Making and Casting Difference Marked

For reproducing a sculpture, artwork, or almost anything else molds and casts have emerged as popular and accepted art forms. However, it is possible to recreate just about anything in its entirety with the use of basic techniques of mold making and casting.

Often a layperson gets confused between the two terms of mold making and casting. Below is a provided explanation of the methods that will help you to understand them:

Mold making: A mold is a negative or reverse impression of an object or sculpture. Right down to every fold and undercut it accurately captures the surface detail of the object.

Different materials such as moulage, clay, plaster, thermoset-mold rubber, polyurethane rubber, wax, silicone rubber, liquid latex rubber, and more molds can be prepared. Plaster bandages are generally used to make supportive shell molds and yield rough form molds. As alginate is skin-safe it is used in making body molds.

Similarly, depending on the type of object, mold making material is used. For the proficiency of the artist, there are various techniques of making a mold - ranging from simple to complex. In two basic categories - block mold and blanket mold the techniques are divided. On the object, the material is usually poured or brushed to form the mold. In making a mold Injection and slush are other methods. Mold makers are required to make molds.

Casting: After the mold is ready this is the subsequent step. Of an object or sculpture, this is the actual method of reproducing identical copies. However, to work on it requires a negative impression in the form of a mold.

To form the final cast reproduction of the object the casting material is usually poured into or onto the mold. It is quite possible to make multiple cast reproductions from the same mold but it all depends on the type of mold. Mold maker china are very popular.

To a wide variety of materials such as plaster, liquid latex rubber, epoxy resin, gypsum, polyester resin, polyurethane resin, gypsum, urethane rubber, molten metals, and more casting is open. Alternatively, to duplicate the look and feel of real metal cold casting powders can be mixed with resin.

2 notes

·

View notes

Text

Know the Advantages of Plastic Injection Molding

Plastic injection molding creates objects with the use of plastics and special molds. With the emergence of this technique, many industries have started earning billions of dollars. Because of this reason, it's considered on the list of best methods. In this particular article, we will focus on the advantages of this technique.

First of all, one thing you should always keep in your mind is in a short period and a cost-effective manner, this injection molding is suitable for producing tons of parts. Let’s discuss some of the main advantages of this process.

Used in Drinks and Food

You can find plastic utensils, such as spoons, forks, and plates in almost every food outlet and restaurant. By using plastic injection molding all of these utensils are made.

Suitable for Making Toys

Today, in making different types of toys, such as action figures and collectors there is the use of plastic injection molding technique.

Making of Medical Equipment

For making medical tools and equipment like cups, jars, and vials this technique is ideal. This is another great reason for the popularity of this injection molding technology across the globe.

Best for making Electronic Parts

Manufacturers have been this technique to make different types of electronic components because the type of plastic injection mold used in injection molding doesn't expand or absorb humidity. So, on the part, the exposure to heat doesn't have any kind of negative impact.

Skills Needed for Injection Molding

Strong skills are required for injection molding. A sample is sent to the inspection team before the production starts. Once it passes the inspection stage, for mass level production it goes through the final stage. They are packed in cartons and details are printed on the cartons once all the units have been made.

The entire process relies on the skills of the employees that operate the machines. It is also important to take safety measures. The product should be investigated if there is any type of defect to find out why it got deformed.

2 notes

·

View notes

Text

The Injection Molding Evolution in Plastic Industry

Plastic injection molding, to those less familiar, may be defined as a manufacturing process for the creation of products from the plastic element. The plastic loses the heat and solidifies to the configuration of the mold cavity after it is forced into a mold cavity pushed into a heated barrel and mixed.

Six years hence, the first screw injection machine was constructed by American inventor James Watson Hendry, which provided greater control over the quality of articles produced and the speed of injection.

Ranging from buttons and combs to an array of technological products for several industries including toys, medical, automotive, consumer products, aerospace, etc., the industry has evolved and started manufacturing a huge range of plastic goods during the ensuing decades. injection molding China is the most popular although there are various methods used in the manufacture of plastic goods.

Unlike metals, Plastic is lightweight and durable. Plastic is resistant to wearing, corrosion, and tearing. Some striking advantages of this technique are no to finish parts after molding, repeatable high tolerances, high production capability, minimum scrap losses, and low labor costs. Of course, its share of demerits is there in this technique - the process entails the need to design mouldable parts, potentially high operational costs, and high investment in equipment.

However, the rise of the plastic molding industry has occurred due to the steadily increasing demand for plastic products. Today, to those used in critical industry sectors like building construction and aviation, you would find the use of plastic from products of daily use - amongst others.

The most common method of plastic part manufacturing is plastic injection molding. For mass producing of the same product, it is ideal. Today in almost all industrial sectors, we need machines, and the demands for plastic products are growing at a rapid pace.

The latter is called a CNC plastic machine while the earlier versions are known just like plastic injection machines. In solving some of the problems associated, CNC plastic machine has succeeded with conventional molding processes.

1 note

·

View note