#thermal printer advantages and disadvantages

Text

Thermal paper and Plain paper is differences are there?

What is thermal paper roll?

Thermal paper rolls are special printing media that react chemically when heated to produce images or text. Thermal paper is mainly used in thermal printers, which do not require the use of ink or ribbon. Common thermal paper applications include receipts, labels, tickets, and fax paper.

What is plain paper?

Ordinary paper is the most common paper in our daily lives and is widely used for writing, printing, painting, etc. Regular paper often requires ink, toner, or other printing supplies to render text and images. There are many types of paper, including printing paper, copy paper, notebook paper, etc.

The main differences between thermal paper rolls and ordinary paper?

Printing Principle

Thermal paper: The thermal paper is heated through the thermal print head, causing the chemical coating on the thermal paper to react to form images or text.

Plain paper: Images or text are formed on the surface of the paper through external substances such as ink or toner.

Consumables Requirements

Thermal paper: No ink or ribbon required, lower printing cost, suitable for mass printing or temporary recording.

Plain paper: requires ink, toner or ribbon, and the long-term use cost is higher.

Service life

Thermal paper: Due to the characteristics of the chemical coating, the images and text on the thermal paper are easily affected by light, heat and friction, and the storage time is relatively short, usually starting after 1-3 years Blackened, yellowed.

Plain paper: Content on plain paper can last for years, even decades, if printed with high-quality ink or toner.

Plication Scenario

Thermal Paper: Mostly used in restaurants, retail stores, banks, casinos, etc. where fast printing and instant viewing are required.

Plain paper: widely used in scenarios that require long-term storage and frequent use such as office, study, and file preservation.

Environmental protection and economy

Thermal paper: The printing process is more environmentally friendly (because no ink and toner are required), and Pony Packaging-thermal paper does not contain BPA, and because it uses 100% lint-free paper, it can reduce printer jam waste, Images printed on thermal paper are displayed clearly.

Plain paper: Ink and toner are required during the printing process, which consumes more resources, but the paper itself is easier to recover and recycle.

How to choose the appropriate paper?

The choice of paper type mainly depends on the specific use needs and environment.

If you need fast, low-cost printing** and the content is not stored for a long time, such as receipt paper, express delivery slips, thermal labels, etc., Pony Packaging-thermal paper roll is a good choice.

If you need to keep documents for a long time**, such as contracts, reports, study materials, etc., ordinary paper is undoubtedly a better choice. With high-quality printing supplies, the content can be guaranteed to be clear and durable.

Conclusion

Thermal paper rolls and ordinary paper have their own advantages and disadvantages. Their differences are mainly reflected in printing principles, consumable requirements, service life, application scenarios, environmental protection and economy. Understanding these differences can help you make smarter choices in different scenarios, improve work efficiency, and save costs.

Whether you are an individual or a business, choosing the right paper can not only meet actual needs, but also save resources and protect the environment to a certain extent. I hope this article can provide you with useful information to help you better understand and use thermal paper rolls and regular paper.

0 notes

Text

Advantages & Disadvantages of Inkjet Dyes

Various segments of the business and home market are embracing multi-color inkjet technology. The packaging, publication, and specialty printing industries have a significant and thriving inkjet market. Inkjet Dyes are highly concentrated colorants that are designed to meet the ever-growing needs of today’s inkjet markets.

Many different dyes can be used for Inkjet Inks, including direct, reactive, acid, and pigment dyes. Inkjet dyes come in both powder and liquid forms. To produce inkjet printing, extensive purification and filtration processes are used, and the physicochemical properties of the printing ink have a great impact on the quality.

Dye inks are designed by dissolving the liquid-colored dyes into a fluid carrier which makes the dyes easy to apply. Inkjet dyes are uniformly saturated into the paper, so they reflect light very evenly, as printing is a highly precise process, and dyes need to be more stable and have superior colors with physical properties that are outstanding.

They provide a wide range of colors and possess high-purity dyes that are found to be low in chlorides and designed to address all standard criteria for the inkjet industry segment.

However, Inkjet dyes have some of their pros and cons and if you are curious to know what they are, then the article is for you. Keep reading this further to know more about the advantages & disadvantages of Inkjet Dyes.

Advantages of Inkjet Dyes

The dye-based ink is usually very inexpensive, but the price of the ink varies depending on various factors, such as the manufacturing cost. They are widely used to print better, finest, and smoother details using a higher resolution. Inkjets have the advantage of practically no warm-up time and often lower costs as compared to technologies like thermal wax, dye sublimation, and laser printing.

Inkjet dyes have following several advantages, some of them listed below:

Inkjet dyes are more stable and soluble.

They offer a wide range of colors.

Best suited for providing bright intense colors.

Come up with a wide selection.

Disadvantages of Inkjet Dyes

Unlike most dyes, when dyes are exposed to light or ultraviolet light, the molecules of the dyes get broken and lose their color, which causes the prints to lose their original colors over time. If the ink is set to dry very fast on paper, the drying time of the ink is directly correlated with that of the solvent on the paper (often leading to the untimely nozzle closing).

The following are some of the disadvantages of using inkjet dyes in printers as experienced by users:

It causes more damage to attacks such as sunlight, ozone and ultraviolet rays.

Best suited for low-volume printing.

Low tendency stabilization.

The low thickness of the print.

They are the best fit for high-volume printing

Conclusion

Thus, Inkjet dyes have some of their own advantages and disadvantages, although they are widely used in various industrial applications. Inkjet dyes manufacturers prepare a variety of industrial applications ranging from textiles, 3-D printing, ceramics, and signage to biomedical applications and conductive circuitry.

0 notes

Text

Thermal Paper Rolls

Thermal Paper Rolls: The Future of Receipts and PrintingThermal paper rolls have revolutionized the way receipts and other documents are printed. These paper rolls are coated with a special chemical that changes color when exposed to heat, allowing for the creation of high-quality prints without the need for ink or toner. The result is a more efficient and cost-effective printing process that has become increasingly popular in recent years.Thermal paper rolls are used in a variety of applications, from cash registers and credit card machines to parking meters and label printers. They are particularly useful in environments where fast and accurate printing is essential, such as in retail stores, restaurants, and hospitals. Thermal paper rolls are also environmentally friendly, as they do not require the use of ink cartridges or toner cartridges that can harm the environment.One of the key advantages of thermal paper rolls is their speed. Because the printing process is based on heat rather than ink, thermal printers can produce prints at a much faster rate than traditional printers. This is particularly important in busy retail environments, where speed and accuracy are essential for customer satisfaction.Another advantage of thermal paper rolls is their durability. Unlike traditional paper, thermal paper is less susceptible to fading and smudging over time, making it ideal for printing documents that need to be preserved for long periods of time. This is particularly important for businesses that need to keep detailed records of transactions, such as financial institutions and government agencies.However, there are also some disadvantages to thermal paper rolls that should be taken into account. For example, the quality of the print can be affected by factors such as humidity, light, and heat, which can cause the paper to darken or fade over time. In addition, thermal paper rolls are not suitable for printing images or graphics, as they are limited to black-and-white text.Despite these limitations, thermal paper rolls continue to be a popular choice for businesses looking for an efficient and cost-effective way to print receipts and other documents. As technology continues to evolve, it is likely that thermal printing will become even more widespread, providing businesses with a reliable and sustainable way to print documents for years to come.#To know about more visit our website:https://internationalpaymentsolutions.ca/product-tag/thermal-paper-rolls/

1 note

·

View note

Text

PART DECORATION FOR PLASTIC INJECTION MOLDING

Many plastic injection molded parts need to have some form of decoration applied to them after being manufactured. Possible reasons for decorating or marking parts include identification, tracking, branding, notices, warnings, instructions, as a product attribute, or otherwise. There are some standard methods of decorating plastic parts, and each has certain advantages and considerations, depending on the part application, the decorating purpose, and the resin being used.

PAD PRINTING

Historically, one of the more popular methods for decorating plastic parts has been with pad printing. There are three different types of pad printing machines: open inkwell, closed ink cup, and rotary gravure, which is used for printing 360 degrees on a part. Machines have a printing plate or a cliché, which commonly are made out of steel for durability. The artwork to be printed onto the parts is etched into the printing plate.

As the name suggests, the machines have transfer pads that come in a few different shapes and that are made out of silicone rubber with various hardness or shore levels. Pad life ranges from 10,000 to 100,000 cycles with an average of about 50,000.

The process consists of the pad picking up ink in the etched image on the cliché and placing it onto the part. Pad printing uses a type of solvent-based ink specifically designed for this purpose. This type of decoration also requires the fabrication of nesting fixtures to hold the parts in place during the printing process.

HEAT TRANSFER

A newer and usually more effective method of part decoration is thermal or heat transfer. With this process, the image is printed on a polyester film, which is coated with an adhesive so the image will stick to the part. Rolls of this film with the digitally printed images are placed on the printing machine’s reels, which index forward to print successive parts. Fixtures to hold parts are used here, as they are in pad printing. Additionally, a silicone decorating head or pad applies heat and pressure to print the transfer image onto the part.

Some advantages of heat transfer include the ability to create an image with four colors plus white in as high as 1200 dpi. In addition, there is no drying or curing time with decorating plastic parts, as there is with pad printing. Further, heat transfer decorations generally are tougher than pad printing and can be dishwasher safe.

HOT STAMP

Another common technique used to decorate plastic injection molded parts is hot stamping. A hot stamp machine transfers an image with pre-dried ink to a part with a die, again using heat and pressure and a fixture to hold the part, as with the previous methods.

One main advantage of hot stamping is the ability to apply a metallic foil or embossing to a plastic part. If you’re reading this article on a desktop computer, chances are the monitor in front of you has a logo that has been hot stamped on it. It also is a relatively clean process, compared to the wet ink used in pad printing.

LASER MARKING

Another method for decorating injection molded parts is by utilizing a laser marking system. This approach includes laser marking, laser engraving, and laser etching. Laser marking (or foaming) changes the color of the part where the text or graphic is, while the surface stays relatively unchanged. Alternatively, laser engraving removes some of the surface material, whereas laser etching melts the surface resin and creates a raised mark.

Of course, laser marking, engraving and etching all require a laser decorating machine. Additionally, fixtures to hold the parts usually are required, as with other decorating methods, although some fixtureless laser decorating systems have been developed. Some advantages of laser decorating include less wear and tear on the decorating equipment, it’s a precise and repeatable process, and it provides the ability to decorate some hard-to-reach part areas. Due to these benefits, industries like medical, automotive and aerospace often utilize the process.

IN-MOLD DECORATION

The method of in-mold decoration involves placing a pre-printed plastic film or appliqué in an injection mold before the part is molded, and the graphic then adheres to the part after it forms in the mold’s cavity. In-mold decoration requires a uniquely designed and built plastic injection mold and a carrier film feeder. The film can be manually placed into the mold between each cycle, but that greatly increases the manufacturing time and labor costs associated with the parts. However, even with a feeder, parts requiring in-mold decoration generally tend to be more expensive than other decorated parts, due to the specialized design, tooling and manufacturing required.

INKJET DECORATION

Inkjet printing on plastics is a relatively newer process, and it involves digitally printing a graphic onto a part. The system essentially is the same as inkjet printers for paper, with which most of us are familiar, although it uses a different type of ink. These machines typically use either conventional or LED lamps, and the process eliminates labels, films, printing plates, clichés or screens, as required with other decorating methods, although they do require a printhead and ink. Historically, this kind of decorating is somewhat slower and more costly than other forms, although advances are being made.

SCREEN PRINTING

Most people are familiar with screen printing in the context of t-shirts, and this also can be referred to as silk screening. Screen printing can be used for parts with flat or cylindrical surfaces but is not recommended for parts with complex curves and shapes. One advantage of screen printing is that it can print metallic graphics onto parts, which some other methods cannot do. Although providing the option of printing with multiple colors, a separate screen is needed for each separate hue, which increases cost and decorating time. The surface to be decorated needs to be prepared prior to printing, too.

PAINTING

When injection molding a part cannot achieve the desired texture, finish or color, painting the parts sometimes is utilized as a secondary operation. This approach can include spray painting and powder coating. As most injection molders do not perform painting as a finishing operation, the parts will need to go to a secondary provider, which often results in increased costs.

PLATING

When looking for a metal finish on an injection molded part, hard chrome plating and electroless nickel plating are two commonly used options. Plating offers a decorative finish, and it provides a certain level of corrosion protection. One item to note is that any surface imperfections on the part can affect the look of the plating, so consideration needs to be given there. Additionally, few molders also perform plating services, so those two suppliers will need to coordinate their work. There also are some design and material considerations that must be taken into account.

CONCLUSION

There are many different methods of decorating a plastic injection molded part, and each has its own unique advantages and disadvantages, depending on the requirements of the project. When developing a new product with components that may need to be decorated in some way, attention should be given to the part design, the polymer being used, the decorating purpose, the part application, the governing regulations, and the cost considerations. If we can answer any questions, don’t hesitate to reach out to us.

--

Ash Brown // VP, Business Development

1 note

·

View note

Text

Why Use Injection Molding

Injection Molding is a manufacturing procedure for creating parts in huge volume. It is most normally made use of in mass-production procedures where the exact same part is being created thousands or even countless times in sequence.

Benefits of Injection Molding:

The major benefit of injection molding is the ability to range production en masse. As soon as the preliminary expenses have actually been paid the cost per unit throughout injection built production is very reduced.

Injection Molding produces low scrap prices about conventional manufacturing procedures like CNC machining which cut away significant percentages of an original plastic block or sheet. This nevertheless can be an adverse about additive production procedures like 3D printing that have even lower scrap prices. Note: waste plastic from injection molding production usually comes consistently from 4 locations: the sprue, the joggers, eviction locations, and also any type of overflow material that leaks out of the component dental caries itself (a condition called "flash").

A sprue is merely the channel that guides molten plastic from the nozzle of the injection molding equipment to the entry factor for the whole injection mold tool. It is a different part from the mold tool itself. A runner is a system of channels that meet the sprue, typically within or as part of the mold tool, that overviews the molten plastic into the part tooth cavities within the mold device. There are two major categories of runners (cold and hot) which you can review below. The gateway is the part of the channel after the runner that leads straight right into the part cavity. After an injection mold cycle (normally just seconds long) the entirety of the molten plastic will certainly cool leaving solid plastic in the sprue, joggers, entrances, part cavities themselves, as well as a little of overflow possibly on the edges of the parts (if the seal isn't 100% right).

They grind up the sprues/runners and any deny components. They include that material back right into the raw material that goes right into the injection molding press. Typically regrind material is utilized for low-grade components that don't require high efficiency residential properties.

Injection Molding is really repeatable. That is, the second part you generate is going to be almost the same to the very first one etc. This is a terrific particular when attempting to produce brand name consistency as well as part reliability in high quantity production.Injection _ molding_plastic models style and engineering company

The Downside In Injection Molding:

Up front costs often tend to be really high due to style, testing, and also tooling demands. If you are going to generate parts in high volumes you want to make sure you get the layout right the very first time.

Designing and after that prototyping the component itself to requirements

First model advancement is generally finished on a 3D printer and often in a various product (such as ABS plastic) than the final part will be built inDesigning an injection mold tool for a first manufacturing round

Typically generating 300-1000 injection molded prototypes in the manufacturing product calls for the growth of an injection mold device.

Refining any type of and all information in the injection mold device prior to mass-production in an injection mold manufacturing plant.

Disadvantages of Injection Molding:

2 of the major disadvantages to injection molding are the high tooling costs as well as big needed preparation. Tooling is nearly a project per se and just one phase of the whole injection molding procedure. Prior to you can create an injection molded part you initially have to develop and also model a component (probably by means of CNC or 3D printing), after that you have to develop and prototype a mold device that can generate reproductions of the part in quantity. And commonly after comprehensive screening in both of the aforementioned stages, you obtain to injection mold a component. As you can picture, every one of the version needed to get the device appropriate before automation needs both time and money. It is uncommon that you would certainly prototype an injection molding device. It does take place though, particularly for parts that will certainly be made in a multi-cavity tool.

What Are Some of The Considerations For Injection Molding:

Prior to you seek to produce a part through injection molding take into consideration a few of the complying with things:

Financial Considerations

Entry Cost: Preparing an item for injection molded manufacturing needs a huge first financial investment. Make sure you recognize this crucial point up front.

Production Quantity

Establish the number of components generated at which injection molding becomes one of the most inexpensive technique of production

Identify the variety of parts generated at which you expect to recover cost on your investment (take into consideration the expenses of design, screening, manufacturing, assembly, advertising, and also distribution as well as the anticipated rate point to buy). Build in a conservative margin.

Style Considerations

Part Design: You wish to design the part from day one with injection molding in mind. Streamlining geometry as well as lessening the number of parts early will certainly pay dividends down the road.

Device Design: Make sure to make the mold tool to stop issues throughout production. For a list of 10 common injection molding issues and just how to repair or prevent them read here. Take into consideration entrance locations as well as run simulations making use of moldflow software application like Solidworks Plastics.

Manufacturing Considerations

Cycle Time: Minimize cycle time in as much as it is possible. Making use of machines with hot jogger technology will help as will certainly well-thought-out tooling. Small changes can make a large difference and also reducing a couple of seconds from your cycle time can convert right into large financial savings when you're producing countless components.

Assembly: Design your component to lessen assembly. Much of the factor injection molding is done in southeast Asia is the cost of constructing basic parts throughout an injection molding run. To the extent that you can develop assembly out of the process you will certainly conserve considerable money on the expense of labor.

Designing a part that's ideal for injection molding versus one that's ideal for machining, thermal developing, or 3D printing indicates taking into account a few of the differences in between the different fabrication strategies and also identifying when your project is much better matched to one or the various other. Common parts you might intend to injection mold include joints, braces, or housings. Many customer electronic tools are made with a plastic covering (real estate) that's injection molded as well as made use of for the body of the device.

One of the most obvious advantages to injection molding is that the housing offers numerous objectives. It offers as a deal with for the end user to engage with. It additionally functions as a receptacle for the battery and also electric motor as well the location of various screw bosses that will certainly be utilized to secure the device with each other once the inner components are set up. Simply put, injection molding is extremely efficient when you need to arrange a great deal of interior parts within a real estate. As a consequence, it's a great means to minimize the variety of complete parts (" piece matter"). Of note, this component is likewise an over-molded part.

Injection molding is wonderful for this kind of high volume manufacturing due to the fact that the high first prices pay the supplier back over time with low per unit costs. For this very same factor injection molding can be a poor choice for low quantity manufacturing. Additionally of note, there are some layout restrictions if making use of injection molding.

The part has almost consistent wall surface density (which is essential in order to stay clear of issues), and the part is made with a polycarbonate material (enabling for solid plastic stock to be continuously thawed for the procedure). If you were making a get rid of a thermoset material after that injection molding would certainly be more nuanced.

Attempting to melt a thermoset plastic a 2nd time will certainly lead to shedding the material. Similarly, a get rid of varied wall thickness would certainly call for even more attention in the mold device design to make certain uniform air conditioning and also to stay clear of problems during production.

Verdict

Injection molding is an excellent modern technology for completed manufacturing on a huge scale. It is likewise useful for finalized models that are utilized for customer and/or product screening. Before this late phase in production, however, 3D printing is far more budget-friendly as well as adaptable for items in the early stages of design.

1 note

·

View note

Text

The Lazy Man's Guide to CD DVD Blu-Ray Disc Printers

All Pro Solutions is a major producer and inventor of CD, DVD, and Blu-ray duplicators and publishers. All Pro Solutions is setting the bar for the CD Duplication market by offering the most extensive variety accessible. All Pro Solutions has everything covered, from entry-level CD Duplicators and Blu-Ray printers to extremely complex and network-based, mission-important Blu-Ray DVD CD Publishers systems.

All Pro Solutions is based in South Carolina, USA, in the Charlotte metropolitan region, where all equipment, ranging from low-end automated CD DVD Duplicators to mid-range CD DVD Publishers and high-end Blu-Ray Publishers, is made.

The Apollo Series systems are PC-connected and completely automated CD DVD Blu-Ray printers or printer autoloaders (PA). The systems are available in a variety of autoloader sizes and capacities for each of the CD printers, ranging from 220 to 900-disc capacity. Inkjet CD printers or thermal DVD printers are incorporated into the systems. The systems are compatible with Windows operating systems ranging from Windows XP to the most recent Windows 10. Each integrated DVD printer is designed for industrial automation. The systems can be CD, DVD, or Blu-Ray printers; the format is irrelevant as long as the disc has a printed surface. The production software includes a label editor and enables an infinite number of tasks to be queued. Users can also configure email alerts for particular alerts.

What are the finest printing options for the face of a CD, DVD, or Blu-ray disc?

We use the most up-to-date CD, DVD, and Blu-ray disc face printing processes, such as silk screen, offset, and inkjet. Each of these processes has advantages and disadvantages depending on criteria such as cost, turnaround time, artwork setup, and quantity. Knowing which printing procedure is appropriate for you before beginning your next audio or video production will save you time and money while also ensuring that your CDs turn out exactly as you envisioned.

The most popular method for printing on duplicated discs is silk screen printing. This method is great for uneven surfaces like CDs, DVDs, and Blu-rays, as well as textile items like t-shirts and table linens. Silk screen printing, which employs the CMYK colour scheme, provides a full spectrum of colour as well as white. The artwork from your disc face is utilised to produce negative films, one for each colour used. These films are then utilised to transmit the picture to displays positioned on the press. A rubber squeegee pushes colour through onto the disc surface when the screens are inked. This procedure is then carried out for each separate colour.

Silkscreen has the advantage of being printed at 120 LPI (lines per inch) on a standard CD, DVD, or Blu-ray. Furthermore, silkscreen prints are scratch and weather-resistant, and have a faster turnaround time than offset printing. One of the constraints of silk screen printing is that it requires a minimum order of 500-1000 pieces. Furthermore, while the silk screen looks fantastic on art with solid backgrounds or colors, highly detailed prints like pictures and images appear washed out and slightly fuzzy.

Bottom Line

Whatever sort of information documentation is required, All Pro Solutions has the solution for you. We give frameworks for saving messages and office reports, programming source code, document log records, and video or clinical photographs that were taken on your computer.

Similarly, All Pro Solutions Blu-ray Disk documentation frameworks ensure that information is clear of even the least sign of damage, whether stored to satisfy legal responsibilities or protect organizational assets. All Pro Solutions Archiving and Storage solutions decrease recording costs and expedite review while also properly keeping and safeguarding essential data for a prolonged length of time, all while being fully unattached.

0 notes

Text

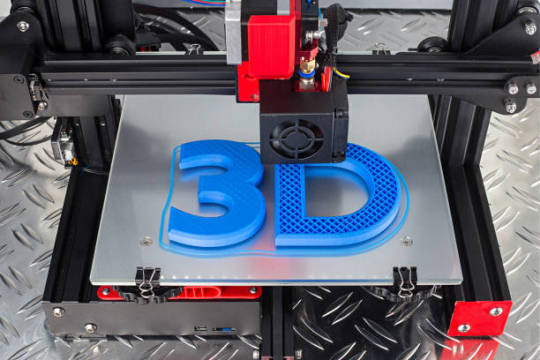

These Are The Most Important 3d Printing Materials.

The need for special materials is growing with the advancements in 3D printing. This article will provide an overview of the most essential metals, plastics, and other materials utilized in 3D printing.

Nowadays, a variety of different 3D printing materials is used in the field. Metals are also becoming more popular. Metals are utilized in additive manufacturing for the creation of manufacturing tools (rapid tooling) or as final components (rapid manufacturing), among other things. But, the majority of people in the private and industrial sectors still use plastics wood 3d printer. For many years, 3D printing on plastic was typically used for the production of models and prototypes. However, additively processed polymers are now being used to create final components and complete products.

In the shadow of metal and polymer materials,, different 3D printing materials are finding more and more new areas of use. Ceramics, concrete, glass and glass are only a few of the many alternatives. Industrial mould making is increasingly dependent on sand-based materials. A lot of foundries employ 3d printing miniatures to build their moulds. In recent times, 3D concrete printing has witnessed rapid technological advancement.

PLA melts at 70 degrees Celsius, which is lower than ABS. This makes PLA attractive for people who are not experts. Furthermore, PLA usually remains dimensionally stable during the cooling process and there is little deformation. Both private and professional users benefit from PLA's printing in a wide range of colours. PLA is not suitable for high stress components since it's not able to handle heat and heavy weights.

ABS (Acrylonitrile Butadiene Styrene)

Apart from PLA, ABS is among the most widely used plastic materials in 3D printing. This synthetic polymer is made from acrylonitrile, 1.3 butadiene and styrene. ABS's stiffness, toughness and strength are among its most significant advantages. It is thus suitable for prototyping and final product manufacturing.

While ABS is less resistant to weather than PLA, it is still more robust than PLA. In addition, ABS is relatively cheap and comes in a variety of colours. ABS can be printed at temperatures ranging from 220 to 250°C, which is a disadvantage for amateur users. It is therefore recommended to utilize a heated printing room or print bed. This will ensure that components cool in a controlled way that helps prevent deformation.

PEEK (Polyetheretherkton).

PEEK is a synthetic ether the ether. With it, it is possible to produce highly resilient components that are also temperature-resistant. It is biocompatible and resists chemicals. PEEK weighs 70% less than comparable metals, but it has similar thermal and mechanical properties. These characteristics make PEEK a very popular material in aerospace, automotive, and chemical industries. Since PEEK has a temperature for processing of 360 to 380 degC which is not suitable for use by amateurs. It is necessary to have a heated chamber for cooling the components. Find out more about metal injection molding, on our site.

HIPS (High Impact Polystyrene)

This thermoplastic polymer is produced by polymerising polybutadiene and transforming it into polysterol. HIPS is distinguished from ABS materials by its high impact strength and toughness. Probably the most important property of HIPS is its solubleness in certain chemicals, with limonene often being used in the industry. Because of this solubility, it is particularly suitable as a material to support other polymers. It is removed chemically but not mechanically. This makes it much easier to ensure that the tolerances are maintained for the final components.

0 notes

Text

These Are The Most Important 3d Printing Materials

With the growing popularity and development of 3D printing, the need for specialised materials is growing in line with the demand. This article provides an overview of major metals, plastics and other materials used in 3D printing.

Nowadays, a variety of different 3D printing materials is used in the field. Alongside plastics metals are becoming increasingly well-known. Metals are being used in additive manufacturing for the production of production tools (rapid technology) and final components (rapid production), among others. But, the majority of industrial and private users still make use of plastics wood filament. 3D plastic printing has been utilized for many years, mostly to make models and prototypes. Today, however, the final components and entire products are becoming increasingly produced through the use of additively processed polymers.

But, 3d printer materials that aren't made of polymer or metal are finding new applications. They include ceramics, sand glass, concrete, and glass. Mold making in the industrial sector is becoming more dependent on sand materials. A lot of foundries employ 3d pen ideas to create their moulds. 3D concrete printing has experienced rapid technical development over the past few years.

PLA melts at 70°C, which is lower than ABS. This makes the material interesting for users who are amateurs. Additionally, PLA usually remains dimensionally stable throughout the cooling process and has a low amount of deformation. Professional and private users both benefit from PLA's printing in a wide range of colours. However, PLA cannot be used to make components that are extremely stressed due to its inability to handle heavy loads and heat.

ABS (Acrylonitrile Butadiene Styrene)

In addition to PLA, ABS is one of the most widely used plastic materials in 3D printing. It is a synthetic polymer made from acrylonitrile, 1.3 butadiene, and styrene. One of the main advantages of ABS are its rigidity and toughness that can be made through it. It is therefore ideal for the production of the final product and prototyping.

However the weather resistance of ABS isn't particularly great however, it is still superior to the one of PLA. Furthermore, ABS is relatively cheap and comes in a variety of colours. ABS is able to be printed at temperatures ranging from 220 to 250 degrees Celsius, which is a disadvantage for amateur users. It is recommended to make use of a heated printing space or bed. This is the only way to make sure that the parts be cooled down in a controlled manner, which prevents deformation.

PEEK (Polyetheretherkton)

PEEK is a synthetic ether the ether. With it, it is possible to produce highly resilient components that are also temperature-resistant. It is biocompatible and resists chemical corrosive substances. PEEK is around 70 percent lighter than other metals with similar properties, and yet provides the same mechanical and thermal stability. These characteristics make PEEK a highly sought-after material for the chemical, automotive and aerospace industries. PEEK is not suitable for amateur use because it has a processing temperature of between 360 and 380 degrees Celsius. It also requires a heated build chamber, where the parts can cool in a controlled manner. Learn more information about thingiverse alternatives on our site.

HIPS (High Impact Polystyrene)

Polymerizing polybutadiene to polysterol creates this thermoplastic polymer. HIPS possesses a very high toughness and impact strength that makes it different from other substances like ABS. HIPS's solubility is one of its most significant properties. Limonene is a popular chemical that is used in industry. This makes it an ideal supporting material for polymers. It is removed chemically but not mechanically. This makes it much easier to ensure that the tolerances are maintained for the final components.

0 notes

Text

The Uses and Advantages of Thermal Paper Rolls

Thermal paper is not just an ordinary paper but it has many various advantages attached to it. These papers are different from the ones we use in our daily lives such as in note pads and registers. TP (Thermal paper) rolls are now extensively being used in banking and other industries all over the world. TP is a special type of paper which is coated with chemicals on the outside and this chemical helps the paper to change color when it is exposed to heat.

The surface of the thermal paper is saturated with a mixture of a dye and few chemicals. When the paper is exposed to heat the dye reacts with the acid and then the paper changes its color. There is also a protective coating on top of the TP so that it does not fade due to UV rays, water and oil and does not cause much damage to it. This layer also protects the paper from getting messed by the printer heat.

Before the extensive use of thermal paper started this paper was expensive and was used very limitedly. They have started being popular in the matter of past few years only. These thermal papers are now regularly used by banks: the receipt and the ATM receipt papers are thermal papers and also the receipt that you usually get when you are shopping elsewhere.

There are few certain advantages of TP and these are the reasons why they are extensively used. These papers have a good printing quality which means that the quality of the print is much better than on normal papers and these papers are easy to handle with all other applications used for printing as you can align on this papers easily. You will get a high definition print quality on this paper and this print is clearer and the words are easily readable.

Thermal papers are widely used in airline tickets, gas stations, hotels and retail stores and in many other industries. Thermal paper rolls are now widely available and are not expensive either, they are just about the same price as other papers but they are now regularly by many businesses for their daily needs.

The other advantage of TP rolls is that they never get stuck in the printer or get affected by the printer head's heat. If you are running an eco friendly business then you should consider recycled TP which is made from post consumer waste. This paper is not as bright as the original TP but it is low priced and of good quality.

Thermal paper rolls only has one major disadvantage to it and that is the paper contains harmful chemical which is called Bisphenol A, this chemical helps the paper to change color when it is exposed to heat. So this paper is harmful it is accidentally chewed and swallowed.

1 note

·

View note

Text

Introduction Of Heat Transfer Printing

We often see various patterns on cups, and we can even customize cups with the patterns we want. The printing process on the cup is generally heat transfer printing technology. But do you know what is the heat transfer technology? Today, let's introduce it.

What is heat transfer printing?

Heat transfer printing technology was developed by European printing technologists in the late 1960s. This process uses the sublimation principle of disperse dyes or inks, takes paper as the carrier, and transfers the patterns printed on paper to fabric through temperature sublimation.

Classification of heat transfer printing

Heat transfer printing is usually divided into hot-melt transfer printing and heat sublimation transfer printing. Hot-melt transfer printing is commonly used in all cotton products. The disadvantage is poor hand feel and air permeability. Thermal sublimation transfer printing is often used in polyester transfer printing, but its disadvantage is that the plate making cost is high.

Sublimation is the most commonly used method in heat transfer printing. The principle is to transfer and fix disperse dyes to synthetic fibers such as polyester at high temperature by using the sublimation characteristics of disperse dyes. Cups are generally used for heat sublimation transfer printing.

The specific process is to pass the pattern through the plate making roller or flat screen, or the circular screen printing machine can print it on the paper with disperse dye or ink. Then, the transfer printing paper printed with pattern will be combined with the fabric through the transfer printing machine under the applicable temperature and pressure conditions. Through the physical and chemical action, the pattern on the paper will be sublimated and transferred to the fabric surface instantly, and diffuse and penetrate into the fiber inner layer to be fixed. This is the process of heat transfer printing of polyester fabric.

Thermal sublimation transfer printing can be divided into offset printing, gravure printing, silk screen printing and data printing according to different printing methods.

What is heat sublimation transfer printing?

First, what is heat sublimation? Generally speaking, we all know that solid will become liquid when heated to a certain temperature, and liquid will become gas when heated to a certain temperature. Then when the finger is heated to a certain temperature, the process of directly turning into a gas is called heat sublimation.

Heat sublimation transfer printing is currently used in polyester fabrics or fabrics containing more than 80% polyester. Or on materials that can withstand a temperature of more than 210℃ (a layer of thermal sublimation coating needs to be coated on the surface of the material), common ones are DIY mugs, DIY porcelain plates and DIY photo frames, which are mostly realized by thermal sublimation transfer.

Advantages of heat sublimation transfer printing

⭕ It will not change the texture of clothes. Unlike hot stamping, it will feel colloidal, like sticking a layer of glue on the surface of clothes, but ink directly penetrates into the fabric.

⭕ Not easy to fade, high color fastness.

Disadvantages of heat sublimation transfer printing

❌ It can not be applied to pure cotton fabric for the time being.

Using heat sublimation transfer for digital printing requires heat sublimation printer, heat sublimation ink, heat sublimation transfer digital paper and heat press transfer machine. Although heat sublimation transfer can be completed by using ordinary A4 paper, the pattern transfer rate of transfer is low and the color difference is large. Therefore, special heat sublimation transfer digital paper should be selected.

A complete heat sublimation transfer process is to select the pattern - use the thermal sublimation printer to mirror print the pattern on the heat sublimation transfer digital paper - and use the hot press transfer machine to transfer the pattern on the transfer paper to the material.

Zhejiang Sowinpak Co., Ltd is the leading and professional custom print cup exporter, any interests, plz feel free to contact us!

0 notes

Text

Thermal Transfer Label Printer Market -In-Depth Industry Analysis with Key Manufacturers Analysis

The Thermal Transfer Label Printer Market Research Report gives CAGR value, Industry Chains, Upstream, Geography, End-user, Application, Competitor analysis, SWOT Analysis, Sales, Revenue, Price, Gross Margin, Market Share, Import-Export, Trends and Forecast. The Report Also Gives Insight On Entry and Exit Barriers of the Industry.

The study report offers a comprehensive analysis of Thermal Transfer Label Printer Market size across the globe as regional and country level market size analysis, CAGR estimation of market growth during the forecast period, revenue, key drivers, competitive background and sales analysis of the payers. Along with that, the report explains the major challenges and risks to face in the forecast period. Thermal Transfer Label Printer Market is segmented by Type, and by Application. Players, stakeholders, and other participants in the Thermal Transfer Label Printer Market will be able to gain the upper hand as they use the report as a powerful resource.

Download Free Sample PDF of Thermal Transfer Label Printer Market @https://www.deepresearchreports.com/contacts/request-sample.php?name=1922554

The report takes into account the impact of the novel COVID-19 pandemic on the Thermal Transfer Label Printer Market also provides assessment of market definition along with the identification of topmost prominent key manufactures are analyzed emphatically by competitive landscape contrast, with respect to Price, Sales, Capacity, Import, Export, Thermal Transfer Label Printer Market Size, Consumption, Gross, Gross Margin, Revenue and Market Share.The Thermal Transfer Label Printer Market report provides information about the industry, including valuable facts and figures. This research study explores the Market in detail such as industry chain structures, raw material suppliers, with manufacturing The Industrial IoT Sales market examines the primary segments of the scale of the market. This intelligent study provides historical data from 2015 alongside a forecast from 2021 to 2027.

Download Complete Report @ https://www.deepresearchreports.com/contacts/purchase.php?name=1922554

Additionally, the research report on Thermal Transfer Label Printer Market provides an in depth analysis about market status, market size, revenue share, industry development trends, products’ advantages and disadvantages of the enterprise, enterprise competition pattern, industrial policy and regional industrial layout characteristics. The Thermal Transfer Label Printer Market report covers recent developments, strategic market growth analysis, area marketplace expanding, product launches, technological innovations and many more. Research report also offers an in-depth analysis about the Agreements, collaboration and partnership among different vendors across the globe. Therefore the report is beneficial for all kinds of clients.

Impact of Covid-19 in Thermal Transfer Label Printer Market: The utility-owned segment is mainly being driven by increasing financial incentives and regulatory supports from the governments globally. The current utility-owned Thermal Transfer Label Printer Market are affected primarily by the COVID-19 pandemic. Most of the projects in China, the US, Germany, and South Korea are delayed, and the companies are facing short-term operational issues due to supply chain constraints and lack of site access due to the COVID-19 outbreak. Asia-Pacific is anticipated to get highly affected by the spread of the COVID-19 due to the effect of the pandemic in China, Japan, and India.

Check Out Other Reports:

https://www.deepresearchreports.com/

Contact Us

Name: Deep Research Reports

Email: [email protected]

Phone: + 1 888 391 5441

0 notes

Text

5 major news in plastic molding industry

Will 3d printing replace traditional plastic molding manufacturing?

With development of Industry 4.0, development speed of China's manufacturing industry from "manufacturing" to "intelligence" has become more and more rapid in recent years. 3D printing technology has been widely used in China's manufacturing industry. 3D printers provide efficient, low-cost support for molding design and manufacturing. Even with rapid development of 3D printing technology, it has gradually begun to subvert mold technology and form a direct competitive relationship with it in some areas.

“Compared with 3D printing technology, traditional plastic molding manufacturing requires more steps and processes, and mold making cycle is longer. When a plastic molding company introduces a new product, it must pass strict international standards and certification before going on market. Certification of many components will take a long time. This will put new product in a very disadvantageous position in the time to seize market. 3D printing injection moulding are an efficient solution. Well-known plastic molding company are doing this by using 3D printing technology to make injection moulding in their open labs.” According to Luo Baihui, secretary general of International Mould Association, it usually takes several weeks to two months to produce a mold, while mold prototype can be completed in a few hours using 3D printing technology in a few hours and can be modified immediately according to test results. The final sample is then injected. These product samples can be sent directly for certification, while traditional plastic molding manufacturing may still be in production, and even before mold is determined, 3D printed product has been certified, greatly shortening development cycle. Only in mold making cycle, 3D printing technology has had a certain impact on plastic molding manufacturing.

However, industry experts said that although 3D printing technology has many advantages such as short production cycle, convenient raw materials, and uniform product pressure, 3D printing technology can not completely replace traditional plastic molding manufacturing method, because 3D printing technology still has some problems in injection moulding process. For example, 3D printing technology is a layer-by-layer processing of product, which will shorten production cycle of mold, but it will also lead to a step effect on surface of mold. Similar problems exist with directly printed molds, which require later machining or sandblasting to eliminate these small, toothed edges. In addition, holes smaller than 1 mm must be drilled, larger holes require reaming or drilling, and thread features require tapping or milling. These secondary treatments greatly reduce speed advantage of 3D printing dies. At the same time, in order to ensure good material flow performance, injection moulding needs to be heated to a very high temperature. Aluminum and steel molds typically experience temperatures of 500 F (260℃) or higher, especially when processing high temperature plastics such as PEEK and PEI materials. It is easy to produce thousands of parts with metal molds. It can also be used as a transition mold before final mass production mold comes out. Mold materials using 3D printing technology are typically photosensitive or thermosetting resins that are cured by ultraviolet light or laser light. Although these plastic molding are relatively hard, they are destroyed very quickly under thermal cycling conditions of injection moulding. In fact, 3D printing molds typically fail within 100 times in mild environments. For glass filled polycarbonate and high temperature resistant plastics, only a few parts can be produced.

In addition, a major reason for using 3D printing dies is their low cost. Cost of production-grade machining molds is typically $20,000 or more, while similar printing molds cost as little as $1,000. However, this analogy is unfair, and cost of printing molds is usually only considered for material consumption, without labor, assembly and installation, injection systems and hardware. For example, ProtoLabsd's aluminum molds cost

$1,500 for production. If you need to produce more parts, use 3D printing molds, you need to reprint and assemble new molds for every 50-100 products. On the other hand, aluminum molds are still in good service after producing 10,000 parts, regardless of plastic used. Therefore, in terms of production cost, 3D printing is no more cost effective than conventional plastic molding manufacturing methods.

In addition, in product design, principle and practice of traditional plastic molding manufacturing has more than a century of history, industry is relatively thorough in its research, such as draft angle must be greater than or equal to 5 degrees to meet most aluminum mold requirements. 3D printing molds are challenging to mold plastic parts, and extra care is required for number and mounting position of plastic molding thimbles. 3D printing dies (especially high injection temperatures) are somewhat more flexible in terms of increasing cavity wall thickness and reducing pressure. Design of gate is also different, tunnel and dot gates should be avoided. Direct gates, fan gates, and wing gates should be increased to three times normal size. Flow direction of polymer in print mold should be consistent with 3D print line to avoid high packing caused by stickiness and low pressure. Cooling system can increase life of mold to a certain extent, but it does not significantly reduce number of cycles of printing mold, because heat dissipation capability of 3D printing mold is not as good as that of aluminum mold or steel mold.

In summary, 3D printing technology will not completely replace traditional plastic molding manufacturing industry. Because 3D printing molds have certain deficiencies compared with traditional plastic molding manufacturing in terms of finished product quality, product cost and molding design. Moreover, 3D printing is not suitable for mass production, and unit price for producing one piece and producing 10,000 pieces is basically close, and time required for 3D printing is also long. Current 3D printing technology can only produce tight mold production for small batch production cycles, and large-scale production is still based on traditional plastic molding manufacturing.

What kind of spark will RFID technology combine with mold?

Mold, as mother of industry, has become an essential basic industry with rapid development of industry. Mold market has been continuously breaking through in technology. Plastic molding industry is no longer just a simple machine like traditional one. Nowadays, mold needs to combine a lot of technologies, and it is moving toward trend of intelligence and networking. RFID mold electrode management system can better realize intelligent management of mold, reduce professional skill requirements and human error factor of mold operator.

Modern industrial development has been reflected in many fields. Industry has always been an important hub for national economy. Plastic molding industry has been increasing in China in recent years, but there are still many management problems in plastic molding industry market. Mold is an indispensable processing tool and process equipment for mass production in modern manufacturing. It has same industrial status as all machined machine tools. Along with diversification of number of molds for enterprise products, processing of a mold often requires dozens or even hundreds of electrodes and electrode has become a huge number of key resources in plastic molding manufacturing industry. By installing RFID electronic tags on electrode holders, correlating electrode holder, electrode information and handheld RFID reader, it is expected to reduce copper raw materials by 15%~35% and reduce CNC operators by 15%~40%. CNC and EDM machine tools have a utilization rate of around 5%. For small and medium-sized plastic molding company, informationization is a good choice with less investment and quick results. It can be done by section. After automation technology is mature, it is easy to realize full automation by simply connecting various sections in series, adding robot arm and guide rail.

Traditional mold management registers mold number and position number through paper, mold storage can be found irregularly, storage operation is free to stack and delivery is not timely, and it is easy to cause registration errors, record loss, management confusion, and extremely inconvenient to find.

How to use high-tech means to strengthen safety and quality management of plastic molding industry market, supplier management, reduce operating costs, enable real-time and effective data collection and tracking, provide visual real-time data for management. It is an urgent problem for enterprise management molds.

RFID technology has characteristics of fast reading speed, non-contact, multi-target recognition, etc. In terms of physical characteristics, RFID technology has advantages of waterproof, high and low temperature resistance, bendability, no mechanical failure, long life, and resistance to harsh environments; In storage, RFID technology information storage capacity is large, data is readable and writable, can be updated at any time, and each label has a unique ID number. Technology with such characteristics is the most suitable mold management solution.

Mold management site installation is generally more complicated. To manage these molds well, you must choose a series of right hardware equipment as a support. Most of molds are made of metal. If you want to manage these molds well, electronic labels for metal environments are the most suitable choice;

Using unique ID number of RFID UHF tag, mold information is written into tag one by one, including mold type, number, production date, mold position, model inventory, processing materials and so on. RFID electronic tag on the mold can be read by RFID UHF multi-channel reader and transmitted to application system for verification. Then make judgment to realize rapid search of mold.

Benefits of using RFID technology to manage molds:

1. Provide storage status of molds in warehouse, such as available, to be repaired, and obsolete, to improve search efficiency.

2. Detailed records of history for use of mold, such as important number of total stampings, help analyze cause for loss of mold, and evaluate life of mold.

3. Record in detail repair data of each set of molds,

precautions for use of mold, install mold conditions and mechanical use, etc., to quickly and accurately know matching molds needed to produce a product.

4. Quickly and conveniently count actual materials of each set of molds, cost of each process and cost of outward processing, strengthen control and improve work efficiency.

Is there a shortage of supply in precision injection molding market?

Prospect of plastic molding industry is broad, and demand for precision injection molding market is in short supply. However, proportion of high-end and low-end molds produced in China's plastic molding industry is extremely unbalanced, which is not conducive to development of China's plastic molding industry. There is an urgent need to speed up pace of structural adjustment, develop high-end market segments, and keep pace with international market.

Speed up structural adjustment

Compared with before, China's mold technology level has been greatly improved, but proportion of high-end and low-end products produced by domestic plastic molding industry is extremely unbalanced, which is not conducive to development of China's plastic molding industry. Although in recent years, China's plastic molding industry structure and system have made great changes, mainly in performance of: high-end molds, large, sophisticated, complex, long life. However, due to excessive demand for medium and low-grade molds in China, self-sufficiency rate of medium and high-grade molds is less than 60%. It is not difficult to see that it is unreasonable.

They are mainly manifested in following aspects: First, constraints of mold steel and other factors; Second, standardization level needs to be improved; Third, high-end mold talents urgently need to be cultivated; Fourth, accelerate pace of mold product structure adjustment; Fifth, increase investment to strengthen innovation capabilities; Sixth, promote joint restructuring among mold companies; Seven, overseas market development needs to be deepened.

Luo Baihui, a mold expert, pointed out that in addition to continuing to increase production capacity, China's plastic molding industry should focus on internal structural adjustment and technological development. Mainly enterprise structure to professional adjustment, product structure towards development of high-end molds, improvement of import and export structure, mold forming analysis and structural improvement of high-end automotive cover parts, multi-functional compression moulding and composite processing and laser technology in molding design and manufacture application, high-speed cutting, super-finishing and polishing technology, information technology development.

Facing world mold market, a promising cake especially high-end market, everyone will be heart-warming. In response to development status of plastic molding industry, develop related mold machine tools to seize market.

Enterprises that live in 2019 will surely become more and more vital.

Yao Xiaochun, president of Dongguan Machinery Mould Industry Association, said in an interview with "Brand China" column that Pearl River Delta industry peers face situation of international trade war and domestic economic downturn. Holding an exchange meeting is to provide a platform for dialogue, exchanges and cooperation to gain growth through endogenous opportunities.

In 2019, company has already prepared and planned to survive crisis. Next, through internal research and development benefits, process management improvement, enterprises that survived in 2019 will surely become more and more vital. Association will also focus on industry development and enterprise needs, strive to promote deep exchanges and cooperation in the industry, and exert efforts in finance, enterprise management, personnel training, and supply chain cooperation and cooperation to actively promote healthy and orderly development of industry.

World plastic molding industry will continue to maintain a good development trend?

According to statistics of China Die & Mould Industry Association, China, United States, Japan, Germany, South Korea and Italy are the world's major producers of injection moulding and stamping dies. Among them, China's mold production value is the highest in the world. According to data released by Luo Baihui, secretary general of International Mold Association, global plastic molding industry is in a steadily rising stage in 2008-2018. By 2018, market size has reached 1.8 trillion yuan. With implementation of industrial upgrading strategies of countries such as “Re-industrialization of United States”, “German Industry 4.0” and “Japan Industry 4.0”, it is foreseeable that world plastic molding industry will continue to maintain its good development trend.

0 notes

Text

Plastic Fabrication, Cutting and Moulding: What are my options?

There is an extremely large variety of plastic fabrication methods available, with each process offering distinct advantages and disadvantages. Choosing the right method depends on the products you require and on their size. The important thing is that no matter what product you need, whether that is acrylic cut to size or larger high impact polystyrene sheet, there is a fabrication method suitable for you!

This article will give you a tour among the most popular and effective plastic fabrication, cutting, and moulding methods so you can make an informed decision and choose the one that will suit your needs best.

CNC Laser Cutting

CNC stands for computerised numerical controlled. This refers to the automated control of machining tools and 3D printers through the use of a computer. Instead of a manual operator directly controlling the machining operation, a computer directs the process by following instructions from pre-programmed software and code. The instructions can be written by a person or generated by computer-aided design software (CAD).

This computerized manufacturing process involves a laser beam melting the material away creating a cut; the excess is then removed by a high-pressure gas.

Advantages of CNC laser cutting:

- Making it possible to cut different shapes;

- No need to exchange tools for different cuts;

- Easy to make intricate cuts;

- More accuracy compared to thermal cutting;

- Faster than traditional mechanical cutting methods;

- A highly automated process requiring little manpower.

Disadvantages of CNC laser cutting:

- It requires a high level of expertise;

- Limitations to plastic thickness;

- Large upfront costs;

- It emits dangerous gas and fumes.

CNC laser cutting can be used with the majority of plastic variants, including harder plastics like acrylic. Typical applications of CNC plastic laser cutting are creative designs and signage, but the method is also used to manufacture automotive parts and plumbing.

CNC Router Cutting

A CNC router is a pre-programmed, computerised machine used for cutting various materials, such as steel, aluminium, foam, wood, composites, and plastic. The equipment uses computerised numerical control to route tool paths and manufactures a wide variety of items faster and with less waste.

Like the previous method, CNC router cutting also uses pre-programmed commands. Designs are created using CAD software, they are next converted to G-code, and eventually the CNC software runs the G-code that delivers instructions to the machine.

Advantages of CNC router cutting

- Making precision cuts;

- Not requiring human control and supervision;

- Multiple safety features to reduce accident risk;

- A CNC router is easy to update.

Disadvantages of CNC router cutting

- Large upfront costs;

- Decreasing the demand for manual machine operators;

- Creating a skills gap in the manufacturing industry.

Items created with a CNC router are used as advertising signs, for crafts and arts, and for moulds and prototypes.

CNC Water Jet Cutting

CNC water jet cutting is one of the most versatile processes for shape cutting. It can be used for cutting virtually any material. This technique allows you to obtain a variety of products, including Perspex cut to size, all with a smooth, precise cut surface.

The water jet cutting process needs an intensifier pump that creates ultra-high pressure so it can cut through a variety of materials.

Advantages of CNC water jet cutting

- Provides the highest precision cutting;

- Can be combined with plasma or oxy-fuel on the same part;

- Produces high tolerance parts with fine contours;

- No heat affected zones, no melted plastic;

- Lack of hazardous fumes and vapours;

- Environmentally safe as no airborne dust is produced.

Disadvantages of CNC water jet cutting

- Not suitable for brittle material like tempered glass or certain types of ceramics;

- Is slower and more expensive than other techniques.

This method has been used to produce parts for the automotive, medical and aerospace industries.

Thermo Forming

Thermo forming is a technique for moulding plastic to obtain versatile products. There are two types of thermo forming: vacuum forming and pressure forming.

It all starts with high density polyethylene a high impact polystyrene sheet that is heated to make it easy to manipulate. When the sheet reaches a certain temperature, it is formed over a mould. The next step is cooling the new form, followed by trimming in order to increase usability.

Advantages of thermo forming

- Adaptability to customer’s design needs;

- Fast, which makes it suitable for building prototypes;

- Low production costs;

- Final results are very aesthetically pleasing.

Disadvantages of thermo forming

- This method is limited to thin-walled parts;

- The complexity of shapes it can be used to create has certain limitations;

- The need for trimming lengthens production times;

- It creates scrap plastic (which is recycled by most manufacturing companies).

The range of uses for thermo forming is very wide: rigid packaging for consumer goods, toys, plastic bins, and other products obtained from sheets.

CNC Vacuum Forming

CNC vacuum forming is a plastic manufacturing process consisting of heating a plastic sheet such as high density polyethylene and forming it into a shaped vacuum forming tool. The plastic sheet is cooled until it becomes hard and the part can be removed from the tool.

The procedure is relatively simple and can be used with a wide range of thermoplastic materials, such as acrylic, high impact acrylic, high impact styrene, polyethylene, polypropylene, and others.

Advantages of CNC vacuum forming

- The process is very fast and versatile;

- Allows you to obtain a variety of 3D objects;

- Suitable for short run production;

- Low manufacturing costs;

- Consistent shapes and sizes from batch to batch;

- Easy to scale production up or down.

Disadvantages of CNC vacuum forming

- Only one part of product can be made at a time;

- The need of additional costs and resources to finish components;

- The number of details you can achieve with this technique is limited;

- Prone to errors such as unwanted bubbles due to excess moisture or debris from the mould imprinted on clear or light-coloured parts.

CNC vacuum forming applications are similar to products obtained through thermo forming.

2D Laser Engraving

2D laser engraving is a technique enabling you to change the surface of an object using a laser beam. It is mostly used to create images on the surface of an object. 2D laser engraving is mostly used on acrylic materials.

The laser creates high heat that vaporizes matter and exposes cavities that form the desired image or text. A vectored file of the desired image or text is required from the client in order to produce the 2D engraving.

Advantages of 2D laser engraving

- Can be used to engrave small objects;

- The risk of damaging or deforming the material is low;

- High precision;

- The process does not include toxic solvents or inks;

- Markings are not affected by time and tear.

Disadvantages of 2D laser engraving

- Can be used for two-dimensional objects only;

- Cannot be used for deep carving;

- Not suitable for very hard materials or materials with a low ignition point.

The method is used for medical devices, fine art, and industrial applications.

3D Laser Engraving

3D laser engraving is used to create 3D engravings of photos and designs of various materials, including Perspex cut to size. Unlike 2D laser engraving, it also works on curved surfaces, creating distinct effects that were not possible to achieve in the past.

3D laser engraving can be described as burning away some parts of a materials surface in order to create depths for a great aesthetic finish.

Advantages of 3D laser engraving

- Superior to 2D laser engraving and being used more and more as the surface shape of industrial products is rarely plane;

- Suitable for deep carving;

- Allows for multi-colour engraving;

- High personalisation degrees;

Disadvantages of 3D laser engraving

- More time-consuming compared to traditional 2D engraving, so it requires more patience.

Applications are similar to that of 2D laser engraving, with the difference that objects with curved surfaces can be engraved.

Which combination of plastic fabrication, cutting, and moulding techniques suits your production and business needs the best? Plastic Online offers so much more than simply acrylic cut to size or standard plastic sheets. Plastic Online boasts two local factories, knowledgeable staff and a wide range of plastic products to fit all your requirements. Contact the premier Gold Coast plastic fabrication specialists Plastic Online today and discuss your custom plastic fabrication needs today.

0 notes

Text

The Difference Between Saddle Stitch Books and Perfect Bound Books

If you’re planning to print a run of small pamphlets, guides, or small booklets, you might have run into the terms saddle stitch books and perfect bound books. Both are popular binding methods, and though they both have their advantages, many characteristics are shared between the two. They’re both much less expensive than hardcover bindings and are well suited for books with low page counts. So long as those qualities fit your project and you work with competent wholesale book printers, either method would be fine. That said, we can do better than fine. Keep reading, and we’ll give you a breakdown of both methods, and their pros and cons.

How are Saddle Stitch Books Are Made?

Saddle stitch books are bound together with staples made of thin metal wire. First, the sheets are printed out and collated according to page number, then they are folded in half along the middle, creating two pages per sheet of paper. This way, a saddle stitch book can lay completely flat, a benefit that perfect and hardcover bindings can’t offer. Finally, the book is trimmed down to size on all sides except for the spine. Because of the simplicity of this process, saddle stitch books can be produced very quickly.

How are Perfect Bound Books Made?

Rather than using staples, perfect bound books are held together with a thermal glue. After printing, a block of loose pages is arranged in order, and the side of the block that will become the book’s spine is roughed up in order to loosen fibers of paper that the thermal glue will be able to bind to. Glue is applied, and the pages bind to each other and to the cover of the book, which is usually made out of card stock or thicker paper than the inner pages. Softcover books can be bound using different types of glue, with the most popular options being EVA and PUR glue. When referring to perfect binding, we’re usually talking about EVA glue, which is slightly cheaper but less durable than PUR glue. That said, the process for applying PUR glue is nearly the same as for EVA glue, and if you’re concerned with the lifespan and durability of your books, you should opt for PUR glue whenever possible.

Advantages and Disadvantages

The most significant difference between perfect binding and saddle stitching is that perfect binding is a widely applicable softcover binding technique that can be used for a variety of project types, whereas saddle stitching is specialized for books of around ninety pages which need to be produced quickly and in large numbers.

Another significant difference between the two methods lies in their cultural context. Saddle stitching is usually used for magazines and pamphlets, so when somebody sees a saddle-stitched booklet, they might assume it’s a less significant piece of writing than if it were perfect bound. Because perfect binding is often used for novels and nonfiction works like biographies, it has a bit more prestige than saddle stitching, though not as much as a hardcover binding.There are also a handful of miscellaneous differences between the two that it’s worth knowing about. We’ve collected them in the lists below.

Saddle stitch books

Lay flat when opened

Often have covers made of the same material as their pages

Don’t degrade much over time, but are susceptible to tearing

Are inexpensive to produce and can be made quickly.

Perfect bound books

Have flat spines which titles can be printed on

Stack well and pack without much-unused space

Have covers made of sturdier material than their pages

Can have more pages than saddle-stitched books

How to Choose Between the Two

The method that will serve you best depends on the kind of project you have planned. If you’re planning on producing a large run of disposable booklets, like manuals to accompany a product, then saddle stitching is the best option. It will save money, and saddle-stitch books are easier to recycle than perfect bound books, only needing to have their staples removed.

The primary reasons to choose perfect binding for your project are to give it more durability and a sense of significance. An employee handbook that people are expected to keep and use for years on end would benefit from a perfect binding or PUR glue binding. Otherwise, they’re likely to

break down with the wear and tear of extended use.

Of course, there will be use cases beyond the norm that might call for an unusual binding method. In cases where it isn’t immediately obvious which binding method to use, there are a few key questions that you can ask yourself to figure out the proper course of action. First, imagine the lifespan of the book after it’s been printed. After it reaches the hands of its intended audience, where does it go? How long do they keep it? Is it long enough for the book to start to break down?

Perfect bound books can last for years, even with fairly frequent use, but saddle stitch books could easily be completely destroyed by an overturned glass of water. Ask yourself how you want the reader to think about the book. Should they give it the respect they would give to a novel or a magazine?