#teflon seals

Explore tagged Tumblr posts

Text

Discover the unmatched quality and performance of Clariannt’s P.T.F.E. Teflon Tape, also known as thread seal tape or plumber’s tape. Our high-quality PTFE tape is designed to ensure leak-free plumbing and smooth joint connections, making it an essential tool for both professional plumbers and DIY enthusiasts. Learn how Clariannt’s Teflon tape can simplify your installations and provide lasting reliability.

#P.T.F.E. Teflon Tape#thread seal tape#plumber's tape#leak-proof tape#Clariannt#PTFE tape#plumbing sealant#thread sealant#plumbing solutions

0 notes

Text

PTFE Stamped and Turned Parts Components Supplier from India

Rubber Gaskets for Sealing and Teflon Components supplier from India, specializing in PTFE Stamped (Sheet) and Turned Parts (Rod)

#Rubber Gaskets for Sealing and Teflon Components supplier from India#PTFE Stamped(Sheet) and Turned Parts( Rod) components supplier from India

0 notes

Text

#Mechanical Seal#Mechanical Shaft Seals#Carbon Seals#Pump Seals#Agitator Seals#Reactor Seals#Metal Bellow Seals#Labyrinth Seals#Teflon Bellow Seals#Mechanical Seals Manufacturers#Blower Seals#Compressor Seals

0 notes

Text

Demystifying Mechanical Seals: A Comprehensive Guide

Welcome to our blog, where we delve into the intricate world of mechanical seals. If you've ever wondered what exactly a mechanical seal is and how it functions, you've come to the right place. In this guide, we'll break down the basics, explore the importance of mechanical seals, and shed light on Omega Seals Company's role in this crucial industry.

What is a Mechanical Seal?

Let's start with the fundamentals. A mechanical seal is a device used to prevent fluid leakage between two mating surfaces in a mechanical system. These surfaces can be rotating or stationary, and the seal is typically installed in equipment such as pumps, compressors, and agitators where the containment of fluids is essential. Mechanical seals provide a higher level of sealing compared to traditional packing seals, offering greater efficiency and reliability.

How Do Mechanical Seals Work?

Understanding the workings of a mechanical seal is key to appreciating its significance. Essentially, a mechanical seal consists of two primary components: a rotating element (typically attached to a shaft) and a stationary element (housed within the equipment). These elements are held together under mechanical pressure to create a tight seal. The seal faces, usually made of materials like carbon, ceramic, or silicon carbide, come into contact to prevent fluid leakage. Additionally, a secondary sealing mechanism, such as an elastomer O-ring, provides further protection against leakage.

Importance of Mechanical Seals:

Mechanical seals play a critical role in various industries, including oil and gas, chemical processing, pharmaceuticals, and wastewater treatment. Their ability to withstand high pressures, temperatures, and corrosive environments makes them indispensable in ensuring the safe and efficient operation of equipment. By preventing leaks and contamination, mechanical seals help maintain product quality, minimize downtime, and enhance workplace safety.

Omega Seals Company: A Leading Provider of Seal Solutions

Based in India, with a presence in Mumbai, UAE, Saudi Arabia, and Brazil, Omega Seals Company is a reputable manufacturer of a diverse range of seal equipment. With a commitment to quality, innovation, and customer satisfaction, Omega Seals Company delivers reliable sealing solutions tailored to the specific needs of each industry. Whether its standard seals or custom-designed products, Omega Seals Company's expertise and experience make it a trusted partner for businesses worldwide.

Mechanical seals are essential components in various industrial applications, serving to prevent fluid leakage and ensure the efficient operation of equipment. Omega Seals Company stands out as a leading provider of high-quality seal solutions, catering to the needs of industries across the globe. With a focus on innovation and customer service, Omega Seals Company continues to uphold its reputation as a reliable partner in the field of sealing technology.

Contact us at: https://www.omegaseals.com/ | +91 9820045787 | [email protected]

#Mechanical Seal#Mechanical Shaft Seals#Carbon Seals#Pump Seals#Agitator Seals#Reactor Seals#Metal Bellow Seals#Labyrinth Seals#Teflon Bellow Seals#Mechanical Seals Manufacturers#Blower Seals#Compressor Seals

0 notes

Text

#mechanical seals#manufacturer#mumbai#pune#gujarat#quantech seals#qtseals#supplier#tamilnadu#uae#teflon bellow#ptfe#karnataka#maharashtra#tamil nadu#petrochemical#food and beverages#biotech and pharmaceuticals#oil gas industry#biotechnology

1 note

·

View note

Text

here's what I've learned to never pay full price for, because people are giving these items away for free or almost free on Craigslist, Nextdoor, Facebook, at Goodwill, and on eBay (which has a local pickup section) in every sufficiently populated location in the USA.

cost of acquiring these items ranges from "carrying it home from the sidewalk" to "getting a friend with a car to help you pick it up" which is the same amount of effort as going to IKEA for worse quality that costs more, with the notable exception of it being a pain in the ass to coordinate with craigslist sellers, and you often have to wait and watch for what you want to actually show up. it took me about a year to find an acceptable gamer chair left out on the sidewalk, for example. but they cost $100+ new, so I chose to wait.

a lot of this stuff is the kind of thing you don't necessarily intend to keep, just to use in transitional housing or until you can afford a better one.

1. printers of any kind. basic office inkjets are free. ink is easily refillable or has generic ink cartridges way cheaper than brand name for any inkjet up to about 2015, not sure how difficult the newer smart printers are to hack but there's no reason to own a newer one because printing technology has not improved since about 2005. you want a color laser for making zines and wheatpastes? it's on Craigslist RN and someone's mom is desperate to get rid of it

2. bedframes

3. desks

4. tables

5. chairs

6. bookshelves, nice oak bookshelves that don't bend like al dente spaghetti when you put books on them, are rotting on sidewalks rn because they didn't fit in someone's house. go get them

7. scanners. I find a working scanner by a dumpster at least once a quarter, and I don't pick them up because I already have one that I picked up from a dumpster years ago

8. hot tubs. everyone thinks they want a hot tub and that the maintenance and upkeep will be worth it, and they are wrong. Craigslist.

9. sofas, with the caveat that if you are in a bedbug region like New York State you need to be very confident in your bedbug screening skills

10. quality leather shoes. these last forever and are expensive new. eBay is best for these

11. plates, glassware, silverware. all of these are able to be sterilized to whatever standard you feel comfortable with but if you eat in restaurants you've already put a fork in your mouth that hundreds of people have drooled on so try not to fool yourself

12. televisions and computer monitors

13. houseplants. similar to the bedbug warning above, you need to screen these for pests like fungus gnats and mealybugs

14. dressers, wardrobes, china hutches, cabinets, chests of drawers, etc

15. mirrors

16. clothes hangers

17. moving boxes

18. mattresses to a certain extent. I don't like secondhand used mattresses but unstained, unused mattresses are surprisingly common, especially since the foam mail order mattress boom started and people keep getting told by the mattress companies to just get rid of/keep any mattresses they want to return for flaws or wrong sizes or whatever. bedbug warning on this obviously

19. sheets and towels. you gotta launder them obviously

20. basic clothing, especially for kids. normie type clothing is so numerous people often just throw them away because they can't get anyone to take them

21. kitchenware like cooking utensils and pots n pans. don't use chipped or scratched Teflon/nonstick if you can help it. everyone needs one basic steel chef knife, which can be sharpened and maintained indefinitely. people throw these away CONSTANTLY

22. household consumables like laundry soap and dish soap. people often accidentally buy the wrong brand, scent, or develop allergies and want to get rid of extra

23. pet supplies like collars, leashes, dog crates, litter boxes, litter itself, dog beds, toys, carriers, etc

24. medical equipment of all kinds. people who take care of all kinds of patients end up with tons of leftover, sealed, miscellaneous stuff when that person recovers or dies, and they often give it away. adult diapers, hospital beds, IV stands, crutches, walkers, wheelchairs, fracture boots and splints, knee braces, canes, catheter packs, ice packs, heat packs, sterile paper sheeting, gauze, slings, over-the-door stretching and rehab pulleys, mattress protectors, etc

25. washers and dryers, both the basic household cube type and the small twin tub or rock tumbler type. people upgrade these when the old ones are still working, just squeaky or a little weird or sometimes just old

26. vacuum cleaners. secondhand ones are sort of icky but you can get rid of the ickiness by wiping them down with a rag and isopropyl alcohol inside and out. use an exacto or utility knife to slice off the hair and string wrapped around the roller. buy a new filter on Amazon. people throw away vacuums that work perfectly all the time because they don't actually know how to clean them out or do maintenance. bedbug and pet hair warning obviously

27. microwaves

28. refrigerators

30. lamps

31. any kind of exercise equipment including stationary bikes, ellipticals and weights/weight benches

32. any kind of piano. there's a grand on my local Craigslist for free rn

33. scrap wood and lumber

34. pallets

35. wood shipping crates

36. newborn, toddler and baby equipment like breast milk pumps and storage, bottles, bottle racks, diapers, etc. anything a little guy will grow out of fast will end up being given away

37. air conditioners, humidifiers and dehumidifiers. these will be most numerous during their respective off seasons

list updated 2/13/24 based on recent Craigslist trawling

38. jars, both canning type jars and clean food jars like from pickled or jelly bought at the store

39. rugs. most of my rugs are sidewalk finds. rugs will almost always be dirty. a decent consumer grade rug cleaner costs under $100, it's cheaper to just buy one if you have the space to store it. flushing the scavenged rug with soap, hot water, vinegar, alcohol, etc will clean almost anything but huge bedbug and allergen warning on this item

2K notes

·

View notes

Text

Astronaut's 'science of opportunity' experiments help prepare for launch to the International Space Station

Science ideas are everywhere. Some of the greatest discoveries have come from tinkering and toying with new concepts and ideas. NASA astronaut Don Pettit is no stranger to inventing and discovering. During his previous missions, Pettit has contributed to advancements for human space exploration aboard the International Space Station resulting in several published scientific papers and breakthroughs.

Pettit, accompanied by cosmonauts Alexey Ovchinin and Ivan Vagner, will launch to the orbiting laboratory in September 2024. In preparation for his fourth spaceflight, read about previous "science of opportunity" experiments Pettit performed during his free time with materials readily available to the crew or included in his personal kit.

Freezing ice in space

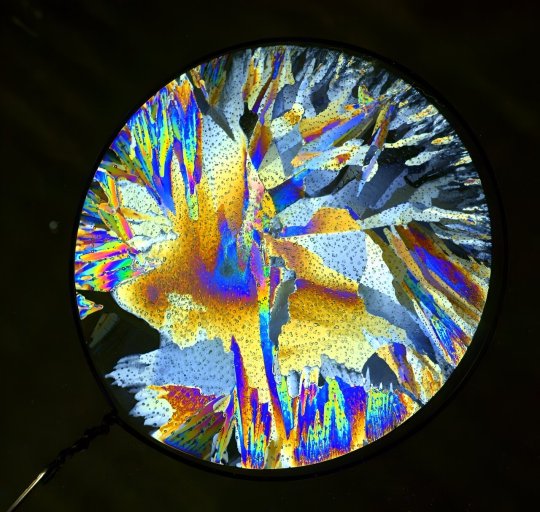

Have you ever noticed a white bubble inside the ice in your ice tray at home? This is trapped air that accumulates in one area due to gravity. Pettit took this knowledge, access to a -90° Celsius freezer aboard the space station, and an open weekend to figure out how water freezes in microgravity compared to on Earth. This photo uses polarized light to show thin frozen water and the visible differences from the ice we typically freeze here on Earth, providing more insight into physics concepts in microgravity.

Space cup

Microgravity affects even the most mundane tasks, like sipping your morning tea. Typically, crews drink beverages from a specially sealed bag with a straw. Using an overhead transparency film, Pettit invented the prototype of the Capillary Beverage, or Space Cup. The cup uses surface tension, wetting, and container shape to mimic the role of gravity in drinking on Earth, making drinking beverages in space easier to consume and showing how discoveries aboard station can be used to design new systems.

Planetary formation

Using materials that break into very small particles, such as table salt, sugar, and coffee, Pettit experimented to understand planetary formation. A crucial early step in planet formation is the aggregation or clumping of tiny particles, but scientists do not fully understand this process. Pettit placed different particulate mixtures in plastic bags, filled them with air, thoroughly shook the bags, and observed that the particles clumped within seconds due to what appears to be an electrostatic process. Studying the behavior of tiny particles in microgravity may provide valuable insight into how material composition, density, and turbulence play a role in planetary formation.

Orbital motion

Knitting needles made of different materials arrived aboard station as personal crew items. Pettit electrically charged the needles by rubbing each one with paper. Then, he released charged water from a Teflon syringe and observed the water droplets orbit the knitting needle, demonstrating electrostatic orbits in microgravity. The study was later repeated in a simulation that included atmospheric drag, and the 3D motion accurately matched the orbits seen in the space station demonstration. These observations could be analogous to the behavior of charged particles in Earth's magnetic field and prove useful in designing future spacecraft systems.

Astrophotography

An innovative photographer, Pettit has used time exposure, multiple cameras, infrared, and other techniques to contribute breathtaking images of Earth and star trails from the space station's unique viewpoint. These photos contribute to a database researchers use to understand Earth's changing landscapes, and this imagery can inspire the public's interest in human spaceflight.

TOP IMAGE: A fisheye lens attached to an electronic still camera was used to capture this image of NASA astronaut Don Pettit. Credit: NASA

CENTRE IMAGE: Thin ice under polarized light frozen aboard the International Space Station. Credit: NASA

LOWER IMAGE: Top: NASA astronaut Don Pettit photographed in the International Space Station cupola surrounded by cameras. Bottom: Star trails photographed by NASA astronaut Don Pettit in March of 2012. Credit: NASA

5 notes

·

View notes

Text

youtube

Installing a UV Water Purification Light: Step by Step Guide

Welcome back to Base Camp WNC. Today, we embark on an informative journey on how to seamlessly install UV lights in your existing water systems. UV lights are essential for purifying water, ensuring that it is free from harmful microorganisms.

Getting Started with the UV Light System The UV light system we're focusing on today is a 55-watt, 110-volt unit, designed specifically for the United States. It comes equipped with two holes at each end, accommodating water fittings. Versatility is key with this design; it can be mounted horizontally, vertically, or at any desired angle. The kit includes a slender glass tube, reminiscent of an elongated test tube. When assembling, slide this tube into the provided ring until it slightly protrudes from the other end. Ensure the ring's pyramid-shaped fixture is correctly aligned to secure the tube. This is a delicate procedure, and I have some tips to prevent the glass tube from breaking.

Assembly Tips

Slide the glass tube gently to ensure it doesn't snap.

The flange present will accommodate a seal, which when pressed, ensures a tight fit. Just let the glass tube protrude slightly and secure it hand-tight.

When sealing both ends of the tube, do not use pliers or exert excessive force. Gentle hand-tightening is sufficient.

Water flows between the glass tube and the metal frame, getting purified as it passes by the UV light, before exiting from the other end.

The kit I’m showcasing comes with one glass tube and three UV light bulbs. An important note on the longevity of these bulbs: while they may still emit heat and light after a year, their purification capability diminishes. Hence, an annual replacement is recommended. Handle these bulbs with care and avoid touching them with bare hands.

Installation Essentials For the perfect fitting, I've innovated with a shower fitting, designed to accommodate the PEX pipe. Applying two wraps of Teflon tape in the direction of the screw ensures a smooth slide. This is especially crucial with PVC components that may have residual bits from the molding process. Add a layer of pipe dope for a tight seal. The location of installation plays a vital role. In my setup, the spring below the house feeds a tank, which then directs the water towards the house. The UV light system sits in between. To ensure a sturdy installation, mount a board (like a 1 by 4) on the wall as a base. Once set, the PEX pipe is clamped onto this board with two plastic clips. This setup allows easy access for future maintenance or bulb replacement. The UV light system's transformer has an indicator – a green light – to show it's functioning.

Wrapping Up Installation can be swift with a bit of experience – it takes me about 15-20 minutes, having installed numerous before. But even if you're new to this, with the right guidance, it's a straightforward process. Thank you for joining us. If you found this guide useful, please like, share, and subscribe. For any further queries or if you need specialized assistance, feel free to shoot me an email or drop a comment on YouTube. I offer free advice and guidance online, but consultations or installations at specific locations would be a paid service.

Until next time, stay informed and stay safe!

Visit us at: Carolina Homestead Planner We offer services to help with your homestead planning and preparedness needs.

2 notes

·

View notes

Text

In a fume hood break open an ampule of the liquid and transfer the whole contents to several previously labeled 1 ml REACTI-VIAL vials from PIERCE (catalog 13221Z; $69 for 12 vials; the cap liner must have a Teflon face to contain these materials). The transfer is safest with a positive displacement pipet (Gilson Microman M250). DO NOT use an air displacement pipet (Pasteur or Gilson Pipetman). Close each vial with the special cap provided. Wrap the cap with a strip of Parafilm. Each vial is stored inside a 50 ml polypropylene centrifuge tube with a plug seal screw cap. Cover the cap with Parafilm. Store each individual centrifuge tube inside a larger container (glass jar or metal) sealed with parafilm and label it EXTREMELY TOXIC. These compounds should be stored in a freezer to minimize their vapor pressures. No food should be stored in this freezer.

No food should be stored in this freezer.

5 notes

·

View notes

Text

Resideo AM100-US-1LF Union Sweat Mixing Valve 1/2" Lead Free 70-145°F | PartsHnC

Manufacturer Name: Resideo Product Number: AM100-US-1LF OEM Part Number: AM100-US-1LF Product Description: 1/2"Unsw Mixvlv70/145Fleadfre Weight:2.01lbs/911.72g

The Resideo AM100-US-1LF Union Sweat Mixing Valve is used to mix hot and cold water to achieve the required temperature in HVAC systems. The body is constructed with Teflon-coated and nickel-plated brass and the seals are EPDM rubber.

For an efficient and reliable HVAC system, the Resideo Union Sweat Mixing Valve is the choice for optimal system performance.

0 notes

Text

Enhance Your Sealing Solutions With Colored Teflon Tape

The Importance of Colored Teflon Tape

When it comes to plumbing, gas fitting, or industrial applications, colored Teflon tape plays a crucial role in ensuring leak-proof connections. Unlike traditional white Teflon tape, colored variations serve a dual purpose: they provide superior sealing and help professionals easily identify different applications.

Whether you're working with gas pipes, water systems, or high-pressure fittings, using the right Teflon tape color can improve efficiency and safety.

Types of Colored Teflon Tape and Their Uses

Colored Teflon tape is available in various shades, each designated for specific applications:

White Teflon Tape: General-purpose plumbing tape for water pipes.

Yellow Teflon Tape: Specifically designed for gas lines and propane applications.

Pink Teflon Tape: Heavy-duty tape used for water lines in commercial and industrial settings.

Green Teflon Tape: Oil-free tape suitable for oxygen lines.

Blue Teflon Tape: Used for potable water systems.

By selecting the appropriate colored Teflon tape, you can ensure compliance with industry standards and prevent cross-contamination between different pipe systems.

Where to Buy High-Quality Colored Teflon Tape

For top-quality colored Teflon tape, visit AllTape. Their collection features a variety of Teflon tapes suitable for multiple applications, ensuring durability and superior performance.

Conclusion

Colored Teflon tape is an essential tool for professionals looking to maintain reliable and efficient pipe connections. Its color-coded system simplifies identification and enhances safety across various industries. Upgrade your sealing solutions today with premium colored Teflon tape from AllTape.

0 notes

Text

Oil-Free Air Compressors: Frequently Asked Questions and Expert Answers

In industries where air purity is essential, oil free air compressors have become an essential solution. From healthcare and pharmaceuticals to food processing and electronics, businesses depend on oil free air compressors to ensure contamination-free operations. But how do they work? Are they worth the investment? Whether you’re a professional or a DIY enthusiast, having the right understanding of air compressors is essential for selecting the right equipment and maintaining its efficiency, safety, and durability. In this guide, we answer the most frequently asked questions and provide expert insights into these advanced machines.

1. What is an oil free compressor?

An oil free compressor is a type of compressor that does not use oil for lubrication in the compression chamber. Rather, it depends on alternative technologies such as Teflon-coated materials, water lubrication, or advanced sealing mechanisms to produce 100% contaminant-free compressed air.

Key benefits:

100% pure air: Ideal for industries requiring uncontaminated air.

Lower maintenance costs: No oil changes or messy disposals.

Eco-friendly: Reduces environmental impact.

Compact & lightweight: Easier to move and install.

2. Why should you choose an oil free air compressor India?

If your business requires high air purity, an oil free compressor is perfect for your industry. Industries such as healthcare, pharmaceuticals, food processing, and electronics cannot afford even the smallest fractions of oil in their compressed air systems.

Industries that depend on oil free air compressors:

Medical & dental clinics – For sterilized air supply during surgeries.

Pharmaceutical manufacturing – To prevent contamination in drug production.

Food & beverage industry – Ensures safe and clean packaging.

Electronics & semiconductor industry – Prevents damage to sensitive components.

Automotive & textile sectors – Provides precision air for painting and finishing tasks.

3. How does an oil free air compressor India work?

Oil free air compressors use alternative lubrication systems and coatings to minimize friction between moving parts. They generally operate in two ways:

Single-stage compression: Compresses air once before release.

Two-stage compression: Compressed air in two phases, reducing heat buildup and improving efficiency.

Some models even use water-injected mechanisms to cool and lubricate the compressor without needing oil.

4. What is the difference between oil free and oil lubricated compressors?

Oil free air compressors provide cleaner air, require less maintenance, and are more eco-friendly than oil-lubricated models. While oil-lubricated compressors may last longer in heavy-duty applications, oil free air compressors are ideal for industries where air quality is non-negotiable.

5. How long do oil free air compressors last?

The lifespan of an oil free compressor depends on its usage and maintenance. High-quality models from trusted oil free air compressor manufacturers in India can last 10-15 years with proper care.

Pro Tip: Regular servicing and timely filter replacements can greatly extend the lifespan of your compressor.

6. What maintenance is required for an oil free compressor?

Oil free air compressors are easier to maintain compared to oil-lubricated models. Here are some tips that can help to keep your compressor in top shape:

Inspect regularly: Check for wear and tear.

Replace air filters: Ensures optimal airflow and efficiency.

Drain moisture traps: Prevents internal corrosion.

Monitor pressure & temperature: Avoids overheating and ensures smooth operation.

7. What factors should you consider when buying an oil free compressor?

Choosing the right oil free compressor depends on several factors. Here’s the following:

Air purity requirements: Ensure compliance with industry regulations.

Compressor size & capacity: Match it to your airflow and pressure needs.

Noise levels: Some models are designed for quieter operation.

Energy efficiency: Look for compressors with low power consumption to cut costs.

Manufacturer reputation: Choose trusted oil free air compressor manufacturers in India for reliability and quality.

8. Where can I find the best oil free air compressors in India?

If you’re looking for a premium-quality, oil free air compressor India, Indo Air is your go-to solution. As a leading manufacturer, we offer advanced, energy-efficient compressors tailored to industrial needs. We offer a wide series of oil free air compressors that deliver contaminant-free compressed air for critical applications. Our compressors ensure pure, impurity-free air, offering long-lasting reliability and enhanced energy efficiency.

Why choose Indo Air?

Advanced technology: Advanced engineering for superior performance.

Industry-specific solutions: Custom solutions for medical, food, and pharma industries.

Energy-efficient models: Designed to lower operational costs.

9. Are oil free air compressors cost-effective?

Yes! While the upfront cost of an oil free compressor may be slightly higher, the long-term savings on maintenance, energy consumption, and oil disposal make it a cost-effective investment. Plus, the benefits of uncontaminated air far outweigh the additional cost.

Summary:

Oil free air compressors are a game-changer for industries where air purity is non-negotiable. With Indo Air’s high-quality, oil free air compressors India, you can enjoy cleaner air, lower maintenance costs, and enhanced efficiency. Looking for the best oil free air compressor manufacturers in India? Contact us today and explore our wide range of premium air compressors tailored to your business needs! Visit our website, www.indoair.com, to learn more about how we can power your industry with high-performance, oil free air compressors!

#oil free air compressors#best oil free air compressors in India#oil free compressor#oil free air compressor India

0 notes

Text

High-Pressure Radial Shaft Seals Precision Engineering by CV Technik

In the bustling industrial landscape of Pune, India, CV Technik stands out as a beacon of innovation and quality in the field of sealing solutions. Specializing in High-Pressure Radial Shaft Seal and high-pressure oil seals, CV Technik has been instrumental in addressing the critical needs of various industries that demand reliable and efficient sealing mechanisms.

Understanding High-Pressure Seals

High-pressure environments, prevalent in industries such as automotive, aerospace, and manufacturing, necessitate seals that can withstand extreme conditions without compromising performance. High-pressure radial shaft seals and high-pressure oil seals are engineered to prevent fluid leakage and protect machinery from contaminants under elevated pressures. These seals ensure the longevity and efficiency of equipment by maintaining optimal lubrication and preventing the ingress of harmful particles.

CV Technik's Expertise in High-Pressure Sealing Solutions

CV Technik has carved a niche for itself by offering a diverse range of high-pressure sealing solutions tailored to meet the unique requirements of various applications. Collaborating exclusively with VR Dichtungen GmbH, a renowned name in the sealing industry, CV Technik brings German precision and quality to the Indian market.

Product Highlights

1. High-Pressure Radial Shaft Seals: Designed for applications where traditional seals may fail, these seals can withstand pressures up to 25 Bar and shaft speeds up to 40 m/s. They are ideal for compact spaces and can operate efficiently across a temperature range of -40°C to 220°C.

2. High-Pressure Oil Seals: These seals are essential for preventing oil leakage in high-pressure systems, ensuring that machinery operates smoothly without the risk of contamination or lubricant loss.

3. Teflon/PTFE Lip Seals: Known for their low friction and high chemical resistance, these seals are suitable for applications involving aggressive media or high temperatures.

4. Fabric-Reinforced Oil Seals: Enhanced with fabric reinforcement, these seals offer superior strength and durability, making them suitable for heavy-duty applications.

Engineering Excellence and Customization

One of the standout features of CV Technik is its commitment to engineering excellence High-Pressure Oil Seal. Understanding that each industrial application may have unique challenges, the company offers customized sealing solutions. Their team of experts collaborates closely with clients to design and manufacture seals that perfectly align with specific operational requirements. This bespoke approach ensures optimal performance, longevity, and reliability of the seals in their respective applications.

Quality Assurance and Materials

Quality is the cornerstone of CV Technik's operations. The company utilizes premium materials such as NBR (Nitrile Butadiene Rubber) and FKM (Fluorine Rubber) to manufacture their seals. NBR is celebrated for its excellent mechanical properties and abrasion resistance, making it suitable for a wide range of applications. FKM, on the other hand, offers exceptional chemical and heat resistance, ideal for high-temperature and chemically aggressive environments.

Applications Across Industries

CV Technik's high-pressure seals find applications across a multitude of industries:

Automotive: Ensuring the integrity of engines and transmission systems by preventing oil leaks and contamination.

Aerospace: Providing reliable sealing solutions for hydraulic systems and other critical components exposed to high pressures.

Manufacturing: Maintaining the efficiency of machinery by offering seals that can withstand the rigors of continuous operation under high pressure.

Hydraulic Systems: Preventing fluid leakage in hydraulic applications, ensuring smooth and efficient operation.

Global Reach with Local Presence

While CV Technik is rooted in Pune, its reach extends globally. With a presence in Germany, the company caters to international clients, bringing world-class sealing solutions to a global audience. This international collaboration ensures that clients receive products that adhere to global standards of quality and performance.

Commitment to Innovation and Sustainability

In an era where sustainability is paramount, CV Technik is dedicated to developing seals that not only meet performance expectations but also contribute to environmental conservation. By ensuring that their seals prevent leaks and contamination, they help industries minimize waste and reduce their environmental footprint.

Customer-Centric Approach

At the heart of CV Technik's operations is a customer-centric philosophy. The company offers engineering consulting services, assisting clients in selecting the most suitable sealing solutions for their applications. Additionally, their express products service ensures that clients receive their orders promptly, minimizing downtime and enhancing operational efficiency.

Conclusion

CV Technik's unwavering commitment to quality, innovation, and customer satisfaction has established it as a leader in the High-Pressure Radial Shaft Seal solutions industry. Their extensive range of products, combined with engineering expertise and a bespoke approach, ensures that clients across various sectors receive sealing solutions that are both reliable and efficient. As industries continue to evolve, CV Technik remains at the forefront, delivering products that meet the ever-changing demands of high-pressure applications.

0 notes

Text

GI Socket for Plumbing in Uttar Pradesh

Introduction

GI (Galvanized Iron) sockets are essential plumbing components used for connecting pipes in water supply, gas pipelines, and industrial applications. In Uttar Pradesh, finding high-quality GI sockets is crucial for ensuring durability and leak-proof connections.

What is a GI Socket?

A GI socket is a short pipe fitting with internal threads on both ends, allowing seamless connection between two GI pipes. These sockets are galvanized to prevent corrosion and enhance longevity.

Benefits of Using GI Sockets

Corrosion-resistant – Ideal for long-term plumbing applications.

High durability – Withstands high pressure and rough usage.

Leak-proof connections – Ensures secure fitting between pipes.

Cost-effective – Affordable and widely available in the market.

Types of GI Sockets Available in Uttar Pradesh

TypeDescriptionBest UsagePlain SocketStandard socket with internal threadsWater supplyReducing SocketConnects pipes of different diametersIndustrial useHeavy-duty SocketFor high-pressure applicationsGas pipelines

Top GI Socket Suppliers in Uttar Pradesh

Jindal Pipe Fittings – Lucknow (Best for bulk orders)

Mahadev Industries – Kanpur (Affordable pricing)

Shree Ram Pipe Traders – Varanasi (Wide product range)

Aggarwal Hardware – Agra (Quick delivery options)

Delhi Trading Co. – Meerut (Trusted by professionals)

How to Choose the Right GI Socket?

Check the Threading: Ensure proper fit with pipe threads.

Look for Galvanization Quality: Prevents rusting and enhances lifespan.

Verify Pressure Rating: Select based on water or gas pressure needs.

Compare Prices: Buy from trusted suppliers for cost efficiency.

Installation Guide for GI Sockets

Clean the pipe ends to remove dirt and rust.

Apply Teflon tape for a leak-proof seal.

Tighten the socket using a pipe wrench.

Test the connection by running water or gas.

FAQs

1. What is the standard size of a GI socket?

GI sockets come in sizes ranging from 1/2 inch to 6 inches, depending on the application.

2. Are GI sockets suitable for underground plumbing?

Yes, but they should be properly coated to prevent corrosion over time.

3. Where can I buy GI sockets in Uttar Pradesh?

You can purchase from local hardware stores, industrial suppliers, or online platforms like IndiaMART and TradeIndia.

4. How long does a GI socket last?

With proper installation and maintenance, GI sockets can last 10-20 years.

0 notes

Text

Low Density Plumber Tape Market, Global Outlook and Forecast 2025-2032

Low-density plumber tape, often referred to as Teflon tape or PTFE (Polytetrafluoroethylene) tape, is a type of thread-sealing tape used in plumbing applications to seal pipe threads and prevent leakage. It is made of a high-quality, flexible, and chemically resistant material that is particularly effective at sealing threaded connections, especially in water and gas systems. The tape is wound around the threads of pipes or fittings before they are tightened, providing a tight seal that helps prevent leaks and ensures system integrity.

Low-density plumber tape is typically used in applications where the sealing of threads in piping and plumbing fixtures is required. It’s especially useful in areas subject to high pressure and temperature fluctuations, as the tape can withstand extreme conditions while maintaining a secure seal. It’s commonly used in residential, commercial, and industrial plumbing systems, including those that involve water, gas, and other fluid transmission.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/287649/global-low-density-plumber-tape-forecast-market-2025-2032-653

Market Size

The global Low Density Plumber Tape market was valued at USD 215 million in 2023 and is projected to grow to USD 284.84 million by 2030, exhibiting a compound annual growth rate (CAGR) of 4.10% over the forecast period. This growth is attributed to the increasing demand for plumbing materials in both residential and commercial construction, as well as the expansion of the industrial sector, particularly in the areas of water treatment and gas distribution.

In North America, the Low Density Plumber Tape market was valued at USD 56.02 million in 2023. The region is expected to witness a steady growth rate of 3.51% CAGR from 2024 through 2030, driven by construction activities, the rising adoption of plumbing solutions in residential buildings, and increasing repair and maintenance activities in the commercial sector.

Market Dynamics

Drivers

Growth in Residential and Commercial Construction: The increasing demand for housing and commercial spaces, particularly in emerging markets, is driving the growth of plumbing materials such as Low Density Plumber Tape. As the construction industry booms, the need for effective and reliable sealing materials in plumbing systems continues to rise.

Industrial Expansion and Infrastructure Development: Significant investments in infrastructure development, especially in the water and gas sectors, have further fueled the demand for Low Density Plumber Tape. The tape’s role in ensuring leak-proof, durable, and efficient connections in pipelines is crucial to supporting industrial growth.

Rising Adoption in Maintenance and Repair Applications: With a growing number of plumbing systems reaching their service life, the repair and maintenance sector is expanding. Low Density Plumber Tape is widely used in plumbing repair tasks to prevent leaks and extend the lifespan of existing systems, driving the demand for the product.

Increased Awareness of Leak Prevention and Efficiency: Consumers and industries are becoming more conscious of water and energy efficiency. The use of Low Density Plumber Tape to ensure leak-free systems contributes to energy conservation, which is particularly significant in industries where energy and resource management is crucial.

Restraints

Raw Material Price Fluctuations: The price of materials used in the production of Low Density Plumber Tape, such as PTFE, can fluctuate based on the availability and cost of raw materials. These price fluctuations can impact manufacturers’ costs and, consequently, product prices, potentially affecting market growth.

Substitution by Other Sealing Solutions: Although Low Density Plumber Tape is widely used, other sealing solutions such as liquid sealants, pipe dope, or gasket seals could serve as alternatives. These options may offer advantages in certain applications, limiting the overall market potential for plumber tape.

Limited Awareness in Emerging Markets: In some emerging markets, the awareness of the benefits and usage of Low Density Plumber Tape may be limited, leading to slower adoption in certain regions. Additionally, the reliance on traditional sealing methods could hinder growth in these areas.

Opportunities

Rising Demand in Emerging Markets: As economies in Asia-Pacific, Latin America, and the Middle East continue to grow, the demand for plumbing materials, including Low Density Plumber Tape, is set to rise. Urbanization and industrialization in these regions present significant opportunities for market expansion.

Technological Advancements in Manufacturing: Manufacturers are exploring advanced production techniques to improve the quality and performance of Low Density Plumber Tape. Innovations in tape design, material enhancements, and the introduction of eco-friendly variants could create new opportunities within the market.

Sustainability Trends and Eco-Friendly Products: As environmental concerns rise, there is a growing trend towards using sustainable, non-toxic, and recyclable materials in plumbing products. Low Density Plumber Tape made from eco-friendly materials or manufactured using green processes could appeal to environmentally conscious consumers and businesses.

Challenges

Regulatory Compliance and Standards: Compliance with various regulatory standards and certifications, such as ISO or NSF certifications, can be challenging for manufacturers. The need to meet these standards in different regions may impact production timelines and costs.

Market Competition and Price Sensitivity: The market for Low Density Plumber Tape is highly competitive, with many manufacturers offering similar products. Price sensitivity among consumers and businesses could lead to pressure on manufacturers to maintain low prices while ensuring product quality.

Counterfeit and Substandard Products: The proliferation of counterfeit and low-quality plumber tapes poses a challenge to the market. These inferior products may compromise system integrity and lead to customer dissatisfaction, ultimately affecting brand reputation and market share.

Regional Analysis

North America

North America holds a significant share of the Low Density Plumber Tape market, driven by the robust construction and industrial sectors in the U.S. and Canada. The demand for high-quality plumbing solutions, along with stringent standards for plumbing systems, has contributed to the steady growth of the market. Moreover, a growing trend toward sustainable building practices and efficient water usage continues to push demand for reliable sealing solutions like plumber tape.

Europe

In Europe, countries like Germany, the U.K., and France are key contributors to the Low Density Plumber Tape market. The region’s developed infrastructure and high standards for building materials drive the demand for plumbing solutions in both residential and commercial sectors. The European market is also seeing an uptick in demand for eco-friendly plumbing solutions, as regulations on water conservation and energy efficiency become more stringent.

Asia-Pacific

The Asia-Pacific region is expected to experience the highest growth rate in the Low Density Plumber Tape market, driven by rapid urbanization, industrial growth, and an increase in infrastructure projects. Countries such as China, India, and Japan are witnessing significant demand for plumbing materials, driven by the growing need for clean water, gas systems, and sewage infrastructure.

Latin America and Middle East & Africa

While the market in these regions is relatively smaller, the demand for Low Density Plumber Tape is expected to increase in line with infrastructure growth, urbanization, and industrialization. As these regions focus on developing their plumbing systems, the need for leak-free connections will support the market's growth.

Competitor Analysis

The Low Density Plumber Tape market is fragmented, with numerous global and regional manufacturers competing for market share. Key players in the market are actively investing in research and development to improve the quality and performance of their products. Some of the major players in the market include companies specializing in plumbing materials, adhesives, and sealing solutions, as well as manufacturers focusing on eco-friendly and sustainable tape options.

Global Low Density Plumber Tape: Market Segmentation Analysis

This report provides a deep insight into the global Low Density Plumber Tape market, covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trends, niche markets, key market drivers, and challenges. The analysis helps readers shape the competition within the industries and develop strategies for the competitive environment to enhance potential profit.

Market Segmentation (by Application)

Residential Plumbing: Low Density Plumber Tape is widely used in residential buildings for plumbing installations, repair, and maintenance. It ensures leak-proof connections in water and gas systems.

Commercial Plumbing: Commercial buildings, including offices, restaurants, and hotels, rely on Low Density Plumber Tape for their plumbing needs. The tape is essential in preventing leaks in high-traffic, high-use systems.

Industrial Plumbing: Industrial facilities, especially those in manufacturing and production, utilize plumber tape for robust sealing in high-pressure pipelines and gas systems.

Market Segmentation (by Type)

Standard Low Density Plumber Tape: The most commonly used form of plumber tape, suitable for a wide range of plumbing applications.

Eco-Friendly Low Density Plumber Tape: A growing segment, offering sustainable, non-toxic materials for consumers and industries focused on environmental responsibility.

Key Company

The key companies in the Low Density Plumber Tape market include global leaders in plumbing solutions, such as companies that specialize in sealing products, adhesives, and other related materials for the plumbing industry.

Geographic Segmentation

This report also provides a detailed geographic segmentation of the global Low Density Plumber Tape market, analyzing key regions such as North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

FAQ Section

What is the current market size of the Low Density Plumber Tape market? The global Low Density Plumber Tape market was valued at USD 215 million in 2023.

Which are the key companies operating in the Low Density Plumber Tape market? Key companies include global manufacturers of plumbing materials and sealing products, focusing on both traditional and eco-friendly plumber tapes.

What are the key growth drivers in the Low Density Plumber Tape market? Key drivers include the growing construction industry, increasing demand in residential and commercial sectors, and rising awareness about leak prevention and efficiency.

Which regions dominate the Low Density Plumber Tape market? North America and Europe dominate the market, with significant demand from developed infrastructure and industrial sectors. The Asia-Pacific region is also experiencing rapid growth.

What are the emerging trends in the Low Density Plumber Tape market? Emerging trends include the rising demand for eco-friendly plumber tapes and innovations in manufacturing technologies aimed at improving performance and sustainability

Get the Complete Report & TOC @ https://www.24chemicalresearch.com/reports/287649/global-low-density-plumber-tape-forecast-market-2025-2032-653 Table of content

Table of Contents 1 Research Methodology and Statistical Scope 1.1 Market Definition and Statistical Scope of Low Density Plumber Tape 1.2 Key Market Segments 1.2.1 Low Density Plumber Tape Segment by Type 1.2.2 Low Density Plumber Tape Segment by Application 1.3 Methodology & Sources of Information 1.3.1 Research Methodology 1.3.2 Research Process 1.3.3 Market Breakdown and Data Triangulation 1.3.4 Base Year 1.3.5 Report Assumptions & Caveats 2 Low Density Plumber Tape Market Overview 2.1 Global Market Overview 2.1.1 Global Low Density Plumber Tape Market Size (M USD) Estimates and Forecasts (2019-2030) 2.1.2 Global Low Density Plumber Tape Sales Estimates and Forecasts (2019-2030) 2.2 Market Segment Executive Summary 2.3 Global Market Size by Region 3 Low Density Plumber Tape Market Competitive Landscape 3.1 Global Low Density Plumber Tape Sales by Manufacturers (2019-2024) 3.2 Global Low Density Plumber Tape Revenue Market Share by Manufacturers (2019-2024) 3.3 Low Density Plumber Tape Market Share by Company Type (Tier 1, Tier 2, and Tier 3) 3.4 Global Low Density Plumber Tape Average Price by Manufacturers (2019-2024) 3.5 Manufacturers Low Density Plumber Tape Sales Sites, Area Served, Product Type 3.6 Low Density Plumber Tape Market Competitive Situation and Trends 3.6.1 Low Density Plumber Tape Market Concentration Rate 3.6.2 Global 5 and 10 Largest Low Density Plumber Tape Players Market Share by Revenue 3.6.3 Mergers & Acquisitions, Expansion 4 Low Density Plumber TaCONTACT US: North Main Road Koregaon Park, Pune, India - 411001. International: +1(646)-781-7170 Asia: +91 9169162030

Follow Us On linkedin :- https://www.linkedin.com/company/24chemicalresearch/

0 notes

Text

When to Replace Your Shower Head?

When to Replace Your Shower Head?

Your shower head is an essential part of your daily routine, but like any fixture, it doesn't last forever. Experts recommend replacing your shower head every 5 to 8 years, or sooner if you experience certain issues. Keeping your shower head in good condition ensures optimal water pressure, efficiency, and hygiene.

Signs That Your Shower Head Needs Replacing

If you notice any of the following issues, it may be time to replace your shower head:

Weak or inconsistent water pressure: If your shower no longer delivers a strong, steady stream, mineral buildup or wear and tear could be to blame.

Leaks: Water dripping from the shower head even when the faucet is turned off can indicate damage or worn-out seals.

Sudden changes in water temperature: If your water temperature fluctuates unexpectedly, the shower head may not be regulating water flow properly.

Strange noises: Unusual sounds like whistling or rattling could signal internal damage or clogging.

Corrosion and buildup: Over time, mineral deposits and rust can affect performance and water quality.

Why You Should Replace Your Shower Head

Upgrading your shower head comes with several benefits:

Water conservation: Modern shower heads are designed to be more water-efficient, reducing your overall water usage.

Energy savings: By using less hot water, energy-efficient shower heads can lower your utility bills.

Improved aesthetics and functionality: New models offer sleek designs, multiple spray settings, and better durability.

How to Replace Your Shower Head

The good news is that replacing a shower head is a simple DIY task. If you opt for an easy-to-install model like the AquaCare Shower Head, you’ll have everything you need in the installation kit, including a manual and plumber’s tape.

How to Install the AquaCare Shower Head

Tools & Materials Needed:

Adjustable wrench (optional)

Teflon tape (included in the kit)

Mesh washers (included)

Steel wool (if necessary)

Step-by-Step Installation Guide

Step 1: Remove the Old Shower HeadTurn the existing shower head counterclockwise to unscrew it from the shower arm. Remove any debris from the threads. If necessary, use steel wool to clean the threads.

Step 2: Prepare the Shower ArmWrap Teflon tape around the shower arm threads 2-3 times in a clockwise direction to create a watertight seal.

Step 3: Attach the Hose ConnectionInsert a mesh washer inside the hose connector. Attach the hose to the shower arm by turning it clockwise until secure.

Step 4: Connect the Hose to the Shower HeadWrap Teflon tape around the shower head’s threaded connection. Insert another mesh washer into the hose end and twist the hose onto the shower head securely.

Step 5: Attach the Shower Head to the HolderPlace the shower head into its designated holder or mount. Ensure it is properly tightened without over-tightening.

Step 6: Test for LeaksTurn on the water and check for leaks at all connection points. If you notice any leaks, tighten the connections slightly or add another layer of Teflon tape.

Enjoy your AquaCare Shower Experience with improved water flow, efficiency, and style! 🚿✨

Replacing your shower head is an easy and cost-effective way to enhance your bathroom experience. Keep an eye out for signs of wear and upgrade when necessary to enjoy the benefits of modern shower technology.

Upgrade Your Shower Today! 🚿 Shop now at www.buyaquacare.com for the best in shower innovation!

0 notes