#small quantity garment manufacturer

Explore tagged Tumblr posts

Note

hi! if you're comfortable with sharing, i'm curious to know what shops that send lbs of fabric for the cost of shipping you were referring to in your contribution to the sustainable lifestyle post. or were these shops local to you? i'm getting into sewing and textiles to make clothes for myself and to give away to others and i feel this could be a very useful and affordable resource if you believe it possible to share!

A lot are local to me! Many small fabric shops will sell you their remnants in small quantities, sure, but many are also willing to simply sell you that scrap as a random assortment by weight! If they don't say so online, it never hurts to ask in person while you're checking their one-off remannt bins.

That said, more and more companies that have their own internal manufacture "remnant resale" process! So online shops like Quilt N Things, FabCycle, FabScrap, and MuuMuu Outlet will often carry "scrap by weight" purchase options in their shops! Your best bet is going to be finding where the local quilting community shops. These are people who are QUITE accustomed to purchasing fabric in wholesaler quantities with home-maker budgets, and they'll be able to direct you towards the best deals on this stuff.

I will say that it pays to learn how to identify fabrics when you do this, because random means random. I've received freight with scraps of brocade silk, embroidered and beaded fabric, raw muslin, pleather, oilcloth, wool, and so much more. You never know what might find its way into your box, and different fabrics do different things when incorporated into a garment. You can get more or less specific, but generally my biggest questions are always "is this an all-natural fabric or does it include polyester and other synthetic blends?" Because these I'm more likely to use outside as upholstry, garden fabric, or decor. That synthetic ingredient allows it to endure weather and moisture with less degredation, and makes it a worse option (for me due to medical issues) to use close to the skin, although it can be useful as an outer layer on raincoats and pants. Meanwhile, natural fibers like flax or cotton are extremely useful to me as lining fabric for garments, and fibers like wool are great for thermal regulation. My next question is usually about identifying the drape of a fabric, a mixture of understanding fiber content and weave and how that will look in the garment itself. Depending on what you're trying to do, you may have more questions you need to be able to answer, but it's all about your project needs.

Honestly, though, if you're an experimental sewer of any kind (e.g. a beginner still practicing stitching and construction techniques, or a tailor looking to drape a garment), these random assortments are a great way of always having enough fabric on hand that you don't mind sacrificing to the cause. I've found that one of the best ways to really get good at fiber craft is to lower the stakes of perceived failure. If I'm afraid to try something new, I try it on old moth eaten bedsheets I got for a dollar at the thrift shop, or on a 1000yd bundle of the cheapest imagineable yarn. Makes it easier to laugh off the cost of materials if it all goes lopsided. I'm able to get a lot more practice and test out a lot more approaches when it doesn't feel like an expensive waste of resources every time practice turns out....well. like practice!

Another really good option for you might be looking for free clothes being given away on Craigslist. These are most likely going to be mostly clothes not in shape for wearing, or they'd be sold or given to a thrift shop (although gems are always a possibility!). But given a good washing at the laundromat, they're a treasure trove of fabric scrap, and if there are any you like you can deconstruct them for patterning first before deconstructing for fabric purposes after! Voila, now you have 5-15lbs of fabric scrap and new patterns to boot, all for the cost of a laundromat and stock paper for pattern cutting.

Best of luck getting into your sewing! It's great fun, and when you start to get the hang of it, often you open up a whole world of possibilities you may bot otherwise have noticed!

8 notes

·

View notes

Note

Minority opinion obvs, but I was actually kind of bummed by the shorter mini lengths? I have some OG minis that don't quite cover as much of my booty as they used to, so I was hoping the longer back panel would help, but with the new sizes, it's more like the butt coverage is the same and the front is just shorter 😩 But the new sizes seem REALLY popular, so maybe this is a sign that I'm just not built for minis anymore!! I'll just have to keep an eye out for the next round of midis, and I'm SUPER excited to try out the wrap shirts, they look amazing!! Thank you to you and your team for being awesome!

they’re defs not for everyone!

but i wanted to make a true miniskirt this time around, since the minis before were really just skater skirts and not true miniskirts. especially bc in order to achieve the same length for the largest size as the smaller ones, with the skater skirt length the size D would have to be like 23-24” long and our midis are only like 25-27” long so the midi and skater skirts ended up being a little too similar in length/silhouette for my taste

there is potential for us to maybe eventually fill that middle length at some point but it would likely be a different type of skirt and it could be years in the future.

to draw back the curtain so what: we are a really small brand and it’s important for our different products to be significantly different from each other, since doing lots of small variations is more likely to split our consumer base and complicate our back end instead of expanding our consumer base. like imagine if i’m selling 2 shirts with the same design, but one is on red and the other is on black. there are some people who have absolutely no interest in black shirts and will ONLY buy a red shirt, but most people are gonna be happy with the black one and adding a red option mostly just serves to split the existing customer base instead of adding to it, and because i know have 2 very similar but separate products and because i have to hit a minimum order quantity per garment type/color (bc the fabric is made and dyed to order and there is a minimum quantity to make this worthwhile for the manufacturer), i’ve basically doubled my minimum required inventory, my cost and logistics without significantly increasing sales.

i hope this explanation makes sense haha! and sorry the new miniskirts don’t meet your needs 😅

66 notes

·

View notes

Text

How to Choose the Best T-Shirt Manufacturers in Chennai for Your Business

Introduction

Are you looking for reliable t shirt manufacturers in Chennai to supply high-quality T-shirts for your business? Whether you’re starting a clothing brand, running a promotional campaign, or need bulk orders for corporate uniforms, choosing the right manufacturer is crucial.

With so many options available, it can be challenging to find t shirt manufacturers in Chennai that match your budget, quality expectations, and delivery requirements. This guide will help you navigate the selection process with ease.

1. Understanding Your Business Needs

Before selecting t shirt manufacturers in Chennai, define your business goals and requirements:

✔️ Bulk vs. Custom Orders – Do you need a large stock of standard T-shirts, or are you looking for custom designs? ✔️ Fabric Type & Quality – Cotton, polyester, blends, or organic fabric? Choose based on comfort, durability, and pricing. ✔️ Printing & Embroidery Needs – Do you need screen printing, DTG, sublimation, or embroidery for branding? ✔️ Budget & Pricing – Compare costs among different t shirt manufacturers in Chennai to get the best deal.

💡 Tip: Having a clear requirement list will help you filter manufacturers and negotiate better deals.

2. Evaluating Fabric & Material Quality

The quality of T-shirts depends on the fabric used. Here are the most common materials provided by t shirt manufacturers in Chennai:

🔹 100% Cotton – Soft, breathable, and ideal for premium T-shirts. 🔹 Cotton-Polyester Blend – Wrinkle-resistant and durable, best for casual wear. 🔹 Polyester – Lightweight and moisture-wicking, suitable for sportswear. 🔹 Organic Cotton – Sustainable and eco-friendly, perfect for premium brands.

💡 Tip: Ask for fabric samples before placing a bulk order with any t shirt manufacturers in Chennai.

3. Choosing the Right Printing & Branding Options

If you need branded or customized T-shirts, ensure the manufacturer offers various printing techniques:

🎨 Screen Printing – Best for bulk orders with a simple design. 🎨 Direct-to-Garment (DTG) Printing – Ideal for full-color prints on small batches. 🎨 Sublimation Printing – Best for polyester T-shirts with vibrant designs. 🎨 Embroidery – Great for premium corporate and uniform branding.

💡 Tip: Work with t shirt manufacturers in Chennai who provide in-house printing and branding services for better quality control.

4. Checking Manufacturer’s Reputation & Experience

When selecting t shirt manufacturers in Chennai, check their market reputation and experience:

✔️ Years in Business – Look for manufacturers with at least 5+ years of experience. ✔️ Client Reviews & Testimonials – Check Google reviews and social media feedback. ✔️ Past Work Samples – Request T-shirt samples to assess fabric and print quality. ✔️ Certifications – Ensure they follow ethical and sustainable production practices.

💡 Tip: Trustworthy t shirt manufacturers in Chennai will have a solid client base and transparent business policies.

5. Comparing Pricing & Bulk Order Discounts

Pricing plays a major role when choosing t shirt manufacturers in Chennai. Consider these factors:

📌 Minimum Order Quantity (MOQ) – Some manufacturers require large MOQ commitments. 📌 Cost per T-Shirt – Prices vary based on fabric type, design complexity, and quantity. 📌 Bulk Discounts – Ordering 500+ T-shirts can significantly reduce per-unit costs. 📌 Hidden Costs – Ask about shipping fees, printing charges, and additional costs.

💡 Tip: Get detailed price quotes from multiple t shirt manufacturers in Chennai before making a final decision.

6. Evaluating Production Capacity & Delivery Timelines

Timely delivery is critical for business operations. When choosing t shirt manufacturers in Chennai, check their production capacity and lead times:

📌 Production Speed – Can they handle bulk orders within your deadline? 📌 Delivery Network – Do they offer shipping across India or international exports? 📌 Order Tracking – Ensure they provide real-time order tracking for transparency.

💡 Tip: Reliable t shirt manufacturers in Chennai will offer on-time delivery guarantees and order tracking systems.

7. Choosing a Manufacturer with Ethical & Sustainable Practices

Eco-friendly and ethical manufacturing is becoming a key consideration for businesses. Look for t shirt manufacturers in Chennai that:

🌱 Use organic or recycled fabrics. 🌱 Follow fair labor practices. 🌱 Offer sustainable printing methods like water-based inks.

💡 Tip: Ethical t shirt manufacturers in Chennai help build a responsible and eco-conscious brand.

Conclusion

Finding the right t shirt manufacturers in Chennai is essential for ensuring high-quality T-shirts, cost-effective production, and timely delivery. By focusing on fabric quality, printing options, pricing, and manufacturer reliability, you can make an informed decision.

Call to Action

Looking for the best t shirt manufacturers in Chennai? Contact us today for custom designs, bulk orders, and competitive pricing! 📩

0 notes

Text

Comprehensive Guide to Foam & Textile Recycling Machines

In an era marked by increased environmental consciousness, recycling technology plays a pivotal role in sustainability efforts, particularly in the foam and textile industries. Foam and textiles contribute significantly to landfill waste, and recycling these materials can drastically reduce environmental impact while providing economic benefits. This article explores essential recycling machines such as foam cutting machines, textile shredders, cloth shredders, fabric shredding machines, cloth shredder machines, and PU foam shredders.

Foam Cutting Machine

Foam cutting machines are specialized equipment designed to efficiently and precisely cut various types of foam materials, including polyurethane foam (PU foam). They are instrumental in repurposing foam waste into usable forms. Foam cutting machines range from manual hot wire cutters to advanced automated CNC cutting equipment.

Key Features:

High precision cutting

Adjustable speed and temperature controls

Suitable for various foam densities

Minimal wastage during cutting

Applications:

Recycling foam waste from mattresses, furniture, and packaging

Creating insulation panels

Crafting foam inserts for packaging

PU Foam Shredder

PU foam shredders specifically target polyurethane foam, converting large foam blocks or scraps into small, manageable pieces. Shredded foam is easier to handle, transport, and repurpose, significantly reducing waste volumes.

Key Features:

Robust construction

Efficient shredding blades designed for PU foam

High throughput capacity

Easy maintenance and cleaning

Applications:

Mattress recycling

Production of recycled foam for upholstery

Padding material for automotive and furniture industries

Textile Shredder

Textile shredders play a critical role in the recycling process by shredding used textiles into smaller, reusable fibers. These machines handle various materials, including cotton, wool, polyester, and blended fabrics, making textile waste manageable and ready for secondary applications.

Key Features:

Powerful shredding blades

Ability to handle mixed textile materials

Efficient processing speed

Automated material feeding systems

Applications:

Textile waste recycling facilities

Production of recycled yarns and fabrics

Insulation and padding production

Cloth Shredder / Cloth Shredder Machine

Cloth shredders or cloth shredder machines specialize in breaking down fabric waste into smaller fragments or fibers, suitable for repurposing. They are highly efficient at processing old clothing, industrial fabric waste, and manufacturing leftovers.

Key Features:

Heavy-duty blades capable of shredding dense fabrics

Variable shred size settings

Durable construction for continuous operation

Applications:

Recycling garments and textile scraps

Creating industrial cleaning rags

Manufacturing padding and insulation materials

Textile Shredding Machine

Textile shredding machines are comprehensive devices designed for industrial-scale recycling of large quantities of textile waste. They integrate robust shredding systems with automated sorting and conveying features, significantly enhancing productivity and efficiency.

Key Features:

Industrial-scale shredding capacity

Automated sorting and separation capabilities

Efficient handling of large textile batches

Applications:

Industrial recycling facilities

Production lines for textile-based insulation

Recovery of fibers for new textile manufacturing

Fabric Shredding Machine

Fabric shredding machines specifically target various fabric types, converting textile scraps into reusable fibers or stuffing materials. These machines are crucial in achieving zero-waste manufacturing practices within the textile industry.

Key Features:

Precision shredding technology

Adaptability to different fabric thicknesses

High safety standards and automated shutdown mechanisms

Applications:

Production of recycled fabric products

Manufacture of eco-friendly stuffing materials

Textile waste reduction initiatives

Importance of Foam & Textile Recycling Machines

Investing in foam and textile recycling machines such as foam cutting machine, PU foam shredders, textile shredders, cloth shredder machines, textile shredding machines, and fabric shredding machines provides substantial environmental and economic advantages:

Waste Reduction: Significantly decreases landfill waste, mitigating environmental pollution.

Resource Efficiency: Recovered materials can be reused, reducing dependency on virgin resources.

Economic Benefits: Lowers disposal costs and generates revenue from recycled products.

Sustainability Goals: Supports corporate and community sustainability targets, enhancing eco-friendly practices.

Conclusion

Foam and textile recycling machines are essential components of modern recycling processes, turning what would otherwise be waste into valuable resources. These advanced technologies, including foam cutting machines, PU foam shredders, and various textile shredding machines, provide viable solutions to address the critical challenge of textile and foam waste. By adopting these recycling systems, industries can significantly enhance their environmental responsibility, promote sustainable production, and achieve economic benefits through efficient waste management practices.

youtube

0 notes

Text

Screen Printing vs. Sublimation: What T-Shirt Manufacturers in Chennai Recommend

When it comes to custom apparel, choosing the right printing technique is essential for achieving high-quality results. Two of the most popular methods used by t shirt manufacturers in Chennai are screen printing and sublimation printing. Each method has its unique advantages, making it suitable for different types of fabrics, designs, and purposes.

If you're planning to start a clothing brand, create promotional merchandise, or order bulk t-shirts, understanding the difference between screen printing and sublimation can help you make the right choice. Let’s explore these techniques in detail and see what leading t shirt manufacturers in Chennai recommend.

What is Screen Printing?

Screen printing, also known as silk screen printing, is one of the oldest and most widely used t-shirt printing methods. It involves pushing ink through a mesh stencil onto the fabric to create a design.

Advantages of Screen Printing:

Durability: The prints are long-lasting and can withstand multiple washes.

Vibrant Colors: Produces bright and opaque colors, even on dark fabrics.

Cost-Effective for Bulk Orders: Ideal for large-scale printing as the setup cost is high but cost per unit decreases in bulk.

Compatible with Different Fabrics: Works well on cotton, polyester, and blended fabrics.

Limitations of Screen Printing:

Not Ideal for Complex Designs: Limited to a few colors per design due to stencil setup.

Higher Setup Costs: Requires separate screens for each color, making small orders expensive.

Longer Production Time: Setup takes time, making it less efficient for quick, one-off prints.

Example: A sportswear brand in Chennai used screen printing for their team jerseys, ensuring long-lasting, vibrant logos and text on breathable cotton fabrics.

What is Sublimation Printing?

Sublimation printing is a heat-based process where designs are transferred from a special sublimation paper to fabric using heat and pressure. The ink turns into gas and bonds with polyester fibers, creating a permanent, high-resolution print.

Advantages of Sublimation Printing:

High-Quality, Full-Color Prints: Produces photo-realistic designs with no color limitations.

Soft and Breathable: The ink becomes part of the fabric, ensuring no extra layers or textures.

Long-Lasting and Fade-Resistant: Colors do not crack, peel, or fade over time.

Eco-Friendly: Uses less water and fewer chemicals compared to screen printing.

Limitations of Sublimation Printing:

Only Works on Polyester: The process bonds best with polyester or polyester-coated materials, limiting fabric options.

Not Suitable for Dark Fabrics: Works best on white or light-colored garments as it doesn’t print white ink.

Higher Cost for Small Orders: The initial investment in sublimation printers and inks can be costly.

Example: A Chennai-based fashion startup used sublimation printing for their custom athleisure line, ensuring high-definition prints on moisture-wicking polyester t-shirts.

Which Printing Method is Best for You?

The choice between screen printing and sublimation depends on your specific needs. Here’s a quick comparison to help you decide: Feature Screen Printing Sublimation Printing Best For Bulk orders, simple designs High-resolution, full-color prints Fabric Works on cotton, polyester, blends Works only on polyester Durability Very durable but may crack over time Permanent, doesn’t fade or crack Color Options Limited to a few colors Unlimited, full-color printing Cost Cheaper for large orders More cost-effective for small orders Best Use Cases Company t-shirts, uniforms, event merch Personalized t-shirts, fashion wear, sportswear

What T-Shirt Manufacturers in Chennai Recommend

Leading t shirt manufacturers in Chennai suggest choosing the right printing method based on the purpose, quantity, and fabric type:

For bulk orders (corporate t-shirts, promotional wear): Screen printing is the best choice due to its cost-effectiveness and durability.

For fashion brands and personalized t-shirts: Sublimation printing offers unmatched quality and vibrant designs.

For dark-colored t-shirts: Screen printing works better as sublimation is not suitable for dark fabrics.

For quick, one-off prints: Sublimation is more efficient as it doesn’t require setup like screen printing.

Final Thoughts: Which One Should You Choose?

Both screen printing and sublimation have their advantages. If you're looking for long-lasting, cost-effective printing for bulk orders, screen printing is the way to go. However, if you want high-resolution, colorful, and seamless designs, sublimation printing is your best bet.

If you're still unsure, consult experienced t shirt manufacturers in Chennai to guide you based on your specific requirements. Ready to get started? Reach out to trusted t shirt manufacturers in Chennai today and bring your custom designs to life! 🎨👕

0 notes

Text

Wholesale Clothing in Europe: A Growing Industry with Endless Opportunities

The Landscape of Wholesale Clothing in Europe

Europe has long been a key player in the global fashion industry, with countries like Italy, France, the United Kingdom, and Spain being well-known for their rich history in fashion and textile production. Today, European wholesale clothes Europe suppliers offer a wide range of apparel to meet the needs of retailers across the continent. Whether it’s high-end, luxury garments or trendy streetwear, the wholesale sector provides options for businesses of all sizes.

One of the key benefits of buying wholesale clothing in Europe is the ability to source products from within the continent. This not only reduces shipping times and costs but also supports sustainability efforts by reducing the carbon footprint associated with long-distance shipping. In addition, many European manufacturers uphold high-quality standards, which adds value to the products sold and helps maintain the reputation of the retailers that stock them.

The Role of Online Wholesale Platforms

With the rise of e-commerce, online Fashion Wholesale Europe platforms have become an essential tool for connecting European clothing suppliers with global buyers. These platforms allow retailers to browse vast product catalogs, compare prices, and place orders with ease, all from the comfort of their own offices. By offering a wide range of clothing styles, sizes, and designs, these platforms make it easier than ever for retailers to source inventory that matches their target market.

The convenience and accessibility of online wholesale platforms have led to a surge in small and medium-sized businesses that may have otherwise struggled to access wholesale suppliers. In fact, many online platforms offer low minimum order quantities (MOQs), allowing even smaller retailers to stock popular clothing items without the financial burden of bulk purchasing.

Key Trends in European Wholesale Clothing

As the wholesale clothing market continues to evolve, several trends are shaping the industry:

Sustainability and Ethical Production: Consumers are becoming more conscious of the environmental and social impact of their purchasing decisions. As a result, there is a growing demand for wholesale clothing that is sustainably produced, made from eco-friendly materials, and manufactured under ethical working conditions. Retailers who prioritize these values are more likely to attract environmentally and socially conscious consumers.

Customization and Personalization: Another key trend is the growing demand for personalized or custom-designed clothing. Wholesale suppliers are responding by offering customizable options, from embroidered logos to unique prints and colors, allowing retailers to create a distinctive brand identity.

Technology and Innovation: The incorporation of new technologies into the wholesale clothing industry has also seen significant growth. From augmented reality tools for virtual garment fitting to data analytics that help predict fashion trends, technology is revolutionizing how businesses source and sell clothing. Suppliers who adopt these innovations can stay ahead of the curve and offer unique experiences to their clients.

The Advantages of Wholesale Clothing Transactions

Engaging in wholesale clothing transactions offers numerous advantages for retailers. First and foremost, buying clothing in bulk helps reduce per-unit costs, which can lead to higher profit margins. Wholesale prices often offer significant savings compared to retail pricing, enabling businesses to pass on the savings to consumers or reinvest them into expanding their inventory.

In addition to cost savings, wholesale clothing transactions also allow retailers to offer a broader range of products to their customers. This helps them keep up with ever-changing fashion trends and consumer preferences, ensuring their stores remain competitive in the fast-paced fashion industry.

0 notes

Text

How to Export to the USA from India: A Complete Guide for Indian Exporters

The United States is one of the biggest markets for Indian products. Every year, thousands of businesses in India export goods to the USA, taking advantage of the high demand and trade opportunities. If you are looking to export to usa from india, this guide we will explore the process step by step.

Why Export to the USA?

The USA is one of the top trading partners of India, with billions of dollars worth of goods exchanged every year. Indian products, especially textiles, pharmaceuticals, IT services, and food products, have a huge demand in the US market. Here are some reasons why exporting to the USA is beneficial:

Large Market: The USA has a massive customer base looking for high-quality imported goods.

Diverse Opportunities: From handmade crafts to industrial machinery, Indian businesses can export a wide variety of products.

Trade Agreements: India and the USA have trade relationships that provide benefits like reduced tariffs and easier trade regulations.

High Profit Margins: Indian products are often cost-effective, allowing exporters to make good profits in the US market.

Step-by-Step Guide to Export to the USA

1. Identify the Right Products to Export

Before starting, research what products are in demand in the USA. Some of the top Indian exports to the USA include:

Textiles and garments

Pharmaceuticals and medical equipment

IT services and software

Handicrafts and home decor

Spices and food products

Automobile parts and machinery

Choosing the right product ensures better market success and profitability.

2. Obtain the Necessary Licenses and Registrations

To export legally, you need to have the right documents and registrations:

Import Export Code (IEC): You must apply for an IEC from the Directorate General of Foreign Trade (DGFT) in India.

GST Registration: Ensure that your business is registered under the Goods and Services Tax (GST) in India.

FDA Approval (for food and pharmaceutical products): If you are exporting food or medicine, you need approval from the US Food and Drug Administration (FDA).

Certificate of Origin: This proves that your goods are manufactured in India and are eligible for trade agreements.

3. Find Buyers in the USA

Finding reliable buyers is crucial for successful exports. Here are some ways to connect with potential buyers:

Online Marketplaces: Platforms like Exporters Worlds, Amazon, and TradeIndia can help you reach international buyers.

B2B Portals: Register on B2B platforms like Exporters Worlds to connect with US importers.

Trade Fairs and Exhibitions: Attending trade shows in India and the USA can help you find direct buyers.

Networking: Use LinkedIn and other social media to connect with businesses looking for Indian products.

4. Understand USA Import Regulations

The USA has strict import regulations that every exporter must follow. Here are some key points:

Customs Duties & Tariffs: Check the US Harmonized Tariff Schedule (HTS) to know the duty rates for your products.

Labeling & Packaging: Products must have clear labels with details like ingredients, manufacturing date, and country of origin.

Compliance with US Laws: Ensure your products meet US safety and quality standards (such as FDA, EPA, or FCC regulations).

5. Choose the Right Shipping Method

Export to usa from india requires efficient logistics. You can choose from different shipping methods based on your product type and budget:

Air Freight: Faster but more expensive, best for high-value or perishable goods.

Sea Freight: Cost-effective for bulk shipments but takes longer.

Courier Services: Good for small shipments but may have higher costs.

6. Complete Customs Clearance

When your goods reach the USA, they must go through customs clearance. Here’s what you need:

Bill of Lading (BOL) or Airway Bill: Proof of shipment details.

Commercial Invoice & Packing List: Details of the goods, their value, and quantity.

US Customs Declaration: Filed electronically through the Automated Commercial Environment (ACE) system.

Importer Security Filing (ISF): Required for sea shipments before goods are loaded in India.

Hiring a customs broker in the USA can help speed up this process and avoid any delays.

7. Market and Expand Your Business in the USA

Once your products reach the US market, you need strong marketing strategies to grow your business:

Digital Marketing: Create a website and use SEO to attract US customers.

Social Media Advertising: Promote your brand on Facebook, Instagram, and LinkedIn.

E-commerce Platforms: Sell directly on Exporters Worlds, eBay, or Walmart Marketplace.

Local Distributors: Partner with local sellers and wholesalers for better reach.

Challenges in Exporting to the USA and How to Overcome Them

While exporting to the USA is profitable, there are challenges that exporters face. Here’s how to handle them:

1. High Competition

The US market is highly competitive. To stand out, focus on quality, competitive pricing, and strong branding.

2. Complex Regulations

US import laws can be strict. Hiring an export consultant or customs broker can help navigate regulations smoothly.

3. Currency Exchange Fluctuations

Since trade happens in USD, currency fluctuations can impact profits. Using forex hedging services can help manage risks.

4. Shipping Delays

Delays in shipping can affect business. Work with reliable logistics partners to ensure smooth delivery.

How Exporters Worlds Can Help You Export to the USA

At Exporters Worlds, we help Indian exporters successfully enter the US market. Our services include:

Expert Consultation: Guidance on licenses, documentation, and regulations.

Buyer Connections: Helping you find genuine buyers in the USA.

Logistics Support: Assisting with shipping, customs clearance, and warehousing.

Marketing Assistance: Helping you promote your products in the US market.

Conclusion

Exporting to the USA from India is a great opportunity for businesses looking to expand globally. By following the right steps, understanding regulations, and finding the right buyers, you can successfully grow your export business.

If you’re ready to start exporting to the USA, Exporters Worlds is here to support you every step of the way. Contact us today to take your business global!

#export to USA from India#Indian exporters to USA#how to export from India to USA#USA import regulations#best products to export from India#export business India to USA#shipping from India to USA#customs clearance USA#Indian export documentation#trade with USA from India

0 notes

Text

Exploring the Trend of Wholesale Vintage Clothing: A Blend of History and Fashion

Wholesale vintage clothing

https://italianvintagewholesale.com/

has seen a remarkable rise in popularity, transforming the fashion industry into a vibrant mix of nostalgia and sustainability. As more consumers turn towards eco-friendly options and a desire to stand out from fast fashion trends, vintage clothing offers a unique alternative. Whether it’s a treasured leather jacket from the '70s or a floral dress from the '80s, vintage pieces bring with them stories, quality, and individuality. For businesses looking to tap into this growing market, wholesale vintage clothing provides an opportunity to curate collections that celebrate both the past and the future of fashion.

In today’s fashion world, vintage clothing is no longer a niche market. It has become a significant part of mainstream fashion culture, embraced by influencers, celebrities, and fashion-forward individuals alike. This surge in popularity has led to an increased demand for vintage clothing, especially in bulk quantities, for retailers looking to offer a wide array of authentic styles. Wholesale suppliers, therefore, play a crucial role in connecting vintage lovers with businesses that wish to curate their own collections, offering everything from one-of-a-kind pieces to carefully selected, era-specific clothing.

What makes wholesale vintage clothing so appealing to modern buyers is its emphasis on sustainability. As environmental concerns continue to grow, more people are moving away from disposable fashion, looking for items that are not only timeless but also have a minimal environmental footprint. Vintage clothing is inherently sustainable because it reuses existing materials, reducing the need for new manufacturing processes. Many businesses now focus on sourcing high-quality, durable items from previous decades, ensuring that these garments live on for years to come.

The beauty of vintage clothing lies not only in its style but in the quality of craftsmanship. Before the age of mass production, clothes were often made by hand or produced in small quantities with great attention to detail. This is why vintage items, particularly those from the mid-20th century, are prized for their sturdiness and unique designs. Retailers dealing in wholesale vintage clothing often prioritize pieces that reflect this craftsmanship, helping consumers invest in quality rather than quantity. From tailored suits to handmade accessories, the timeless appeal of vintage garments lies in their superior construction and individuality.

For businesses looking to enter the world of wholesale vintage clothing, the key to success is sourcing wisely. It's important to find suppliers that offer authentic pieces with a guarantee of quality. This can involve traveling to vintage warehouses, thrift stores, or working with trusted curators who specialize in collecting and preserving fashion history. By choosing high-quality suppliers, businesses can offer their customers genuine, rare items that hold both value and sentiment.

As the vintage clothing market continues to expand, it's clear that this trend is more than just a passing phase. It's a way to reconnect with history while supporting sustainable practices and celebrating unique styles. Whether you’re a small boutique or a large retailer, embracing wholesale vintage clothing is a powerful way to meet the demand for unique, eco-conscious fashion while ensuring that timeless pieces remain in circulation for generations to come.

0 notes

Text

How to Find the Best Denim Manufacturer for Small Clothing Brands: A Guide to Low-Quantity Production

Denim—it's the fabric that never goes out of style. From classic jeans to trendy jackets and skirts, denim has long been a staple in wardrobes worldwide. For emerging clothing brands looking to tap into the denim market, however, producing quality denim wear can be a challenge—especially when the goal is to start with low-quantity orders. Whether you’re based in the USA, UK, Australia, Canada, or Europe, finding the right denim manufacturer who can accommodate small batches while maintaining the quality and sustainability standards your brand stands for can make all the difference.

If you're wondering how to get started, here's a comprehensive guide on everything you need to know about denim manufacturing for small orders. Let’s break down what the process looks like, the benefits of low-quantity denim production, and how to partner with the right manufacturer for your brand’s success.

What Does Denim Manufacturing Involve?

Denim manufacturing isn't just about producing jeans. It's about creating high-quality, durable garments that are crafted with care. From sourcing the fabric to applying finishing techniques, each step of the process is crucial. Here's a look at the denim manufacturing stages:

1. Denim Fabric Sourcing

The first step in denim manufacturing is sourcing the fabric. Denim fabric typically comes in a woven twill pattern, often dyed with indigo to achieve that iconic blue look. For small batch production, you might choose to either source pre-made denim or work with your manufacturer to create a custom denim fabric that suits your specific needs.

Popular fabric choices for denim include:

Raw Denim: Unwashed and untreated denim that will fade naturally over time.

Stonewashed Denim: A pre-washed, faded denim for a more worn-in look.

Eco-Friendly Denim: Made from organic cotton or recycled fibers, this type of denim is growing in popularity as sustainability becomes a top priority for many brands.

2. Pattern Making and Cutting

Once the fabric is sourced, the next stage is creating the patterns that will be used to cut the fabric into pieces. Whether you’re making jeans, jackets, skirts, or accessories, pattern-making ensures each piece is cut precisely, reducing fabric waste and making the most out of your materials.

For low-quantity denim orders, you’ll often work with a manufacturer who can create custom patterns that match your designs, whether it's a classic cut or something more experimental.

3. Sewing and Assembly

After the fabric is cut, it’s time to sew the pieces together. This is where the craftsmanship comes into play. Each piece of denim is carefully sewn to create the final garment. During this phase, you may also add elements like zippers, buttons, rivets, and labels—all of which are considered trimmings.

For smaller runs, manufacturers often focus more on precision and quality to ensure every stitch is perfect. If your brand is known for attention to detail, this is the stage where your product really starts to take shape.

4. Washing and Finishing

Denim can be finished in several ways to achieve different looks and textures. This includes:

Stone washing to give denim a faded, worn look.

Distressing or whiskering to mimic natural wear patterns.

Rinsing to soften the fabric and remove excess dye.

The finishing process gives each pair of jeans or denim jacket its unique personality. For small orders, you can work with manufacturers who offer custom finishing techniques, which means you can experiment with various washes and distressing methods to create a truly one-of-a-kind product.

The Benefits of Low-Quantity Denim Production

While mass production often offers lower unit costs, low-quantity denim manufacturing has several key advantages for small clothing brands looking to build their niche and identity in the denim market:

1. Customization

Low-quantity production allows you to have greater control over the design. You can select the denim weight, finishes, and even the stitching methods to create products that align perfectly with your brand’s aesthetic. This flexibility is especially valuable if you're building a unique collection or experimenting with new styles.

2. Lower Risk

When producing small batches, you're not committing to large quantities of inventory, which means there’s less risk involved. You can test the market with smaller orders to see which styles or fits resonate best with your target audience. This is an ideal approach for startups and emerging brands.

3. Sustainability

Small-batch production can be much more sustainable than mass manufacturing. You can work with manufacturers who prioritize eco-friendly practices, such as using organic cotton or recycled denim. Additionally, smaller runs tend to have fewer waste materials, reducing the overall environmental impact of your production process.

4. Faster Turnaround Times

With low-quantity orders, production times tend to be shorter. You can work with manufacturers who are agile enough to deliver products faster, enabling you to respond to trends or adjust your collections more quickly.

How to Choose the Right Denim Manufacturer for Small Orders

When looking for a denim manufacturer who specializes in small orders, there are a few key factors to consider:

1. Expertise and Experience

Look for manufacturers with extensive experience in denim production. Denim is a unique fabric that requires specialized knowledge to work with, especially if you’re looking for high-quality finishes or customized designs.

2. Sustainability Practices

If sustainability is important to your brand, make sure the manufacturer offers eco-friendly options like organic denim, waterless dyeing, and low-impact finishing techniques. These practices can help reduce your brand's carbon footprint.

3. Flexibility with Low Minimum Order Quantities (MOQs)

Not all manufacturers are open to small-batch production, so look for companies that offer flexible minimum order quantities. This allows you to test different designs or styles without committing to large quantities.

4. Quality Control

With smaller orders, you want to make sure your denim products meet your quality standards. Choose a manufacturer that offers detailed quality control checks throughout the production process to ensure that every garment is up to par.

Sustainable Denim: An Essential Element for Future Fashion

Sustainability is becoming increasingly important to denim consumers. More and more brands are turning to eco-friendly denim production to reduce their environmental impact. This includes using recycled denim, organic cotton, and adopting more energy-efficient production processes.

By working with a sustainable denim manufacturer, you can not only create beautiful products but also build a brand that aligns with the growing demand for environmentally responsible fashion.

Conclusion: Start Your Denim Journey with the Right Manufacturing Partner

Launching a successful denim collection with low-quantity production is entirely possible with the right denim manufacturing partner. By working with experts who understand the complexities of denim fabric, design, and sustainable production methods, you can bring your denim vision to life while staying true to your brand’s values.

At Ro & RItzy, we specialize in small-batch denim production and offer a wide range of eco-friendly denim options. Whether you’re based in the USA, UK, Canada, Australia, or Europe, we provide custom solutions for clothing brands looking to make an impact with quality, sustainable denim. Reach out today to get started on creating your perfect denim collection!

#Denim Manufacturer#Denim Manufacturing#Low-Quantity Denim Orders#Small Batch Denim Production#Sustainable Denim Manufacturing#Denim Fabric Sourcing#Denim Manufacturing USA#Denim Manufacturing UK#Denim Manufacturer Australia#Denim Jeans Manufacturing#Denim Apparel Production#Denim Apparel Manufacturing#Denim Manufacturers near me#Jeans Manufacturers near me#Jeans manufacturers in UK

0 notes

Text

Mriganka’s Guide to Ethical Fashion

In today’s fast-paced world, fashion trends often change quickly, leaving a trail of overproduction, waste, and environmental damage. The rise of fast fashion has contributed significantly to the depletion of natural resources, pollution, and exploitation of workers in developing countries. However, there is a growing movement toward ethical fashion—a movement that focuses on sustainability, fairness, and responsibility. One such advocate for ethical fashion is Mriganka, a brand dedicated to creating clothing that not only looks good but also feels good, both for the wearer and the planet.

In this blog, we’ll take a closer look at what ethical fashion is, why it’s important, and how Mriganka is leading the charge toward a more sustainable and responsible future for the fashion industry.

What is Ethical Fashion?

Ethical fashion, at its core, is a way of producing and consuming clothing that minimizes harm to the environment and society. It is about making thoughtful choices that support the well-being of the planet, workers, and communities. Ethical fashion includes aspects such as:

Sustainable Materials: Using organic or recycled fabrics and materials that have a lower environmental footprint.

Fair Labor Practices: Ensuring workers are paid fairly, work in safe conditions, and are treated with respect.

Eco-friendly Production: Reducing waste and energy consumption during the manufacturing process.

Animal Welfare: Avoiding the use of animal products like leather or fur unless sourced responsibly.

The movement towards ethical fashion is part of a broader shift in the fashion industry, where more consumers are demanding transparency from brands and choosing sustainable options over mass-produced garments.

Mriganka: A Brand with a Vision

Mriganka is one of the leading names in the ethical fashion world. The brand’s mission is to provide consumers with stylish, high-quality clothing that reflects their values of sustainability and social responsibility. Whether it’s through the use of eco-friendly fabrics, transparent supply chains, or supporting local artisans, Mriganka is committed to reshaping the fashion landscape.

The company’s commitment to sustainability is evident in its collection, which incorporates eco-friendly materials like organic cotton, hemp, and bamboo. By prioritizing these materials, Mriganka ensures that its clothing is not only kind to the earth but also safe for the skin.

Furthermore, Mriganka emphasizes the importance of fair wages and safe working conditions for its employees. The brand collaborates with artisans from various regions, providing them with opportunities for fair compensation and professional growth. This practice supports both the workers and their communities, making it a truly ethical fashion brand.

The Importance of Ethical Fashion

The importance of ethical fashion cannot be overstated. In a world where overconsumption and environmental degradation are major concerns, ethical fashion offers a way to take control of our impact on the planet. Here are some key reasons why ethical fashion is crucial:

Environmental Impact: The fashion industry is responsible for a significant amount of pollution. By opting for ethical fashion, consumers can reduce their carbon footprint, water usage, and waste.

Fair Treatment of Workers: Many workers in the fashion industry, especially in low-wage countries, suffer from poor working conditions and unfair pay. Ethical fashion ensures that workers are treated fairly and paid a living wage.

Support for Local Communities: Ethical fashion often involves supporting small-scale artisans and local businesses, which strengthens communities and preserves traditional craftsmanship.

Quality Over Quantity: Ethical fashion promotes quality over quantity, encouraging consumers to invest in timeless pieces that last longer, rather than buying cheap, disposable items.

How Mriganka is Paving the Way for Ethical Fashion

Mriganka’s dedication to ethical fashion goes beyond just offering sustainable products—it’s about creating a movement that encourages others to adopt more sustainable practices. Here’s how Mriganka is making a difference:

Sustainable Sourcing: Mriganka ensures that its raw materials are sourced from sustainable farms or recycled products. By reducing the demand for virgin materials, they help minimize environmental harm.

Eco-friendly Production: Mriganka’s manufacturing process focuses on minimizing waste and energy consumption. The brand uses water-saving dyeing techniques and reduces chemical use in production.

Transparency and Accountability: One of the standout features of Mriganka’s approach is its transparency. The brand openly shares information about where its materials come from and how the clothing is made. This level of transparency builds trust with consumers and sets a new standard for the industry.

Innovative Designs: Mriganka’s collection is a perfect blend of contemporary fashion and timeless style. The clothing pieces are not only sustainable but also fashionable, proving that ethical fashion does not have to compromise on style.

How to Embrace Ethical Fashion in Your Wardrobe

Adopting ethical fashion principles in your own life is easier than you might think. Here are some tips to help you make more sustainable choices when it comes to your wardrobe:

Choose Quality Over Quantity: Invest in pieces that are versatile, durable, and timeless. Look for well-made items that will last for years.

Look for Ethical Brands: Choose brands like Mriganka, which prioritize ethical practices and transparency. Check labels to ensure the brand’s commitment to sustainability and fair labor.

Buy Less, Choose Wisely: Instead of buying impulsively, take the time to choose clothes you truly love and need. This will help you reduce unnecessary waste.

Take Care of Your Clothes: Properly maintain and repair your clothes to extend their lifespan. Washing in cold water, air drying, and repairing minor damages can make a big difference.

Consider Secondhand Clothing: Thrift stores and secondhand shops are great alternatives to buying new clothing. Vintage pieces are often of higher quality and have a lower environmental impact.

Mriganka is more than just a clothing brand; it’s a movement toward a more sustainable and responsible fashion industry. By prioritizing ethical practices and promoting transparency, Mriganka is leading by example in creating a better future for fashion. As consumers, we have the power to make a difference with the choices we make. By supporting brands like Mriganka, we can contribute to a more ethical, sustainable, and fashionable world.

For more information on how Mriganka is changing the world of fashion, visit their official website Mriganka and explore their latest collections and sustainable fashion initiatives.

0 notes

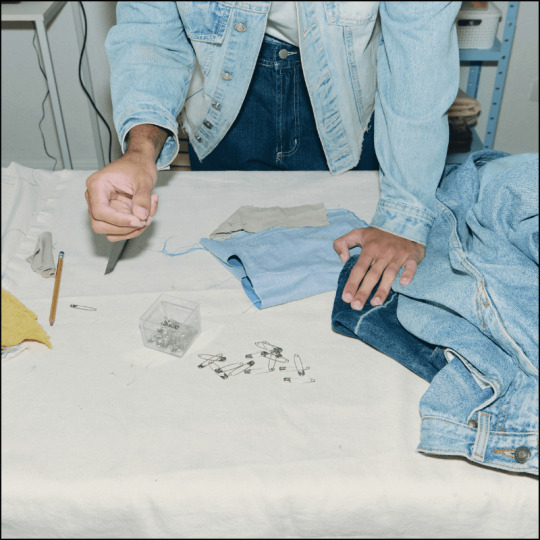

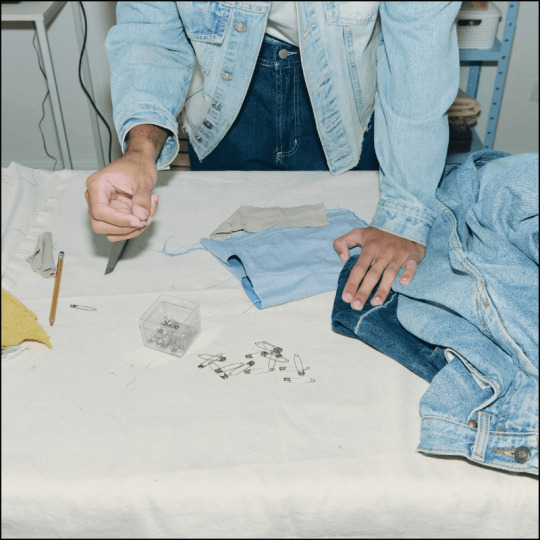

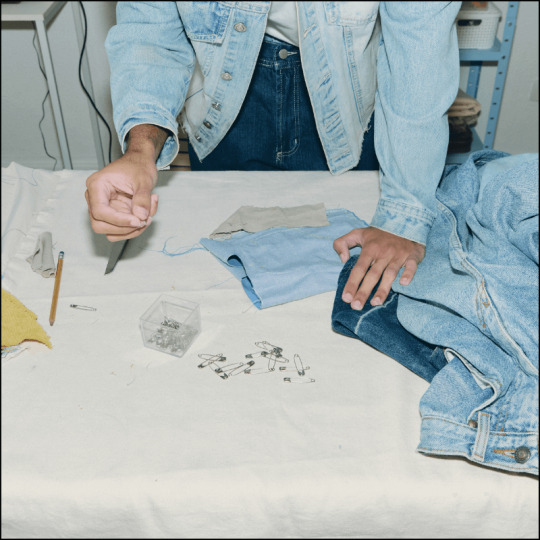

Photo

Looking for clothing manufacturers for small orders to help take your fashion brand from idea to made? New brands are often intimidated by the high MOQs - lowest minimum order quantities - that many of the well-known factories demand. So they feel like they are left with only two options – invest heavily in large quantities of inventory or give up. It might take a little extra work, but I want you to know there are small batch clothing manufacturers out there that are perfect for your small business. This blog post is going to teach you how to find and work with clothing manufacturers for small businesses in two parts. First, I will teach you best practices for working with small quantity clothing manufacturers; then I will share a few of my favorites. Here is why the first part is soooo important. Just because you have the email address, or direct phone number to an amazing factory, that doesn’t mean they will want to work with you. Competition to get into good factories is steep, and making a good first impression is critical. Think of it this way. It’s like getting a resi to an amazing restaurant, you wait 2 weeks to get to go, then you show up and can’t get in because you didn’t know about the dress code. So, close yet so far. I want factories excited to work with you (not ignoring you), so please don’t skip this first part. I am here to help you on your clothing business journey, and sometimes that means not just giving you the info you are looking for, but even more! BUT BEFORE WE GET STARTED... I love helping startup brand founders succeed, so I created a bunch of free guides that will help you with your business. They won’t be free forever, so make sure to grab them while you can. In this post, you will learn: Why finding a clothing manufacturer with low minimum orders is hard 3 things you need to do, to turn a no from a factory into a yes The best sourcing trip you can take for your small business Online sourcing resources I love to find clothing manufacturers for small orders Nontraditional supply chain options perfect for small brands 3 things a manufacturer must do before you work with them (I know, it can feel like such a relief when someone finally says yet to you - but you still need to do your due diligence) Additional resources to help you even more NO TIME TO READ? CHECK OUT THIS 60 SECOND SLIDE DECK WHY ARE FASHION MANUFACTURING MOQs SO HIGH? First things first . . . Quick reminder – MOQ means minimum order quantity, or the minimum amount you need to order for a factory to agree to work with you. The reality is it takes a factory the same amount of effort to source and develop styles for an order of 10 shirts as it does for an order of 10,000. Sounds crazy, but it's true. Let me explain. There are nine steps leading up to a style moving to production, and these steps are exactly the same no matter what size the production order is. If you want to learn more about each step, you can check out this article. But to quickly recap it – here are all the things that need to happen. Pattern making Fit samples Fit sample revisions Pattern revisions Fabric, trim, and component sourcing (sometimes working with up to 10 different supply chain partners to get everything needed to make a garment - from fabric to thread to labels and tags) Fabric, trim, and component sampling Proto samples/production quality sample (includes ordering sample fabric, trim, etc.) Pattern grading Ordering all components and organizing shipping and logistics to the factory A LOT of time, energy, and resources (read money) go into all of this. And again, it’s the same whether a factory is making 10 garments or a million. So, from just a staying-in-business perspective, some factories need to have high MOQs just to cover the cost of all the development and pre-production work that goes into sampling. IF IT COSTS SO MUCH TO DEVELOP, HOW ARE FACTORIES ABLE TO TAKE ON SMALL MOQs? Traditionally, a factory will charge a client about 2x the bulk production rate for sampling, including pattern making, sourcing, and the whole shebang. So if a shirt costs $10 in production, the sample will cost $20. The factory ends up losing a lot of money. But there is this unspoken deal in the industry that if you sample with someone, you will work with them in production. And in production, the factory will make back the sampling costs, plus a lot in profits. This is also why factories don’t really like working with startups – there is no guarantee the brand will ever launch, give them a bulk order, and help the factory recoup the money spent on product development. Now, if a factory is making tiny MOQs, there is no way they can sustain this, so manufacturing partners that help startups with small orders charge a fair rate for the costs of the sampling. So instead of $20, factories might charge $200 or more for the same sample with a low MOQ. And, this way, you can make as little as 10 pieces if you want to – because they aren’t relying on that bulk order to make their money back. Now, please don’t get any cute ideas and try to lie and say you are going to make big MOQs to get cheap sampling. It’s a great way to burn bridges and get a terrible reputation in the fashion manufacturing world. We all talk, we all know each other, and you don’t want factories to start deleting your emails without even opening them because they know you lied to their friend about big orders that never came last season. DO THESE 3 THINGS BEFORE YOU START WORKING WITH A SMALL BATCH CLOTHING MANUFACTURER Now that you understand why finding a low MOQ factory can be difficult, I want to help prepare you to make the best first impression possible. So, before you press send on that email, I need you to do these three things. Remember low MOQ factories are scarce, and there are more and more people starting brands every day. Some factories even have 3-month waits, before they will even schedule the first meeting with you. So, this means you need to stand out as a professional. TASK 1 - CREATE A BUDGET This is the most important thing you can do for the success of your brand. And it is often the most overlooked. If you don’t have a budget, you can’t get started. One more time for the people in the back – even if you plan to crowdfund, you still need a budget. Because crowdfunding is unpredictable, you could raise $100 or thousands. Your budget is what is going to allow you to estimate the number of styles you can afford to make and your MOQ. The point of your budget at this time isn’t to figure everything out to the penny. It’s just to get a general idea. By the end of your first budgeting exercise, you should be able to say, “With the money I have, I can afford to make about x styles in y colors and place a production order of z pieces per style. Now, a lot of new founders think they need to talk to a factory to figure this out. You don’t. In this post about working with fabric suppliers, I break down exactly how to estimate your costs without ever having to contact a supplier. The bottom line? When you set a budget, you set yourself up for success. I have helped over 200 people start their fashion businesses, and I can tell you this – the ones that have a solid budget are much more likely to succeed than the brands that don’t. Because, at the end of the day, it doesn’t matter how good your idea is, or how much the world needs it if you run out of money. And knowing your budget looks good to manufacturing partners. Because when you can show them your have taken the time to make a budget, they trust you will make it past sampling and into production (again, production is where clothing manufacturers for small orders will be making most of their profits). TASK 2: NAIL DOWN YOUR DESIGNS You need to know what you want to make. And not just a vague idea. Your designs should be nailed down and about 90% finalized before you start talking to custom clothing manufacturers. That is because the factory you work with will be determined by the designs. There are some clothing manufacturers for small orders that make everything, but most factories are very specialized. They only make one type of product, whether it's woven women's wear, t-shirts, or swimsuits. Some factories will not work with luxury fabrics like silk and satin, while others only do that. A lot of times, I see new founders thinking they found the perfect supplier.But once they finalize their designs and send them to the factory, the factory says, “Sorry, we don’t do those types of styles.” (It actually happens way more than you think). I know, I get it. You’re probably very anxious about finding a factory and checking that off your to-do list. But finalizing your designs will save you time in the long run. TASK 3: DECIDE WHERE YOU WANT YOUR CLOTHES TO BE MADE Where in the world do you want to make your product? Some parts of the world specialize in different types of products. An example of this is with swimwear – there are actually five major hubs of swimwear production, they are – the USA, China, Brazil, Bali, and Italy. If you want to learn more about the pros and cons of deciding where to make your clothing line, you can check out this article. The reason you want to decide where you want your clothes to be made first is because, domestic and overseas clothing manufacturers opperate very differently. And, you you try to research both at the same time you will probably end up feeling overwhelmed. THE BIG QUESTION - Domestic Clothing Manufacturers vs. Overseas Here is my opinion on this great debate. For startup brands, I recommend getting started close to home for not just one, but three different reasons. 1. Work in person without time zone or communication issues. I like to call this face time. No, not the video calling thing, but actually spending time with your factory in person. What over a decade in this industry has taught me is that anything is possible and everything is negotiable. That is, if your supply chain partner likes you. And the best way to get them to like you and build a strong working relationship with you is to spend time with them in person. Sorry, Zoom, the digital stuff will never replace IRL, IMO. When I worked in fast fashion, I can’t tell you how many times my boss would beg a factory to do something for him, and the factory would refuse. Then I would ask, and they would be like, “sure” (because they liked me). The other benefit of working with a factory close to home is that you won’t have language barriers. Different countries communicate in different ways and have their own fashion industry lingo. For example, what most of us know as a clothing seam is often called a joint in India. Speaking the same language makes learning a new fashion language a lot easier. 2. Save on shipping and logistics prices. Shipping these days is expensive. And if you are shipping fabric swatches, lab dips, strike-offs, samples, and all the product development things halfway across the world, those costs are going to add up quickly. Even though the production cost in developing countries tends to be much lower than in the West, by the time brands factor in all the development costs and shipping, they aren’t actually saving very much money. 3. No cultural learning curve, holidays, etc. When you work in a different country for the first year or two, you are going to be constantly surprised. Random holidays you had no idea existed and even the weather are going to delay your timelines. One thing most people don’t realize when working in India is how slow things become in the monsoon. Yeah, during the fall, they might be able to crank out your order in a month, but during the rainy season, good luck – another month to two could be added to your calendar. Once a brand is a few seasons in, their orders are growing, and they’re learning the ins and outs of the garment manufacturing world, then they can start exploring overseas options. Now, if you want to skip straight to overseas, I suggest hiring someone to help manage your project who knows the lay of the land. I offer private consulting, which you can check out here. To sum it all up - the reason small businesses often have more luck finding a manufacturer close to home for the small orders is because it is just easier. Overseas partners often feel like not only are they spending time teaching new brands the ins and outs of getting their garments made, but also have to offer them a crash course in the local culture. It’s just too much free work for them. For example every time I have a new client working in India for the first time, that first bank transfer is painful. Something as simiple as paying a deposit becomes a days long tutorial (sorry we don’t have Zelle, Venmo, or even Paypal here). THE ONLY GARMENT SOURCING TRIP YOU SHOULD PLAN Trade shows! I have said it before, and I’ll say it again. I love trade shows. Here is a list of my favorite textile trade shows. And, this is why trade shows are so great. They are a one-stop shop for global suppliers who actually want to work with you. So much so, that these suppliers are paying tens of thousands of dollars to travel and participate in the shows. Back in the day, tradeshow suppliers were mostly focused on big orders. But, times have changed, and that is no longer the case. Some shows even have special fashion startup areas that feature clothing manufacturers for small orders. And when you attend a trade show, there are also tons of free seminars and talks. So they are a great place to get educated at no cost to you. If your budget for your brand is going to restrict your ability to travel, going to a trade show is what I would spend those limited dollars on. Can’t make it to a show live? Most trade shows now have digital components as well. So, you can check out digital showrooms and chat with suppliers on their websites from your home. ONLINE SOURCING RESOURCES THAT EVERY STARTUP FASHION BRAND SHOULD KNOW ABOUT Speaking of digital sourcing . . . Here are a few of the most buzzworthy online sourcing resources that every fashion startup founder should know about. Not only do they have deep connections to suppliers, but they also help you stay organized and on top of your communication and orders. Their promoted partners range from mega suppliers with huge MOQs to clothing manufacturers for small orders that are perfect for startup brands. But, they do have their downfalls. Fabric sourcing and garment manufacturing are very physical businesses - it’s important to see, feel, and touch the quality. So, be careful and understand the limitations when working online. SEWPORT “Built to support emerging brands and aspiring fashion designers who struggled to connect with the right clothing manufacturers to launch their businesses.” SEAMLESS SOURCE “We developed an automated omnichannel sourcing platform and integrated order management tool to help your brand build a digitalized, faster, leaner and more responsible supply chain, all in one place with industry-leading, reliable, responsible and sustainable suppliers across the globe.” FOURSOURCE “A global network that brings people, organizations, and innovative ideas together. We make textile sourcing smarter, transparent, and more sustainable.” (FYI - I DO NOT RECOMMEND MAKERS ROW AFTER 2 BAD EXPERIENCES WITH THE COMPANY AND THEIR CLOTHING MANUFACTURING SERVICES) THE BEST NON-TRADITIONAL SUPPLY CHAIN HACK TO FIND CLOTHING MANUFACTURERS FOR SMALL ORDERS Sample rooms and home sewers. Sample rooms are like mini-factories, with one or two sewing machines. And an alternative to that would be a home sewer, just like it sounds, someone who sews from their home. Now, the pro is that these apparel manufacturers are more than happy to take on really tiny production orders. The downside is that they might not be able to scale with you, so they are not always a long-term solution. When I tell founders to try out one of these options, I usually get pushback because they are convinced that if their product is not made in a traditional factory, it will not be professional or high quality. But this is very false. Independent sewers are some of the best clothing manufacturers for small orders around! A lot of people (especially women) go out on their own after working in factories for years. They are highly trained and are starting their own mini businesses for the same reason you are starting your own clothing business. The freedom, control of their own paycheck, and all the other perks that come along with being a small business owner. I would even go as far as to argue that if you are into true women’s empowerment, this is the ONLY option to choose. 3 THINGS A MANUFACTURER NEEDS TO DO BEFORE YOU START WORKING WITH THEM You know - what you need to do and, how to find a manufacturer for your small business. Now, let’s discuss some things THEY should do before you decide to work with them. Remember, you are always in control of your supply chain. Yes, finding a supplier that is a good fit is hard. But I hate it when new brands start working with the first person that answers their emails. You don’t just have to accept the first person that responds to you. Be picky! Just because your order is small doesn’t mean you shouldn’t have options. Or, that you shouldn't be able to vet your supplier properly. Be choosey. Before you start working with anyone, make sure to do these three things. 1. TALK TO REFERENCES If a factory tells you they sign NDAs so they can’t share clients with you, that is a blazing red flag. Whenever a new supplier gives me this excuse, I respond, “I am sure you must have one client that you have become friends with over the years that would be happy to vouch for you.” If they don’t, I can’t stress this enough. Don’t work with them. 2. LOOK AT SAMPLES Most factories have showrooms with samples from past projects that they can show you. This can give you an idea about the type of garments they can make and prove that they can make good quality clothing for your brand. While clothing manufacturers for small orders might have fewer examples to show than a big factory showroom, they should still have something. Quick tip. When you look at samples, you are not just looking at the quality, but also the type of garment. If you want to make swimsuits and every sample in the showroom is a t-shirt... Well, this factory might not be the best fit. 3. GIVE PRICING It is impossible for clothing manufacturers for small orders to give you accurate pricing until they make your sample. They need to see how much fabric the garment consumes (the more fabric, the higher the price) and how long the garment takes to make (the longer it takes to sew, the higher the price). But what they can do is tell you approximately how much it will cost. Because if your target price is $30 per garment in production and they are quoting $50, you know they won’t be a good fit. So, why waste your time sampling with them? ADDITIONAL SOURCING RESOURCES Here are a few more articles to check out for even more help. Where to source sustainable fabrics (list includes suppliers) Affordable mentorship options My favorite hack to launch your brand faster Tips for working with fabric suppliers Everything you need to know about tech packs WHAT DID YOU THINK? What step are you on in finding your perfect clothing manufacturing partner? Let me know in the comments. Source link

0 notes

Photo