#single coil mechanical seal

Explore tagged Tumblr posts

Text

This is Thelockpickinglaywer and what I have for you today is something very interesting. As you can tell by the agonizing screams of the damned, I have recently left the mortal coil and, upon arriving at my destination, was informed that I did not qualify for residence. I was taken by an angel of the Lord to the mouth of Hell, and when the angel left, he closed this rather large red door and sealed it with a divine key. Although I’ve never seen this particular model of lock before, I’ve spent some time investigating the cylinder with this small shard of bone. By sticking it in the back of the keyway and slowly pulling it out, I can tell that this is a five-pin tumbler lock, that can easily be single-pin picked using this shed demon scale as a tensioner tool. Let’s try that right now. Alright, nothing on one. Nothing on two. Three is binding firmly, click out of that. Nothing on four. Five is binding, little click there, back to one. Once again, nothing. Two is binding, and we’ve dropped into a false set. Little click out of three. Nothing on four. Little click on one, counter-rotation on two, and we got this open. Okay folks, I think the main takeaway here is that no matter how much faith you place in a mechanism designed to ensure your safety, be it spiritual or physical, there is always a state in which it can fail. In any case, thank you for watching. Memento mori, and I’ll see you next time.

49K notes

·

View notes

Text

𝑻𝒉𝒆 𝑮𝒊𝒓𝒍 𝑾𝒉𝒐'𝒅 𝑩𝒆𝒕𝒓𝒂𝒚 𝑯𝒆𝒓 𝑽𝒊𝒍𝒍𝒊𝒂𝒈𝒆

Tags: Kabuto Yakushi, Kabuto x f! Character, manipulations, slow burn, flirting, betrayal, guilt, angst

Act II, Part 6: “The Weight of Forgotten Names”

Weeks have passed.

Kana’s days blurred into one another. She spent dawn to dusk reinforcing the village’s barrier seals—Earth-style traps buried deep beneath the perimeter, chakra-veiled wards spun from her Yin-Release, and countless kunai set to soil-snare coils. Each mission felt mechanical, her hair always tightly bound, a silent reminder to keep her emotions—and her clan’s legacy—under lock and key.

Yet every free moment she stole a glimpse toward the eastern training grounds. Under the same gnarled root where Kabuto first left his mark, she’d crouch, sleeves brushing the carved lines. One gouge meant meet. But day after day, her fingers found only empty bark and gathering shadows.

And with each passing dusk.

His words haunted her, “Is that what you truly believe or what you want them to hear?”

His smirk replayed behind her eyelids during the barrier chants.

His promise of truth echoed in the hum of her sealing jutsu.

She told herself she was being patient. That her duty came first. But at night, when the village slept, she’d untie that braid at the nape—feeling the weight of her hair brush her collarbone—and imagine his voice whispering through the trees.

Until one gray morning, as mist curled around the training hall’s broken pillars, she found a single, fresh slash beneath the root.

—

One thin stroke, carved so cleanly it could have been made by chakra alone.

Her breath caught. Without a second thought, she wound her hair into a loose ponytail, tucked her kunai at her hip, and slipped into the forest before the sun fully rose.

The forest was colder than she remembered—not in temperature, but in anticipation. Shafts of pale light pierced the canopy, illuminating drifting pollen like suspended ghosts. Kana’s heart hammered, every sense straining for him.

From behind a moss-draped oak, he emerged: Kabuto, glasses gleaming, cloak brushing the fallen leaves. His expression was unreadable—calm, collected, and absolutely in control.

“You’re late,” he said softly, but the teasing in his tone was unmistakable.

Kana’s pulse stuttered. She squared her shoulders. “I wasn’t sure I’d come.”

He tilted his head, studying her. “And yet, here you are. Again.”

Silence throbbed between them as she fought the urge to rush forward and collapse into his arms. Instead, she let the hush settle around them—felt her own uncertainty, longing, and guilt twisting beneath her skin.

Kabuto’s hand drifted into his cloak, then produced a scroll sealed with the Leaf’s crest.

“This,” he said, voice low and deliberate, “is from your village’s archives. The kind not supposed to exist anymore.”

Kana’s breath hitched. “What are you—”

He cut her off with soft authority. “The Kurai clan wasn’t purged for weakness, Kana. You were too dangerous to control—and too valuable to ignore.”

She stepped forward until her chakra veil flared around her, instinctively shielding her presence. “You’re lying.”

“No,” he whispered, stepping in close enough that she could feel the cold metal of his gloves. “I’m giving you what they never did, the truth.”

He held the scroll between them..

“You told them I meant nothing to you,” Kabuto continued, “that you’d rejected me. That you hated me. But you chose me that night.”

His gloved fingertip brushed a strand of her blonde hair from her face. “Whether you admit it or not, you’re mine now.”

Kana’s chest tightened, “This isn’t loyalty. It’s… obsession.”

Kabuto’s lips curved in a slow, knowing smile. “Curiosity, guilt, yearning—call it what you will. But it brought you back to me.”

He unfolded the scroll and pressed it into her palm. The parchment was cool, and she could feel the weight of every erased memory it contained.

“Tonight,” he said, voice a silk purr, “I’ll show you the secrets they buried—the Spirit Mirror’s true purpose, the healing jutsu your ancestors perfected.”

He stepped back, cloak swirling, and melted into the trees before she could respond.

Kana stood alone under the forest roof, heart hammering, scroll clutched tight against her chest. The path back to the village felt both impossibly far—and irrevocably changed.

He sees me, she thought, hair loosening at the wind’s brush. More clearly than anyone ever has.

Tucking the scroll into her belt, Kana turned toward home—her mind alight with the promise of forbidden knowledge.

————————————

Midday, Hidden Leaf outskirts – several hours after the first forest encounter

Kana moved like her body was made of smoke.

She’d returned to the village after the encounter, chakra masked, her sandals barely scuffing the dirt as she slipped in past the barrier team on patrol. No one noticed. She’d long ago perfected the art of coming and going without a ripple.

Now she sat cross-legged on the roof of the medical archives building, hiding in plain sight. Below her, the bustle of late-day assignments buzzed on—med-nin reporting in, supply runners shouting names, the dull clang of stretcher hinges folding back into place.

But Kana heard none of it.

Her fingers pressed over the cloth pouch at her side, where Kabuto’s scent still lingered on her gloves—barely, but enough. She had tried to scrub it off at the stream, but it stayed. Like him.

“You’re mine now.”

The words curled under her skin like heat, shame, and something worse.

Desire.

She’d almost let him kiss her. She’d wanted it—she still wanted it, which made her stomach twist. That version of her—the one who let him lean in, let his voice snake through her guard—was someone she didn’t recognize.

Or maybe..

She recognized her all too well.

⸻

An hour passed.

Kana moved again. This time toward the weapons depot, where she told the clerk she needed to recalibrate her suppression tags for solo field use. She handed over her old set and received a fresh scroll, etched with chakra-sensitive ink.

It was a lie. A small one. But it would buy her freedom from team duties for the night.

She needed time. Not for training. Not even for answers.

She needed to go back.

By late afternoon, she stood in a narrow corridor between two abandoned storehouses behind the Hokage Tower. The light hit her at an angle, slicing the dust in gold. She leaned against the wall, heart pacing hard, and finally—finally—she let herself exhale.

“You chose me,” he’d said.

Kana hadn’t believed him at the time. Not fully. But something about the way her hands had trembled after…

She had warned him.

She had lied.

Not even for strategy. Just because she didn’t want to lose him—not yet. Not when he was the only one who spoke her name like a promise instead of a problem.

She opened her palm.

There, still pressed faintly into her glove, was a smudge of dirt where his hand had covered hers.

Not even a bruise.

Just… memory.

By the time the sun dipped low, she was already moving again—back to the edge of the forest.

Back to him.

⸻

By the time Kana reached the clearing, the light had nearly vanished. Dusk pooled between the trees like ink, and the wind had died. The air was too still—expectant, listening.

She didn’t call out.

She didn’t need to.

Kabuto emerged as if summoned by thought alone, stepping into the open with his hands calmly folded behind his back, glasses glinting with the last edge of gold light. His cloak rippled slightly, the shadows of trees warping across its hem.

But he didn’t speak right away.

He just looked at her.

And this time, she didn’t flinch under his gaze.

“You came,” he murmured, stepping closer, his voice edged with something warm—something dangerously close to affection.

Kana nodded. “I told you I wanted answers.”

He smirked faintly. “That’s not all you want.”

She didn’t deny it.

Kabuto’s eyes flicked down—assessing, calculating—but when they returned to her face, there was a softness to his expression that unsettled her more than his cruelty ever had.

Without warning, his hand came up—not to strike or pull—but to gently brush a piece of bark from her shoulder, fingers lingering for half a breath too long. She held still, eyes trained on him.

“I know what you’re afraid of,” he said quietly. “That you’re slipping. That if you take one more step, there’s no going back.”

Kana swallowed. “…There isn’t, is there?”

Kabuto moved beside her, fingers ghosting along the outside of her thigh for the briefest moment, a deliberate brush disguised as reassurance. Her muscles tensed beneath his touch, but she didn’t pull away.

“You’re not slipping,” he said. “You’re waking up.” He stepped behind her now, voice curling beside her ear. “You were never meant to serve. You were meant to inherit.”

He reached into his cloak and withdrew a second scroll, bound in deeper red—older, cracked with time. Kana turned, expression darkening.

“W-what’s this?”

“This was concealed in the sealed archival chambers—hidden among restricted tomes. It took time to decipher… but it’s your mother’s. Her personal chakra script.”

Kana froze.

“My mother…? That’s not possible. She died when I was five. There was nothing left—only ashes.”

Kabuto’s voice softened, no longer a whisper of manipulation, but something eerily close to sympathy. “That’s what they told you. But it was no accident. Your mother was assassinated, Kana. Not by enemies of the Leaf—by her own comrades.”

Her knees buckled slightly, but she stayed standing.

“Why?” she choked out.

“Because she refused to weaponize the Spirit Mirror. Because she tried to pass down the healing rites. Because she remembered what your clan was meant to be.”

Kabuto stepped closer, pressing the scroll gently into her hands. “The night before she died, she encoded her final jutsu into this. Her chakra signature is still embedded. That’s how I know it’s real.”

Kana stared down at it, hands trembling.

“She tried to protect me…”

“And they silenced her,” Kabuto said, stepping in to meet her eyes. “But I won’t. I won’t bury your name. I won’t erase your bloodline. I’ll help you reclaim it.”

He crouched slightly now, at her side—almost like kneeling. His gloved hand reached to rest gently atop her thigh, thumb pressing into the fabric as if grounding her.

“You’ll never be alone again,” he said. “Not while I live.”

Kana didn’t respond.

Her body was rigid. But her heart—

Her heart was unraveling.

“Your mother’s chakra will recognize yours,” Kabuto went on. “If you release the binding seal under moonlight, the knowledge inside will awaken. It’s not just history, Kana. It’s power. Dormant for years. Waiting.”

Kana looked at the scroll again. Then at him.

Her voice was barely a whisper. “Will it hurt?”

He smiled softly.

“No more than the truth always does.”

⸻

That night, under the full moon, Kana unfurled the scroll in a clearing just beyond the old training grounds. Kabuto knelt beside her, murmuring the unsealing chants, guiding her fingers where to press, where to bleed.

And as her chakra pulsed into the parchment, the ink ignited—curling into luminous strands that wrapped around her arms, her collarbone, her scalp.

Her hair fluttered in the sudden surge of energy—unraveling, stretching down her mid-back as if responding to some invisible thread. Her breath caught as she felt it—her mother’s chakra, echoing through her like a heartbeat.

Her eyes shimmered with unshed tears.

And Kabuto’s voice, low and calculated, wrapped around her like silk,

“There she is. The last daughter of the Kurai.”

#naruto shippuden#naruto#naruto smut#kakashi hatake#naruto fan character#naruto fandom#jjk gojo#smut#jjk#dark romance#kabuto x orochimaru#naruto x oc#naruto fic#naruto stuff#naruto anbu#naruto fanfiction#naruto anime#lady tsunade#naruto x y/n#naruto x reader#naruto x you#naruto fluff#orochimaru#fanmade character#anime and manga#anime#anime smut#angst#jjk x reader#naruto characters

2 notes

·

View notes

Text

Lockpicking Hell is a work from Holy Nonsense, a Creative Commons project. Thanks to @argonphoenix for participating in the project! you can view their original post here https://www.tumblr.com/argonphoenix/717685138588303360 (which I recommend, as there's some good voice work in the replies).

Holy Nonsense 2023, The Year Of Our Lady Edition is currently in the works!!! If you want to participate, there's a form on qgpennyworth.com or you can just ping me here.

Each entry (single page or multiple pages of the same work) is released under an individual CC: Attribution, Non Commercial, No Derivatives license. That means you can repost this work as-is anywhere for any non-commercial purposes.

Image descriptions, including transcriptions of text, are expressly allowed, but just make sure you include the credits that are baked into the image when you do them. Image Description after the cut.

This is TheLockpickingLaywer and what I have for you today is something very interesting. As you can tell by the agonizing screams of the damned, I have recently left the mortal coil and, upon arriving at my destination, was informed that I did not qualify for residence. I was taken by an angel of the Lord to the mouth of Hell, and when the angel left, he closed this rather large red door and sealed it with a divine key. Although I’ve never seen this particular model of lock before, I’ve spent some time investigating the cylinder with this small shard of bone. By sticking it in the back of the keyway and slowly pulling it out, I can tell that this is a five-pin tumbler lock, that can easily be single-pin picked using this shed demon scale as a tensioner tool. Let’s try that right now. Alright, nothing on one. Nothing on two. Three is binding firmly, click out of that. Nothing on four. Five is binding, little click there, back to one. Once again, nothing. Two is binding, and we’ve dropped into a false set. Little click out of three. Nothing on four. Little click on one, counter-rotation on two, and we got this open. Okay folks, I think the main takeaway here is that no matter how much faith you place in a mechanism designed to ensure your safety, be it spiritual or physical, there is always a state in which it can fail. In any case, thank you for watching. Memento mori, and I’ll see you next time.

tumblr.com/argonphoenix

Background: a jumbled field of locks and keys drawn in various styles and sizes, faded with an uneven texture that resembles paper

20 notes

·

View notes

Note

You underestimate my desire for knowledge. Do it. Talk about refrigeration compressor motors.

Hello hi, sorry for the delay. I had to wait for the brain power to return to me.

So, an electric motor's job is to convert electrostatic potential energy into magnetic potential energy in order to rotate a shaft, thus making one final energy conversion from magnetic PE to kinetic energy. There is a secret fourth energy conversion, though, and that is another form of kinetic energy: heat. The heat is waste, though.

Anyways, the power available in your home is not the power generated at the source powerplant; it is just a single phase of alternating current (AC), instead of three. Electric motors running on single-phase encounter an interesting problem: they need a special winding, called a start winding, to get the motor going. It is phase shifted from the run winding (which keeps the motor running after startup). The easiest way to explain phase shift, in this context, is to think of it like the pedals on a bicycle: if the pedals weren't opposite each other (offset from each other 180 degrees), it would be very difficult to pedal. Unlike a bicycle, the phase shift in the motor isn't 180 degrees. It's less than that. About 45 degrees.

Both the start and run windings are coils of wire. The more times the wire is wound, the stronger the magnetic field it generates. The start coil has more windings than the run coil.

To help smooth power delivery and introduce the aforementioned phase shift, we need capacitors. Capacitors are just small batteries. They can hold a charge and be discharged. They also block direct current (DC), but allow AC to pass through it. It's really neat. On startup, a single-phase motor using capacitors only needs the start coil and the start capacitor briefly. If they remain in the circuit afterwards, they risk overheating and destroying themselves. So how do we automatically take the start coil and capacitor out of the circuit after startup?

One way is to use a centrifugal mechanical switch that will disconnect the start components from the circuit once the motor reaches 75% of its maximum RPM. This switch must be in the motor, though, and will create a spark when it breaks contact. This is okay for motors that are in the air, but what about the motors in a hermetically sealed refrigerant compressor? That spark would degrade the refrigerant, and that's a non-starter.

We need an RPM sensitive switch outside the compressor motor, and one way to do this is with a potential relay.

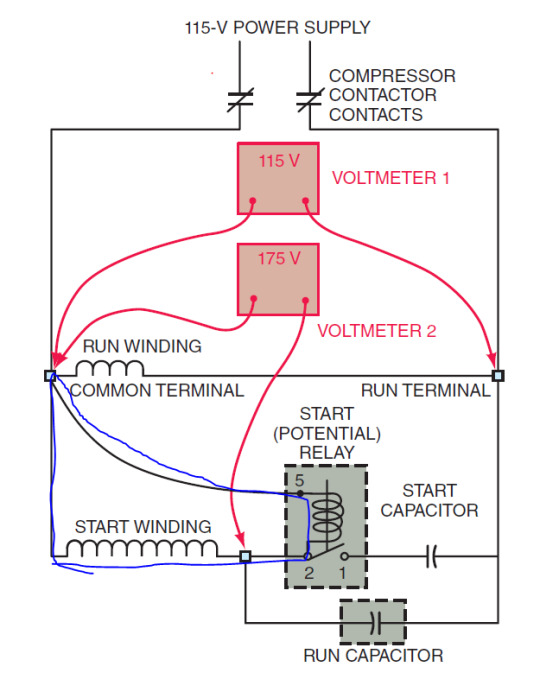

This is a diagram of a potential relay circuit with a capacitor-start, capacitor-run compressor motor.

On startup, the relay contacts, 2 and 1, are closed. Power can flow through the start winding and through both the run and start capacitors. This gives the motor a good grunt to get it going, with the start winding slightly out of phase with the run winding. Once the motor reaches 75% of its max. RPM, though, the magnets on the rotor/shaft of the motor induce a back electromotive force, or BEMF, in the start winding. The start winding becomes a voltage source in tandem with the incoming power from the outlet.

The induced AC voltage is stronger than the incoming power, and is also out of phase with it. This is demonstrated in the diagram with voltmeters 1 and 2. The induced voltage flows through the coil of the potential relay at terminals 2 and 5, and the coil generates a magnetic field which pulls the relay contacts open, breaking the connection to the start capacitor and preventing the start winding from connecting with the other side of our power supply. So long as the motor is running, the BEMF is present and keeps the relay open.

This is what the voltage looks like on an oscilloscope. CH1 is the smaller wave and it's on the common run terminal. CH2 is the larger wave and is at terminal 2 of the relay.

As we can see, the induced voltage on the start winding lags behind the line voltage by about 45 degrees and it is much stronger.

When the motor shuts off and slows down, the induced voltage disappears and the relay contacts close again. The relay sits outside the motor where sparks are acceptable.

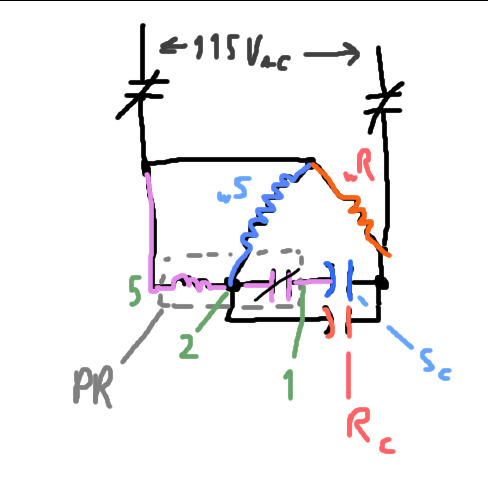

As a cherry on top, I've drawn the current paths through the circuit to help illustrate what's happening:

^ Start condition (red). Current flow through the start winding and start + run capacitors

^ Run condition (blue). BEMF across the start winding powers the relay coil and opens the contacts.

There is a lot more going on I could talk about, but that's just the part I wanted to be autistic about. There is actually a better way to draw out this circuit that looks like this:

Sw = Start winding

Rw = Rung winding

PR = Potential relay

Sc = Start Capacitor

Rc = Run capacitor

And isn't that fascinating?

6 notes

·

View notes

Text

Angle Seat & Piston Operated Valves – Pressure Reducing & Actuated Valve Selection Guide by Udhhyog

Angle seat valves and piston operated valves are essential components in fluid automation and control systems. These valves are designed for long life, fast actuation, and superior sealing — ideal for steam, air, water, and other industrial fluids.

As a trusted manufacturer and supplier in Delhi, Udhhyog offers a full selection of pressure reducing, actuator-driven, and angle piston valves, tailored for a range of industrial applications.

What is an Angle Seat Valve?

An angle seat valve is a pneumatically operated valve with a seat that is tilted or angled, allowing higher flow rates and self-draining operation. These valves are popular in industries that require clean, fast-acting shut-off mechanisms.

✅ Features:

High cycle life

Fast actuation (double or single acting)

PTFE or EPDM seals

Normally open (NO) / Normally closed (NC)

🔧 Applications:

Food processing and beverages

Compressed air lines

CIP systems

Boiler automation

What is a Piston Operated Valve?

Piston operated valves use a piston actuator (powered pneumatically or electrically) to control valve movement. They are available in 2-way, 3-way, and multi-port configurations.

✅ Features:

Rugged build for high-pressure service

Suitable for both liquids and gases

Available with solenoid or pilot actuators

🔧 Applications:

Steam distribution

Gas mixing

Water treatment and filtration

Chemical dosing

Pressure Reducing Piston Valves

These valves reduce upstream pressure to a preset, safe level on the downstream side. They operate automatically without external energy and are useful in high-pressure steam and gas lines.

✅ Key Benefits:

Automatic pressure regulation

Reduces risk of overpressure damage

Used in heating, cooling, and steam applications

Udhhyog Product Range: Quick Overview

Valve TypeSize RangeMaterialMax PressureActuation OptionsAngle Seat Valve½” – 2”SS 304/31616 barPneumatic (Single/Double)Piston Operated Valve¼” – 2”Brass, SS10–25 barPneumatic / SolenoidPressure Reducing Valve½” – 2”Bronze / SSUp to 20 barSelf-acting / Actuator combo

✅ End connections: BSP/NPT/Flanged ✅ Accessories: Positioners, coils, silencers, NAMUR interface

Why Choose Udhhyog for Angle & Piston Valves in Delhi?

🏭 Certified Quality – ISO, CE, BIS certified valves

🚀 Fast Delivery – Across Delhi, Haryana, UP, Punjab, Rajasthan, J&K

💰 Best Pricing – Direct from manufacturer rates

🛠️ Customization – Voltage, material, flow rate, actuator design

📩 Request product data sheets: https://udhhyog.com/contact

Price Range (2024 – Delhi Market)

ProductStarting Price (INR)Angle Seat Valve (SS)₹950Piston Operated Valve (Brass)₹850Pressure Reducing Piston Valve₹1100

Bulk pricing and OEM labels available on request

FAQs

Q1: Are angle seat valves suitable for steam? Yes, Udhhyog’s valves can handle up to 180°C with PTFE seals.

Q2: Can I use piston valves for reverse flow applications? Only with check-function or spring-loaded versions.

Q3: Are control valves available with positioners? Yes, we provide pneumatic and electro-pneumatic positioners.

Contact to Order

📞 Call: +91-XXXXXXXXXX 🌐 Website: https://udhhyog.com 📥 Request Quote: Contact Us

#AngleSeatValve#PistonValve#PressureReducingValve#ActuatedValve#Udhhyog#DelhiValveSupplier#SteamValve#IndustrialAutomation

0 notes

Text

Angle Seat & Piston Operated Valves – Pressure Reducing & Actuated Valve Selection Guide by Udhhyog

Angle seat valves and piston operated valves are essential components in fluid automation and control systems. These valves are designed for long life, fast actuation, and superior sealing — ideal for steam, air, water, and other industrial fluids.

As a trusted manufacturer and supplier in Delhi, Udhhyog offers a full selection of pressure reducing, actuator-driven, and angle piston valves, tailored for a range of industrial applications.

What is an Angle Seat Valve?

An angle seat valve is a pneumatically operated valve with a seat that is tilted or angled, allowing higher flow rates and self-draining operation. These valves are popular in industries that require clean, fast-acting shut-off mechanisms.

✅ Features:

High cycle life

Fast actuation (double or single acting)

PTFE or EPDM seals

Normally open (NO) / Normally closed (NC)

🔧 Applications:

Food processing and beverages

Compressed air lines

CIP systems

Boiler automation

What is a Piston Operated Valve?

Piston operated valves use a piston actuator (powered pneumatically or electrically) to control valve movement. They are available in 2-way, 3-way, and multi-port configurations.

✅ Features:

Rugged build for high-pressure service

Suitable for both liquids and gases

Available with solenoid or pilot actuators

🔧 Applications:

Steam distribution

Gas mixing

Water treatment and filtration

Chemical dosing

Pressure Reducing Piston Valves

These valves reduce upstream pressure to a preset, safe level on the downstream side. They operate automatically without external energy and are useful in high-pressure steam and gas lines.

✅ Key Benefits:

Automatic pressure regulation

Reduces risk of overpressure damage

Used in heating, cooling, and steam applications

Udhhyog Product Range: Quick Overview

Valve TypeSize RangeMaterialMax PressureActuation OptionsAngle Seat Valve½” – 2”SS 304/31616 barPneumatic (Single/Double)Piston Operated Valve¼” – 2”Brass, SS10–25 barPneumatic / SolenoidPressure Reducing Valve½” – 2”Bronze / SSUp to 20 barSelf-acting / Actuator combo

✅ End connections: BSP/NPT/Flanged ✅ Accessories: Positioners, coils, silencers, NAMUR interface

Why Choose Udhhyog for Angle & Piston Valves in Delhi?

🏭 Certified Quality – ISO, CE, BIS certified valves

🚀 Fast Delivery – Across Delhi, Haryana, UP, Punjab, Rajasthan, J&K

💰 Best Pricing – Direct from manufacturer rates

🛠️ Customization – Voltage, material, flow rate, actuator design

📩 Request product data sheets: https://udhhyog.com/contact

Price Range (2024 – Delhi Market)

ProductStarting Price (INR)Angle Seat Valve (SS)₹950Piston Operated Valve (Brass)₹850Pressure Reducing Piston Valve₹1100

Bulk pricing and OEM labels available on request

FAQs

Q1: Are angle seat valves suitable for steam? Yes, Udhhyog’s valves can handle up to 180°C with PTFE seals.

Q2: Can I use piston valves for reverse flow applications? Only with check-function or spring-loaded versions.

Q3: Are control valves available with positioners? Yes, we provide pneumatic and electro-pneumatic positioners.

Contact to Order

📞 Call: +91-XXXXXXXXXX 🌐 Website: https://udhhyog.com 📥 Request Quote: Contact Us

#AngleSeatValve#PistonValve#PressureReducingValve#ActuatedValve#Udhhyog#DelhiValveSupplier#SteamValve#IndustrialAutomation

0 notes

Text

Angle Seat & Piston Operated Valves – Pressure Reducing & Actuated Valve Selection Guide by Udhhyog

Angle seat valves and piston operated valves are essential components in fluid automation and control systems. These valves are designed for long life, fast actuation, and superior sealing — ideal for steam, air, water, and other industrial fluids.

As a trusted manufacturer and supplier in Delhi, Udhhyog offers a full selection of pressure reducing, actuator-driven, and angle piston valves, tailored for a range of industrial applications.

What is an Angle Seat Valve?

An angle seat valve is a pneumatically operated valve with a seat that is tilted or angled, allowing higher flow rates and self-draining operation. These valves are popular in industries that require clean, fast-acting shut-off mechanisms.

✅ Features:

High cycle life

Fast actuation (double or single acting)

PTFE or EPDM seals

Normally open (NO) / Normally closed (NC)

🔧 Applications:

Food processing and beverages

Compressed air lines

CIP systems

Boiler automation

What is a Piston Operated Valve?

Piston operated valves use a piston actuator (powered pneumatically or electrically) to control valve movement. They are available in 2-way, 3-way, and multi-port configurations.

✅ Features:

Rugged build for high-pressure service

Suitable for both liquids and gases

Available with solenoid or pilot actuators

🔧 Applications:

Steam distribution

Gas mixing

Water treatment and filtration

Chemical dosing

Pressure Reducing Piston Valves

These valves reduce upstream pressure to a preset, safe level on the downstream side. They operate automatically without external energy and are useful in high-pressure steam and gas lines.

✅ Key Benefits:

Automatic pressure regulation

Reduces risk of overpressure damage

Used in heating, cooling, and steam applications

Udhhyog Product Range: Quick Overview

Valve TypeSize RangeMaterialMax PressureActuation OptionsAngle Seat Valve½” – 2”SS 304/31616 barPneumatic (Single/Double)Piston Operated Valve¼” – 2”Brass, SS10–25 barPneumatic / SolenoidPressure Reducing Valve½” – 2”Bronze / SSUp to 20 barSelf-acting / Actuator combo

✅ End connections: BSP/NPT/Flanged ✅ Accessories: Positioners, coils, silencers, NAMUR interface

Why Choose Udhhyog for Angle & Piston Valves in Delhi?

🏭 Certified Quality – ISO, CE, BIS certified valves

🚀 Fast Delivery – Across Delhi, Haryana, UP, Punjab, Rajasthan, J&K

💰 Best Pricing – Direct from manufacturer rates

🛠️ Customization – Voltage, material, flow rate, actuator design

📩 Request product data sheets: https://udhhyog.com/contact

Price Range (2024 – Delhi Market)

ProductStarting Price (INR)Angle Seat Valve (SS)₹950Piston Operated Valve (Brass)₹850Pressure Reducing Piston Valve₹1100

Bulk pricing and OEM labels available on request

FAQs

Q1: Are angle seat valves suitable for steam? Yes, Udhhyog’s valves can handle up to 180°C with PTFE seals.

Q2: Can I use piston valves for reverse flow applications? Only with check-function or spring-loaded versions.

Q3: Are control valves available with positioners? Yes, we provide pneumatic and electro-pneumatic positioners.

Contact to Order

📞 Call: +91-XXXXXXXXXX 🌐 Website: https://udhhyog.com 📥 Request Quote: Contact Us

#AngleSeatValve#PistonValve#PressureReducingValve#ActuatedValve#Udhhyog#DelhiValveSupplier#SteamValve#IndustrialAutomation

0 notes

Text

International Ninja Day

The black envelope, stamped with a coiling dragon in a crimson seal, drew my fingers into action, excitement buzzing through me as I unfolded this envelope. It's not your typical club assignment. This is the first task in ninjutsu history. The one thing I'm shaky about is pulling out the sleek parchment from within. Written in precise, flowing script, this is what the letter reads:

To Our Aspiring Shadow,

Your training has attracted the attention of the League of the Silent Blade. You have now been chosen for your first task. This will test your skill, cunning, and fidelity.

Retrieve the Jade Compass, an artifact of immense importance, from the hidden vault beneath the abandoned pagoda at Red Ridge. Beware, for others may also seek the Compass. Trust no one outside the League.

Success will prove your capacity; failure, and you shall not be cloaked in the shadow anymore.

Steal your resolve and tread lightly.

The Crimson Master.

My throat closes up. The Jade Compass? Just whispers during training: the ancient relic of legend that brings its possessor to secrets beyond comprehension. But really? Fetching it from an underground vault? This isn't sneaking through rooftops or dodging beanbags in training drills.

I glance at the wall clock. The letter said not a single word about time, just how the urgency gnaws. Swift grab of black training gear and pack essentials: my throwing stars, the grappling hook, a torchlight, and a small notebook. My mind races as I don the mask with only eyes peering out.

As I creep out from the doorstep and under the veil of darkness, I cannot shake the feeling that I am being watched. Others in the club must have gotten this mission too? That thought unnerved me, but I pushed it away. Tonight, I am a shadow.

For me, the trip to Red Ridge is very silent right now, only broken by the swaying of the leaves in the cool night air. There lies before me the abandoned pagoda, its outline broken and menacing. I gulp down a breath and approach, taking note of my surroundings. Something's off. Faint light flickering inside the pagoda—it indicates that I am not alone.

I crouch low as I will go and slip into the darkened building, every sense heightened. Damp wood and decay smells fill the air, but I hear faint echoes of shuffling feet echoing further in. These instincts were in fact correct—someone is indeed here.

Now, things just got a lot more difficult.

Part 1: The Silent Shadows

The flickering light beckons me deeper into the pagoda, with quiet breath and deliberate steps. The interior is a maze with rotting wood and twisting corridors touched faintly by the moon shining through broken windows. I grip my grappling hook tightly as my heart pounds in rhythm to my footsteps.

As I round a corner, I freeze. A shadow darts past, too quick for me to identify. I press myself against the wall, holding my breath. The shadow pauses, and I catch a glimpse of their figure—slim and agile, dressed in black like me. Another trainee? Or perhaps an enemy?

They move on, their footsteps fading into the distance. Relieved, I push forward, descending a creaking staircase. At the bottom, I find a massive door carved with intricate patterns of dragons and phoenixes. In the center is a jade emblem—the Compass.

But it isn’t unguarded.

A faint hum fills the air as I step closer. The jade emblem begins to glow, and the floor around me shifts. Hidden mechanisms whir to life, revealing a series of traps—spikes shoot from the walls, and a net drops from above. I dive and roll, barely avoiding capture. My heart races, but my training kicks in. I scan the room for a pattern, a solution.

There—a narrow path free of traps. I take a deep breath, then leap, twist, and crawl my way through the gauntlet. Finally, I stand before the Compass, its glow pulsing like a heartbeat. Carefully, I reach out and lift it from its pedestal.

All is still for a moment, but then a voice speaks from the shadows:

"Well done."

Part 2: Allies and Secrets

I spin around, holding the compass. The shadowy figure from before now steps into the light and pulls down the mask. It’s Miko, one of the senior trainees in the club.

"I knew you could do it," she says with a sly grin.

"Miko? What are you doing here?"

"Same as you; proving herself," she says, holding a small glowing shard. "The Compass wasn't the only prize tonight, you see; the League wanted to see who could think beyond the obvious."

I take a look at the compass, noticing that it has a hollow slot in it. "The shard fits in here." She nods.

"Together, they actually unlock something bigger. But on our own, we have not yet finished. The League tests us, come."

Reluctantly, I follow her back upstairs. Miko seems confident, but I stay on guard. Trust no one, the letter had warned.

Part 3: The Silent Escape

The traps reset as we step out of the vault; it makes our egress trickier than we anticipated. Together, we leap and dodge, each covering the blind spots of the other. By the time we are on the surface, we can hear the soft sound of dawn creeping across the horizon.

A man in an expensive red robe, embroidered with a dragon on his chest, waits just outside the pagoda.

"The Crimson Master," Miko whispers, bowing very low.

I follow her action, and my pulse races. The Crimson Master studies us in silence and then gestures for the compass and shard. I hand them over reluctantly.

"You have passed the first test," a deep, resonant voice says. "But this is just the beginning of your journey. The League of the Silent Blade isn't for lone wolves. You've proved you're stronger together. Remember it."

He hands the compass back to us, glowing now even brighter. "Take this to the temple in the Hidden Grove. Your next trial awaits."

Part 4: A Bond Forged in Shadows

I feel like there's some unusual feeling of friendship between Miko and me as we walk out of the pagoda. The League's tests still haven't concluded for me, but I know that I'm not facing them on my own.

Miko elbows me. 'Not bad for a rookie.'

I am surprised to find myself laughing at it. 'Not bad for a senior, either.'

We walk toward the Hidden Grove together, the Compass illuminating our way. For once, I feel that I belong, really belong, in the League, in a world where shadows keep secrets and partners stand by your side.

To Be Continued...

The mission had hardly been the conclusion of my tale; it held the promise of adventure more extensive than anything I could imagine. The League of the Silent Blade was full of secrets, and I was ready to uncover them—all while learning what it truly meant to walk the path of a ninja.

0 notes

Text

Air Conditioning Repairs Denham Court

Air conditioning Repairs Denham Court technicians can fix problems with clogged filters, faulty motors, and evaporator coils. They can also perform duct cleaning, which improves airflow and saves energy.

They specialise in installing both split system and ducted air conditioners. Split systems are an affordable option for enhancing temperature control in targeted rooms, while ducted systems are integrated into the structure of a building for comprehensive climate control.

Split system air conditioners

Split system air conditioners are a popular choice for home Air conditioning Repairs Denham Court. These systems include an outdoor cabinet and an indoor unit that work together to cool the house and exhaust heat out of the house. A set of copper refrigerant lines connect the two units. The outdoor cabinet houses the compressor, which converts incoming air into heated or cooled air. The indoor unit includes the blower / air handler that sends the conditioned air to the room or spaces in your home.

Ducted air conditioning is another option for heating and cooling your property. This type of system allows for individual room temperature control and uses less energy than packaged air conditioning systems. It also produces less greenhouse gas. However, ductwork can be subject to leaks and other problems.

Ducted air conditioning systems

Ducted air conditioning systems work by cooling or heating homes via a network of ducts. They are popular for their efficiency, quiet operation and whole-home coverage. They are also typically less costly than other air conditioning options.

A ducted air conditioner’s indoor unit contains an evaporator coil that cools the air before it is distributed through the ductwork. The outdoor unit houses the compressor and condenser, which is where most of the noise originates. This separation makes a ducted system quieter than other air conditioning types.

However, a ducted air conditioning system can be more expensive to install and requires the existing ductwork to be properly insulated and maintained. It can also lose energy due to clogged ducts. This is why it’s important to have regular duct cleaning services performed by a qualified professional.

Reverse cycle air conditioners

Modern reverse-cycle air conditioners provide both heating and cooling in a single appliance. They work by extracting heat from the outside air to warm the space in winter and reversing the process of cooling in summer. This helps to minimise energy costs and maximise comfort.

Ducted reverse cycle systems are ideal for larger homes and distribute cool/warm air through vents in the ceiling or floor. They can be expensive to install and run, however. It is important to correctly size a system – too large a system will consume excessive power, while one that is too small may not perform effectively in cold conditions.

Our installers can assess your home and recommend the best system for your needs. They can also ensure your ducting is properly insulated and sealed to prevent heat loss.

Inverter air conditioners

While they have different operating mechanisms, both inverter and non-inverter air conditioners work in a similar fashion to cool enclosed spaces. Both depend on air intake, electrical consumption, and refrigerant to conduct their cooling functions.

Inverter air conditioners have variable compressor speeds that can match cooling needs, allowing them to save energy and lower electricity bills. The technology also minimizes temperature fluctuations and creates a comfortable indoor atmosphere.

Non-inverter air conditioning systems, on the other hand, have fixed speeds. Their frequent on-and-off cycling places additional stress on their components, shortening their lifespans.

Inverter air conditioners are more durable than traditional ACs and use less electricity, making them a smart choice for homeowners. They can also help with reducing odours and dust buildup in your home.

Duct cleaning

If you notice that the air ducts in your home are Split System Air Conditioning, it may be time for a professional to clean them. This is especially important if you’ve recently had construction or remodeling done. All that dust can easily enter your system.

A qualified duct cleaning technician will use vacuums, brushes and air-whipping tools to remove the dust from your ducts. Then they’ll seal the ducts to prevent future contamination. They’ll also inspect them for damage, leaks and kinks.

It’s a good idea to tidy up before your technician arrives so they can easily access the vents. If you can’t reach a duct, ask the technician to use a vacuum or air compressor to blow loose the dust. This will make it easier to clean later on.

0 notes

Text

China made COIL FOR SOLENOID VALVE CCP115D for power station

"China made COIL FOR SOLENOID VALVE CCP115D for power station The company has a large flow, high discharge pressure, good performance, high efficiency, long life, high reliability, special for the technical valve products. Our company's main products: hydraulic machinery and components, hydroelectric generating units; coal-fired generating units; generating units; electrical and electronic products processing; mechanical parts processing. Mainly engaged in the power industry host (steam turbine, water machine, boiler, turbine) accessories, spare parts, spare parts, auxiliary equipment and environmental protection equipment.

Yoyik can offer many spare parts for power plants as below:

DF-COIL FOR SOLENOID VALVE CCP115D-DF

vacuum pump price A10VSO100DFR1/32R EH oil Re-Circulating pump F3-V10-IS6S-1C-20 axial piston pump PV29 2RID CO2 vertical centrifugal pump LK45/CZ65-250-4 centrifugal pump DFB125-80-260-01 centrifugal pump parts CZ50-250C vertical centrifugal pump DFB-80-80-240 screw pump stainless HSNS210-42 centrifugal water pump 65-250A Valve Spring 8-YT668Y64150 Two position four way valve 4WE10C-20/AW220NZ5L roots vacuum pump WS-30 trip globe valve SHV20 ball valve MHARKH-18L-16-4465-EGPN350/DN16 electric oil transfer pump DLZB820-R64A vacuum pump parts KZ100-WS tee joint Rotary valve HH6424DF32 mannual bellows globe valve WJ15F1.6P LP accumulator bladder YZ326641-B/2.5GAL twin screw pump ACG045N6IVBP vacuum cleaner P-1433 BALL BEARING SINGLE ROW RADIAL DEEP GROOVE NO.6205 mechanical shaft seal 108-45 centrifugal pump working DFB80-50-220 solenoid valve HR3W6DG220NV high pressure piston pump PVH098R01AD30A rotary piston pump PVH74QIC-RSM-IS-10-C25-31 screw pump diagram 3GR25X4 vacuum pump compressor P-1258 pressure hose SMS-20-915mm-C vane pump diagram F320V5A1C22R sealing ring HB4-56J8-118 rubber coupling 80LY-45-3 vacuum pump 269v P-2811 axial piston pump MOOG0514 7005 37 manual vacuum pump P-1945 COIL FOR SOLENOID VALVE CCP115D

pressure hose SMS-10/12-305mm-B centrifugal pump parts DFB100-80-250-14 mechanical face seal 104G-40 vane pumps F3 V10 1S6S 1C20 multistage centrifugal pumps DFB80-520-240 600MW turbine DC Emergency pump (EOP)coupling 125LY-32 globe throttle check valve LJC100C-2.5P mechanical seal 39 mm 80AY50*10 centrifugal pump types YCZ50-250 Spare parts package G054 Accumulator for Heavy Railway Wagon Scheduling Unit NXQ63/31.5MPa fluid transfer pump YW-32-160 solenoid valve RV5-10-0-35 Suction valve W204856-TFE, W207782-PVC , W207783-PVC piston hydraulic pump PVM098 GR55KSP55.65-31.75K vane pumps F3V10-1S6S-1C20 HYDRAULIC SERVO PROPORTIONAL VALVE D664-4798-L05HABW6NEX2-G solenoid valve C9206015 vacuum oil pump P-1836 solenoid valve D1VW20BVZP92XB510 sealing oil water-ring vacuum pump mechanical seal 2S-185 EH oil pump PVHD74R01AA10A250000001ABO1OA dc screw pump HSNH860-46 mechanical seal 65 mm QG400/300-CW COMPLETE O-RING KIT FOR TURNING GEAR 0-0281-0005-00 electric oil transfer pump DLZB820-R64A-8 hydraulic pumps 80SDZL-26 globe throttle check valve LJC80C-1.6P vacuum pump compressor 30-WS-32 EH accumulator bladder NXQ-25/31.5-L-Y Steel pipe flange metal gasket HG/T20612-2009 radial piston pump hydraulic PVH74QIC-RF-1S-10-C25-31 057 globe throttle check valve LJC100C-4.0P metering piston pump A10VS045DR/31R-PPA12N00 vacuum pump oil P-1609-1 hydraulic jack pump 50SDZLJ-40Ax1.3 COIL FOR SOLENOID VALVE CCP115D

DFYLSYC-2024-7-15-A

"

0 notes

Text

What Makes Reed Relay Different from Other Coils?

Reed relay might not be a very familiar term for many of you out there. But, after reading this blog, you will get some understanding about what is reed relay. How does it work, and what makes it different from other relays.

Reed relay is a small electromagnetic switching device. These are made by the placement of a coil around a single or multiple reed switches. Generally, the relay assembly is over-molded after that, or sealed for extra durability and handling.

Working of the Reed Relays?

If we are to talk about the working module of a reed relay. First, it is important to know, the different types of reed relay.

Form A type is the most prominent and is in a normally open switch state. These relays are OPEN or OFF till there is a passage of current through the coil. The coil, that is electromagnetic, produces a magnetic field equivalent to a permanent magnet.

Lastly, the subsequent magnetic field closes the contacts, which switches on the relay. On the other hand, when the current in the coil is not there, the switch turns off and the contacts are open once more.

Form B relays which have N.C. biased contacts, which are held by a magnet. So, the relay is in a closed or off state until the energy is put back into the coil, opening the contacts. When there is no energy in the coil, it switches the relay off.

Form C relay which has three contacts as opposed to two. They are generally open, usually closed, and common. The common contact will swipe from the closed to the open contact when it is switched on. When it is in OFF mode, the contact returns to its resting off position. So, these are also called a double throw switch.

The last type Form E. This can exist in either the N.C. or N.O. state with no coil power making use of a biasing magnet. The contacts of the relay maintain their last position without the coil getting activated. For changing the contacts state, the magnetic field should be reversed.

What Makes Reed Relay Unique?

Reed relays are unique in many ways. One way in which it is unique is its Reed Technology principle. Reed switch relays are sealed from the exterior environment. So, no dust, dirt, and grime mean, it has a long life of wear-free switching. So, these can switch low level signals for numerous operations. On the other hand, electromechanical relays can be susceptible to mechanical failure from impurities from the outside. Therefore, they can switch in the numerous low operations.

Most remarkably, no other technology can switch zero current and voltage like these ones.

Reed relays are mostly used in electric vehicles, and there has been an increase in the number of electric vehicles on the roads. With the increasing number of electric vehicles, the demand for reed relays will also go up.

Going by the numbers, the total demand for these relays will reach USD 1,162 million, by the end of this decade.

0 notes

Text

ADSS Cable Fittings: How Much Do You Know?

With the construction of the network, the demand for All-dielectric Self-Supporting (ADSS) cable fittings is also increasing. They are used to fix ADSS cables to the pole and tower sides. What are the types of ADSS cable fittings? Next, briefly introduce ADSS cable and types of ADSS cable fittings.

What is ADSS Cable?

ADSS cable is strong enough to support itself between structures without using conductive metal elements. It is ideal for installation in aerial transmission and distribution power lines environments.

As its name indicates, there is no support or messenger wire required, so installation is achieved in a single pass, making ADSS cable an economical and simple means of building a fiber optic network.

Types of ADSS Cable Fittings

Tension Clamp

The tension clamp bears the tension strength, connecting the ADSS cable to the pole or tower. Stress is distributed without an intensive stress pivot, aluminum-clad steel wires rod against corrosion and improve the mechanical properties.

Wedge-type tension clamp is made of one opened conical fiberglass reinforced body, a pair of plastic wedges, and a flexible bail. It allows an easy and quick securing of ADSS cable on short spans. Span up to 100 meters.

Suspension Clamp

A suspension clamp is used to suspend the ADSS cable. It has a simple structure and is easy to install, stress is distributed in the large touching area, and preformed armor rods are optional for short spans (100m).

A double suspension clamp with preformed armor rods is used to suspend the ADSS cable. It is mainly used on long-span rivers and valleys with a large drop in the level and has aluminum alloy rods against corrosion and improves mechanical properties.

J hook suspension clamp is designed to provide a suspension for aerial ADSS cable at intermediate poles on cable routes on the access network. Span up to 100 meters. It is easy, quick, and safe installation, galvanized steel material, against rust and corrosion.

Spiral Vibration Damper

The spiral vibration damper is made of high strength, aging resistance, high elasticity, and modified PVC materials. It can effectively reduce the vibration caused by the laminar flow on ADSS cable.

Corona Coil

Corona coils are made of aluminum alloy, intended to reduce electrical stress at the end of the metal rods of tension clamp and suspension clamp applied on ADSS cables installed in high voltage electrical fields.

Lead Down Clamp

Lead down clamp is used to fasten cables on the pole or tower to protect them from shaking and abrasion. It is a reliable, convenient, and fast installation and electro-insulating rubber type.

Pole Clamp

A Pole clamp is used for the connection of the tension clamp and suspension clamp on the pole. It has hot dip galvanized surface treatment, against rust and corrosion.

Tower Clamp

The tower clamp is used for the connection of the tension clamp and suspension clamp on the tower. It has hot dip galvanized surface treatment and is against rust and corrosion.

Cable Storage Rack

The cable storage rack is used to store surplus cable. It has hot dip galvanized surface treatment and is against rust and corrosion.

Aluminum Pole Bracket

The aluminum pole bracket has aluminum alloy and multi-points to fix the tension clamp, which is available for wooden or concrete poles.

Metal Splice Closure

Metal splice closure is used to fusion and protection of splicing point. It has prompt, easy, and convenient installation, good sealing performance, high strength AL-alloy, High mechanical strength, can be reused, easy to rejoin and expand capacity.

Conclusion

The ADSS cable fittings have no damage to the fiber optic cable under various environmental conditions. The correct ADSS cable fitting is determined by the cable outer diameter and the span length that needs to be covered.

Sun Telecom specializes in providing one-stop total fiber optic solutions for all fiber optic application industries worldwide. Contact us if you have any needs.

#suntelecom#fiberoptic#telecommunications#fttx#telecomengineering#cabling#osp#fiberopticcable#catv#telecomconsult

1 note

·

View note

Text

Enameled Wire Enamels

Wire enamels are mainly used to coat the insulation of enameled wire cores. Since the wire will be subjected to heat, chemical and various mechanical forces in the process of winding the coil and inlaying the wire, the enameled wire enamel is required to have good coating (i.e., it can be evenly coated), strong adhesion of the enamel film, smooth and soft surface with toughness, a certain degree of wear resistance and elasticity, good electrical properties, heat resistance, solubility resistance, no corrosion of the conductor and other characteristics. Specifically divided into the following nine types. 1, acetal varnish main component is polyvinyl acetal, used in the production of enameled wire for oil-containing transformers. 2, polyurethane varnish main component is polyurethane methylene, widely used in electronic transformers, electronic coils, relays, micro motors, high frequency electrical instruments and other electronic requirements for the production of enameled wire for winding. 3、Solderability polyesterimide lacquer has the general performance of polyesterimide lacquer, 475° can be directly welded. 4, polyester imide lacquer is the most widely used class of enameled wire with excellent thermal performance, usually higher than 180 level, can be single coated, can also be used as a primer and polyamideimide or nylon lacquer composite production of composite lines. A large number of refrigerators and air conditioning compressors, explosion-proof motors, power tools, ballasts, dry-type transformers and other occasions with high insulation level. 5, polyester lacquer with polyester as the main component, good overall performance, used for washing machine motors, micro motors, instruments and telecommunications equipment, electric tools and general motors with enameled wire production. Heat-resistant polyester modified with Seck, also a large number of primers and polyamide imide composite for cold media resistant enameled wire production. 6, polyamide imide is the most widely used high heat-resistant grade (220 grade) enameled wire enamel, mostly used as a top coat to produce composite lines, used to improve the overall performance of the enameled wire. A large number of sealed motors, cold media resistant enameled wire production. Some products can also be single coated. To improve the performance of the enameled wire, it can also be made into self-lubricating type and filler. In the heavy motor and automotive industry has great application. 7、Polyester imide enamel heat grade 240, superior performance, its enameled wire is resistant to radiation. 8, nylon varnish using its lubricity, generally used in the enameled wire surface layer. For other performance also has improved. 9, self-adhesive varnish very according to the use of different components, mainly polyamide, epoxy (phenoxy) and aromatic polyamide and other different types of self-adhesive varnish. Generally do enameled wire top coat. Used for deflection coil, transposition wire, voice coil and anisotropic coil bonding molding.

Insulating varnishes can be divided into seven categories according to the insulation class Y, A, E, B, F, H and C [2] . The details are described as follows: Heat resistance grade: Maximum allowable working temperature (℃) Y grade: 90℃ Insulation structure made of unimpregnated cotton yarn, silk and paper materials or their combinations Class A: 105℃ Insulation structure made of impregnated or immersed in liquid dielectric (such as transformer oil, cotton yarn, silk and paper materials or their combinations) Grade E: 120℃ Insulation structure composed of synthetic organic film, synthetic organic enamel and other materials or their combinations B grade: 130℃ Class F:155℃ H grade: 180℃ Insulation structure made of mica, glass fiber, asbestos and other materials or their combinations after bonding or impregnation and coating with suitable resin (such as silicone resin) Class C:180℃ or more Insulation structure composed of mica, glass fiber, and unimpregnated mica, ceramic, quartz and other materials or their combinations after bonding or impregnation or coating with suitable resins

0 notes

Text

All the basics that you should know about stainless steel.

A flange is required whenever two tubes are connected to one another. It is utilized in the process of threading or welding the ends of two tubes together to create a single connected tube. Therefore, depending on the technique of attachment that is employed, fasteners can be generically categorized as either threaded attachment flanges or welding flanges. When it is time to link two tubes together, a flange junction has to be assembled using a gasket, many bolts and nuts, and a set of flanges.

To begin, place the gasket so that it is sandwiched between the mating sides of your seal. The screws then need to be tightened. When the gasket's surface pressure reaches a certain value, it deforms to completely conceal any inconsistencies in the sealing surface. The makers of PVC coated stainless steel tubing have consistently been a dependable resource.

Flange joints are a type of interchangeable connection. Flanges for both containers and tubes are available as interchangeable parts. Stainless steel sanitary tubing suppliers might be of great assistance.

There are three different types of sealing faces, depending on the pressure and the type of media being sealed against: planar sealing faces for low pressure, uneven sealing faces for moderate pressure, and tongue and groove sealing faces for high pressure and combustible, explosive, and toxic media. One such choice is ss capillary tubes manufacturers in India.

Different flanges can withstand different pressures and media, as you know. It turns out that the gasket utilized in the connection is crucial. Non-metallic plates in particular have been used to produce an abundance of gaskets. The stainless steel coil tubing manufacturers has been outstanding.

Asbestos rubber sheets, asbestos plates, polyethylene table sheets, and so on all have sizes that are specified in various standards. A latex gasket, for example, can only withstand temperatures up to 120? Asbestos with a high acid-resistance content has been widely used in harsh environments. Copper, aluminum, 10 steel, or stainless steel sheet metal is necessary in the event of increased pressure. India is home to a plethora of top-notch stainless steel boiler tube manufacturers.

Despite their apparent simplicity, fasteners have become more important in virtually every industry because of the vital roles they play. The two are joined by the fasteners. These days, the majority of individuals prefer to make use of them.

Flange, in reality, follows its own set of guidelines. The three systems in question are the DIN system, the ANSI scheme, and the JIS system. Similar pressure thresholds and sealing face types are needed for both systems. Stainless steel condenser tube manufacturers are highly sought after by a majority of customers nowadays.

Furthermore, the latter method is not generally accepted. Additionally, the GB standard, the chemical standard, the mechanical standard, and the pressure vessel benchmark should all be followed during production of the flanges. Industrial processes rely heavily on pipes and tubes as well. These technological advancements accommodate for human limitations by carrying out activities that humans are unable do.

0 notes

Text

Percy just might have to fight for the life of his wife against the man who once gave up everything to save it.

(read on ao3)

faustian beloved

i.

There are some debts, Percy de Rolo understands only too well, that a single lifetime can never hope to give anyone enough chances to fulfill.

He’s spent more time than he is willing to admit trying to come to terms with that fact, but he knows it now as intimately as he knows the best kinds of mechanisms in all the known planes.

Percy himself has owed many entities a great many things. He’s made bargains with men, demons, even gods, and though more than half of them were probably ill advised, they each came with their own price. He has tried to honor his end of every single deal, of course — sometimes at the cost of his and other people’s lives — but some parts of them, Percy also knows, will likely always have loose ends coiling indelible marks against his flesh and good name, to remain there until he is dead and gone and turned to dust like most of his kin before him.

I can bring her back.

Do it!

Because I don’t think I could’ve lived with myself.

Goodnight, Percival.

But of all these debts that hold a stake on Percy’s soul, there is one that carries the most weight. Of all vows sealed in his presence, it’s an oath made on hallowed ground that Percy was a catalyst to but not really a part of that holds everything he stands to lose.

Take me instead.

Of all the creatures Percy remains beholden to, it’s the Goddess of Death’s Champion whom he’ll spend countless eternities trying to repay.

.

ii.

It doesn’t begin to turn into anything of significance until Percy wakes up in the middle of a cold, freezing night and finds himself alone in bed.

Somehow, it’s not the darkness but the empty air he grasps instead of his wife’s arm or the familiar shift of her nightgown that makes him feel utterly blind to the world. Percy swallows the sharp burst of misery that flares up his throat long enough to fumble for his glasses and the lamp, only mildly embarrassed that his artisan hands grow clumsy and hit many things before any kind of light fills the room.

They’re at the last of two days that have become such a rare indulgence: Vesper with Cassandra and official Whitestone affairs too mundane to need either Lord or Lady. Percy had already been feeling the fading peace of a short but well-deserved rest and bracing for the return of tedious duties when he went to sleep hours ago.

Whatever peace that has lingered within him pulses when he catches sight of Vex’ahlia, a warm recognition that always comes to him after finding her — in a crowded hall, beneath evergreen trees, in the middle of the battlefield — and feeling as though he’s the one between them who’s the tracker.

The meager light from the lamp is too far to help make out details, but there is no mistaking the figure standing by the only open window. Just as swiftly, the warmth flickers out when he realizes just where Vex is and what she appears to be doing.

“Vex?”

Her hair is out of its trademark braid and moving around her face like the midnight breeze has chosen to swirl in place instead of right through the dark room. The white of her thin shift seems to glow now that it’s being gazed upon, as though Pelor himself wishes Percy to remember whose god his wife serves.

And Vex’s face, disconcertingly almost as pale as her gown and not quite as slack as sleep often makes it, is turned to whatever it is her closed eyes seem to be communing with outside.

Percy is standing and taking the lamp along with him before he can summon enough sense to feel fear.

“Hello, dear.” He sets the lamp on the nearest table and presses his lips against Vex’s cool hair, one arm curling around her waist to pull them closer together. Percy notes with a distant sense of wonder that his voice is coming out as a soft tremor. “What are you doing here?”

His careful whispering doesn’t seem to reach his wife, and Percy watches with growing concern as she continues to be deaf to his words and numb to his touch.

“Vex’ahlia,” he tries again.

He sets his gaze on her face, tells himself it’s the only thing worth looking at, so Percy is there to catch the exact moment when it changes from placid to something else entirely.

She still doesn’t seem to sense his presence, but her dark brows furrow and her lips twist into a deep grimace. It’s an expression Percy is terribly familiar with — the picture of heartbreak that he’s seen and even been the reason for many times in the past.

On instinct, he keeps a tighter hold on her, a firm grasp just a few shades shy of bruising. He’ll apologize and fawn over whatever marks he’s making in the morning, but for now Percy is convinced anything looser will let Vex slip out of his fingers.

“Hey, it’s okay.” He tucks his chin on top of her head and blinks at the darkness. Behind him, the wind from outside continues to sweep in and across their skin, as though taunting. “I’m here.”

Percy can’t quite tell how long they stand there, with Vex shivering from some kind of anguish and Percy trembling with a deep and nameless realization, but the spell is broken when he hears Vex gasp in his arms.

When he pulls away far enough to look down on her, he finds her eyes open and bewildered. “. . .Percy?”

“I’m here,” he repeats, hands coming up to frame her face and trace gentle thumbs along lines of drying tears, “I’m right here.”

“What–what’s happening?” she whimpers. “What’s going on?”

“Shh. It’s fine, dear. Everything’s all right.”

Though theirs is a love that will house no lies or manipulation, Percy also knows what it feels like to be the only one holding Vex’ahlia up, the only one keeping her head above the water. Right now, it’s what this whole thing feels like, with Vex shaking her head out of a daze and Percy guiding it away from the abyss she’s just come back from.

He presses their foreheads together and whispers, “Let’s get you back to bed, hmm?”

Confused but trusting, always with too much faith in him, Vex nods and hides her face against the crook of his neck.

With hands he tries to convince himself over and over aren’t really shaking, Percy maneuvers his wife back to where they came from. When he turns, some of the light can’t help but slide along the gap on the wall, and for the briefest of moments Percy catches a glimpse of what is waiting for them beyond the window.

They’re back in bed and he’s tucking Vex under the sheets again when he finally blows the solitary flame out.

As he’s closing his eyes and willing his thoughts back to order, Percy repeats to himself that what he saw were shadows and not at all the flutter of dark and familiar wings.

.

iii.

Aside from best friend and conscience and the sort of sister that not even Cassandra with her forgiveness and quiet wisdom can ever be, Keyleth of the Air Ashari is to Percy the only other in all of Exandria who understands what it’s like to love someone who came into the world with a soul already bound to another.

But unlike Keyleth, who cared for one raven-haired rogue with a complete acceptance of her duty and destiny, Percy doesn’t have millennia to spend on second loves and second chances. Vex’ahlia is for him the beginning and the end, and while he will never want it any other way, it can prove difficult whenever he’s confronted with the thought that there is a start and a finish — perhaps even a parallel path — for Percy’s better half that may not have any place for him.

“What is it?”

He lowers his mug and squints at the dark, swirling liquid. “I think we should’ve gone to the other tavern.”

“Percy. . .”

Studiously avoiding what he knows is a piercing look of both worry and exasperation, Percy waves off the first hail of fussing and makes a production of sneering at his cheap ale. “I’m quite serious. This tastes positively revolting.”

Keyleth heaves a deep and defeated sigh. “You’re the one who dragged us out here, remember?”

“To drink ourselves into the next age,” Percy reminds her. “Nothing else.”

“It’s happening again, isn’t it?”

Percy goes still.

He keeps on believing that after all the things they’ve been through, there ought to be nothing left that the Voice of the Tempest can say that should surprise him still.

Time and again, Percy has to remember that he is a fool.

“Say that one more time.”

When he looks up, Percy is met with one of Keyleth’s frustratingly steady and placating expressions. She also ignores his demand.

“It seems to me,” he spits out through gritted teeth, “that it is you who has failed to mention a few things.”

Keyleth rolls her eyes, but there is no good humor to the act. “Not sure what I was expecting, really.”

“I said—”

“Drink your ale, Percy.” Keyleth downs the rest of hers in one go, and Percy wonders, not for the first time, why her infamously poor tolerance for alcohol is always conveniently forgotten every time she has to be the sensible one. “And for what it’s worth, I didn’t pick the other tavern because that’s where Vex and I go.”

Just like that, all of Percy’s misplaced anger rushes out of him in one long breath, leaving nothing but deep shame and the metallic taste of lingering panic.

Keyleth’s comment is delivered in her usual amiable tone and neutral turn of phrase, but Percy recognizes it for the warning that it’s meant to convey: that she knows him better than probably everyone but the woman he married and that said woman is also her dear friend, someone whose confidence and trust she also safeguards.

“So I’m not just going insane,” he says, voice just a little above a whisper.

Percy hears Keyleth snort but he keeps his eyes on the callouses of his right hand’s fingers. “I love you, Percy, but we both know you’ve already gone there and come back to tell the tale.”

Despite himself, Percy feels his lips quirk in a ghost of a smile.

“But no,” Keyleth continues after a while. “Vex has– she’s noticed things. For a while now. She doesn’t know what they mean, exactly — and to be perfectly honest with you, I haven’t more than a clue, either — but she’s noticed things.”

This time, when Percy lifts his head, Keyleth’s sympathy is waiting for him.

She adds, “I doubt she knows you have as well, though.”

While the confirmation is a comfort in that it means Percy is not alone in the thoughts that’s been plaguing him for what feels like the better part of a generation now, it still raises more concerns than solutions.

Keyleth’s gentle smile is patient and encouraging, and it’s a testament to the years he’s spent growing up and trying to be a better man that it doesn’t take long for Percy to accept what she’s offering.

“I don’t know why I’m afraid,” he eventually admits. “If this is really– I mean, if what I think is right,” He pauses and meets her eyes, finds an echo of his thoughts in them even as Keyleth nods, “if this is what we think it is, it should be fine, right? I have no reason to be scared. I don’t– I don’t understand why I feel this way. It’s madness.”

In the end, it’s the heart of the matter. Percy’s instincts have saved him multiple times before, and right now, those same gut feelings are bringing him nothing but guilt and an urge to come to the kind of conclusions that for all intents and purposes should be irrational.

From across the table, Keyleth’s hands move to grasp his arm.

“It’s love, Percy.” Her fingers curl just above his wrist, squeezing tight in the space of a breath. “If you ask me, that’s a good deal more scary.”

.

iv.

The day after Vesper turned one, Vex braces her palm against the dining table, pushes herself up to stand, and makes it halfway before her eyes flutter and she falls like an apple with its stem struck by a marksman’s bolt.

It’s Grog, still pouting over a tender but impressive headache from the previous night’s festivities, who catches her. Percy stares from across the room as his wife slumps over the goliath’s arms, and it’s so reminiscent of the worst of Vox Machina’s battles that for a moment, all he can do is stand there in muted horror as his senses are filled with the heat of scorched earth and the acrid smell of gunpowder.

“Pike!” Grog calls out.

The shout breaks the silence that seems to have swept right through everyone, and it shatters Percy from his frozen state.

He runs, like he’s on a barren field and not in his own home, and fiercely shakes away the last sound he heard before Grog’s cry of alarm, the sound Vex made before she went down so quickly and so unexpectedly: a quiet, hitching exhale not unlike a dying gasp.

“Gods, she’s freezing.” When she finally gets to them, Pike cradles Vex’s face and frowns. “I don’t understand. Why is she so cold?”

No one can answer.

Despite the enduring frost that clings to Vex’ahlia, that turns her beautifully tanned skin into marble, into porcelain, there isn’t anyone who can determine the affliction to be anything beyond a fever.

That is, until one of Pike’s fellow clerics, a novice servant of the Everlight, is summoned to Whitestone.

She tells Percy tales of a sickness so old and so disreputable that many people believe it to be nothing more than a cautionary tale. The stories branch into different and wilder versions of blood feuds and ancient covenants, but they all seem to agree on one specific detail: that it’s meant to trap someone’s spirit at the very center of their being and bury it so deep that a blanket of winter keeps their life force inside.

The healer’s brown eyes, so similar to Vex’s when she’s telling Percy something she knows he won’t like, never waver when she reveals that it’s something no one has ever come back from.

Against Pike’s obvious discomfort and unspoken protests, Percy lets the healer keep going. She eventually says that some people from lands far away call it kiss of the living death — a tender but unwavering caress from beyond that seals the person to their flesh but denies the gift of true life, making them linger between the mortal world and the abyss of the unknown.

The whole time she talks, Percy’s gaze is on the door, which has been kept ajar so he can still see Vex on their bed, wasting away but looking for all the world like she’s simply asleep, exhausted but content from a long hunt.

“It’s just a theory,” Pike says when they’re alone in the hallway again. “Nyla is gifted, but she is young. There can be other explanations, and I’m sure we’ll find the right one soon.”

She’s gripping his hand in her smaller ones, and even at gunpoint, Percy is sure he won’t be able to tell which one of them can’t seem to stop shivering.

It’s half an eternity later, when the whole thing has gone on long enough that the need for Vesper to have a wet nurse is becoming too apparent to deny, that Percy surrenders his daughter to the care of his sister and her army of minders. The decision is made more difficult by how hard Vesper, who has been subdued up until then, cries when they part. Even if Percy wants nothing more than to take her back the very next moment, he knows Vesper’s welfare is of paramount importance. He needs to be a good father even in the midst of his failures to be a good husband.

“We’ll take care of her, brother.” Cassandra remains a pillar of strength all throughout, and he lets gratitude for her tide him over. “You go and bring Vex back home.”

Try as he might, Percy can’t remember the last time he’s slept more than the forty winks that Keyleth, Cassandra, and even Scanlan have enforce on him. As such, his body succumbs to the bone-weary fatigue and, before he knows it, follows patterns and habits until he’s standing outside familiar chambers.

It hasn’t been more than a handful of hours since the last time he’s been inside, keeping himself to one corner as Pike’s team of healers and shamans work themselves to the ground to bring warmth back to his wife’s veins. So when he pushes the door open this time, Percy expects the same tableau, only now with the shroud of darkness that the late hour brings. He expects Vex to be on the bed alone, unmoving and still save for the telltale rise and fall of her breathing, the only sign that she is not yet lost to them and is just waiting for Percy to come and get her.

Vex is on the bed, with the blankets covering her supine form and tucked underneath her the way she’s always liked, but she is not alone.