#similar to cutter's usage.

Explore tagged Tumblr posts

Text

minkowski and hera (indirectly; to herself) are the only ones who call eiffel "doug", eiffel is the only one who calls minkowski "renée", hilbert is the only one who calls lovelace "isabel", and no one calls hilbert by (any of) his first names. kepler calls jacobi "daniel" and maxwell "alana", and maxwell and jacobi use each other's first names too, but neither of them ever calls him "warren" - the only person who does is rachel, while he calls her "miss young." pryce and cutter are the only people who use each other's first names (though cutter's habit of almost always only using first names is a whole other thing.)

#wolf 359#w359#there's a more specific point i want to make but i'm putting this part out separately.#only including major characters and things that are said directly. eris calls lovelace 'isabel' but you could consider that#similar to cutter's usage.#and technically so does eiffel once but it's when they're listening to her logs before he met her.#stuff like that.#and of course eiffel calls himself 'doug' often in a way none of the other characters address themselves by name#but that's. again. a whole other topic.

130 notes

·

View notes

Text

Best IPTV Service Provider: What You Need to Know

Explore the best IPTV service provider, key features, benefits, and tips to choose the perfect streaming solution for seamless entertainment.

Install IPTV for Firestick (IPTV Smarters Player)

The era of traditional cable and satellite television is waning as Internet Protocol Television (IPTV) takes center stage in the entertainment world. Offering flexibility, affordability, and access to an extensive array of channels and on-demand content, IPTV has become the go-to solution for cord-cutters. However, with countless providers on the market, choosing the Best IPTV service Service can be overwhelming. This guide will help you understand what IPTV is, its benefits, and how to choose the best service provider for your needs.

🟦 What is IPTV?

IPTV, or Internet Protocol Television, delivers television content over the internet instead of traditional broadcasting methods like cable or satellite. This technology allows you to stream live TV, on-demand shows, and even premium channels via an internet connection.best IPTV services provider work on various devices, including smart TVs, smartphones, tablets, PCs, and streaming boxes.

<< Visit IPTV Website >>

🟪 Why is IPTV Gaining Popularity?

◼ Affordability: IPTV services are often significantly cheaper than traditional cable or satellite packages.

◼ Flexibility: Viewers can watch content on multiple devices, giving them the freedom to enjoy entertainment anytime, anywhere.

◼ Variety of Content: From local channels to international programming, IPTV services often provide a broader selection of channels.

◼ On-Demand Services: Many IPTV platforms include vast libraries of on-demand movies, series, and documentaries.

◼ Customizable Plans: Users can choose from tailored packages, allowing them to pay only for the content they want.

⚫ Types of IPTV Services

IPTV services come in various forms, depending on your entertainment needs:

◾ Live TV: Provides real-time streaming of TV channels, including news, sports, and entertainment.

◾ Video-on-Demand (VOD): Offers access to a library of movies, TV shows, and documentaries that can be watched anytime.

◾ Time-Shifted Media: Allows users to watch previously aired shows and events at their convenience.

◾ Catch-Up TV: Similar to time-shifted media, but specifically designed for accessing content from the last few days.

Factors to Consider When Choosing an IPTV Service Provider

To choose the best IPTV service provider, consider these crucial factors:

🔷 Content Availability

Does the service offer the channels you want, including local, international, or niche content?

Check for exclusive sports, movies, or regional programming if these are important to you.

🔷 Video Quality

Ensure the provider offers HD or 4K streaming for an optimal viewing experience.

Reliable IPTV providers will offer adaptive streaming to prevent buffering issues.

🔷 Device Compatibility

Look for services that work across multiple devices, including smart TVs, smartphones, and streaming devices like Firestick and Roku.

🔷 Ease of Use

A user-friendly interface with intuitive navigation is crucial for hassle-free usage.

Check if the service has an electronic program guide (EPG) or search functionality.

🔷 Reliability and Uptime

A trustworthy IPTV service should offer at least 99% uptime with minimal buffering.

Ensure the provider has robust server infrastructure to handle peak viewing times.

🔷 Pricing and Packages

Compare subscription plans to ensure they align with your budget and content requirements.

Look for discounts on annual plans or bundled services.

🔷 Customer Support

Reliable customer service is essential, especially if you encounter technical issues.

Check for live chat, email support, or detailed FAQs.

🔷 Trial and Refund Policy

Many IPTV providers offer free trials or money-back guarantees, allowing you to test the service before committing.

🟩 Top IPTV Providers in 2024

Here’s a list of some of the best IPTV Service provider based on content, quality, and customer feedback:

1. ARIS IPTV

Aris IPTV is one of the most popular IPTV service providers in the United States, offering a variety of channels and on-demand content. While Aris IPTV is known for its affordable pricing, it also provides high-quality streaming options for select content.

Features: Over 16,000 channels, including sports, movies, and international content.

Video Quality: HD and 4K.

Compatibility: Works on smart TVs, Firestick, and mobile devices.

Why Choose: High reliability and excellent customer support.

2. Sapphire Secure IPTV

Features: 4,000+ channels, including sports and premium networks.

Video Quality: HD streaming.

Why Choose: Affordable and feature-rich for budget-conscious users.

3. Xtreme HD IPTV

Features: Over 20,000 channels, VOD options, and an electronic program guide.

Video Quality: 4K and HD streams.

Compatibility: Compatible with most devices, including iOS, Android, and Windows.

Why Choose: Excellent for users who want high-quality streams and global channels.

4. Beast TV IPTV

Features: Offers live sports, entertainment, and international channels.

Video Quality: HD with minimal buffering.

Compatibility: Works on multiple platforms, including streaming devices and apps.

Why Choose: Great for sports enthusiasts.

5. Voodoo Streams

Features: Comprehensive sports coverage, international channels, and VOD.

Video Quality: HD and 4K.

Compatibility: Firestick, Roku, and Android.

Why Choose: Perfect for sports fans and live TV viewers.

How to Get Started with IPTV

Choose a Service Provider

Research and select a provider that meets your needs.

Set Up Your Device

Install the IPTV app compatible with your device.

Subscription and Login

Purchase a subscription plan and receive your login credentials.

Stream Content

Log in to the app and start enjoying your favorite channels.

Benefits of IPTV Over Traditional TV Services

Cost-Effectiveness: IPTV often provides more content at a fraction of the cost.

Global Access: You can watch content from anywhere, provided you have an internet connection.

Personalization: Tailored content and recommendations enhance the user experience.

Ad-Free Viewing: Many IPTV services include premium content without ads.

⏹ Common Challenges with IPTV

While IPTV has many advantages, it’s not without challenges:

🔹 Internet Dependency: A stable and high-speed internet connection is essential.

🔹 Legal Concerns: Not all IPTV services operate legally; choose reputable providers.

🔹 Buffering Issues: Poor-quality services may struggle with consistent streaming.

⏹ Legal Aspects of IPTV

Not all IPTV services are legitimate. Legal IPTV providers pay for licensing to distribute channels and content. To avoid legal issues:

Check if the provider mentions licensing agreements.

Avoid services that seem too cheap or offer pirated content.

✅Why Choose Aris IPTV

Aris IPTV is a service provider offering over 18,000 live channels and more than 88,000 video-on-demand (VOD) titles, including movies, TV series, and documentaries. Subscribers can enjoy content in high-definition (HD), full high-definition (FHD), and ultra-high-definition (4K) resolutions.

🔷 Key Features of Aris IPTV:

Extensive Channel Lineup: Access a wide range of channels from various genres, including sports, news, entertainment, and international programming.

High-Quality Streaming: Enjoy content in HD, FHD, and 4K resolutions, ensuring a superior viewing experience.

Device Compatibility: Aris IPTV is compatible with multiple devices, such as smart TVs, smartphones, tablets, and streaming devices like Amazon Firestick and Android TV.

Electronic Program Guide (EPG): Navigate channels and schedules easily with the integrated EPG.

24/7 Customer Support: Receive assistance anytime through their dedicated support channels.

<< Visit ARIS IPTV Website >>

🟩 Conclusion

IPTV is revolutionizing the way we consume television. With its affordability, variety, and flexibility, it's no surprise that more people are turning to this modern solution. When choosing the best IPTV service provider, focus on factors like content, video quality, pricing, and reliability. By doing thorough research and taking advantage of free trials, you can find a provider that perfectly suits your entertainment needs.

Switching to IPTV is a step towards modernizing your entertainment experience—don’t be left behind in the age of digital TV!

0 notes

Text

Iron Knights

The Iron Knights was a secretive organisation formed by the NIS in tandem with Destiny Liminal, allowing a small group of elite knights to become modified with godly DNA and mechanical armor in order to make them more efficient and on par with shifters. This group would eventually become the basis of the terrorist cell Protobeast, an anti-shifter group that used similar technology to hunt and kill known shifters and Chosens.

Known members of the group often only use singular-word aliases, pertaining to their abilities. One prominent member, Kim Soohong, was killed by accident in the line of duty to the military and his death subsequently covered up - but with that, his armor "Jugilis" was lost, and his then partner, Sangyi retired, swearing to investigate Soohong's death to his last breath and taking his set of armor, "Thorns" with him.

Made up of a mixture of Destiny Liminal subjects and modified elite soldiers, most of the group's identities are kept secret to the public and often have public personas.

Known Iron Knight Members

"Crown" (real name Ha Yoonsu): an obsessive and tough-talking young man who was promoted to leader of the Iron Knights when the original leader, "Leaves" (Chanyoung) disappeared. When he finds out Chanyoung was in fact still alive, he repeatedly tries to silence the now weakened Chanyoung in an attempt to secure his position once and for all. He was human, and chose to be modified in order to ensure he could keep up with the Destiny Liminal subjects - his favoured weapons are two long blades known as Tachyon Cutters.

"Leaves" (DV-23): the now mild-mannered software engineer Chanyoung with his dark past mired in highly skilled assassinations of political targets for the NIS. He chooses to keep his past self secret, but when Crown reappears, he is left with no choice but to once again mobilise his "Leaves" armor to take Crown down through a series of extensive fights. He eventually accepts his mother Shinrok's help in distributing his psychic abilities through the usage of her invention, containment units named "Booster Energies" that are injected through shafts on his spine.

"Spoons" (DM-21): the skittish and driven history student Joosang who had once been used as a profiler and interrogator, he escapes after his diagnosis and chooses to stand with Chanyoung when Crown reappears. He takes down Crown once through overloading Crown's brain with stolen memories, forcibly shutting down the armor in the process, but with his guardians' help, he has created a far more efficient armored suit to help with his condition.

"Boulder" (DT-26): created initially alongside DV-23 to assist him, the woman who takes the alias "Yeeun" would eventually turn against him due to perceived betrayal, and now devotes her time to trying to turn both the subjects in - she strongly believes that this is their only way to ensure that both of them don't get killed by Crown's rampage, and uses a greatsword in combat allowing her to parry and use mighty cleaves to break others' defenses.

"Jugilis" (real name Kim Soohong): deceased due to an accident in his day job in the military, he chose modification in the hopes of alleviating the burden of his ill mother and overworked brother. Became a vengeful spirit that eventually would find peace as an enforcer for the hellish realms, but able to take on temporary corporeal form through possessing his old Jugilis armor. Lovers with Sangyi, he chooses neutrality in this conflict due to being dead, and harbors no ill will to either group.

"Thorns" (real name Lee Sangyi): A reserved, cheerful art therapist who left his previous position due to the sudden death of his boyfriend Soohong, Sangyi took the Thorns armor with him and chose to retire from the NIS in the process. Along with Soohong, he also chose modification in an act of solidarity. He owns an art clinic that eventually ends up serving as a shelter for Boulder when she shows up wounded at his doorstep, but he, on behest of one of his past patients, chooses not to act until he finally can't.

"Treads" (real name unknown)

"Bundle" (real name unknown)

"Hands" (real name unknown)

"Moth" (real name unknown)

"Valiant" (real name unknown; often mistaken as Eunchae, Myron's personal nurse and angel familiar)

0 notes

Text

Comprehensive Guide to Hydraulic Hose Repair and Maintenance

In many industries, hydraulic hoses play a crucial role in maintaining the efficiency of operations. However, over time, these hoses can wear down, suffer damage, or become ineffective due to constant pressure and usage. Whether you’re dealing with hydraulic hose repair, SS hose repair, fuel hoses, or pressure wash hoses, understanding the proper techniques and procedures is essential for ensuring optimal performance. This guide will walk you through the common issues associated with these hoses and how to effectively repair and maintain them.

Understanding Hydraulic Hoses and Their Importance

Hydraulic hoses are used in a wide range of applications, from construction equipment to industrial machinery. They are designed to transport hydraulic fluid between different components in a system, allowing machines to operate smoothly and efficiently.

Over time, these hoses experience wear and tear due to high pressure, exposure to chemicals, extreme temperatures, and physical stress. That’s why hydraulic hose repair becomes necessary to keep systems running efficiently. If these hoses are not maintained or repaired promptly, the entire hydraulic system can malfunction, leading to expensive repairs or replacements.

Common Issues with Hydraulic Hoses

Hydraulic hoses are subject to a range of problems, and recognizing these issues early can save you time and money. Some of the most common problems include:

Abrasion: Constant rubbing or friction can wear down the hose’s outer layer, exposing the inner layers to damage.

Leaks: Hoses that are old, damaged, or improperly installed may start leaking, which can affect the overall performance of the hydraulic system.

Bursting: A hydraulic hose can burst if subjected to too much pressure, especially if the hose has worn down over time.

Kinking: Bending a hose beyond its flexibility range can cause kinks, leading to internal damage and reduced flow capacity.

Steps to Perform Hydraulic Hose Repair

Hydraulic hose repair is a detailed process that requires careful attention to ensure the hose operates correctly after being fixed. Here’s a step-by-step guide to follow:

Assess the Damage: Before you can repair a hose, it’s essential to understand the extent of the damage. Is the hose leaking, cracked, or completely severed? Understanding the issue will help determine the best repair method.

Remove the Hose: Turn off the hydraulic system and release any stored pressure in the hose. Use proper tools to disconnect the damaged hose from the machine or system.

Cut and Replace the Damaged Area: If the hose is damaged in one section, you can cut out the affected area using a hose cutter. Make sure the cut is clean and straight.

Attach New Fittings: After cutting the hose, attach new fittings to both ends of the hose. Ensure that the fittings are securely attached and match the specifications of the original hose.

Reinstall the Hose: Once the new fittings are attached, reconnect the hose to the hydraulic system. Double-check all connections to ensure they are tight and secure.

Test the System: Turn the system back on and check for any leaks or other issues. If the repair was successful, the hose should operate without any problems.

SS Hose Repair: Best Practices

SS hoses (stainless steel hoses) are used in environments where extreme temperatures, chemical exposure, or high-pressure levels are common. Like other hydraulic hoses, SS hoses can suffer damage due to wear and tear.

SS hose repair follows a similar process to hydraulic hose repair, but it requires specialized tools and fittings due to the stainless steel construction. Be sure to use appropriate tools designed for SS hoses, as improper handling can damage the hose further.

When repairing an SS hose:

Always inspect the entire length of the hose for cracks, kinks, or abrasions.

Use only high-quality replacement parts and fittings to maintain the integrity of the hose.

Avoid over-tightening fittings, as this can lead to future leaks or cracks.

Fuel Hose Maintenance and Repair

Fuel hoses are another type of hose commonly used in vehicles, machinery, and other applications where fuel needs to be transferred safely and efficiently. These hoses are typically made of rubber or synthetic materials, but over time, they can degrade, crack, or leak due to exposure to fuel and other chemicals.

To repair a fuel hose:

Turn off the engine and ensure that there is no pressure in the hose.

Identify the damaged area: Look for signs of cracking, leaking, or brittleness.

Cut out the damaged section of the hose and replace it with a new section that matches the original hose’s specifications.

Secure the new hose with proper fittings or clamps and check for leaks before turning the engine back on.

Regular inspection and maintenance of fuel hoses can help prevent major failures and costly repairs.

Pressure Wash Hose Repair

Pressure wash hoses are designed to handle high-pressure water used in cleaning tasks. Due to the constant high-pressure environment, these hoses are prone to leaks, abrasions, and bursts. Proper care and repair techniques are essential to keep them functioning correctly.

Here’s how to repair a pressure wash hose:

Inspect the hose: Check for any visible damage, such as leaks, kinks, or abrasions.

Turn off the water source: Make sure the system is depressurized before attempting any repairs.

Cut out the damaged section: Similar to other hoses, use a hose cutter to remove the damaged part.

Attach new fittings: Use pressure washer-compatible fittings and secure them tightly to prevent future leaks.

Test the hose: Once the hose is reinstalled, turn the water source back on and check for leaks.

The Role of Metal Hoses in Industrial Applications

Metal hoses are used in industries where flexibility and durability are critical. These hoses are commonly made from stainless steel or other metals and are used to transfer liquids or gases in high-pressure environments. The unique design of metal hoses allows them to withstand extreme temperatures and pressures, making them essential in many industrial applications.

Although metal hoses are incredibly durable, they are not immune to damage. Common issues with metal hoses include:

Cracking: Due to extreme temperatures or pressure changes, metal hoses can develop cracks over time.

Kinks: If a metal hose is bent beyond its flexibility range, it may kink, which can reduce its flow capacity or cause leaks.

Corrosion: Over time, exposure to certain chemicals or fluids can lead to corrosion, compromising the integrity of the hose.

When performing repairs on metal hoses, it’s essential to use specialized tools and fittings that are compatible with the hose material. Ensure that any replacement parts match the original hose’s specifications to maintain the integrity of the system.

Preventive Maintenance Tips for All Hoses

Proper maintenance is the key to extending the life of hydraulic hoses, SS hoses, fuel hoses, and pressure wash hoses. Follow these tips to ensure your hoses remain in good condition:

Regularly inspect hoses for signs of wear, leaks, or damage.

Replace hoses before they fail to avoid costly downtime and system failures.

Use protective coverings to prevent abrasions and damage from external elements.

Store hoses properly when not in use, keeping them away from direct sunlight or harsh chemicals.

Clean hoses regularly to remove any debris, dirt, or chemicals that could cause damage.

Conclusion

Understanding the importance of hydraulic hose repair and maintaining other types of hoses like SS hoses, fuel hoses, pressure wash hoses, and metal hoses is critical for the longevity of industrial machinery and systems. Regular inspections, timely repairs, and preventive maintenance are essential to avoid costly breakdowns and ensure efficient operations.

By following the repair steps and maintenance tips outlined in this guide, you can ensure that your hoses perform reliably and continue to support your industrial or commercial applications.

0 notes

Text

How to Understand the Advantages and Disadvantages of Fiber Laser Cutting Machine?

Advantages Of fiber Laser Cutting Machine

The powerful laser light released by a fiber laser cutting machine can easily cut through thick materials like steel. Fiber laser generators perform better than many other similar laser generators. These benefits have led to the widespread usage of fiber laser cutting machine in a variety of industries, including aviation and industrial. We will provide you with a thorough overview of the seven advantages of fiber laser cutting machine in this part.

Precision Cut

Higher power densities, better beam quality, and the ability to focus intensely are all advantages of fiber laser generators. Tight nesting of parts is made possible by the rapid, clean, and efficient production of components with tight tolerance and minimal kerfs made possible by the precision laser beam. This is benefits for many industries, including electronics, where the beam operates at a very small scale without harming any components that are required to maximize yield and reduce material waste.

Versatility

Fiber laser cutting machine adaptability is one of its strengths; it allows for accurate, fine cuts in a range of materials, such as iron, carbon steel, stainless steel, and various reflecting materials. Its versatility in cutting a range of materials has led to its increasing use in creative fields including metalworking and sculpture.

High Speed And Efficiency

Another notable feature of fiber laser generators is their speed; when cutting straight lines with a thickness of 1mm, they may cut three times quicker than conventional laser generators. Compared to traditional sheet metal cutting machinery, fiber laser technology is quick and energy-efficient, enabling you to complete more work in less time.

Low Cost

The best option for cutting expenditures and operating expenses is a fiber laser generator. It is a financially sensible alternative, with very low maintenance costs and the highest outlay of any kind during the machine's lifetime being the purchase price. Installing a fiber laser generator would not only reduce energy consumption each time it is utilized, but it will also help hardware last longer because it uses less energy.

Easy To Operate

The equipment can be operated by an intelligent control system thanks to the laser cutting machine. Data is received by the computer-aided design workstation, which then configures the laser cutting material to create a desired pattern or design. Even someone with little expertise running a machine can do simple activities.

Ease Of Maintenance

While fiber laser cutting machine are long-lasting, require less adjustment and part replacement, and are less likely to break down, they demand less maintenance money. Nitrogen assistance is another tool that fiber laser generators can utilize to speed up and improve the accuracy of their cuts.

Customization

If the standard laser cutter not be able to fulfill your manufacturing requirements, you have the option to ask the manufacturer for customisation. Customized machines may better satisfy the flexibility of firm production, and the majority of highly qualified manufacturers in the sector offer customized services. One way to improve the machine's fit in your workplace and save time when changing materials is to modify the size of the machine table.

Disadvantages Of Fiber Laser Cutting Machine

Metal Thickness Limitation

When it comes to cutting really thick sheets, fiber laser cutting is not as effective as other thermal cutting techniques. The machine's power and level of competence determine the maximum thickness that can be cut. Metal fabrication businesses typically utilize lasers to cut metal that is between 15 and 30 mm thick. Though the cutting speed for thicker metal is slower, the fiber laser cutting machine current power of up to 50kw allows it to partially cut through the limit of metal thickness.

Hazardous Gas Smoke

While many materials do not emit hazardous fumes during cutting, many polymers and some metals react to produce fumes and dangerous fumes. For example, polytetrafluoroethylene and various fluoropolymers generate phosgene when heated to high temperatures. Poor ventilation can cause operator discomfort and damage the machine itself, so a good ventilation system is a must for a safe working environment.

Professional Knowledge Required

A skilled machine operator is necessary for a laser cutting machine to reach its maximum potential. The cut quality of the metal will be as predicted if the cutting parameters are adjusted properly.

Purchase Cost

It's likely that purchasing a fiber laser cutting machine will require a substantial financial outlay. Purchasing a fiber laser cutting can be twice as expensive as purchasing a waterjet or plasma cutter. Long-term savings on operating expenses and reduced inefficiencies more than offset the purchase price.

Partial Material Evaporates

A significant disadvantage of fiber laser cutting machine is evaporation, which usually happens while cutting materials like plastics. Although a skilled machine operator may easily overcome this flaw, preventing this issue can be highly expensive.

For more information on the benefits of using laser cutting for your parts, contact Supreme Technologies.

#fiber laser cutting machine#buy fiber laser cutting machine#fiber laser cutting machine india#laser cutting machine price

0 notes

Text

Enhance Your Machinery's Functionality Along With Quality Shredder And Crusher Spare Parts

To optimize your equipment's functionality, prioritizing quality crusher and shredder wear parts is actually paramount. These elements function as the basis of your machinery, making certain smooth functionality as well as durability. By picking top-tier wear components, you may significantly enrich working effectiveness as well as lessen unanticipated malfunctions. The dependability and also toughness that premium wear parts deliver can easily be actually a game-changer for your machinery's result. Remain tuned to uncover the key points to consider when opting for these vital elements as well as just how they may revolutionize your machines's productivity.

Importance of Quality Wear Parts

Quality wear components are essential for making the most of the functionality and also endurance of your crusher as well as shredder machinery. When it pertains to apron feeder pans, picking top notch components makes sure that your equipment operates efficiently, squashing materials efficiently without unexpected failures.

In a similar way, committing in premium shredder wear parts assures that your shredding machinery functionalities at its own height, keeping optimum performance degrees. Poor wear parts may cause frequent replacements, downtime, as well as poor performance, inevitably costing you money and time.

Benefits Of Making Use Of Superior Components

Purchasing superior apron feeder pans supplies a myriad of conveniences that straight influence the productivity and durability of your equipment. Through going for top quality wear parts, including crusher extra components, you guarantee strengthened functionality as well as reduced down time.

Superior components are actually developed to resist massive usage, leading to less recurring replacements as well as servicing prices. The resilience of these wear parts suggests your machinery works at peak effectiveness for extended time frames, improving total performance.

Furthermore, making use of premium wear parts lessens the danger of unpredicted malfunctions, permitting smoother operations as well as boosted productivity. Ultimately, choosing quality crusher and shredder wear components is actually a tactical financial investment that repays in regards to functionality as well as functional superiority.

Variables Affecting Equipment Efficiency

To optimize your equipment's performance, comprehending the key aspects that affect its procedure is crucial. Two important aspects that considerably affect the efficiency and also longevity of your machinery are actually the quality of the mill liners as well as apron feeder pans.

Mill liners take an important duty in shielding the interior layer of the grinding mill from weathering brought on by the grinding method. Deciding on premium mill liners may enrich the general functionality of the mill by reducing recovery time as well as upkeep prices.

In a similar way, apron feeder pans are essential parts that assist in the hassle-free and constant function of your equipment by making certain a constant circulation of products. Picking tough apron feeder pans may aid stop interruptions and also optimize the performance of your machinery.

Maintenance Tips For Prolonged Life-Span

Making sure frequent evaluation and also prompt repair services may substantially expand the life expectancy of your crusher and shredder wear parts. By partnering with Qiming Casting for high-quality crusher wear parts, you can boost the resilience of your equipment.

Begin by setting up a regular servicing routine to look for any type of signs of wear or harm. Inspect elements such as the crusher liners, rotor disks, and shredder cutters for any type of abnormalities. Without delay take care of any kind of concerns by changing worn out sacrifice genuine QimingCasting substitutes.

Frequently lubricate moving components to lessen abrasion and also protect against premature wear. In addition, qualify your personnel on appropriate machinery function and also maintenance practices to guarantee ideal performance as well as long life of your crusher and shredder wear components.

Picking the Right Wear Parts

Choosing the ideal wear parts for your crusher as well as shredder machinery is crucial for optimizing efficiency and longevity. When deciding on wear components for your crusher, consider aspects like material structure, layout, and also toughness.

High-quality wear components can easily assist lower recovery time, strengthen productivity, and also ultimately conserve you money in the end. Make sure that the wear parts you pick are compatible along with your certain crusher model and treatment criteria.

Regularly evaluate and check the condition of wear components to identify signs of deterioration beforehand. Acquiring quality wear components for your crusher machinery is a positive amount that may dramatically impact the general performance and productivity of your equipment.

Verdict

Purchasing high-quality crusher and shredder wear parts is actually essential for taking full advantage of equipment efficiency and longevity. Through choosing premium parts, you can guarantee hassle-free procedure, minimize downtime, as well as ultimately enhance earnings.

Do not risk on quality when it pertains to wear parts-- produce the key expenditure in exceptional parts for optimum performance as well as productivity.

Qiming Casting

Address: 2th,Taixi Road, Pukou Area, Nanjing City, Jiangsu Province, China

Phone number: +0086 15251744209

0 notes

Text

The Ultimate Guide to Kitchen Drawer Organizers: Streamline Your Culinary Space

In the heart of every home, the kitchen plays a vital role in nourishing both body and soul. However, as a hub of activity, the kitchen can quickly become cluttered and chaotic, making meal preparation a challenging task. Enter the kitchen drawer organizer, a versatile tool designed to transform your culinary space into an efficient and well-organized haven. In this comprehensive guide, we'll delve into the world of kitchen drawer organizers, exploring their benefits, types, installation tips, and creative usage ideas to help you create a kitchen that not only looks great but functions seamlessly.

I. Benefits of Kitchen Drawer Organizers

A well-organized kitchen can significantly enhance your cooking experience, and kitchen drawer organizers play a crucial role in achieving that. Here are some compelling benefits:

1. Efficient Space Utilization Drawer organizers optimize drawer space, ensuring that every inch is utilized effectively. By creating designated compartments for different kitchen essentials, you can store more items in an orderly manner.

2. Easy Access to Tools and Utensils Say goodbye to rummaging through cluttered drawers! Kitchen drawer organizers allow you to neatly arrange cooking tools, utensils, and gadgets, making them easily accessible when you need them.

3. Streamlined Meal Preparation Having a designated spot for each cooking utensil or ingredient means you can work efficiently, saving precious time during meal preparation.

4. Reduced Clutter and Stress A clutter-free kitchen is a stress-free kitchen. Drawer organizers help you keep your cooking space tidy, which contributes to a more relaxed and enjoyable cooking experience.

5. Enhanced Safety With organized drawers, the risk of accidents caused by reaching into a jumble of sharp objects or hot tools is minimized.

II. Types of Kitchen Drawer Organizers

Kitchen drawer organizers come in a variety of styles, each catering to specific kitchen needs. Let's explore the options:

1. Utensil and Cutlery Organizers Designed to hold spatulas, ladles, knives, and other cooking utensils, these organizers keep your essential tools neatly arranged and easily accessible.

2. Divided Trays for Flatware Perfect for keeping forks, knives, spoons, and other flatware separated and organized.

3. Spice Drawer Inserts These organizers feature compartments for spice jars, ensuring you can easily find and reach the seasonings you need while cooking.

4. Expandable Drawer Dividers Ideal for customizing spaces for items of various sizes, such as mixing spoons, whisks, and rolling pins.

5. Deep Drawer Organizers Designed for larger items like pots, pans, and baking sheets, these organizers ensure that your cookware remains orderly and accessible.

III. Installation and Organization Tips

1. Assess Your Needs Examine your cooking habits and kitchen essentials to determine which types of organizers you require. Consider factors such as the number of utensils, cookware, and gadgets you use regularly.

2. Measure Drawer Space Accurate measurements are crucial for selecting organizers that fit snugly within your drawers. Be sure to measure the width, length, and depth of the drawers.

3. Group Similar Items Organize your kitchen tools and utensils into categories before placing them in the organizers. This practice ensures that items are easy to locate and return after use.

4. Prioritize Accessibility Place frequently used items in the most accessible drawers, making your cooking process more efficient.

5. Declutter Before Organizing Before adding organizers, go through your kitchen tools and utensils. Discard or donate items you no longer use or need, reducing clutter and making space for essentials.

IV. Creative Uses for Kitchen Drawer Organizers

1. Baking Supplies Arrange measuring cups, spoons, rolling pins, and cookie cutters neatly in an organizer for hassle-free baking sessions.

2. Coffee and Tea Station Create a designated space for your coffee and tea essentials, including filters, stirring spoons, and tea bags.

3. Kitchen Linens Keep dish towels, pot holders, and oven mitts in order by using a drawer organizer with divided sections.

4. Kid-Friendly Storage Teach children about organization by using drawer organizers to store their lunchbox items, reusable straws, and small snacks.

5. Specialty Utensils For items like zesters, cheese graters, and garlic presses, a specific organizer can prevent them from getting lost in the mix.

Conclusion

The kitchen is the heart of the home, and maintaining an organized cooking space can significantly enhance your culinary experience. Kitchen drawer organizers offer a practical and efficient solution to keep your utensils, tools, and essentials neatly arranged and easily accessible. By exploring the various types, benefits, and creative applications of kitchen drawer organizers, you're taking a significant step toward transforming your kitchen into a well-organized, stress-free haven where you can cook with joy and creativity.

Visit to know more: https://www.homestrap.com/products/kitchen-drawer-organizer

0 notes

Text

Where can I find the official Mach3 documentation for more information on system requirements?

To find the official Mach3 documentation for detailed information on system requirements, you can visit the official website of Mach3. As of my knowledge cutoff in September 2021, the official website for Mach3 is www.machsupport.com.

On the Machsupport website, you should be able to find comprehensive documentation, manuals, and user guides related to Mach3 for fast wire machine. These resources will provide in-depth information on various aspects of the software, including system requirements, installation instructions, configuration settings, and usage guidelines.

Here's a step-by-step guide to finding the official Mach3 documentation on the Machsupport website:

Visit the website: Go to www.machsupport.com using a web browser.

Navigate to the Documentation section: Look for a navigation menu or a section on the website that mentions "Documentation," "Support," or "Resources."

Explore the available documentation: Within the Documentation section, you should find links to user manuals, installation guides, configuration guides, and other relevant resources. Look for documentation specifically related to system requirements to get the detailed information you need.

Download or view the documentation: Click on the links provided to download the documentation in PDF format or view it directly on the website. The documentation will provide comprehensive information about Mach3, including the system requirements and other essential details.

If you have trouble finding the specific fast wire machine you need on the Machsupport website, you can also try searching for "Mach3 documentation" or similar keywords in search engines. This may lead you to other reliable sources, forums, or user communities where you can find additional information and resources related to Mach3.

Remember to verify the relevance and currency of the documentation, as software and its documentation may be updated over time.

0 notes

Text

What is the Significance of Performing a Stiffness Test on Paper/Board

The foremost question is why exactly is stiffness important for paper? Well, it is the stiffness that differentiates paper for different usages. In other words, it is the stiffness of why a paper could be used for one purpose but not another application. Of course, there are many other reasons too, however, stiffness plays a great role in determining the right grade of paper/board for varied packaging applications.

A stiffness tester is a high-performance equipment, designed to measure the bending strength of the paper. That is, it determines the degree to which the paper/board can withstand bending when a bending force is applied to it. There are many manufacturers of this tester, however, numerous paper/packaging manufacturers trust UEC for stiffness testers and other paper testing instruments.

Let us know a little about this instrument and also understand its benefits in the following section.

UEC’s Stiffness Tester

The Taber-type stiffness tester by UEC is crafted by experts to measure the stiffness as well as the flexibility levels of a material. It evaluates these properties in those materials that have around 10,000 Taber stiffness units. Besides, it can test paper, paper products, boards, plastic metal sheets, and similar flexible materials.

Manufacturers can also buy a triple shear cutter along with this tester to prepare samples without damage and deformation. Also, to get accurate results, using a cutter is crucial.

Other information:

Applicable Standards: TAPPI 489 m-69, ASTM D-747-61-T, and JIS P-8185

Weight: Stiffness tester - 6.350 kilograms and Triple shear cutter - 5 kilograms

Dimensions: Tester - 24.0 x 28.0 x 41.5 centimeters and Triple shear cutter - 24.0 x 12.5 x 8.5 cm.

Benefits of using a Stiffness Tester

The tester evaluates the bending resistance and flexibility of the paper in both machine and cross direction.

It is versatile to test paper, laminated plastic, light metal foil, cardboard, wire, and other flexible materials.

The tester gives accurate results and when used in collaboration with the triple shear cutter, samples of good shape can be tested, promoting highly accurate results.

It is easy to use and hence does not require much training of the users.

Being a lightweight machine, it can be shifted from one place to another place very easily.

Conclusion

If you’re looking to invest in a highly reliable stiffness tester, visit UEC to read more about it and drop inquiries. Buying Paper testing instruments from UEC comes with the additional benefit of demonstrations. Hence, it is time to connect with the experts.

0 notes

Text

Laser Engraving - A Recognised Technique of Etching On Materials

The acceptance of metal engraving by laser beams has led to large industries to employ this method to a variety of marking usages like normal typing of text and information to intricate designs and codes. This distinctive method is normally used to generate descriptions on the surface of a material. In order to achieve the desired, the laser beam creates a high intensity of heat thereby vaporizing the material matter, exposing fissures that form the final image. There are different material surfaces that are being used for the purpose of laser engraving, but however, metals are the most preferred surface materials and stays ahead in the list. The most relevant reason for this is that metals are generally used with every other material as a supporting structure or as the main surface to be exposed and so on. This popularity and preference is once again because they are strong, durable, they posses high thermal resistance and are in a way more aesthetically appealing when compared to many other materials. Owing to this reason different engraving metals with multiple uses have become significantly important. Due to the versatility of laser engraving which is more efficient, quick and accurate, especially on metal surfaces, the automobile industry whether it may be parts, full or part of the machine, pipes and other similar hardware, has made it its the most preferred method to etch barcodes, engine and chassis numbers and the manufacturing company logos. Due to the fact that that this method leaves a mark which is not only clear and legible but also permanent, on metal surface, it is considered as a onetime job and are also widely employed in such sectors where a permanent etching is required. Likewise laser beams are also used in metal cutting, which are generally known and referred as plotters. These plotters come in various types such as straight cutters, corner cutter and cutters of different shapes too. Even though the metals for a major portion of the engraving material surfaces, other surfaces like wood, plastic and similar surfaces are also quite prominently used. Signvec Technology established in 1997 is one of the reputed manufacturer and seller of the best quality laser engravers cutters. With vast experience in engraving and signage sector, the company is a specialist in laser engraving, cutting and marking machines. In Order To Find Out More Details On Engraving Products Please Be Touch With Us Today Onwards..!

#engraver#Engravers#laser engravers#laserengraver#laser marking machine#Laser Cutting Machine#Laser Cutter#corner cutter#cuttingplotter

0 notes

Text

Q&A: Japanese Weapon Permit Laws

Can a javelin be used to fight like a staff? I’m currently working on a character who uses a staff to fight, and I wanted him to have a ranged weapon (he’s a teenager living in Japan so obviously I can’t give him a gun) and I had the idea of a collapsible staff that turns into a javelin.

You couldn’t give him a spear, either.

To answer the first question quickly, it depends. Generally speaking, a javelin would not make a good melee weapon, and some are especially ill suited to hand to hand combat. Javelins are intended to be light weight throwing weapons, and while they do have a bladed tip, they’re not designed for melee combat.

Spear combat does share some similarity to staff combat, and there overlapping techniques that work with both. (The difference is that spears tend to be longer and heavier than javelins.)

As far as I know, collapsible staves are basically a non-start. You can’t have a telescopic staff or spear because the weapon would, “fold up,” during normal combat usage. You might find ones that can be dismantled (such as with multiple segments which screw together), but that wouldn’t be particularly concealable, as you’d need to take the time to reassemble your weapon when needed.

Now, you can find collapsible spears, specifically for LARPing, but those intended to collapse when used to avoid injuring the other participants.

So, a collapsible javelin isn’t and option, but dropping that character in Japan makes that a moot point; Japanese weapon laws are exceptionally strict. Owning a spear would require a permit from the Prefecture Public Safety Commission (this is the same body which issues firearms permits.) Note that I said, “owning,” and not, “carrying,” because it’s very likely that said permit would only allow you to keep it in your house as a display piece.

Private ownership of weapons is governed by the Swords and Firearms Possession Control Law of 1958. This law has been updated several times, and that wasn’t the first Japanese firearms legislation (that goes back to 1629), but the 1958 law separated ownership from carrying. In Japan, permits grant the ability to legally own an item, but not the ability to carry it without further dispensation.

You can dig up a lot of information on the ’58 law because it applies to gun ownership, however it’s far more encompassing than that. Any katana, sword, spear, or halberd is automatically considered a weapon. For, fixed blade knives the magic number is 15cm, if it’s over that, it’s a weapon. (There’s a bit of complexity, with three different groupings. Fixed blade knives have a lower length limit if they’re carried “unpacked,” outside the home, and folding blade knives have an even lower limit. Though, the simple takeaway there is that pocket knives are legal and unregistered, box cutters are weapons.) Incidentally, the spear would be licensed as a, “sword,” under the law.

(You can find an English translation by Mark Allerman published in the Washington International Law Journal here. However, that was published in 2000, and the law was updated in 2008, and again in 2018, so it doesn’t reflect the current version of the text.)

It’s unlikely your character could even obtain a permit to carry a sword outside of the home, even if they were an iaido practitioner. Age alone is a major factor. Normally someone under the age of 18 cannot obtain a permit. (There is a specific exemption for someone who is at least 14 to own an air gun, but, as far as I can tell, this doesn’t apply for sword permits.) So, they wouldn’t be able to even buy this hypothetical collapsing javelin, never mind carrying it.

As I said, Japan’s weapon laws are very strict, to the point that your character couldn’t, realistically, get their hands on much more than a kitchen knife (which would be an illegal weapon once it left the house.) More than that, Japanese authorities are very strict about violations. If your character is carrying any weapon, it will go very badly for them once they start using it.

-Starke

This blog is supported through Patreon. If you enjoy our content, please consider becoming a Patron. Every contribution helps keep us online, and writing. If you already are a Patron, thank you.

Q&A: Japanese Weapon Permit Laws was originally published on How to Fight Write.

135 notes

·

View notes

Text

((I’ve only had this chaos child for a day but already I have an AU Idea for him, thanks due to in part @kaiju-crimson-storyandask ‘s conversation about him and John Silver.)) ((AU Description under cut))

‘Pork Pie Hat Kid’

Real Name:Unknown Race: Unknown (Aquatic type) Description: Despite only being 50 Years old (12-14 Years for his species), the kid has seen better days. Mostly due to in part his seeming homelessness and wild nature, he is usually never without some kind of dirt or stain on him. He stands at 5′3″, with a few small dorsal fins jutting out of his Light Rust Orange Scales. He has large, bulbous milky gray eyes with hints of yellow and blue in them. Red gills decorate his neck. However, due to similarities with a Cookiecutter Shark, his mouth is probably the most powerful on the crew, even if it only covers a small portion. Though the raw bite strength probably can be outclassed, the cutting method he employs, using his razor sharp teeth and vibrating his jaws almost like an electric cutter, makes him able to take a bite out of most materials. As well, in the back of his mouth lies a metal crank attached to two hooks via. Metal Cables that he can activate and use seemingly mentally. The hooks can extend far, almost 20 Meters in length. As well, they are incredibly powerful, being able to rip through wood with ease and even shatter stone if given proper windup. With repeated usage, it can probably cut through metal, should the kid be persistent enough. Thanks to their constant usage, a depression of where the hooks land has been made on his tongue. His top teeth are sharp, small and needle-like, while his bottom teeth are gigantic and more blade-like, constantly poking out of his lips. His fingers are tipped with pitch black claws where the finger nails would be, and he only sports 4 fingers on each hand, each one webbed. The second most terrifying trait of the kid is his stomach; Specifically, the Gastric Acid. Anything he eats can pretty much be melted down, though with some materials it takes a bit to digest. Hence why he is a bit of a menace to deal with, as he can pretty much eat anything with no consequence. He sports a small vestigial fish tail that doesn’t really help much in the swimming process, but it does wag like a dog when happy. Having pilfered John Silver’s Crew’s clothing, he wears an oversized pirates coat that practically is like a giant tent around him rather than clothing, along with some raggedy cloth shirt and shorts that he wore when he originally entered the ship. Along with a piece of cloth tied around his waist, he also wears a strange bamboo ‘hat.’ Consisting of a bunch of bamboo sticks with a piece of cloth wrapping it all together. He seems to have stacked a bunch of smooth stones in the middle of the Bamboo hat. Backstory: Not much is known, seeing as how he doesn’t really talk about his home much or where he came from in general. All he talks about is how, one day, he decided to run off because there was nothing left for him home. So, he eventually found his way onto John Silver’s ship, where he lives as an unofficial pest. Flippant and strange, he helps out from time to time, but he delights in confusing the crew mates by making objects near them disappear via. his hooks.

#[Wired] - PPHK#[Stowaway] - Treasure Planet AU#[The Commander] - OOC#[A new foe it seems] - kaiju-crimson-storyandask#xilieninvasion

2 notes

·

View notes

Text

The Ultimate Guide to Kitchen Drawer Organizers: Streamline Your Culinary Space

In the heart of every home, the kitchen plays a vital role in nourishing both body and soul. However, as a hub of activity, the kitchen can quickly become cluttered and chaotic, making meal preparation a challenging task. Enter the kitchen drawer organizer, a versatile tool designed to transform your culinary space into an efficient and well-organized haven. In this comprehensive guide, we'll delve into the world of kitchen drawer organizers, exploring their benefits, types, installation tips, and creative usage ideas to help you create a kitchen that not only looks great but functions seamlessly.

I. Benefits of Kitchen Drawer Organizers

A well-organized kitchen can significantly enhance your cooking experience, and kitchen drawer organizers play a crucial role in achieving that. Here are some compelling benefits:

1. Efficient Space Utilization Drawer organizers optimize drawer space, ensuring that every inch is utilized effectively. By creating designated compartments for different kitchen essentials, you can store more items in an orderly manner.

2. Easy Access to Tools and Utensils Say goodbye to rummaging through cluttered drawers! Kitchen drawer organizers allow you to neatly arrange cooking tools, utensils, and gadgets, making them easily accessible when you need them.

3. Streamlined Meal Preparation Having a designated spot for each cooking utensil or ingredient means you can work efficiently, saving precious time during meal preparation.

4. Reduced Clutter and Stress A clutter-free kitchen is a stress-free kitchen. Drawer organizers help you keep your cooking space tidy, which contributes to a more relaxed and enjoyable cooking experience.

5. Enhanced Safety With organized drawers, the risk of accidents caused by reaching into a jumble of sharp objects or hot tools is minimized.

II. Types of Kitchen Drawer Organizers

Kitchen drawer organizers come in a variety of styles, each catering to specific kitchen needs. Let's explore the options:

1. Utensil and Cutlery Organizers Designed to hold spatulas, ladles, knives, and other cooking utensils, these organizers keep your essential tools neatly arranged and easily accessible.

2. Divided Trays for Flatware Perfect for keeping forks, knives, spoons, and other flatware separated and organized.

3. Spice Drawer Inserts These organizers feature compartments for spice jars, ensuring you can easily find and reach the seasonings you need while cooking.

4. Expandable Drawer Dividers Ideal for customizing spaces for items of various sizes, such as mixing spoons, whisks, and rolling pins.

5. Deep Drawer Organizers Designed for larger items like pots, pans, and baking sheets, these organizers ensure that your cookware remains orderly and accessible.

III. Installation and Organization Tips

1. Assess Your Needs Examine your cooking habits and kitchen essentials to determine which types of organizers you require. Consider factors such as the number of utensils, cookware, and gadgets you use regularly.

2. Measure Drawer Space Accurate measurements are crucial for selecting organizers that fit snugly within your drawers. Be sure to measure the width, length, and depth of the drawers.

3. Group Similar Items Organize your kitchen tools and utensils into categories before placing them in the organizers. This practice ensures that items are easy to locate and return after use.

4. Prioritize Accessibility Place frequently used items in the most accessible drawers, making your cooking process more efficient.

5. Declutter Before Organizing Before adding organizers, go through your kitchen tools and utensils. Discard or donate items you no longer use or need, reducing clutter and making space for essentials.

IV. Creative Uses for Kitchen Drawer Organizers

1. Baking Supplies Arrange measuring cups, spoons, rolling pins, and cookie cutters neatly in an organizer for hassle-free baking sessions.

2. Coffee and Tea Station Create a designated space for your coffee and tea essentials, including filters, stirring spoons, and tea bags.

3. Kitchen Linens Keep dish towels, pot holders, and oven mitts in order by using a drawer organizer with divided sections.

4. Kid-Friendly Storage Teach children about organization by using drawer organizers to store their lunchbox items, reusable straws, and small snacks.

5. Specialty Utensils For items like zesters, cheese graters, and garlic presses, a specific organizer can prevent them from getting lost in the mix.

Conclusion

The kitchen is the heart of the home, and maintaining an organized cooking space can significantly enhance your culinary experience. Kitchen drawer organizers offer a practical and efficient solution to keep your utensils, tools, and essentials neatly arranged and easily accessible. By exploring the various types, benefits, and creative applications of kitchen drawer organizers, you're taking a significant step toward transforming your kitchen into a well-organized, stress-free haven where you can cook with joy and creativity.

Visit to know more: https://www.homestrap.com/products/kitchen-drawer-organizer

0 notes

Text

Best Wood Router

A router is a hand device or energy device that routs (hollows out) an area in difficult material, together with wood or plastic. Routers are specifically utilized in woodworking, specifically cabinetry. Usually they are hand held or fastened, with the cutting come to be, in router tables.

The hand device form of router is the real shape. It is a specialized hand plane with a extensive base and a narrow blade that projects properly past its base plate (giving it the nickname antique girl's enamel). The electricity device form of router, with a spindle driven by way of an electric powered powered motor, is now the extra commonplace shape. The hand tool model is now regularly referred to as a router plane; for a few responsibilities, it although has some advantages over the electricity tool. Some employees preserve in mind the electrical router one of the maximum flexible woodworking energy equipment.[1] CNC wood routers put in force the advantages of Computer Numerical Control (CNC). VIsit Here

Related to the router is a smaller, lighter version, designed specially for trimming laminates. It can be used for smaller popular routing artwork. For instance, with the ideal jig it can be used for recessing door hinges and recessing lock faceplates. Even rotary tools can be used as routers even as the right bits and add-ons (at the side of plastic router bases) are related.

Chip formation

Modern plunge router displaying dirt extraction tube Routing and milling are conceptually similar, and surrender mills may be utilized in routers, however routing wood isn't always like milling steel in terms of the mechanics. Chip formation is specific, so the maximum dependable tool geometry is one-of-a-kind. Routing is well applied to pretty susceptible and brittle materials, normally wooden. As the ones substances are inclined in small sections, routers can run at extremely immoderate speeds, so even a small router may also moreover reduce unexpectedly. Owing to inertia at the ones excessive speeds, the everyday timber cutting mechanism of Type I chips cannot take vicinity. The cutter facet angle is blunt, drawing near ninety°, and so a Type III chip bureaucracy, with waste fabric produced as first-rate dust. This dust is a breathing risk, even in benign materials. The forces closer to the cutter are light, so routers may be handheld.

When milling metals, the material is tremendously ductile, despite the fact that remaining sturdy even at a small scale. A Type II chip paperwork, and waste can be produced as non-forestall swarf. Cutter forces are high, so milling machines should be sturdy and rigid, commonly large systems of solid iron.

Intermediate substances, along side plastics and occasionally tender aluminium, can be reduce through way of both technique, although routing aluminium is usually more of an improvised expedient than a production process, and is noisy and hard on gear.

Makita laminate trimmer Routing is typically constrained to tender metals (aluminium and so on.) and rigid non-metals. Specially designed cutters are used for an expansion of styles, cuts, and edging. Both hand managed and system managed/aided routers are not unusual nowadays.

Workpiece geometry Routing is a shaping approach that produces finished edges and shapes. Some substances which might be tough to form with one-of-a-kind methods, which include fiber-glass, Kevlar, and graphite, can be fashioned and completed properly thru diverse routing strategies. Apart from finished edges and shaping, cutaways, holes, and capabilities also can be formed using routers.

The spindle router is positioned on the finer cease of the scale of labor completed by the usage of a moulding spindle. That is to say it can lessen grooves, facet moulding, and chamfer or radius the brink of a piece of timber. It is also feasible to apply it for cutting some joints. The form of cut that is created is decided by way of the scale and shape of the bit (cutter) held within the collet and the intensity via the depth adjustment of the best plate.

Variety of routers There are an expansion of router styles, a few are plunge, a few are D treated, some are double knob dealt with. Different manufacturers produce the routers for one-of-a-kind timber works, as Plunge Routers, Fixed Base Wood Routers, Combo Routers, Variable pace Routers, Laminate Trimmer, CNC Wood Routers.[citation needed] Nowadays, maximum higher exceptional routers have variable velocity controls and could have plunge bases that also may be locked in area so the router can also be used as a hard and fast base router.[citation needed] Some have a gentle-begin feature, which means that they build up velocity progressively. This function is specifically applicable for routers with a large cutter. Holding a 3 horse-strength router and turning it on without a gentle-start might be dangerous, due to the torque of the motor. Holding it with two palms is a ought to. For routers with a toggle kind on / off transfer it's far important to check to affirm the switch is within the off function, previous to plugging it in. For safety, large router cutters can generally only be utilized in a router that is installed in a router table, this makes the tool even greater versatile and stable.[citation needed]

The reason of multiple cope with preparations is relying at the bit, control is much less difficult with different configurations. For instance, when shaping the brink of a first-rate table top, many customers choose a D cope with, with variable pace, as it seems to permit better manage and burning the wood can be minimized.

Routers have many makes use of. With the help of the multitude of jigs and numerous bits, they're able to generating dovetails, mortises, and tenons, moldings of endless sorts, dados, rabbets/rebates, raised panel doorways and frames, reducing circles, and loads more.[citation needed]

Features of the present day spindle router

template manual bushing secured in the base around the router cutter The device usually includes a base housing a vertically installed ordinary electric motor with a collet on the give up of its shaft. The bit is peak-adjustable to allow protrusion thru an opening in a flat sole plate, normally via adjusting the motor-mounting peak (the mechanism of adjustment is widely numerous amongst manufacturers). Control of the router is derived from a deal with or knob on every issue of the tool, or thru the more currently evolved "D-cope with".

There are two wellknown types of router—plunge and glued. When using a plunge-base router, the best of the bottom is located on the face of the art work with the reducing bit raised above the artwork, then the motor is grew to come to be on and the cutter is reduced into the paintings. With a fixed-base router, the lessen depth is about in advance than the device is have become on. The sole plate is then each rested flat on the workpiece overhanging the edge just so the lowering bit isn't always contacting the paintings (after which getting into the artwork from the component as quickly because the motor is have become on), or the sole plate is positioned at an angle with the bit above the paintings and the bit is "rocked" over into the paintings as soon because the motor is grew to become on. In each case, the bit cuts its way in, however the plunge router does it in a greater sensitive way, even though the bit used want to be formed so it bores into the timber while reduced.

The baseplate (sole plate) is normally spherical (though this, too, varies with the resource of individual models) and can be used along with a fence attached to the bottom, which then braces the router towards the edge of the artwork, or thru a straight-element clamped across the work to achieve a at once reduce. Other manner of guiding the gadget encompass the template manual bushing secured inside the base around the router cutter, or router cutters with integrated manual bearings. Both of those run closer to a right away facet or original template. Without this, the various reaction of the wood against the torque of the tool makes it no longer viable to govern with the precision generally required.

Table mounted router

View under a router table displaying plunge router attached. A router can be established upside down in a router table or bench. The router's base plate is installation to the bottom of the table, with a hole allowing the bit to protrude above the desk pinnacle. This allows the paintings to be passed over the router, instead of passing the router over the paintings. This has blessings even as jogging with smaller objects and makes some router operations more secure to execute. A router desk can be equipped with a fence, fingerboards and other paintings-guiding accessories to make the operation more secure and further correct.

A easy router desk includes a inflexible pinnacle with the router bolted or screwed immediately to the lowest. More complex answers may be advanced to allow the router to be without difficulty eliminated from the desk in addition to facilitate adjusting the router's bit height using a boost mechanism; there's a sizable range of commercially to be had systems.

In this mode, the router can carry out obligations similar to a spindle moulder. For smaller, lighter jobs, the router used in this way can be extra convenient than the spindle moulder, with the venture of set up being without a doubt quicker. There is likewise a much wider range of bit profiles available for the router, no matter the fact that the size is constrained.

The router desk is normally orientated just so the router bit is vertical and the table over which the work is exceeded is horizontal. Variations on this encompass the horizontal router desk, in which the table stays horizontal but the router is set up vertically above the desk, in order that the router bit cuts from the aspect. This alternative is for side operations, which consist of panel raising and slot cutting.

Profiles made in timber with the aid of several common router bits.

Two typical router bits: (pinnacle) a ¼-inch shaft Roman Ogee with bearing, (backside) 1/4-inch shaft dovetail bit. Router bits are available hundreds of types to create either decorative results or joinery aids. Generally, they're categorized as both excessive-speed steel (HSS) or carbide-tipped, but a few recent innovations consisting of solid carbide bits offer even extra range for specialized duties.

Aside from the materials they're manufactured from, bits can be labeled as part bits or non-component bits, and whether or not or now not the bit is designed to be anti-kickback. Edge bits have a small wheel bearing to act as a fence against the work in making aspect moldings. These bearings may be changed via using using commercially to be had bearing kits. Changing the bearing, in effect, adjustments the diameter of the lowering place. This is particularly vital with rabbeting/rebating bits. Non-facet bits require using a fence, either on a router desk or attached to the work or router. Anti-kickback bits rent delivered non-reducing bit material across the circumference of the bit's shoulders which serves to restrict feed-rate. This reduces the threat that the workpiece is driven too deeply into the bit (that may result in first rate kickback from the reducing issue being unable to compensate).

Bits additionally range via way of the diameter in their shank, with ½ inch, 12mm, 10mm, ⅜ inch, 8mm and ¼ inch and 6mm shanks (ordered from thickest to thinnest) being the most commonplace. Half-inch bits cost greater however, being stiffer, are a whole lot less at risk of vibration (giving smoother cuts) and are much less probable to interrupt than the smaller sizes. Care need to be taken to ensure the bit shank and router collet sizes match exactly. Failure to do so can motive permanent damage to either or each and might lead to the damaging state of affairs of the bit popping out of the collet for the duration of operation. Many routers encompass removable collets for the well-known shank sizes (within the USA ½-in and ¼-in, in Great Britain ½-in, 8mm and ¼-in, and metric sizes in Europe—no matter the truth that within the United States the ⅜-in and 8mm sizes are regularly most effective available for extra value).

Many cutting-edge routers allow the speed of the bit's rotation to be various. A slower rotation lets in bits of big decreasing diameter for use efficaciously. Typical speeds variety from 8,000 to 30,000 rpm.

Router bits can be made to in shape nearly any possible profile. Custom router bits may be ordered. They are mainly useful for domestic restoration initiatives, in which manufacturing of the specific trim and molding has been discontinued.

Sometimes complementary bits are to be had in devices designed to facilitate the joinery used in body and panel production. One bit is designed to reduce the grove inside the rail and stile quantities at the same time as the other shape the edge of the panel to in form inside the grove.

CNC router

A CNC timber router is a pc controlled device to which the router or spindle mounts. The CNC Machine may be both a transferring gantry fashion, wherein the desk is constant and the router spindle movements over it, or consistent bridge design, in which the desk movements under the router spindle, or hand-held style, in which the operator movements the system to the location to be reduce and the device controls the superb adjustments. CAD/CAM software programming is used to model the component this is to be created in the computer after which create a device direction for the device to comply with to reduce out the part. The CNC moves alongside three axes (X-Y-Z). Most CNC routers have a 3 motor power machine the use of either servo or stepper automobiles. More advanced routers use a four motor gadget for added velocity and accuracy.

Similar tools A tool just like a router, however designed to maintain smaller reducing bits—thereby making it less difficult to deal with for small jobs—is a laminate trimmer.

A related device, referred to as a spindle moulder (UK) or shaper (North America), is used to maintain larger cutter heads and may be used for deeper or large-diameter cuts. Another related device is the pin router, a bigger static version of the hand electric powered powered router but typically with a far extra effective motor and exclusive abilities which includes automatic template copying.

Some profile cutters use a decreasing head reminiscent of a spindle router. These want to now not be stressed with profile cutters used for metallic plate which use a flame because the slicing technique.

We wish this may clear your visions approximately wood routers work, to buy the quality one please visit at: https://bestwoodrouter.Stay/

1 note

·

View note

Text

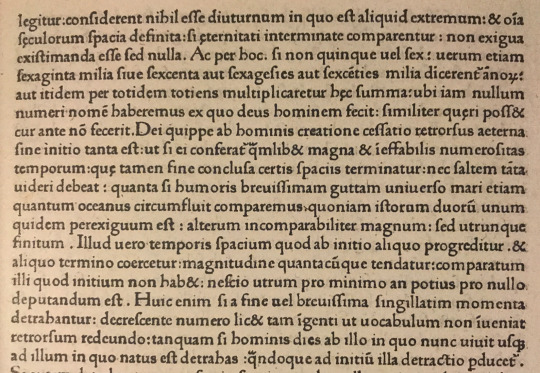

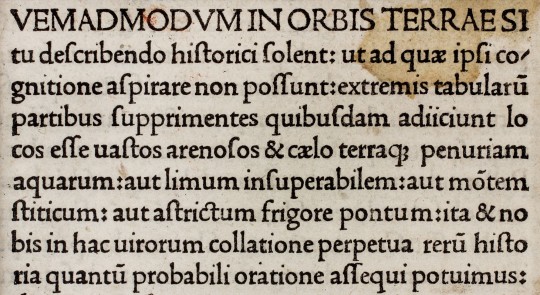

Typographical development up to and beyond Nicolas Jenson’s roman typeface

Introduction

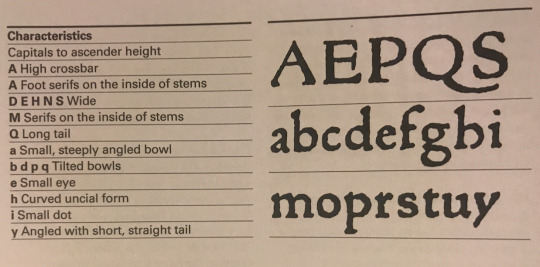

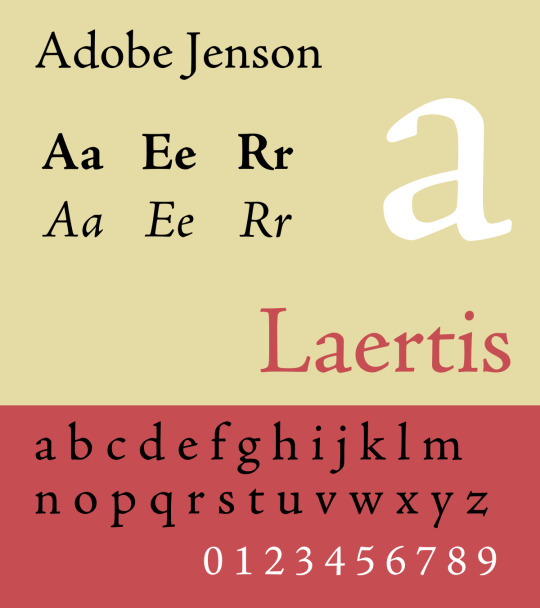

While reading about the history and early development of typography, I grew interested in the point at which typographic design became, for the first time, abstract; moving away from letterforms that mimicked handwritten script towards new styles that were driven by a growing awareness and appreciation of the formal possibilities allowed by the nascent technique of letterform printing. This technical and conceptual shift is generally attributed to the French typographer, Nicolas Jenson, who designed one of the earliest and finest Roman style typefaces in 1470s Venice: a typeface now referred to as Jenson.

Background/history of writing

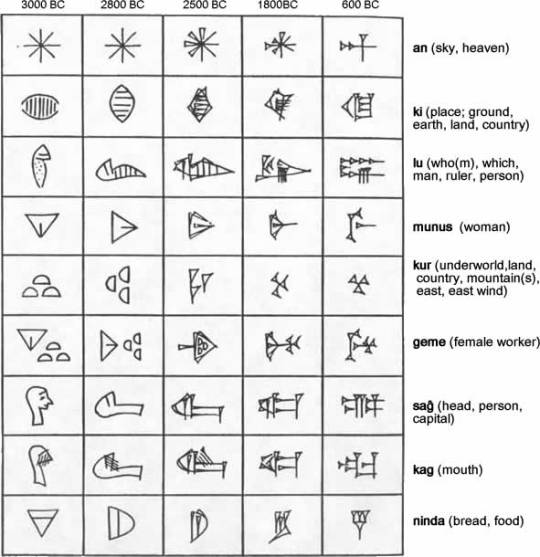

Typography, of course, derives from writing, which can be traced back to the 3rd millennia BC, an era in which cultural interactions between the societies of ancient Egypt and Mesopotamia, saw the Sumerian cuneiform script of the latter influence the development of hieroglyphics in the former, both written forms establishing themselves as powerful communicative aids before developing into new forms which influenced the creation of subsequent abjadic and alphabetic stems of writing.

Sumerian cuneiform

Egyptian hieroglyphics

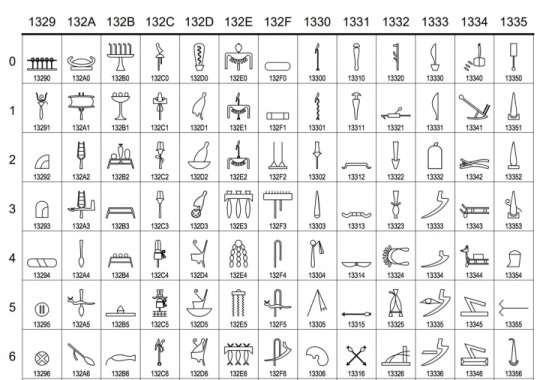

The Phoenicians simplified the act of writing by drastically reducing the number of letterforms, creating what is now recognised as the first abjadic alphabet, consisting entirely of consonantal sounds. The Greek alphabet derived from the Phoenician, but included letters for vowel sounds, making it the first of a new form of alphabet. This, in turn, informed the development of written Latin - a system that, according to Eric Gill, ‘reached a permanent type about the first century AD.’

Development of the Phoenician, Greek and Latin alphabets

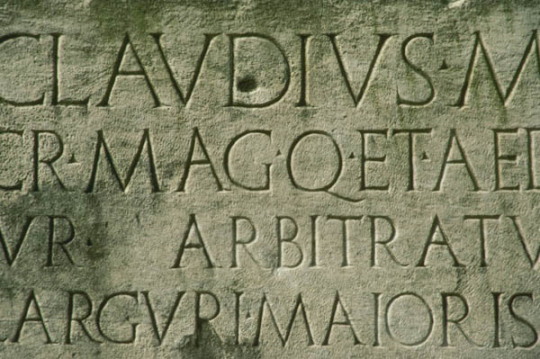

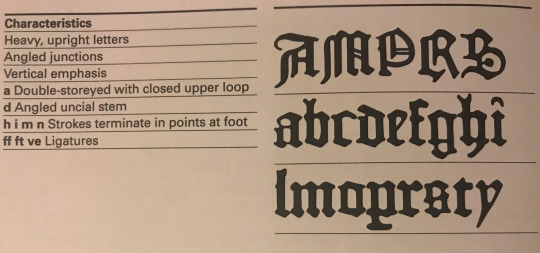

During the next fifteen-hundred years, a period in which the Latin alphabet itself remained for the most part fixed, the forms of lettering written in the languages derived from Latin developed in manifold ways: from the square capitals that were a characteristic of Roman lapidary inscriptions, through later and less formal cursive, insular and uncial scripts that eventually found a level of standardisation from the ninth to the early thirteenth centuries in the form now referred to as Corolignian miniscule. In turn this form of script developed into blackletter, or Gothic script, that was used from the 1150s through to the invention of printing and beyond.

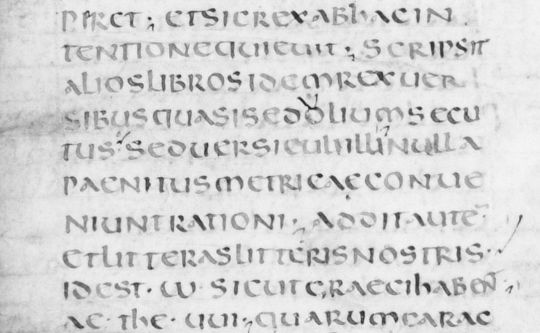

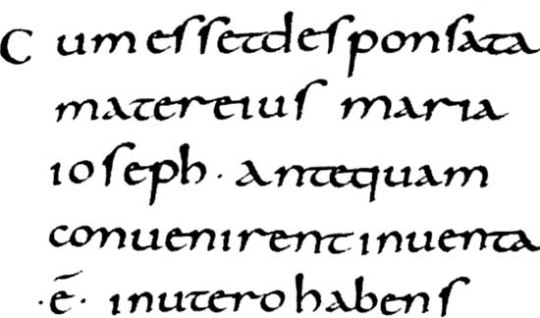

Roman lapidary inscription

An example of uncial script

Carolignan miniscule

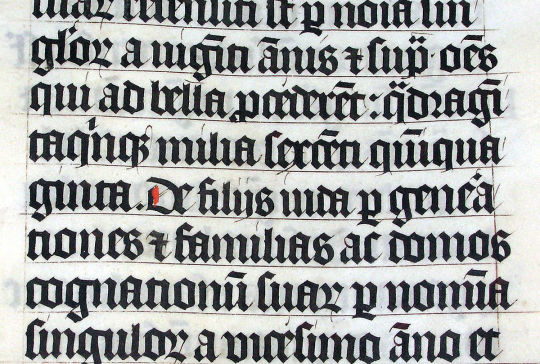

Gothic blackletter

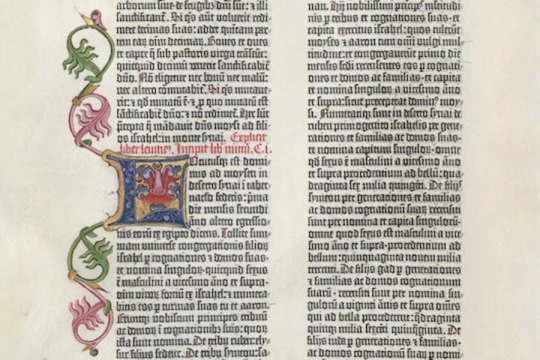

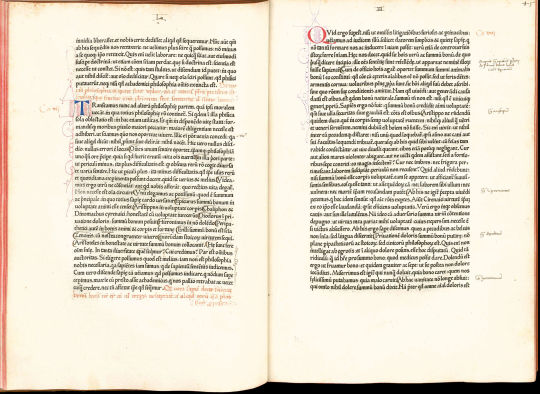

At the time Johannes Gutenberg introduced printing with moveable type in 1439, the new technology was conceived as a means by which texts - specifically indulgences - that had previously been produced, painstakingly, by hand could be mass produced and the process of manufacture and dissemination made more efficient. The focus was on the speed and convenience that the mechanical process allowed, rather than clarification or any improvement in the aesthetic quality of handwritten script. This meant that the initial conceptual scope of mechanical printing was to produce scripts in the style in which they would, previously, have been handwritten. The standard method of writing in the germanic world used Gothic letterforms and, since printing was invented in Germany, the early typefaces mimicked Gothic script.

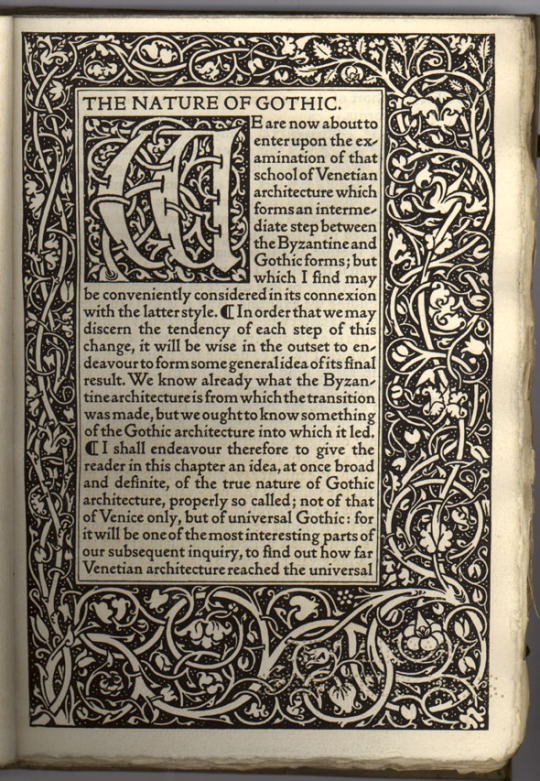

A page from Gutenberg’s bible of 1454

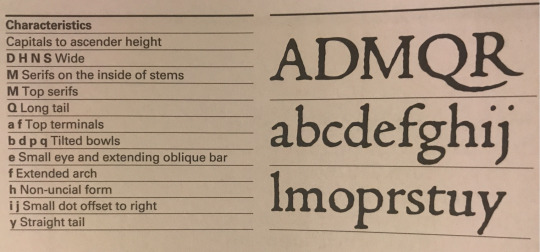

However, as Italy was the most culturally developed country in Europe at the time, German printers moved south to cities like Venice and began creating typefaces that took account of humanistic handwriting that was developing in Italy - a form that took as its inspiration the clarity of Roman lettering, marrying this with minuscule forms that had developed during later eras.