#siemens digital twin case study

Explore tagged Tumblr posts

Text

Title: Laser Technology in PCD Tool Manufacturing: Key Innovations, Industry Leaders, and Future Trends

1. Overview of Laser Applications in PCD Tool Machining 1.1: Why Lasers Dominate PCD Tool Manufacturing Polycrystalline diamond (PCD), with its extreme hardness (7,000–8,000 HV) and wear resistance, is critical for precision cutting tools, semiconductor packaging, and automotive components. However, traditional mechanical methods struggle with PCD’s hardness, leading to rapid tool wear and low accuracy. Laser technology has emerged as a game-changer, offering:

Non-contact processing: Eliminates tool wear. Ultra-fine heat-affected zones (HAZ <5 μm): Preserves material integrity. Complex geometry shaping: Enables intricate tool designs.

2: Core Laser Technologies & Challenges 2.1Ultrafast Lasers (Femtosecond/Picosecond)

Femtosecond lasers (e.g., Coherent Monaco Series): Pulse width <500 fs: Achieves nanoscale precision for micro-tools (<0.1 mm edges). Zero thermal damage: Ideal for edge preparation of micro-drills. Picosecond lasers (e.g., Trumpf TruMicro 5000): 5–10 ps pulses: Balances speed and accuracy for separating PCD composites (diamond + carbide). 2.2 Water-Guided Laser (Laser MicroJet)

Synova LCS 150: Combines laser beams with high-pressure water jets to reduce thermal stress, achieving surface roughness Ra <0.2 μm (critical for aerospace tools).

2.3 Multi-Axis Laser Systems

DMG MORI Lasertec 65 Shape: Integrates 5-axis motion and real-time monitoring for spiral grooves and 3D chip breakers in a single setup. Key Challenges:

Thermal management: PCD’s high thermal conductivity (2,000 W/m·K) demands precise energy control. Interfacial bonding: Thermal expansion mismatch between diamond and carbide causes delamination.

3: Top 5 Companies Driving Innovation 3.1 Ewag AG (Switzerland)

Flagship Product: Laser Line Ultra Series Tech Highlights: Femtosecond lasers + adaptive optics: ±1 μm edge control for micro-tools (0.05–3 mm diameter). AI-powered optimization: 30% faster processing via machine learning. Case Study: Supplies Apple with iPhone PCB micro-drills (500,000 holes per edge).

3.2. COBORN (UK)

Flagship Product: ORBIT 360° Laser System Tech Highlights: Ring-shaped beam: Minimizes edge chipping (taper angle <0.5°). Multi-wavelength compatibility: Adapts to PCD grain sizes (2–30 μm). Clients: Volkswagen, Bosch (crankshaft machining tools).

3.3 Synova (Switzerland)

Flagship Product: Laser MicroJet Hybrid Tech Highlights: Water-cooled laser: HAZ reduced to 2 μm; Ra 0.1 μm surface finish. 20:1 aspect ratio: Deep-hole drilling for fuel injectors. Partnership: Sandvik wind turbine gearbox tools (40% cost reduction).

3.4 Coherent (USA)

Flagship Product: HighLight FL4000 Femtosecond Laser Tech Highlights: 400 W average power: Cuts 3 mm PCD sheets in 5 minutes. Beam shaping: Square/ring profiles for complex edges. Application: Tesla 4680 battery casing tools (99.5% yield).

3.5 TKD CO.,LTD (China)

Flagship Product: TKD-300F/TKD-023F Tech Highlights: Ultra-precision optics: 0.06 mm line width at 3 m/s. Fiber laser system: Maintenance-free, high-accuracy cutting. Markets: PCD tools, ceramic machining (e.g., TSMC 3nm wafer dicing).

4: Future Trends & Challenges (2025–2030) 4.1. Hybrid Manufacturing Techniques

Laser + ECM/ultrasonic: GF Machining Solutions’ hybrid systems address micro-cracks at PCD-carbide interfaces.

4.2. Smart Manufacturing

Digital twins: Siemens NX reduces trial costs by 60% via full-process simulation.

4.3. Sustainability Demands

EU Green Tool Directive: Mandates carbon footprint <5 kg CO₂/kg, driving renewable energy adoption. Key Challenges:

High costs: Femtosecond systems exceed $2 million, limiting SME access. Lack of standards: No global certification for laser-based PCD processes.

5: Conclusion: Precision, Power, and Sustainability Laser technology is redefining PCD tool manufacturing:

Precision pioneers (Ewag, Synova) focus on submicron accuracy. Industrial giants (Coherent, DMG) leverage high-power, smart systems. Niche experts (TKD, COBORN) dominate sector-specific applications. With the EV and semiconductor boom, the laser-processed PCD tool market is projected to grow at 18% CAGR, reaching $2.5 billion by 2030. Companies must prioritize precision, efficiency, and eco-design to stay competitive.

1 note

·

View note

Text

Smart Factories: The Next Leap in Manufacturing

As the manufacturing sector evolves, the rise of smart factories marks a transformative leap into the future. Powered by the Internet of Things (IoT), predictive maintenance, and advanced robotics, these intelligent production environments are redefining efficiency, innovation, and scalability across industries worldwide. In this blog, we’ll explore how these technologies drive change, examine global trends, and highlight real-world case studies showcasing their profound impact.

The Essence of Smart Factories

A smart factory is more than an automated facility; it’s an ecosystem where physical production processes are seamlessly integrated with digital technologies. Leveraging interconnected devices, data analytics, and intelligent automation, smart factories enhance operational efficiency while minimizing downtime and waste. They embody the principles of Industry 4.0, propelling manufacturing into a digitally optimized future.

Key pillars of smart factories include:

IoT-enabled Devices: Real-time monitoring and communication across machines and systems.

Predictive Maintenance: Anticipating failures before they occur, reducing costly disruptions.

Robotics and AI: Enhancing precision, speed, and adaptability in production lines.

Digital Twins: Virtual simulations of physical processes to optimize design and operation.

The Role of IoT in Manufacturing

The Internet of Things (IoT) is the backbone of smart factories, enabling devices, sensors, and systems to exchange data in real-time. This connectivity drives unprecedented transparency, allowing manufacturers to monitor operations and make data-driven decisions.

Global Trends in IoT Manufacturing

Edge Computing: Processing data closer to where it’s generated reduces latency, enabling faster responses in production environments.

5G Connectivity: Ultra-fast, low-latency networks are critical for real-time communication between IoT devices.

Smart Supply Chains: IoT enhances supply chain visibility, tracking goods from raw materials to finished products.

Case Study: Siemens Amberg Electronics Plant

At Siemens’ Amberg plant in Germany, IoT plays a pivotal role. The factory achieves a production efficiency of over 99% by connecting 1,000 IoT devices across its production line. These devices analyze data to detect anomalies, optimize workflows, and maintain product quality.

Predictive Maintenance: The Game-Changer

Traditional maintenance models often involve reactive or scheduled maintenance, which can lead to unnecessary costs or unexpected downtime. Predictive maintenance, driven by IoT and AI, changes the game by identifying potential equipment failures before they happen.

How Predictive Maintenance Works

Data Collection: Sensors on machines gather data on temperature, vibration, and other parameters.

Analysis: AI algorithms detect patterns indicating wear or failure.

Actionable Insights: Operators receive alerts to perform maintenance at the optimal time.

Benefits of Predictive Maintenance

Reduced Downtime: Machines are serviced only when needed, ensuring maximum uptime.

Cost Efficiency: Minimizes unnecessary maintenance and avoids expensive repairs.

Extended Equipment Lifespan: Prevents excessive wear and tear.

Case Study: General Motors (GM)

GM employs predictive maintenance across its assembly plants using IoT sensors and analytics platforms. This approach has resulted in a 50% reduction in unexpected downtime, saving millions annually while improving production efficiency.

Advanced Robotics: The Workforce of the Future

Robotics has been integral to manufacturing for decades, but today’s smart robots are powered by AI, making them more versatile and capable than ever. These robots not only execute repetitive tasks with precision but also adapt to complex environments.

Trends in Robotics

Collaborative Robots (Cobots): Designed to work alongside humans, cobots enhance productivity without replacing human workers.

AI-powered Robots: Machine learning enables robots to learn and improve over time, adapting to new tasks.

Autonomous Mobile Robots (AMRs): These robots navigate factory floors independently, transporting materials efficiently.

Case Study: Tesla Gigafactories

Tesla’s Gigafactories exemplify cutting-edge robotics. Robots perform tasks such as welding, assembly, and material handling, ensuring consistency and speed in electric vehicle production. The integration of AI enables these robots to adjust operations dynamically, reducing errors and waste.

Digital Twins: Bridging the Physical and Digital Worlds

A digital twin is a virtual replica of a physical system, enabling manufacturers to simulate, monitor, and optimize operations. This technology provides invaluable insights, from design to production, enhancing both speed and accuracy.

Applications of Digital Twins

Product Design: Simulate prototypes to refine designs without costly physical trials.

Process Optimization: Test and adjust manufacturing workflows digitally.

Performance Monitoring: Track real-time performance and predict potential issues.

Case Study: Boeing

Boeing uses digital twins to streamline aircraft production. By simulating assembly processes, the company reduces errors and shortens production cycles, ensuring faster delivery without compromising quality.

Global Trends Shaping Smart Factories

1. Sustainability

Smart factories prioritize energy efficiency and waste reduction. By analyzing energy usage patterns, manufacturers can minimize their environmental footprint. Example: Schneider Electric’s smart factory in India reduced energy consumption by 10% and water usage by 20% using IoT and analytics.

2. Resilience

The COVID-19 pandemic highlighted the need for resilient supply chains. Smart factories enhance agility, enabling manufacturers to adapt quickly to disruptions. Example: Procter & Gamble leveraged IoT and AI to maintain production during the pandemic, ensuring consistent supply despite fluctuating demand.

3. Workforce Evolution

Automation does not eliminate the need for human workers; instead, it shifts their roles toward higher-value tasks like strategy and oversight. Upskilling programs are critical to prepare the workforce for this transition. Example: Foxconn’s “automation-first” strategy includes extensive training programs to reskill employees for new roles alongside robots.

Challenges and the Path Forward

While smart factories offer immense potential, they also face challenges:

Cybersecurity: Increased connectivity poses risks of cyberattacks. Robust security protocols are essential.

High Initial Costs: The adoption of advanced technologies requires significant investment.

Skill Gaps: The transition to smart manufacturing demands a skilled workforce comfortable with digital tools.

Future Outlook

Despite these challenges, the momentum toward smart factories is unstoppable. By 2030, the global smart manufacturing market is projected to reach $514 billion, driven by advances in AI, IoT, and robotics. Governments and private sectors must collaborate to address barriers, ensuring equitable access to these transformative technologies.

Conclusion: A New Era of Manufacturing

Smart factories represent the pinnacle of manufacturing innovation, combining IoT, predictive maintenance, robotics, and digital twins to revolutionize the industry. From enhanced efficiency to greater sustainability, the benefits are undeniable. As companies like Siemens, GM, and Tesla lead the way, the future of manufacturing promises to be smarter, faster, and more resilient.

The next leap in manufacturing is already here. Embracing smart factory technology isn’t just an option — it’s an imperative for companies aiming to stay competitive in an increasingly dynamic global market.

So, is your business ready to step into the future of manufacturing?

#Tech4bizsolutions #SmartFactories #Industry40 #ManufacturingInnovation#DigitalTransformation #IoTInManufacturing #AIInManufacturing #PredictiveMaintenance #IndustrialAutomatio #RoboticsInManufacturing #SmartManufacturing #FactoryOfTheFuture#AdvancedManufacturing #TechInIndustry #AutomationRevolution #SustainableManufacturing#DigitalTwins #SupplyChainInnovation #FutureOfManufacturing #IndustrialIoT #ManufacturingTechnology

0 notes

Text

21 ways medical digital twins will transform health care

Where does your enterprise stand on the AI adoption curve? Take our AI survey to find out.

The health care industry is starting to adopt digital twins to improve personalized medicine, health care organization performance, and new medicines and devices. Although simulations have been around for some time, today’s medical digital twins represent an important new take. These digital twins can create useful models based on information from wearable devices, omics, and patient records to connect the dots across processes that span patients, doctors, and health care organizations, as well as drug and device manufacturers.

It is still early days, but the field of digital twins is expanding quickly based on advances in real-time data feeds, machine learning, and AR/VR. As a result, digital twins could dramatically shift how we diagnose and treat patients, and help realign incentives for improving health. Some proponents liken the current state of digital twins to where the human genome project was 20 years ago, and it may require a similar large-scale effort to take shape fully. A team of Swedish researchers recently wrote, “Given the importance of the medical problem, the potential of digital twins merits concerted research efforts on a scale similar to those involved in the HGP.”

While such a “moon shot” effort may not be immediately underway, there are many indicators that digital twins are gaining traction in medicine. Presented here are 21 ways digital twins are starting to shape health care today, broken roughly into personalized medicine, improving health care organizations, and drug and medical devices and development. In fact, many types of digital twins span multiple use cases and even categories; it is these cross-domain use-cases that form a major strength of digital twins.

Personalized medicine

Digital twins show tremendous promise in making it easier to customize medical treatments to individuals based on their unique genetic makeup, anatomy, behavior, and other factors. As a result, researchers are starting to call on the medical community to collaborate on scaling digital twins from one-off projects to mass personalization platforms on par with today’s advanced customer data platforms.

1. Virtual organs

Several vendors have all been working on virtual hearts that can be customized to individual patients and updated to understand the progression of diseases over time or understand the response to new drugs, treatments, or surgical interventions. Philip HeartModel simulates a virtual heart, starting with the company’s ultrasound equipment. Siemens Healthineers has been working on a digital twin of the heart to improve drug treatment and simulate cardiac catheter interventions. European startup FEops has already received regulatory approval and commercialized the FEops Heartguide platform. It combines a patient-specific replica of the heart with AI-enabled anatomical analysis to improve the study and treatment of structural heart diseases.

Dassault launched its Living Heart Project in 2014 to crowdsource a virtual twin of the human heart. The project has evolved as an open source collaboration among medical researchers, surgeons, medical device manufacturers, and drug companies. Meanwhile, the company’s Living Brain project is guiding epilepsy treatment and tracking the progression of neurodegenerative diseases. The company has organized similar efforts for lungs, knees, eyes, and other systems.

“This is a missing scientific foundation for digital health able to power technologies such as AI and VR and usher in a new era of innovation,” Dassault senior director of virtual human modeling Steve Levine told VentureBeat. He added that this “could have an even greater impact on society than what we have seen in telecommunications.”

2. Genomic medicine

Swedish researchers have been mapping mice RNA into a digital twin that can help predict the effect of different types and doses of arthritis drugs. The goal is to personalize human diagnosis and treatment using RNA. The researchers observed that medication does not work about 40% to 70% of the time. Similar techniques are also mapping the characteristics of human T-cells that play a crucial role in immune defense. These maps can help diagnose many common diseases earlier when they are more effective and cheaper to treat.

3. Personalized health information

The pandemic has helped fuel the growth of digital health services that help people assess and address simple medical conditions using AI. For example, Babylon Health‘s Healthcheck App captures health data into digital twins. It works with manually entered data such as health histories, a mood tracker, symptom tracker, and automatic capture from fitness devices and wearables like the Apple Watch. The digital twin can provide basic front-line information or help guide priorities and interactions with doctors to address more severe or persistent conditions.

4. Customize drug treatment

The Empa research center in Switzerland is working on digital twins to optimize drug dosage for people afflicted by chronic pain. Characteristics such as age and lifestyle help customize the digital twin to help predict the effects of pain medications. In addition, patient reports about the effectiveness of different dosages calibrate digital twin accuracy.

5. Scanning the whole body

Most approaches to digital twins build on existing equipment to capture the appropriate data, while Q Bio’s new Gemini Digital Twin platform starts with a whole-body scan. The company claims to capture a whole-body scan in 15 minutes without radiation or breath holds, using advanced computational physics models that are more precise than conventional MRI for many diagnoses. The company has received over $80 million from Andreessen Horowitz, Kaiser Foundation Hospitals, and others. Q Bio is also developing integrations to improve these models using data from genetics, chemistry, anatomy, lifestyle, and medical history.

6. Planning surgery

A Boston hospital has been working with Dassault’s digital heart to improve surgical procedure planning and assess the outcomes afterward. The digital twins also help them to generate the shape of a cuff between the heart and arteries.

Sim&Cure’s Sim&Size is a digital twin to help brain surgeons treat aneurysms using simulations to improve patient safety. Aneurysms are enlarged blood vessels that can result in clots or strokes. These digital twins can improve the ability to plan and execute less invasive surgery using catheters to install unique implants. Data from individual patients helps customize simulations that run on an embedded simulation package from Ansys. Preliminary results have dramatically reduced the need for follow-up surgery.

Improving health care organizations

Digital twins also show promise in improving the way health care organizations deliver care. Gartner coined the term digital twin of the organizations to describe this process of modeling how an organization operates to improve underlying processes.

In most industries, this can start by using process mining to discover variations in business processes. New health care-specific tools can complement these techniques.

7. Improving caregiver experience

Digital twins can also help caregivers capture and find information shared across physicians and multiple specialists. John Snow Labs CTO David Talby said, “We’re generating more data than ever before, and no one has time to sort through it all.” For example, if a person sees their regular primary care physician, they will have a baseline understanding of the patient, their medical history, and medications. If the same patient sees a specialist, they may be asked many of the same repetitive questions.

A digital twin can model the patient and then use technologies like NLP to understand all of the data and cut through the noise to summarize what’s going on. This saves time and improves the accuracy of capturing and presenting information like specific medications, health conditions, and more details that providers need to know in context to make clinical decisions.

8. Driving efficiency

The GE Healthcare Command Center is a major initiative to virtualize hospitals and test the impact of various decisions on changes in overall organizational performance. Involved are modules for evaluating changes in operational strategy, capacities, staffing, and care delivery models to objectively determine which actions to take. For example, they have developed modules to estimate the impact of bed configurations on care levels, optimize surgical schedules, improve facility design, and optimize staff levels. This allows managers to test various ideas without having to run a pilot. Dozens of organizations are already using this platform, GE said.

9. Shrinking critical treatment window

Siemens Healthineers has been working with the Medical University of South Carolina to improve the hospital’s daily routine through workflow analysis, system redesign, and process improvement methodologies. For example, they are working to reduce the time to treat stroke patients. This is important since early treatment is critical but requires the coordination of several processes to perform smoothly.

10. Value-based health care

The rising cost of health care has many nations exploring new incentive models to better align new drugs, interventions, and treatments with outcomes. Value-based health care is one approach that is growing in popularity. The basic idea is that participants, like drug companies, will only get compensation proportionate to their impact on the outcomes. This will require the development of new types of relationships across multiple players in the health delivery systems. Digital twins could provide the enabling infrastructure for organizing the details for crafting these new types of arrangements.

11. Supply chain resilience

The pandemic illustrated how brittle modern supply chains could be. Health care organizations immediately faced shortages of essential personal protection equipment owing to shutdowns and restrictions from countries like China. Digital twins of a supply chain can help health care organizations model their supply chain relationships to understand better how to plan around new events, shutdowns, or shortages. This can boost planning and negotiations with government officials in a pinch, as was the case in the recent pandemic. A recent Accenture survey found that 87% of health care executives say digital twins are becoming essential to their organization’s ability to collaborate in strategic ecosystem partnerships.

12. Faster hospital construction

Digital twins could also help streamline construction of medical facilities required to keep up with rapid changes, such as were seen in the pandemic. Atlas Construction developed a digital twin platform to help organize all the details for health care construction. The project was inspired long before the pandemic when Atlas founder Paul Teschner saw how hard it was to get new facilities built in remote areas of the world. The platform helps organize design, procurement, and construction processes. It is built on top of the Oracle Cloud platform and Primavera Unifier asset lifecycle management service.

13. Streamlining call center interactions

Digital twins can make it easier for customer service agents to understand and communicate with patients. For example, a large insurance provider used a TigerGraph graph database to integrate data from over 200 sources to create a full longitudinal health history of every member. “This level of detail paints a clear picture of the members current and historical medical situation,” said TigerGraph health care industry practice lead Andrew Anderson.

A holistic view of all diagnosis claims prescriptions, refills, follow-up visits, and outstanding claims reduced call handling time by 10%, TigerGraph claimed, resulting in over $100 million in estimated savings. Also, shorter but more relevant conversations between the agents and members have increased Net Promoter Score and lowered churn.

Drug and medical device development

There are many ways that digital twins can improve the design, development, testing, and monitoring of new medical devices and drugs. The U.S. FDA has launched a significant program to drive the adoption of various types of digital approaches. Regulators in the U.S. and Europe are also identifying frameworks for including modeling and simulation as sources of evidence in new drug and device approvals.

14. Software-as-a-medical device

The FDA is creating the regulatory framework to allow companies to certify and sell software-as-a-medical device. The core idea is to generate a patient-specific digital twin from different data sources, including lab tests, ultrasound, imaging devices, and genetic tests. In addition, digital twins can also help optimize the software in medical devices such as pacemakers, automated insulin pumps, and novel brain treatments.

15. Classifying drug risks

Pharmaceutical researchers are using digital twins to explore the heart risks of various drugs. This could help improve drug safety of individual drugs and drug combinations more cost-effectively than through manual testing. They have built a basic model for 23 drugs. Extending this model could help reduce the estimated $2.5 billion required to design, test, get approved, and launch new drugs.

16. Simulating new production lines

Siemens worked with several vaccine manufacturers to design and test various vaccine production line configurations. New mRNA vaccines are fragile and must be precisely combined using microfluidic production lines that precisely combine nanoscale-sized particles. Digital twins allowed them to design and validate the manufacturing devices, scale these processes, and accelerate its launch from 1 year down to 5 months.

17. Improve device uptime

Philips has launched a predictive maintenance program that collates data from over 15,000 medical imaging devices. The company is hoping that digital twins could improve uptime and help their engineers customize new equipment for the needs of different customers. In addition, it is hoping to apply similar principles across all of its medical equipment.

18. Post-market surveillance

Regulators are beginning to increase the emphasis for device makers to monitor the results of their equipment after-sales as part of a process called post-market surveillance. This requires either staffing expensive specialists to maintain the equipment or embedding digital twins capabilities into the equipment. For example, Sysmex worked with PTC to incorporate performance testing into its blood analyzer to receive a waiver from these new requirements, PTC CTO Steve Dertien told VentureBeat. This opened the market for smaller clinical settings closer to patients, which can speed diagnosis.

19. Simulating human variability

Skeletons and atlases commonly depict the perfect human. However, real-life humans typically have some minor variations in their muscles or bones that mostly go unnoticed. As a result, medical device makers struggle with how common anatomical variations among people may affect the fit and performance of their equipment. Virtonomy has developed a library of common variations to help medical equipment makers test conduct studies on how these variations may affect the performance and safety of new devices. In this case, they simulate the characteristics representing common variations in a given population rather than individuals.

20. Digital twin of a lab

Modern drug development often requires testing out thousands or millions of possibilities in a highly controlled environment. A digital twin of the lab can help to automate these facilities. It can also help to prioritize tests in response to discoveries. Digital twins could also improve the reproducibility of experiments across labs and personnel in the same lab. In this quest, Artificial recently closed $21.5 million in series A funding from Microsoft and others to develop lab automation software. The company is betting that unified data models and platforms could help them jump to the front of the $10 billion lab automation market.

21. Improving drug delivery

Researchers at Oklahoma State have been working with Ansys to develop a digital twin to improve drug delivery using models of simulated lungs as part of the Virtual Human System project. They found that only about 20% of many drugs reached their target. The digital twins allowed them to redesign the drug’s particle size and composition characteristics to improve delivery efficiency to 90%.

VentureBeat

VentureBeat's mission is to be a digital town square for technical decision-makers to gain knowledge about transformative technology and transact. Our site delivers essential information on data technologies and strategies to guide you as you lead your organizations. We invite you to become a member of our community, to access:

up-to-date information on the subjects of interest to you

our newsletters

gated thought-leader content and discounted access to our prized events, such as Transform 2021: Learn More

networking features, and more

Become a member

0 notes

Text

21 ways medical digital twins will transform health care

New Post has been published on https://tattlepress.com/health/21-ways-medical-digital-twins-will-transform-health-care/

21 ways medical digital twins will transform health care

Where does your enterprise stand on the AI adoption curve? Take our AI survey to find out.

The health care industry is starting to adopt digital twins to improve personalized medicine, health care organization performance, and new medicines and devices. Although simulations have been around for some time, today’s medical digital twins represent an important new take. These digital twins can create useful models based on information from wearable devices, omics, and patient records to connect the dots across processes that span patients, doctors, and health care organizations, as well as drug and device manufacturers.

It is still early days, but the field of digital twins is expanding quickly based on advances in real-time data feeds, machine learning, and AR/VR. As a result, digital twins could dramatically shift how we diagnose and treat patients, and help realign incentives for improving health. Some proponents liken the current state of digital twins to where the human genome project was 20 years ago, and it may require a similar large-scale effort to take shape fully. A team of Swedish researchers recently wrote, “Given the importance of the medical problem, the potential of digital twins merits concerted research efforts on a scale similar to those involved in the HGP.”

While such a “moon shot” effort may not be immediately underway, there are many indicators that digital twins are gaining traction in medicine. Presented here are 21 ways digital twins are starting to shape health care today, broken roughly into personalized medicine, improving health care organizations, and drug and medical devices and development. In fact, many types of digital twins span multiple use cases and even categories; it is these cross-domain use-cases that form a major strength of digital twins.

Personalized medicine

Digital twins show tremendous promise in making it easier to customize medical treatments to individuals based on their unique genetic makeup, anatomy, behavior, and other factors. As a result, researchers are starting to call on the medical community to collaborate on scaling digital twins from one-off projects to mass personalization platforms on par with today’s advanced customer data platforms.

1. Virtual organs

Several vendors have all been working on virtual hearts that can be customized to individual patients and updated to understand the progression of diseases over time or understand the response to new drugs, treatments, or surgical interventions. Philip HeartModel simulates a virtual heart, starting with the company’s ultrasound equipment. Siemens Healthineers has been working on a digital twin of the heart to improve drug treatment and simulate cardiac catheter interventions. European startup FEops has already received regulatory approval and commercialized the FEops Heartguide platform. It combines a patient-specific replica of the heart with AI-enabled anatomical analysis to improve the study and treatment of structural heart diseases.

Dassault launched its Living Heart Project in 2014 to crowdsource a virtual twin of the human heart. The project has evolved as an open source collaboration among medical researchers, surgeons, medical device manufacturers, and drug companies. Meanwhile, the company’s Living Brain project is guiding epilepsy treatment and tracking the progression of neurodegenerative diseases. The company has organized similar efforts for lungs, knees, eyes, and other systems.

“This is a missing scientific foundation for digital health able to power technologies such as AI and VR and usher in a new era of innovation,” Dassault senior director of virtual human modeling Steve Levine told VentureBeat. He added that this “could have an even greater impact on society than what we have seen in telecommunications.”

2. Genomic medicine

Swedish researchers have been mapping mice RNA into a digital twin that can help predict the effect of different types and doses of arthritis drugs. The goal is to personalize human diagnosis and treatment using RNA. The researchers observed that medication does not work about 40% to 70% of the time. Similar techniques are also mapping the characteristics of human T-cells that play a crucial role in immune defense. These maps can help diagnose many common diseases earlier when they are more effective and cheaper to treat.

3. Personalized health information

The pandemic has helped fuel the growth of digital health services that help people assess and address simple medical conditions using AI. For example, Babylon Health‘s Healthcheck App captures health data into digital twins. It works with manually entered data such as health histories, a mood tracker, symptom tracker, and automatic capture from fitness devices and wearables like the Apple Watch. The digital twin can provide basic front-line information or help guide priorities and interactions with doctors to address more severe or persistent conditions.

4. Customize drug treatment

The Empa research center in Switzerland is working on digital twins to optimize drug dosage for people afflicted by chronic pain. Characteristics such as age and lifestyle help customize the digital twin to help predict the effects of pain medications. In addition, patient reports about the effectiveness of different dosages calibrate digital twin accuracy.

5. Scanning the whole body

Most approaches to digital twins build on existing equipment to capture the appropriate data, while Q Bio’s new Gemini Digital Twin platform starts with a whole-body scan. The company claims to capture a whole-body scan in 15 minutes without radiation or breath holds, using advanced computational physics models that are more precise than conventional MRI for many diagnoses. The company has received over $80 million from Andreessen Horowitz, Kaiser Foundation Hospitals, and others. Q Bio is also developing integrations to improve these models using data from genetics, chemistry, anatomy, lifestyle, and medical history.

6. Planning surgery

A Boston hospital has been working with Dassault’s digital heart to improve surgical procedure planning and assess the outcomes afterward. The digital twins also help them to generate the shape of a cuff between the heart and arteries.

Sim&Cure’s Sim&Size is a digital twin to help brain surgeons treat aneurysms using simulations to improve patient safety. Aneurysms are enlarged blood vessels that can result in clots or strokes. These digital twins can improve the ability to plan and execute less invasive surgery using catheters to install unique implants. Data from individual patients helps customize simulations that run on an embedded simulation package from Ansys. Preliminary results have dramatically reduced the need for follow-up surgery.

Improving health care organizations

Digital twins also show promise in improving the way health care organizations deliver care. Gartner coined the term digital twin of the organizations to describe this process of modeling how an organization operates to improve underlying processes.

In most industries, this can start by using process mining to discover variations in business processes. New health care-specific tools can complement these techniques.

7. Improving caregiver experience

Digital twins can also help caregivers capture and find information shared across physicians and multiple specialists. John Snow Labs CTO David Talby said, “We’re generating more data than ever before, and no one has time to sort through it all.” For example, if a person sees their regular primary care physician, they will have a baseline understanding of the patient, their medical history, and medications. If the same patient sees a specialist, they may be asked many of the same repetitive questions.

A digital twin can model the patient and then use technologies like NLP to understand all of the data and cut through the noise to summarize what’s going on. This saves time and improves the accuracy of capturing and presenting information like specific medications, health conditions, and more details that providers need to know in context to make clinical decisions.

8. Driving efficiency

The GE Healthcare Command Center is a major initiative to virtualize hospitals and test the impact of various decisions on changes in overall organizational performance. Involved are modules for evaluating changes in operational strategy, capacities, staffing, and care delivery models to objectively determine which actions to take. For example, they have developed modules to estimate the impact of bed configurations on care levels, optimize surgical schedules, improve facility design, and optimize staff levels. This allows managers to test various ideas without having to run a pilot. Dozens of organizations are already using this platform, GE said.

9. Shrinking critical treatment window

Siemens Healthineers has been working with the Medical University of South Carolina to improve the hospital’s daily routine through workflow analysis, system redesign, and process improvement methodologies. For example, they are working to reduce the time to treat stroke patients. This is important since early treatment is critical but requires the coordination of several processes to perform smoothly.

10. Value-based health care

The rising cost of health care has many nations exploring new incentive models to better align new drugs, interventions, and treatments with outcomes. Value-based health care is one approach that is growing in popularity. The basic idea is that participants, like drug companies, will only get compensation proportionate to their impact on the outcomes. This will require the development of new types of relationships across multiple players in the health delivery systems. Digital twins could provide the enabling infrastructure for organizing the details for crafting these new types of arrangements.

11. Supply chain resilience

The pandemic illustrated how brittle modern supply chains could be. Health care organizations immediately faced shortages of essential personal protection equipment owing to shutdowns and restrictions from countries like China. Digital twins of a supply chain can help health care organizations model their supply chain relationships to understand better how to plan around new events, shutdowns, or shortages. This can boost planning and negotiations with government officials in a pinch, as was the case in the recent pandemic. A recent Accenture survey found that 87% of health care executives say digital twins are becoming essential to their organization’s ability to collaborate in strategic ecosystem partnerships.

12. Faster hospital construction

Digital twins could also help streamline construction of medical facilities required to keep up with rapid changes, such as were seen in the pandemic. Atlas Construction developed a digital twin platform to help organize all the details for health care construction. The project was inspired long before the pandemic when Atlas founder Paul Teschner saw how hard it was to get new facilities built in remote areas of the world. The platform helps organize design, procurement, and construction processes. It is built on top of the Oracle Cloud platform and Primavera Unifier asset lifecycle management service.

13. Streamlining call center interactions

Digital twins can make it easier for customer service agents to understand and communicate with patients. For example, a large insurance provider used a TigerGraph graph database to integrate data from over 200 sources to create a full longitudinal health history of every member. “This level of detail paints a clear picture of the members current and historical medical situation,” said TigerGraph health care industry practice lead Andrew Anderson.

A holistic view of all diagnosis claims prescriptions, refills, follow-up visits, and outstanding claims reduced call handling time by 10%, TigerGraph claimed, resulting in over $100 million in estimated savings. Also, shorter but more relevant conversations between the agents and members have increased Net Promoter Score and lowered churn.

Drug and medical device development

There are many ways that digital twins can improve the design, development, testing, and monitoring of new medical devices and drugs. The U.S. FDA has launched a significant program to drive the adoption of various types of digital approaches. Regulators in the U.S. and Europe are also identifying frameworks for including modeling and simulation as sources of evidence in new drug and device approvals.

14. Software-as-a-medical device

The FDA is creating the regulatory framework to allow companies to certify and sell software-as-a-medical device. The core idea is to generate a patient-specific digital twin from different data sources, including lab tests, ultrasound, imaging devices, and genetic tests. In addition, digital twins can also help optimize the software in medical devices such as pacemakers, automated insulin pumps, and novel brain treatments.

15. Classifying drug risks

Pharmaceutical researchers are using digital twins to explore the heart risks of various drugs. This could help improve drug safety of individual drugs and drug combinations more cost-effectively than through manual testing. They have built a basic model for 23 drugs. Extending this model could help reduce the estimated $2.5 billion required to design, test, get approved, and launch new drugs.

16. Simulating new production lines

Siemens worked with several vaccine manufacturers to design and test various vaccine production line configurations. New mRNA vaccines are fragile and must be precisely combined using microfluidic production lines that precisely combine nanoscale-sized particles. Digital twins allowed them to design and validate the manufacturing devices, scale these processes, and accelerate its launch from 1 year down to 5 months.

17. Improve device uptime

Philips has launched a predictive maintenance program that collates data from over 15,000 medical imaging devices. The company is hoping that digital twins could improve uptime and help their engineers customize new equipment for the needs of different customers. In addition, it is hoping to apply similar principles across all of its medical equipment.

18. Post-market surveillance

Regulators are beginning to increase the emphasis for device makers to monitor the results of their equipment after-sales as part of a process called post-market surveillance. This requires either staffing expensive specialists to maintain the equipment or embedding digital twins capabilities into the equipment. For example, Sysmex worked with PTC to incorporate performance testing into its blood analyzer to receive a waiver from these new requirements, PTC CTO Steve Dertien told VentureBeat. This opened the market for smaller clinical settings closer to patients, which can speed diagnosis.

19. Simulating human variability

Skeletons and atlases commonly depict the perfect human. However, real-life humans typically have some minor variations in their muscles or bones that mostly go unnoticed. As a result, medical device makers struggle with how common anatomical variations among people may affect the fit and performance of their equipment. Virtonomy has developed a library of common variations to help medical equipment makers test conduct studies on how these variations may affect the performance and safety of new devices. In this case, they simulate the characteristics representing common variations in a given population rather than individuals.

20. Digital twin of a lab

Modern drug development often requires testing out thousands or millions of possibilities in a highly controlled environment. A digital twin of the lab can help to automate these facilities. It can also help to prioritize tests in response to discoveries. Digital twins could also improve the reproducibility of experiments across labs and personnel in the same lab. In this quest, Artificial recently closed $21.5 million in series A funding from Microsoft and others to develop lab automation software. The company is betting that unified data models and platforms could help them jump to the front of the $10 billion lab automation market.

21. Improving drug delivery

Researchers at Oklahoma State have been working with Ansys to develop a digital twin to improve drug delivery using models of simulated lungs as part of the Virtual Human System project. They found that only about 20% of many drugs reached their target. The digital twins allowed them to redesign the drug’s particle size and composition characteristics to improve delivery efficiency to 90%.

VentureBeat

VentureBeat’s mission is to be a digital town square for technical decision-makers to gain knowledge about transformative technology and transact.

Our site delivers essential information on data technologies and strategies to guide you as you lead your organizations. We invite you to become a member of our community, to access:

up-to-date information on the subjects of interest to you

our newsletters

gated thought-leader content and discounted access to our prized events, such as Transform 2021: Learn More

networking features, and more

Become a member

Source link

0 notes

Link

The report provides a detailed assessment of the “Global Electrical Digital Twin Market”. This includes enabling technologies, key trends, market drivers, challenges, competition, standardization, regulatory landscape, deployment models, market size, operator case studies, opportunities, future roadmaps, value chains, ecosystem player profiles, and strategies included. The report also presents a SWOT analysis and forecast for Electrical Digital Twin investments from 2020 to 2026.

0 notes

Text

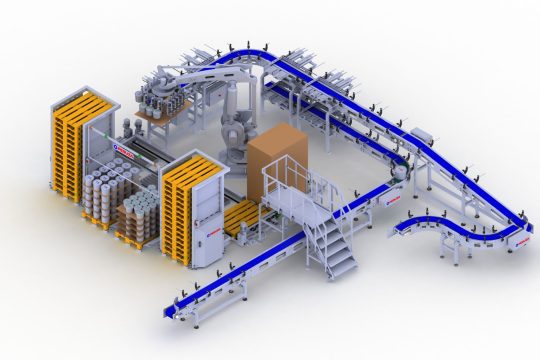

The Benefits Of Robotic Palletizing

For a Free Demonstration using your actual product, fill out the form and a QComp representative click here will get back to you to schedule an appointment. After assessing and designing your end-of-line layout, Fuji staff will match you up with the right integrator to ensure that you have someone you can trust installing your system.

In these instances, determine whether the porosity of the corrugated board has changed. Another fact to be aware of is that high acceleration does not work well with vacuum tools. Dense array tools have their own compressed-air generator for greater air flow. Find out what the world’s most innovative companies are doing to improve productivity in their plants and distribution centers.

If you evaluated all of the speculative articles on artificial intelligence in the last decade, you could conclude that that we are on the verge of building a robot that is self-aware and can think just like a human. But there is a new threat that is striking fear into the heart of working people.

Gains associated to purchasing robotic palletizer system are often related to lower labor costs but also linked to increased productivity. The KR 1000 titan stacks the heaviest loads with utmost speed and maximum reach. When it comes to heavy loads, the KR 700 PA comes into its own – and stacks higher than any other robot. The KR 40 PA stacks europallets faster than any other robot – up to a height of 1.8 meters.

HMI/controller – The HMI (human/machine interface) allows for product to be changed over easily and provides system information and alerts. Non specialized integrated robotic palletizer components utilized standard industry manufacturers, such as Hytrol and ABB . A means to identify bags using a non-contact UV ink application, detection and verification system, thereby uniquely identifying bags according to originating filling station.

A Leader In The Robot Palletizing And Packaging Industries

Frequent cleaning of corrugated dust off the vacuum cups is part of routine maintenance. Occasionally, even with clean vacuum heads and a vacuum that is operating perfectly, cases simply fail to lift or detach from the tool.

Multi-Conveyor recently built three mild-steel constructed conveyors that passive off transfer from narrow to wide side leading to facilitate multiple side case printing. Sign up for our newsletter to receive the latest in packaging tips, case studies and more. Working with an experienced integrator will help you make informed choices and specify the equipment best suited for your application. Look for an integrator that’s certified by the robotic palletizer association . This independent, nonprofit organization awards the title of RIA Certified Robot Integrator only to the most accomplished organizations who demonstrate a high level of skill and experience.

And while there is certainly nothing wrong with manual labor, there are few people who would choose meeting a quota of stacked boxes during their workday over more meaningful tasks. Our team consults with our customers from the initial design specifications through final design, fabrication, programming and final testing.

Over millions of years, the human brain grew in size and complexity until it developed conscious thought and self-awareness. The author assumes that to really achieve artificial intelligence that has self- awareness will require designing a computer that has most of the features and capabilities of the human brain.

— Some tools can cause indentations in shrink-wrap or leave marks on your packaging, which may be unacceptable for items intended for display. — The tooling you choose can significantly affect your throughput capabilities. Start by determining an acceptable range of cases per minute, which will help you make informed decisions when evaluating tooling options.

Integrating an existing industrial communication standard with an up-and-coming method often creates headaches. But several industry experts see an easy path to integrating IO-Link and Single Pair Ethernet. Companies want to rely less on skilled labor and more on AI and robotic palletizer intelligence, but currently only 1% of all manufacturers are utilizing this technology in their operations. The Industrial Internet Consortium releases a white paper that provides direction on the use of blockchain applications for Industrial Internet of Things applications. Predictive analytics, digital twinning, and augmented and virtual reality technologies are all finding uses in manufacturing operations – from line installation and maintenance to process training.

Applications That Favor Robotics

Customer consultation and feedback are critical to creating a high-performance solution that our customers can count on. With this wide range of payload capacity, it’s your choice to pick single-case or an entire layer for stacking and breaking down pallet loads.

The human brain is a living, wet analogue of networks that can perform massively parallel processes at the same time and operates in agreement with biological laws. There is no programming, and the brain has the ability to change from one moment to the next, constantly forming new synapses. The human brain also includes areas we call the subconscious and conscious mind, which are absolutely essential in reaching consciousness or sentience.

Sign Up Stay current with the latest industry trends and news about our innovations. Robotic Palletizing – A cost effective robotic palletizer solution that improves profitability. Hamer-Fischbein has the equipment to meet all your needs with the innovation, durability, and quality you have come to expect from Hamer-Fischbein.

This article shows that for the brain to evolve to self-aware status requires developing an unconscious mind, using emotions, having modulated neurons and content addressable memory, and combining processing with memory. The only model that we know that has evolved to self-awareness and consciousness is the human brain.

It is the possibility that artificial intelligence will progress to the point that machines will become sentient and replace people in all working environments. This idea has been popularized in movies like the Terminator, when scientists created a computer chip that made machines conscious and self-aware. Tesla founder Elon Musk and physicist Stephen Hawking both warned that machines will eventually start programming themselves, and trigger the collapse of civilization. Red Devil hoped to reduce injuries and labor costs, while improving the efficiency of its lines. The APT MOD-PAL-PAIL can handle up to 10 ppm depending upon the product weight and size.

Fuji has been optimizing end-of-line operations since the 1940's and our engineers know how to choose the right equipment and put them in the best layout for your facility. When you work with Fuji, you receive all the benefits of the Fuji Advantage. Our team will work with you from design to install, and support your operation for the life of the system. Material Transfer & Storage completed an expansion that doubles its assembly space and enables additional processes to be brought in-house.

Servo motion control is the main driver in gantry systems and MESH is an expert in Rockwell and Siemens servo systems. Additionally, we have developed HMI screens that are intuitive and flexible. Delkor Palletizer offers seamless integration, simplified operation, and ease of installation to any Delkor end-of-line packaging system. This approach could ensure greater safety for both two- and four-legged soldiers. Don’t be too quick to use vacuum tooling; clamping may offer better performance and flexibility.

There is no one place which stores this information; it is stored all over the brain from the pre-frontal cortex, to the thalamus, and many other different parts of the brain. The unconscious mind does not reason or think; it simply stores all of the information needed by the conscious mind for the thinking process. But to simulate the typical 3.5 pound human brain would require matching the brain’s billions of interactions between cell types, neurotransmitters, neuromodulators, axonal branches and dendritic spines. Because the brain is nonlinear, and because it has so much more capacity than any computer, it functions completely different from a digital computer.

Consciousness is a holistic phenomenon occurring simultaneously in the entire brain. This may be feelings, experiences, memories, or facts that the brain views as related to the problem. Just how the brain can access the right neurons to gather the relevant information for the conscious mind to think is still unknown. It is not like a computer hard drive because it records everything we have smelled, touched, tasted, or heard including perceptions, memories, feelings, reflections, thoughts, hope since birth.

Increase Efficiency With Pearson Robotic Palletizers

Our engineered gripper also handles both slip sheets and pallet placement. Form, fit, and function are met with the design and selection of materials for each application. As organizations continue to see the value in industrial analytics, making sense of the sheer amount of data produced can be a difficult task. Finding the right product and developing a proper workflow is important to get long-term use out of the system.

Unlike the digital computer, in the brain, processing and memory are performed by the same components. To solve a problem or find and answer, the digital computer processes information from memory using CPUs, and then writes the results of that processing back to memory. All conscious thinking processes begin in the subconscious mind and are outside human awareness.

Ocura Robotic Palletizer Solutions - Courtesy of ESS Technologies - When floor space and interaction with employees is high on your requirement list, FANUC's CR Collaborative Robot Series is the best choice. With payloads ranging from 15 to 35kg and the ability to stop immediately upon contact, a collaborative solution eliminates the need for expensive and space-consuming safety guarding. Fork EOATs require the most space to operate, which may or may not be a problem, depending on the plant space available. Due to their weight and size, these tools may require a heftier robot than either vacuum or clamp EOATs, adding to cost.

0 notes

Text

Applying AI to Process Manufacturing

What do Rolls Royce, Siemens, and General Motors have in common? All of them use Artificial Intelligence to increase production efficiency and reduce costs. According to recent studies, the AI market will reach a fascinating $190.61 billion by 2025, which only proves that more companies will adopt this technology and use data for their benefit.

Here are some of the ways you can apply AI in manufacturing to achieve greater production speed and better user experience:

Predictive Maintenance

One of the biggest concerns for any manufacturer is downtime, faulty machinery or unexpected issues. Reactive maintenance or solving the failure after it occurs costs a lot of money.

That’s why predictive maintenance is a smart and productive implementation of AI in manufacturing.

By using machine learning, the AI’s algorithm can leverage and analyze any current and previous data about the machine, and provide useful insights about unplanned failures.

This way, Artificial Intelligence anticipates the possible downtime and creates an opportunity for an engineer to come up with a better and smarter decision in the manufacturing process.

If you want to read more on this topic check out our blog post – Big Data Analytics for Manufacturing – Getting Started with Predictive Maintenance.

Quality Control

With the rise of technology, manufacturers feel the pressure to provide a product or machine with a skyrocketing quality. Applying AI in manufacturing is one way to maintain steady quality, especially in the production phase.

An effective way to do this is by using computer vision. Even though the production process can be managed by a team of qualified and experienced engineers, some product flaws are too small to be noticed by the human eye. If you set up cameras to your AI machine, the machine can catch even the smallest flaws or defects that may occur, take a picture, and send it to an expert to evaluate it.

Nowadays, this entire process can be automated without an expert’s evaluation, and the system can notice the flaw, and alert the engineer to fix it immediately.

Want more?

Subscribe to receive articles on topics of your interest, straight to your inbox.

Success!

First Name

Last Name

Email

Subscribe

Digital Twins

Another productive use of AI in manufacturing is by building an accurate virtual representation of a product or a machine. This process includes using a combination of data, different AI tools, and CAD to develop a virtual representation of a real-world data.

In simpler words, you are creating a digital twin of the physical characteristics of a real object.

All the data AI collects is connected to a cloud-based service which is afterward analyzed and processed. Developing digital twins is extremely important to design engineers.

AI enables them to monitor and analyze the performance of the object, the change in quality with the smallest design changes, and all this before the product is developed.

Not only that a lot of time and resources are saved by applying AI in manufacturing, but also the overall positive user experience increases since the number of critical mistakes are cut down entirely.

With Syntelli and our solution in AI and machine learning, your company can experience all these benefits too. Contact us to learn more.

SIMILAR POSTS

Python & R vs. SPSS & SAS

Although computer programming has improved exponentially in the past several decades, not all programming languages are capable of processing the data used for machine learning. Big data has grown significantly, and the resulting data sets are both larger and more...

read more

Cloud Migration – Is it too late to adopt?

“Action is the foundational key to all success.” – Pablo Picasso No technology gets adopted overnight. On-premise environment provides full ownership, maintenance, responsibility. You pay for physical machines and virtualizations to meet your demands. Lately, such...

read more

The Power of Big Data and AI in the Fight Against COVID-19

The emergence of a novel coronavirus in December 2019 has had the medical community on edge. Public health officials around the world have faced an uphill battle in treating current cases and preventing the further spread of the virus. The 2002 SARS outbreak, and...

read more

The post Applying AI to Process Manufacturing appeared first on Syntelli Solutions Inc..

https://www.syntelli.com/applying-ai-to-process-manufacturing

0 notes

Text

Digitalisation: helping business thrive and survive

Success stories of businesses using technology to advance were at the forefront of Siemens’ Digitalize 2019 conference. The event showcased discussions on cybersecurity, smart infrastructure, scalability in manufacturing, Australia’s energy transition, future of work in the industry and opportunities presented by Industry 4.0. At the core of these discussions was digitalisation; particularly its role within organisations of all sizes — from large entities such as Powerlink Queensland and Deloitte; start-ups such as Brogan’s Way distillery; and SMEs such as Sage Automation and HeliMods.

Energy transition

The digitalised world is demanding change in the energy sector, perhaps more so than any other. The centralisation of the industry has brought new demands that have seen previous innovations rendered outdated much faster than anticipated.

Powerlink Queensland Executive General Manager Kevin Kehl discussed the challenges his company was facing and boiled it down to the ‘three Ds’: the decarbonisation of power generation; the decentralisation of customers and storage; and digitalisation itself, which, if capitalised on, could facilitate and enhance the other two.

Kehl cited the importance of predicting customer behaviour as critical to shaping the energy transition. He explained that Powerlink Queensland conducts a household energy survey every two years, with the local distribution companies in Queensland, to discover what customers are thinking in order to help predict behaviours and expectations.

“I think, irrespective of any policy objectives, consumers will largely lead the change as they have,” Kehl said. “Indeed, that’s going to be the biggest driver of the change for us.”

Customers are investing more capital in rooftop solar and increased storage, making transmission infrastructure the glue that holds together the system. Australia is predicted to be the most distributed grid worldwide in the next decade and Kehl emphasised that this will require a much more dynamic and information-intensive approach.

Smart infrastructure

Urbanisation is occurring across the world, with approximately 55% of the global population currently living in urban areas. Predictions suggest that by 2050, this will rise to 68%. Australia is no exception. Melbourne, for example, is predicted to have 7.3 million people by 2050, up from the current 4.6 million who live there now.

It’s clear that new approaches need to be adopted, such as the building of smart infrastructure, which is key to sustainability. According to Siemens Global Head of Urban Development Martin Powell, combining infrastructure with data analytics will provide countless opportunities to counter these problems.

“Using weather data analytics to gather readings on air quality could allow cities to create low-emission zones,” Powell said. “We could introduce ‘no school on bad air days’ or penalise people who drive in the affected areas.”

Other innovations are based on the idea of the digital twin, allowing for ideas and concepts to be worked through digitally to find any problems before any money is spent. This would also allow for different cities facing similar problems to share data and make adjustments according to their own unique challenges.

“We are applying machine learning so that we can reduce the amounts of maintenance that we need across our cities,” Powell added.

Scalable manufacturing in Industry 4.0

Industry 4.0 and automation is being increasingly adopted by small and medium manufacturers, debunking the myth that it’s only of value and affordable to big companies.

Hon. Cameron Dick, Queensland State Minister for State Development, Manufacturing, Infrastructure and Planning, commended the state’s manufacturers for being “well advanced on their Industry 4.0 journey”, calling it a showcase of the diversity in the sector.

Case study: Kaiju Brewery

Kaiju Brewery co-owner Callum Reeves explained that his brewery exemplifies the scalability of modern automation technology.

Reeves’ business was growing at a rate of 100% per annum but faced the issue of losing consistency with expansion. Technology came to his rescue.

“One of the biggest things is maintaining the quality that people expect of your brand as you scale,” Reeves said.

Reeves’ passion for technology and futureproofing is what encouraged him to begin using Deacam’s Fermecraft technology combined with Siemens’ MindSphere software to monitor the brewing process and ensure each brew remained uniform.

The investment in upgrading automation and digital technology has prepared Kaiju for the next few years of manufacturing.

Case study: HeliMods

Queensland-based SME HeliMods utilised digital twin technology to track and change product designs to make a real, practical difference to its helicopter operators.

HeliMods CEO Will Shrapnel said, “You wouldn’t set up a workshop with physical assets and leave them lying about the place. It’s no different in the digital world. If you’re going to invest in digital technologies, you[’ve] got to understand how those assets are going to be used, re-used, stored and how you’re going to develop them over time. It’s critically important,” he said.

Cybersecurity

Unlike most industries in the current climate, there is less of a requirement to transition from an old model, but a need to grow the sector to meet the demands of the digital world.

AustCyber CEO Michelle Price said that, “Digitalisation is both an opportunity and a risk, but you must be on top of your game and vigilant.

“There are enormous opportunities available to us when we embrace cybersecurity and recognise that it is an investment in our future.”

Australia is claimed to be the number one per capita ransomware target in the world and is in the top 10 nations for email phishing attacks. Australia also has a $3 trillion superannuation system that, according to Price, “makes every single corner of every single populated space in Australia a high-value target”.

Price challenged businesses to take stock of their own security and ask themselves if they are “cyber prepared or cyber scared?”

Futureproofing the workforce

It’s important to recognise that the future of work will require an adjustment to the way in which employees are continuously trained and upskilled, as well as changes in the higher education sector to ensure that students are being prepared sufficiently for the workforce.

Professor Bronwyn Fox, Director of the Manufacturing Futures Research Institute at Swinburne University of Technology, was involved in a panel on the subject and discussed the work Swinburne is doing in partnership with Siemens and Ai Group to facilitate this education process.

“We’ve learnt a lot from our partners in Germany and we’ve learnt a lot from the Austrian Industry 4.0 network, which has allowed us to really translate that to the Australian environment,” Fox said.

“We can create six cyber-physical labs that are an immersive environment for industry leaders and newcomers to come and understand the concepts of digitalisation.”

Collaboration from industry leaders, tertiary education institutions, unions and government agencies is crucial for the future of employment.

Ultimately, the consistent message across all speakers and discussions at the conference was that everybody needs to be able to adapt and cooperate so that the Australian market can thrive.

Image courtesy of Siemens Australia.

source http://sustainabilitymatters.net.au/content/sustainability/article/digitalisation-helping-business-thrive-and-survive-732543160

from WordPress https://davidkent.home.blog/2019/08/29/digitalisation-helping-business-thrive-and-survive/

0 notes

Text

Investing Big in RPA is Not a Fool’s Game | Sherpas in Blue Shirts

The news of another big round of funding for UiPath, US$225 million series C, and a valuation of US$3 billion created a lot of excitement and amazement in the market. It followed on from Automation Anywhere’s whopping series A funding round of US$250 million in July, which valued the company at US$1.8 billion, and which surpassed UiPath’s earlier series B funding of US$153 million and a valuation of US$1 billion in Q1 2018.

These valuations are phenomenal. In UiPath’s case, the rise from US$1 billion to US$3 billion in less than six months is, I believe, unprecedented. You might think that investors are living on a different planet than us ordinary folks, and that this kind of valuation is plain wrong. I beg to differ.

Investing in the Future of RPA

My case rests on the rapid increase in market adoption and the huge investments that vendors are making in their platforms. As much has already been said about the fast rate of enterprise adoption, there’s no need for me to repeat it again here. Jumping to the second part of my case: RPA today is not the RPA that launched this market three to four years ago. The original developments lacked many of the features that we see today, e.g., computer vision to pick objects on the screen and robust control panels. Similarly, tomorrow’s RPA will be superior to today’s.

As someone who assesses RPA technology on an annual basis, I see a fast rate of product development, not just year on year, but in some cases quarter by quarter.

Everest Group’s “RPA Virtuous Circle” highlights the continuous cycle of developments in the market.

Much has been said of organizations struggling to scale their deployments. I completely agree with this, and for a while I’ve been asking vendors to do something about this issue. I am delighted to see that they have been listening and are investing in features for scaling. These include enhanced robot run time control and management features including intelligent control systems for dynamic workload balancing, auto-scaling, and even identifying processes for further automation. Another major stream of development is turning RPA platforms into the glue that holds together business process management systems (BPMS), different varieties of machine learning, and narrow artificial intelligence. These will ultimately be integrated and will combine seamlessly to provide end-to-end process automation.

While vendors do their bit for scale, organizations should also examine their deployment models for RPA and take a more programmatic approach. Automation is going to be a serious competitive differentiator, and a programmatic approach would significantly speed up organizations’ adoption and realization of desired outcomes. Everest Group’s RPA Pinnacle study highlights some of the approaches that organizations have taken to achieve excellence in RPA.

Of course, these enormous investments in RPA do carry some risks. There is the possibility of tech giants bringing their own RPA solutions to market, in turn pushing out the current RPA vendors. But that wouldn’t be easy to do, as the existing vendors have gained a lot of hard to emulate know how in the past few years. And any one of the existing RPA vendors could be acquired in a major acquisition, but then the investors would get the handsome returns they anticipated…just in a different way.

Taking the Manufacturing Model to Business Processes

Another reason for my optimism about the recent investments in RPA and vendor valuations is that I recently got a glimpse into the future of business automation by looking at manufacturing. On a visit to Siemens Digital, I saw how the concept of digital twin and simulation of manufacturing processes is helping speed up production times and efficiency, even in manual/human processes.

For years, corporate global services functions have attempted to copy manufacturing principles, e.g., adopting Lean and Six Sigma methodologies. Today, they have moved on to automation, which manufacturing adopted decades ago. Having started on automation of global services, enterprises are not going to turn back. They will continue to follow manufacturing’s lead.

Leading organizations are already giving their processes version numbers with supporting documentation, having taken each step through a rigorous Lean Six Sigma methodology. On the automation front, while the focus has been primarily on tactical needs, it will increasingly move to outcomes and the finished “product,” as in manufacturing.

We will see enterprises develop digital twins of their processes or robots, and run complex functions end-to-end in virtual reality before committing to the final model for deployment in the real world. Future versions of RPA will have to support these requirements, and that is where some of the millions of funding will be spent; on product development and advanced features.

Today’s RPA products are paving the way for a far bigger change in automation of global services than we have seen to date. They are the building blocks of the platforms of the future for an inevitable automation journey that every organization will have to take sooner or later. That is why the current group of vendors are so attractive to investors. They are betting not just on today’s growing revenues, but what is to come.

The post Investing Big in RPA is Not a Fool’s Game | Sherpas in Blue Shirts appeared first on Everest Group.

from pesonivt2a https://www.everestgrp.com/2018-09-investing-big-rpa-not-fools-game-sherpas-blue-shirts-46859.html/ via http://www.rssmix.com/

0 notes

Text

Medtech firms get personal with digital twins

New Post has been published on http://newsintoday.info/2018/09/02/medtech-firms-get-personal-with-digital-twins-2/

Medtech firms get personal with digital twins

HEIDELBERG, Germany (Reuters) – Armed with a mouse and computer screen instead of a scalpel and operating theater, cardiologist Benjamin Meder carefully places the electrodes of a pacemaker in a beating, digital heart.

Using this “digital twin” that mimics the electrical and physical properties of the cells in patient 7497’s heart, Meder runs simulations to see if the pacemaker can keep the congestive heart failure sufferer alive – before he has inserted a knife.

The digital heart twin developed by Siemens Healthineers is one example of how medical device makers are using artificial intelligence (AI) to help doctors make more precise diagnoses as medicine enters an increasingly personalized age.

The challenge for Siemens Healthineers and rivals such as Philips and GE Healthcare is to keep an edge over tech giants from Alphabet’s Google to Alibaba that hope to use big data to grab a slice of healthcare spending.

With healthcare budgets under increasing pressure, AI tools such as the digital heart twin could save tens of thousands of dollars by predicting outcomes and avoiding unnecessary surgery.

A shortage of doctors in countries such as China is also spurring demand for new AI tools to analyze medical images and the race is on to commercialize products that could shake up healthcare systems around the world.