#pp compounding process india

Explore tagged Tumblr posts

Note

Hi! You seem to be the JTTW expert and I was wondering if you could clarify something for me; If I understand correctly, Wujing ate 9 of Tripitaka’s previous incarnations, right? If so, shouldn’t he be super-powered by all of them? After all, the reason the demons want to eat him is because Tripitaka cultivated power in his previous lives, which will give them immortality and power. Didn’t that apply to the previous monks?

The 13th-century oral JTTW openly states that Sha Wujing's antecedent has continually eaten Tripitaka:

Deep Sand said: "I am the one who devoured you twice before, monk. Slung from my neck are all your dry bones!" (Wivell, 1994, p. 1190). 深沙云:「項下是和尚兩度被我吃你,袋得枯骨在此。」

And since Tripitaka is the tenth reincarnation of Master Golden Cicada and Sha claims to have eaten nine previous scripture pilgrims (Wu & Yu, 2012, vol. 1, p. 210), it's reasonable to assume that Sha has eaten the monk's past nine lives. However, to my knowledge, JTTW never openly states that the Buddhist master had made previous attempts in his past lives to travel to India, or that he had been eaten by Sha in the process (someone please correct me if I'm wrong).

It's important to remember that Tripitaka, better known as Xuanzang (玄奘, 602-664), is not the only Chinese monk who has traveled to India for scriptures. Another famous scripture pilgrim is Faxian (法顯, 337- c. 422). So, the novel could be referring to other such monks.

But if we were to view the aforementioned nine monks as Tripitaka's past lives, I think the reason why Sha Wujing isn't empowered by their flesh is because their compounding life-long austerities only results in the tenth and final reincarnation being holy.

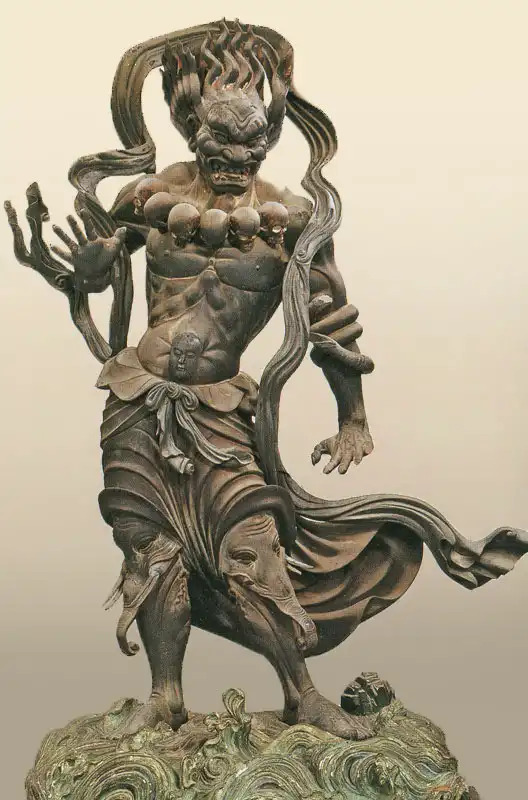

Fun Fact: The "Deep Sands" demon mentioned above is actually a vilified version of a spirit said to have originally helped Xuanzang in his 7th-century biography. This figure came to be worshiped as Jinja Taishō (深沙大將, “General of the Deep Sands”), a minor protector deity in Japanese Buddhism. One 11th-century Japanese source claims that the General manifested before Faxian in a wrathful form. Most importantly, the skulls around his neck are said to be those of demons, not monks (Dudbridge, 1970, p. 20)!

A 13th to 14th-century Japanese Kamakura carving of the General of the Deep Sands.

Sources:

Dudbridge, G. (1970). The Hsi-yu chi: A Study of Antecedents to the Sixteenth-Century Chinese Novel. Cambridge: Cambridge Univ. Press.

Wivell, C.S. (1994). The Story of How the Monk Tripitaka of the Great Country of T’ang Brought Back the Sūtras. In V. Mair (Ed.), The Columbia Anthology of Traditional Chinese Literature (pp. 1181-1207). New York: Columbia University Press.

Wu, C., & Yu, A. C. (2012). The Journey to the West (Vols. 1-4) (Rev. ed.). Chicago, Illinois: University of Chicago Press.

#Sha Wujing#Sandy#Friar Sand#Xuanzang#Tang Monk#Tripitaka#Tang#Journey to the West#JTTW#Lego Monkie Kid#LMK#Sun Wukong#Monkey King#MK

118 notes

·

View notes

Text

Bulk Chemicals in Chennai: Fuelling the Growth of Diverse Industries

Chennai is the capital city of Tamil Nadu and has been considered as one of the major industrial centers in South India. This city has turned out to be a significant hub for manufacturing, cars, chemicals, and medicines due to its good location, strong infrastructure, and a developed industrial environment. Among the key resources supporting this developing economy are bulk chemicals in Chennai, which are of prime importance in many industrial processes in textiles, automotive, pharmaceuticals, water treatment, and many more.

What Are Bulk Chemicals?

Bulk chemicals are big quantities of chemicals produced and sold in large amounts, mainly for industrial use. They are mostly transported in big containers such as tankers, drums, or bulk carriers since they are produced in such big quantities. They are used in making products, creating formulas, and as raw materials for producing other products in various industries. Bulk chemicals can be acids and solvents to plastics and special chemicals.

Significance of Bulk Chemicals in the Industrial Scenario of Chennai

Major industries in the city include automobile manufacturing, textiles, pharmaceuticals, chemicals, and food processing. The reasons for its industrial growth are mainly the easy availability and utilization of bulk chemicals. The continuous production efficiency, along with a reduced cost and quality consistency, by these sectors demand a steady supply of bulk chemicals.

In the car industry, large quantities of chemicals such as oils, paints, and adhesives are required for the manufacture of car parts and construction of cars. In the textile industry in Chennai, large quantities of chemicals like colors, dyes, and finishing products are required to produce various types of fabrics. The drug industry also requires bulk chemicals since large quantities of compounds and chemicals are required for the preparation and manufacture of medicines.

Major Bulk Chemicals Used in Industries of Chennai

Acid and Bases: Strong acids, such as sulfuric acid, hydrochloric acid, and nitric acid, along with caustic soda (sodium hydroxide), are used commonly in Chennai for various purposes. These chemicals play an important role in industries that involve metal cleaning, water treatment, and fertilizer manufacturing.

Solvents: Bulk solvents like toluene, acetone, ethanol, and methanol are used across several sectors, particularly in manufacturing paints, coatings, and adhesives. These solvents are also pivotal in the pharmaceutical and petrochemical industries for various chemical reactions and formulations.

Polymers and Plastics: The polymers such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC) are a part of important basic materials in the manufacturing industries of Chennai. These bulk chemicals are used to manufacture several products including packaging materials, car parts, and building materials.

Fertilizers and Agricultural Chemicals: Large chemicals like ammonia, urea, and phosphoric acid are required for the manufacture of fertilizers that support farming. These fertilizers are used in large quantities in the regions surrounding Chennai, which is a major hub for agriculture.

Water Treatment Chemicals: Chlorine, alum, and various coagulants are major chemicals used to treat water. This is highly required in factories and the city's water supply. Because Chennai faces problems with water scarcity, there is a high requirement for these chemicals.

Supply Chain and Infrastructure for Bulk Chemicals in Chennai

Chennai has good infrastructure that helps supply bulk chemicals to industries. The city is close to important ports like Chennai Port and Ennore Port, which makes it easy to import and export bulk chemicals. Also, a strong road and rail network makes sure chemicals are transported on time to different industrial areas in and near the city.

Most of the chemical suppliers and distributors in Chennai are striving to obtain and provide large quantities of chemicals. This provides them with a huge range of products so that businesses do not have to wait to get raw materials. In general, these suppliers operate at the manufacturer's level and ensure quick delivery so that handling stock becomes easier and less expensive.

Environmental Issues and Sustainable Practices

Availability of bulk chemicals in Chennai supports the growth of the industrial sector; however, associated environmental issues during chemical manufacturing and usage also require attention. Usage of bulk chemicals, especially for large-scale uses, has environmental impacts if their management is not proper. Government and industries are adopting sustainable methods in Chennai: using eco-friendly chemicals, ensuring less generation of waste, and safe disposal of by-products of chemical production.

Industries in Chennai are giving more importance to green chemistry innovations. These include safe, biodegradable chemicals and processes that reduce harm to the environment.

Conclusion

Bulk chemicals Chennai play a significant role in the city's different industrial sectors. They help businesses in automotive, textiles, pharmaceuticals, and water treatment make high-quality products efficiently and at lower costs. As the need for these chemicals keeps increasing, industries should practice sustainable methods that lessen harm to the environment and ensure they can last a long time. With its strong infrastructure and expanding industrial base, Chennai will definitely stand as an important center for the bulk chemicals industry in India.

0 notes

Text

India — The Land of Turmeric! Did you know?

India is the largest producer and exporter of turmeric, supplying over 80% of the world’s demand.

At Prabhu Group, we bring you premium-quality Turmeric and Turmeric Powder directly from India. With decades of expertise, we specialize in sourcing, processing, and exporting turmeric with unmatched flavor, aroma, and color.

Our Turmeric Offerings

Whole Turmeric: Carefully selected and sun-dried for natural richness.

Turmeric Powder: Finely ground for uniform texture and intense color.

Why Choose Prabhu Group?

✅ Purity Guaranteed: 99.99% pure turmeric with zero adulteration.

✅ Certified Quality: Registered with the Indian Spices Board and ISO Certified.

✅ Customizable Packaging: PP bags, multi-layer paper bags, and BOPP bags in 25, 30, 50 kg, or as per buyer requirements.

✅ Global Reach: Trusted supplier to exporters and national brands worldwide.

Nutritional Benefits

Turmeric is celebrated for its health-boosting properties, thanks to its active compound, curcumin, which is known for its:

Anti-inflammatory effects, Antioxidant properties, Support for digestive health, Immunity-boosting abilities, 100g of turmeric contains, Calories: 354 kcal, Protein: 7.83 g, Carbohydrates: 64.9 g, Fiber: 21.1 g, Calcium: 168 mg, Iron: 55 mg, Magnesium: 193 mg, Potassium: 2525 mg

We are committed to delivering only the finest turmeric products.

📧 Email us at: [email protected], [email protected]

Let’s spice up the world together with the vibrant taste of Indian turmeric!

0 notes

Text

Growth of Post-Consumer Recycled Plastics Market: Key Factors Driving Demand

The global post-consumer recycled plastics market was valued at approximately USD 10.66 billion in 2023 and is anticipated to grow at a compound annual growth rate (CAGR) of 10.7% from 2024 to 2030. This market expansion is primarily driven by the increasing sustainability initiatives adopted by food and beverage as well as packaging companies, which are making efforts to integrate recycled plastic materials into their operations. Additionally, the growing emphasis on building a circular economy by end-users, coupled with the rising adoption of recycled plastics across various sectors such as packaging, textiles, and other end-use industries, is expected to significantly boost the global demand for post-consumer recycled (PCR) plastics.

Technological innovations in recycling processes that enable the creation of highly effective and advanced post-recycled plastics have also emerged as a major factor driving market growth. For example, in October 2023, Repsol S.A. and Signode Industrial Group LLC introduced a ready-to-use strap made from a polypropylene (PP) composition containing 30% recycled content, specifically designed for use in high-tenacity applications.

Furthermore, the global market's expansion can be attributed to the increasing demand for PCR plastics from a wide range of industries, including building and construction, packaging, electrical and electronics, textiles, and automotive. These industries are increasingly turning to recycled plastics as a more sustainable alternative to traditional virgin, fossil-based plastics. In particular, the construction sector is experiencing growth in countries like China, India, the United States, and Saudi Arabia, driven by various redevelopment projects that are contributing to higher demand for PCR plastics in construction materials.

Gather more insights about the market drivers, restrains and growth of the Post-consumer Recycled Plastics Market

Regional Insights:

North America Post-consumer Recycled Plastics Market

In 2023, North America accounted for a significant share of the global post-consumer recycled plastics market. This growth is attributed to the presence of major industry players like Eastman Chemical Company and the increasing regulatory pressure to reduce plastic waste. Concerns over landfill overflow and rising environmental awareness are pushing both consumers and businesses to turn to recycled plastic solutions. The increasing focus on reducing carbon footprints and the growing consumer preference for sustainable products such as eco-friendly packaging, building materials, and electrical & electronics products are expected to further boost the demand for post-consumer recycled plastics, including materials like PE (Polyethylene), PP (Polypropylene), and PET (Polyethylene Terephthalate), which are commonly used in packaging.

U.S.

The U.S. post-consumer recycled plastics market is poised for significant growth due to the rising volume of plastic waste generated by consumers. This increase in waste directly correlates with an uptick in recyclability efforts, fueling the demand for PCR plastics. These plastics are widely used in the production of consumer electronics, such as wearables and other electronic appliances.

Canada

In 2023, Canada dominated the North American market, accounting for more than 50% of the regional market share. The Canadian government and private sector are increasing efforts to address landfill overflows and plastic waste, thereby fostering the demand for post-consumer recycled plastics. This trend is particularly evident in the packaging industry, where companies are looking for ways to replace virgin plastics with PCR plastics to meet sustainability goals.

Asia Pacific Post-consumer Recycled Plastics Market

The Asia Pacific region accounted for over 45% of the global market revenue in 2023 and is expected to maintain its dominant position through 2030. The growth is driven by increasing demand for PCR plastics in industries like automotive and construction, where recycled plastics are increasingly used for manufacturing components and materials. The growing focus on sustainability in these industries is contributing to the shift toward recycled plastic solutions.

China

China is one of the fastest-growing markets for post-consumer recycled plastics, largely due to the rapid growth in the food & beverage industry and the rising popularity of food delivery services. The increase in demand for plastic packaging materials, including polyethylene, polypropylene, and PET, has spurred a surge in recycling efforts, driving the production of PCR plastics.

Japan

Japan is also projected to witness significant growth in the PCR plastics market. The country has been making considerable progress in plastic recycling rates, and growing concerns over plastic waste reduction are expected to create favorable conditions for PCR plastics in applications like packaging and consumer electronics.

Europe Post-consumer Recycled Plastics Market

The European market for post-consumer recycled plastics is expected to see steady growth over the forecast period, driven by the region's commitment to a circular economy aimed at reducing plastic waste. A significant driver is the European Union's initiative to mandate the use of PCR plastics in packaging, which is likely to increase the demand for recycled plastics across the region. This regulatory framework is aimed at promoting sustainability and reducing reliance on virgin plastics.

Germany

Germany, a leader in European waste management practices, is expected to witness consistent growth in the market. With advancements in waste management infrastructure and a significant increase in post-consumer recycling activities, Germany is set to play a pivotal role in driving the consumption of PCR plastics, particularly in the packaging and construction sectors.

UK

In the UK, the growing use of PCR plastics in consumer electronics driven by the increasing demand for wearables like fitness trackers and smartwatches is expected to create a surge in demand. Innovations in product development and growing consumer awareness of environmental issues are also anticipated to drive further market growth in the country.

Central & South America Post-consumer Recycled Plastics Market

In Central and South America, the post-consumer recycled plastics market is expected to grow steadily, fueled by the increasing efforts to reduce plastic waste and its harmful effects on marine environments. Countries like Brazil, Argentina, Chile, Colombia, and Costa Rica are focused on minimizing land-based plastic waste, which contributes to marine pollution. The demand for food and non-food plastic bottles across various industries is one of the major factors driving the growth of PCR plastics in the region’s packaging sector

Middle East & Africa Post-consumer Recycled Plastics Market

The market in the Middle East & Africa is expected to grow at a steady pace during the forecast period. This growth is primarily driven by rising environmental concerns and the increasing demand for sustainable plastic products. Governments and industries in this region are gradually recognizing the environmental benefits of recycled plastics, prompting businesses to shift toward more sustainable production processes.

Browse through Grand View Research's Category Plastics, Polymers & Resins Industry Research Reports.

• The global cross-linked polyethylene market size was valued at USD 8.0 billion in 2023 and is projected to grow at a CAGR of 6.9% from 2024 to 2030.

• The global poly alpha olefin market size was valued at USD 1.48 billion in 2023 and is projected to grow at a CAGR of 2.8% from 2024 to 2030.

Key Companies & Market Share Insights:

Leading companies in the post-consumer recycled plastics (PCR plastics) market are employing a variety of both organic and inorganic growth strategies to maintain and expand their market positions. These strategies include new product development, mergers & acquisitions, and joint ventures, which help to enhance their product portfolios, enter new markets, and leverage new technologies in the recycling space. Below are some notable recent developments by key players in the industry:

In November 2023, LyondellBasell Industries Holdings B.V., a global leader in the chemical and plastics industry, announced the establishment of an industrial-scale catalytic advanced plastic recycling demonstration plant at its Wesseling site in Germany.

In August 2023, Borouge, a joint venture between Borealis and the Abu Dhabi National Oil Company (ADNOC), launched a new series of polypropylene (PP) products for the automobile sector that contain up to 70% post-consumer recycled (PCR) materials.

In January 2023, PureCycle Technologies, a company specializing in advanced recycling technologies, partnered with the Port of Antwerp-Bruges to announce plans for developing PureCycle's first polypropylene (PP) recycling facility in Europe.

Key Post-consumer Recycled Plastics Companies:

• BASF SE

• SABIC

• Evonik Industries AG

• Sumitomo Chemical Co., Ltd.

• Arkema

• Celanese Corporation

• Eastman Chemical Company

• Chevron Phillips Chemical Company

• Exxon Mobil Corporation

• Covestro AG

Order a free sample PDF of the Post-consumer Recycled Plastics Market Intelligence Study, published by Grand View Research.

#Post-Consumer Recycled Plastics Market#Post-Consumer Recycled Plastics Market Analysis#Post-Consumer Recycled Plastics Market Report#Post-Consumer Recycled Plastics Market Regional Insights

0 notes

Text

Post-consumer Recycled Plastics Industry Revenue, Opportunity, Forecast Report 2030

The global market for post-consumer recycled (PCR) plastics was valued at approximately USD 10.66 billion in 2023, and it is projected to grow at a compound annual growth rate (CAGR) of 10.7% from 2024 to 2030. This market expansion is primarily driven by increasing sustainability initiatives from food & beverage and packaging companies, which are actively incorporating recycled plastic materials to reduce their environmental footprint. Additionally, the shift towards a circular economy where resources are reused and recycled rather than discarded is boosting the demand for PCR plastics across industries like packaging, textiles, and construction. Advanced recycling technologies that allow for high-quality recycled plastic production have further accelerated market growth.

For instance, in October 2023, Repsol S.A. collaborated with Signode Industrial Group LLC to launch a durable polypropylene (PP) strap containing 30% recycled content, designed for high-strength applications. Such innovations underscore the growing demand for PCR plastics across diverse sectors, including building & construction, packaging, electronics, textiles, and automotive, where PCR plastics are increasingly used as eco-friendly alternatives to conventional virgin plastics. The demand for PCR plastics is particularly high in construction activities within regions like China, India, the U.S., and Saudi Arabia, where various development projects, including residential and commercial buildings, affordable housing, and healthcare infrastructure, are on the rise.

Gather more insights about the market drivers, restrains and growth of the Post-consumer Recycled Plastics Market

One of the primary challenges for the PCR plastics market lies in managing waste and advancing plastic recycling technologies. High-income countries often export plastic waste to lower-income nations due to environmental and economic reasons, creating complex waste management issues. However, increasing governmental regulations targeting plastic waste reduction and disposal are positively impacting market growth. Many countries have banned single-use plastics, while others have introduced extended producer responsibility (EPR) programs, which require manufacturers to manage the end-of-life disposal of their products.

The stringent regulations governing the plastics industry encourage companies to invest in recycling technology advancements and quality control measures to ensure that the recycled materials meet safety and sustainability standards. By adhering to these regulatory frameworks, companies can not only reduce their environmental impact but also enhance customer trust and support sustainable innovation.

Source Segmentation Insights:

In terms of source material, the plastic bottles segment led the market in 2023, capturing a substantial revenue share. Plastic bottles are among the most common sources of PCR plastics, as they are widely used in packaging for beverages, cleaning products, cosmetics, and other goods. Due to the large volume of discarded plastic bottles, they serve as a readily available raw material for recycling processes. Additionally, heightened awareness about sustainability and the need to reduce plastic waste is expected to drive further growth in this segment.

Government regulations promoting plastic recycling worldwide also contribute to the adoption of plastic bottle recycling, thereby increasing PCR plastic production from this source. As a result, the demand for recycling plastic bottles is likely to remain strong.

The non-bottle rigid plastics segment is anticipated to grow at a CAGR of 10.4% during the forecast period. This category includes durable and non-durable plastic items such as pallets, crates, carts, 5-gallon buckets, electronic housings, dairy and deli containers, lids, yogurt cups, jars, and other similar food packaging. The diversity and wide use of non-bottle rigid plastics in various industries make them a valuable source for recycling, further supporting the growth of the PCR plastics market.

Order a free sample PDF of the Post-consumer Recycled Plastics Market Intelligence Study, published by Grand View Research.

0 notes

Text

Post-consumer Recycled Plastics Market 2030 Size, Share, Business Growth, Demand and Applications

The global market for post-consumer recycled (PCR) plastics was valued at approximately USD 10.66 billion in 2023, and it is projected to grow at a compound annual growth rate (CAGR) of 10.7% from 2024 to 2030. This market expansion is primarily driven by increasing sustainability initiatives from food & beverage and packaging companies, which are actively incorporating recycled plastic materials to reduce their environmental footprint. Additionally, the shift towards a circular economy where resources are reused and recycled rather than discarded is boosting the demand for PCR plastics across industries like packaging, textiles, and construction. Advanced recycling technologies that allow for high-quality recycled plastic production have further accelerated market growth.

For instance, in October 2023, Repsol S.A. collaborated with Signode Industrial Group LLC to launch a durable polypropylene (PP) strap containing 30% recycled content, designed for high-strength applications. Such innovations underscore the growing demand for PCR plastics across diverse sectors, including building & construction, packaging, electronics, textiles, and automotive, where PCR plastics are increasingly used as eco-friendly alternatives to conventional virgin plastics. The demand for PCR plastics is particularly high in construction activities within regions like China, India, the U.S., and Saudi Arabia, where various development projects, including residential and commercial buildings, affordable housing, and healthcare infrastructure, are on the rise.

Gather more insights about the market drivers, restrains and growth of the Post-consumer Recycled Plastics Market

One of the primary challenges for the PCR plastics market lies in managing waste and advancing plastic recycling technologies. High-income countries often export plastic waste to lower-income nations due to environmental and economic reasons, creating complex waste management issues. However, increasing governmental regulations targeting plastic waste reduction and disposal are positively impacting market growth. Many countries have banned single-use plastics, while others have introduced extended producer responsibility (EPR) programs, which require manufacturers to manage the end-of-life disposal of their products.

The stringent regulations governing the plastics industry encourage companies to invest in recycling technology advancements and quality control measures to ensure that the recycled materials meet safety and sustainability standards. By adhering to these regulatory frameworks, companies can not only reduce their environmental impact but also enhance customer trust and support sustainable innovation.

Source Segmentation Insights:

In terms of source material, the plastic bottles segment led the market in 2023, capturing a substantial revenue share. Plastic bottles are among the most common sources of PCR plastics, as they are widely used in packaging for beverages, cleaning products, cosmetics, and other goods. Due to the large volume of discarded plastic bottles, they serve as a readily available raw material for recycling processes. Additionally, heightened awareness about sustainability and the need to reduce plastic waste is expected to drive further growth in this segment.

Government regulations promoting plastic recycling worldwide also contribute to the adoption of plastic bottle recycling, thereby increasing PCR plastic production from this source. As a result, the demand for recycling plastic bottles is likely to remain strong.

The non-bottle rigid plastics segment is anticipated to grow at a CAGR of 10.4% during the forecast period. This category includes durable and non-durable plastic items such as pallets, crates, carts, 5-gallon buckets, electronic housings, dairy and deli containers, lids, yogurt cups, jars, and other similar food packaging. The diversity and wide use of non-bottle rigid plastics in various industries make them a valuable source for recycling, further supporting the growth of the PCR plastics market.

Order a free sample PDF of the Post-consumer Recycled Plastics Market Intelligence Study, published by Grand View Research.

0 notes

Text

Post-consumer Recycled Plastics Market – Industry Insights, Trends and Growth Opportunity Analysis to 2030

The global market for post-consumer recycled (PCR) plastics was valued at USD 10.66 billion in 2023 and is anticipated to grow at a compound annual growth rate (CAGR) of 10.7% from 2024 to 2030. This growth is driven by the increasing sustainability initiatives of food and beverage as well as packaging companies that are transitioning to recycled plastic materials. These sustainability efforts align with the circular economy principles, as more end-users across various sectors adopt PCR plastics to reduce waste and environmental impact. Rising demand in key industries such as packaging, textiles, automotive, and construction further supports this trend. Additionally, technological advancements in recycling processes have led to the production of highly efficient and innovative PCR plastics, making recycling solutions more accessible and impactful.

A notable example of this technological advancement occurred in October 2023, when Repsol S.A. and Signode Industrial Group LLC launched a high-performance strap made from polypropylene (PP) with 30% recycled content, intended for high-strength applications. The demand for PCR plastics as a replacement for traditional, virgin fossil-based plastics is robust across various end-use industries, including construction, packaging, electronics, textiles, and automotive. Countries such as China, India, the U.S., and Saudi Arabia are witnessing a surge in construction activity, spurred by redevelopment initiatives and government investments in affordable housing and healthcare infrastructure. This increase in construction projects is expected to drive the demand for PCR plastics in the building and construction sectors.

However, one of the primary challenges faced by the PCR plastics market is waste management and the need for advanced recycling technologies. Global plastic waste flows tend to move from high-income countries to low-income countries, raising environmental concerns and presenting both logistical and economic challenges. Efforts to enhance plastic recycling infrastructure and policies are essential to addressing these issues and promoting sustainable practices.

Gather more insights about the market drivers, restrains and growth of the Post-consumer Recycled Plastics Market

Type Segmentation Insights:

In 2023, the polyethylene (PE) segment held the largest market share by revenue, accounting for over 20%. Post-consumer recycled PE is derived from a variety of plastic products, including films, sheets, and pellets, and offers effective barrier properties that make it suitable for food and beverage packaging applications. Its protective properties are particularly valuable for maintaining the quality and safety of packaged goods.

Looking ahead, the polypropylene (PP) segment is expected to grow significantly. Post-consumer recycled PP is known for its excellent chemical and mechanical properties, making it suitable for multiple applications across industries such as packaging, automotive, and household goods. PP’s durability, flexibility, and thermal resistance make it an ideal choice for manufacturing household appliances. Furthermore, as consumer awareness of environmental issues and sustainable practices increases, demand for recycled PP and other sustainable materials in packaging and automotive applications is expected to rise. This growing awareness is pushing manufacturers and consumers alike toward sustainable, recycled plastic solutions, fostering innovation and growth in PCR plastic production.

Order a free sample PDF of the Post-consumer Recycled Plastics Market Intelligence Study, published by Grand View Research.

#Post-consumer Recycled Plastics Industry#Post-consumer Recycled Plastics Market Share#Post-consumer Recycled Plastics Market Analysis

0 notes

Text

Post-consumer Recycled Plastics Market Geographic Segmentation, Analysis by Types, Regions and Forecast to 2030

The global market for post-consumer recycled (PCR) plastics was valued at USD 10.66 billion in 2023 and is anticipated to grow at a compound annual growth rate (CAGR) of 10.7% from 2024 to 2030. This growth is driven by the increasing sustainability initiatives of food and beverage as well as packaging companies that are transitioning to recycled plastic materials. These sustainability efforts align with the circular economy principles, as more end-users across various sectors adopt PCR plastics to reduce waste and environmental impact. Rising demand in key industries such as packaging, textiles, automotive, and construction further supports this trend. Additionally, technological advancements in recycling processes have led to the production of highly efficient and innovative PCR plastics, making recycling solutions more accessible and impactful.

A notable example of this technological advancement occurred in October 2023, when Repsol S.A. and Signode Industrial Group LLC launched a high-performance strap made from polypropylene (PP) with 30% recycled content, intended for high-strength applications. The demand for PCR plastics as a replacement for traditional, virgin fossil-based plastics is robust across various end-use industries, including construction, packaging, electronics, textiles, and automotive. Countries such as China, India, the U.S., and Saudi Arabia are witnessing a surge in construction activity, spurred by redevelopment initiatives and government investments in affordable housing and healthcare infrastructure. This increase in construction projects is expected to drive the demand for PCR plastics in the building and construction sectors.

However, one of the primary challenges faced by the PCR plastics market is waste management and the need for advanced recycling technologies. Global plastic waste flows tend to move from high-income countries to low-income countries, raising environmental concerns and presenting both logistical and economic challenges. Efforts to enhance plastic recycling infrastructure and policies are essential to addressing these issues and promoting sustainable practices.

Gather more insights about the market drivers, restrains and growth of the Post-consumer Recycled Plastics Market

Type Segmentation Insights:

In 2023, the polyethylene (PE) segment held the largest market share by revenue, accounting for over 20%. Post-consumer recycled PE is derived from a variety of plastic products, including films, sheets, and pellets, and offers effective barrier properties that make it suitable for food and beverage packaging applications. Its protective properties are particularly valuable for maintaining the quality and safety of packaged goods.

Looking ahead, the polypropylene (PP) segment is expected to grow significantly. Post-consumer recycled PP is known for its excellent chemical and mechanical properties, making it suitable for multiple applications across industries such as packaging, automotive, and household goods. PP’s durability, flexibility, and thermal resistance make it an ideal choice for manufacturing household appliances. Furthermore, as consumer awareness of environmental issues and sustainable practices increases, demand for recycled PP and other sustainable materials in packaging and automotive applications is expected to rise. This growing awareness is pushing manufacturers and consumers alike toward sustainable, recycled plastic solutions, fostering innovation and growth in PCR plastic production.

Order a free sample PDF of the Post-consumer Recycled Plastics Market Intelligence Study, published by Grand View Research.

#Post-consumer Recycled Plastics Industry#Post-consumer Recycled Plastics Market Share#Post-consumer Recycled Plastics Market Analysis

0 notes

Text

Manufacturer of PP Storage Tank

Sunfiber is a Supplier and Manufacturer of PP Storage Tank in Rajasthan, India. Our Manufacturing Unit is in Ahmedabad, Gujarat, India. Polypropylene (PP) storage tanks are widely recognized for their exceptional chemical resistance and durability. Ideal for storing a variety of substances, including corrosive chemicals, wastewater, and other liquids, these tanks offer a safe and reliable solution for industries ranging from chemical processing to pharmaceuticals. Why Choose PP Storage Tanks? Safety: The non-reactive nature of polypropylene reduces the risk of contamination and ensures safe storage. Environmental Impact: You can design PP tanks with sustainability in mind, reducing the overall carbon footprint of your operations. Compliance: Manufactured to meet industry standards, PP storage tanks help ensure regulatory compliance across various sectors. Applications of PP Storage Tanks: Chemical Industry: Ideal for storing a wide range of chemicals safely. Wastewater Treatment: Efficiently holds and manages wastewater before treatment processes. Food and Beverage: Safe storage of food-grade materials and ingredients. Pharmaceuticals: Ensures the integrity of sensitive substances and compounds. Sunfiber is a Supplier and Manufacturer of PP Storage Tank in Rajasthan, India Including Ajmer, Alwar, Anupgarh, Balotra, Banswara, Baran, Barmer, Beaware, Bharatpur, Bhilwara, Bikaner, Bundi, Chittorgarh, Churu, Dausa, Deeg, Dholpur, Didwalna-Kuchaman, Dudu, Dungarpur, Ganganagar, Gangapur City, Hanumangarh, Jaipur, Jaipur, Jaisalmer, Jalore, Jhalawa, Jhunjhunu, Jodhpur, Jodhpur, Karauli, Kekri, Kherthal-Tijara, Kota, Kotputli-Behror, Nagaur, Pali, Phalodi, Pratapgarh, Rajsamand, Salumbar, Sanchore, Sawai Madhopur, Shahpura, Sikar, Sirohi, Tonk, Udaipur. Feel free to contact us for more information and inquiries. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alwar#Anupgarh#Balotra#Banswara#Baran#Barmer#Beaware#Bharatpur#Bhilwara#Bikaner#Bundi#Chittorgarh#Churu#Dausa#Deeg#Dholpur#Didwalna-Kuchaman#Dudu#Dungarpur#Exporter#ExporterofPPStorageTank#Ganganagar#GangapurCity#Hanumangarh#India#Jaipur#Jaisalmer#Jalore

0 notes

Text

Industrial Plastic Market Forecasts Strong Growth Trends

Industrial plastics are synthetic or semi-synthetic organic solids that are used in various industrial applications such as manufacturing, construction, packaging, automotive and transportation due to their high strength, resistance to corrosion and other desirable physical properties. Some common examples of industrial plastics include polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), polyurethane (PU), polytetrafluoroethylene (PTFE) and others. They are used in manufacturing a wide variety of durable and non-durable goods across many industries. The growing infrastructure and manufacturing activities along with increased usage of lightweight and high-performance materials are the key factors driving the demand for industrial plastics globally.

The industrial plastic market is estimated to be valued at USD 93.19 Bn in 2024 and is expected to reach USD 141.05 Bn by 2031, exhibiting a compound annual growth rate (CAGR) of 6.1% from 2024 to 2031.

Key Takeaways Key players operating in the industrial plastics market are Exxon Mobil Corporation, Sumitomo Chemical Co., Ltd., BASF SE, SABIC, Dow, Inc., Evonik Industries AG, Arkema, Celanese Corporation, Eastman Chemical Company, Chevron Phillips Chemical Co., LLC, Formosa Plastics Corporation, Covestro AG, Toray Industries, Inc., Mitsui & Co. Plastics Ltd., TEIJIN LIMITED, LG Chem, Huntsman International LLC, Chevron Phillips Chemical Co., LLC, and LyondellBasell Industries Holdings B.V. The global Industrial Plastics Market Size is driven by the growing infrastructure development and construction activities around the world. The ease of processing, forming and molding industrial plastics into components for construction is fueling their demand. Rapid urbanization is resulting in new residential, commercial and industrial construction projects in developing economies boosting consumption. Geographically, the Asia Pacific region dominates the global industrial plastics market and is expected to witness the fastest growth during the forecast period. This can be attributed to the increasing investments in the manufacturing and infrastructure development projects in major economies such as China, India, Indonesia, Thailand and Malaysia among others. Moreover, availability of cheap labor and raw materials is encouraging manufacturing facilities to set up production bases in the region. Market Key Trends The usage of recycled plastics in industrial applications is emerging as a key trend in the Industrial Plastic Companies. Recycling industrial plastic waste helps reduce the consumption of raw materials and dependence on fossil fuel based sources of plastics production. It also lowers carbon footprint making the plastic products more environmentally sustainable. Technological developments are supporting improved recycling processes for various industrial plastic types such as PET, HDPE, LDPE and others. Most leading plastic manufacturers are targeting a specific percentage of recycled content usage in their product lines over the next decade. This will drive the demand for recycled industrial plastics. Porter's Analysis Threat of new entrants: Plastic production requires substantial capital investments and established distribution networks. This makes entry difficult for new players. Bargaining power of buyers: Industrial buyers have significant bargaining power due to the availability of substitute products and commoditized nature of plastics. Bargaining power of suppliers: A few large multinational companies dominate the supply of raw materials. This gives them substantial bargaining power over plastic producers. Threat of new substitutes: Alternatives like paper, glass, and metals pose a minor threat as plastics offer distinct technical and economic advantages. Competitive rivalry: The industrial plastics industry is highly competitive due to many established players and abundant supply. Geographical Regions North America accounts for the largest share of the global industrial plastics market, both in terms of value and volume. This is attributed to high demand from various end-use industries such as packaging, automotive, consumer goods, construction, and others. Asia Pacific is projected to be the fastest-growing regional market between 2024 and 2031. Rapid industrialization and urbanization coupled with growing manufacturing sector are driving plastic consumption in the region, especially in China and India.

Get more insights on Industrial Plastics Market

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

0 notes

Text

Manufacturing Process of Masterbatch: How is Masterbatch Made?

Masterbatches are vital components in the realm of plastic products. They play a pivotal role in imparting colour and functionality to thermoplastics. In this blog, we explore the complex manufacturing process of masterbatches, providing a comprehensive view of how these innovative pigments are created.

What is a Masterbatch?

Masterbatches are granular materials that are composed of carrier resin and various additives. The carrier resin is compatible with the main plastic, which is later blended during molding while imparting colour and functionality to the end product. The manufacturing process of masterbatch plays a pivotal role in determining the end products' properties and quality.

Manufacturing Process of Masterbatch: What is Needed?

When it comes to how is masterbatch made, it is a complex process that needs careful selection of suitable raw materials and equipment to create high-quality masterbatches.

Ingredients:

The master batch manufacturer in India uses top-quality ingredients to formulate precise MBs. Here are some key ingredients needed to manufacture masterbatches:

Base Resin: The base resin acts as the foundation of the masterbatch’s properties. These base resins comprise polymers like PP, PE, PS, and other plastics. This determines the compatibility with end products and processing conditions.

Additives & Pigments: These active ingredients add colours and functional and desired characteristics like UV protection, anti-slip, anti-fog or anti-bacterial.

Carrier Resin: The carrier resins help to disperse the additives within the master batch. It ensures uniform dispersion, resulting in consistent color, texture, and properties.

Equipment

The top master batch company in India uses various equipment to achieve consistency and quality in the final product.

Mixer or Compounder: This equipment is used to mix the base resin, pigments & additives, and carrier resins to get a homogeneous mixture. The mixer ensures uniform dispersion of additives and pigments.

Extruder: It is used to melt and process the compounded resin mixture. The extruder transforms the blended resin mixture into a high-quality melt that can be easily pelletized.

Pelletizing Machines: This equipment gives the molten resin mixture uniform pellets. This allows ease of handling, transportation and storage.

Quality Control Devices: Devices like spectrophotometer, rheometer and other equipment are used for testing quality and ensuring the masterbatch meets the desired specifications.

Perfect Colourants & Plastics Pvt. Ltd uses suitable high-quality ingredients and state-of-the-art equipment to produce masterbatches for different industries with consistent quality and tailored properties.

The Masterbatch Manufacturing Process

Developing a masterbatch involves various intricate manufacturing processes. This process needs careful attention to detail to ensure consistent quality and performance of the MB.

Formulation & Compounding: The formulation involves deciding the the accurate ratio of base resin, pigments, carrier resins, and desired additives. This determines the final colour, functionality, and compatibility with the end product.

Mixing of Ingredients: After the formulation is ready, the ingredients are put into a mixer or compounder. This equipment blends the base resin, pigment, and additives to create an even homogenous mixture. This mixing step ensures that pigment and additives are evenly dispersed throughout the mixture.

Extrusion: The compounded mixture is put into an extruder that melts and processes the resin blend. In the extruder equipment, the mixture is exposed to controlled pressure and temperature to form into a consistent molten form. This process breaks down any cluster to ensure a uniform distribution of pigments and removes any moisture or air.

Pelletization: In this process, the molten resin is put through a pelletizing unit to shape the resins into granular or pellets.

Quality Control & Testing: Various equipment and devices are used for quality control and testing. Spectrophotometers and rheometers are used to check the colour, lightfastness, dispersion, and other characteristics to ensure the masterbatches meets the specific requirements and performance standards.

Wrapping Up

After the masterbatch meets the standards, it is packed and stored under controlled conditions to preserve its quality. At PCPPL, we offer an array of products like colour, white, black, additive, and liquid masterbatches. Developed using hi-tech equipment and precise formulation, it delivers exceptional dispersion, is cluster-free, and high performance. We provide tailored solutions to meet your specific requirements. Contact us today to transform your plastic products.

Visit:- How to Import Quality Masterbatches in Your Country?

#How is Masterbatch Made#Manufacturing Process of Masterbatch#Master Batch Manufacturer in India#Master Batch Company in India#Liquid Masterbatches

0 notes

Text

KPLEX Expo 2024 Bangalore International Polymer Exhibition

We hope this message finds you well. R Mech Machines LLP extends a warm invitation to the upcoming KPLEX International Polymer Exhibition. R Mech Machines LLP is Based in Ahmedabad, Gujarat, India. R Mech Machines LLP specializes in manufacturing a wide range of innovative products, including Pet Bottle Scrap Plastic Washing and Recycling Plants, Municipal Solid Waste Segregation Management, HDPE Scrap Film Washing Plants, and HDPE PP Article Scrap Washing Plants. Event Details: Name: KPLEX International Polymer Exhibition Date: April 26th to 29th, 2024 Venue: BIEC, Bengaluru, Karnataka Hall: 3A Stall No: I22 You'll have the opportunity to explore the latest products, technologies, and innovations showcased by top manufacturers, suppliers, and service providers in the polymer industry. From polymer resins and compounds to processing machinery and equipment, exhibitors will unveil their newest offerings and solutions. Our commitment lies in delivering high-quality products that adhere to global standards such as ASTM, ANSI, API, and DIN. For attendance confirmation or further inquiries, please reach out to us at [email protected], [email protected], or call 9327320386. Stay updated with the latest information by visiting our website at www.rmechmachines.com. We genuinely appreciate your time and eagerly anticipate your presence in Bengaluru. Read the full article

0 notes

Text

Innovation in Polymers: The Crucial Role of Talc Powder

In the dynamic landscape of industrial materials, talc holds a significant position as a versatile mineral with diverse applications. Among the myriad of industries that benefit from talc, the polymer industry stands out, relying on high-quality talc powder to enhance the performance and characteristics of polymers. In this realm, A.N. Enterprises has emerged as a trailblazer, playing a pivotal role in providing top-notch Polymer Grade Talc Powder in India. Its unique properties and tailored processing make it a sought-after material for manufacturers across various sectors, reinforcing the importance of quality and precision in the sourcing process.

The Significance of Polymer Grade Talc Powder:

Polymer Grade Talc Powder is a critical component in the polymer manufacturing process. Talc, a naturally occurring mineral, is characterized by its unique combination of properties, including lubricity, chemical inertness, and high thermal conductivity. These attributes make it an ideal reinforcement and filler material for polymers, enhancing their mechanical properties, dimensional stability, and overall performance.

In the realm of polymers, where precision and reliability are paramount, A.N. Enterprises stands out for providing Polymer Grade Talc Powder that meets and exceeds industry standards. The company's commitment to quality assurance is evident in every aspect of their production process, from sourcing raw materials to the final product.

A.N. Enterprises' Commitment to Quality:

We take pride in its state-of-the-art manufacturing facilities that adhere to stringent quality control measures. The Polymer Grade Talc Powder undergoes a rigorous testing process to ensure it meets the specific requirements of the polymer industry. The company's dedication to quality is reflected in the consistency, purity, and performance of its talc powder, making it the preferred choice for leading polymer manufacturers in India.

Advantages of A.N. Enterprises' Polymer Grade Talc Powder:

Enhanced Mechanical Properties: The addition of Polymer Grade Talc Powder improves the tensile strength, modulus, and impact resistance of polymers, contributing to the overall durability of the final product.

Dimensional Stability: Talc acts as a nucleating agent, minimizing the risk of deformation and warping during the polymer cooling process, resulting in enhanced dimensional stability.

Cost Efficiency: Our talc powder not only improves the performance of polymers but also offers a cost-effective solution, as talc is a naturally abundant and economically viable material.

Environmental Sustainability: Talc is an environmentally friendly mineral, and we take pride in promoting sustainable practices in its mining and production processes.

Applications in the Indian Polymer Industry

Polypropylene (PP) and Polyethylene (PE) Compounds:

Polymer grade talc finds widespread use in the production of polypropylene and polyethylene compounds. Its incorporation enhances the overall properties of these polymers, making them suitable for various applications.

Automotive, Packaging, Construction, and Consumer Goods:

The versatility of polymer grade talc makes it a key ingredient in industries such as automotive, packaging, construction, and consumer goods. Its impact on mechanical and thermal properties contributes to the production of high-quality polymer products.

Choosing Excellence with Polymer Grade Talc in India

In the dynamic landscape of the Indian polymer industry, selecting the right polymer grade talc is paramount for achieving optimal results. As you embark on your sourcing journey, prioritize reputable suppliers who adhere to rigorous quality control measures. By understanding the specific requirements of your polymer applications and considering factors such as particle size, purity, and surface treatment, you ensure the seamless integration of polymer grade talc into your formulations. Elevate your products with the enhanced mechanical and thermal properties that polymer grade talc provides. Make the choice for excellence, and propel your polymer creations to new heights with the reliable performance of high-quality talc powder sourced from trusted suppliers in India.

Contact us today to explore how our polymer grade talc can elevate the performance and quality of your polymer products.

Contact Information:

A. N. Enterprises

Plot No. 8, New Navratan Complex

Udaipur – 313001, Rajasthan, India

+91-9414167212

We look forward to the opportunity to collaborate with you and contribute to the success of your polymer-related endeavors.

0 notes

Text

Pharmaceutical Packaging Market Challenges, Strategies And Forecast Report 2024 - 2030

The global pharmaceutical packaging market size was valued at USD 139.37 billion in 2023 and is expected to grow a compound annual growth rate (CAGR) of 9.7% from 2024 to 2030.

The enormous growth of the pharmaceutical sector is one of the primary growth factors for the pharmaceutical packaging sector. The pharmaceutical business has been expanding quickly in recent years due to scientific and technological advancements, and this trend is predicted to continue over the projection period, particularly in developing nations like China, India, Saudi Arabia, and Brazil.

The U.S. accounted for the largest pharmaceutical market worldwide. Large healthcare system, high per capita income, and large investments in drug development in the country are some of the key factors driving the U.S. market. Furthermore, growing importance of generic drugs and access to better healthcare services are anticipated to provide lucrative opportunities for pharmaceutical packaging in the coming years. The 21st Century Cures Act (Cures Act) was signed on December 13, 2016, in the U.S. and is designed to accelerate medical product development. The law is expected to drive new innovations in product developments in pharmaceutical industry. This is expected to drive the demand for pharmaceutical packaging in U.S.

Gather more insights about the market drivers, restrains and growth of the Pharmaceutical Packaging Market

Pharmaceutical Packaging Market Report Highlights

• Asia Pacific is expected to register the fastest CAGR of more than 12% from 2024 to 2030. This growth is due to the rapidly expanding pharmaceutical market, particularly in China & India, and rising cases of various diseases, such as cancer and heart problems

• In terms of material, the glass segment is projected to ascend at the highest CAGR of 10.3% over the forecast period. Strong chemical resistance to various medicinal products and the ability to withstand heating treatment during the sterilization process is expected to expand the penetration of glass packaging

• Pharma manufacturing is the key end-use segment that accounted for the highest share of 49.9% in 2023 and is expected to witness strong growth from 2024 to 2030. This is owing to the increasing demand for medicines.

• In April 2022, Amcor has launched new and more sustainable High Shield laminates to its pharmaceutical packaging portfolio. This is low carbon, recycle-ready, and moisture resistant packaging solution, thus end use companies’ recyclability agendas

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

• The global flexible paper packaging market size was estimated at USD 50.35 billion in 2023 and is projected to grow at a CAGR of 4.2% from 2024 to 2030.

• The global seaweed packaging market size was valued at USD 699.23 million in 2023 and is expected to expand at a CAGR of 6.6% from 2024 to 2030.

Pharmaceutical Packaging Market Segmentation

Grand View Research has segmented the pharmaceutical packaging market on the basis of on material, product, drug delivery mode, end-use, and region:

Pharmaceutical Packaging Material Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• Plastics & Polymers

o Polyvinyl Chloride (PVC)

o Polypropylene (PP)

o Homo

o Random

o Polyethylene Terephthalate (PET)

o Polyethylene (PE)

o HDPE

o LDPE

o LLDPE

o Polystyrene (PS)

o Others

• Paper & Paperboard

• Glass

• Aluminium Foil

• Others

Pharmaceutical Packaging Product Outlook (Revenue, USD Million, 2018 - 2030)

• Primary

o Plastic Bottles

o Caps & Closures

o Parenteral Containers

o Syringes

o Vials & Ampoules

o Others

o Blister Packs

o Prefillable Inhalers

o Pouches

o Medication Tubes

o Others

• Secondary

o Prescription Containers

o Pharmaceutical Packaging Accessories

• Tertiary

Pharmaceutical Packaging Drug Delivery Mode Outlook (Revenue, USD Million, 2018 - 2030)

• Oral Drugs

• Injectables

• Topical

• Ocular/ Ophthalmic

• Nasal

• Pulmonary

• Transdermal

• IV Drugs

• Others

Pharmaceutical Packaging End-use Outlook (Revenue, USD Million, 2018 - 2030)

• Pharma Manufacturing

• Contract Packaging

• Retail Pharmacy

• Institutional Pharmacy

Pharmaceutical Packaging Regional Outlook (Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o UK

o France

o Italy

o Spain

o Russia

o Turkey

• Asia Pacific

o China

o India

o Japan

o South Korea

o Australia

o Southeast Asia

• Central & South America

o Brazil

o Argentina

• Middle East & Africa

o Saudi Arabia

o UAE

o South Africa

o Egypt

Order a free sample PDF of the Pharmaceutical Packaging Market Intelligence Study, published by Grand View Research.

#Pharmaceutical Packaging Market#Pharmaceutical Packaging Market size#Pharmaceutical Packaging Market share#Pharmaceutical Packaging Market analysis#Pharmaceutical Packaging Industry

0 notes

Text

Global Commodity Plastics Market Overview – Market Growth Analysis And Key Drivers

The Commodity Plastics Global Market Report 2023, provides comprehensive information on the commodity plastics market across 60+ geographies in the seven regions - Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa for the 27 major global industries. The report covers a ten year historic period – 2010-2021, and a ten year forecast period – 2023-2032.

Learn More On The Commodity Plastics Market’s Growth:

As per The Business Research Company’s Commodity Plastics Global Market Report 2023, the market size is expected to grow from $465.38 billion in 2022 to $498.49 billion in 2023 at a compound annual growth rate (CAGR) of 7.1%. The Russia-Ukraine war disrupted the chances of global economic recovery from the COVID-19 pandemic, at least in the short term. The war between these two countries has led to economic sanctions on multiple countries, a surge in commodity prices, and supply chain disruptions, causing inflation across goods and services and affecting many markets across the globe. The market size of commodity plastics is expected to grow to $637.15 billion in 2027 at a CAGR of 6.3%.

Get A Free Sample Of The Report (Includes Graphs And Tables):

Product advancement is a key trend gaining popularity in the commodity plastics market. Major market players are focusing on technological advancements to sustain their position in the commodity plastics market. For instance, in August 2021, Krehalon, a Netherlands based packaging company, launched the KreCycleTM to meet the demand for more sustainable packaging options, as well as a portfolio of conveniently recyclable high barrier flexible films for fresh food applications. The KreCycleTM product line includes polyester (PET), polyethylene (PE), and polypropylene (PP) based solutions with customized barrier qualities to meet the needs of specific applications. It is perfect for packaging fresh protein products such as red meat, poultry, processed meat, fish, and hard cheese. Flexible thermoforming films, flowrap films with a high barrier option, lidding films, and vacuum pouches are among the products available. For the convenience of the consumer, there are additional lock and peel seal options.

The commodity plastics market is segmented:

1) By Type: Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), Polystyrene (PS), Acrylonitrile Butadiene Styrene (ABS), Polyethylene Terephthalate (PET), Poly (Methyl Methacrylate) (PMMA)

2) By Plastic Type: Reusable, Recyclable

3) By End-User: Packaging, Construction, Consumer Goods, Automotive, Electronics, Textiles, Medical and Pharmaceutical, Other End Use Industry

Asia-Pacific was the largest region in the commodity plastics market in 2022.

The table of contents in TBRC’s commodity plastics market report includes:

1. Executive Summary

2. Market Characteristics

3. Market Trends And Strategies

4. Impact Of COVID-19

5. Market Size And Growth

6. Segmentation

7. Regional And Country Analysis

.

.

.

27. Competitive Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

Learn About Us: The Business Research Company is a market intelligence firm that pioneers in market, company, and consumer research. TBRC’s specialist consultants are located globally and are experts in a wide range of industries that include healthcare, manufacturing, financial services, chemicals, and technology. The firm has offices located in the UK, the US, and India, along with a network of proficient researchers in 28 countries. Through the report businesses can gain a thorough understanding of the market’s size, growth rate, major drivers and leading players.

Contact Us: The Business Research Company Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Importance of black masterbatch in plastic based industries

In this business-centric blog, we are going to highlight plastic black masterbatch, an important product that has found immense application in a variety of plastic-based industries.

At the outset, let’s define black masterbatch, helping readers to relate to the blog better.

Learning about black masterbatch

In simple words, a black masterbatch is a mix of black pigment, combined with virgin resin and specific additives in a granular form. The composition, percentage, etc. are adjusted and customized to suit the requirement of the end user. Dialogue with a black masterbatch manufacturer will help you learn extensively about the product.

Learning about the salient features of plastic black masterbatch

Why do plastics-based manufacturing companies rely on black masterbatch? What is special about this masterbatch is that it has become one of the most sought-after masterbatches in the plastic industry. These and many similar questions will be answered in this section. The unique features of black masterbatch make it special and give it an edge over others. These include:

High Jets

UV Stability

Uniform Dispersion

High-Temperature Resistance

No Issues of bleed or bloom

Ease of processibility

In this regard, you can connect with a leading black masterbatch manufacturer in India. We suggest you prepare a list of questions to be raised while having a dialogue with the company.

Industrial use and applications of the plastic black masterbatch

From the application section, let’s now shift our focus to industrial use and applications of the product. What are its applications? Over the years, black masterbatch manufacturer is meeting the requirement of a wide range of plastic based industries that depend on black masterbatch for manufacturing a variety of products. Some of these comprise Pipes and Film Extrusion, Rotomolded Tank Molding, HDPE Pipes and extrusion, Geo Membranes, Non-Woven Bags, Drip Irrigation, For High Jet, Gloss film, UV sensitive, Geo Textiles, Laterals, Mulch Film, Tarpaulin, Laminations, Thin Film, Molding, Economical glade for injection molding and thick film, PP fiber grade for Multifilament and Mono-Filament, and many more.

For in-depth information, you can connect with a prominent black masterbatch manufacturer.

Industries

Plastic black masterbatch has found applications in numerous industries. These include:

Building & construction

Agriculture

Automotive

Packaging

Just a piece of humble advice. Before placing your order, have a lengthy discussion with the black masterbatch manufacturer in Ahmedabad. Why? You shouldn’t buy the wrong product that may lead to poor quality.

Plastic black masterbatch market size and growth estimation

As far as the market size is concerned, the black masterbatches market size is estimated to be US$ 2.4 billion in 2021 and is projected to reach US$ 3 billion by 2026, at a CAGR of 4.4% between 2021 and 2026. The plastic black masterbatch market is growing steadily, powered by increasing demand for innovative and attractive plastic-based products in the packaging industry, quotes a leading market report. In addition, there is one more important element that is aiding the growth of plastic black masterbatch. It has been noticed that most of the polymer manufacturers are switching the processing method of plastics from compounding to masterbatch.

Conclusion

We hope this short informative blog will expand your knowledge about the

plastic black masterbatch

. Never compromise with the quality. Only buy the black masterbatch from a reputed

black masterbatch manufacturer

in Ahmedabad.

0 notes