#pond liner company

Explore tagged Tumblr posts

Text

GMMTV Up & Above 2024 Part 1 & 2

The Thailand Production Company did a 2 part previews of series to release presumably in 2024 or perhaps early 2025. Will these series make it to air.

UP & ABOVE Part 1 Series yet to air...

Enigma 2: Not my cup of tea, but no word of when or if this Win Metawin series will be released.

My Golden Blood: A BL and the union of JossGawin or JossFluke whatever. A vampire themed BL has no release date...yet.

UP & ABOVE Part 2

Scarlet Heart Thailand: Another adaptation from China. Not a BL but it boasts a lot of BL actors known and loved such as Win, Phuwin, Fourth, Tay, Nanon, Perth and Force along with actress Tu. It also has a Korean Adaptation.

The Ex-Morning: a BL slated to re-pair SOTUS duo SingtoKrist has already been moved to 2025 according to MDL but no official date.

The Dark Dice: A non BL starring popular GMMTV actor, singer & dancer Gemini sans partner Fourth. A supernatural thriller. No word on it's filming or release.

Sweet Tooth, Good Dentist: a new BL with a new pairing MarkOhm. Not that Ohm but the Ohm that's playing the other Ohm's little brother in Kidnap: The Series. And Mark from Only Friends (where he was more or less paired with Neo) this series is said to be released soon as in this year. But will air on IQIYI for most and YouTube for others.

ReVamp: The UnDead Story - Another vampire BL inherited from Studio Wabi Sabi and BounPrem reunion. This series has also been officially moved to 2025 with no date yet. However star Boun is also the screenwriter for this series

Break Up Service: a non BL series starring Off without Gun. A rom-com. No word but this series may appear in 2025.

Thame-Po: The Heart That Skips A Beat: a BL with the much anticipated ship of WilliamEst. Most likely a BL for 2025

Hide & Sis: a non BL that has been fairly quiet with an A-List of GMMTVers such as Piploy, Jan, Lookjun, JingJing along with Luke, Pepper, Gawin and Chimon. As Chimon took time off to deal with mental health issues he step aside from Perfect 10 Liners and separated from BL Ship Perth but was said to be still with this series. Probably another 2025 series.

Friendshit Forever: Initially this seemed very GL ish but no. A non BL with 2 male leads known for their BL's New (Dark Blue Kiss, Cherry Magic TH etc) and Boun (Until We Meet Again, Between Us and upcoming Revamp) and the female leads are Pat and Mook. This is a revenge plot series.

US: A very promising GL starring popular actress lately Emi. Emi appears in Perfect 10 Liners but recently appeared in Last Twilight, Wandee Goodday, The Rebound and The Trainee. She is being paired with Bonnie (newbie to GMMTV currently in supporting role in High School Frenemy) this series is also likely to hit at the end of December or maybe 2025

Leap Day: a non BL starring Pond, Gun and Dew. This one I hear was in the shooting stage and Pond was hurt on his arm. Pond says he's fine and was in sling. So depending if film was delayed due to this injury this one might be in 2024.

and finally

OSSAN'S LOVE THAILAND: Yet another Adaptation from Japan with EarthMix reuniting will likely be a 2025 BL Series unless GMMTV has a secret. Krit is set to play the older man that falls for employee Heng (played by EARTH) while roommate Momo (played by MIX) also falls for Heng.

@pose4photoml @just-another-boyslove-blog

#NON AIRED SERIES#GMMTV#UP AND ABOVE 2024#STRAIGHT SERIES#BL SERIES#A GL SERIES#2024 to 2025 SERIES#WHEN WILL THESE SERIES RELEASE?

5 notes

·

View notes

Text

Understanding HDPE T Rib Liner Sheets: The Ultimate Solution for Structural Integrity

HDPE T Rib Liner Sheets have emerged as an essential material in various industries, particularly in construction and engineering applications. These specialized sheets offer significant advantages in terms of strength, durability, and flexibility, making them an ideal choice for numerous applications. In this article, we will explore the features, benefits, and applications of HDPE T Rib Liner Sheets, highlighting the role of HDPE T Rib Liner manufacturers in providing these innovative products.

What Are HDPE T Rib Liner Sheets?

HDPE T Rib Liner Sheets are engineered sheets made from high-density polyethylene, designed with a unique T-shaped rib structure. This ribbing provides enhanced strength and stability, making the sheets suitable for demanding environments. HDPE T Rib Liner is commonly used in applications that require resistance to chemicals, moisture, and impact, making them a reliable choice for both indoor and outdoor use.

Key Features of HDPE T Rib Liner Sheets

Durability: One of the standout characteristics of HDPE T Rib Liner Sheets is their exceptional durability. They can withstand significant loads and resist damage from harsh environmental conditions, including UV exposure and extreme temperatures.

Chemical Resistance: These liner sheets are highly resistant to a wide range of chemicals, including acids, bases, and solvents. This makes them suitable for industrial applications where chemical exposure is a concern.

Lightweight: Despite their strength, HDPE T Rib Liners are relatively lightweight, making them easy to transport and install. This characteristic also helps reduce shipping costs.

Flexibility: The design of the T rib structure allows for flexibility, enabling the sheets to adapt to various shapes and contours during installation.

Eco-Friendly: Made from recyclable materials, HDPE T Rib Liner Sheets align with sustainable practices and can contribute to eco-friendly construction efforts.

Applications of HDPE T Rib Liner Sheets

1. Waterproofing

One of the primary uses of HDPE T Rib Liner Sheets is in waterproofing applications. Their excellent moisture resistance makes them ideal for lining ponds, reservoirs, and other water bodies. By preventing water seepage, these liners help maintain water levels and protect surrounding areas from erosion.

2. Chemical Containment

HDPE T Rib Liners are widely used in chemical storage facilities. Their chemical resistance ensures that hazardous materials do not penetrate the liner, providing a secure containment solution that protects both the environment and human health.

3. Structural Support

In construction, these liner sheets are often employed as part of retaining walls and foundations. Their strength and stability help maintain the structural integrity of buildings and other structures, particularly in areas with challenging soil conditions.

4. Agriculture

HDPE T Rib Liner Sheets are increasingly used in agricultural applications, such as lining irrigation ditches and ponds. Their durability and resistance to environmental factors contribute to more efficient water management practices.

The Role of HDPE T Rib Liner Manufacturers

HDPE T Rib Liner manufacturers play a critical role in producing high-quality sheets that meet industry standards. Choosing the right manufacturer is essential for ensuring that the liners provide the desired performance and durability.

Factors to Consider When Choosing a Manufacturer

Quality Assurance: Look for manufacturers that adhere to strict quality control measures, ensuring that their products meet relevant industry standards.

Customization Options: Many projects require specific sizes and thicknesses of liner sheets. Manufacturers offering customization options can better meet the unique needs of their clients.

Experience and Reputation: Research the manufacturer’s reputation in the industry. A well-established company with positive reviews is more likely to deliver reliable products.

Customer Support: Good customer service is essential. A manufacturer that provides expert advice and support can help ensure a smooth purchasing process.

FAQs About HDPE T Rib Liner Sheets

1. How long do HDPE T Rib Liner Sheets last?

With proper installation and maintenance, HDPE T Rib Liner Sheets can last anywhere from 20 to 30 years or more. Their durability and resistance to environmental factors contribute to their longevity.

2. Can HDPE T Rib Liners be used in extreme temperatures?

Yes, HDPE T Rib Liners are designed to withstand a wide range of temperatures. They perform well in both high and low-temperature environments, making them suitable for various applications.

3. How are HDPE T Rib Liner Sheets installed?

Installation typically involves preparing the surface, laying down the sheets, and securing them in place. Depending on the application, additional measures such as sealing seams may be necessary to ensure water tightness.

Summary

HDPE T Rib Liner Sheets are an excellent solution for various applications requiring durability, chemical resistance, and moisture protection. Their unique T rib design enhances strength and flexibility, making them ideal for waterproofing, chemical containment, structural support, and agricultural use. As the demand for high-quality HDPE T Rib Liners continues to grow, choosing a reliable HDPE T Rib Liner manufacturer becomes increasingly important. By investing in these innovative sheets, businesses can ensure the longevity and integrity of their projects, contributing to sustainable practices and improved environmental management. Whether for construction, agriculture, or industrial applications, HDPE T Rib Liner Sheets are a versatile and effective choice.

0 notes

Text

HDPE Pond Liner Manufacturer & Supplier in India | Solos Polymers

Solos Polymers is one of the globally trusted flexible packaging company. We are the manufacturer, supplier and exporter of HDPE Pond liners.

#PondLiner#HDPEPondLiner#PondLinerManufacturer#PondLinerManufacturerIndia#PondLinerSupplier#PondLinerSupplierIndia#HDPEPondLinerManufacturer#HDPEPondLinerSupplier#HDPEPondLinerManufacturerIndia#HDPEPondLinerSupplierIndia

0 notes

Text

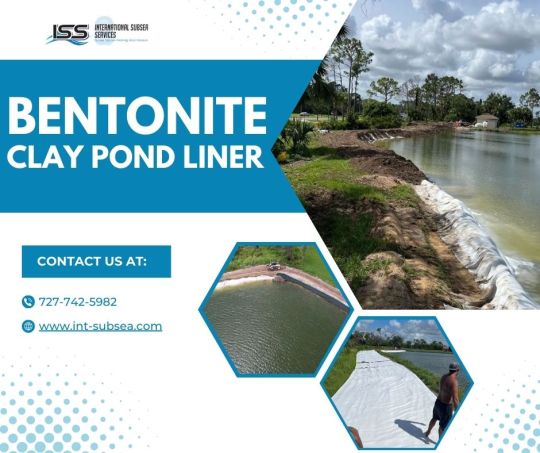

Bentonite Clay Pond Liner

Secure your pond with the Bentonite Clay Pond Liner! This natural, effective solution prevents water seepage and ensures long-lasting durability. Easy to install, the Bentonite Clay Pond Liner forms a strong barrier that maintains water levels while supporting a healthy ecosystem. Ideal for any pond project, this liner offers reliable and eco-friendly performance. Protect your pond today with the trusted bentonite installer company near your area.

#BentoniteClayPondLiner#PondSealing#EcoFriendlySolution#ShorelineStabilization#MarineGuard#GCLPondLiners#IntSubsea

0 notes

Text

The Versatility and Benefits of PE Film: A Comprehensive Guide

Introduction to PE Film

Polyethylene (PE) film is an incredibly versatile material with a wide range of applications across various industries. Known for its durability, flexibility, and cost-effectiveness, PE plastic film plays a crucial role in packaging, agriculture, construction, and more. This comprehensive guide explores the composition, types, applications, benefits, and environmental considerations of PE film.

Understanding PE Film

PE film is made from polyethylene, a thermoplastic polymer derived from ethylene. It is produced through a process called extrusion, where polyethylene pellets are melted and formed into thin sheets or films. PE film is prized for its excellent barrier properties, chemical resistance, and ease of fabrication, making it a popular choice in numerous industries.

There are two primary types of polyethylene used in the production of PE film: High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE).

High-Density Polyethylene (HDPE) Film:

HDPE film is known for its high strength-to-density ratio.

It is more rigid and less permeable than LDPE film.

HDPE film is commonly used in applications requiring durability and puncture resistance, such as industrial packaging and geomembranes.

Low-Density Polyethylene (LDPE) Film:

LDPE film is more flexible and has a lower density.

It is softer and more stretchable compared to HDPE film.

LDPE film is often used for applications requiring flexibility and clarity, such as plastic bags, shrink wraps, and agricultural films.

Versatility of PE Film

The versatility of PE film is evident in its widespread use across various sectors.

1. Packaging Solutions:

PE film packaging industry, providing solutions for a wide range of products. It is used to create bags, pouches, and wraps that protect goods from moisture, dust, and contamination. In the food industry, PE film is used to package perishable items, ensuring freshness and extending shelf life. Its excellent barrier properties make it ideal for protecting sensitive products such as pharmaceuticals and electronics.

2. Agricultural Applications:

PE film plays a significant role in agriculture, where it is used for greenhouse covers, mulch films, and silage wraps. Greenhouse covers made from PE film provide a controlled environment for plant growth, enhancing crop yields and quality. Mulch films help conserve soil moisture, suppress weeds, and regulate soil temperature, promoting healthy plant growth. Silage wraps protect stored forage crops from spoilage, preserving their nutritional value.

3. Construction and Industrial Uses:

In construction, PE film is used as a vapor barrier, protecting buildings from moisture and improving energy efficiency. It is also used as a protective covering for materials and equipment, shielding them from dust, debris, and weather conditions. In industrial settings, PE film is used for lining and covering purposes, such as pond liners, landfill liners, and containment membranes.

Benefits of PE Film

PE film offers numerous benefits that make it a preferred choice for various applications.

1. Cost Efficiency:

PE film is more cost-effective than many alternative materials. Its low production costs, combined with its lightweight properties, reduce transportation and storage expenses. This affordability allows businesses to optimize their budgets without compromising on quality or performance.

2. Performance and Protection:

PE film provides excellent protection against external elements. Its resistance to moisture, chemicals, and contaminants ensures that the contents remain safe and intact. This performance is crucial for maintaining the quality and shelf life of products, particularly in the food and pharmaceutical industries.

3. Customization:

Advancements in manufacturing technology enable extensive customization of PE film. Companies can produce films with specific properties such as UV resistance, anti-static, and anti-fog capabilities. Additionally, PE film can be printed with logos, brand messages, and product information, enhancing brand visibility and customer engagement. The availability of various thicknesses, sizes, and colors allows businesses to tailor packaging solutions to specific needs.

4. Environmental Sustainability:

The environmental impact of PE film is a significant consideration in today’s market. Efforts to recycle PE film are gaining traction, supported by technological innovations that improve sorting and processing capabilities. Recycled PE film can be used to manufacture new products, reducing the demand for virgin materials and minimizing environmental impact. Additionally, the development of biodegradable PE film offers eco-friendly options that break down more easily in natural environments.

Sustainability and Environmental Considerations

As global awareness of environmental issues grows, the sustainability of PE film has come under scrutiny. While traditional PE film is not biodegradable and can contribute to plastic pollution, advancements in recycling and biodegradable options are mitigating these concerns.

1. Recycling:

PE film recycling, and many recycling programs accept it. The recycling process involves cleaning, melting, and reprocessing the plastic into new products. However, contamination and improper disposal can hinder recycling efforts. Public awareness and participation in recycling programs are crucial to maximizing the benefits of PE film recycling.

2. Biodegradable PE Film:

Biodegradable PE film is designed to decompose more quickly than traditional plastic film. These films are typically made from a blend of polyethylene and biodegradable additives or alternative materials such as starch. While they offer an eco-friendly alternative, it’s important to ensure that they meet specific environmental standards and certifications to validate their biodegradability.

3. Regulations and Standards:

International regulations and standards govern the production, use, and disposal of PE film. Compliance with these regulations ensures that manufacturers adopt responsible production methods and contribute to global environmental goals. For example, the European Union’s directives on plastic waste and the United States’ initiatives to reduce plastic pollution aim to promote sustainable practices and reduce the environmental impact of plastic film.

Case Studies and Examples

Several businesses have successfully integrated PE film into their operations, achieving both operational efficiency and environmental sustainability. For instance, a leading agricultural company implemented PE film for greenhouse covers, resulting in increased crop yields and reduced water usage. This initiative not only improved the company’s bottom line but also enhanced its sustainability credentials.

Another example is a construction firm that used PE film as a vapor barrier in building projects. This application improved the energy efficiency of the buildings, leading to cost savings and a reduced environmental footprint. The firm’s commitment to using sustainable materials also bolstered its reputation in the industry.

Conclusion

In conclusion, PE film is a versatile and beneficial material that caters to a wide range of industries and applications. Its cost efficiency, performance, and customization options make it an attractive choice for businesses, while its potential for recycling and biodegradability addresses environmental concerns. As advancements in technology and sustainability practices continue, PE film will remain a valuable component of modern industry, balancing functionality with environmental responsibility.

FAQS

1. What is PE film made of?

PE film is made from polyethylene, a thermoplastic polymer derived from ethylene. Polyethylene is produced through a polymerization process and can be manufactured in various densities, resulting in different types of PE film such as High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE). These films are known for their durability, flexibility, and resistance to moisture and chemicals.

2. What are the main types of PE film and their differences?

There are two primary types of PE film:

1. High-Density Polyethylene (HDPE) Film:

HDPE film is characterized by its high strength-to-density ratio, making it more rigid and less permeable. It is commonly used in applications that require durability and puncture resistance, such as industrial packaging, geomembranes, and certain construction uses.

2. Low-Density Polyethylene (LDPE) Film:

LDPE film is more flexible and has a lower density compared to HDPE film. It is softer and more stretchable, making it ideal for applications that require flexibility and clarity, such as plastic bags, shrink wraps, and agricultural films.

3. In which industries is PE film commonly used?

PE film is utilized across a wide range of industries due to its versatility:

1. Packaging Industry:

PE film is used for creating bags, pouches, and wraps that protect goods from moisture, dust, and contamination. It is particularly prevalent in the food industry for packaging perishable items and in pharmaceuticals for safeguarding sensitive products.

2. Agriculture:

PE film is used for greenhouse covers, mulch films, and silage wraps, helping to enhance crop yields, conserve soil moisture, suppress weeds, and protect stored forage crops from spoilage.

3. Construction:

PE film serves as a vapor barrier in buildings, protecting against moisture and improving energy efficiency. It is also used to cover materials and equipment, shielding them from dust, debris, and weather conditions.

4. Industrial Applications:

PE film is used for lining and covering purposes, including pond liners, landfill liners, and containment membranes in various industrial settings.

4. What are the key benefits of using PE film?

PE film offers several advantages:

1. Cost Efficiency:

PE film is cost-effective compared to many alternative materials, with lower production, transportation, and storage expenses. This affordability allows businesses to optimize their budgets while maintaining quality and performance.

2. Performance and Protection:

PE film provides excellent protection against external elements such as moisture, chemicals, and contaminants, ensuring that the contents remain safe and intact. This is crucial for maintaining the quality and shelf life of products, particularly in the food and pharmaceutical industries.

3. Customization:

Advances in manufacturing technology allow for extensive customization of PE film. Companies can produce films with specific properties, such as UV resistance, anti-static, and anti-fog capabilities. Additionally, PE film can be printed with logos, brand messages, and product information, enhancing brand visibility and customer engagement.

4. Environmental Sustainability:

PE film is recyclable, and advancements in biodegradable options offer eco-friendly alternatives that break down more easily in natural environments. Recycling and biodegradable PE films contribute to reducing the environmental impact of plastic waste.

5. How does PE film contribute to environmental sustainability?

PE film can be environmentally friendly through several approaches:

1. Recycling:

PE film is recyclable, and many recycling programs accept it. The recycling process involves cleaning, melting, and reprocessing the plastic into new products, which reduces the demand for virgin materials and minimizes environmental impact. Proper participation in recycling programs is essential to maximize the benefits.

2. Biodegradable PE Film:

Biodegradable PE films are designed to decompose more quickly than traditional plastic films. These films are typically made from a blend of polyethylene and biodegradable additives or alternative materials such as starch. They offer an eco-friendly alternative, provided they meet specific environmental standards and certifications to validate their biodegradability.

3. Regulatory Compliance:

Compliance with international regulations and standards ensures that the production, use, and disposal of PE film adhere to sustainable practices. Regulations such

0 notes

Text

From Packaging to Piping: HDPE Sheets in Various Industries

High-density polyethylene (HDPE) sheets have revolutionized various industries due to their versatility, durability, and cost-effectiveness. Known for their high strength-to-density ratio, HDPE sheets have become indispensable in fields ranging from packaging to piping. This article explores the multifaceted applications of HDPE sheets and how they have become a vital component in numerous industrial processes. Keywords such as "hdpe sheet price," "hdpe sheet suppliers," and "hdpe sheet thickness" will also be discussed to provide a comprehensive understanding of this material's significance.

HDPE Sheets in the Packaging Industry

The packaging industry relies heavily on HDPE sheets due to their excellent moisture resistance, chemical resistance, and durability. These properties make HDPE sheets ideal for creating sturdy packaging that can protect goods during transportation and storage. HDPE sheets are used to produce a variety of packaging products, including bottles, containers, and liners. Their flexibility allows for easy molding into different shapes and sizes, catering to specific packaging needs.

The cost-effectiveness of HDPE sheets is another crucial factor for their widespread use in packaging. When considering the hdpe sheet price, businesses find that investing in HDPE packaging solutions offers a good return on investment due to their long lifespan and reliability. HDPE sheet suppliers provide a range of options in terms of size and thickness, ensuring that companies can find the perfect material to meet their packaging requirements.

HDPE Sheets in the Construction Industry

In the construction industry, HDPE sheets are valued for their robustness and resistance to environmental stress. They are used in various applications, including as liners for ponds and canals, as well as for roofing and wall protection. HDPE sheets provide an effective barrier against water and chemicals, making them ideal for waterproofing and protective layering.

The versatility of HDPE sheet thickness allows construction professionals to select the appropriate grade for different projects. Thicker sheets are used for applications requiring greater strength and durability, while thinner sheets are sufficient for less demanding tasks. The availability of HDPE sheets in various thicknesses from hdpe sheet suppliers ensures that construction projects can be completed with the most suitable materials, enhancing overall efficiency and durability.

HDPE Sheets in the Agricultural Sector

Agriculture is another industry that benefits significantly from the use of HDPE sheets. Farmers and agricultural businesses use these sheets for lining irrigation channels, creating durable storage tanks, and constructing greenhouses. The UV resistance and weatherproof nature of HDPE sheets make them ideal for outdoor agricultural applications.

The economic aspect, including the hdpe sheet price, plays a crucial role in their adoption in agriculture. HDPE sheets offer a cost-effective solution for long-term agricultural infrastructure. Additionally, hdpe sheet suppliers provide materials that are easy to handle and install, which is essential for large-scale agricultural operations. The varied hdpe sheet thickness options allow for customization according to the specific needs of different agricultural projects.

HDPE Sheets in the Automotive Industry

The automotive industry utilizes HDPE sheets in various components due to their lightweight and durable nature. HDPE sheets are used in manufacturing car parts such as fuel tanks, door panels, and fenders. The impact resistance and strength of HDPE make it an excellent material for these applications, contributing to vehicle safety and longevity.

The affordability and availability of HDPE sheets also play a significant role in their use in the automotive sector. The competitive hdpe sheet price ensures that manufacturers can produce high-quality parts without incurring excessive costs. HDPE sheet suppliers offer a range of thicknesses, allowing automotive engineers to select the most appropriate materials for different parts of the vehicle, optimizing performance and cost-efficiency.

HDPE Sheets in the Chemical Industry

In the chemical industry, the non-reactive and chemical-resistant properties of HDPE sheets are highly valued. These sheets are used to line chemical tanks, create protective barriers, and fabricate containers that store hazardous substances. The ability of HDPE sheets to withstand corrosive environments ensures the safe storage and handling of chemicals.

HDPE Sheets in the Marine Industry

The marine industry benefits from the use of HDPE sheets in the construction of boats, docks, and other water-related structures. HDPE sheets' resistance to water, salt, and UV radiation makes them ideal for marine applications. These sheets do not corrode or degrade easily, ensuring long-lasting performance in harsh marine environments.

HDPE Sheets in the Healthcare Industry

In healthcare, HDPE sheets are used to manufacture medical devices, hospital equipment, and sterile packaging. Their chemical resistance and ease of sterilization make HDPE sheets ideal for medical applications where hygiene and safety are paramount. HDPE sheets are also used to create clean room environments and protective barriers in medical facilities.

HDPE Sheets in the Environmental Sector

Environmental applications of HDPE sheets include waste management, landfill liners, and recycling systems. The durability and impermeability of HDPE sheets make them suitable for containing waste and preventing contamination. HDPE sheets are also used in the construction of recycling facilities and equipment, contributing to sustainable waste management practices.

The cost-effectiveness and availability of HDPE sheets are crucial for environmental projects, where budget constraints are often a concern. The competitive HDPE sheet price allows for the implementation of effective waste management solutions without compromising quality. HDPE sheet suppliers provide a range of thicknesses to meet the specific requirements of different environmental applications, ensuring that these projects are both efficient and sustainable.

Conclusion

HDPE sheets have proven to be a versatile and essential material across various industries. From packaging to piping, their applications are vast and varied, driven by their durability, chemical resistance, and cost-effectiveness. Keywords such as "hdpe sheet price," "hdpe sheet suppliers," and "hdpe sheet thickness" highlight the economic and practical considerations that make HDPE sheets a preferred choice in many fields. As industries continue to evolve and seek efficient, sustainable solutions, the role of HDPE sheets is likely to expand, further solidifying their place as a cornerstone material in modern industrial applications.

FAQs

What are the key benefits of using HDPE sheets? HDPE sheets offer several benefits, including high impact resistance, chemical resistance, moisture resistance, and durability. They are lightweight, easy to handle, and suitable for a wide range of temperatures.

Can HDPE sheets be recycled? Yes, HDPE sheets are recyclable. They can be reprocessed into new products, reducing plastic waste and contributing to environmental sustainability.

How to choose the right HDPE sheet suppliers? When choosing HDPE sheet suppliers, consider factors such as the supplier's reputation, product quality, customer reviews, and after-sales support. It's essential to ensure the supplier provides detailed information about the product specifications.

0 notes

Text

Stress-Free Ponds: Uncovering the Best Cleaning Service

Your pond is a haven of beauty, tranquility, and wildlife. But keeping it sparkling clean is a chore. Pond cleaning services can help, but choosing the right one can be tricky.

Know Your Pond:

Before searching, consider your pond's size, type (natural/liner), fish/plants, and desired cleaning frequency.

Finding the Perfect Fit:

Research companies with experience in similar ponds and certifications. Ensure their services match your needs (natural ponds, fish care, etc.) and prioritize eco-friendly methods. Verify proper insurance and licensing, and check online reviews or ask for referrals.

Consultation is Key:

A good service, like Reflections Water Garden, offers free consultations to discuss your expectations, their process, and pricing.

Invest Wisely:

Compare quotes and services before choosing. A reliable company fosters a long-term partnership, ensuring consistent care for your backyard paradise.

0 notes

Text

Fish Pond Liner Manufacturer in India

Craft a beautiful and functional fish pond with a reliable liner manufactured in India. High-density polyethylene (HDPE) pond liners are prized for their strength and longevity, making them a perfect choice for your project. Among the leading Indian manufacturers is Pulkit Plastic Products, a company that supplies top-notch HDPE geomembrane sheets domestically and exports them worldwide. Their dedication to excellence guarantees you receive a premium pond liner built to last for years.

#HDPEPondLiner, #GeomembraneSheet, #LargePondLiners, #PulkitPlasticProductsFishPondLiner, #PlasticSheetForAgriculture

#manufacturer#plastic#supplier#polypropylene#HDPEPondLiner#GeomembraneSheet#LargePondLiners#PulkitPlasticProductsFishPondLiner#PlasticSheetForAgriculture

0 notes

Text

Geomembrane Sheet: Durable Waterproof Barrier for Environmental Protection

Introduction

In the realm of environmental protection and civil engineering, geomembranes play a pivotal role as durable waterproof barriers. These engineered sheets, manufactured by leading companies like Geo membrane manufacturers in India and Geomembrane manufacturers in Ahmedabad, serve multifaceted purposes across various industries. Let's explore the uses, benefits, advantages, and overall impact of geomembrane sheets in environmental conservation and infrastructure development.

Uses

Waste Containment: One of the primary uses of geomembranes is in waste containment systems. They prevent the migration of contaminants into surrounding soil and groundwater, thus safeguarding the environment from pollution caused by landfills and hazardous waste sites.

Water Storage: Geomembrane liners are used in reservoirs, ponds, and canals for efficient water storage. They prevent seepage and leakage, ensuring water conservation and supply reliability.

Mining Industry: Geomembranes are utilized in mining operations to contain and manage mine tailings, reducing environmental impact by preventing the release of harmful substances. Geomembrane manufacturers in India offer high-quality solutions tailored to the specific needs of mining projects, ensuring effective containment and environmental protection.

Landscaping: They are employed in landscaping projects for lining artificial ponds, golf course water features, and decorative water bodies.

Agricultural Applications: Geomembranes aid in irrigation and water management by lining canals and agricultural ponds, optimizing water usage and preventing water loss.

Benefits and Advantages

Waterproofing: They provide effective waterproofing, crucial in applications like reservoirs and containment systems, where preventing leakage is paramount.

Chemical Resistance: Geomembranes exhibit resistance to a wide range of chemicals, making them suitable for applications involving exposure to various substances.

Environmental Protection: By containing pollutants and preventing soil contamination, geomembranes contribute significantly to environmental conservation.

Ease of Installation: Geomembranes are relatively easy to install, reducing labor costs and project timelines.

Conclusion

In conclusion, geomembrane sheets manufactured by industry leaders like Geo membrane manufacturers in India and Geomembrane manufacturers in Ahmedabad represent a vital component in modern environmental engineering and infrastructure development. Their versatility, durability, and effectiveness make them indispensable in projects aimed at protecting our natural resources and promoting sustainable practices. FAQs (Frequently Asked Questions) Q1: What materials are geomembranes typically made from? Ans- Geomembranes are commonly made from materials such as HDPE (High-Density Polyethylene), PVC (Polyvinyl Chloride), EPDM (Ethylene Propylene Diene Monomer), and LLDPE (Linear Low-Density Polyethylene).

Q2: How are geomembranes installed? Ans- Geomembranes are typically installed by unrolling the sheets over prepared surfaces and sealing the seams using heat fusion, adhesive bonding, or mechanical methods.

Q3: Can geomembranes be recycled? Ans- Yes, some types of geomembranes, especially those made from recyclable plastics like HDPE, can be recycled after their service life, contributing to sustainability efforts.

Q4: What factors should be considered when selecting a geomembrane for a project? Ans- Important factors include the type of containment, site conditions (including soil characteristics and potential chemical exposure), required longevity, and installation method.

In summary, geomembrane sheets are a cornerstone of environmental protection, offering effective solutions for waterproofing and containment across a spectrum of applications. Collaborating with reputable manufacturers like those in India ensures access to high-quality geomembrane products that meet stringent industry standards and contribute positively to sustainable development goals.

#geo membrane manufacturers in india#geomembrane manufacturers in Ahmedabad#geomembrane manufacturers in india

0 notes

Text

Top Geomembrane Suppliers in India: Providing Quality Solutions for Environmental Protection

The environment faces numerous challenges, and safeguarding it requires innovative solutions. Geomembranes, impermeable liners made from high-performance materials, play a crucial role in various environmental protection applications. This blog, by Singhal Industries, a manufacturer of flexible packaging solutions, explores the importance of geomembranes and highlights the leading Geomembrane suppliers India.

The Power of Geomembranes: Beyond Liners

Geomembranes are more than just liners; they offer a multitude of benefits for environmental protection:

Containment and Containment: Geomembranes act as effective barriers, containing pollutants like landfill leachate, industrial wastewater, and hazardous materials, preventing them from contaminating soil and groundwater.

Longevity and Durability: These liners are designed to withstand harsh environmental conditions and resist degradation for extended periods.

Versatility: Geomembranes come in various materials and thicknesses, catering to diverse applications, from landfills and containment ponds to canals and infrastructure projects.

Leak Prevention: High-quality geomembranes minimize the risk of leaks, ensuring the protection of the surrounding environment from harmful substances.

The Rise of the Geomembrane Industry in India: A Growing Commitment

India's geomembrane industry has witnessed significant growth in recent years due to several factors:

Focus on Environmental Sustainability: The Indian government is prioritizing environmental protection, leading to increased demand for geomembrane solutions in landfills, wastewater treatment plants, and mining projects.

Infrastructure Development: Rapid infrastructure development across India necessitates effective containment measures for construction projects, driving the demand for geomembrane liners.

Technological Advancements: The development of new geomembrane materials with enhanced properties ensures better performance and longer lifespans.

Increased Awareness: Growing public awareness about environmental issues fuels the demand for reliable geomembrane solutions.

Leading the Charge: Top Geomembrane Suppliers in India

The Indian ghdpe Geomembrane manufacturers landscape boasts a diverse range of companies catering to various needs and project requirements. While we cannot directly promote specific companies, this blog acknowledges the vital role they play in environmental protection:

Choosing the Right Geomembrane Supplier: Key Considerations

Material Expertise: Look for suppliers offering geomembranes made from high-quality materials suitable for your specific application.

Product Range and Thickness Options: Choose a supplier with a diverse product range to ensure you find the right thickness and material for your project needs.

Quality Certifications: Opt for suppliers whose geomembranes comply with relevant industry standards and quality certifications.

Installation and Support: Consider suppliers who offer installation guidance or partner with qualified installation contractors.

Singhal Industries: Your Partner in Flexible Packaging Innovation

At Singhal Industries, our core focus lies in innovative flexible packaging solutions. While we don't directly manufacture geomembranes, we understand the importance of developing durable and reliable flexible materials. The advancements in geomembrane technology and their positive impact on environmental protection resonate with our commitment to innovation for a sustainable future. Our expertise in material science positions us to appreciate the role these liners play in safeguarding our environment.

The Future of Geomembranes: A Sustainable Trajectory

The future of Geomembrane manufacturers India, with a focus on:

Sustainable Materials: Research and development are underway to create geomembranes from recycled materials or bio-based polymers, minimizing environmental impact throughout the product lifecycle.

Improved Durability and Longevity: Advancements in material science can lead to geomembranes with even greater resistance to degradation, extending their lifespan and reducing replacement needs.

Advanced Joining Technologies: Innovations in geomembrane joining techniques can ensure stronger and more reliable seams, minimizing the risk of leaks.

By working together – geomembrane suppliers, project developers, and government agencies – we can ensure a future where our environment is protected for generations to come. Let's embrace sustainable practices, utilize high-quality geomembranes, and work towards a cleaner and healthier planet.

FAQS

What is a geomembrane, and what are its primary functions? Geomembranes are synthetic liners or barriers used in various environmental protection applications, including containment of liquids, solids, and gases. They serve as impermeable membranes to prevent the migration of contaminants, control fluid flow, and protect the environment.

What materials are geomembranes typically made of? Geomembranes are commonly made from high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), ethylene propylene diene monomer (EPDM), and other synthetic polymers. Each material offers specific properties suited to different environmental conditions and containment requirements.

What are the primary applications of geomembranes? Geomembranes find widespread use in applications such as landfill liners, mining and pond liners, wastewater treatment facilities, agricultural and aquaculture ponds, canal and reservoir lining, and environmental remediation projects.

How are geomembranes installed and maintained? Geomembranes are installed by trained professionals using specialized equipment and techniques such as welding, seaming, and anchoring. Proper installation is crucial for ensuring the integrity and effectiveness of the liner. Maintenance typically involves regular inspections for damage, punctures, or deterioration and prompt repairs as needed.

What factors should be considered when selecting a geomembrane for a specific project? Factors such as environmental conditions, site characteristics, required containment properties, chemical resistance, UV stability, installation method, and budget should be considered when selecting a geomembrane. Consulting with experienced suppliers and engineers can help determine the most suitable option for a particular application.

0 notes

Text

Investment Opportunities in the Asia-Pacific Shrimp Sector

The Asia-Pacific region has long been a hub for seafood production, with its vast coastlines and favourable climate providing ideal conditions for aquaculture. Among the various seafood options, shrimp stands out as a particularly lucrative sector, offering significant investment opportunities. In this blog post, we will delve into the Asia-Pacific shrimp market, exploring its potential for growth and why investors should consider this sector for their portfolios.

Understanding the Asia-Pacific Shrimp Market

The Asia-Pacific region dominates the global shrimp market, accounting for a substantial share of both production and consumption. Countries such as China, India, Vietnam, Indonesia, and Thailand are major players in shrimp farming, collectively contributing to the region's market dominance. According to recent industry reports, the Asia-Pacific shrimp market is projected to experience robust growth in the coming years, driven by several key factors.

Factors Driving Growth

Rising Demand: Shrimp is a highly sought-after seafood item globally, thanks to its versatile culinary uses and perceived health benefits. As disposable incomes rise in emerging economies across Asia-Pacific, so does the demand for premium seafood, including shrimp.

Export Opportunities: Many Asia-Pacific countries are major exporters of shrimp, supplying markets worldwide. This export-oriented approach opens up significant avenues for growth, especially as international demand for sustainably sourced seafood continues to increase.

Technological Advancements: The shrimp farming industry has seen notable advancements in technology, leading to improved production efficiency, disease management, and sustainability. This enhances the sector's appeal to investors looking for innovative and environmentally conscious opportunities.

Government Support: Governments in several Asia-Pacific nations are actively supporting the aquaculture industry through policies and incentives. This support creates a conducive environment for investment and growth.

Investment Opportunities

Aquaculture Companies

Investing in aquaculture companies involved in shrimp farming is a direct way to tap into the Asia-Pacific shrimp market. These companies often have established operations, access to prime shrimp farming regions, and expertise in breeding high-quality shrimp.

Key Players:

CP Foods (Thailand): One of the largest shrimp producers globally, CP Foods has a strong presence in the Asia-Pacific region.

Charoen Pokphand Indonesia: This Indonesian company is a significant player in the shrimp sector, benefiting from Indonesia's favourable aquaculture conditions.

Vietnam Shrimp Company: Vietnam is a key exporter of shrimp, and investing in leading Vietnamese shrimp producers can offer exposure to this growing market.

Technology and Equipment Suppliers

Another avenue for investment is in companies that provide technology and equipment for shrimp farming. This includes companies specialising in feed, water treatment systems, pond liners, and disease management solutions.

Key Suppliers:

Thai Union Group: Although primarily known for its seafood processing, Thai Union also invests in aquaculture technologies, making it a diversified option for investors.

Charoen Pokphand Foods (CP Foods): In addition to its farming operations, CP Foods is a major supplier of aquaculture equipment and technologies.

Sustainable Shrimp Farming

With increasing focus on sustainability, investors can explore opportunities in companies that prioritise environmentally friendly shrimp farming practices. This includes firms adopting responsible sourcing, organic certifications, and eco-friendly production methods.

Eco-Friendly Farms:

BAP-Certified Farms: Best Aquaculture Practices (BAP) certification ensures that shrimp farms meet stringent environmental and social standards. Investing in BAP-certified farms supports sustainability while tapping into premium markets.

Challenges and Considerations

While the Asia-Pacific shrimp market presents significant opportunities, investors should be aware of potential challenges:

Disease Risks: Shrimp farming can be susceptible to diseases that may impact production and profitability. Investing in companies with robust disease management protocols is crucial.

Environmental Concerns: Intensive shrimp farming can lead to environmental degradation if not managed sustainably. Companies with strong sustainability practices are better positioned for long-term success.

Market Volatility: Like any commodity, shrimp prices can fluctuate due to various factors such as weather events, supply chain disruptions, and currency fluctuations. Diversification within the sector can mitigate this risk.

Conclusion

The Asia-Pacific shrimp market offers compelling investment opportunities driven by rising demand, export potential, technological advancements, and government support. Whether investing in established aquaculture companies, technology suppliers, or sustainable farming practices, there are various avenues for investors to participate in this thriving sector.

As with any investment, thorough research and due diligence are essential. Investors should consider factors such as company performance, sustainability practices, market trends, and risk management strategies. By navigating these considerations, investors can capitalise on the growth potential of the Asia-Pacific shrimp market while contributing to the sustainable development of the aquaculture industry.

In conclusion, the Asia-Pacific shrimp market is a dynamic and promising sector for investors seeking exposure to the seafood industry's growth story. With its blend of tradition, innovation, and sustainability, shrimp farming in the region presents a compelling case for long-term investment.

Keyword: Asia-Pacific Shrimp Market

Investment opportunities in the Asia-Pacific shrimp market are ripe for exploration, offering a blend of tradition, innovation, and sustainability. As demand for premium seafood rises and technology advances, investors can tap into this thriving sector through aquaculture companies, technology suppliers, and sustainable farming practices. With careful consideration of market trends and risk factors, investing in the Asia-Pacific shrimp market can be a rewarding venture for those looking to diversify their portfolios and participate in the region's seafood growth story.

0 notes

Text

HDPE Pond Liner Manufacturer & Supplier in India | Solos Polymers

Solos Polymers is one of the globally trusted flexible packaging company. We are the manufacturer, supplier and exporter of Pond Liners.

#PondLiners#PondLinerSuppliers#FishPondLiners#PlasticPondLiner#LargePondLiners#RoundPondLiner#ColoredPondLiners#SquarePondLiner#WaterfallLiner#FountainLiner#CustomPondLiners#FIBC#India#USA#UnitedStates#NewYork#America

0 notes

Text

0 notes

Text

Tandhan Polyplast, for the best solution to all your tarp issues

Tandhan Polyplast Private Limited is one of the leading enterprises in manufacturing, trading and exporting of the Tarpaulin, cross laminated multilayered and mono layered tarpaulins, Ponchos, Roof Covers, Vehicle covers, Pond Liners, and other products to different corners of the globe. The company is pioneer in its products and customer service provided to all its valued customers. The company…

View On WordPress

0 notes