#pearlites

Explore tagged Tumblr posts

Text

New oc alert

#artists on tumblr#art#warrior cats#my art shit#cats#wcue#warriors#Crocodile wc#Pearlite wc#Ocs#oc art#oc artwork#:)

13 notes

·

View notes

Text

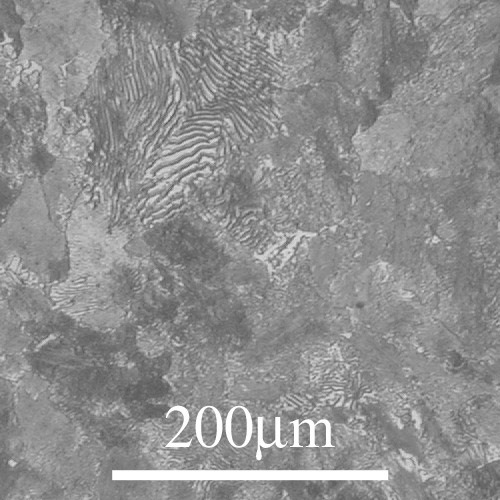

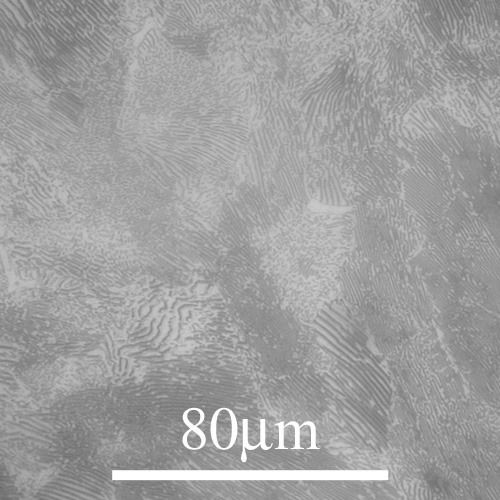

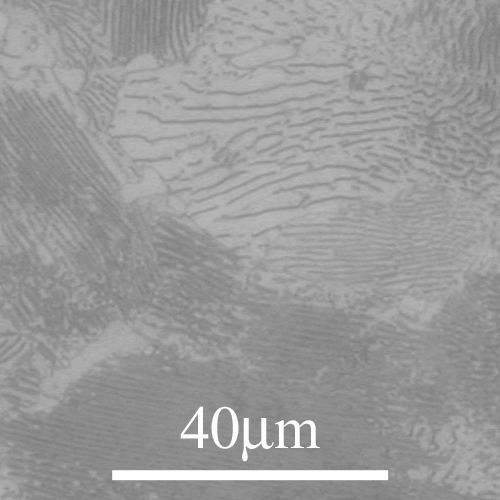

Fe, C 0.8 (wt%), eutectoid transformation - pearlite (coarse)

Processing Slow cooled [...] Technique Reflected light microscopy Length bar 200 μm / 80 µm / 40 µm Further information This steel is of the eutectoid composition. Once the temperature is lowered below the eutectoid temperature the steel becomes simultaneously supersaturated with both ferrite and cementite. A eutectoid transformation results (g to a + Fe3C). The resultant microstructure, known as pearlite, comprises lamellae of cementite (dark) embedded in ferrite (white). The platelets are parallel to each other and do not follow a specific crystallographic direction. Each pearlite colony is made up of a number of subgrains. Thus each pearlite colony consists of two interpenetrating single crystals having an orientation relationship with respect to each other and with respect to the austenite grain they grow from, but not with respect to the austenite grain they have grown into. Changes in the apparent interlamellar spacing from colony to colony in the photograph are due to differences in the lamellae spacing with respect to the polished surface. The coarseness of the pearlite is determined by the interlamellar spacing. This spacing is inversely proportional to the undercooling. This is primarily because of the increased rate of carbide nucleation with increased undercooling. The pearlite in this sample is coarse due to it being slowly cooled. The undercooling is low so the lamellae spacing is relatively large resulting in a coarse microstructure. [...] Organisation Department of Materials Science and Metallurgy, University of Cambridge

Sources: ( 1 ) ( 2 ) ( 3 )

#Materials Science#Science#Pearlite#Microstructures#Steel#Alloys#Magnified view#Optical microscopy#DoITPoMS#University of Cambridge

19 notes

·

View notes

Text

I just opened up my last survival world after three months of not playing minecraft. In that world I decided to focus on exploration and the joy of simply "finding things", so as soon as I got some leather, paper, and an inc sack, I kept an in-game & in-character diary.

It was nice to be able to read back on what I'd been doing (I was only 8 days in) and I decided to explore a bit and get my bearings again.

So I'm walking back to my temporary settlement from a nearby village, and wanna know what I found? Just chilling out in the open?

A pink sheep.

0.164% chance of spawning.

I've set her up in a little pen & cheated a name tag in so she doesn't despawn. I am beaming.

#minecraft#minecraft survival#pink sheep#ive named her “Pearlite” for now but im open to suggestions#posting this moment so future me never forgets#fav

19 notes

·

View notes

Text

using routines and algorithms to analyse images means at some point you have to decide if that specific shade of grey is or isn't something you want to take into account and it will have a 1% influence on your result which is actually significant for the thing you're doing so yeah that's FUN

#going to live in the woods because if i have to look at pearlite for one more minute i will rip my eyes out#worst of all is that to actually know you'd need to put it in the sem

1 note

·

View note

Text

High Standard Sentinel R-101 snub nose revolver in the sought-after turquoise and chrome finish9-shot snub nose revolver in .22 caliber with 2 3/8 inch barrel, salt blued sights, turquoise anodized frame, chromed small parts, and smooth pearlite grips.

23 notes

·

View notes

Text

This is my attempt at a brinkborg wedding cake that just tuned into a mini cake and some cupcakes with my ideas for the wedding under this

Bart would be the officiant/wedding planner/musician

Dr.Ahem/ maybe Bart or mudd would walk kyborg down the use

Gum Gum would be the flower person and gumbo would help out

Fred and Hannibal would be the ring bearers (

Mudd would be kyborgs best man

Pearlite would be Brinks best man

Sleique would have been really sad he wasn’t the best man and spectril would have to convince him he was still wanted. kyborg would have tried to give him a fake date but everyone else would have felt bad and he would have eventually came and helped Bart with the music and kyborg would have pretended it was bad music but he would actually love it.

(To be possibly continued)

#tftsd#tales from the stinky dragon#stinkydragonpod#I can probably think of more ideas for this just not right now#also I can’t decide if the wedding would be fancy or casual#noname talks

23 notes

·

View notes

Note

Hello! I adore your blog and have been following for a long while! I'm struggling with a name currently. Could I please get some names with a fem feel related to space or crystals? Thank you so much if you take this on.

hi love! welcome back! im so sorry it took us so long to open up again and i love the themes you picked.

i hope these help! if not im happy to make another list with more names!

space fem names:

astra, astrea, astre/astray, astral, astora, aurora, andromeda, astrid, astera bellatrix cassiopeia, celeste, celestia, cosmette, cosmica, cosmicia, comette

estel/estell/estelle, estella galactica, galaxia, galaxie lyra

nova planette stel/stell/stelle, stella, spacey/spacie, spacette

crystal fem names:

amber beryl crystal/crystalle, crystelle, crystella, crystaline/crystalline, coral/corral, coraline, coralie, citrine, citrina, carnelia, celestine

diamond, diamonda esmerelda/esmeralda, emeralda/emerelda gernet/garnett/garnette, gem/gemm, gemma, gemmalyn, giada

jade/jaide/jayde, jewel, jewela, jewelie(julie), jemsa meralda opal, opaline, opalite pearl, pearly, pearline, pearlite

rubetta, rubette, rubine, rubinia, ruby/rubi/rubie selen, selene, seleni, selenite, safira/sapphira, sapphire tiffany/tiffani/tiffanie yulla

#name blog#name list#names#list of names#names list#baby names#first names#name inspiration#name suggestions#name ideas#space names#crystal names#name request#requested#requested names#requested list#request answered#anon answered#nonnie requests

28 notes

·

View notes

Text

Writers, readers, if you've ever wondered how medieval blacksmiths knew exactly when to quench a blade to make it a certain type of hardness...here you go, the secrets exposed & explained scientifically, replete with color chart, heat ranges, and an explanation of which tempering type is useful for which type of metal you want to create.

I can't remember if it was in the BBC series Secrets of the Castle or in the series Tudor Monastic Farm, but at one point the presenters (same clutch of people in both shows, lol) go to a blacksmithing forge to discuss getting a stonecutting chisel re-shaped and re-hardened. (I honestly think it's in Secrets, since they're constantly having to re-make the chisels as they wear down from the quarrying and masonry work, but can't find the exact moment, sorry. It's totally worth watching both series imho, though!)

Anyway, the blacksmith literally shows a golden sheen reaching the tip of the chisel...and quickly quenches it to freeze the molecules of the metal to the right ratio between toughness (versus being brittle, causing it to spall and break) and hardness (versus being too soft to hold the point for a reasonable length of operational time), in order to be a good stone chisel.

This, by the way, is why scrubbing the iron toward the end of it being forged is so important, because these color-changes are iron oxides. So you genuinely want to remove the traces of all previous oxidation before putting it through one more round of heating, cooling, and quenching it at just the right moment.

This is also why clay would be applied to the non-edge parts of a blade, such as a katana, to help thermally insulate it from the brief high heat needed for creating a tempered edge sharp enough to be a literal razor-edge. The main body of the blade needs to be tough to resent bending and cracking, but the edge needs to be hard to hold its edge and not crumple like tinfoil.

Here's a quote from Wikipedia on the process of creating the "hamon" or "wavy line" on a katana blade: " The hamon outlines the transition between the region of harder martensitic steel at the blade's edge and the softer pearlitic steel at the center and back of the sword. This difference in hardness is the objective of the process; the appearance is purely a side effect. "

The "softness" being referenced in the quote refers to the resistance against cracking and breaking, which is the same as the "toughness" I mentioned above. For a medieval blacksmith (of any ironworking region around the world in a technologically comparable era), being able to gauge just the right moment to quench the iron/steel was absolutely vital to the success of their product. This in turn affected their reputation as a smith.

If John the Smith makes metal sheets that are flexible but not brittle (great for armor), but isn't good at making knife blades that are sharp, you go to him for the flexible metal panels to make you plate armor. If Stephen the Smith makes really sharp knives but can't make big panels without it cracking under stress, you go to him for the knife blades and go find someone else for the other stuff.

And if Claudette the Smith (because there were women blacksmiths!!) can do both types, and do them consistently to order, you go to Claudette the Smith, and you send your children to apprentice with Claudette the Smith if she'll take them on, and you hope & pray she imparts the secrets of her skills to her apprentices if she does take them on.

Anyway...that's how a pre-modern blacksmith would know how to temper their iron & steel to achieve specific types of metal for specific types of uses. So writers, if you want to slip a little bit of information & education into your stories about how it all works, hopefully this gives you a good starting point for doing some fun research!

4 notes

·

View notes

Text

0 notes

Text

💋Blonde Temptress – 1955 Pearlite Enterprises Classic

Collect it: https://coolstuffoutpost.com/b/ey8xY

💋 Blonde Temptress – 1955 Pearlite Enterprises Classic 💋

A sultry slice of mid-century glamour, this Special Publication from Pearlite Enterprises captures the timeless allure of the blonde bombshell in all her monochrome mystique.

📖 Details:

• Softcover digest format

• Just 4" x 5" – perfectly pocket-sized

• 32 pages of vintage black & white photography

• A treasure trove of classic charm and retro seduction

Whether you're a collector of vintage pin-up art, a fan of retro aesthetics, or just love the iconic beauty of the '50s — Blonde Temptress is a must-have.

✨ Small in size, big on old-school allure.

#BlondeTemptress#1950sGlamour#RetroPhotography#VintageVixen#PearliteEnterprises#PinupClassic#OldHollywoodStyle#PocketPinup#BlackAndWhiteBeauty#MidCenturyMuse#VintageCollectible#ClassicTemptation#GlamourArchives#vintagepinup#classicbeauty#figurestudy#pinup#collectiblemagazine#coolstuffoutpost#pinupart#timelessglamour#1950s

0 notes

Text

0 notes

Text

As cast carbon steel

Sample preparation Nital Technique Reflected light microscopy Length bar 400 μm / 200 µm Further information Low carbon steel with a microstructure consisting mostly of ferrite with the darker pearlite regions around the ferrite grains. Upon cooling the steel the ferrite forms initially, either on austenite grain boundaries or inclusions. This causes carbon to be partitioned into the austenite. Eventually the remaining austenite will be at the eutectoid condition and the transformation to pearlite will then take place. Contributor Dr R F Cochrane Organisation Department of Materials, University of Leeds

Sources: ( 1 ) ( 2 )

#Materials Science#Science#Microstructures#Optical microscopy#Magnified view#Steel#Casting#University of Leeds#DoITPoMS

9 notes

·

View notes

Note

1 and 27 for asks!!

1. What song makes you feel better?

OK this one is hard because i shift too much to have one specific song, but right now I'd say benny goodman by saint motel. You're gonna hear me in icicles forming.

https://open.spotify.com/track/37IRXXvOKvzHmwU3sJPhJd?si=vgSJSL6_Qhqhi9gErzoyWw

Ever since i saw saint motel in concert last year its like 80% of their songs scratch an itch in my brain nd gives me motivation to keep going

27. Do you like to garden? Have you ever grown something?

I do like gardening!! But I kinda suck at it hehe, I grew a strawberry plant outside last year and its still alive but kinda choked out by weeds TT. My pride and joy is a tiny monstera plant that is kinda indestructable, lives in my bathroom & taught me how to propogate roots. (Its been on my to do list to get it pearlite soil for way too long... TT)

1 note

·

View note

Note

favorite word?

"Sanguine! It sounds a little funny. I guess, I could also say... maybe, defenestrating? Something about windows, I don't completely remember what it means. Oh, I like aviator, too; so, errh... Airy, and spacey. But If I had to, I'd pick sanguine! I definitely love that one. :o)" -Maybevisor

"Nebula is a nice word. It reminds me of people I know, and some of the experiences that I have had. Fluorescent is a nice word, too. I work with light a lot... maybe that's where it comes from." -Yesvisor

"Alloy... or pearlite. If I had to choose, most likely, pearlite. Metal, something so cold and undying... so unfeeling, and stinging..." -Novisor

1 note

·

View note

Note

I'm confused about your accusations as a reader of WOF

you say aqua and auklet show signs of being from the same system

just because they are both from similar source?

i know at least a dozen systems with WOF sourced headmates

and some communities are tight-knit

i don't blame you for any other points but this one just feels like you're stretching as hard as possible to make every point possible that they are that blog..

~🔆🎀

That was from Pearlite's post. I didn't write it myself. You can read the whole thing here:

Here's another screenshot from that post:

Some of it, I'll admit, seems a little tenuous. But I do think they can be relevant when taken together.

How many systems have headmates sourced from WoF? Probably a lot, but it narrows things down?

Of those from that source, how many are pro-endo who have expressed anti-willogenic views?

How many have dismissed people who want to be systems because being a system is not "silly little guys in your head"?

How many have said transplurals "make a mockey" of trans people?

And from the last post on the subject, how many have used the exact phrase "nothing is impossible with systems" to refer to an ideology they see as too accepting? (The answer is none. That particular string of words seems exclusive to those two blogs.)

I don't think the source itself really shows that much, and I'm not sure if I would have brought attention to it myself had I made the post, but it is another piece when added to all the others.

4 notes

·

View notes

Text

The Science Behind Strength: Understanding TMT Bars Manufacturing

TMT (Thermo-Mechanically Treated) bars are a vital component in modern construction, known for their superior strength, flexibility, and durability. The manufacturing process of TMT bars integrates advanced metallurgical science to ensure these bars meet the rigorous demands of structural applications. Here’s a look at the science behind their production:

1. Raw Material Selection: The process begins with high-quality billets made from iron ore, coal, or scrap metal. The purity and composition of the raw materials directly influence the final strength and flexibility of TMT bars.

2. Heating and Rolling: The billets are heated in a furnace to temperatures of around 1100°C. This makes the metal malleable and ready for shaping. The red-hot billets are then passed through a series of rolling stands to achieve the desired diameter.

3. Quenching: The hot-rolled bars are quickly cooled using a specialized water spray system. This rapid cooling, known as quenching, forms a hard martensitic layer on the surface while keeping the core hot and soft. This unique combination provides TMT bars with their characteristic strength and ductility.

4. Self-Tempering: After quenching, the residual heat from the core tempers the outer layer. This process, called self-tempering, transforms the martensitic surface into a tempered martensite, enhancing toughness without compromising flexibility.

5. Atmospheric Cooling: The bars are then laid on cooling beds to normalize at room temperature. This gradual cooling process ensures uniform strength throughout the bar, resulting in a fine-grained ferrite-pearlite structure in the core.

6. Testing and Quality Control: To ensure reliability, TMT bars undergo rigorous testing for tensile strength, elongation, and bendability. Advanced machines and techniques ensure every bar meets industry standards, such as IS 1786 in India.

Advantages of TMT Bars: High Strength: Ideal for high-rise buildings, bridges, and other infrastructure.

Ductility: Allows for better energy absorption, which is crucial during seismic events.

Corrosion Resistance: Enhanced longevity in humid or saline environments.

Weldability: Facilitates easy fabrication without compromising strength

The science behind TMT bar manufactures involves a delicate balance of metallurgical processes. The result is a product that combines strength, flexibility, and durability, making it indispensable in the construction industry.

0 notes