#non-combustible-aluminium-sheet

Explore tagged Tumblr posts

Text

Aluminium Honeycomb Sheet: Know Its Benefits & Applications

An aluminium honeycomb sheet can be depicted as a sandwich plate that comes with a honeycomb structure at its core. It is inspired by the hexagonal shape of a natural honeycomb. This special structure makes its weight way lighter than other materials of the same volume. What is more, the overall stability and stiffness are also very good. Let us find out more about the honeycomb sheet in the following passages.

Benefits of Aluminium Honeycomb Sheet

Fire Resistance:

These panels are non-melting type and non-combustible with a fire rating of FR grade A2+. There is a hexagonal design honeycomb sheet in the core that prevents the fire from spreading rapidly.

Lightweight

Since the honeycomb sheet comes with a hollow core, it is of low density. Also, that is why the overall weight of the panel is light which makes it useful especially in aerospace engineering, metro coaches, as well as theatres.

Highly Efficient

The hexagonal honeycomb core connects with the aluminium skin on the top and bottom which makes an I-beam structure. This particular feature makes the panel highly durable and enables high-impact stress resistance.

Recyclable Material

The honeycomb panel is made with 100% recyclable and reusable aluminium alloy.

Hassle-free Installation

As these panels are lightweight and thin, they are easy to install. These can be easily installed with rivets and nuts as wall panels or in other applications.

Key Applications Of Honeycomb Sheet

These honeycomb sheets are suitable for installation in ceilings, Metro coaches, railway stations, facades, airports, etc. Suitable for both interior and exterior installation these are highly efficient and aesthetic.

Final Words

If you want to buy the best quality aluminium honeycomb sheet at the best prices, always deal with a trusted supplier. Only they offer premium quality products at competitive prices ensuring the best return on your investment.

2 notes

·

View notes

Text

EUROCORE, Where Strength and Safety Merge!

Aluminium Composite Panels (ACP Sheets) have quickly climbed the popularity charts of the Construction and Architectural world. The city skylines bear larger-than-life witnesses that ACPs are here to rule the roost in the exterior cladding material world. But then the world of interior décor is no less a witness! A peek at building interiors also reveals a growing transition towards exquisite ACPs to adorn and beautify interiors at offices, malls, hotels, airports, and residences.

The reasons for ACPs racing to the top of these popularity charts are manifold. Their beauty and elegance strike a chord within hearts, and give the owners and occupants a sense of joy and pride! But of course, when it comes to building material, popularity is a multi-parameter decision, with safety, security, strength, durability, cost, aesthetics, etc. also playing important roles in determining what gets to the top of the charts – and ACPs score well on all these fronts too.

In this article, we put the spotlight on EUROCORE – Aluminium Core Composite Panel – a specialized ACP with an extra focus on strength and fire safety – both of which are of uncompromising importance in the construction world. ACPs are traditionally sandwich panels comprising two aluminium sheets bonded to a non-aluminium core. However, EUROCORE Panels are a result of innovation in the core technology, which replaces combustible LDPE core with non-combustible Pure Aluminium Core, making them safer and stronger than the traditional ACPs.

When combined, the terminal trio – Fuel, Oxygen, and Heat can result in a fire disaster. EUROCORE Panels promote fire safety by eliminating one element i.e., ‘Fuel’ from this terminal trio. This is done by using a non-combustible Aluminium core instead of the combustible core used in ordinary ACPs. This simple yet brilliant move goes a long way in making the cladding fire-retardant thus restricting the upward spread of fire. Being non-combustible, they also prevent the formation of droplets, and this curtails the downward spread of fire too. Yet another advantage of the non-combustible core is that it does not produce toxic smoke which tends to suffocate people and add to the casualties. This is how EUROCORE Panels aid in containing fires, providing more time for evacuation and saving valuable lives and property in case of an unfortunate fire.

Having understood the safety angle of EUROCORE panels, let’s briefly explore its other benefits too.

Benefits of EUROCORE Panels

Fire Retardant, Safe, Secure

The fire-retardant benefit has already been dwelt on and it is indeed one of the greatest advantages of EUROCORE Panels. They also provide safety as it protects the building structure from weather conditions as well as from external dangers.

Cost-Efficient

EUROCORE Panels are among the most cost-efficient, safe, and value-for-money options among building cladding materials available today. What’s important to note is that they are economical, without compromising on safety and security. They also regulate the amount of sunlight that comes into the building, keeping the interiors cooler and thus bringing cost-efficiency in power bills too.

Durable and Sustainable

EUROCORE Panels are robust and long-lasting and come with the in-built strength of Aluminium, which is also free from corrosion. These panels are termite-resistant, scratch-resistant, and stain-resistant which means they last longer and look good even after years.

Light-Weight

Another great advantage of EUROCORE Panels is that they are very light in weight, and hence they are perfect for reducing the load on the structure as compared to other building materials. Though they are light in weight, they are very strong and offer the best strength-to-weight ratio. These sheets are easy to lift, adaptable, and construction-friendly.

Weather-Resistant

EUROCORE Panels are suitable for all kinds of weather as they do not warp or go out of shape. They are not affected by cold, heat, or rain, making them suitable for all kinds of weather. Furthermore, as a cladding material, these panels even protect the building structure against harsh weather conditions.

Low Maintenance Costs

EUROCORE Panels are easy to clean and do not require any complex maintenance. This is another great benefit as it does not involve high, recurrent maintenance costs.

Easy Installation

Since EUROCORE Panels do not involve complex installation, they can be set up quickly, economically, and without much hassle.

Aesthetically Appealing

EUROCORE panels come in a variety of colours, textures, and designs, adding to the beauty and elegance of building exteriors as well as interiors.

Thermal and Acoustic Insulation

These panels cut out the external sounds making the interiors peaceful. They also regulate the light and heat that come into the building, keeping out the harsh sunlight and yet letting in its gentle rays. Additionally, they provide insulation from the cold winds in winter. Thus, they are an effective way to insulate the interiors.

Environment-Friendly

EUROCORE panels do not use scarce resources, as they are made from aluminium which is said to be the most abundant metal in the earth's crust. They also last for decades thus avoiding the need for frequent replacement, and this helps avoid unnecessary waste generation. They are fully recyclable which means that even at the end of their life, they do not pollute the environment.

For those looking for a good, reliable, value-for-money building material, it would be prudent to check out EUROCORE – Aluminium Core Composite Panels from Eurobond which is a trusted name in ACPs, backed by two decades of experience, innovation, and trust. EUROCORE sheets come with fire-retardant properties and offer the best strength-to-weight ratio. These sheets are formable, construction friendly, and are also completely recyclable, making them an eco-friendly option. Non-combustible and very light in weight, they are safe, have low installation costs, and reduce load-bearing on the structure.

Furthermore, Eurobond offers the twin benefits of unmatched quality, coupled with unparalleled European designs. Choose from the wide variety of designs, colours, and textures to give your buildings the unique beauty they deserve – whether it is Offices or residences; Malls, Hotels, Multiplexes, Airport Terminals, or other Private and Public spaces. Eurobond’s steadfast commitment makes them a household name across the worldwide construction and corporate spheres. Choosing Eurobond is, therefore, a safe, stress-free way to decorate and protect your building exteriors as well as interiors with international standards of strength, beauty, elegance, and safety.

2 notes

·

View notes

Text

Colorbond Fence Installation Brisbane: Durable, Stylish and Built for Queensland Conditions

Choosing the right fencing solution for your Brisbane property isn’t just about marking boundaries—it’s about privacy, security, aesthetics, and longevity. As weather conditions, urban density, and visual preferences evolve across South East Queensland, Colorbond fence installation in Brisbane has become a go-to option for homeowners and businesses alike.

More than just a sleek, modern-looking material, Colorbond offers unmatched durability, design flexibility, and resistance to the elements. In this guide, we’ll walk through why Colorbond fencing continues to dominate the Brisbane market, what the installation process looks like, and how to choose the right contractor for the job.

What Is Colorbond and Why Is It Ideal for Fencing?

Colorbond is a pre-painted steel product manufactured by BlueScope, developed specifically for the Australian climate. It’s made with a zinc-aluminium core for rust resistance, a durable baked-on paint finish, and a design that allows for minimal maintenance over time.

For fencing, Colorbond panels are commonly installed between steel posts and rails to create a clean-lined, highly secure, and weather-resistant boundary. In Brisbane—where harsh sun, humidity, storms, and varying soil conditions can take a toll—Colorbond performs exceptionally well.

Key benefits of Colorbond fencing include:

Corrosion resistance, even in coastal or high-moisture zones

Low maintenance, with no need for repainting or sealing

Non-combustible, making it suitable for bushfire-prone areas

Clean, modern design with multiple colours and profile options

Enhanced privacy with no gaps or footholds

With such practical advantages, it’s no surprise that more locals are turning to trusted providers like EVO Landscapes colorbond fence installation brisbane to help them transform their properties with this high-performance material.

Where Colorbond Fencing Works Best in Brisbane

From suburban backyards to commercial properties and acreage sites, Colorbond fencing is suitable for a wide range of applications, including:

Residential boundary fencing – Secure and stylish, ideal for homes with pets or children.

Privacy screens and side gates – Effective at blocking views and reducing noise.

Pool enclosures – Fully compliant options available when installed to Australian Standards.

Garden divisions and retaining walls – Blends easily with landscaping and hardscape designs.

Commercial perimeters – Provides a low-maintenance, professional finish for business premises.

Whether you live in leafy Kenmore or coastal Wynnum, Colorbond adapts to the character of the suburb while providing year-round protection from Brisbane’s elements.

Curious how landscaping and fencing come together in a cohesive outdoor design? Check out this Tumblr blog post on modern garden structures for visual inspiration.

The Installation Process: What to Expect

Installing a Colorbond fence isn’t just a matter of dropping in panels. It requires careful planning, ground preparation, accurate levelling, and proper anchoring for long-term stability. Here's a general overview of what to expect:

1. Site Inspection and Measurement

An experienced installer will assess site slope, soil type, existing boundaries, and access. This is when decisions around panel height, colour, and layout are finalised.

2. Marking Out and Post Installation

Once approved, the boundary is marked and holes are drilled for posts, which are then concreted into position. Attention to spacing and level is critical.

3. Panel Assembly and Mounting

Colorbond sheets are then slid into position between rails and posts. The structure is secured with specialised fixings to withstand Brisbane’s weather extremes.

4. Finishing Touches

Capping rails, post caps, and gates are added for function and visual polish. Clean-up and removal of any leftover materials are also handled.

When working with professionals like EVO Landscapes colorbond fence installation brisbane, the process is efficient and tailored to the property’s unique features, including sloping blocks or shared boundary requirements.

Customising Your Colorbond Fence

Colorbond fences don’t have to be “one-size-fits-all.” They’re highly customisable, and this flexibility allows for a design that complements your home or commercial space.

Popular choices include:

Panel Heights: Typically 1.5m to 2.1m, depending on privacy needs.

Colours: From neutral tones like Surfmist and Basalt to deeper shades like Monument or Woodland Grey.

Lattice and slat extensions: Add aesthetic detail or boost height.

Stepped or raked designs: Accommodate sloped ground while maintaining consistency.

For creative takes on combining Colorbond with timber or stone, this Tumblr guide on landscape fusion highlights trends in layered fencing and structure.

Regulations and Brisbane Council Requirements

Before any fencing project begins, it’s important to check local council regulations. In Brisbane, most fences under 2m in height at the rear or side boundary do not require approval, but there are exceptions—particularly when fences are near roadways, involve retaining walls, or sit on flood-prone land.

Your installer should:

Confirm height and boundary compliance

Consult with neighbours when required under QLD law

Ensure setbacks and easement access are preserved

Provide wind rating adjustments if required

A provider like EVO Landscapes colorbond fence installation brisbane will handle these requirements for you, helping to avoid delays or compliance issues down the track.

Comparing Colorbond with Other Fencing Options

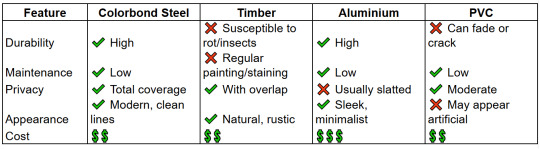

Still deciding if Colorbond is the right material for your needs? Here’s how it stacks up against common alternatives:

For most Brisbane conditions, Colorbond offers the best balance of resilience, ease of care, and value over time.

Maintenance Tips to Keep Your Fence Looking Sharp

Although Colorbond is low-maintenance, a little care ensures it looks great for years to come:

Hose down panels occasionally, especially in coastal areas

Trim back nearby shrubs or trees to prevent scratching

Avoid placing soil or mulch against panels to reduce corrosion risk at the base

Check post stability annually if installed on sloped or clay ground

A simple seasonal inspection and clean can go a long way in preserving your fence’s lifespan and appearance.

Final Thoughts

If you’re looking for a fence that delivers privacy, security, and style—all while standing up to Brisbane’s challenging climate—Colorbond fence installation may be the answer. Whether it’s a suburban yard makeover or a complete boundary upgrade for a commercial site, the benefits of Colorbond steel are hard to match.

For a professional installation backed by experience and attention to detail, EVO Landscapes colorbond fence installation brisbane offers trusted solutions tailored to your site, budget, and vision.

0 notes

Text

Trends in ACP Sheet Manufacturing: Innovations & Future Prospects

The ACP (Aluminium Composite Panel) industry has witnessed significant advancements in recent years, driven by the growing demand for modern, durable, and aesthetically appealing construction materials. As one of the leading ACP sheet manufacturers, Alucobond India continues to innovate and set new benchmarks in quality, sustainability, and performance. Let's explore the latest trends in ACP sheet manufacturing and what the future holds for this dynamic industry.

1. Advanced Coating Technologies

One of the most notable innovations in ACP sheet manufacturing is the use of advanced coating techniques. High-performance PVDF (Polyvinylidene Fluoride) and nano-coatings enhance weather resistance, UV protection, and anti-fungal properties, ensuring long-lasting durability. These coatings also provide self-cleaning capabilities, making ACP sheets an excellent choice for exterior applications.

2. Sustainable & Eco-Friendly Materials

With a rising emphasis on sustainable construction, ACP sheet manufacturers are adopting eco-friendly production processes. The use of recyclable aluminium and non-toxic core materials reduces environmental impact, while energy-efficient manufacturing techniques help lower carbon footprints. At Alucobond India, sustainability is a key priority, ensuring that ACP panels align with green building standards.

3. Fire-Resistant ACP Sheets

Safety concerns have led to the development of fire-retardant ACP sheets that meet stringent global safety standards. Modern ACP sheets now incorporate non-combustible mineral cores, preventing the spread of flames and enhancing fire safety in commercial and residential buildings. Fire-resistant ACP sheets are becoming an industry standard, ensuring safer and more reliable structures.

4. Digital Printing & Customization

Personalization is a major trend in ACP sheet manufacturing. Digital printing technology allows for high-resolution patterns, textures, and even 3D effects on ACP sheets, enabling architects and designers to create unique façades and interiors. The ability to customize ACP panels in terms of color, finish, and design opens up endless possibilities for creative applications.

5. Lightweight & High-Strength Panels

Innovations in material composition have resulted in ACP sheets that are lighter yet stronger, making them easier to install and handle without compromising on durability. The latest ACP sheets are designed to withstand extreme weather conditions, ensuring long-term performance in both residential and commercial settings.

6. Smart ACP Panels

The future of ACP sheet manufacturing is heading towards smart panels that integrate energy-efficient features, such as solar-reflective coatings and insulation properties. These advancements contribute to energy savings in buildings while maintaining the aesthetic appeal of ACP cladding.

Future Prospects for ACP Sheet Manufacturers

As demand for modern construction materials grows, ACP sheet manufacturers, including Alucobond India, are expected to invest more in AI-driven production techniques, automated quality control, and sustainable raw materials. The integration of IoT (Internet of Things) in ACP manufacturing will also enhance process efficiency and product tracking, ensuring better quality management.

The future of ACP sheet manufacturing is bright, with technological innovations, eco-friendly solutions, and enhanced safety features driving the industry forward. With continuous research and development, Alucobond India remains at the forefront, delivering cutting-edge ACP solutions for modern architecture.

To Know More: https://alucobond.in/aluminium-composite-panel-suppliers-india

0 notes

Text

Comparing Aluminium vs. Other Roofing Materials

Choosing the right roofing material? Comparing aluminium with steel, concrete and asphalt to find out which offers better durability, energy efficiency, and cost savings. Hindalco Everlast Aluminium Roofing offers lightweight, rust-resistant, and eco-friendly roofing solutions, ideal for a business or a home. Discover why Hindalco Everlast Aluminium Roofing stands out as the best roofing choice.

Aluminium v/s Other Roofing Materials

Selecting the right roofing material is a crucial decision for any business, as every choice comes with its own long-term costs, durability concerns and energy efficiency. Among all the options available, aluminium roofing sheets stand out due to their lightweight, corrosion-resistant and heat-reflective properties. Here’s a comparison of aluminium roofing to other materials that are commonly used, to help you make an informed decision.

Aluminium vs. Steel Roofing

Steel, while strong, requires protective coatings to prevent it from rusting. Aluminium, on the other hand, does not rust, making it an ideal choice for humid or coastal environments where steel may corrode over time. Aluminium is also significantly lighter than steel, reducing structural load and making installation far easier and faster. Along with that, aluminium can also reflect more heat than steel, contributing to a lower temperature indoors and helping you save on cooling costs.

Aluminium vs. Concrete Tiles

Concrete tiles are heavy and require a stronger support structure, which not only increases construction costs but also brings a structural integrity concern. Aluminium, being lightweight, puts less strain on buildings and makes the installation process easier.

Concrete tiles can crack under extreme temperatures or impact, leading to high maintenance costs. Aluminium roofing, on the other hand, is highly durable and requires minimal maintenance. Concrete can absorb moisture, making it prone to mold and mildew, whereas aluminium remains unaffected by moisture and all extreme weather conditions.

Aluminium vs. Asphalt Shingles

Aluminium roofing lasts significantly longer than asphalt shingles, which may require replacement every 15-20 years. Aluminium can last 50+ years with minimal upkeep. Aluminium is non-combustible, which makes it safer and far more reliable than asphalt shingles, which deteriorate under UV exposure and heavy rains. Aluminium is 100% recyclable, it’s an environment friendly choice. Asphalt shingles contribute to landfill waste and require more frequent replacements.

Conclusion: Why Aluminium Stands Out

For businesses seeking a roofing material that balances durability, cost-effectiveness and sustainability, Hindalco Everlast aluminium roofing is the superior choice. Its resistance to rust, lightweight nature and energy-efficient properties make it an ideal solution for all industrial, commercial and residential projects. By choosing Hindalco Everlast aluminium roofing, businesses can reduce long-term maintenance costs, improve energy efficiency and enhance structural reliability.

Investing in Hindalco Everlast Aluminium Roofing ensures a future-proof solution that delivers value and performance for decades.

0 notes

Text

The highest creative standards and sustainable building quality are represented by this Alucobond cladding installation, which is composed of two aluminium cover sheets and a mineral-filled core that is non-combustible or fire-retardant. For the first time, the legislation has been applied to a claim involving combustible cladding, even though it has long permitted consumers to bring defective product lawsuits against manufacturers they do not directly contact.

0 notes

Text

Premium ALUCOBOND Cladding Solutions – BETTER LIFE LTD

BETTER LIFE LTD specializes in ALUCOBOND A2, a non-combustible aluminium composite panel that meets global fire safety standards. With its mineral-filled core, ALUCOBOND A2 ensures superior durability, impact resistance, and weatherproofing, making it ideal for modern architectural designs. ALUCOBOND PLUS, featuring a polymer core and aluminium cover sheets, enhances creativity and offers versatile solutions for homes, corporate offices, public buildings, industrial complexes, petrol stations, and more. Whether for aesthetic appeal or safety compliance, ALUCOBOND delivers innovative facade solutions. Contact BETTER LIFE LTD for expert installations today!

#ALUCOBOND#BetterLifeLtd#AluminiumCompositePanel#FireSafeCladding#ModernArchitecture#FacadeSolutions#DurableCladding

0 notes

Text

High-Quality Alucobond Cladding – CSS CLADDING LTD

CSS CLADDING LTD specializes in ALUCOBOND A2, a non-combustible aluminium composite panel that meets global fire safety standards. With a mineral-filled core, it offers fire resistance, impact resistance, and weatherproof durability. ALUCOBOND PLUS features aluminium cover sheets and a mineral-filled polymer core, providing endless design possibilities for homes, offices, corporate buildings, petrol stations, and more. Whether for modern facades or corporate branding, Alucobond ensures a durable, stylish, and safe cladding solution. Contact CSS CLADDING LTD today!

#FacadeDesign#NonCombustiblePanels#FireResistantCladding#BuildingMaterials#AluminiumCompositePanels#CSSCladdingLTD

0 notes

Text

Aluminium Composite Panels vs. Solid Aluminium Sheets: Which is Better?

The world of modern construction and architecture is constantly evolving, with materials becoming more sophisticated and versatile to meet the demands of contemporary design and functionality. Among the most popular materials in the construction industry, today are aluminium sheet material, which come in various forms, including Aluminium Composite Panels (ACPs) and Solid Aluminium Sheets.

Both materials have distinct properties and benefits that make them suitable for different applications. However, when it comes to selecting the right material for your project, understanding their differences is essential. In this blog, we will take a deep dive into Aluminium Composite Panels vs. Solid Aluminium Sheets, analyzing their advantages, disadvantages, and the best scenarios to use them, helping you decide which is better for your next project.

What is Aluminium Sheet Material?

Before we compare the two, it’s crucial to understand what aluminium sheet material is and why it has become so popular. Aluminium sheet material refers to flat, thin pieces of aluminium that are widely used in construction, manufacturing, transportation, and other industries due to their durability, lightweight, corrosion resistance, and versatility. These sheets come in various thicknesses and can be treated with finishes like anodizing or powder coating for enhanced durability and aesthetics.

Two of the most common forms of aluminium sheet material are Solid Aluminium Sheets and Aluminium Composite Panels (ACPs). Both materials are used in construction, but each serves different purposes, offering unique advantages depending on the application.

What Are Solid Aluminium Sheets?

Solid aluminium sheets are exactly what they sound like sheets made entirely of aluminium. They come in different thicknesses, or gauges, and can be used in a variety of applications, from roofing to cladding, facades, and even vehicle body parts.

Key Features of Solid Aluminium Sheets

Durability: Solid aluminium is strong, resistant to corrosion, and can withstand extreme weather conditions, making it suitable for outdoor applications.

Lightweight: Aluminium’s strength-to-weight ratio is one of its most celebrated properties. It is significantly lighter than other metals like steel, making it easier to handle and install.

Versatility: Solid aluminium can be cut, shaped, and welded, allowing for a wide range of applications.

Fire Resistance: Solid aluminium is non-combustible and provides excellent fire resistance, making it a safe option for exterior cladding.

What Are Aluminium Composite Panels (ACPs)?

Aluminium Composite Panels (ACPs) consist of two thin layers of aluminium that are bonded to a non-aluminium core, typically made of polyethylene or mineral-filled core materials. ACPs offer a lightweight yet durable alternative to solid aluminium sheets, widely used in cladding, signage, and interior applications.

0 notes

Text

Real-World Case Studies: Successful Implementation of Fire Retardant ACP Sheets in Major Projects

In the modern construction industry, safety and aesthetics often go hand in hand. Among the various materials that have become indispensable to architects and builders, Fire Retardant ACP Sheets (Aluminium Composite Panels) stand out for their ability to provide both fire safety and aesthetic appeal. These panels are designed to resist ignition and slow down the spread of flames, making them a critical component in ensuring building safety. In this article, we explore real-world case studies that showcase the successful implementation of fire retardant ACP sheets in major projects, highlighting their benefits and impact.

The Evolution of Fire Retardant ACP Sheets

Before delving into specific case studies, it's essential to understand the evolution of fire retardant ACP sheets. These panels consist of a non-combustible mineral core sandwiched between two layers of aluminium. The core material is designed to resist fire, ensuring that the panels meet stringent safety standards. Over the years, advancements in technology have improved the fire resistance, durability, and overall performance of ACP sheets, making them a preferred choice for high-rise buildings, commercial complexes, and public infrastructure.

Case Study 1: The Shard, London

Project Overview

The Shard, an iconic skyscraper in London, is one of the tallest buildings in Europe, standing at 310 meters. Designed by architect Renzo Piano, The Shard is a mixed-use development that includes offices, residential apartments, and a hotel. Given its height and the diverse range of functions within the building, fire safety was a top priority during its construction.

Implementation of Fire Retardant ACP Sheets

To ensure the safety of occupants and compliance with fire safety regulations, fire retardant ACP sheets were used extensively in The Shard's cladding system. These panels were selected for their ability to provide both fire resistance and a sleek, modern appearance that complements the building's glass facade. The ACP sheets used in The Shard underwent rigorous testing to ensure they met the highest standards for fire safety.

Results and Impact

The use of fire retardant ACP sheets in The Shard has proven to be a successful implementation. The building's cladding system not only enhances its aesthetic appeal but also provides a robust fire barrier that protects occupants and assets. The Shard has become a benchmark for fire safety in high-rise construction, demonstrating the effectiveness of fire retardant ACP sheets in mitigating fire risks.

3. Case Study 2: Marina Bay Sands, Singapore

3.Project Overview

Marina Bay Sands is a world-renowned integrated resort in Singapore, featuring a hotel, casino, shopping mall, and convention center. Designed by architect Moshe Safdie, the resort's striking design includes three interconnected towers topped by a massive sky park. As a major tourist attraction and entertainment hub, ensuring the safety of visitors and staff was paramount during the construction of Marina Bay Sands.

Implementation of Fire Retardant ACP Sheets

Fire retardant ACP sheets were chosen for the cladding of Marina Bay Sands due to their ability to resist fire and withstand the tropical climate of Singapore. The ACP sheets were used to clad various parts of the resort, including the sky park and the exterior of the towers. The fire retardant properties of the panels were essential in meeting Singapore's stringent fire safety codes, particularly for a building of this scale and complexity.

Results and Impact

The successful implementation of fire retardant ACP sheets at Marina Bay Sands has played a significant role in ensuring the safety of one of the world's most iconic landmarks. The panels not only contribute to the resort's distinctive appearance but also provide peace of mind for the millions of visitors who pass through its doors each year. Marina Bay Sands stands as a testament to the importance of integrating fire safety measures into the design and construction of large-scale projects.

Case Study 3: One World Trade Center, New York

Project Overview

One World Trade Center, also known as the Freedom Tower, is a symbol of resilience and renewal in New York City. Standing at 1,776 feet, it is the tallest building in the Western Hemisphere. The design and construction of One World Trade Center were guided by the principles of safety, sustainability, and innovation, with a strong emphasis on fire protection.

Implementation of Fire Retardant ACP Sheets

Fire retardant ACP sheets were an integral part of the building's exterior cladding system. The panels were chosen because they can resist extreme temperatures while also preventing fires from spreading.Given the building's significance and the need for enhanced safety measures, the fire retardant ACP sheets used in One World Trade Center were subjected to some of the most rigorous fire testing standards in the industry.

Results and Impact

The use of fire retardant ACP sheets in One World Trade Center has been a key factor in the building's overall safety strategy. The panels not only provide an additional layer of fire protection but also contribute to the building's LEED Gold certification by enhancing energy efficiency. One World Trade Center serves as a powerful example of how modern building materials, like fire retardant ACP sheets, can be used to create safe, sustainable, and iconic structures.Visit us :- https://timexbond.com/acp-sheet

0 notes

Text

What is an Aluminium Honeycomb Core and how is it manufactured?

Title: Exploring the Strength and Versatility of Aluminium Honeycomb Core in Modern Engineering

In the world of engineering and construction, the search for lightweight yet durable materials has led to the rise of innovative solutions. Among these, Aluminium Honeycomb Core stands out for its exceptional properties and wide-ranging applications.

Understanding Aluminium Honeycomb Core

At the heart of Aluminium Honeycomb Core lies a hexagonal structure resembling a honeycomb, crafted from thin sheets of aluminum. This core structure is sandwiched between facing sheets, forming a lightweight yet robust composite material. Its unique design offers a myriad of benefits that make it a preferred choice across various industries.

Key Advantages of Aluminium Honeycomb Core

Impressive Strength-to-Weight Ratio: Despite its lightweight composition, Aluminium Honeycomb Core boasts remarkable strength. The hexagonal cells provide optimal load-bearing capacity, making it ideal for applications where weight reduction and structural integrity are paramount.

Lightweight Construction: Aluminium Honeycomb Core is celebrated for its low density, contributing to overall weight savings in structures and products. This feature is particularly advantageous in industries such as aerospace, automotive, and marine, where minimizing weight is critical for fuel efficiency and performance.

Enhanced Stability and Rigidity: The honeycomb structure of Aluminium Honeycomb Core ensures exceptional stability and rigidity, minimizing deformation under load. This property is invaluable in engineering applications where structural integrity is essential for safety and performance.

Excellent Thermal Insulation: Aluminium Honeycomb Core offers excellent thermal insulation properties, helping to regulate temperature and energy consumption in buildings and vehicles. Its insulation capabilities contribute to energy efficiency and occupant comfort in diverse environments.

Fire Resistance: Fire safety is a top priority in engineering and construction materials. Aluminium Honeycomb Core exhibits inherent fire-resistant properties, making it a preferred choice for applications where fire safety standards are stringent. Its non-combustible nature and low combustible content enhance safety in buildings and transportation vehicles.

Versatile Design Options: Aluminium Honeycomb Core provides engineers and designers with flexibility in design and customization. It can be tailored to meet specific project requirements in terms of size, shape, and surface finish, enabling creativity and innovation in structural and industrial applications.

Applications of Aluminium Honeycomb Core

The versatility of Aluminium Honeycomb Core lends itself to a wide range of applications across industries, including:

Aerospace Structures and Components

Automotive Body Panels and Interior Trim

Marine Vessel Construction

Architectural Cladding and Facades

Industrial and Structural Components

Conclusion

Aluminium Honeycomb Core represents a significant advancement in engineering materials, offering a winning combination of strength, durability, and lightweight properties. Its versatility and performance make it a preferred choice for engineers, architects, and manufacturers seeking innovative solutions for diverse applications.

As the demand for sustainable and high-performance materials continues to grow, Aluminium Honeycomb Core emerges as a versatile and eco-friendly option. Whether used in aerospace structures, automotive components, or architectural projects, its exceptional properties contribute to enhanced performance, efficiency, and safety.

0 notes

Text

Vehicle Light Weighting Technologies Market Will See Strong Expansion Through 2032

Vehicle lightweighting is an idea in the automobile business about structure vehicles and trucks that are less heavy as an approach to accomplish better fuel efficiency and handling. Carmakers make parts from carbon fiber, windshields from plastic, and bumpers out of aluminum foam, as approaches to reduce vehicle load. The use of these materials is selected based on their price, lightweight ability, ultimately, processing or consumption limitations. Advanced lightweight technologies help to improve automotive fuel consumption and guarantee safety and performance. The usage of lightweight materials reduces emissions by nearly 0.08g CO2/Kg, as with the launching of battery electric vehicles, which boosts the application of lightweight technology in automotive systems. The adoption of electric vehicles is one of the examples of light weight technologies as the parts and system of these vehicles are considerably less than other vehicles.

Download Sample Report at: https://www.alliedmarketresearch.com/request-toc-and-sample/A08605

The automotive industry has seen critical changes in material and manufacturing processes in the previous decade to conform to the outflow orders. Rules have constrained automakers to discover various options, for example, lightweight materials, improved proficiency in powertrain, and utilization of pure battery electric vehicles. Subsequently, it is simple for lightweight materials to compete in cost when compared with powertrain productivity measures and regulations. Advancements of reinforced and high-quality plastic for its use as windshield and window glass are evaluated to build the lightweight business sector of plastics. The high cost of materials, for example, carbon fibre-strengthened composites, titanium, and magnesium hinder the broad utilization of these materials. As crude materials have a high cost, OEMs in developing nations, who rely more upon economy passenger vehicles prefer to use materials than lightweight materials. However, the utilization of lightweight materials is expected to increase gradually in the coming years. The manufacturing cost of vehicle parts is higher than conventional materials. Along these, high procedure costs can control the development of the car lightweight material market.

Novelis Inc. announced that it is providing the fusion of Toyota Motor Corporation with a premium aluminum car body sheet for the all-new Toyota RAV4. The RAV4 is Toyota's number-one-selling vehicle and the top-rated non-pickup truck in the nation. With an as-good-as-ever plan that includes Novelis aluminum in the hood, bumpers, and liftgate, the fifth-age model of the RAV4 is 4% lighter than previous models.

Inquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/A08605

Key Vehicle Light Weighting Technologies Market Segments:

By Material: • Steel • Magnesium • Aluminium • Plastics

By Application: • Body in white • Chassis & suspension • Powertrain • Closures • Interiors

By Region: • North America (US, Canada) • Europe (Germany, UK, France, rest of Europe) • Asia-Pacific (China, Japan, India, rest of Asia-Pacific) • LAMEA (Brazil, South Africa, rest of LAMEA)

Key Market Players: • Toray Industries, Inc. (Japan) • Tata Steel • General Motors • ArcelorMittal (Luxembourg) • 3M • DuPont • Covestro AG (Germany) • BASF SE (Germany) • Toyota • Honda Motor Co., Ltd. • ThyssenKrupp AG (Germany)

Access the Full Report @ https://www.alliedmarketresearch.com/vehicle-light-weighting-technologies-market-A08605

The surge in usage of electric vehicles

The introduction of electric vehicles has brought about technological advancement and revolution in the automotive business. These vehicles have a predominant execution than their internal combustion counterparts. Since electric vehicles have low-power engines, they utilize lightweight materials that drive the engine's pulling limit. In this manner, the expanding demand for electric vehicles gives a chance to the development of the lightweight material market. As electric vehicles reduce car emissions to help the environment the demand for the electrification of vehicles is also increasing.

Key benefits of the report:

• This study presents the analytical depiction of the global Vehicle light-weighting technologies market with the current trends and future estimations to determine the imminent investment pockets. • The report presents information related to key drivers, restraints, and opportunities along with a detailed analysis of the global Vehicle light-weighting technologies market. • The current market is quantitatively analyzed to highlight the global Vehicle light-weighting technologies market growth scenario. • Porter's five forces analysis illustrates the potency of buyers & suppliers in the market. • The report provides a detailed global vehicle light-weighting technologies market analysis based on competitive intensity and how the competition will take shape in coming years.

Buy the Complete Report (PDF with Insights, Charts, Tables, and Figures) at: https://www.alliedmarketresearch.com/checkout-final/d8c84557957536af2f8dee6a5ac8fbaf

About Us:

Allied Market Research is a top provider of market intelligence that offers reports from leading technology publishers. Our in-depth market assessments in our research reports take into account significant technological advancements in the sector. In addition to other areas of expertise, AMR focuses on the analysis of high-tech systems and advanced production systems. We have a team of experts who compile thorough research reports and actively advise leading businesses to enhance their current procedures. Our experts have a wealth of knowledge on the topics they cover. Also, they use a variety of tools and techniques when gathering and analyzing data, including patented data sources.

Contact Us:

United States 1209 Orange Street, Corporation Trust Center, Wilmington, New Castle, Delaware 19801 USA. Int'l: +1-503-894-6022 Toll Free: +1-800-792-5285 Fax: +1-800-792-5285 [email protected]

0 notes

Text

Revolutionizing Mobility: Advances in Vehicle Weight Optimization

Vehicle Light Weighting Technologies Market is an idea in the automobile business about structure vehicles and trucks that are less heavy as an approach to accomplish better fuel efficiency and handling. Carmakers make parts from carbon fibre, windshields from plastic, and bumper out of aluminium foam, as approaches to reduce vehicle load. The use of these materials is selected on the basis of their price, lightweight ability, ultimately, processing or consumption limitations. Advanced lightweight technologies help to improve automotive fuel consumption and guarantee safety and performance. Usage of lightweight materials reduces emissions by nearly 0.08g CO2/Kg, as with launching of battery electric vehicle, which boosts application of light weighting technology in automotive systems. The adoption of electric vehicles is one of the examples for light weight technologies as parts and system of these vehicles is considerably less than other vehicles.

Top impacting factors: Market Scenario Analysis, Trends, Drivers and Impact Analysis

The automotive industry has seen critical changes in material and manufacturing process in the previous decade to conform to the outflow orders. Rules have constrained automakers to discover various options, for example, lightweight materials, improve proficiency in powertrain, and utilization of pure battery electric vehicles. Subsequently, it is simple for lightweight materials to compete in cost when compared with powertrain productivity measures and regulations. Advancements of reinforced and high-quality plastic for its use as windshield and window glass is evaluated to build the light weighting business sector of plastics. The high cost of materials, for example, carbon fibre strengthened composites, titanium, and magnesium hinder the broad utilization of these materials. As crude materials have a high cost, OEMs in developing nations, who rely more upon economy passenger vehicles prefer to use materials than lightweight materials. However, utilization of lightweight materials is expected to increase gradually in the coming years. The manufacturing cost of vehicle parts made of is higher than conventional materials. Along these, high procedure cost can control the development of the car lightweight material market.

New product launches to flourish the market

Novelis Inc. announced that it is providing the fusion of Toyota Motor Corporation with premium aluminium car body sheet for the all-new Toyota RAV4. The RAV4 is Toyota’s number-one-selling vehicle and the top rated non-pickup truck in the nation. With an as good as ever plan that includes Novelis aluminium in the hood, bumpers, and liftgate, the fifth-age model of the RAV4 is 4% lighter than previous models.

Surge in usage in electric vehicles

The introduction of electric vehicles has brought about a technological advancement and revolution in the automotive business. These vehicles have predominant execution than their internal combustion counterparts. Since electric vehicles have low power engines, they utilize lightweight materials that drive the engine’s pulling limit. In this manner, the expanding demand for electric vehicles gives a chance to the development of the lightweight material market. As the electric vehicles reduce the car emission to help environment the demand for the electrification of vehicles is also increasing.

Key benefits of the report:

This study presents the analytical depiction of the global Vehicle light weighting technologies market with the current trends and future estimations to determine the imminent investment pockets.

The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the global Vehicle light weighting technologies market.

The current market is quantitatively analysed to highlight the global Vehicle light weighting technologies market growth scenario.

Porter’s five forces analysis illustrates the potency of buyers & suppliers in the market.

The report provides a detailed global vehicle light weighting technologies market analysis based on competitive intensity and how the competition will take shape in coming years.

0 notes

Text

Weatherproof Eurobond ACP Panels: The Perfect Solution for All Seasons

In today's rapidly evolving construction industry, architects and builders seek innovative materials that not only enhance the aesthetics of buildings but also offer practical advantages. When it comes to exterior cladding, one name stands out: Eurobond Aluminium Composite Panels (ACP). These versatile and weatherproof ACP panels have become a top choice for architects and construction professionals worldwide. In this blog, we will explore the benefits of Eurobond ACP panels and understand why they are the perfect solution for all seasons.

What are Eurobond ACP Panels?

Eurobond ACP panels are made of two layers of high quality aluminium sheets, there are various types of insulated cores like :

PE Core: Composed entirely of Polyethylene (PE), this material is flammable.

FR Core: Designed with a fire-retardant composite material, it includes non-combustible substances like ATH (Aluminium Trihydrate) and MDH (Magnesium Dihydroxide) compounds. The FR Core is classified as FR Class A2, boasting a 90% mineral core, while FR Class B (Eurobond FR Plus) features a 70% mineral core.

Aluminium Core: This core variation is constructed using either an Aluminium Honeycomb Structure or Solid Aluminium, offering enhanced fire resistance.

This composite structure results in a lightweight yet sturdy material with exceptional properties, making it ideal for exterior cladding and a wide range of applications.

Weatherproof Performance

One of the key reasons Eurobond ACP panels have gained popularity is their exceptional weatherproof performance. These panels are engineered to withstand harsh environmental conditions, including heavy rains, extreme temperatures, UV radiation, and even high winds. Whether it's the scorching heat of summers, the torrential downpours during monsoons, or the freezing cold of winters, Eurobond ACP panels remain intact, maintaining their original appearance and structural integrity.

Durability and Longevity

The durability of Eurobond ACP panels is another feature that sets them apart from traditional cladding materials. The combination of aluminium and the core imparts excellent resistance to corrosion, ensuring that the panels do not deteriorate over time. This longevity not only adds value to the building but also reduces maintenance costs significantly.

Versatile Aesthetic Appeal

Apart from their superior performance, Eurobond ACP panels also offer a wide range of design possibilities, providing architects with the freedom to create visually stunning facades. Available in an array of colours, finishes, and textures, these panels can complement any architectural style, from contemporary to traditional. Whether you're aiming for a modern, sleek appearance or a more rustic facade, Eurobond ACP panels can bring your vision to life.

Energy Efficiency

Eurobond ACP panels contribute to the energy efficiency of buildings due to their insulation properties. The LDPE core acts as a thermal barrier, helping to regulate indoor temperatures and reducing the energy required for heating and cooling. As a result, buildings clad with Eurobond ACP panels can achieve better energy efficiency ratings, which is beneficial for both the environment and the occupants.

Sustainability and Environmentally Friendly

In an era where sustainability is a top priority, Eurobond ACP panels shine as an environmentally friendly choice. These panels are fully recyclable, contributing to waste reduction and a more sustainable construction industry. Additionally, their lightweight nature reduces transportation-related emissions during delivery and installation.

Easy Installation and Maintenance

Eurobond ACP panels are designed for ease of installation, saving time and labour costs during construction. They can be easily cut and shaped to fit any architectural design, making them a convenient choice for both new projects and renovations. Moreover, their weather-resistant properties reduce the need for frequent maintenance, resulting in long-lasting beauty and functionality.

Conclusion

In conclusion, Eurobond ACP panels offer a perfect blend of aesthetics, performance, and sustainability, making them an ideal choice for weatherproof exterior cladding. With their exceptional durability, design versatility, energy efficiency, and low maintenance requirements, Eurobond ACP panels not only protect buildings from the elements but also enhance their overall appeal. For architects and construction professionals looking to elevate their projects to new heights, Eurobond ACP panels are the go-to solution for all seasons.

So, why compromise on quality and performance? Choose Eurobond ACP panels and take your architectural designs to the next level. Experience the perfect synergy of beauty and durability with Eurobond ACP panels - a step towards a greener and more resilient future.

#eurobond acp#acp panel#acp sheet#eurobond#weatherproof#rain proof#eurobond acp panels#rainy season#building facade#building materials#acp cladding#cladding

1 note

·

View note

Text

What Are the Different Types of Core Materials Used in ACP?

Aluminum Composite Panel (ACP) is a popular material for building exteriors, interiors, and signage. The sandwich panel consists of two aluminium sheets bonded to a non-aluminium core, which provides rigidity, insulation, and lightweight properties. The core material used in ACP plays a crucial role in its overall performance and characteristics. This article will discuss the different types of core materials used in ACP.

What is ACP?

ACP is a flat panel of two thin aluminium sheets bonded to a non-aluminium core. The thickness of the aluminium sheets can vary from 0.2mm to 0.5mm, while the core material thickness can range from 2mm to 6mm. The most common ACP thickness is 4mm. ACP offers advantages over traditional building materials like masonry, wood, and steel. These include low weight, ease of installation, cost-effectiveness, weather resistance, and design versatility.

Why is Core Material Important in ACP?

The core material used in ACP significantly affects its mechanical and physical properties, such as rigidity, strength, fire resistance, and thermal insulation. The choice of core material also determines the panel's response to heat and fire. Therefore, choosing the right type of core material for your application is crucial.

Types of Core Materials Used in ACP

Polyethene (PE) Core

PE core is the most widely used core material in ACP due to its cost-effectiveness, lightweight, and ease of processing. The core material is made of low-density polyethene, which is a highly flammable material. PE core ACP is suitable for applications that do not require high fire resistance, such as signage, cladding, and interior decoration. However, it is not recommended for high-rise buildings or areas with strict fire safety regulations.

Fire Retardant (FR) Core

FR core ACP is designed to improve fire resistance and prevent the spread of fire. The core material is treated with fire-retardant additives, such as magnesium or aluminium hydroxide, to reduce flammability and smoke emission. FR core ACP is suitable for areas with strict fire safety regulations, such as hospitals, schools, and high-rise buildings.

Mineral Core

Mineral core ACP comprises non-combustible minerals, such as magnesium oxide or aluminium hydroxide, that provide excellent fire resistance and thermal insulation. The core material is bonded to the aluminium sheets using a unique adhesive that can withstand high temperatures. Mineral core ACP is ideal for applications that require high fire resistance, such as façade cladding, tunnels, and airports.

Aluminium Honeycomb Core

Aluminium honeycomb core ACP comprises hexagonal cells of aluminium foil bonded together to form a lightweight and robust core material. The core material offers excellent rigidity and compression strength while maintaining a low weight. Aluminium honeycomb core ACP is suitable for applications that require high mechanical strength, such as transportation, marine, and aerospace industries.

Polystyrene (PS) Core

Polystyrene core ACP comprises expanded polystyrene foam that offers lightweight and thermal insulation properties. The core material is bonded to the aluminium sheets using an adhesive. Polystyrene core ACP is suitable for applications that require insulation, such as cold rooms, refrigeration trucks, and sound barriers.

A2/B1 FR Core

A2/B1 FR core ACP is a new type of fire-resistant core material that complies with the European fire safety standard EN13501-1. The core material comprises non-combustible minerals, such as magnesium hydroxide and aluminium trihydroxide, that offer excellent fire resistance and smoke emission control. A2/B1 FR core ACP is suitable for high-fire resistance applications, such as high-rise buildings, hospitals, and airports.

Conclusion

The choice of core material in ACP is a crucial factor that can significantly affect the performance and safety of the final product. The core materials used in ACP are PE core, FR core, mineral core, aluminium honeycomb core, polystyrene core, and A2/B1 FR core. Each type of core material has its unique advantages and disadvantages, and the selection of suitable core material depends on the application's specific requirements.

Are you looking for the best company for ACP works in Coimbatore?

If you implement an ACP in your place, ‘Aysh Groups’ are always the best choice.

‘Aysh Groups’ make the process easy and convenient to order your aluminium composite panel (ACP) and get it installed on time.

We are the prominent and best Glass interiors, exteriors, partitions, and ACP work with high-quality materials in Chennai, Coimbatore, Trichy and Madurai.

For more information about the aluminium composite panel-related queries, do contact us via (Phone: 9884450095 or Website: https://ayshgroups.com/)

1 note

·

View note

Text

What is Alucobond Cladding? Mistakes to Avoid During Installation

One composite panel that embodies the greatest creative standards and sustainable building quality is Alucobond cladding. It is made up of a mineral-filled core that is either non-combustible or fire-retardant and two aluminium cover sheets. Alucobond was the first aluminium composite material (ACM) used in the architectural and construction cladding industries.

The highest creative standards and sustainable building quality are represented by this Alucobond cladding installation, which is composed of two aluminium cover sheets and a mineral-filled core that is non-combustible or fire-retardant. For the first time, the legislation has been applied to a claim involving combustible cladding, even though it has long permitted consumers to bring defective product lawsuits against manufacturers they do not directly contact.

Alucobond ACM is composed of two smooth 0.020-inch aluminium sheets that are continually thermobonded to polyethene of various thicknesses. The thickness of the panels ranges from 3 to 6 mm. The Aluminum Composite Material (ACM) comes in three-, four-, and six-millimeter thicknesses. Between two layers of 0.5 mm thick aluminium is a fire-resistant core composed of 70% non-combustible mineral filler.

Table of Contents

Is it Waterproof?

Mistakes to Avoid When Installing Alucobond Cladding

1. Not Enough Preparation and Planning

2. Ignoring Expert Guidance

3. Utilising Low-Cost Materials

4. Untrustworthy Methods of Installation

5. Absence of Frequent Maintenance

6. Disregarding Local Building Codes

7. Underestimating the Needs for the Budget

Conclusion

Is it Waterproof?

The material can tolerate temperature extremes, is water-resistant, resistant to different types of pollution and chemical attacks, and has thermal and acoustic insulation properties. Aluminium panels can last for more than 20 years.Alucobond Plus: Is It ACM?

Among other uses, aluminium composite material (ACM) panels are lightweight metal cladding that is perfect for rain-screen cladding and external facades. Alucobond® facades are composite panels made up of a polymer core filled with minerals and two aluminium cover sheets.

Mistakes to Avoid When Installing Alucobond Cladding

Starting a house recladding project in Auckland may be a thrilling adventure that improves the look and value of your property. However, prudence is necessary to prevent mistakes that could result in high costs and disappointment. In order to ensure a smooth transition, we will discuss the mistakes to avoid while recladding your Auckland home in this post.

1. Not Enough Preparation and Planning

Homeowners often make the mistake of starting a recladding project without sufficient planning and preparation. Examining Alucobond cladding installation options while taking weather, building codes, and architectural style into consideration is essential. This approach will enable you to choose the best cladding material for your house.

2. Ignoring Expert Guidance

Even though do-it-yourselfers may feel confident in their abilities, it is essential to consult an Auckland recladding specialist before beginning any recladding tasks. A competent architect or contractor can spot problems, evaluate the house’s structural soundness, recommend suitable materials, and give precise cost estimates. Their advice greatly lowers the likelihood of errors.

3. Utilising Low-Cost Materials

Cutting corners and using subpar materials might seem like a wise way to save money, but they can lead to major issues later on. Selecting premium cladding materials for your house ensures better insulation and greater energy efficiency, in addition to increased durability. Using high-quality materials from the start will eventually result in lower maintenance costs.

4. Untrustworthy Methods of Installation

Even with high-end cladding materials, proper installation methods should never be disregarded. If these materials are not put appropriately, their efficiency may be weakened. When recladding their homes, many novice builders undervalue the significance of installation methods such as ventilation needs or moisture management systems. For this reason, it’s essential.

5. Absence of Frequent Maintenance

After your property has been reclad, don’t undervalue the importance of routine maintenance. One of the first steps to maintaining your home’s structural soundness and aesthetic appeal is recladding. Although Alucobond cladding installation materials are made to endure severe weather conditions, their lifespan is impacted by regular maintenance. Any home care plan must include cleaning schedules, inspection procedures, and repair suggestions. You can enjoy your reclad home for many years to come if you take good care of your investment.

6. Disregarding Local Building Codes

When doing a recladding project, homeowners frequently forget how important it is to follow building codes. Occasionally, people just assume that renovation regulations cover these initiatives. It’s important to remember, too, that some cladding materials or facade modifications may call for permissions or approvals from the relevant authorities. Infractions of these rules may result in penalties, hold-ups, or even the requirement to remove installed cladding. It’s crucial to speak with authorities or experts who are knowledgeable about building rules and permit requirements before beginning any recladding work.

7. Underestimating the Needs for the Budget

It might be stressful and leave you frantically looking for more money if you underestimate the budget for the Alucobond cladding installation project. Fees like scaffolding, temporary housing fees (if necessary), structural problems that might be discovered during demolition, and other unanticipated costs that might come up during the project should all be taken into account while planning. A more seamless experience will result from having a well-planned budget that considers unforeseen circumstances.

Conclusion

Recladding your house is an activity that enhances the utility and value of your property while modernising its appearance. You can navigate this transformation successfully if you are mindful of pitfalls like inadequate planning, not following the advice of qualified professionals, using inferior materials, not following the recommended installation methods, or failing to plan for necessary maintenance. It is essential to make decisions that prioritise long-term durability and energy efficiency in your project.

If you’ve got the right skills and you’re able to give weight to all the factors you consider, you could make a fabulous finish that will breathe new life into your place. It’s important to stay current on trends in design and consider low-maintenance options that add market value to your home. Results are possible in a committed way with local knowledge. By being thorough at each stage in the build-out process and asking for help as necessary, you can alleviate stress and provide a pathway to the outcome you intended. As you begin this construction project that will, in a meaningful way, materialise your concept, let yourself think out of the box!

0 notes