#metering pump diaphragm

Explore tagged Tumblr posts

Text

7 Benefits of Using Hydraulic Diaphragm Metering Pumps

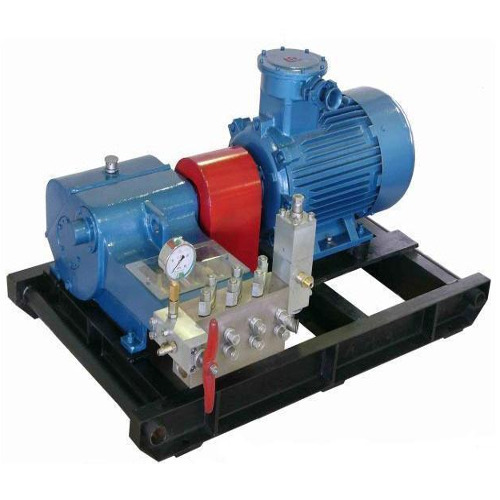

For those of you who don’t know about hydraulic diaphragm metering pumps, here is a simple definition – these are specialized pumps designed to accurately and consistently deliver precise volumes of fluids. These pumps are especially useful in industrial applications that require careful dosing and metering.

Hydraulic Diaphragm Metering Pump consists of a flexible diaphragm that separates the pumped fluid from the pump’s drive mechanism. As a result, there are no leaks or contamination. Besides ensuring a leak-proof system, these pumps also allow for easy adjustment of flow rates, providing flexibility to meet various operational needs.

0 notes

Text

Cartridge Valves Manufacturer, Supplier in Kolkata

Turbine Agitator Controllers, Catalog, Turbine Type Agitator, Agitator Designed, Manufacturer, Supplier in Kolkata, India, Click Now.

#Dosing Pumps#Electronic Dosing Pump Manufacturers#Metering#Chemical Dosing Pumps Exporters#Suppliers in Bangalore#Dosing Pump#Metering Pumps#Dosing System#Diaphragm Dosing Pump#Chemical Dosing Pump#Positive Displacement Pump#Piston Dosing Pump#Chemical Metering Pump#Electromagnetic Dosing Pump#Motor Driven Dosing Pump#Chemical Dosing Pumps#Electronic Dosing Pumps in India#Chemical Dosing Pump Price List#Dosing Pump Manufacturers#Dosing Pump Working Principle#Dosing Pump Wiki#E Dose Dosing Pump Catalogue#Dosing Pump India#Dosing Pump For Water Treatment Plant.

1 note

·

View note

Text

PTFE/Rubber Diaphragm Seals Please contact me for a quote if required. Henan Sixfluorine Chemical Co.,Ltd WhatsApp/Telegram:+(86)15038852660 Mail:[email protected]

1 note

·

View note

Text

The global market for diaphragm metering pump is expected to flourish with significant growth over the period 2017-2024 by reaching noteworthy revenue by the end of the forecast period. Rising number of chemicals, water treatment and oil & petroleum industries are the major factors that are anticipated to drive the growth of the diaphragm metering pump market with notable revenue by the end of 2024.

The diaphragm metering pump market has been segmented by operation into mechanical, hydraulic and by application into oil/gas production, refinery, chemical & petro-chemical, pharmaceutical, cosmetic and food production, out of which, the diaphragm metering pumps are mainly used in the chemical & petro-chemical industries along with oil & gas industries. The adoption of effective & safe machineries in these industries is anticipated to drive the demand for Diaphragm Metering Pumps Market over the forecast period.

In the regional segment, the Asia Pacific diaphragm metering pump market is the most promising and revenue generating market in overall diaphragm metering market and is anticipated to continue its dominance over the forecast period. India and China are the major dominating countries to drive the growth of the diaphragm metering pump market in the Asia-Pacific region. Further, North America and Europe are expected to witness a significant growth by contributing extensively in the global diaphragm metering pump market during the forecast period.

Wide Scale Applications to Augment the Market Factors such as demand for safe drinking water and use of diaphragm metering pump in water treatment industries coupled with the rising use of diaphragm metering pumps in cosmetic industries are believed to supplement the growth of the diaphragm metering pump market across the globe.

The report titled “Diaphragm Metering Pump Market: Global Demand Analysis & Opportunity Outlook 2024” delivers detailed overview of the diaphragm metering pump market in terms of market segmentation by application, by operations and by region.

However, high cost and rising price wars among major players are the major factors that are likely to restrict the growth of the diaphragm metering pump market in the near future.

Further, for the in-depth analysis, the report encompasses the industry growth drivers, restraints, supply and demand risk, market attractiveness, BPS analysis and Porter’s five force model.

This report also provides the existing competitive scenario of some of the key players of the diaphragm metering pump market which includes company profiling ofIDEX Corporation, Injection Technical Control Inc., LEWA GmbH, Mcfarland-Tritan LLC, Milton Roy Company, Prominent Dosiertechnik GmbH, Seko S.P.A., Swelore Engineering Pvt. Ltd., Seepax GmbH and SPX Flow Technology.

Get a Sample Copy of the Report at: @ https://www.researchnester.com/sample-request-358 The profiling enfolds key information of the companies which encompasses business overview, products and services, key financials and recent news and developments. On the whole, the report depicts detailed overview of the diaphragm metering pump market that will help industry consultants, equipment manufacturers, existing players searching for expansion opportunities, new players searching possibilities and other stakeholders to align their market centric strategies according to the ongoing and expected trends in the future.

About Research Nester Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision so as to avoid future uncertainties.

Contact Us AJ Daniel Email: [email protected] U.S. Phone: [+1 646 586 9123] U.K. Phone: [+44 203 608 591]

0 notes

Text

A Complete Guide to Digital Flow Meters: Accurate Measurement in the Digital Age

In today's data-driven world, precise measurement and control of liquid flow is crucial across industries—from automotive and aviation to agriculture and manufacturing. One innovative solution revolutionizing the way fluids are monitored is the Digital Flow Meter.

These compact, tech-enhanced devices are quickly replacing traditional analog systems. Offering greater accuracy, digital displays, and seamless integration with smart monitoring systems, digital fuel flow meters have become the backbone of modern fuel management.

What is a Digital Flow Meter?

A Digital Flow Meter is an electronic device that measures the volume or mass of a fluid (typically liquids like water or fuel) as it passes through a system. Unlike mechanical meters, digital models utilize sensors and microprocessors to provide precise, real-time data displayed on easy-to-read screens.

These meters are used in:

Fuel dispensing systems

Industrial fluid management

Agricultural irrigation systems

Water treatment plants

By minimizing human error and offering data logging capabilities, they help streamline operations and reduce waste.

Why Use a Digital Fuel Flow Meter?

When it comes to tracking fuel consumption, Digital Fuel Flow Meters offer unmatched benefits:

High Accuracy: They offer precise measurement within ±0.5%, which is essential for cost control.

Real-Time Monitoring: Display screens and connectivity options allow for instant feedback.

Low Maintenance: With fewer moving parts than mechanical meters, maintenance needs are drastically reduced.

Data Integration: Advanced models can connect to IoT systems for remote monitoring and automated reporting.

These features make them ideal for use in fleet management, construction, logistics, and marine industries.

Real User Experiences

"After switching to a digital fuel flow meter, our fleet's fuel tracking became incredibly streamlined. No more manual logs—just plug and play." — James T., Logistics Manager

"We saved thousands by detecting small leaks early, thanks to real-time data from our digital flow meters." — Priya R., Operations Head, Water Treatment Facility

Key Features to Look For

When selecting a digital fuel flow meter, consider the following:

Flow Range Compatibility: Ensure it supports the specific volume of fluid your system handles.

Material Durability: Stainless steel and corrosion-resistant polymers are best for long-term use.

Display Type: Look for large, backlit LCDs for readability in low-light environments.

Communication Protocols: Choose meters with Bluetooth, RS-485, or Modbus for system integration.

Battery Life: Industrial versions often run for years on a single set of batteries.

Frequently Asked Questions

Q1: Are digital flow meters only for industrial use? Not at all. While widely used in industries, they’re also suitable for residential and agricultural applications, especially where precision and automation are required.

Q2: Can I install a digital flow meter myself? Many models are designed for easy, inline installation. However, professional setup is recommended for large-scale systems or where integration with software is needed.

Q3: How long do digital fuel flow meters last? With proper maintenance and quality materials, they can last up to 10 years, depending on usage and environmental conditions.

Q4: Do these meters require calibration? Yes, periodic calibration ensures continued accuracy. Many digital meters include automatic calibration prompts or alerts.

The Future of Fluid Measurement

With increasing demand for data transparency and operational efficiency, Air Operated Diaphragm Pump are poised to become standard in all sectors involving fluid transfer. From improving environmental compliance to enhancing fuel economy, these devices are shaping a smarter, more efficient future.

Whether you're overseeing an industrial plant, managing a vehicle fleet, or optimizing a farm irrigation system, investing in a digital fuel flow meter can bring you one step closer to operational excellence.

0 notes

Text

Discover the top-quality Chem-Feed Noir Diaphragm Metering Pump from Marine Shop 7, designed for high precision and consistent chemical dosing. Engineered for industrial and commercial applications, this pump delivers high output with low maintenance, making it ideal for water treatment, chemical processing, and more. Its robust diaphragm design ensures durability, accuracy, and resistance to corrosive fluids. Easy to install and operate, it’s a reliable choice for professionals seeking efficient and long-lasting performance.

Choose the trusted solution – the Chem-Feed Noir Diaphragm Metering Pump from Marine Shop 7 – where performance meets reliability in every drop.

Know More : https://www.marineshopseven.com/product-category/pneumatic-tools-equipment/

0 notes

Text

Reciprocating Pump Market Growth Driven by Expanding Industrial Applications and Rising Energy Efficiency Demands

Introduction

The reciprocating pump market has witnessed significant growth over the past decade, driven by increasing demand from industries such as oil and gas, water treatment, chemical processing, and manufacturing. These pumps, known for their ability to handle high-pressure applications with precision, are widely used for fluid transfer and metering purposes. As industries continue to seek efficient and reliable pumping solutions, the reciprocating pump market is poised for steady expansion in the coming years.

What is a Reciprocating Pump?

A reciprocating pump is a type of positive displacement pump that uses a piston, plunger, or diaphragm to create a back-and-forth (reciprocating) motion, resulting in fluid displacement. The pump's working mechanism allows it to deliver a consistent flow rate, making it highly effective for applications requiring precision and control. Reciprocating pumps are commonly used in situations where the fluid viscosity, pressure, or flow rate needs to be maintained with accuracy.

Market Size and Growth Trends

The global reciprocating pump market was valued at approximately $7.5 billion in 2024 and is expected to grow at a compound annual growth rate (CAGR) of around 5-7% over the next five years. This growth is primarily fueled by rising industrialization, increasing energy demand, and the expansion of water treatment and desalination plants worldwide.

The oil and gas sector continues to be a dominant end-user of reciprocating pumps, particularly for applications such as crude oil transportation, enhanced oil recovery (EOR), and hydraulic fracturing. Meanwhile, the pharmaceutical and chemical industries are also contributing to market growth due to the need for precise fluid handling and metering in production processes.

Key Market Drivers

Increasing Demand from Oil and Gas Industry

The oil and gas sector remains a primary driver of the reciprocating pump market. With the resurgence of exploration activities, the need for high-pressure pumps capable of handling crude oil, natural gas, and other hydrocarbons is growing.

The use of reciprocating pumps in hydraulic fracturing (fracking) and well stimulation has surged, particularly in regions such as North America and the Middle East.

Growing Water Treatment and Desalination Projects

The expanding global population and water scarcity issues have led to increased investments in water treatment and desalination plants.

Reciprocating pumps play a critical role in these facilities by ensuring high-pressure fluid transfer, particularly in reverse osmosis systems.

Rising Industrial Automation

The trend toward industrial automation is driving demand for precision pumps with advanced monitoring and control features.

Modern reciprocating pumps equipped with IoT-enabled sensors offer real-time performance data, enabling predictive maintenance and improving operational efficiency.

Technological Advancements

Advancements in pump materials and designs, including the use of corrosion-resistant alloys and enhanced sealing technologies, are boosting the durability and performance of reciprocating pumps.

Smart pump systems with remote monitoring capabilities are becoming increasingly popular, particularly in large-scale industrial applications.

Challenges in the Market

Despite the promising growth, the reciprocating pump market faces several challenges:

High Maintenance Costs: Reciprocating pumps are prone to wear and tear due to their moving parts, resulting in higher maintenance costs. This can deter small and medium-sized enterprises (SMEs) from investing in these pumps.

Energy Consumption: Although efficient, reciprocating pumps consume considerable energy, particularly in high-pressure applications. Energy efficiency regulations could pose challenges for manufacturers.

Competition from Alternative Pump Technologies: Centrifugal pumps and other advanced pumping technologies are becoming more efficient and cost-effective, posing a potential threat to reciprocating pump market share.

Regional Analysis

North America

North America is one of the leading markets for reciprocating pumps, largely driven by the extensive oil and gas operations in the United States and Canada.

The increasing number of shale gas projects and hydraulic fracturing activities is driving the demand for high-pressure pumps.

Europe

The European market is characterized by its focus on industrial automation and sustainability initiatives.

Countries like Germany, the UK, and France are investing heavily in wastewater treatment plants, boosting demand for reciprocating pumps in the region.

Asia-Pacific

The Asia-Pacific region is experiencing rapid industrialization and urbanization, resulting in increased demand for reciprocating pumps in water treatment, chemical processing, and power generation sectors.

China and India are leading markets due to their expanding manufacturing and infrastructure sectors.

Middle East and Africa

The Middle East, with its strong oil and gas sector, continues to be a major market for reciprocating pumps.

Investments in desalination projects, particularly in Saudi Arabia and the UAE, are further driving market growth.

Market Segmentation

The reciprocating pump market can be segmented based on the following criteria:

Type:

Piston pumps

Plunger pumps

Diaphragm pumps

End-User Industry:

Oil and Gas

Water Treatment

Chemical Processing

Pharmaceuticals

Power Generation

Application:

High-pressure cleaning

Fluid metering

Chemical injection

Desalination

Future Outlook

The reciprocating pump market is expected to continue its growth trajectory, driven by ongoing industrialization, infrastructure development, and the increasing need for reliable pumping solutions. Manufacturers are likely to focus on energy-efficient designs and smart pump systems to meet evolving industry demands.

The integration of predictive maintenance features and the use of eco-friendly materials will also become key differentiators. Furthermore, the demand for custom-engineered pumps tailored to specific applications is expected to rise, particularly in specialized sectors such as pharmaceuticals and food processing.

Conclusion

The reciprocating pump market is set for steady growth, fueled by its extensive application across various industries. While challenges such as high maintenance costs and competition from alternative technologies persist, ongoing technological advancements and the rising demand for efficient fluid transfer solutions will continue to drive market expansion. As industries increasingly embrace automation and energy efficiency, the reciprocating pump sector is expected to witness continuous innovation and evolution.

0 notes

Text

The Ultimate Guide to Metering Pumps: Precision, Efficiency, and Innovation

A Metering Pump is a crucial component in industries requiring precise fluid handling and dosing. Whether in water treatment, chemical processing, or pharmaceuticals, Metering Pumps play a significant role in ensuring accurate and controlled fluid flow. These pumps are designed to deliver precise amounts of liquid at consistent intervals, making them essential for applications where accuracy is paramount.

In industries where precision fluid handling and dosing are critical, Metering Pumps play an indispensable role. These highly specialized pumps are designed to deliver exact quantities of liquid at controlled rates, making them essential for applications ranging from water treatment to chemical processing. The consistent performance and accuracy of Metering Pumps make them a vital component in ensuring product quality, safety, and operational efficiency.

This article explores the world of Metering Pumps, their types, applications, benefits, and how to select the right model to meet your operational needs.

What is a Metering Pump?

A Metering Pump is a precision device engineered to move a specific volume of liquid within a set period, ensuring accurate dosing of chemicals or other fluids. These pumps operate at adjustable flow rates, making them highly versatile for various industries. The primary advantage of a Metering Pump is its ability to deliver fluids with high accuracy and consistency, even under varying pressure conditions.

Key Features of Metering Pumps

The standout features of Metering Pump include:

High Accuracy: Capable of delivering fluids with minimal deviation from set parameters

Adjustable Flow Rates: Allows customization of flow rates to meet operational demands

Chemical Compatibility: Built from materials that resist corrosion and chemical degradation

Pressure Stability: Maintains performance under varying pressure conditions

Automation Integration: Compatible with automated systems for seamless operation

Maintenance and Troubleshooting Tips

Proper maintenance of Metering Pumps ensures their longevity and reliable performance. Here are some essential tips:

Regularly inspect and clean pump components

Replace worn-out diaphragms, seals, and tubing

Calibrate the pump to maintain accuracy

Check for leaks and address them immediately

Follow manufacturer guidelines for routine servicing

Metering Pumps are vital tools for industries requiring precision fluid dosing and handling. Their ability to deliver accurate, consistent, and reliable performance makes them indispensable in various applications, from water treatment to pharmaceutical manufacturing. Understanding the different types, benefits, and maintenance requirements of Metering Pumps will help you select the best solution for your operational needs.

Visit: https://www.uniquedosingsystem.com/metering-pumps-manufacturers.php

Contact: Tel. : +91 9822420535

0 notes

Text

IVD Liquid Waste Handling Pump in Clinical Diagnostics: Technical Analysis and Systematic Advantages

In the field of in vitro diagnostics (IVD), the reliability of waste liquid treatment systems directly impacts the accuracy of test results and the safety of equipment operation. Facing complex media containing biological residues, corrosive reagents, and gas-liquid mixtures, traditional pumps often encounter challenges such as leakage, clogging, and inadequate lifespan. TOPSFLO mini diaphragm pump, through innovative design and material engineering breakthroughs, provides a highly reliable solution for IVD waste liquid treatment.

Technical Challenges and Demand Analysis of IVD Waste Liquid Treatment Systems

Waste Liquid Characteristics and Treatment Process

The waste liquid generated from IVD testing contains the following high-risk components:

Biological contaminants: Blood cell residues, protein clots, etc. (particle size ≤ 2mm)

Chemical corrosive media: Strong acids (pH 1), strong alkalis (pH 14), and disinfectants such as sodium hypochlorite

Gas-liquid mixed phase: Foam content as high as 30%, prone to cavitation

The treatment process must meet stringent requirements

Safe transfer: Physical isolation throughout the process to prevent cross-contamination

Stable discharge: Capable of withstanding long-duration continuous operation and extreme medium corrosion

Technical Innovations of TOPSFLO Miniatuere Diaphragm Pump

Physical isolation mechanism based on volumetric transfer

The diaphragm’s reciprocating movement changes the volume of the cavity, achieving absolute medium isolation:

Suction phase: The diaphragm moves back, expanding the cavity volume, creating negative pressure to open the intake valve

Discharge phase: The diaphragm moves forward, compressing the cavity, creating positive pressure to close the intake valve and open the outlet valve

Key subsystem collaborative design

Elastic diaphragm: Made of medical-grade polymer materials (such as PTFE, fluororubber), resistant to chemical corrosion and has a long lifespan

One-way valve group: Precisely designed valve plates ensure unidirectional flow and prevent backflow contamination

Drive mechanism: DC brushless or brushed motors provide stable power, supporting precise flow adjustment

Cavity structure: Smooth flow paths without dead spots, reducing residue and making cleaning and disinfection easier

Engineering Optimization and Verification for IVD Applications

Extreme medium tolerance verification

Environmental adaptability enhanced design

High-altitude operation: Using special materials and a torque-enhanced motor, pressure build-up time at 3,000 meters is reduced by 44% (from 5.7s to 3.2s)

Wide temperature stability: Flow deviation < 2% in the temperature range of 10℃ to 50℃

Long pipeline adaptation: Supports 8m lift and dynamic load adjustment

Full lifecycle reliability assurance

Diaphragm lifespan: 20 million fatigue tests (equivalent to 10 years of use)

Maintenance cycle: 10,000 hours of maintenance-free design, downtime for cleaning < 5 minutes

Conclusion

Through multiple technical innovations—material engineering breakthroughs (medical-grade PTFE composite diaphragm), intelligent control algorithms, and system integration design (modular flow channels and buffering structures)—TOPSFLO diaphragm pumps systematically solve the cavitation, corrosion, and biological contamination problems in IVD waste liquid treatment. Clinically validated, its overall performance reaches international leading levels. Coupled with localized rapid response services (48-hour spare parts supply), it is driving the domestic substitution process of core components in medical equipment.

Wanna to get custom pump service? Feel free to contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Visit our Web: https://www.topstec.com/ | http://www.topsflo.com/

0 notes

Text

How to Choose the Right Diaphragm Metering Pump for Your Needs

Metering pumps are important to the upstream oil and gas industry as they are responsible for precisely injecting flow assurance chemicals like methanol, monoethylene glycol, and corrosion inhibitors into wells. If the delivery of these vital chemicals falters, well production can grind to a halt. While metering pumps might look like small components on an upstream platform, make no mistake: they are essential. To give you an analogy, their role is as important as that of a rivet on an aeroplane wing—if they fail, the entire operation is at risk. Therefore, choosing the right chemical metering pump is crucial.

#Diaphragm metering pump#Hydraulic diaphragm metering pump#Metering pump#Proportional Dosing Pump#IDEX India

0 notes

Text

Dosing Pumps, Electronic Dosing Pump Manufacturers in India

Dosing Pumps, Electronic Dosing Pump Manufacturers, Metering, Chemical Dosing Pumps Exporters, Suppliers in Bangalore, Call: +91-80-41510097.

Dosing Pumps, Electronic Dosing Pump Manufacturers, Metering, Chemical Dosing Pumps Exporters, Suppliers in Bangalore, Dosing Pump, Metering Pumps, Dosing System, Diaphragm Dosing Pump, Chemical Dosing Pump, Positive Displacement Pump, Piston Dosing Pump, Chemical Metering Pump, Electromagnetic Dosing Pump, Electromagnetic Dosing Pump, Motor Driven Dosing Pump.

www.dosingpumps.in

#Dosing Pumps#Electronic Dosing Pump Manufacturers#Metering#Chemical Dosing Pumps Exporters#Suppliers in Bangalore#Dosing Pump#Metering Pumps#Dosing System#Diaphragm Dosing Pump#Chemical Dosing Pump#Positive Displacement Pump#Piston Dosing Pump

0 notes

Text

0 notes

Text

Fuel Pump Replacement

Fuel pump replacement is a necessary part of your car's maintenance. A fuel pump transfers fuel from your tank to your engine. It supplies the fuel at a constant pressure to ensure that the engine is running smoothly. Mechanical or electronic fuel pumps are standard in your vehicle.

A mechanical pump has a diaphragm mounted on the outside of the fuel tank that expands and contracts, creating a vacuum system that expels fuel out of the gas tank and into the engine. Electronic pumps use an electromagnetic motor inside the fuel tank that forces fuel into the engine at a high pressure. Cars with carburetors contain mechanical pumps while vehicles with fuel injection systems have electric pumps.

The motion of the engine directly drives a mechanical pump. Since mechanical pumps contain few moving parts, they tend to be reliable and easy to diagnose and fix. The most common problems with mechanical pumps occur when the diaphragm is damaged in some way, which throws the pressure system off kilt.

Electronic pumps contain increased complexity and include multiple moving parts. Electronic pumps are linked to electronic control systems. Because of this, electric pumps are more prone to failure. Any part of the control system can fail and lead to fuel pump issues.

SYMPTOMS OF FAILING FUEL PUMPS

The symptoms of failure are similar in both types of pumps, although mechanical and electronic pumps fail for different reasons.

1.CAR JERKS OR SPUTTERS AT HIGH SPEEDS

2.YOU LOSE POWER WHEN ACCELERATING

3.YOU HAVE BEEN LOSING POWER WHILE DRIVING UPHILL OR TOWING A LOAD

4.YOUR ENGINE SURGES

5.YOUR ENGINE WILL NOT START

IF YOU THINK YOU NEED A FUEL PUMP REPLACEMENT

If you have encountered any of the symptoms of a failing fuel pump, it is best to bring your car to us at Autopartsproducts. Other mechanical problems can cause some of the symptoms of a bad pump. Our shop can perform tests to isolate the exact cause of the problem. If no other sources seem likely, they will confirm the fuel pump replacement diagnosis with a variety of procedures.

We will begin by checking your car’s electrical system. Mainly, the fuses that direct power to your fuel system. Blown fuses are well-known but inexpensive to replace. If the fuses are not damaged and fixing them does not solve the problem, our mechanics will then check the voltage on the pump itself. Using a multi-meter, the mechanics will measure the voltage drop on either end of the fuel pump to determine the problems with the pump itself.

Your fuel pump is an indispensable part of your car, providing your engine with a constant quantity of the fuel it needs to keep you driving. Like any device, however, fuel pumps eventually wear out after thousands of miles of use. If your car struggles with weak or unreliable power, it may be time to replace the fuel pump on your vehicle.

Searching for Power Oem Injector, Auto Sensor, Igintion Coils, Fuel Pump, Turn Signal Switch and Oxygen Sensor System Manufacturer in China? FASTWIN EFI SYSTEM mainly focus on the fuel injection parts for Car, Motorcycle, General Motor & SCR System Parts for Diesel Vehicle for Chinese Car, Japanese Car, Korean Car, French Car, American Car & German Car.

For all of your European car maintenance needs including fuel pump replacement, you can count on the experienced automotive professionals at Autopartsproducts! Check out our Specials page for money saving discounts on our repairs or services. We are located at: Yinzhou. Ningbo City. PR.China.

0 notes

Text

https://github.com/anushka224473/BeaconMetrics/blob/main/North America Hydraulic Actuated Diaphragm Metering Pump Market Drivers And Trends.md

0 notes

Text

Exploring Metering Pump Market: Trends and Future Outlook

The global metering pump market size is anticipated to reach USD 8.9 billion by 2030, projected to grow at a CAGR of 4.9% from 2024 to 2030, according to a new report by Grand View Research, Inc. The market is expected to rise as a result of technological advancements and expanding end-use industries like chemical, pharmaceutical, and water & wastewater treatment. The market for metering pumps is also expected to be driven by the increased emphasis on process improvement and the growing requirement for precise chemical dosing across sectors for high-quality manufacturing.

Metering pumps move a predefined, exact amount of fluid from one location to another in a predetermined amount of time. They are made to accomplish a steady fluid flow rate, which is frequently needed in applications where accurate dosage is essential. They are employed in commercial and industrial settings for the transmission of gases and liquids.

One of the main reasons driving up demand for metering pumps in the U.S. is the expansion of the water & wastewater treatment sector. In the water & wastewater treatment industries, metering pumps play a major role in the accurate chemical dosing necessary to purify water by eliminating pollutants, bacteria, and hazardous substances. Furthermore, the U.S. market for metering pumps is anticipated to rise significantly over the projected period due to the development of chemical processing sectors like petrochemicals and food processing industries.

Important market participants are creating more carbon footprint-light and energy-efficient pumps to meet these demands. Variable frequency driver (VFD) is a feature of these recently developed pumps that allow for improved flow and pump speed control. Furthermore, recently introduced metering pumps include a digital control system and are integrated with the Industrial Internet of Things (IIoT) to improve their efficacy.

Gather more insights about the market drivers, restrains and growth of the Metering Pump Market

Metering Pump Market Report Highlights

• Based on type, The diaphragm pump segment held the largest revenue share of 55.5% in 2023 and is projected to grow with the fastest CAGR over a forecast period owing to their ability to handle highly viscous and corrosive fluids and heterogeneous fluids with the presence of suspended impurities

• In terms of end-use, the water & wastewater segment held the largest revenue share of 23.1% in 2023 owing to the need for accurate dosing of chemicals to remove water impurities, microorganisms, and contaminants. They are also used to improve the safety rating and quality of potable water

• The chemical segment is expected to grow at the fastest CAGR of 5.8% due to its ability to handle a wide range of chemicals with different pH levels. Further, these pumps maintain precise control over fluid discharge rates and operate reliably under various thermal & pressure conditions

• The Asia Pacific region held the largest revenue share of 41.4% in 2023, owing to high demand in water & wastewater treatment, chemical, and food processing industries

• The Middle East and Africa region is anticipated to grow at the second fastest CAGR of 5.4% over the forecast period, owing to the rising water treatment facilities and oil production in expanding oil & gas exploration and refining facilities

• In June 2023, Verder Group launched a double diaphragm pump for handling hygienic applications. It is designed to cater to the unique needs of the cosmetics, dairy, food, beverage, and pharmaceutical sectors. It is Electro-polished SS 316L and offers exceptional cleanability

Metering Pump Market Segmentation

Grand View Research has segmented the global metering pump market based on type, end-use, and region:

Type Outlook (Revenue, USD Million; 2018 - 2030)

• Peristaltic Pumps

• Diaphragm Pumps

• Piston/Plunger Pumps

• Others

End-use Outlook (Revenue, USD Million; 2018 - 2030)

• Pharmaceutical

• Water & Wastewater

• Food & Beverage

• Oil & Gas

• Chemical

• Others

Regional Outlook (Revenue, USD Million; 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o UK

o France

o Italy

• Asia Pacific

o China

o India

o Japan

o Australia

• Central & South America

o Brazil

o Argentina

• Middle East & Africa

o UAE

o Saudi Arabia

Order a free sample PDF of the Metering Pump Market Intelligence Study, published by Grand View Research.

#Metering Pump Market#Metering Pump Market Size#Metering Pump Market Share#Metering Pump Market Analysis#Metering Pump Market Growth

0 notes