#metal fasteners

Explore tagged Tumblr posts

Text

1 note

·

View note

Text

#Industrials Fasteners#Nuts and Bolts#Industrial Products#Industrial Equipment#Metal Fasteners#Industrial Fastener Supplies

1 note

·

View note

Text

Moncler

6 notes

·

View notes

Text

what do we think, team?

#ill probs get silver colour hardware (rivets and buckle) but just know i may go over them with nail polish bc cringe most-metals allergy#these eyelets are actually where the rivets will ultimately go too! hence the kinda weird spacing. im just drafting colours you could say#(im not allergic to these eyelets; and these are just the 3 colours i have!)#i have three buckle-holes (is there a name for those?) for fastening- THATS where the eyelets will go#crafts#leather craft#wtf else do i call it i am just makin everything up as i go along 8D

2 notes

·

View notes

Text

Working at a hardware store SUCKS because after a certain point you buy anything premade and your like FUCK this garbage I could do WAY better myself with $5 of ingredients from the hardware section unless the premade thing is something from your store in which case you are like FUCK this garbage I am going to the plumbing man that comes in all the time and seeing if he has something second-hand that is actually of decent quality.

#chit chat#in unrelated news I got the fastenings for project jorset and they feel so cheap#i am about to just buy some fucking metal from my work and make them myself#augh#why do I have to diy anything just to have even mediocre quality shit???#vimes boots but even $50 boots these days only last the winter and you still have wet feet

7 notes

·

View notes

Text

Love fanart where kiryu is not smiling but clearly extremely happy

#Yakuza loveblog#need to be in dead souls so i can dress up like a zombie and have a reason to chase him around snd try to bite him#and when he blows my lungs out my back i just fall over and be like owwww and hes like ... tadashi kun ... did you pretend to be a zombie so#you can chase me around and try to bite me? and id be like mhm :((#‘ash did you just make a sona?’ yea ....#i put my name through google translate and thats what came out ... hō tadashi ...#couldnt add the last word of my name though because then it just turns back to chinese which i think is pretty funny#its kind of fucked up that the peng is a giant bird that transforms from a fish. like thats ... me im bird coded#and there are some depictions of it being a fish with gigantic wings which is badass as fuck#LIKE THATS SO METAL actually i love that ... its like ichibans drgaonfish but its a birdfish very awesome#(thinking) (smiling absently)#i think i could leap at kiryu and cling on him and he wouldnt even stumble#giving his neck a wet slobbery kiss and then fastens my teeth around it and bites so hard#i dont care if i get beaten or kicked you have to understand i just want your blood im like a giant frog

11 notes

·

View notes

Text

One of the top wholesalers, suppliers, and importers of a variety of high-quality Fasteners and Fixing including nuts and bolts, metal screws, machine tools, fastener expansion tubes, heavy-duty anchors, anchors for general fixing, pipe clamps, industrial screws, and other items is Kaizen Metals india Screw India.

Our cutting-edge infrastructure facility located in Jamnagar guarantees standardized product manufacture.

These items, which come in a variety of shapes and sizes, are renowned for their smooth finishes, resistance to corrosion, dimensional precision, and durable construction.

For timely, safe, and secure product delivery to customers, our logistic support specialists leverage a large distribution network.

The superior quality of the things our business creates is the single aspect that supports it, and we never compromise on that in any way.

All of our goods are rigorously tested for their durability and safety. We take steps to ensure that none of our valued customers have ever complained about any of our items.

Our company has achieved an unachievable height that is only attained by a very small number of businesses thanks to our moral business methods and unwavering dedication.

We have been able to provide our clients very consistent and trustworthy items at rock bottom prices because of our extensive experience, thorough understanding of this company range, and the presence of incredibly committed and assiduous employees in our crew.

With the help of a group of knowledgeable, skilled, committed, and diligent individuals, this team approached every assignment with great care. Our staff includes purchasing agents, quality inspectors, packaging specialists, and many more.

These individuals were hired based on their expertise and understanding of their respective fields. Their upbeat demeanor and expert understanding of the field create a productive atmosphere where employees love the work they do. Additionally, this team is periodically refreshed in accordance with the most recent market trends.

#nuts and bolts#metal screw#machine tools#fastener expansion tube#heavy duty anchors#general fixing anchors#pipe clamps#industrial screws#fixings and fasteners#fixings and fastener#screws#bolts#nuts#coach-screws#screw hooks#rivets#cotters#cotter-pins#washers

2 notes

·

View notes

Text

Latin America Automotive Metal Fasteners Market Outlook and Forecast 2025-2032

The Latin America Automotive Metal Fasteners Market was valued at US$ 685 million in 2024 and is expected to grow at a CAGR of 4.8%, reaching US$ 908 million by 2030.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286456/latin-america-automotive-metal-fasteners-market-2025-2032-654

0 notes

Text

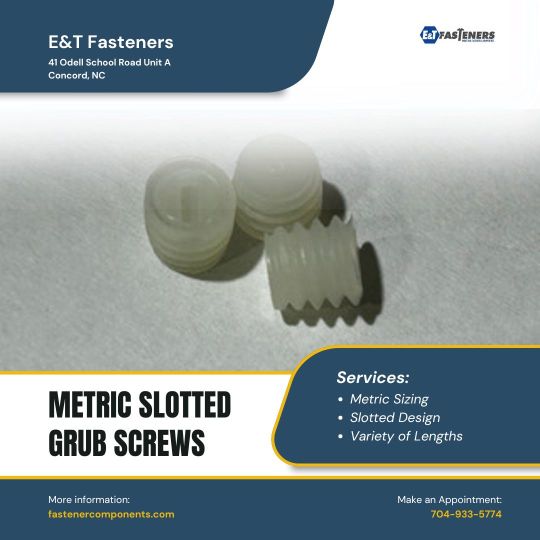

Metric Slotted Grub Screws | E&T Fasteners

E&T Fasteners offers a variety of metric slotted grub screws, which are essential components in many mechanical and engineering applications. These screws are designed for securing objects in place without the need for a traditional head, making them ideal for use in tight spaces. Here’s an overview of metric slotted grub screws and what E&T Fasteners provides:

Overview of Metric Slotted Grub Screws

Definition: Grub screws, also known as set screws, are used to secure an object within or against another object, typically without the use of a nut. Slotted grub screws feature a straight, horizontal slot on the top, allowing for adjustment with a flathead screwdriver.

Material Options: E&T Fasteners provides grub screws in various materials, including stainless steel, carbon steel, and other alloys, ensuring durability and resistance to corrosion.

Key Features

Metric Sizing: Available in standard metric sizes to fit a wide range of applications.

Slotted Design: The slotted head allows for easy installation and removal, making adjustments straightforward.

Variety of Lengths: Offered in different lengths to accommodate various needs and applications.

Customization Options

Tailored Solutions: E&T Fasteners can provide custom sizes and materials based on specific project requirements.

Technical Support: Their knowledgeable team is available to assist with material selection and application advice.

0 notes

Text

The Best Fasteners for Metal Roofing for Secure and Long-Lasting Installations

The Best Fasteners for Metal Roofing: Ensuring Durability and Reliability

When installing a metal roof, one of the most critical decisions you’ll make is choosing the right fasteners for metal roofing. The longevity and durability of your roof largely depend on the quality and type of fasteners used in the installation. At Ejot Octaqon, we provide a range of high-performance fasteners designed specifically for metal roofing systems, ensuring that your roof remains secure and resistant to the elements for years to come.

Choosing the correct fastener can be a challenging task, especially when considering the different materials, conditions, and types of metal roofs available. With Ejot Octaqon, you can trust that you are getting fasteners built for performance, long-term use, and maximum security. Let’s explore the different types of fasteners suitable for metal roofing and what makes them stand out in the industry.

Screw Manufacturers: Quality Fasteners for Metal Roofing

When looking for fasteners for metal roofing, the first step is to choose a reliable and reputable manufacturer. As one of the leading screw manufacturers, Ejot Octaqon offers top-quality solutions for all your metal roofing needs. Our fasteners are engineered with precision to provide strength, stability, and resistance to weathering.

Ejot Octaqon's fasteners are designed for a variety of roofing applications, including residential, commercial, and industrial projects. When considering fasteners, it's essential to keep the following factors in mind:

Corrosion Resistance: Metal roofing systems are exposed to harsh weather conditions such as rain, snow, and UV rays. Fasteners must be resistant to rust and corrosion to ensure that the roof stays intact.

Strength and Durability: Fasteners for metal roofing need to have superior tensile strength and long-lasting performance. The roofing material must be securely fastened to prevent leaks and damage.

Ease of Installation: Fasteners that are easy to install without compromising performance are essential for a smooth roofing project.

Ejot Octaqon provides fasteners that meet these critical requirements, ensuring that your metal roof is secure and reliable for years to come.

Types of Fasteners for Metal Roofing

The market offers a wide range of metal roofing fasteners, each suited to different materials, climates, and types of roofing. Let’s look at the most popular and effective options.

Self-Tapping Screws: A Versatile Solution

Self-tapping screws are a common choice for metal roofing installations due to their ability to create their own threads in metal without the need for pre-drilling holes. These screws provide a tight, secure fit and are ideal for a variety of roofing applications. The self-tapping screw design ensures a precise connection between the metal roofing panels and the underlying structure.

Some key features of self-tapping screws include:

Quick installation: No need for pre-drilling, saving time during installation.

Excellent corrosion resistance: Ideal for use in harsh outdoor environments.

Strong hold: Provides a secure fastening that is resistant to vibration and external stresses.

Ejot Octaqon's self-tapping screws are designed with high-grade materials to ensure optimal performance under all conditions, making them a great choice for a wide range of metal roofing systems.

Self-Drilling Screws: The Ultimate Choice for Efficiency

Self drilling screws are another popular option for metal roofing applications. These fasteners feature a drill point at the tip, enabling them to drill directly into the metal without needing any pre-drilling. The drill bit at the end of the screw makes installation faster, while the sharp tip allows for better penetration into harder materials.

Some benefits of self-drilling screws include:

No pre-drilling required: Reduces time and labor costs.

Better penetration: Works well even with harder metals or thick gauge roofing panels.

Enhanced sealing capabilities: Many self-drilling screws come with rubber washers that ensure a watertight seal, preventing leaks.

At Ejot Octaqon, we provide top-quality self-drilling screws designed for both ease of use and performance. Our range includes the JT3 Self Drilling Screws EJOT and JT2 Self Drilling Screws EJOT, which offer optimal strength and performance for metal roofing applications.

Choosing the Right Fasteners for Your Metal Roof

The right choice of fastener is essential for the security and longevity of your metal roof. Here are some factors to consider when selecting fasteners for metal roofing:

1. Material Compatibility

Make sure that the fastener material is compatible with the type of metal roofing you have. Common roofing materials include steel, aluminum, and copper. You should choose fasteners that are made from materials that resist corrosion and rust when exposed to harsh environmental conditions.

2. Coating and Finish

Many fasteners come with coatings such as zinc or epoxy that improve their corrosion resistance. For coastal areas or places with extreme weather conditions, fasteners with additional protection, such as those with a Galvanized or Xylan coating, offer enhanced longevity.

3. Thread Design

The thread design of a fastener plays a crucial role in how well it will secure the roofing material. For metal roofing, screws with a sharp thread design work best to ensure that they hold tightly and securely.

4. Sealants

In many roofing systems, a watertight seal is necessary to prevent leaks. Some fasteners are designed with built-in rubber washers that act as a seal, preventing water from penetrating the roofing system.

5. Longevity and Warranty

To ensure the best value for your investment, choose fasteners with a long warranty and proven track record for durability. Ejot Octaqon's fasteners come with excellent warranties, giving you peace of mind that your roof will be secure for years.

Conclusion: Trust Ejot Octaqon for Reliable Fasteners

In summary, fasteners for metal roofing are essential for ensuring a secure, long-lasting installation. Whether you're using self-tapping screws, self-drilling screws, or other types of fasteners, it’s important to choose quality products that provide superior performance and durability.

When selecting fasteners for metal roofing, consider working with trusted manufacturers like Ejot Octaqon. With our experience in providing high-quality metal roofing fasteners, including JT3 Self Drilling Screws EJOT and JT2 Self Drilling Screws EJOT, we offer reliable and efficient solutions for all your roofing needs. Choose Ejot Octaqon for fasteners that ensure your metal roof remains strong, secure, and weather-resistant for many years to come.

#Fasteners for metal roofing#Self drilling screws for steel#Metal roofing fasteners#EJOT Solar Fasteners#Self drilling screw manufacturers in india#Screw manufacturers#Screw manufacturers in india#Self tapping metal screws

0 notes

Text

ETICS: External Thermal Insulation Composite System

Understanding ETICS: A Comprehensive Overview

ETICS, or External Thermal Insulation Composite System, is an innovative method for enhancing the energy efficiency of buildings. This system consists of insulating materials fixed to the external walls of a structure, followed by a protective and decorative finish. With energy costs on the rise, many building owners and contractors are turning to ETICS as a reliable solution for thermal insulation, providing significant savings on heating and cooling expenses.

The importance of effective insulation cannot be overstated, especially in climates with extreme temperatures. The ETICS system offers a seamless approach to improving a building's thermal performance while also contributing to aesthetic appeal. In this blog, we will delve into the features and advantages of ETICS, the role of Ejot Octaqon in this domain, and how self-drilling screws and fasteners play a critical role in its implementation.

The Role of Fasteners for Metal Roofing in ETICS

When it comes to the installation of the ETICS system, the choice of fasteners is crucial. Fasteners for metal roofing must be robust and reliable, ensuring that the insulating layers are securely attached to the structure. Ejot Octaqon specializes in providing high-quality fasteners that cater specifically to the needs of the ETICS system.

Key Benefits of Using Quality Fasteners

Durability: Fasteners made from carbon steel are designed to withstand harsh weather conditions, providing longevity and reliability to the ETICS system.

Ease of Installation: Self-drilling screws simplify the installation process, allowing for quicker and more efficient application of the ETICS system.

Enhanced Energy Efficiency: Properly secured insulation means fewer thermal bridges, enhancing the overall energy efficiency of the building.

How ETICS Contributes to Energy Efficiency

The primary advantage of the ETICS system is its ability to drastically improve a building's energy efficiency. Here are some of the key aspects:

Reduced Energy Consumption: By providing continuous insulation, the ETICS system minimizes heat loss during winter and heat gain during summer, leading to reduced energy consumption.

Improved Comfort: With a well-insulated building, occupants enjoy a more comfortable indoor environment, regardless of external weather conditions.

Environmental Impact: Enhanced energy efficiency translates to lower carbon emissions, contributing to a greener planet.

Ejot Octaqon’s Commitment to Quality and Innovation

Ejot Octaqon is dedicated to providing the highest quality components for the ETICS system. Our range of products includes:

Self-Drilling Screws: Designed for fast and easy installation, these screws are ideal for securing insulation materials to various substrates.

Carbon Steel Screws EJOT: Our carbon steel screws offer superior strength and resistance to corrosion, making them perfect for both indoor and outdoor applications.

Why Choose Ejot Octaqon?

Choosing Ejot Octaqon means opting for quality and reliability in your ETICS projects. We understand the intricacies of the ETICS system and ensure that our fasteners and screws meet industry standards, thereby enhancing the overall performance and durability of the insulation system.

Conclusion

In summary, the ETICS system is a vital component for modern buildings, offering superior thermal insulation and energy efficiency. The role of quality fasteners, such as self-drilling screws and carbon steel screws, cannot be understated in this context. With Ejot Octaqon’s expertise and commitment to quality, building owners and contractors can be confident in the performance of their ETICS installations.

By utilizing the ETICS system and the right fasteners, you not only ensure the longevity of your building but also contribute to a more sustainable future. If you’re looking to improve your building's energy efficiency, consider the ETICS system and trust Ejot Octaqon to provide the necessary solutions for your project.

#ETICS#Self drilling screws for steel#Fasteners for metal roofing#Metal roofing fasteners#Self drilling screws#Self tapping screws#JT2 Self Drilling Screws EJOT#JT3 Self Drilling Screws EJOT

0 notes

Text

Discover the efficiency and durability of Clariannt's self-drilling screws, designed to simplify installation and ensure secure fastening for various construction tasks. Available in multiple sizes, these high-quality self-tapping screws eliminate the need for pre-drilling, making them an ideal choice for professionals and DIY enthusiasts alike.

#self-drilling screws#self-tapping screws#Clariannt fasteners#durable screws#construction screws#easy installation#fastening solutions#no pre-drilling#reliable fasteners#versatile screws#DIY screws#high-quality fasteners#screw sizes#wood screws#metal screws#secure fastening

0 notes

Text

Inconel 600 or Monel Fasteners: Choosing the Best Alloy for Your Application

Choosing the right fastener material is crucial for ensuring longevity and affects your project's overall performance. When it comes to high-performance applications that demand resistance to corrosion, high temperatures, and harsh environments, two alloys stand out: Inconel 600 and Monel.

With This blog let’s help you make the right decision for your project: Inconel 600 or Monel fasteners

Let’s begin with understanding both these alloy types and their ideal industry applications:

Inconel 600

Inconel 600 is a nickel-chromium-iron superalloy known for its exceptional strength and resistance to oxidation, creep rupture, and carburization. Its high nickel content makes it highly resistant to corrosion in a wide range of environments, including oxidizing, reducing, and acidic conditions. Here at Online Fittings, we offer a variety of Inconel 600 fasteners, including bolts, nuts, washers, and screws, in various sizes and thread types to meet your specific needs.

Inconel 600 is the ideal choice for applications requiring exceptional high-temperature strength, oxidation resistance, and resistance to creep rupture. Its ability to withstand harsh environments makes it suitable for use in:

1. Jet engines 2. Nuclear reactors 3. Chemical processing equipment 4. Gas turbines 5. Heat exchangers 6. Furnace components 7. Cryogenic applications (at limited temperatures)

Monel

Monel is a nickel-copper alloy that offers excellent resistance to various corrosive media, including seawater, sulfuric acid, and hydrofluoric acid. It also boasts superior mechanical properties at both high and cryogenic temperatures. You have the liberty to choose from our online vast selection of Monel fasteners, including hex cap screws, square neck bolts, U-bolts, and coupling nuts, ensuring you have the right fastener for your application.

Monel is ideally used in industries that demand superior resistance to saltwater corrosion, sulfuric acid, and hydrofluoric acid. Its good strength at both high and low temperatures makes it a versatile option for:

1. Marine equipment 2. Offshore oil and gas rigs 3. Chemical processing plants 4. Pulp and paper mills 5. Pickling tanks 6. Desalination plants

Key Factors to Consider When Choosing Between Inconel 600 and Monel Fasteners

Here’s a breakdown of key factors to consider whilst deciding between Inconel 600 and Monel fasteners:

Property Inconel 600 Monel

Maximum Service Temperature, 1600°F (871°C), 800°F (427°C)

Strength

Higher, Lower

Oxidation Resistance

Excellent, Excellent

Chloride Stress Cracking

Good, Excellent

Cost

Higher, Lower

Additional pointers to consider:

1. Size and thread type: Ensure the fasteners are the correct size and thread type for your application. Look for an alloy fastener manufacturer who can customize each inch for your requirements.

2. Head style: The head style of the fastener (e.g., hex head, socket head) should be compatible with the installation tools and space constraints of your application.

3. Surface finish: Consider the desired surface finish (e.g., plain, zinc-plated) for factors like corrosion resistance and aesthetics.

Why Choose Online Fittings for Your Inconel 600 and Monel Fastener Needs?

At Online Fittings, we are committed to providing our customers with the highest quality Inconel 600 and Monel fasteners. We offer a comprehensive selection of fasteners in various sizes, thread types, and head styles to meet the demands of your project.

The experts at Online Fittings are always here to help you select the right fasteners to ensure the success of your project.

Let Online Fittings be your one-stop shop for all your Inconel 600 and Monel fastener needs. Contact us today to discuss your project requirements and receive a custom quote quote.

0 notes

Text

youtube

CADILLAC BRATZ-HURT SO LONG

0 notes

Text

How Lyn-Tron Inc. Helped a Leading Manufacturer Reduce Costs and Improve Efficiency

Introduction

In today’s competitive manufacturing landscape, reducing costs and improving efficiency are not just goals; they are necessities. This case study delves into how Lyn-Tron Inc., a renowned provider of electronic hardware, helped a leading manufacturer achieve significant cost savings and operational efficiency. Through a blend of innovative solutions, technological advancements, and unwavering support, Lyn-Tron Inc. played a pivotal role in transforming the client’s manufacturing processes.

Background of Lyn-Tron Inc.

Founded several decades ago, Lyn-Tron Inc. has established itself as a leader in the electronic hardware industry. With a diverse product range including spacers, standoffs, and electronic hardware, the company has built a strong reputation for quality and reliability. Lyn-Tron Inc. is known for its customer-centric approach, continually evolving to meet the dynamic needs of the market.

The Client: A Leading Manufacturer

Our client, a prominent manufacturer in the automotive sector, faced escalating production costs and inefficiencies in their processes. With a large-scale operation and a complex supply chain, the client needed a partner who could provide tailored solutions to address their unique challenges. Lyn-Tron Inc. emerged as the ideal choice, given their expertise and track record.

Initial Assessment and Analysis

Lyn-Tron Inc. began the engagement with a thorough assessment of the client’s existing processes. This comprehensive audit included an in-depth analysis of production workflows, machinery, and overall operational practices. The key findings revealed several areas where improvements could be made, particularly in streamlining processes and adopting new technologies.

Customized Solutions by Lyn-Tron Inc.

Based on the assessment, Lyn-Tron Inc. developed a customized strategy tailored to the client’s needs. This strategy included the introduction of innovative products designed to enhance operational efficiency. Additionally, process optimization recommendations were made to reduce waste and improve productivity.

Implementation Phase

The implementation phase was meticulously planned and executed. Lyn-Tron Inc. worked closely with the client’s team to ensure a smooth transition. This collaborative approach involved addressing potential challenges upfront and providing solutions to mitigate risks. Regular updates and open communication were maintained throughout the process to ensure alignment and progress.

Technological Innovations Introduced

One of the critical aspects of the project was the introduction of advanced machinery and tools. Lyn-Tron Inc. brought in state-of-the-art equipment that significantly enhanced production capabilities. Automation played a vital role in reducing manual errors and increasing throughput. The integration of cutting-edge technology also improved precision and consistency in manufacturing processes.

Training and Support

Recognizing the importance of a skilled workforce, Lyn-Tron Inc. implemented comprehensive training programs for the client’s employees. These programs were designed to familiarize staff with new technologies and processes, ensuring they could operate the machinery efficiently. Ongoing support and maintenance were also provided to address any issues promptly and maintain optimal performance.

Cost Reduction Strategies

Lyn-Tron Inc. identified several cost-saving opportunities during their analysis. By applying lean manufacturing principles, they were able to eliminate waste and streamline operations. These efforts resulted in significant cost reductions, allowing the client to reinvest savings into other critical areas of their business.

Efficiency Improvement Techniques

Efficiency improvements were achieved through various techniques, including the streamlining of production processes and reducing downtime. By minimizing waste and optimizing workflows, Lyn-Tron Inc. helped the client enhance overall productivity. The introduction of automated systems further contributed to these efficiency gains, ensuring consistent output and reduced cycle times.

Quality Control Enhancements

To ensure high-quality output, Lyn-Tron Inc. implemented improved quality assurance measures. These enhancements led to a reduction in defects and rework, contributing to higher customer satisfaction. The client reported fewer returns and complaints, underscoring the success of the quality control improvements.

Measurable Outcomes

The success of the project was measured using key performance indicators (KPIs). Before-and-after comparisons highlighted the significant improvements achieved in various areas. The client experienced notable cost reductions, enhanced efficiency, and improved product quality. These long-term benefits have positioned the client for sustained success in their industry.

Client Testimonial

The client’s management team expressed their satisfaction with the partnership. They highlighted the professionalism and expertise of Lyn-Tron Inc. in delivering impactful solutions. The client noted that the collaboration had exceeded their expectations, resulting in tangible benefits and a strengthened competitive position.

Lessons Learned and Best Practices

Several key takeaways emerged from this project. One of the primary lessons learned was the importance of a tailored approach to address specific challenges. Best practices included maintaining open communication, involving all stakeholders in the process, and leveraging technology to drive improvements. These insights can serve as valuable guidelines for other manufacturers seeking similar transformations.

Conclusion

In conclusion, the partnership between Lyn-Tron Inc. and the leading manufacturer exemplifies how targeted solutions and innovative approaches can drive significant improvements in cost and efficiency. Lyn-Tron Inc.’s expertise and dedication were instrumental in achieving the client’s goals. As both companies look to the future, the foundation of this successful collaboration promises continued growth and advancement.

1 note

·

View note

Text

hi, I am Zoe from China, businesswoman dealing in tungsten carbide industry

nice to meet you ~

1 note

·

View note