#maryland diamond cutters

Explore tagged Tumblr posts

Text

Concrete Slab Cutting Services in Maryland: A Comprehensive Guide

Concrete slab cutting is a crucial service in Maryland’s bustling construction industry. From residential home improvements to large-scale commercial projects, cutting through concrete with precision is often essential for plumbing, electrical installations, expansions, and more. With Maryland’s robust mix of urban, suburban, and rural projects, concrete cutting services play a key role in ensuring structural integrity and project efficiency. This article dives into everything you need to know about concrete slab cutting services in Maryland, including why these services are needed, what they entail, and how to choose a reliable provider. visit concrete slab cutting service Maryland

1. What is Concrete Slab Cutting?

Concrete slab cutting is a specialized process of precisely cutting through concrete surfaces or slabs. This may be necessary for a variety of reasons, such as accessing underground utilities, creating openings for new structures, or modifying existing foundations. The work is done by skilled professionals using high-powered tools like saws with diamond-coated blades, which provide the precision needed for accurate cuts without compromising structural stability.

Types of Concrete Cutting Techniques

Concrete slab cutting isn’t a one-size-fits-all process. Several techniques are available, each suited to specific needs:

Flat Sawing: This is the most common technique, used for horizontal surfaces like floors and roadways.

Wall Sawing: For creating precise openings in walls for doors, windows, or mechanical systems.

Core Drilling: Essential for creating circular holes in concrete, often for electrical wiring, plumbing, and HVAC installations.

Wire Sawing: A technique typically used for large-scale cuts, where other sawing methods aren’t feasible.

2. When Do You Need Concrete Slab Cutting Services?

Concrete slab cutting is required in a variety of situations across both residential and commercial settings. Common scenarios include:

Renovation Projects: When remodeling a home or building, concrete cutting is often necessary to make room for new installations or modifications.

Road Repairs and Infrastructure: Many of Maryland’s roads, highways, and bridges require concrete cutting for repair and maintenance.

Utility Installations: Installing plumbing, electrical, or drainage systems often requires precise concrete cutting to access or modify the foundation.

Emergency Repairs: Concrete slab cutting is sometimes needed for emergency repairs, such as fixing leaks, broken pipes, or structural damage.

3. Benefits of Professional Concrete Slab Cutting Services

Opting for a professional concrete slab cutting service in Maryland offers numerous benefits. These experts are equipped with the right tools, techniques, and experience to execute precise cuts safely and efficiently. Here’s why hiring a professional service is advantageous:

Precision and Safety: Professional concrete cutters use advanced equipment and follow stringent safety protocols. This ensures that the cuts are precise, minimizing the risk of structural damage.

Time Efficiency: With specialized tools and experience, professional concrete cutting services can complete projects faster than non-professional attempts.

Cost-Effectiveness: Although hiring professionals may seem costly upfront, it often saves money in the long run by avoiding errors, material waste, and potential repair costs.

Environmentally Friendly: Professional services often use methods that minimize dust and debris, helping to maintain a cleaner, safer work environment.

Regulatory Compliance: Maryland, like other states, has specific regulations for construction and renovation projects. Professional concrete cutters are knowledgeable about these requirements, ensuring that your project is compliant.

4. How to Choose a Reliable Concrete Slab Cutting Service in Maryland

Selecting the right concrete cutting service is crucial for a successful project. Here are some key factors to consider when choosing a provider:

Experience and Expertise: Look for companies with years of experience and specialized knowledge in concrete cutting. An experienced service provider will have a solid understanding of Maryland’s unique construction needs.

Reputation and Reviews: Check online reviews, testimonials, and ratings to gauge the quality of service provided by a company. Positive feedback from previous clients is a good sign of reliability.

Equipment and Technology: The best concrete cutting services use advanced, high-quality equipment that can handle a range of materials and depths.

Safety Practices: Concrete cutting can be hazardous. Choose a company that prioritizes safety, with employees trained in OSHA standards and using protective gear.

Licensed and Insured: Ensure that the company is properly licensed and carries insurance, which can protect you from liability in case of accidents or damage.

5. Leading Concrete Slab Cutting Service Providers in Maryland

Maryland is home to several reputable concrete slab cutting service providers. Some top companies include:

Penhall Company: Known for its nationwide presence and extensive range of services, Penhall offers concrete cutting, scanning, and demolition services in Maryland. With a focus on quality and safety, Penhall is a trusted choice for complex projects.

Capital Concrete Cutting: This locally-based company specializes in residential and commercial concrete cutting. They offer various services, including slab cutting, core drilling, and curb sawing.

Atlantic Concrete Cutting, Inc.: Serving Maryland and neighboring states, Atlantic Concrete Cutting is well-regarded for its experience, advanced technology, and reliable results.

6. Costs of Concrete Slab Cutting in Maryland

The cost of concrete slab cutting services varies depending on factors such as project complexity, slab thickness, cutting technique, and location. Here’s a rough guide:

Basic Cuts: For simple cuts (up to 4 inches deep), rates typically range from $3 to $7 per linear foot.

Medium Depth Cuts: For cuts between 4 and 12 inches, prices may go from $7 to $15 per foot.

Deep or Specialized Cuts: Complex cuts, including core drilling, wire sawing, or cuts deeper than 12 inches, often range from $15 to $30 per foot or more.

Additional costs may include travel fees for projects located farther from the provider’s base and any permit fees required by local jurisdictions in Maryland.

Conclusion

Concrete slab cutting is an essential service in Maryland, supporting a range of residential, commercial, and infrastructure projects. With various cutting techniques and specialized equipment, these services ensure precision, safety, and efficiency in all types of construction and renovation projects. By choosing an experienced, reputable provider, you can benefit from the latest cutting technology and best practices, ensuring a high-quality outcome for your project.

If you’re planning a project in Maryland that involves concrete cutting, consider consulting with a professional service. Whether you’re modifying a home, repairing a road, or installing utilities, Maryland’s concrete slab cutting experts are equipped to meet your needs with skill and precision.

0 notes

Text

This Website Is Selling All The Junk TSA Confiscated From You

The state of Pennsylvania is auctioning off 14 pounds of assorted knives, 12 pounds of scissors, and six pounds of reading glasses in bulk at deep discount prices.

That's according to postings on GovDeals, a website where government agencies sell off surplus inventory—including property confiscated from travelers by the Transportation Security Administration (TSA).

Twitter user Cliff Jerrison shared a series of screenshots of various listings from GovDeals, which include some truly bizarre deals on bulk items. “I found the website where the TSA sells your stuff,” he wrote.

The listings advertise approximately 12 pounds of scissors starting at $12, and 11 pounds of assorted box cutters and knives starting at $20. Both listed the Pennsylvania Federal Surplus Property as the seller, but the items are described as "The Commonwealth of Pennsylvania Sale of TSA Property."

Scissors for sale in bulk on GovDeals after being confiscated from airline travelers

Everybody has tried to carry something they shouldn't through a TSA checkpoint at some time or another—whether it's oversized beauty products, nail clippers, or Swiss Army knives. But these listings raised concerns about what happens when you leave your item with TSA security.

TSA regional spokesperson Lisa Farbstein told Motherboard that travelers have a series of options when they are stopped for carrying a prohibited item. Using a knife for example, Farbstein explained that a traveler could put the knife in their checked bag, leave it with someone who is not traveling, mail it somewhere using the airport’s mailing service, or surrender it to the TSA agents.

According to a 2015 investigation done by The Washington Post, belongings that are taken by the TSA and items left in the airport are collected at the end of every day. They estimated that around 100 to 150 pounds of items can be taken on a typical day, sometimes more during the holidays.

Items that are surrendered to TSA then get boxed up and transferred to the state, or commonwealth. The state then has the authority to sell or auction the items off using websites such as GovDeals.

Other listings from the Pennsylvania Federal Surplus Property Program include a variety of nail clippers, FitBits and Apple AirPods. All of these listings are categorized as “confiscated/forfeited/personal property” on the GovDeals website.

Previously-owned Apple AirPods for sale on the GovDeals website

Farbstein told Motherboard that any profit made from these sales goes to the state, not TSA.

Troy Thompson, press secretary of the Pennsylvania Department of General Services, told Motherboard that the Pennsylvania Federal Surplus Property Program has always been “profitable.” He estimates that the program, which has been running since 2004, has earned millions of dollars over the years.

Cars, tools, airplanes, and more from government agencies across the country are available on GovDeals. A quick search of the “confiscated/forfeited/personal property” category shows listings such as diamond jewelry being sold by Knox County, Tennessee, an Apple iPad of unknown condition being sold by the Jessup, Maryland Police Department, and a stainless steel Rolex from the Kenton, Kentucky County Fiscal Court that is currently bidding for $9,200.

This Website Is Selling All The Junk TSA Confiscated From You syndicated from https://triviaqaweb.wordpress.com/feed/

0 notes

Text

Unique Ways to Bury your Pet

When a beloved pet passes away, there are a few options for their final resting place. People often choose to cremate their animals, place them in a local pet cemetery, or bury them in the backyard. Have you ever wondered about some of the more unique options available? Here is a list of 4 ways to bury your pet in style.

Pet Mummification

If you want a unique and historically inspired end for your pet, you can get them mummified at the Summum Pyramid in Salt Lake City, Utah. Once your beloved pet is delivered to their facility, their Thanatogeneticists will begin the mummification process. They start by treating the body with oil and wrapping it in cloth. For 5-10 months they continue to use their modern mummification techniques until the body is preserved. It is then placed inside a unique bronze mummiform and returned to the owner. Mummification can cost anywhere from $4,000 to $28,000 depending on the size of the pet, and the bronze mammiform can cost anywhere from $5,000 to $100,000 depending on the bronze finishes and custom work.

Image: Vincent

Eternal Reefs

If you want an environmentally friendly way to inter your pet, an eternal reef could be the solution for you. Eternal reefs take the cremated remains of pets and people and mix them into an environmentally safe concrete. The concrete is molded into a shape designed to recreate natural reef formations to facilitate the growth of coral and fish habitats. The family of your pet can come and help mix the ashes into the cement, add handprints, messages, and small mementos like a dog tag or favorite treats. The reefs are placed on reef sites that are designated for fishing and diving, so you can dive down and visit your pet’s reef anytime you want. Eternal reefs have been placed off the coasts of Florida, South Carolina, North Carolina, Maryland, New Jersey, Texas and Virginia. The reefs cost $4,000 to $7,500 depending on the size of memorial you choose.

Image Eternal Reef

Pet Diamond

One way to keep your pet close to you at all times is to transform their ashes into a beautiful diamond ring. LifeGem is a company that takes the carbon from cremated remains and refines them into a beautiful stone. Once LifeGem has the cremains, they heat them to a high temperature to convert the carbon into graphite. The graphite is then placed inside of a diamond press which replicates the pressure and heat that happens within the earth to create a raw diamond. Then the diamond is given to their skilled diamond cutters and cut to your specifications and certified for authenticity. The diamonds come in a variety of colors, carats, cuts, and sizes. The price ranges from $2,500-$25,000 depending on how many carats you want your gem to have.

Image Life Gem

Freeze Dry Taxidermy

If burial or cremation isn’t for you and you’d rather keep your pet in your sights, freeze dry taxidermy could be. Freeze drying your pet is different than traditional taxidermy because it’s less invasive and creates a more realistic looking end result. Freeze drying uses a process called lyophilization that gently freezes the animal and uses a vacuum to extract the water vapor. The process generally takes around 2 to 4 months to complete and your pet can be positioned any way you want.

Image PreservedPets.com

0 notes

Text

Diamonds are forever – whether made in a lab or mined from the earth

Are you in the market for some sparkle? clearviewstock/Shutterstock.com

Joshua Wilhide, University of Maryland, Baltimore County and William LaCourse, University of Maryland, Baltimore County

It's diamond season. Almost 40 percent of American engagements happen between Thanksgiving and Valentine's Day, with Christmas the most popular day to pop the question – and hand over a sparkly piece of ice. Jewelry stores do at least double their usual monthly sales in December.

Since at least the late 1800s, with the discovery of huge diamond mines in South Africa, people have treasured these dazzling gems. The beauty and splendor of diamonds goes well beyond the surface. Like a diamond hunter digging in an underground mine, one must look deeper to their atomic characteristics to understand what sets these stones apart – and what makes them valuable not just for romantics but also for scientists.

On the atomic level

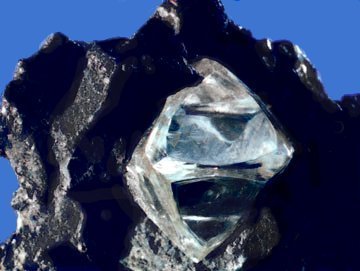

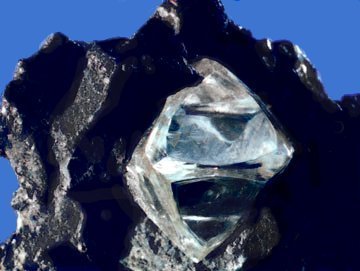

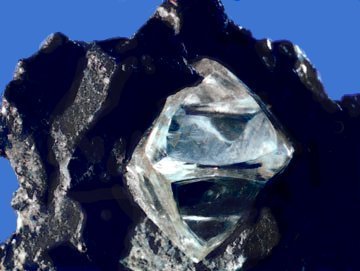

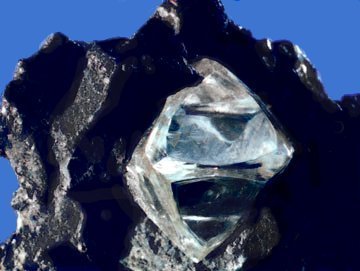

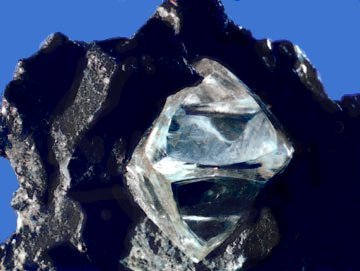

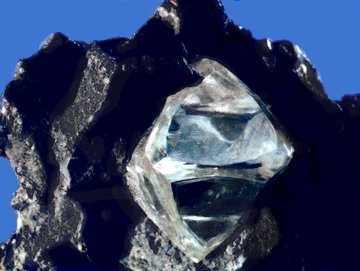

A literal diamond in the rough, before it's been removed from the matrix within which it formed. USGS, CC BY

When mined from the earth, diamonds look like cloudy rocks before they're cut and polished. Their chemical nature and structure were unknown for centuries. It was Isaac Newton's experiments in the 1600s that first suggested diamonds are made up of the fourth-most abundant element, carbon.

People doubted Newton's discovery, which is understandable considering how different diamonds look from other common forms of carbon, like the graphite in pencils or the ash left over in a wood-burning fireplace. But in 1797, English scientist Smithson Tennant confirmed the composition of diamonds.

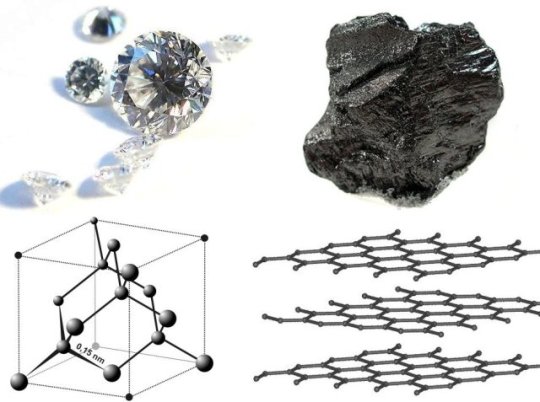

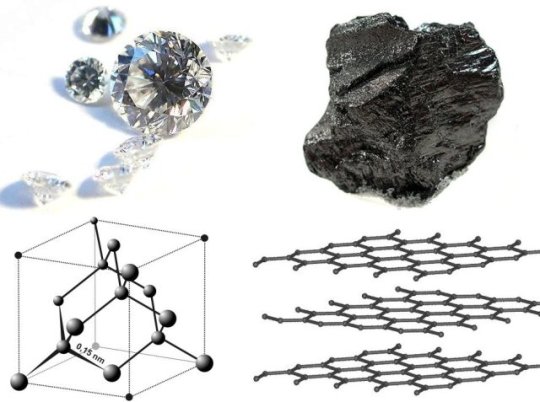

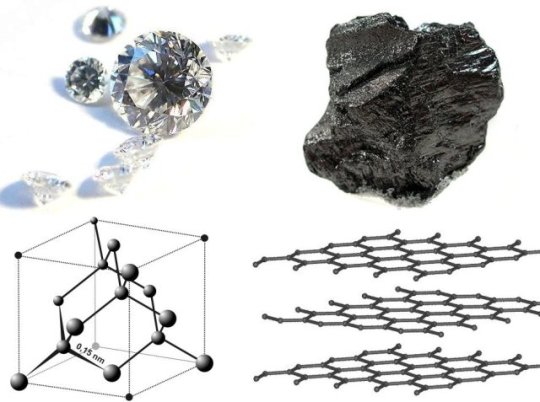

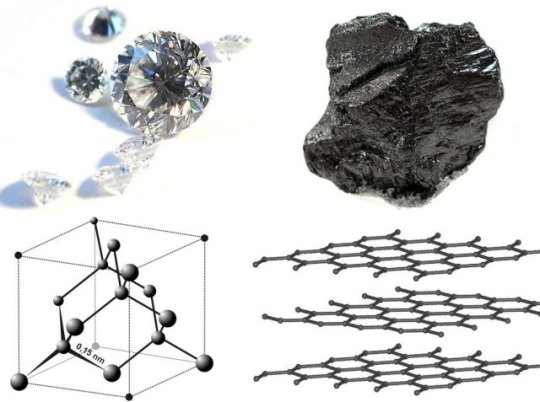

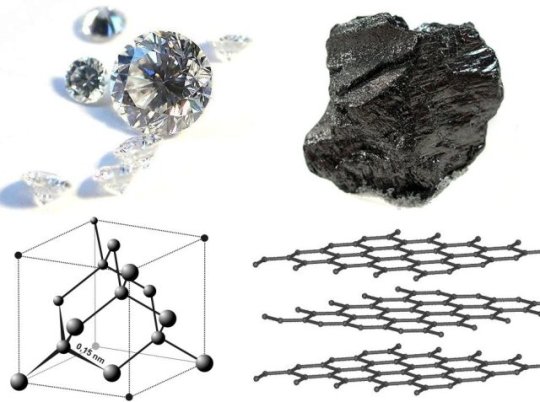

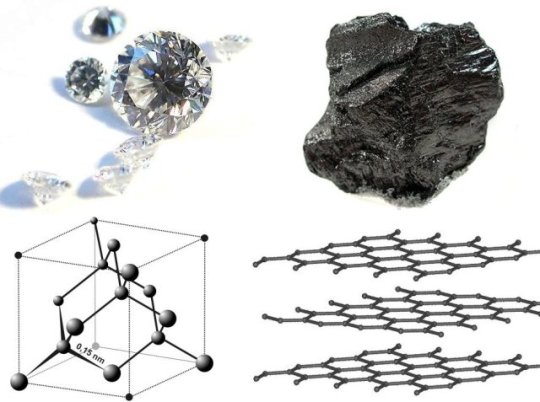

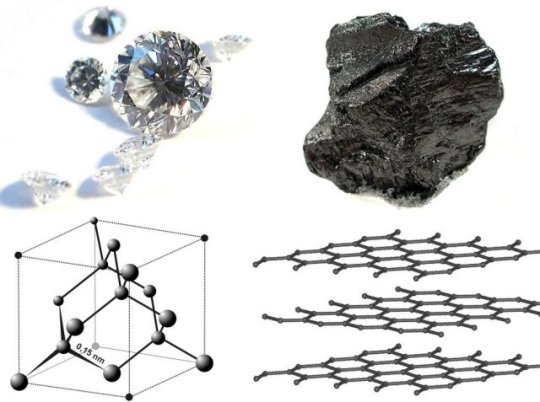

Diamond and graphite are both made of carbon atoms, but organized in different structures. Materialscientist/Wikimedia Commons, CC BY-SA

It turns out that carbon takes two common forms that have crystalline structures on the atomic level. Graphite is a repeating two-dimensional, honeycomb-like shape, with layers stacking on top of each other. Alternatively, carbon can form a repeating three-dimensional shape, a tetrahedron – and that's your diamond.

Where do they come from?

There are two sources of the precious gemstone: natural mining or synthesis within a laboratory.

Natural diamonds are formed under intense pressure and heat in the Earth's crust over millions of years. Natural deposits have been found all over the world, from Northern Canada to Western Australia, even underwater in Namibia.

Mines were the only source of the gemstone until 1955, when General Electric produced the first synthetic diamond using what's called the high-pressure, high-temperature process. This process works by applying hundreds of thousands pounds of pressure to graphite at 2,700 degrees Fahrenheit to force the carbon into the correct crystalline structure. It's sort of like an artificial version of the extreme conditions that produce diamonds deep within the earth.

In the 1970s, labs started to use the chemical vapor deposition method to grow diamonds at lower pressures. At the time, the HPHT technique couldn't produce a gem-quality stone. This improved method converts a hydrocarbon gas mixture by breaking it down to its components, carbon and hydrogen molecules, with an intense heated filament or plasma and deposits it onto a substrate, ultimately forming a solid diamond. Originally, this process had a very slow growth rate, but it's now optimized to grow quality diamonds within days.

Together these techniques are largely responsible for human-made diamonds – upwards of 4 billion carats worldwide annually.

There's a common misconception that a natural diamond must be inherently different than a synthetic diamond. To the contrary, they are chemically identical and share the same physical properties. Even the most sophisticated techniques can not detect a difference between a flawless mined diamond and a flawless human-made diamond – both are “real” diamonds. However, truly flawless diamonds of either type are extremely scarce.

Assessing a diamond

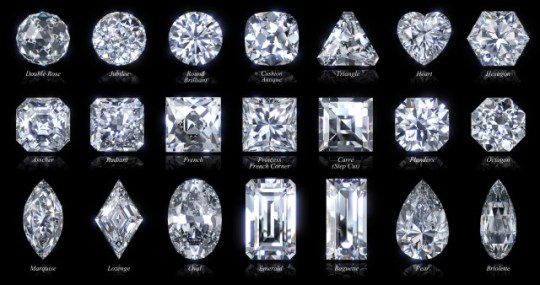

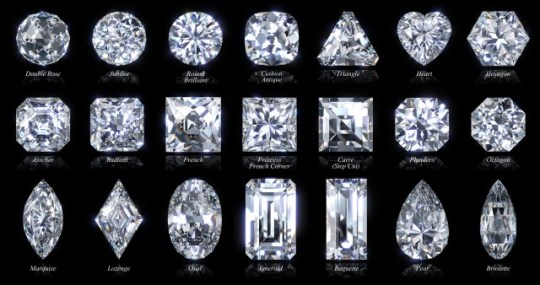

No matter its origin, a diamond can be assessed by the “four Cs” of cut, color, clarity and carat weight. Specialized laboratories grade each category, as created by the Gemological Institute of America.

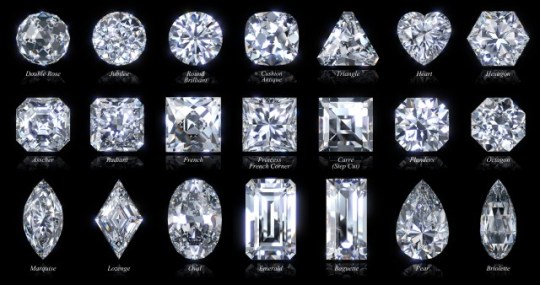

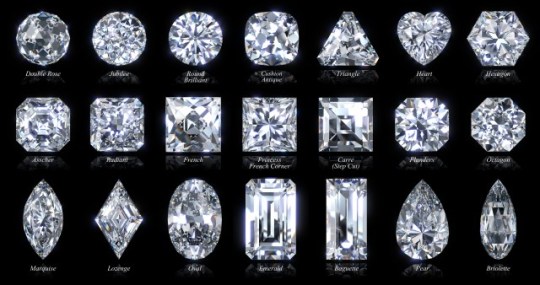

Diamond cutters choose the shape of the finished stone. SPbPhoto/Shutterstock.com

The cut of a diamond is defined in two ways. There's “the general shape of the cut stone,” with shapes including round brilliant (most common), oval, emerald, pear, princess, trilliant, triangle, heart and radiant. And there's “the degree of perfection achieved by the cutting and polishing process” as rated on a scale ranging from excellent to poor. The type and quality of the cut ultimately determines the way light reflects in the stone, contributing to its “brilliance.”

The color of a diamond is graded on a scale from “D,” being perfectly colorless, to “Z” having the most color. Originally, the color of the stone was a huge hint about how it was formed because until 2007 about 90 percent of the high-pressure, high-temperature synthetic stones were yellow orange or yellow. Almost no stones from that process were colorless, so a colorless stone was almost certainly natural. But the HPHT growing process has greatly improved and as of 2016, 43 percent of synthetic diamonds were colorless.

Diamond clarity indicates the presence of inclusions, or tiny imperfections, in the stone. Inclusions make every diamond unique and provide strong clues to whether a diamond is natural or synthetic. The HPHT process uses metal flux, or a hot metal liquid, which acts as a solvent to dissolve the carbon source, graphite, to be rearranged and grown into a diamond. Diamonds grown this way can have inclusions of metals. The resulting stones may be magnetic – if a diamond reacts with a magnet, it is certainly synthetic. Additionally, most synthetic diamonds receive high clarity grades, while natural diamonds contain larger inclusions.

Many consumers focus on carat weight – that is, diamond size. The stone is weighed on a scale where one carat is 200 milligrams (0.007 ounces). Diamonds larger than four carats are almost guaranteed to be natural because that's the limit for the size of the diamonds that the synthetic processes can grow.

Although the “four Cs” of diamonds ultimately define retail value, sentimental value can be even greater. Buyers must decide if a natural or synthetic stone fits the bill for them, based on factors that might include the ecological and ethical ramifications of diamond mining as well as the lower price tag for synthetic rocks.

Diamonds found beyond your ring finger

Although diamonds are well known for their place in the jewelry industry, they play other valuable roles, too.

Their physical properties, especially hardness, are ideal for abrasive applications. Small diamonds can be found coating cutting wheels, drill bits and grinding wheels, which are used for cutting concrete or brickwork.

Diamonds also have certain optical properties that make them suitable for various spectroscopy techniques, or measurements involving the electromagnetic spectrum. Scientific researchers use these tests to help identify the composition of materials they're investigating.

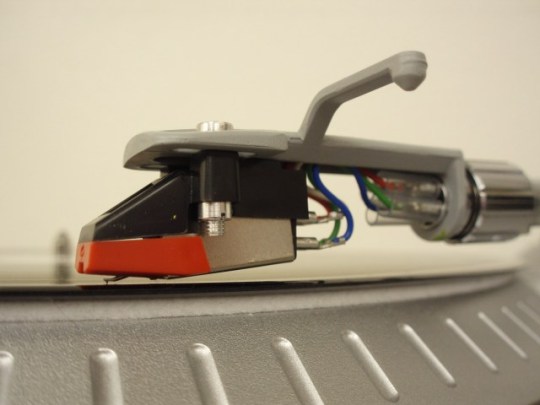

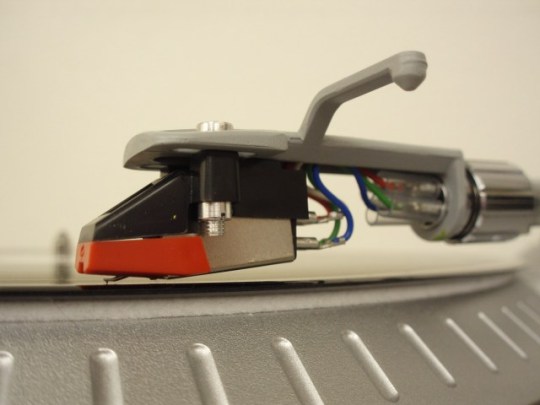

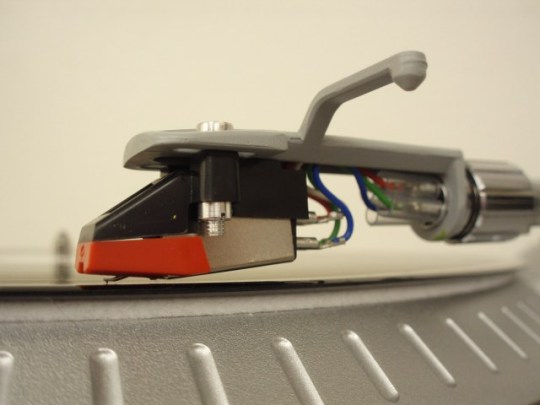

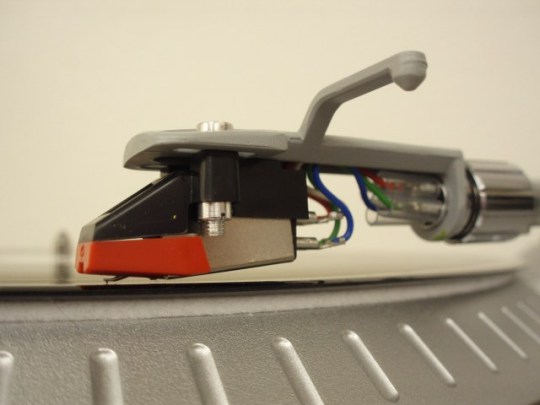

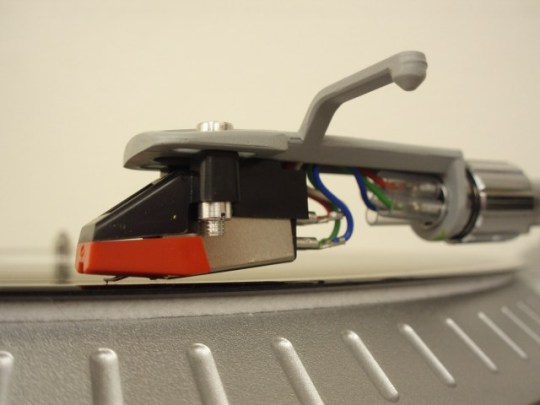

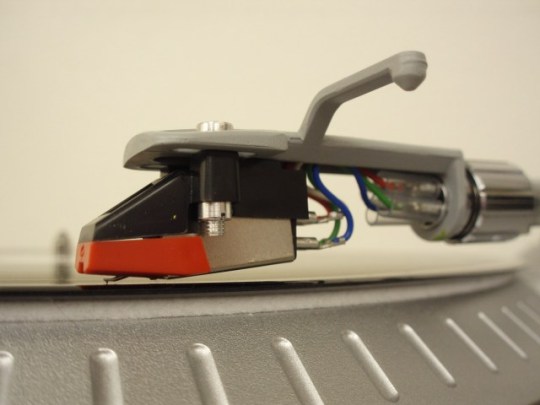

A diamond needle is what's in contact with the grooves on a record. Michelle Hawkins-Thiel/Flickr, CC BY

A previously common place for diamonds was on record players, where to this day the needle that touches the record can be a very small diamond sliver.

Whether one appreciates the aesthetic or scientific characteristics of the gem more, diamonds can dazzle.

Joshua Wilhide, Manager of the Molecular Characterization and Analysis Complex, University of Maryland, Baltimore County and William LaCourse, Professor of Chemistry and Dean of the College of Natural and Mathematical Sciences, University of Maryland, Baltimore County

This article is republished from The Conversation under a Creative Commons license. Read the original article.

0 notes

Text

Metal Shearing From Baco Enterprises Inc.

youtube

When looking for metal shearing go to http://www.bacoent.com/category/400/metal-shearing.html or call 877-594-4729.

Metal shearing is used for cutting sheet metal to size for various fabrications and operations. Also referred to as metal cutting, the process is completed through a metal shear cutter, which uses a fixed lower blade and an upper blade that moves vertically across the material to be cut.

The combined action of these blades penetrates the material and creates a slip plane, which then allows the material to be smoothly and efficiently separated. To complete the steel cutting process correctly, the strength and thickness of the material must be accounted for through an adjustment of the upper and lower blade.

Positioning the angle at which the blades align and the distance between them are essential in completing the steel shearing process efficiently. It’s very important to choose a fabricator that has the capabilities and experience to properly perform this service.

When fabricators need cutting and shearing to supplement their own jobs, Baco Enterprises can provide them as needed. While customers typically turn to Baco for structural fasteners and other products that are essential for the construction industry, they can also help steel fabricators get smaller, fill-in jobs done in order to save time and money.

They are able to perform cutting services on A36 steel, grade 50 steel, and stainless steel to produce cut-to-size squares, gussets, galvanized strips, stiffeners, and plates that include steel anchor, web, flitch, connection, access, kick, leveling, and bearing varieties, as well as aluminum diamond plates, Corten steel cover plates, and other forms.

Baco Enterprises serves the needs of steel fabricators with jobs to complete in the Northeast and Mid-Atlantic. They can complete supplemental cutting and shearing quickly, reliably, and at competitive prices. They can also provide exceptionally fast shipment throughout New York, New Jersey, Connecticut, Pennsylvania, Massachusetts, Rhode Island, Maryland, Delaware, New Hampshire, Maine, Vermont, and Virginia.

To get a quote on these and other supplemental fabrication services, as well as a variety of construction fasteners, visit bacoent.com or call Baco Enterprises directly.

Company: BACO Enterprises Inc. Address: 1190 Longwood Avenue City: Bronx State: New York Zip: 10474 Phone: 877-594-4729 http://www.bacoent.com Watch video on YouTube here: https://youtu.be/ZoHYzbVQVQk via Magoda | Manufacturing America by ROIGROUP

0 notes

Text

Metal Shearing From Baco Enterprises Inc.

youtube

When looking for metal shearing go to http://www.bacoent.com/category/400/metal-shearing.html or call 877-594-4729.

Metal shearing is used for cutting sheet metal to size for various fabrications and operations. Also referred to as metal cutting, the process is completed through a metal shear cutter, which uses a fixed lower blade and an upper blade that moves vertically across the material to be cut.

The combined action of these blades penetrates the material and creates a slip plane, which then allows the material to be smoothly and efficiently separated. To complete the steel cutting process correctly, the strength and thickness of the material must be accounted for through an adjustment of the upper and lower blade.

Positioning the angle at which the blades align and the distance between them are essential in completing the steel shearing process efficiently. It’s very important to choose a fabricator that has the capabilities and experience to properly perform this service.

When fabricators need cutting and shearing to supplement their own jobs, Baco Enterprises can provide them as needed. While customers typically turn to Baco for structural fasteners and other products that are essential for the construction industry, they can also help steel fabricators get smaller, fill-in jobs done in order to save time and money.

They are able to perform cutting services on A36 steel, grade 50 steel, and stainless steel to produce cut-to-size squares, gussets, galvanized strips, stiffeners, and plates that include steel anchor, web, flitch, connection, access, kick, leveling, and bearing varieties, as well as aluminum diamond plates, Corten steel cover plates, and other forms.

Baco Enterprises serves the needs of steel fabricators with jobs to complete in the Northeast and Mid-Atlantic. They can complete supplemental cutting and shearing quickly, reliably, and at competitive prices. They can also provide exceptionally fast shipment throughout New York, New Jersey, Connecticut, Pennsylvania, Massachusetts, Rhode Island, Maryland, Delaware, New Hampshire, Maine, Vermont, and Virginia.

To get a quote on these and other supplemental fabrication services, as well as a variety of construction fasteners, visit bacoent.com or call Baco Enterprises directly.

Company: BACO Enterprises Inc. Address: 1190 Longwood Avenue City: Bronx State: New York Zip: 10474 Phone: 877-594-4729 http://www.bacoent.com Watch video on YouTube here: https://youtu.be/ZoHYzbVQVQk via Magoda | Manufacturing America by ROIGROUP

0 notes

Text

Metal Shearing From Baco Enterprises Inc.

youtube

When looking for metal shearing go to http://www.bacoent.com/category/400/metal-shearing.html or call 877-594-4729.

Metal shearing is used for cutting sheet metal to size for various fabrications and operations. Also referred to as metal cutting, the process is completed through a metal shear cutter, which uses a fixed lower blade and an upper blade that moves vertically across the material to be cut.

The combined action of these blades penetrates the material and creates a slip plane, which then allows the material to be smoothly and efficiently separated. To complete the steel cutting process correctly, the strength and thickness of the material must be accounted for through an adjustment of the upper and lower blade.

Positioning the angle at which the blades align and the distance between them are essential in completing the steel shearing process efficiently. It’s very important to choose a fabricator that has the capabilities and experience to properly perform this service.

When fabricators need cutting and shearing to supplement their own jobs, Baco Enterprises can provide them as needed. While customers typically turn to Baco for structural fasteners and other products that are essential for the construction industry, they can also help steel fabricators get smaller, fill-in jobs done in order to save time and money.

They are able to perform cutting services on A36 steel, grade 50 steel, and stainless steel to produce cut-to-size squares, gussets, galvanized strips, stiffeners, and plates that include steel anchor, web, flitch, connection, access, kick, leveling, and bearing varieties, as well as aluminum diamond plates, Corten steel cover plates, and other forms.

Baco Enterprises serves the needs of steel fabricators with jobs to complete in the Northeast and Mid-Atlantic. They can complete supplemental cutting and shearing quickly, reliably, and at competitive prices. They can also provide exceptionally fast shipment throughout New York, New Jersey, Connecticut, Pennsylvania, Massachusetts, Rhode Island, Maryland, Delaware, New Hampshire, Maine, Vermont, and Virginia.

To get a quote on these and other supplemental fabrication services, as well as a variety of construction fasteners, visit bacoent.com or call Baco Enterprises directly.

Company: BACO Enterprises Inc. Address: 1190 Longwood Avenue City: Bronx State: New York Zip: 10474 Phone: 877-594-4729 http://www.bacoent.com Watch video on YouTube here: https://youtu.be/ZoHYzbVQVQk via Magoda | Manufacturing America by ROIGROUP

0 notes

Text

Metal Shearing From Baco Enterprises Inc.

youtube

When looking for metal shearing go to http://www.bacoent.com/category/400/metal-shearing.html or call 877-594-4729.

Metal shearing is used for cutting sheet metal to size for various fabrications and operations. Also referred to as metal cutting, the process is completed through a metal shear cutter, which uses a fixed lower blade and an upper blade that moves vertically across the material to be cut.

The combined action of these blades penetrates the material and creates a slip plane, which then allows the material to be smoothly and efficiently separated. To complete the steel cutting process correctly, the strength and thickness of the material must be accounted for through an adjustment of the upper and lower blade.

Positioning the angle at which the blades align and the distance between them are essential in completing the steel shearing process efficiently. It’s very important to choose a fabricator that has the capabilities and experience to properly perform this service.

When fabricators need cutting and shearing to supplement their own jobs, Baco Enterprises can provide them as needed. While customers typically turn to Baco for structural fasteners and other products that are essential for the construction industry, they can also help steel fabricators get smaller, fill-in jobs done in order to save time and money.

They are able to perform cutting services on A36 steel, grade 50 steel, and stainless steel to produce cut-to-size squares, gussets, galvanized strips, stiffeners, and plates that include steel anchor, web, flitch, connection, access, kick, leveling, and bearing varieties, as well as aluminum diamond plates, Corten steel cover plates, and other forms.

Baco Enterprises serves the needs of steel fabricators with jobs to complete in the Northeast and Mid-Atlantic. They can complete supplemental cutting and shearing quickly, reliably, and at competitive prices. They can also provide exceptionally fast shipment throughout New York, New Jersey, Connecticut, Pennsylvania, Massachusetts, Rhode Island, Maryland, Delaware, New Hampshire, Maine, Vermont, and Virginia.

To get a quote on these and other supplemental fabrication services, as well as a variety of construction fasteners, visit bacoent.com or call Baco Enterprises directly.

Company: BACO Enterprises Inc. Address: 1190 Longwood Avenue City: Bronx State: New York Zip: 10474 Phone: 877-594-4729 http://www.bacoent.com Watch video on YouTube here: https://youtu.be/ZoHYzbVQVQk via Magoda | Manufacturing America by ROIGROUP

0 notes

Text

Metal Shearing From Baco Enterprises Inc.

youtube

When looking for metal shearing go to http://www.bacoent.com/category/400/metal-shearing.html or call 877-594-4729.

Metal shearing is used for cutting sheet metal to size for various fabrications and operations. Also referred to as metal cutting, the process is completed through a metal shear cutter, which uses a fixed lower blade and an upper blade that moves vertically across the material to be cut.

The combined action of these blades penetrates the material and creates a slip plane, which then allows the material to be smoothly and efficiently separated. To complete the steel cutting process correctly, the strength and thickness of the material must be accounted for through an adjustment of the upper and lower blade.

Positioning the angle at which the blades align and the distance between them are essential in completing the steel shearing process efficiently. It’s very important to choose a fabricator that has the capabilities and experience to properly perform this service.

When fabricators need cutting and shearing to supplement their own jobs, Baco Enterprises can provide them as needed. While customers typically turn to Baco for structural fasteners and other products that are essential for the construction industry, they can also help steel fabricators get smaller, fill-in jobs done in order to save time and money.

They are able to perform cutting services on A36 steel, grade 50 steel, and stainless steel to produce cut-to-size squares, gussets, galvanized strips, stiffeners, and plates that include steel anchor, web, flitch, connection, access, kick, leveling, and bearing varieties, as well as aluminum diamond plates, Corten steel cover plates, and other forms.

Baco Enterprises serves the needs of steel fabricators with jobs to complete in the Northeast and Mid-Atlantic. They can complete supplemental cutting and shearing quickly, reliably, and at competitive prices. They can also provide exceptionally fast shipment throughout New York, New Jersey, Connecticut, Pennsylvania, Massachusetts, Rhode Island, Maryland, Delaware, New Hampshire, Maine, Vermont, and Virginia.

To get a quote on these and other supplemental fabrication services, as well as a variety of construction fasteners, visit bacoent.com or call Baco Enterprises directly.

Company: BACO Enterprises Inc. Address: 1190 Longwood Avenue City: Bronx State: New York Zip: 10474 Phone: 877-594-4729 http://www.bacoent.com Watch video on YouTube here: https://youtu.be/ZoHYzbVQVQk via Magoda | Manufacturing America by ROIGROUP

0 notes

Text

Concrete Slab Cutting Services in Maryland: A Comprehensive Guide

Concrete slab cutting is a crucial service in Maryland’s bustling construction industry. From residential home improvements to large-scale commercial projects, cutting through concrete with precision is often essential for plumbing, electrical installations, expansions, and more. With Maryland’s robust mix of urban, suburban, and rural projects, concrete cutting services play a key role in ensuring structural integrity and project efficiency. This article dives into everything you need to know about concrete slab cutting services in Maryland, including why these services are needed, what they entail, and how to choose a reliable provider. for more visit concrete slab cutting service Maryland

1. What is Concrete Slab Cutting?

Concrete slab cutting is a specialized process of precisely cutting through concrete surfaces or slabs. This may be necessary for a variety of reasons, such as accessing underground utilities, creating openings for new structures, or modifying existing foundations. The work is done by skilled professionals using high-powered tools like saws with diamond-coated blades, which provide the precision needed for accurate cuts without compromising structural stability.

Types of Concrete Cutting Techniques

Concrete slab cutting isn’t a one-size-fits-all process. Several techniques are available, each suited to specific needs:

Flat Sawing: This is the most common technique, used for horizontal surfaces like floors and roadways.

Wall Sawing: For creating precise openings in walls for doors, windows, or mechanical systems.

Core Drilling: Essential for creating circular holes in concrete, often for electrical wiring, plumbing, and HVAC installations.

Wire Sawing: A technique typically used for large-scale cuts, where other sawing methods aren’t feasible.

2. When Do You Need Concrete Slab Cutting Services?

Concrete slab cutting is required in a variety of situations across both residential and commercial settings. Common scenarios include:

Renovation Projects: When remodeling a home or building, concrete cutting is often necessary to make room for new installations or modifications.

Road Repairs and Infrastructure: Many of Maryland’s roads, highways, and bridges require concrete cutting for repair and maintenance.

Utility Installations: Installing plumbing, electrical, or drainage systems often requires precise concrete cutting to access or modify the foundation.

Emergency Repairs: Concrete slab cutting is sometimes needed for emergency repairs, such as fixing leaks, broken pipes, or structural damage.

3. Benefits of Professional Concrete Slab Cutting Services

Opting for a professional concrete slab cutting service in Maryland offers numerous benefits. These experts are equipped with the right tools, techniques, and experience to execute precise cuts safely and efficiently. Here’s why hiring a professional service is advantageous:

Precision and Safety: Professional concrete cutters use advanced equipment and follow stringent safety protocols. This ensures that the cuts are precise, minimizing the risk of structural damage.

Time Efficiency: With specialized tools and experience, professional concrete cutting services can complete projects faster than non-professional attempts.

Cost-Effectiveness: Although hiring professionals may seem costly upfront, it often saves money in the long run by avoiding errors, material waste, and potential repair costs.

Environmentally Friendly: Professional services often use methods that minimize dust and debris, helping to maintain a cleaner, safer work environment.

Regulatory Compliance: Maryland, like other states, has specific regulations for construction and renovation projects. Professional concrete cutters are knowledgeable about these requirements, ensuring that your project is compliant.

4. How to Choose a Reliable Concrete Slab Cutting Service in Maryland

Selecting the right concrete cutting service is crucial for a successful project. Here are some key factors to consider when choosing a provider:

Experience and Expertise: Look for companies with years of experience and specialized knowledge in concrete cutting. An experienced service provider will have a solid understanding of Maryland’s unique construction needs.

Reputation and Reviews: Check online reviews, testimonials, and ratings to gauge the quality of service provided by a company. Positive feedback from previous clients is a good sign of reliability.

Equipment and Technology: The best concrete cutting services use advanced, high-quality equipment that can handle a range of materials and depths.

Safety Practices: Concrete cutting can be hazardous. Choose a company that prioritizes safety, with employees trained in OSHA standards and using protective gear.

Licensed and Insured: Ensure that the company is properly licensed and carries insurance, which can protect you from liability in case of accidents or damage.

5. Leading Concrete Slab Cutting Service Providers in Maryland

Maryland is home to several reputable concrete slab cutting service providers. Some top companies include:

Penhall Company: Known for its nationwide presence and extensive range of services, Penhall offers concrete cutting, scanning, and demolition services in Maryland. With a focus on quality and safety, Penhall is a trusted choice for complex projects.

Capital Concrete Cutting: This locally-based company specializes in residential and commercial concrete cutting. They offer various services, including slab cutting, core drilling, and curb sawing.

Atlantic Concrete Cutting, Inc.: Serving Maryland and neighboring states, Atlantic Concrete Cutting is well-regarded for its experience, advanced technology, and reliable results.

6. Costs of Concrete Slab Cutting in Maryland

The cost of concrete slab cutting services varies depending on factors such as project complexity, slab thickness, cutting technique, and location. Here’s a rough guide:

Basic Cuts: For simple cuts (up to 4 inches deep), rates typically range from $3 to $7 per linear foot.

Medium Depth Cuts: For cuts between 4 and 12 inches, prices may go from $7 to $15 per foot.

Deep or Specialized Cuts: Complex cuts, including core drilling, wire sawing, or cuts deeper than 12 inches, often range from $15 to $30 per foot or more.

Additional costs may include travel fees for projects located farther from the provider’s base and any permit fees required by local jurisdictions in Maryland.

Conclusion

Concrete slab cutting is an essential service in Maryland, supporting a range of residential, commercial, and infrastructure projects. With various cutting techniques and specialized equipment, these services ensure precision, safety, and efficiency in all types of construction and renovation projects. By choosing an experienced, reputable provider, you can benefit from the latest cutting technology and best practices, ensuring a high-quality outcome for your project.

If you’re planning a project in Maryland that involves concrete cutting, consider consulting with a professional service. Whether you’re modifying a home, repairing a road, or installing utilities, Maryland’s concrete slab cutting experts are equipped to meet your needs with skill and precision.

1 note

·

View note

Text

Diamonds are forever – whether made in a lab or mined from the earth

Are you in the market for some sparkle? clearviewstock/Shutterstock.com

Joshua Wilhide, University of Maryland, Baltimore County and William LaCourse, University of Maryland, Baltimore County

It's diamond season. Almost 40 percent of American engagements happen between Thanksgiving and Valentine's Day, with Christmas the most popular day to pop the question – and hand over a sparkly piece of ice. Jewelry stores do at least double their usual monthly sales in December.

Since at least the late 1800s, with the discovery of huge diamond mines in South Africa, people have treasured these dazzling gems. The beauty and splendor of diamonds goes well beyond the surface. Like a diamond hunter digging in an underground mine, one must look deeper to their atomic characteristics to understand what sets these stones apart – and what makes them valuable not just for romantics but also for scientists.

On the atomic level

A literal diamond in the rough, before it's been removed from the matrix within which it formed. USGS, CC BY

When mined from the earth, diamonds look like cloudy rocks before they're cut and polished. Their chemical nature and structure were unknown for centuries. It was Isaac Newton's experiments in the 1600s that first suggested diamonds are made up of the fourth-most abundant element, carbon.

People doubted Newton's discovery, which is understandable considering how different diamonds look from other common forms of carbon, like the graphite in pencils or the ash left over in a wood-burning fireplace. But in 1797, English scientist Smithson Tennant confirmed the composition of diamonds.

Diamond and graphite are both made of carbon atoms, but organized in different structures. Materialscientist/Wikimedia Commons, CC BY-SA

It turns out that carbon takes two common forms that have crystalline structures on the atomic level. Graphite is a repeating two-dimensional, honeycomb-like shape, with layers stacking on top of each other. Alternatively, carbon can form a repeating three-dimensional shape, a tetrahedron – and that's your diamond.

Where do they come from?

There are two sources of the precious gemstone: natural mining or synthesis within a laboratory.

Natural diamonds are formed under intense pressure and heat in the Earth's crust over millions of years. Natural deposits have been found all over the world, from Northern Canada to Western Australia, even underwater in Namibia.

Mines were the only source of the gemstone until 1955, when General Electric produced the first synthetic diamond using what's called the high-pressure, high-temperature process. This process works by applying hundreds of thousands pounds of pressure to graphite at 2,700 degrees Fahrenheit to force the carbon into the correct crystalline structure. It's sort of like an artificial version of the extreme conditions that produce diamonds deep within the earth.

In the 1970s, labs started to use the chemical vapor deposition method to grow diamonds at lower pressures. At the time, the HPHT technique couldn't produce a gem-quality stone. This improved method converts a hydrocarbon gas mixture by breaking it down to its components, carbon and hydrogen molecules, with an intense heated filament or plasma and deposits it onto a substrate, ultimately forming a solid diamond. Originally, this process had a very slow growth rate, but it's now optimized to grow quality diamonds within days.

Together these techniques are largely responsible for human-made diamonds – upwards of 4 billion carats worldwide annually.

There's a common misconception that a natural diamond must be inherently different than a synthetic diamond. To the contrary, they are chemically identical and share the same physical properties. Even the most sophisticated techniques can not detect a difference between a flawless mined diamond and a flawless human-made diamond – both are “real” diamonds. However, truly flawless diamonds of either type are extremely scarce.

Assessing a diamond

No matter its origin, a diamond can be assessed by the “four Cs” of cut, color, clarity and carat weight. Specialized laboratories grade each category, as created by the Gemological Institute of America.

Diamond cutters choose the shape of the finished stone. SPbPhoto/Shutterstock.com

The cut of a diamond is defined in two ways. There's “the general shape of the cut stone,” with shapes including round brilliant (most common), oval, emerald, pear, princess, trilliant, triangle, heart and radiant. And there's “the degree of perfection achieved by the cutting and polishing process” as rated on a scale ranging from excellent to poor. The type and quality of the cut ultimately determines the way light reflects in the stone, contributing to its “brilliance.”

The color of a diamond is graded on a scale from “D,” being perfectly colorless, to “Z” having the most color. Originally, the color of the stone was a huge hint about how it was formed because until 2007 about 90 percent of the high-pressure, high-temperature synthetic stones were yellow orange or yellow. Almost no stones from that process were colorless, so a colorless stone was almost certainly natural. But the HPHT growing process has greatly improved and as of 2016, 43 percent of synthetic diamonds were colorless.

Diamond clarity indicates the presence of inclusions, or tiny imperfections, in the stone. Inclusions make every diamond unique and provide strong clues to whether a diamond is natural or synthetic. The HPHT process uses metal flux, or a hot metal liquid, which acts as a solvent to dissolve the carbon source, graphite, to be rearranged and grown into a diamond. Diamonds grown this way can have inclusions of metals. The resulting stones may be magnetic – if a diamond reacts with a magnet, it is certainly synthetic. Additionally, most synthetic diamonds receive high clarity grades, while natural diamonds contain larger inclusions.

Many consumers focus on carat weight – that is, diamond size. The stone is weighed on a scale where one carat is 200 milligrams (0.007 ounces). Diamonds larger than four carats are almost guaranteed to be natural because that's the limit for the size of the diamonds that the synthetic processes can grow.

Although the “four Cs” of diamonds ultimately define retail value, sentimental value can be even greater. Buyers must decide if a natural or synthetic stone fits the bill for them, based on factors that might include the ecological and ethical ramifications of diamond mining as well as the lower price tag for synthetic rocks.

Diamonds found beyond your ring finger

Although diamonds are well known for their place in the jewelry industry, they play other valuable roles, too.

Their physical properties, especially hardness, are ideal for abrasive applications. Small diamonds can be found coating cutting wheels, drill bits and grinding wheels, which are used for cutting concrete or brickwork.

Diamonds also have certain optical properties that make them suitable for various spectroscopy techniques, or measurements involving the electromagnetic spectrum. Scientific researchers use these tests to help identify the composition of materials they're investigating.

A diamond needle is what's in contact with the grooves on a record. Michelle Hawkins-Thiel/Flickr, CC BY

A previously common place for diamonds was on record players, where to this day the needle that touches the record can be a very small diamond sliver.

Whether one appreciates the aesthetic or scientific characteristics of the gem more, diamonds can dazzle.

Joshua Wilhide, Manager of the Molecular Characterization and Analysis Complex, University of Maryland, Baltimore County and William LaCourse, Professor of Chemistry and Dean of the College of Natural and Mathematical Sciences, University of Maryland, Baltimore County

This article is republished from The Conversation under a Creative Commons license. Read the original article.

0 notes

Text

Diamonds are forever – whether made in a lab or mined from the earth

Are you in the market for some sparkle? clearviewstock/Shutterstock.com

Joshua Wilhide, University of Maryland, Baltimore County and William LaCourse, University of Maryland, Baltimore County

It's diamond season. Almost 40 percent of American engagements happen between Thanksgiving and Valentine's Day, with Christmas the most popular day to pop the question – and hand over a sparkly piece of ice. Jewelry stores do at least double their usual monthly sales in December.

Since at least the late 1800s, with the discovery of huge diamond mines in South Africa, people have treasured these dazzling gems. The beauty and splendor of diamonds goes well beyond the surface. Like a diamond hunter digging in an underground mine, one must look deeper to their atomic characteristics to understand what sets these stones apart – and what makes them valuable not just for romantics but also for scientists.

On the atomic level

A literal diamond in the rough, before it's been removed from the matrix within which it formed. USGS, CC BY

When mined from the earth, diamonds look like cloudy rocks before they're cut and polished. Their chemical nature and structure were unknown for centuries. It was Isaac Newton's experiments in the 1600s that first suggested diamonds are made up of the fourth-most abundant element, carbon.

People doubted Newton's discovery, which is understandable considering how different diamonds look from other common forms of carbon, like the graphite in pencils or the ash left over in a wood-burning fireplace. But in 1797, English scientist Smithson Tennant confirmed the composition of diamonds.

Diamond and graphite are both made of carbon atoms, but organized in different structures. Materialscientist/Wikimedia Commons, CC BY-SA

It turns out that carbon takes two common forms that have crystalline structures on the atomic level. Graphite is a repeating two-dimensional, honeycomb-like shape, with layers stacking on top of each other. Alternatively, carbon can form a repeating three-dimensional shape, a tetrahedron – and that's your diamond.

Where do they come from?

There are two sources of the precious gemstone: natural mining or synthesis within a laboratory.

Natural diamonds are formed under intense pressure and heat in the Earth's crust over millions of years. Natural deposits have been found all over the world, from Northern Canada to Western Australia, even underwater in Namibia.

Mines were the only source of the gemstone until 1955, when General Electric produced the first synthetic diamond using what's called the high-pressure, high-temperature process. This process works by applying hundreds of thousands pounds of pressure to graphite at 2,700 degrees Fahrenheit to force the carbon into the correct crystalline structure. It's sort of like an artificial version of the extreme conditions that produce diamonds deep within the earth.

In the 1970s, labs started to use the chemical vapor deposition method to grow diamonds at lower pressures. At the time, the HPHT technique couldn't produce a gem-quality stone. This improved method converts a hydrocarbon gas mixture by breaking it down to its components, carbon and hydrogen molecules, with an intense heated filament or plasma and deposits it onto a substrate, ultimately forming a solid diamond. Originally, this process had a very slow growth rate, but it's now optimized to grow quality diamonds within days.

Together these techniques are largely responsible for human-made diamonds – upwards of 4 billion carats worldwide annually.

There's a common misconception that a natural diamond must be inherently different than a synthetic diamond. To the contrary, they are chemically identical and share the same physical properties. Even the most sophisticated techniques can not detect a difference between a flawless mined diamond and a flawless human-made diamond – both are “real” diamonds. However, truly flawless diamonds of either type are extremely scarce.

Assessing a diamond

No matter its origin, a diamond can be assessed by the “four Cs” of cut, color, clarity and carat weight. Specialized laboratories grade each category, as created by the Gemological Institute of America.

Diamond cutters choose the shape of the finished stone. SPbPhoto/Shutterstock.com

The cut of a diamond is defined in two ways. There's “the general shape of the cut stone,” with shapes including round brilliant (most common), oval, emerald, pear, princess, trilliant, triangle, heart and radiant. And there's “the degree of perfection achieved by the cutting and polishing process” as rated on a scale ranging from excellent to poor. The type and quality of the cut ultimately determines the way light reflects in the stone, contributing to its “brilliance.”

The color of a diamond is graded on a scale from “D,” being perfectly colorless, to “Z” having the most color. Originally, the color of the stone was a huge hint about how it was formed because until 2007 about 90 percent of the high-pressure, high-temperature synthetic stones were yellow orange or yellow. Almost no stones from that process were colorless, so a colorless stone was almost certainly natural. But the HPHT growing process has greatly improved and as of 2016, 43 percent of synthetic diamonds were colorless.

Diamond clarity indicates the presence of inclusions, or tiny imperfections, in the stone. Inclusions make every diamond unique and provide strong clues to whether a diamond is natural or synthetic. The HPHT process uses metal flux, or a hot metal liquid, which acts as a solvent to dissolve the carbon source, graphite, to be rearranged and grown into a diamond. Diamonds grown this way can have inclusions of metals. The resulting stones may be magnetic – if a diamond reacts with a magnet, it is certainly synthetic. Additionally, most synthetic diamonds receive high clarity grades, while natural diamonds contain larger inclusions.

Many consumers focus on carat weight – that is, diamond size. The stone is weighed on a scale where one carat is 200 milligrams (0.007 ounces). Diamonds larger than four carats are almost guaranteed to be natural because that's the limit for the size of the diamonds that the synthetic processes can grow.

Although the “four Cs” of diamonds ultimately define retail value, sentimental value can be even greater. Buyers must decide if a natural or synthetic stone fits the bill for them, based on factors that might include the ecological and ethical ramifications of diamond mining as well as the lower price tag for synthetic rocks.

Diamonds found beyond your ring finger

Although diamonds are well known for their place in the jewelry industry, they play other valuable roles, too.

Their physical properties, especially hardness, are ideal for abrasive applications. Small diamonds can be found coating cutting wheels, drill bits and grinding wheels, which are used for cutting concrete or brickwork.

Diamonds also have certain optical properties that make them suitable for various spectroscopy techniques, or measurements involving the electromagnetic spectrum. Scientific researchers use these tests to help identify the composition of materials they're investigating.

A diamond needle is what's in contact with the grooves on a record. Michelle Hawkins-Thiel/Flickr, CC BY

A previously common place for diamonds was on record players, where to this day the needle that touches the record can be a very small diamond sliver.

Whether one appreciates the aesthetic or scientific characteristics of the gem more, diamonds can dazzle.

Joshua Wilhide, Manager of the Molecular Characterization and Analysis Complex, University of Maryland, Baltimore County and William LaCourse, Professor of Chemistry and Dean of the College of Natural and Mathematical Sciences, University of Maryland, Baltimore County

This article is republished from The Conversation under a Creative Commons license. Read the original article.

0 notes

Text

Diamonds are forever – whether made in a lab or mined from the earth

Are you in the market for some sparkle? clearviewstock/Shutterstock.com

Joshua Wilhide, University of Maryland, Baltimore County and William LaCourse, University of Maryland, Baltimore County

It's diamond season. Almost 40 percent of American engagements happen between Thanksgiving and Valentine's Day, with Christmas the most popular day to pop the question – and hand over a sparkly piece of ice. Jewelry stores do at least double their usual monthly sales in December.

Since at least the late 1800s, with the discovery of huge diamond mines in South Africa, people have treasured these dazzling gems. The beauty and splendor of diamonds goes well beyond the surface. Like a diamond hunter digging in an underground mine, one must look deeper to their atomic characteristics to understand what sets these stones apart – and what makes them valuable not just for romantics but also for scientists.

On the atomic level

A literal diamond in the rough, before it's been removed from the matrix within which it formed. USGS, CC BY

When mined from the earth, diamonds look like cloudy rocks before they're cut and polished. Their chemical nature and structure were unknown for centuries. It was Isaac Newton's experiments in the 1600s that first suggested diamonds are made up of the fourth-most abundant element, carbon.

People doubted Newton's discovery, which is understandable considering how different diamonds look from other common forms of carbon, like the graphite in pencils or the ash left over in a wood-burning fireplace. But in 1797, English scientist Smithson Tennant confirmed the composition of diamonds.

Diamond and graphite are both made of carbon atoms, but organized in different structures. Materialscientist/Wikimedia Commons, CC BY-SA

It turns out that carbon takes two common forms that have crystalline structures on the atomic level. Graphite is a repeating two-dimensional, honeycomb-like shape, with layers stacking on top of each other. Alternatively, carbon can form a repeating three-dimensional shape, a tetrahedron – and that's your diamond.

Where do they come from?

There are two sources of the precious gemstone: natural mining or synthesis within a laboratory.

Natural diamonds are formed under intense pressure and heat in the Earth's crust over millions of years. Natural deposits have been found all over the world, from Northern Canada to Western Australia, even underwater in Namibia.

Mines were the only source of the gemstone until 1955, when General Electric produced the first synthetic diamond using what's called the high-pressure, high-temperature process. This process works by applying hundreds of thousands pounds of pressure to graphite at 2,700 degrees Fahrenheit to force the carbon into the correct crystalline structure. It's sort of like an artificial version of the extreme conditions that produce diamonds deep within the earth.

In the 1970s, labs started to use the chemical vapor deposition method to grow diamonds at lower pressures. At the time, the HPHT technique couldn't produce a gem-quality stone. This improved method converts a hydrocarbon gas mixture by breaking it down to its components, carbon and hydrogen molecules, with an intense heated filament or plasma and deposits it onto a substrate, ultimately forming a solid diamond. Originally, this process had a very slow growth rate, but it's now optimized to grow quality diamonds within days.

Together these techniques are largely responsible for human-made diamonds – upwards of 4 billion carats worldwide annually.

There's a common misconception that a natural diamond must be inherently different than a synthetic diamond. To the contrary, they are chemically identical and share the same physical properties. Even the most sophisticated techniques can not detect a difference between a flawless mined diamond and a flawless human-made diamond – both are “real” diamonds. However, truly flawless diamonds of either type are extremely scarce.

Assessing a diamond

No matter its origin, a diamond can be assessed by the “four Cs” of cut, color, clarity and carat weight. Specialized laboratories grade each category, as created by the Gemological Institute of America.

Diamond cutters choose the shape of the finished stone. SPbPhoto/Shutterstock.com

The cut of a diamond is defined in two ways. There's “the general shape of the cut stone,” with shapes including round brilliant (most common), oval, emerald, pear, princess, trilliant, triangle, heart and radiant. And there's “the degree of perfection achieved by the cutting and polishing process” as rated on a scale ranging from excellent to poor. The type and quality of the cut ultimately determines the way light reflects in the stone, contributing to its “brilliance.”

The color of a diamond is graded on a scale from “D,” being perfectly colorless, to “Z” having the most color. Originally, the color of the stone was a huge hint about how it was formed because until 2007 about 90 percent of the high-pressure, high-temperature synthetic stones were yellow orange or yellow. Almost no stones from that process were colorless, so a colorless stone was almost certainly natural. But the HPHT growing process has greatly improved and as of 2016, 43 percent of synthetic diamonds were colorless.

Diamond clarity indicates the presence of inclusions, or tiny imperfections, in the stone. Inclusions make every diamond unique and provide strong clues to whether a diamond is natural or synthetic. The HPHT process uses metal flux, or a hot metal liquid, which acts as a solvent to dissolve the carbon source, graphite, to be rearranged and grown into a diamond. Diamonds grown this way can have inclusions of metals. The resulting stones may be magnetic – if a diamond reacts with a magnet, it is certainly synthetic. Additionally, most synthetic diamonds receive high clarity grades, while natural diamonds contain larger inclusions.

Many consumers focus on carat weight – that is, diamond size. The stone is weighed on a scale where one carat is 200 milligrams (0.007 ounces). Diamonds larger than four carats are almost guaranteed to be natural because that's the limit for the size of the diamonds that the synthetic processes can grow.

Although the “four Cs” of diamonds ultimately define retail value, sentimental value can be even greater. Buyers must decide if a natural or synthetic stone fits the bill for them, based on factors that might include the ecological and ethical ramifications of diamond mining as well as the lower price tag for synthetic rocks.

Diamonds found beyond your ring finger

Although diamonds are well known for their place in the jewelry industry, they play other valuable roles, too.

Their physical properties, especially hardness, are ideal for abrasive applications. Small diamonds can be found coating cutting wheels, drill bits and grinding wheels, which are used for cutting concrete or brickwork.

Diamonds also have certain optical properties that make them suitable for various spectroscopy techniques, or measurements involving the electromagnetic spectrum. Scientific researchers use these tests to help identify the composition of materials they're investigating.

A diamond needle is what's in contact with the grooves on a record. Michelle Hawkins-Thiel/Flickr, CC BY

A previously common place for diamonds was on record players, where to this day the needle that touches the record can be a very small diamond sliver.

Whether one appreciates the aesthetic or scientific characteristics of the gem more, diamonds can dazzle.

Joshua Wilhide, Manager of the Molecular Characterization and Analysis Complex, University of Maryland, Baltimore County and William LaCourse, Professor of Chemistry and Dean of the College of Natural and Mathematical Sciences, University of Maryland, Baltimore County

This article is republished from The Conversation under a Creative Commons license. Read the original article.

0 notes

Text

Diamonds are forever – whether made in a lab or mined from the earth

Are you in the market for some sparkle? clearviewstock/Shutterstock.com

Joshua Wilhide, University of Maryland, Baltimore County and William LaCourse, University of Maryland, Baltimore County

It's diamond season. Almost 40 percent of American engagements happen between Thanksgiving and Valentine's Day, with Christmas the most popular day to pop the question – and hand over a sparkly piece of ice. Jewelry stores do at least double their usual monthly sales in December.

Since at least the late 1800s, with the discovery of huge diamond mines in South Africa, people have treasured these dazzling gems. The beauty and splendor of diamonds goes well beyond the surface. Like a diamond hunter digging in an underground mine, one must look deeper to their atomic characteristics to understand what sets these stones apart – and what makes them valuable not just for romantics but also for scientists.

On the atomic level

A literal diamond in the rough, before it's been removed from the matrix within which it formed. USGS, CC BY

When mined from the earth, diamonds look like cloudy rocks before they're cut and polished. Their chemical nature and structure were unknown for centuries. It was Isaac Newton's experiments in the 1600s that first suggested diamonds are made up of the fourth-most abundant element, carbon.

People doubted Newton's discovery, which is understandable considering how different diamonds look from other common forms of carbon, like the graphite in pencils or the ash left over in a wood-burning fireplace. But in 1797, English scientist Smithson Tennant confirmed the composition of diamonds.

Diamond and graphite are both made of carbon atoms, but organized in different structures. Materialscientist/Wikimedia Commons, CC BY-SA

It turns out that carbon takes two common forms that have crystalline structures on the atomic level. Graphite is a repeating two-dimensional, honeycomb-like shape, with layers stacking on top of each other. Alternatively, carbon can form a repeating three-dimensional shape, a tetrahedron – and that's your diamond.

Where do they come from?

There are two sources of the precious gemstone: natural mining or synthesis within a laboratory.

Natural diamonds are formed under intense pressure and heat in the Earth's crust over millions of years. Natural deposits have been found all over the world, from Northern Canada to Western Australia, even underwater in Namibia.

Mines were the only source of the gemstone until 1955, when General Electric produced the first synthetic diamond using what's called the high-pressure, high-temperature process. This process works by applying hundreds of thousands pounds of pressure to graphite at 2,700 degrees Fahrenheit to force the carbon into the correct crystalline structure. It's sort of like an artificial version of the extreme conditions that produce diamonds deep within the earth.

In the 1970s, labs started to use the chemical vapor deposition method to grow diamonds at lower pressures. At the time, the HPHT technique couldn't produce a gem-quality stone. This improved method converts a hydrocarbon gas mixture by breaking it down to its components, carbon and hydrogen molecules, with an intense heated filament or plasma and deposits it onto a substrate, ultimately forming a solid diamond. Originally, this process had a very slow growth rate, but it's now optimized to grow quality diamonds within days.

Together these techniques are largely responsible for human-made diamonds – upwards of 4 billion carats worldwide annually.

There's a common misconception that a natural diamond must be inherently different than a synthetic diamond. To the contrary, they are chemically identical and share the same physical properties. Even the most sophisticated techniques can not detect a difference between a flawless mined diamond and a flawless human-made diamond – both are “real” diamonds. However, truly flawless diamonds of either type are extremely scarce.

Assessing a diamond

No matter its origin, a diamond can be assessed by the “four Cs” of cut, color, clarity and carat weight. Specialized laboratories grade each category, as created by the Gemological Institute of America.

Diamond cutters choose the shape of the finished stone. SPbPhoto/Shutterstock.com

The cut of a diamond is defined in two ways. There's “the general shape of the cut stone,” with shapes including round brilliant (most common), oval, emerald, pear, princess, trilliant, triangle, heart and radiant. And there's “the degree of perfection achieved by the cutting and polishing process” as rated on a scale ranging from excellent to poor. The type and quality of the cut ultimately determines the way light reflects in the stone, contributing to its “brilliance.”

The color of a diamond is graded on a scale from “D,” being perfectly colorless, to “Z” having the most color. Originally, the color of the stone was a huge hint about how it was formed because until 2007 about 90 percent of the high-pressure, high-temperature synthetic stones were yellow orange or yellow. Almost no stones from that process were colorless, so a colorless stone was almost certainly natural. But the HPHT growing process has greatly improved and as of 2016, 43 percent of synthetic diamonds were colorless.

Diamond clarity indicates the presence of inclusions, or tiny imperfections, in the stone. Inclusions make every diamond unique and provide strong clues to whether a diamond is natural or synthetic. The HPHT process uses metal flux, or a hot metal liquid, which acts as a solvent to dissolve the carbon source, graphite, to be rearranged and grown into a diamond. Diamonds grown this way can have inclusions of metals. The resulting stones may be magnetic – if a diamond reacts with a magnet, it is certainly synthetic. Additionally, most synthetic diamonds receive high clarity grades, while natural diamonds contain larger inclusions.

Many consumers focus on carat weight – that is, diamond size. The stone is weighed on a scale where one carat is 200 milligrams (0.007 ounces). Diamonds larger than four carats are almost guaranteed to be natural because that's the limit for the size of the diamonds that the synthetic processes can grow.

Although the “four Cs” of diamonds ultimately define retail value, sentimental value can be even greater. Buyers must decide if a natural or synthetic stone fits the bill for them, based on factors that might include the ecological and ethical ramifications of diamond mining as well as the lower price tag for synthetic rocks.

Diamonds found beyond your ring finger

Although diamonds are well known for their place in the jewelry industry, they play other valuable roles, too.

Their physical properties, especially hardness, are ideal for abrasive applications. Small diamonds can be found coating cutting wheels, drill bits and grinding wheels, which are used for cutting concrete or brickwork.

Diamonds also have certain optical properties that make them suitable for various spectroscopy techniques, or measurements involving the electromagnetic spectrum. Scientific researchers use these tests to help identify the composition of materials they're investigating.

A diamond needle is what's in contact with the grooves on a record. Michelle Hawkins-Thiel/Flickr, CC BY

A previously common place for diamonds was on record players, where to this day the needle that touches the record can be a very small diamond sliver.

Whether one appreciates the aesthetic or scientific characteristics of the gem more, diamonds can dazzle.

Joshua Wilhide, Manager of the Molecular Characterization and Analysis Complex, University of Maryland, Baltimore County and William LaCourse, Professor of Chemistry and Dean of the College of Natural and Mathematical Sciences, University of Maryland, Baltimore County

This article is republished from The Conversation under a Creative Commons license. Read the original article.

0 notes

Text

Diamonds are forever – whether made in a lab or mined from the earth

Are you in the market for some sparkle? clearviewstock/Shutterstock.com

Joshua Wilhide, University of Maryland, Baltimore County and William LaCourse, University of Maryland, Baltimore County

It's diamond season. Almost 40 percent of American engagements happen between Thanksgiving and Valentine's Day, with Christmas the most popular day to pop the question – and hand over a sparkly piece of ice. Jewelry stores do at least double their usual monthly sales in December.

Since at least the late 1800s, with the discovery of huge diamond mines in South Africa, people have treasured these dazzling gems. The beauty and splendor of diamonds goes well beyond the surface. Like a diamond hunter digging in an underground mine, one must look deeper to their atomic characteristics to understand what sets these stones apart – and what makes them valuable not just for romantics but also for scientists.

On the atomic level

A literal diamond in the rough, before it's been removed from the matrix within which it formed. USGS, CC BY

When mined from the earth, diamonds look like cloudy rocks before they're cut and polished. Their chemical nature and structure were unknown for centuries. It was Isaac Newton's experiments in the 1600s that first suggested diamonds are made up of the fourth-most abundant element, carbon.

People doubted Newton's discovery, which is understandable considering how different diamonds look from other common forms of carbon, like the graphite in pencils or the ash left over in a wood-burning fireplace. But in 1797, English scientist Smithson Tennant confirmed the composition of diamonds.

Diamond and graphite are both made of carbon atoms, but organized in different structures. Materialscientist/Wikimedia Commons, CC BY-SA

It turns out that carbon takes two common forms that have crystalline structures on the atomic level. Graphite is a repeating two-dimensional, honeycomb-like shape, with layers stacking on top of each other. Alternatively, carbon can form a repeating three-dimensional shape, a tetrahedron – and that's your diamond.

Where do they come from?

There are two sources of the precious gemstone: natural mining or synthesis within a laboratory.

Natural diamonds are formed under intense pressure and heat in the Earth's crust over millions of years. Natural deposits have been found all over the world, from Northern Canada to Western Australia, even underwater in Namibia.

Mines were the only source of the gemstone until 1955, when General Electric produced the first synthetic diamond using what's called the high-pressure, high-temperature process. This process works by applying hundreds of thousands pounds of pressure to graphite at 2,700 degrees Fahrenheit to force the carbon into the correct crystalline structure. It's sort of like an artificial version of the extreme conditions that produce diamonds deep within the earth.