#laminated pouch manufacturer

Explore tagged Tumblr posts

Text

Unveiling the Future: How Flexible Packaging Reshapes E-Commerce Packaging Challenges

In the rapidly evolving landscape of e-commerce, packaging plays a pivotal role in ensuring product integrity, minimizing damage during transit, and delighting customers. However, traditional packaging solutions often fall short in meeting the unique challenges posed by online retail. Enter flexible packaging – a versatile and innovative solution that is revolutionizing e-commerce packaging. In this article, we explore how companies like Miracle Group, a leading Flexible Packaging Company in Jaipur, are addressing the packaging challenges of e-commerce through flexible packaging solutions.

Protection During Transit:

One of the primary challenges in e-commerce packaging is ensuring that products arrive at their destination intact. Flexible packaging offers superior protection against shocks, vibrations, and rough handling during transit, minimizing the risk of damage and returns. Miracle Group, with its expertise as a Flexible Pouch Manufacturer, specializes in designing packaging solutions that provide optimal protection for products of all shapes and sizes, safeguarding them throughout the shipping process.

Customization for Varied Product Sizes:

E-commerce retailers often deal with a wide range of product sizes and shapes, making standardized packaging solutions impractical. Flexible packaging offers the versatility to accommodate products of varying dimensions, thanks to its adjustable nature and customizable design options. Miracle Group, as a trusted Pouch Packaging Company, collaborates closely with e-commerce businesses to develop tailor-made packaging solutions that fit their unique product requirements perfectly.

Branding and Consumer Experience:

In the digital realm of e-commerce, packaging serves as the first physical touchpoint between the brand and the customer. Flexible packaging offers ample opportunities for branding and customization, enabling e-commerce retailers to create memorable unboxing experiences that resonate with their target audience. Miracle Group, leveraging its expertise as a Flexible Packaging Manufacturer, assists e-commerce businesses in designing visually appealing packaging solutions that reinforce brand identity and enhance customer satisfaction.

Sustainable Packaging Solutions:

With growing environmental concerns, e-commerce retailers are under increasing pressure to adopt sustainable packaging practices. Flexible packaging, with its lightweight construction and material efficiency, offers a more eco-friendly alternative to traditional packaging materials. Miracle Group, committed to sustainability, offers a range of eco-friendly packaging options made from recyclable materials and biodegradable laminates, helping e-commerce businesses reduce their carbon footprint and minimize environmental impact.

Cost-Efficiency and Logistics Optimization:

E-commerce packaging must strike a balance between cost-efficiency and product protection. Flexible packaging excels in this regard, as it is lightweight, compact, and easy to store and transport, reducing shipping costs and optimizing logistics. Miracle Group, as a leading Flexible Packaging Company, understands the importance of cost-effectiveness in e-commerce operations and offers competitively priced packaging solutions without compromising on quality or performance.

Conclusion:

Flexible packaging is poised to transform the e-commerce packaging landscape, offering solutions that address the unique challenges faced by online retailers. With its superior protection, customization capabilities, branding opportunities, sustainability benefits, and cost-efficiency, flexible packaging is an indispensable asset for e-commerce businesses striving to deliver exceptional customer experiences. Partnering with a trusted Flexible Packaging Company like Miracle Group ensures that e-commerce retailers have access to innovative packaging solutions that meet their evolving needs and propel their business forward in the digital age.

#Flexible Packaging Company in Jaipur#Flexible Pouch Manufacturers#Flexible Packaging Manufacturers#Pouch Manufacturer#Pouch Packaging Company#Laminates Manufacturer#Pouch Packaging Manufacturer#Flexible Packaging Company#Miracle Group

0 notes

Text

WHY YOU TRUST " VENUS "

WHY YOU TRUST US:

We at Gaylord Packers India Private Limited assured you if you trust us and build a business relationship with us you never compromise on quality. and you will get the best price in the market, we entered in the market and started from scratch in 1992, and today we are a renowned manufacturer of thermal lamination film, tinsel garland, glitter powder, metallized film, Flexible Packaging, mettalic yarn, hot stapping foil, Mettalized paper and gift wrapping paper, etc apart from this we serve different industries like the printing press, publishers, laminating press, packaging, and printing industry, etc

#bopp film#bopp thermal lamination film#pet thermal lamination film#thermal lamination#thermal lamination film#packaging#business card printing#lamination pouch#lamination#thermal film#thermal lamination film manufacturer#venus thermal lamination film#glittler powder#tinsel garland#metalized film#rigid box corner tape#gloss thermal lamination film#mat thermal lamination film

0 notes

Text

Flexible Packaging Products Manufacturer | Flexible Pouch Packaging

We have been an established FIBC manufacturer &exporter based at Ahmedabad, Gujarat, India who is dealing into Flexible Packaging Products & Pouch Packaging.

#Flexible Packaging Company#Flexible Packaging Products#Flexible Pouch Manufacturers#Flexible Packaging Film Manufacturer#Flexible Laminated Pouches#Vacuum Pouch Manufacturers#Gas Flushing Packaging Manufacturer#FIBC#India#USA#United States#New York#America

0 notes

Text

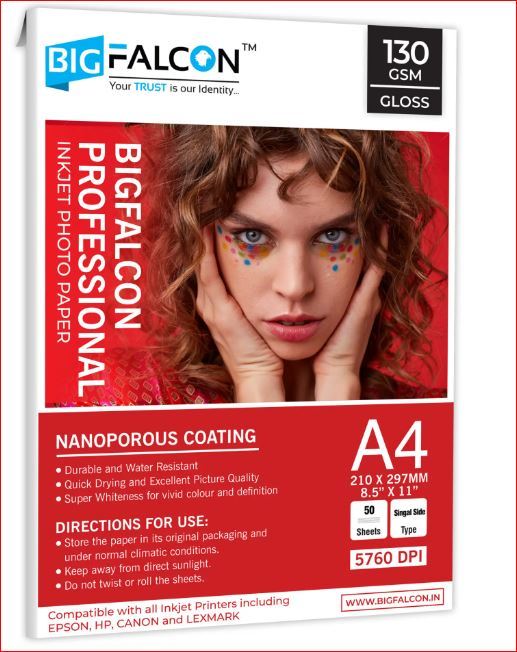

Top PVC Tray Manufacturer

Looking for a reliable PVC tray manufacturer? Look no further than Bigfalcon Group! We offer top-quality PVC trays that are perfect for your business needs. Check out our wide range of options online and choose the best one for you. For more details, call us at 9137559944.

#glossy photo paper#a4 size photo paper#kodak photo paper#aadhar pvc card#premium lamination pouch#lamination pouch a4 size#sticker photo paper#PVC Tray Manufacturer#Transparent sticker sheet#Sticker photo paper

0 notes

Text

Shrinath Rotopack Private Limited. aims to develop a customized flexible packaging company for the brands on a regular basis, training the manpower for better efficiency, constant check on customer preferences, improving customer service to gain a competitive edge, and providing an environmentally friendly production process. we can manufacture printed laminates, packaging materials, printed and plain pouches etc.

#packaging pouches#flexiblepackaging#flexiblelaminates#printedpackaging#printed laminates#packaging manufacturers#packaging materials company#plain pouches#printed pouches#food packaging pouches

1 note

·

View note

Text

Bambrew’s range of eco-friendly packaging alternatives

Bambrew, an Indian startup specializing in sustainable packaging, is making strides in the fight against single-use plastics by offering a range of 'eco-friendly' alternatives, says Vaibhav Anant, founder & CEO. The company provides packaging solutions made from renewable, biodegradable materials such as bamboo, seaweed, banana fiber, and agro-waste. According to Anant, these materials are fully compostable and serve as viable alternatives for businesses seeking to reduce their environmental footprint.

“Our solutions are governed by four core principles of sustainability—eco-friendliness, functionality, cost-efficiency, and scalability. These guiding principles enable us to deliver packaging options that are not only environmentally responsible but also commercially viable for businesses of all sizes,” Anant says.

Bambrew offers a range of packaging alternatives, including mailer bags, flexible pouches, rigid boxes, and custom solutions, all designed to meet the functional needs of various sectors while remaining scalable. It has developed solutions for industries such as FMCG, CPG, fresh fruits and vegetables (F&V), food and beverages (F&B), and e-commerce and retail packaging.

Notable clients include Amazon, Nykaa, Hindustan Unilever, Mahindra Logistics, and Tata 1mg.

Material-Agnostic Company

Anant explains that Bambrew is a material-agnostic company, meaning it develops solutions using various materials, all adhering to the four core principles of sustainability as mentioned earlier.

Bambrew prioritizes sustainability not only in its products but throughout the entire product development lifecycle, from sourcing and compounding to conversion processes, says Anant. The company works closely with raw material providers and maintains complete control over production with the latest technology machines for in-house manufacturing. It also operates tech-assisted warehousing and logistics to ensure timely delivery to customers.

“By reducing our reliance on fossil fuels through the use of biofuels and solar energy, we are significantly lowering our carbon footprint. Equally important is the well-being of our workers, and we are committed to maintaining a healthy work-life balance. We adhere to an 8-hour shift structure and offer a range of benefits to ensure a supportive and positive work environment, with a strong emphasis on mental health,” Anant states.

The company has its manufacturing facility in Bangalore and collaborates with several contract manufacturing units across India to expand its reach and capabilities.

Rapid Growth

According to Anant, the company has made big progress over the last 12 months, with growth exceeding 8x.

“This momentum has been incredibly encouraging, and we’re excited to continue building on it in the years to come. As the demand for sustainable solutions grows, we’re committed to scaling responsibly and staying focused on our mission,” he says.

New Offerings

Bambrew is actively working towards the continuous development of advanced meta-materials. It has been extensively researching materials such as Biophil, a home-compostable bioplastic alternative, while also exploring other renewable resources. These materials are designed to offer high performance while being environmentally friendly.

In August of this year, the company introduced a new category of rigid boxes that utilize Kappa boards produced from post-consumer recycled fibers. The product features components like non-animal-based glue, recycled paper cladding, plastic-free Biophil lamination, and plant-based inks. Each element of this product is designed to meet Bambrew's environmental goals and contribute to a fully sustainable manufacturing cycle.

“Additionally, we are actively developing alternative solutions for pharmaceutical packaging, as well as advanced barrier films for food packaging within the FMCG sector. While these are only a few examples, all our efforts are directed towards the broader aim of pushing the envelope of what’s possible within the realm of sustainability and delivering solutions that meet the highest standards of quality while supporting a greener, more sustainable transition into the future,” Anant concludes.

10 notes

·

View notes

Text

Transform Packaging Efficiency with Film Lamination Adhesives

In today's fast-paced world, efficiency and sustainability are more important than ever. For film manufacturers, print industry professionals, and product packaging designers, finding ways to reduce waste while improving efficiency is crucial. Enter film lamination adhesives—a game-changing solution that can transform your packaging processes. This blog post explores how film lamination adhesives can help you achieve these goals, making your packaging not just better but also greener.

Understanding Film Lamination Adhesives

Film lamination adhesives are specialized compounds designed to bond layers of film together, creating a single, cohesive material. Used extensively in packaging, these adhesives offer numerous benefits, including enhanced durability and improved barrier properties.

Why Use Film Lamination Adhesives?

Film lamination adhesives are essential for creating multi-layered packaging that protects products effectively. They provide a strong bond between different types of films, ensuring that the final product is both durable and functional.

Types of Film Lamination Adhesives

There are several types of film lamination adhesives available, each designed for specific applications. These include water-based, solvent-based, and solvent-free adhesives. Each type has its own set of advantages, making them suitable for various packaging needs.

Applications in Packaging

Film lamination adhesives are used in a wide range of packaging applications. From seed and pesticide packaging to dairy products and vacuum pouches, these adhesives offer versatile solutions for various industries.

Benefits of Film Lamination Adhesives

Using film lamination adhesives in your packaging processes can significantly reduce waste and improve efficiency. Here are some key benefits:

Enhanced Durability

One of the primary advantages of film lamination adhesives is their ability to create highly durable packaging. This means your products are better protected, reducing the risk of damage during transit.

Improved Barrier Properties

Film lamination adhesives help enhance the barrier properties of packaging, making it more resistant to moisture, oxygen, and other external factors. This is particularly important for products like dairy and vacuum-sealed items.

Versatility

Film lamination adhesives are incredibly versatile, making them suitable for a wide range of applications. Whether you're packaging seeds, pesticides, or consumer goods, these adhesives can meet your needs.

Improving Efficiency in Packaging

Efficiency is key to staying competitive in the packaging industry. Film lamination adhesives can streamline your processes, making them more efficient and cost-effective.

Faster Production Times

Film lamination adhesives can significantly speed up production times. By creating strong bonds quickly, they allow for faster assembly of multi-layered packaging, increasing your overall output.

Reduced Downtime

Using high-quality film lamination adhesives can reduce downtime caused by equipment malfunctions or material failures. This ensures a smoother production process and higher efficiency.

Cost Savings

By minimizing waste and improving production efficiency, film lamination adhesives can lead to significant cost savings. This makes them a smart investment for any packaging operation.

The Future of Packaging with Film Lamination Adhesives

The packaging industry is constantly evolving, and film lamination adhesives are at the forefront of this evolution. By adopting these advanced adhesives, you can stay ahead of the curve and ensure your packaging processes are both efficient and sustainable.

Innovations on the Horizon

Ongoing research and development in film lamination adhesives promise even more exciting innovations in the future. Stay tuned for new products and technologies that will further enhance your packaging capabilities.

Commitment to Sustainability

At [Your Company Name], we're committed to sustainability. Our film lamination adhesives are designed to minimize environmental impact while delivering superior performance. Join us in our mission to create a better, more sustainable future.

Taking the Next Step

Ready to revolutionize your packaging processes? Contact us today to learn more about our film lamination adhesives and how they can benefit your business. Our team of experts is here to help you find the perfect solution for your needs.

2 notes

·

View notes

Text

Aluminium Foil Market Growth Fueled by Rising Demand in Food, Pharma, and Eco-Friendly Packaging

Aluminium Foil Market: Growth, Trends, and Opportunities

The aluminium foil market has seen a steady evolution over the past decades, driven by rising demand across industries such as packaging, electronics, and construction. Its lightweight, non-toxic, corrosion-resistant, and recyclable properties make aluminium foil a versatile material. As global consumption patterns shift toward sustainability and efficiency, aluminium foil is expected to play an increasingly vital role in meeting these goals.

Market Overview

Aluminium foil is made by rolling aluminium slabs cast from molten aluminium in a rolling mill to the desired thickness. It is available in various gauges, widths, and finishes. The global aluminium foil market was valued at over USD 25 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of approximately 5% between 2024 and 2030.

One of the primary factors fueling market growth is the increasing demand for flexible and sustainable packaging. The food and beverage industry accounts for the lion’s share of aluminium foil usage, with applications in food containers, wraps, lids, and pouches. The pharmaceutical sector also contributes significantly to demand, utilizing foil for blister packaging and barrier protection.

Key Market Drivers

1. Growing Demand in Food Packaging

Aluminium foil offers a barrier to light, oxygen, moisture, and bacteria, making it ideal for food preservation. As convenience foods and ready-to-eat meals become more popular, the need for effective packaging solutions is rising. The foil helps in extending shelf life, preserving aroma, and ensuring safety.

With the growth of online grocery delivery and takeout services, especially post-COVID-19, demand for durable, lightweight, and eco-friendly packaging materials has surged. Aluminium foil, often laminated with paper or plastic, meets these criteria while being recyclable.

2. Sustainability and Recyclability

Sustainability is a significant focus area for manufacturers and consumers alike. Aluminium foil is 100% recyclable without loss of quality, which supports circular economy initiatives. This advantage has led many packaging companies to switch from plastic-based options to aluminium foil to reduce environmental impact.

In addition, regulatory pressures and environmental concerns are driving industries to replace single-use plastics with recyclable materials. This policy-driven trend is expected to further accelerate the growth of the aluminium foil market.

3. Technological Advancements

Continuous innovation in rolling technologies, coating, and lamination processes has improved the strength, flexibility, and performance of aluminium foils. New production techniques have also helped reduce manufacturing costs and waste, which improves the overall profitability for foil producers.

Micro-embossed and patterned foils are gaining popularity for their aesthetic appeal in packaging design, especially in the cosmetics and confectionery sectors. These innovations help brands stand out while maintaining protective qualities.

Regional Insights

Asia-Pacific

Asia-Pacific is the largest and fastest-growing market for aluminium foil, accounting for more than 50% of global consumption. China, India, and Japan are key contributors due to rapid industrialization, population growth, and urbanization. The expanding food processing industry and strong demand for personal care and pharmaceutical products continue to support this growth.

China is both a major consumer and exporter of aluminium foil, with state-backed incentives boosting domestic production capacity. However, international trade disputes and anti-dumping measures have led to market fluctuations in recent years.

North America and Europe

In North America and Europe, sustainability concerns and regulatory changes are pushing industries to adopt greener packaging solutions. Aluminium foil has become an attractive alternative to plastic films, particularly in food service, retail, and healthcare packaging.

Although mature markets, both regions continue to innovate in foil recycling programs and invest in technologies to reduce carbon footprints. Additionally, consumer preferences for organic, minimally processed, and safely packaged foods are driving aluminium foil usage in the premium product segment.

Challenges and Constraints

Despite its advantages, the aluminium foil market faces several challenges:

Fluctuating Raw Material Prices: The cost of aluminium is influenced by global supply chain dynamics, energy prices, and geopolitical events. Volatility in pricing can impact production costs and profit margins.

Environmental Concerns Over Energy Use: Although aluminium foil is recyclable, its production is energy-intensive. Critics argue that unless powered by renewable energy, foil production may offset some of its environmental benefits.

Competition from Alternatives: Bioplastics and other sustainable packaging options are gaining traction, especially in regions with stringent environmental policies. These alternatives could affect aluminium foil's market share if they become more cost-effective and scalable.

Future Outlook

The future of the aluminium foil market looks promising, with sustained demand in core sectors like food and healthcare. Innovation in lightweight foil grades, coatings for improved barrier properties, and designs for branding will be key differentiators.

Investment in green manufacturing processes, such as closed-loop recycling and renewable energy sourcing, will also play a crucial role in shaping the industry's image and compliance with future regulations. Emerging economies offer untapped potential due to their growing middle-class populations and increasing packaged food consumption.

Conclusion

The aluminium foil market is poised for continued growth, fueled by its versatility, sustainability, and widespread application across sectors. With increasing awareness of environmental impacts and shifts in consumer behavior, aluminium foil presents a compelling solution for modern packaging needs. Companies that invest in innovation, sustainability, and strategic expansion are well-positioned to capitalize on the market’s upward trajectory.

0 notes

Text

[ad_1] Nelipak® Corporation ("Nelipak®"), a leading global manufacturer of packaging solutions for medical device, diagnostic, pharmaceutical drug delivery, and other demanding applications, announced it is enhancing its commitment to service customers in the Asia-Pacific region on a direct basis, and through its preferred partners.The Nelipak® medical packaging product lineup includes a comprehensive range of custom designed sterile-barrier packaging solutions. Nelipak's flexible packaging product line includes coated roll-stock, die cut lids and sheets, pouches, and bags. These products incorporate a wide range of material substrates (Tyvek®, medical papers, films, foil-laminates) and Nelipak® heat-seal coating technologies (Nelipak® CR27 and Nelipak® SBP2000 coatings; Nelipak® PS-series coated papers). These well-known flexible medical packaging solutions became part of the Nelipak® Healthcare Packaging portfolio as a result of Nelipak's 2019 acquisition of Bemis® Healthcare Packaging Europe. In addition, Nelipak's medical packaging solutions include rigid thermoformed trays and medical tray sealing machines."Our healthcare packaging solutions are widely used globally and have been used extensively in the Asia-Pacific region for over 30 years," said Pat Chambliss, CEO of Nelipak®. "Our products are available to customers in the Asia-Pacific region on a direct basis, and through our preferred partners. Direct engagement enables us to work closely with customers to ensure that our packaging solutions are tailored to specific requirements, from concept to completion. By working directly, we can deliver value by streamlining processes, reducing costs, and avoiding validation of alternatives – without compromising quality or service."With over 70 years of experience designing, developing, and delivering custom sterile barrier packaging solutions for the healthcare sector, Nelipak® recognizes the unique technical requirements and aspirations of customers in the Asia-Pacific region. Nelipak® is investing in the future of sterile barrier medical packaging in the Asia-Pacific region, aiming to expand its capabilities to meet evolving customer needs.To support evolving customer needs, Nelipak® is strengthening its capabilities in the Asia-Pacific region by expanding expertise, technologies, and in-region resources. This includes leveraging existing global resources, establishing additional in-region resources (commercial, technical, service, etc.), and introducing innovative packaging solutions tailored to the needs of Asia-Pacific healthcare companies.Nelipak® healthcare packaging experts are ready to collaborate, offering insights and solutions that drive success in the healthcare market. Customers in the Asia-Pacific region are invited to connect with the Nelipak® team (email: [email protected]) to explore Nelipak's healthcare packaging solutions. About Nelipak® Nelipak® is a leading global manufacturer of rigid and flexible packaging solutions for medical device, diagnostic, pharma drug delivery and other demanding applications. To support the development of innovative sustainable packaging solutions, Nelipak® offers in-house design, prototyping, tooling, simulation, validation, laboratory, and other value-added services as well as a line of tray sealing equipment. With 1,400 employees and 11 sites globally, including 6 sites in North America (US, Costa Rica, Puerto Rico) and 5 sites in Europe (Ireland, Netherlands, UK), Nelipak® is committed to delivering superior quality, service, and customer experience through world-class cleanroom manufacturing.For more information, visit www.nelipak.com.DuPont™ and Tyvek® are trademarks or registered trademarks of DuPont or its affiliates. !function(f,b,e,v,n,t,s) if(f.fbq)return;n=f.fbq=function()n.callMethod? n.callMethod.apply(n,arguments):n.queue.push(arguments); if(!f._fbq)f._fbq=n;n.push=n;n.loaded=!0;n.version='2.0'; n.queue=[];t=b.createElement(e);t.async=!0; t.src=v;s=b.getElementsByTagName(e)[0];

s.parentNode.insertBefore(t,s)(window,document,'script', 'https://connect.facebook.net/en_US/fbevents.js'); fbq('init', '311356416665414'); fbq('track', 'PageView'); [ad_2] Source link

0 notes

Text

[ad_1] Nelipak® Corporation ("Nelipak®"), a leading global manufacturer of packaging solutions for medical device, diagnostic, pharmaceutical drug delivery, and other demanding applications, announced it is enhancing its commitment to service customers in the Asia-Pacific region on a direct basis, and through its preferred partners.The Nelipak® medical packaging product lineup includes a comprehensive range of custom designed sterile-barrier packaging solutions. Nelipak's flexible packaging product line includes coated roll-stock, die cut lids and sheets, pouches, and bags. These products incorporate a wide range of material substrates (Tyvek®, medical papers, films, foil-laminates) and Nelipak® heat-seal coating technologies (Nelipak® CR27 and Nelipak® SBP2000 coatings; Nelipak® PS-series coated papers). These well-known flexible medical packaging solutions became part of the Nelipak® Healthcare Packaging portfolio as a result of Nelipak's 2019 acquisition of Bemis® Healthcare Packaging Europe. In addition, Nelipak's medical packaging solutions include rigid thermoformed trays and medical tray sealing machines."Our healthcare packaging solutions are widely used globally and have been used extensively in the Asia-Pacific region for over 30 years," said Pat Chambliss, CEO of Nelipak®. "Our products are available to customers in the Asia-Pacific region on a direct basis, and through our preferred partners. Direct engagement enables us to work closely with customers to ensure that our packaging solutions are tailored to specific requirements, from concept to completion. By working directly, we can deliver value by streamlining processes, reducing costs, and avoiding validation of alternatives – without compromising quality or service."With over 70 years of experience designing, developing, and delivering custom sterile barrier packaging solutions for the healthcare sector, Nelipak® recognizes the unique technical requirements and aspirations of customers in the Asia-Pacific region. Nelipak® is investing in the future of sterile barrier medical packaging in the Asia-Pacific region, aiming to expand its capabilities to meet evolving customer needs.To support evolving customer needs, Nelipak® is strengthening its capabilities in the Asia-Pacific region by expanding expertise, technologies, and in-region resources. This includes leveraging existing global resources, establishing additional in-region resources (commercial, technical, service, etc.), and introducing innovative packaging solutions tailored to the needs of Asia-Pacific healthcare companies.Nelipak® healthcare packaging experts are ready to collaborate, offering insights and solutions that drive success in the healthcare market. Customers in the Asia-Pacific region are invited to connect with the Nelipak® team (email: [email protected]) to explore Nelipak's healthcare packaging solutions. About Nelipak® Nelipak® is a leading global manufacturer of rigid and flexible packaging solutions for medical device, diagnostic, pharma drug delivery and other demanding applications. To support the development of innovative sustainable packaging solutions, Nelipak® offers in-house design, prototyping, tooling, simulation, validation, laboratory, and other value-added services as well as a line of tray sealing equipment. With 1,400 employees and 11 sites globally, including 6 sites in North America (US, Costa Rica, Puerto Rico) and 5 sites in Europe (Ireland, Netherlands, UK), Nelipak® is committed to delivering superior quality, service, and customer experience through world-class cleanroom manufacturing.For more information, visit www.nelipak.com.DuPont™ and Tyvek® are trademarks or registered trademarks of DuPont or its affiliates. !function(f,b,e,v,n,t,s) if(f.fbq)return;n=f.fbq=function()n.callMethod? n.callMethod.apply(n,arguments):n.queue.push(arguments); if(!f._fbq)f._fbq=n;n.push=n;n.loaded=!0;n.version='2.0'; n.queue=[];t=b.createElement(e);t.async=!0; t.src=v;s=b.getElementsByTagName(e)[0];

s.parentNode.insertBefore(t,s)(window,document,'script', 'https://connect.facebook.net/en_US/fbevents.js'); fbq('init', '311356416665414'); fbq('track', 'PageView'); [ad_2] Source link

0 notes

Text

What Should You Look for in Pouch Packaging Machines?

In today’s fast-paced packaging industry, pouch packaging machines play a crucial role in ensuring efficiency, accuracy, and product safety. Whether you're in the food, pharmaceutical, or cosmetic industry, choosing the right machine is essential for seamless operations. But with so many options available, how do you select the best one? If you’re searching for a reliable Pouch Packaging Machine manufacturer, look no further than Ambika Packaging Solution!

1. Machine Type – Selecting the Right One for Your Needs

The first thing to consider is the type of pouch packaging machine that suits your product. Ambika Packaging Solution, a leading Pouch Packaging Machine manufacturer, offers various types, including:

✅ Vertical Form Fill Seal (VFFS) Machines – Ideal for packaging granular, powder, and liquid products. ✅ Horizontal Form Fill Seal (HFFS) Machines – Best for pre-made pouches and flexible packaging. ✅ Automatic Pouch Packaging Machines – Ensure speed and precision in high-volume production.

2. Packaging Speed – Boost Your Productivity

A good pouch packaging machine should match your production needs. If you have a high-demand business, selecting a fast and efficient machine from a trusted Pouch Packaging Machine manufacturer like Ambika Packaging Solution ensures smooth operations. Machines with adjustable speed settings allow flexibility based on different product types.

3. Material Compatibility – Ensure Durability and Versatility 📦

Different products require different packaging materials, such as plastic, foil, or laminated pouches. A high-quality pouch packaging machine should support multiple materials to maintain product freshness and durability. Ambika Packaging Solution, as a trusted Pouch Packaging Machine manufacturer, provides machines that can handle various materials efficiently.

4. Automation Level – Reduce Manual Effort 🤖

Fully automated pouch packaging machines improve efficiency by reducing labor costs and minimizing human errors. Semi-automatic options are also available for businesses looking for controlled automation. With Ambika Packaging Solution, you get cutting-edge technology designed to enhance productivity.

5. Maintenance and After-Sales Support 🛠️

Regular maintenance is essential for the long-term performance of any pouch packaging machine. A good Pouch Packaging Machine manufacturer like Ambika Packaging Solution provides excellent after-sales support, easy spare part availability, and technical assistance to keep your machines running smoothly.

Final Thoughts

Investing in the right pouch packaging machine can make a huge difference in your business. Whether you need speed, precision, or versatility, choosing the right Pouch Packaging Machine manufacturer like Ambika Packaging Solution ensures high performance, durability, and excellent support. Make the right choice today and take your packaging process to the next level!

#Packaging Machine Manufacturer#Pouch Packaging Machine manufacturers#Automatic Pouch Packaging Machine Manufacturer#Food Packaging Machine Manufacturer#Liquid Packaging Machines Manufacturer#Auger Filler Machines#Packaging Equipment

0 notes

Text

Are Doypack pouches suitable for retort packaging

Doypack pouches, known for their convenience and versatility, have become popular in packaging various products. One important consideration in their application is whether they are suitable for retort packaging, which involves sterilization processes to ensure product safety and shelf stability.

Understanding Doypack Pouches

Doypack pouches, or stand-up pouches, are flexible containers made from multiple layers of laminate films. They are characterized by their ability to stand upright on shelves, making them ideal for retail displays. These pouches typically feature a reclosable zip seal or a spout for easy dispensing, enhancing their convenience for consumers.

Retort Packaging and Its Requirements

Retort packaging is a method used to sterilize food and beverage products inside their containers to extend shelf life without the need for refrigeration. This process involves subjecting the packaged product to high temperatures (usually above 100°C) under pressure for a specified time.

Challenges of Retort Packaging with Doypack Pouches

While Doypack pouches offer several advantages, they present unique challenges in retort packaging:

Heat Resistance: The materials used in Doypack pouches must withstand high temperatures without compromising the integrity of the package or the safety of the product inside.

Seal Integrity: Ensuring a hermetic seal is crucial during retort processing to prevent contamination and spoilage.

Structural Stability: Doypack pouches need to maintain their shape and strength throughout the retort process, which can be demanding due to the pressure and heat involved.

Advancements in Doypack Technology

Manufacturers have been actively improving Doypack pouch designs and materials to meet the requirements of retort packaging:

Barrier Properties: Enhanced barrier films with superior heat resistance have been developed to ensure product safety and quality.

Sealing Technology: Advanced sealing techniques, such as ultrasonic or high-frequency welding, contribute to better seal integrity under high-temperature conditions.

Structural Design: Optimized pouch structures, including reinforcement at seal areas, help maintain pouch integrity during sterilization.

Doypack Packing Machine Applications and Considerations

Doypack pouches are widely used in retort packaging for various products, including:

Ready-to-Eat Meals: Soups, sauces, and pre-cooked dishes.

Beverages: Juices, energy drinks, and flavored water.

Pet Foods: Wet pet foods that require sterilization for safety.

Conclusion

In conclusion, Doypack pouches can indeed be suitable for retort packaging when designed and manufactured with the appropriate materials and technologies. Advances in pouch design, barrier materials, and sealing techniques have significantly improved their performance in sterilization processes. However, careful consideration of pouch specifications and testing under simulated conditions are essential to ensure product safety and quality. With ongoing innovations in packaging technology, Doypack pouches continue to offer a promising solution for retort packaging across various industries.

0 notes

Text

Bigfalcon Digi Print A4size Photo Paper For Your Extreme Needs

A4 size photo paper is nowadays highly practiced for digital printing, and one need to know its features to get all kind of benefits. It is developed to exceed studio standards, and Bigfalcon offers excellent beauty and seamless, realistic output. Premium resin-coated waterproof paper instantly dries and prints the image or picture without signs of fading.

A4 Size Photo Paper

Compatible paper

The photo paper is perfectly suited to most desktops and large-format printers. In addition to this, you will get experienced of uninterrupted services that makes you’re buying this kind of printing machine highly make sense and choice.

High grade realistic result

A4size photo paper is always recommended for providing printouts of your copy with higher resolution and clarity of picture. You will be amazed to see the amount of durability and flexibility it offers to your printing experience.

Buying an A4size photo paper will indeed give you all types of printing benefits as you can scan and take screenshots to work effectively engaged with your official work successfully. A4 size photo paper is recommended simply because it is the perfect size to get photos and images as per the requirements of your business brochures, fliers and visiting or business cards. A4 size usually gives you the best size to render more appealing images and turn them into virtual business objectives in a professional manner.

High-grade realistic image you can generate with A4 size photo paper. Bigfalcon inkjet paper comes in different variants and provides a premium and affordable range of photo paper for casual project deliberation.

Photograph lasts for a long time

The fade-resistant feature of photo paper is meant to protect photographs from gases and light and keep important memories protected for years. Your appealing and eye-catching photos look, and texture brings the photos class and excellence. Excellent paper and affordable cost are some of the pros of A4size photo paper extensively practiced for creating a new benchmark in printing services.

In conclusion

A4size photo paper is generally practiced and preferred for businesses as they work on and try to make their business logo appealing and captivate visitors or customers' attention. With that, A4size photo paper is highly preferred and worth a lot. Try to bring your images and photos real and trendiest.

#Glossy Photo Paper#Kodak Photo Paper#A4 Size Photo Paper#Waterproof photo paper#Lamination Pouch A4 Size#PVC Tray Manufacturer#Transparent sticker sheet#Sticker photo paper#Premium Lamination Pouch#Aadhar Pvc Card

0 notes

Text

What is Flexible Packaging?

Packaging is an essential part of the modern consumer experience. It plays a critical role in protecting products, making them easier to transport, and helping to communicate the brand’s identity. In recent years, flexible packaging has become one of the most popular types of packaging, revolutionizing the way we store, transport, and sell products. But what exactly is flexible packaging, and why is it gaining so much attention in various industries? We’ll explore the fundamentals of flexible packaging, its benefits, types, and its impact on sustainability, among other key aspects.

Understanding Flexible Packaging

Flexible packaging refers to packaging that is made from materials that can bend, fold, and stretch. Unlike rigid packaging, which uses materials like glass, metal, or rigid plastic, flexible packaging is primarily made from materials such as plastic films, paper, foil, and laminates. These materials are lightweight and can be shaped to suit the needs of various products, from snacks and liquids to cosmetics and pharmaceuticals.

Some common examples of flexible packaging include:

Pouches: Used for everything from food and beverages to pharmaceuticals and personal care items.

Bags: Available in many forms, including resealable and zipper bags for everything from groceries to pet food.

Films: Thin sheets used to wrap products like fresh produce, candy, or baked goods.

Roll stock: Packaging material that can be formed into various shapes, commonly used in automated packaging lines.

Key Characteristics of Flexible Packaging

Flexible packaging is defined by several important characteristics that differentiate it from other forms of packaging:

1. Pliability

The key defining feature of flexible packaging is its pliability. The materials used—whether they are plastic films, paper, or foil—can be bent, twisted, or squeezed without breaking. This makes flexible packaging ideal for products that need to conform to specific shapes and sizes.

2. Lightweight

Flexible packaging is considerably lighter than rigid alternatives, which reduces the overall weight of the product and makes transportation more efficient. This can lead to cost savings in logistics and a reduction in environmental impact, as it takes less fuel to transport lighter goods.

3. Customizability

Flexible packaging can be highly customized, making it perfect for businesses looking to create unique packaging that stands out on store shelves. It can be printed with eye-catching designs, logos, and product information, and tailored to different sizes, shapes, and functionalities (e.g., resealable pouches or stand-up bags).

4. Durability

Despite being lightweight, flexible packaging is often surprisingly durable. Materials like multi-layered laminates or high-density polyethylene (HDPE) provide excellent protection against moisture, air, and light, which is crucial for preserving the freshness and quality of products, particularly food and beverages.

The Benefits of Flexible Packaging

Flexible packaging has grown in popularity due to the numerous advantages it offers to manufacturers, consumers, and the environment. Here’s a closer look at some of the key benefits:

1. Cost-Effective

Compared to rigid packaging options like glass or metal, flexible packaging is often more affordable to produce. The materials used in flexible packaging are cheaper, and the manufacturing process is typically faster and more energy-efficient. This cost savings can be passed on to the consumer, making flexible packaging an attractive option for businesses looking to reduce packaging costs.

2. Space-Efficient

Flexible packaging is lightweight and takes up less space compared to rigid alternatives. When products are packaged in flexible materials, the packaging can be designed to take up less storage space, which is especially valuable for e-commerce businesses. Additionally, the ability to compress or roll flexible packaging means that products can be packed more efficiently during transit, reducing shipping costs.

3. Shelf Appeal

Flexible packaging can be made in a variety of shapes, sizes, and finishes, making it easy to create eye-catching designs that enhance a product’s visual appeal. Packaging materials can be printed with vibrant colors, intricate designs, and high-quality images, which not only help to attract consumers but also increase the perceived value of the product.

4. Extended Shelf Life

Flexible packaging can help extend the shelf life of perishable products by using advanced materials like vacuum-sealed pouches or barrier films. These materials protect products from exposure to oxygen, moisture, and light, helping to preserve freshness and prevent spoilage.

5. Consumer Convenience

With features like resealable pouches, zip-lock bags, and easy-tear openings, flexible packaging provides a level of convenience that is highly valued by consumers. This makes it easier for consumers to store products and access them at their convenience, improving overall user experience.

Types of Flexible Packaging

Flexible packaging comes in various forms, each tailored to meet specific needs and requirements. Here are some of the most common types:

1. Pouches

Pouches are versatile and widely used in food packaging, especially for snacks, sauces, and beverages. They can be sealed with a zipper or a simple press-to-seal closure, making them easy to open and reseal. Pouches are also commonly used for non-food items like cosmetics, pet food, and pharmaceuticals.

2. Bags

Flexible bags are often used for bulk products or consumer goods such as grains, coffee, pet food, and candies. These bags can be sealed in a variety of ways, such as with heat-sealing, zipper sealing, or fold-over closure.

3. Films

Packaging films are thin, flexible sheets used to wrap products. These films can be clear or opaque and are typically used for individual items like candy, chips, or frozen foods. They provide a protective layer while allowing for clear visibility of the product.

4. Roll Stock

Roll stock refers to large rolls of flexible packaging material that are used to create custom-shaped packages for various products. Roll stock is particularly useful for companies with high-volume production lines, as it can be fed into automated machinery to create pouches, bags, or wrappers quickly.

The Environmental Impact of Flexible Packaging

While flexible packaging offers numerous benefits, its environmental impact is an ongoing concern. The materials used in flexible packaging, particularly plastics, can contribute to waste if not properly disposed of or recycled. However, there are positive strides being made in creating more sustainable solutions. Many manufacturers are now using recyclable, biodegradable, or compostable materials to reduce the environmental footprint of flexible packaging.

Moreover, because flexible packaging uses less material compared to rigid packaging, it often generates less waste overall. The lightweight nature of flexible packaging also reduces transportation-related emissions, as less energy is required to move lighter products.

Sustainable Innovations in Flexible Packaging

The rise of bioplastics and plant-based materials is a game-changer for flexible packaging. Materials like PLA (polylactic acid) and PHA (polyhydroxyalkanoates) are derived from renewable sources such as corn or sugarcane and are biodegradable, offering a more environmentally friendly alternative to traditional plastic.

Conclusion

Flexible packaging is an essential and versatile solution in the world of packaging. Its lightweight, customizable, and cost-effective nature makes it a popular choice for manufacturers across a variety of industries. From food and beverage products to cosmetics and electronics, flexible packaging offers superior protection, convenience, and branding opportunities. As sustainability becomes an increasingly important concern, the packaging industry is evolving, with flexible packaging leading the way in terms of innovative, eco-friendly materials and practices.

Whether you’re a consumer looking to make more sustainable purchasing decisions or a business owner seeking to optimize your packaging, understanding the value of flexible packaging is key. It’s a flexible solution—literally and figuratively—that can meet the diverse needs of modern products and changing market demands.

0 notes

Text

Best Diaper Packaging Services in India: A Complete Guide for Manufacturers

Packaging plays a crucial role in the diaper industry, ensuring product safety, hygiene, and market appeal. Whether you manufacture baby diapers or adult diapers, selecting the right packaging service can significantly impact your brand’s success. India has several top-tier diaper packaging service providers that offer innovative, cost-effective, and sustainable solutions to meet the growing demand in the market.

This guide will help diaper manufacturers understand the importance of high-quality packaging, key factors to consider, and the best diaper packaging services in India.

Why Is Diaper Packaging Important?

Multiple essential functions, Diaper packaging serves, including:

Protection & Hygiene: Prevents contamination and damage during storage and transportation.

Branding & Marketing: Attractive designs help establish brand identity and appeal to customers.

Convenience: Easy-to-use packaging enhances customer experience.

Sustainability: Eco-friendly materials help brands align with global environmental standards.

Cost Efficiency: Optimized packaging reduces material costs and transportation expenses.

Key Factors to Consider When Choosing a Diaper Packaging Service

Before selecting a packaging provider, consider these important aspects:

1. Material Quality & Durability

Choose packaging made from high-quality, non-toxic, and eco-friendly materials.

Ensure the packaging maintains diaper freshness and absorbs excess moisture.

2. Customization & Branding

Look for services offering custom designs, logos, and product information printing.

Consider packaging that aligns with your brand’s identity and target audience.

3. Cost & Bulk Order Pricing

Compare prices for different materials and printing techniques.

Ensure competitive bulk pricing to maintain cost-effectiveness.

4. Sustainability & Eco-friendliness

Opt for biodegradable or recyclable packaging materials.

Check for certifications like FSC (Forest Stewardship Council) and ISO 14001 for sustainability.

5. Compliance & Safety Standards

Ensure the packaging service adheres to hygiene regulations and industry standards.

Look for certifications such as ISO, GMP, and CE.

Top Diaper Packaging Service Providers in India

1. Uflex Limited

Location: Noida, Uttar Pradesh Specialties: Flexible packaging, sustainable materials, high-quality printing Certifications: ISO 9001, ISO 14001 Ideal for: Large-scale diaper manufacturers

2. Packman Packaging

Location: Delhi NCR Specialties: Custom-printed diaper packaging, eco-friendly options, fast delivery Certifications: ISO-certified, FSC-approved Ideal for: Small to mid-sized diaper brands

3. Essel Propack (Huhtamaki India)

Location: Mumbai, Maharashtra Specialties: Sustainable flexible packaging, high-quality lamination Certifications: CE, ISO 14001 Ideal for: Internationally exporting brands

4. Manjushree Technopack Limited

Location: Bangalore, Karnataka Specialties: Rigid and flexible packaging solutions, innovative designs Certifications: GMP, ISO-certified Ideal for: High-volume production companies

5. FlexiPack India

Location: Ahmedabad, Gujarat Specialties: Moisture-resistant packaging, lightweight yet durable materials Certifications: WHO-GMP, ISO 9001 Ideal for: Budget-conscious manufacturers

Types of Diaper Packaging Solutions Available in India

Plastic Film Packaging – Affordable and lightweight, commonly used for baby diapers.

Paper-Based Packaging – Eco-friendly, biodegradable, and gaining popularity.

Flexible Pouches – Space-saving and ideal for bulk packaging.

Rigid Boxes – Premium packaging for high-end diaper brands.

Resealable Zip Packaging – Enhances convenience and keeps diapers fresh.

Where to Source Diaper Packaging Services in India?

Online Platforms

IndiaMART

TradeIndia

Alibaba India

Direct Manufacturer Collaboration

Contact packaging companies directly for bulk orders and custom branding.

Most manufacturers offer consultation on sustainable packaging solutions.

Local Packaging Suppliers

Major industrial cities like Mumbai, Delhi, and Bangalore have specialized packaging markets.

Conclusion

Choosing the right diaper packaging service in India is essential for maintaining product quality, enhancing brand visibility, and ensuring cost efficiency. Whether you prioritize sustainability, durability, or affordability, the manufacturers listed above provide excellent solutions for diaper brands of all sizes.

For bulk packaging solutions, reach out directly to these top providers and ensure your diapers are packed with quality, hygiene, and sustainability in mind. Investing in high-quality packaging can make a significant difference in customer satisfaction and long-term brand success!

1 note

·

View note