#insulation resistance tester

Explore tagged Tumblr posts

Text

T-3630L DIGITAL INSULATION RESISTANCE TESTER

T-3630L Digital insulation resistance meter also known as megohmmeter, high voltage insulation resistance tester, etc., for the insulation resistance test. The instrument has a large LCD screen gray backlight display, data storage, data access, alarm, automatic shutdown and other functions. At the same time, it also has the function of measuring AC voltage absorption ratio and polarization index of DC voltage. The machine is beautiful and upscale, has a wide range, high resolution, convenient operation, easy to carry, accurate, reliable, stable performance, strong anti-interference ability. Moreover, it has a shockproof, dust-proof, moisture-proof structure and is a commonly used and indispensable instrument for telecommunications, electricity, meteorology, computer rooms, oil fields, electromechanical installation and maintenance, and industrial enterprises that use electricity as industrial power or energy. T-3630L insulation resistance meter is suitable for measuring the resistance value of various insulating materials and the insulation resistance of transformers, motors, cables and electrical equipment. T-3630L Digital insulation resistance meter consists of medium and large scale integrated circuits. The output power of T-3630L is large, and its output voltage level is 5 voltage levels. Rated insulation test voltage range 100-2500V, insulation resistance measurement range 0.01MΩ - 200GΩ. DC voltage measurement range 0-1000V, AC voltage measurement range 0-750V.

FUNCTION & FEATURES ■ 0-200GΩ; ■ Accuracy 3%; ■ DC Voltage test; ■ AC Voltage test; ■ AC voltage 0-750V; ■ With gray backlight; ■ DC voltage 0-1000V; ■ Recorder 500 sets data; ■ With replacement battery; ■ 100V, 250V, 500V, 1KV, 2.5KV; ■ Digital insulation resistance test; ■ User friendly menu guided operation;

APPLICATION ■ Universities; ■ Power plant; ■ Oil gas company; ■ Research institutes; ■ Electrical laboratory; ■ Electrical testing center; ■ Communication company; ■ Railway electrical department; ■ Electrical equipment manufacturers; ■ Electricity power bureau & power company; ■ Power engineering commissioning company; ■ Electrical department of industrial and mining enterprises;

0 notes

Text

Decade Resistance Boxes Exporter In India - Vaiseshika

Unlocking Precision: Vaiseshika, the leading Decade Resistance Boxes exporter in India, revolutionizes electronic testing. Over the past decade, Vaiseshika has consistently delivered state-of-the-art resistance boxes, catering to diverse industries with unparalleled precision. As a trusted name in the market, their products boast superior quality and reliability. Engineers and technicians across India rely on Vaiseshika's Decade Resistance Boxes for accurate measurements in testing circuits and electronic components. With a commitment to excellence, Vaiseshika continues to shape the future of electronic testing, solidifying its position as the go-to exporter of precision instruments in the country.

#decade box#Decade Resistance Boxes#Decade Megohm Boxes#High Voltage Probes#Kelvin Bridges / Wheatstone Bridges#Precision Standard Resistors#Fixed Value Insulation Tester Calibration System#Micro/Milliohm Meter Calibration System

1 note

·

View note

Text

footwear Electrical Insulation Testing Machine / shoe voltage resistance tester

ASTM F2412 footwear Electrical Insulation Testing Machine / shoe voltage resistance tester 1. Introductions The footwear electrical insulation testing machine passes a certain high voltage through the footwear sample to measure the magnitude of the leakage current of the footwear or determine whether the footwear has been electrocuted, thereby testing the high voltage insulation resistance of…

View On WordPress

#footwear Electrical Insulation Testier#footwear Electrical Insulation Testing Machine#shoe voltage resistance tester#shoe voltage resistance testing machine

0 notes

Text

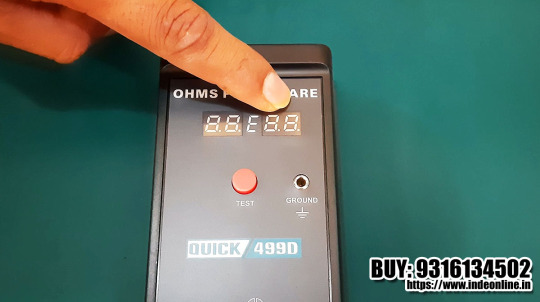

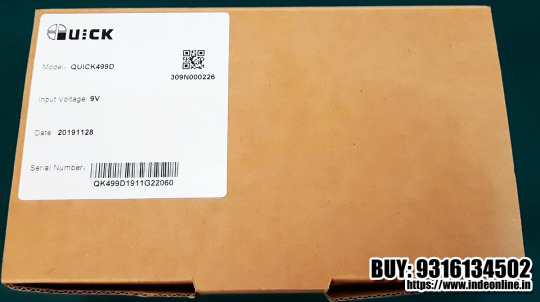

ESD Surface & Grounding Digital Resistivity Tester Model: 499D

Tests antistatic materials and insulations in compliance of ASTM Standard D-257.

Specifications:

Test range: 10³ ~ 10¹² Ω

Power: 9V battery

Resolution ratio: 0.1 order of magnitude

Precision: ±10%

Condition: 0°C~49°C, RH 0%–80%

Size: 130(L)×72(W)×35(H)mm

Weight: about 170 g (battery included)

#tester#Esdtester#esd tester#testers#static shock#static#tumblr engineering#engineering#repair#computer repair#tv repair near me

2 notes

·

View notes

Text

You Should Try the Wall Test Coordination Challenge - SpeedPowerTraining

Coordination is a crucial skill that involves controlling and moving multiple body parts smoothly and efficiently. It requires a good level of balance, strength, and agility. Hand-eye or foot-eye coordination is essential for performing various sports and everyday activities such as throwing, catching, hitting, or kicking a ball.

You can test your coordination skills by taking the wall test coordination challenge. It is a simple but effective exercise that enhances your hand-eye coordination, reaction time, and accuracy. In this challenge, you throw a ball underhand at a wall and catch it with your other hand. You can perform this task for a set number of repetitions or a specific period.

The wall test coordination challenge is not only a coordination test but also an enjoyable activity that anyone can do anywhere, indoor or outdoor, with just a ball and a wall. You can monitor your progress over time by comparing your performance with normative data or your previous scores. To make the exercise more challenging, you can vary the distance from the wall, the size or weight of the ball, the speed or angle of the throw, or the number of bounces before catching.

The wall test coordination challenge can also be used as a fitness test to measure your coordination level. Improving your coordination skills can have a significant impact on your overall health, fitness, and performance.

Wall test coordination is a process of planning and executing tests on a wall or a part of a wall to evaluate its performance, quality, safety, and durability. Wall tests can serve various purposes such as checking the structural integrity, thermal insulation, fire resistance, sound insulation, moisture resistance, aesthetic appearance, and environmental impact of a wall.

Wall test coordination involves several steps, including defining the objectives and scope of the test, selecting the appropriate test methods and standards, preparing the test plan and schedule, identifying and procuring the necessary resources and equipment, preparing the test site and the wall specimen, conducting the test according to the test plan and procedures, collecting and analyzing the test data and results, and reporting and documenting the test findings and recommendations.

Wall test coordination requires collaboration and communication among various stakeholders such as wall designers, builders, owners, testers, regulators, and consultants. It also requires compliance with relevant codes, regulations, and ethical principles. Wall test coordination can help ensure that a wall meets the desired specifications and expectations and prevent potential failures, defects, and hazards.

If you want to learn more about the benefits of the wall test coordination challenge, visit SpeedPowerTraining.

3 notes

·

View notes

Text

Why You Should Try the Wall Test Coordination Challenge Today - SpeedPowerTraining

Coordination is the ability to move two or more body parts under control, smoothly and efficiently. It is a complex skill that requires good levels of other fitness components such as balance, strength and agility. Coordination is also important for performing many daily activities and sports that involve hand-eye or foot-eye coordination, such as throwing, catching, hitting or kicking a ball.

One of the ways to test your coordination skills is by using the wall test. The wall test is a simple and effective exercise that can help you improve your hand-eye coordination, reaction time and accuracy. The wall test involves throwing a ball underhand at a wall and catching it with the other hand. The test is repeated by throwing the ball with one hand and catching it in the other for a set number of repetitions or a specified period.

The wall test is best considered a coordination test because it requires you to coordinate your eye and body movements to successfully complete the task. You have to track the ball with your eyes, adjust your body position and timing, and use your hands to catch the ball. The wall test also challenges your ability to switch between dominant and non-dominant hands, which can improve your bilateral coordination.

The wall test can be used as a fitness test to measure your coordination level and monitor your progress over time. You can compare your performance with normative data or with your own previous scores. You can also vary the difficulty of the wall test by changing the distance from the wall, the size or weight of the ball, the speed or angle of the throw, or the number of bounces before catching.

The wall test is not only a coordination test, but also a fun and engaging activity that can be done by anyone, anywhere. All you need is a ball and a wall. You can do the wall test alone or with a partner, indoors or outdoors, as a warm-up or a cool-down. The wall test can help you improve your coordination skills, which can benefit your health, fitness and performance in various aspects of life.

Wall test coordination is the process of planning and executing tests on a wall or a part of a wall to evaluate its performance, quality, safety and durability. Wall tests can be done for various purposes, such as checking the structural integrity, thermal insulation, fire resistance, sound insulation, moisture resistance, aesthetic appearance and environmental impact of a wall. Wall test coordination involves several steps, such as:

- Defining the objectives and scope of the test - Selecting the appropriate test methods and standards - Preparing the test plan and schedule - Identifying and procuring the necessary resources and equipment - Preparing the test site and the wall specimen - Conducting the test according to the test plan and procedures - Collecting and analyzing the test data and results - Reporting and documenting the test findings and recommendations

Wall test coordination requires collaboration and communication among various stakeholders, such as wall designers, builders, owners, testers, regulators and consultants. Wall test coordination also requires compliance with relevant codes, regulations and ethical principles. Wall test coordination can help ensure that a wall meets the desired specifications and expectations, as well as prevent potential failures, defects and hazards. More info Why You Should Try the Wall Test Coordination Challenge Today - SpeedPowerTraining

3 notes

·

View notes

Text

How Wire Harness Manufacturers Maintain Quality and Reliability: Processes and Best Practices

Wire harnesses are critical components across various industries, including automotive, aerospace, medical, and consumer electronics. These seemingly simple assemblies’ power intricate systems by ensuring that electrical connections are stable, reliable, and resistant to harsh conditions. Given their essential role, wire harness manufacturers prioritize quality and reliability through rigorous quality assurance (QA) processes and testing. This article outlines some of the most vital QA processes and best practices that top wire harness manufacturers employ to meet industry standards and deliver reliable products.

Continuity Testing: Ensuring Seamless Electrical Flow

Continuity testing is foundational in wire harness manufacturing. It verifies that the electrical current flows seamlessly through each connection in the harness. Using continuity testers, manufacturers check for open circuits, short circuits, and potential miswiring within the assembly. During this test, a low-voltage current is passed through each circuit to ensure there are no breaks, misalignments, or loose connections.

Why It’s Important

Without continuity testing, harnesses could have undetected faults that may cause system failures, product malfunctions, or even safety hazards. Ensuring continuous and consistent current flow is a primary step in confirming the harness’s functional reliability.

Visual Inspections: Identifying Physical Defects Early

Visual inspection involves a thorough, hands-on review of the wire harness to detect physical issues like incorrect pin locations, exposed wires, damaged insulation, and poor-quality crimps. During this stage, inspectors examine each part of the harness closely, looking for wear and tear or visible damage that could impact performance or lead to safety risks.

Why It’s Important

Visual inspections allow for early identification of potential defects that may not be detectable through electronic testing alone. Catching these defects before the harness moves further into production or shipping reduces costly rework and ensures that only high-quality products reach the client.

Pull Testing: Measuring Strength and Durability

Pull testing measures the tensile strength of connections in the wire harness to ensure they can withstand the stress and strain encountered during installation or operation. This test applies force to the connectors, wires, and terminals, confirming that they won’t detach or break when subjected to real-world conditions.

Why It’s Important

A failure in the wire harness can lead to system shutdowns, malfunctions, or, in severe cases, serious safety issues. Pull testing helps verify that all components are durable, secure, and suitable for specific industry demands — particularly in applications like automotive and aerospace, where durability is non-negotiable.

High-Pot (High Potential) Testing: Assessing Insulation Integrity

High-pot testing, or high-voltage testing, checks the insulation’s capacity to endure high voltages without failing. During this test, the harness is exposed to a voltage higher than its operating level to ensure that the insulation can prevent short circuits and withstand electrical stress in demanding environments.

Why It’s Important

This test is particularly critical in industries such as healthcare and aerospace, where wire harnesses may be exposed to high-voltage environments. High-pot testing reassures manufacturers and end-users that the harness will function safely even in harsh conditions.

Insertion Force Testing: Validating Connector Fit and Stability

Insertion force testing evaluates the amount of force needed to properly engage connectors and terminals, ensuring that components fit securely within the assembly. This test involves repeatedly inserting and removing connectors to measure their durability and retention over time.

Why It’s Important

Poorly connected components can lead to intermittent electrical faults and system failures. Insertion force testing is essential for applications where harnesses need frequent handling or maintenance, ensuring connections remain stable and functional throughout the product’s lifespan.

Environmental Testing: Simulating Real-World Conditions

Environmental testing exposes the harness to various conditions it might encounter in its operational environment, such as temperature fluctuations, humidity, vibration, and mechanical shock. These tests help verify that the harness can withstand and operate effectively under extreme conditions, especially in high-stakes industries like aerospace and automotive.

Why It’s Important

Environmental testing provides confidence that the harness can endure challenging conditions without compromising performance. This is vital for applications that demand long-lasting durability and consistent functionality in unpredictable environments.

Regulatory Compliance and Certifications: Meeting Industry Standards

Top wire harness manufacturers follow strict industry regulations and hold relevant certifications to guarantee product quality. Certifications like ISO 9001, ISO 13485, and IATF 16949 demonstrate a manufacturer’s commitment to standardized quality practices and adherence to international manufacturing standards.

Why It’s Important

Compliance with industry standards reassures clients that products meet the regulatory requirements necessary for high-performance applications. This adherence helps establish trust, reduces liability, and often speeds up approval processes for products in regulated industries.

Documentation and Traceability: Ensuring Accountability and Transparency

Documentation and traceability are critical components of QA in wire harness manufacturing. Each step of the manufacturing and testing process is meticulously documented, enabling manufacturers to trace back any issues to their root cause. This process includes recording details about materials, testing procedures, personnel, and batch numbers.

Why It’s Important

By maintaining comprehensive records, manufacturers can easily investigate and address any issues that may arise in the field. Traceability also helps maintain accountability and transparency, which is vital in industries where precision and reliability are paramount.

Conclusion: A Commitment to Quality and Reliability

In wire harness manufacturing, quality assurance processes and thorough testing methods are non-negotiable to ensure that products are reliable, durable, and safe. By implementing continuity testing, visual inspections, pull testing, and more, manufacturers can meet rigorous industry standards, reduce potential product failures, and instill confidence in their clients. This dedication to quality assurance is what distinguishes top wire harness manufacturers apart, making them trusted partners across critical industries worldwide.

Through these best practices, wire harness manufacturers play an integral role in powering essential systems safely and effectively, ensuring that the devices and machines we rely on daily perform at their best.

#cable assembly#manufacturer#wires and cables#manufacturing#customsheetmetal#precisionstamping#partnerwithus#qualitymatters

1 note

·

View note

Text

Unleash the power of precision with our top-of-the-line electrical test equipment

As we navigate through the fast pace of today's technological world, accuracy is what will give you assurance on safety and reliability in electric systems. You may be managing a commercial building, industrial facility, or even a high capacity power plant, but there is no doubt to the importance of quality electrical test equipment. Our company caters to a number of advanced electrical testing services, which are specifically designed to maximize the performance and increase the life cycles of your electrical systems.

Understanding Electrical Test Equipments

Electrical test equipment is the broad range of tools that measures, monitors, and evaluates the health of electrical systems. It involves circuit testers, insulation resistance testers, and high voltage cable testing devices. With the proper tools on your side, you can be assured that your systems are working effectively and safely.

Electrical Testing Services for Safe Operations

Regular electrical testing services form part of any organization's critical infrastructure since proper electrical facilities can go a long way to support the needs of any establishment. Without regular testing, the equipment is likely to fail, and there will be losses in terms of energy. There is also a possibility of an outright catastrophic incident. All our electrical testing services are meant to minimize all such risks by making sure your electric system is compliant with the electrical industry and safe to use.

For instance, in testing the electrical earthing, it is crucial so as to save both the equipment and the personnel. Effective earthing system gives an appropriate way through which fault currents get carried safely to ground, thus reducing shock and causing equipment damage. Our high-voltage cable testing equipment will therefore give you reassurance that the earthing is being undertaken right, enhancing the safety level.

High Voltage Cable Testing: Precision in its Importance

High Voltage Cable Testing-Perhaps the most essential element of electrical testing, high voltage cable testing involves high voltage cables being an essential constituent of distribution systems and failure of which can give rise to some enormous problems in the operational network. Our company offers a high voltage cable testing service facilitated through state-of-the-art equipment that can pinpoint insulation failures, check the integrity of cables, and measure performance in general.

We make certain that possible problems when they become serious issues are detected through high voltage cable testing. With specific electrical test equipment, we carry out insulation resistance tests, partial discharge tests, and time-domain reflectometry-TDR. This way, we will provide you with precise information and recommendations for maintenance or repair to help extend the installation life cycle.

Accurate Power

Electric testing accuracy cannot be overlooked. Our high technology electric test apparatus gives you only the most accurate and reliable outcome, thereby helping you make the right decision for the upkeep and modification of your electrical system. Our tools are made to be innovative and of quality so that they can work well in any environment without creating problems so that you can have precise data to implement required changes.

In addition, proper electrical testing equipment is always in sync with observing standard requirements. Following the NEC and IEC will not only make sure that your systems keep running properly but also that they comply with all legalities required to run them safely. Our team is here to assist you in working through such guidelines and keeping your configurations up and running according to the recommended practice.

All this is possible by liberating the power of precision, using our high-end electrical test equipment, in protecting your facilities, improving reliability of your systems, and complying with electrical codes. With comprehensive electrical testing services, including high-voltage cable testing as well as thorough evaluations on electrical earthing system, you are ensured that the electrical infrastructure under your charge is in the best shape.

Don't just rely on luck regarding your safety or performance. What you need to find for your company today is equipping your organization with the very best in electrical test equipment and testing services. If you're ready to take your electrical testing practice to new heights, get in touch with us today for more details on our programs and how we can help you unleash the power of precision in your electrical systems.

#electrical earthing system#electrical test equipment#electrical testing services#cable fault location#earth testing#lightning protection system#site acceptance testing#electrical test equipment hire#factory acceptance testing

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] The insulation tester has a dustproof and moisture-proof structure and is very suitable for outdoor work. The maximum display is 2000, and the DC and AC voltage test range is 10 to 600V. It has functions such as automatic range, low battery display, and backlight display. It is ideal for measuring various electrical equipment, motors, Ideal tool for insulating materials such as cables, switches, appliances and more. Specification Max Display: 2000 Working Temperature: 0~40°C Weight: 800g (including battery) DC/AC Voltage Range: 10 to 600V AC Voltage Frequency: 40Hz~70Hz Resistance Range: 0.1MΩ to 200GΩ Insulation Resistance: >=500MΩ (1000V) Dimensions: 180*140*70mm/7.1*5.5*2.7in Features Auto Range LCD Backlight Voltage Measure Low Battery Indication Data Hold/Storage/Delete What’s in the box 1 * Insulation Resistance Tester 8 * 1.5V Batteries 2 * Test Lead 2 * Alligator Clip 1 * Storage Bag 1 * User Manual 【Insulation Resistance Tester】The DC/AC voltage range of the insulation resistance tester is 10 to 600V, the AC voltage frequency is 40Hz~70Hz, and the resistance range is 0.1MΩ to 20GΩ. It has range selection, low battery indication, data retention function, and accurate readings. 【Data Storage】The instrument has the functions of storing, reading, and deleting data. Press the MEM key to store measurement data. Up to 100 sets of data can be stored. Reading and deleting data can also be easily operated. 【Large Backlight Display】The tester has a high-definition LCD display with a maximum display of 2000 and clear character display. Backlight allows clear readings in low light or dark environments. The backlight can be selected to be on or off. 【Low Battery Indicator】There will be a low battery indicator in the upper right corner of the display. When the battery is low, the battery should be replaced in time. When installing the battery, pay attention to the location and polarity of the battery. 【Wide Applications】The instrument has a simple appearance and stable performance. Dust and moisture-proof construction is suitable for outdoor use. Meet the maintenance, repair and testing of various electrical equipment. Suitable for measuring various electrical equipment, motors, cables, switches, appliances and other insulating materials. [ad_2]

0 notes

Text

Understanding the Electrical Insulation

Electrical Insulation is a type of resistive layer Which offers very high resistance more than conductors & semiconductors.

Insulations are either used as a layer around the potential carrying conductors or as a medium or as a separation or as a Base for conductive elements.

Ceramic, Glass, PVC, Bakelite are some of the materials used in insulation.

Insulation & Conductors, Both works Hand in Hand; Both are equally important.

Under the voltage rating; Insulation completely restricts the flow of current But higher voltage beyond a certain limit can damage the insulation & current get pass easily through it & That's voltage is known as breakdown voltage for that insulation.

Special devices such as meggar & digital insulation testers are used to measure insulation resistances.

0 notes

Text

Testing and commissioning a substation is a critical process to ensure that the electrical infrastructure operates safely and efficiently. Here’s a step-by-step guide to help you through the process:

Step 1: Pre-Commissioning Preparation

Review Design Documentation:

Ensure you have the latest drawings, specifications, and manuals for all equipment.

Create a Commissioning Plan:

Develop a detailed plan outlining the scope of testing, timelines, resources, and responsibilities.

Gather Tools and Equipment:

Ensure that all necessary testing equipment (e.g., insulation resistance testers, power quality analyzers, etc.) is available and calibrated.

Safety Protocols:

Establish safety procedures and ensure all personnel are trained on them.

Step 2: Visual Inspection

Inspect Equipment:

Check all equipment for physical damage, correct installation, and cleanliness.

Verify Connections:

Ensure all electrical connections are tight and correctly configured.

Check Grounding:

Verify the grounding system for integrity and continuity.

Step 3: Functional Testing

Control Systems:

Test control panels and automation systems for proper operation.

Relay Testing:

Conduct relay functional tests to ensure they respond correctly to simulated fault conditions.

Circuit Breakers:

Perform tests on circuit breakers, including tripping and operational tests.

Transformer Testing:

Test transformers for insulation resistance, winding resistance, and turns ratio.

Protection Schemes:

Verify that all protection schemes function as intended during fault simulations.

Step 4: Performance Testing

Load Testing:

Conduct load tests to verify performance under actual or simulated operating conditions.

Power Quality Analysis:

Measure voltage, current, harmonics, and other power quality parameters to ensure compliance with standards.

Temperature Monitoring:

Monitor temperatures of critical components during load testing to ensure they remain within safe limits.

Step 5: Documentation

Record Results:

Document all test results, including any anomalies and corrective actions taken.

Update As-Built Drawings:

Modify any drawings to reflect changes made during installation and testing.

Compile Commissioning Report:

Prepare a comprehensive report summarizing all tests, findings, and recommendations.

Step 6: Final Review and Handover

Review with Stakeholders:

Conduct a review meeting with all stakeholders to discuss findings and address any concerns.

Handover to Operations:

Officially transfer responsibility to the operations team, ensuring they have all necessary documentation.

Training:

Provide training for operations personnel on the equipment and systems.

Step 7: Post-Commissioning Support

Monitor Performance:

Continue monitoring the substation's performance for a defined period to ensure stability.

Address Issues:

Be prepared to address any operational issues that arise during the initial operation period.

Regular Maintenance:

Schedule regular maintenance and testing to ensure ongoing reliability.

0 notes

Text

How to Test Windings on a Single Phase Motor

To test single-phase motor windings, begin by disconnecting the motor from its power source to ensure safety. Use a multimeter to check for continuity, which confirms the windings are intact, and measure resistance to detect potential issues like shorts or breaks. Additionally, use an insulation tester (megger) to identify ground faults that may indicate worn or damaged insulation. Regularly testing motor windings can help catch potential problems early, enabling timely repairs or rewinding and ultimately extending the motor’s lifespan while ensuring efficient and safe operation of equipment. Click here to learn more

0 notes

Text

WT-6034 footwear insulation against heat testing machine

WT-6034 footwear insulation against heat testing machine 1. Introductions The sole heat resistance testing machine is used to test the heat resistance and insulation performance of finished shoes in high-temperature sand. 2. Relative test methods GB/T20991 / ISO 20344 personal protective equipment—test methods for footwear 3.specifications No.ItemSpec.1Temperature rangeRT-15℃ or…

View On WordPress

#footwear insulation against heat tester#iso 20344 heat insulation tester#shoe hear resistance tester

0 notes

Text

Application and Testing Methods of UL94 Horizontal and Vertical Burning Tester

The UL94 horizontal and vertical burning tester is a precision device used to evaluate the combustion performance of materials. It is applicable in research, production, and quality inspection across a wide range of electrical and electronic products and components, including lighting equipment, low-voltage electrical appliances, household appliances, machine tool electrical devices, motors, power tools, electronic instruments, electrical instruments, IT equipment, office electrical equipment, electrical connectors, and accessories. This equipment is also suitable for industries involving insulation materials, engineering plastics, or other solid combustible materials. Main Testing Methods The UL94 horizontal and vertical burning tester supports five primary testing methods: Horizontal Burning Test (HB): The material is placed horizontally, and after burning for a specific duration, the burn rate and flame extinguishing time are measured. It is used to assess the flammability of materials under horizontal burning conditions. Vertical Burning Test (V-0, V-1, V-2): The material is placed vertically, and after burning for a specified time, the flame extinguishing time and dripping behavior are observed. Based on the flame extinguishing time and dripping behavior, materials are classified into V-0, V-1, and V-2 levels. 5V Test: A more stringent vertical burning test assessing the material’s fire resistance under high-temperature conditions. Classified into 5VA and 5VB levels, where 5VA materials do not allow drips, and 5VB materials allow drips but must not ignite cotton. Foamed Plastic Burning Test (HF-1, HF-2, HBF): Specifically for testing the combustion performance of foamed plastic materials. HF-1 and HF-2 levels are based on burning time and dripping behavior, while HBF assesses horizontal burning performance. The UL94 horizontal and vertical burning tester complies with the following standards: • GB4706.1 • GB8898.1 • GB4943.1 • GB7000.1 • GB4793.1 These standards are applicable to the research, production, and quality inspection of electrical and electronic products and components such as lighting equipment, low-voltage electrical appliances, household appliances, machine tool electrical devices, motors, power tools, electronic instruments, electrical instruments, IT equipment, office electrical equipment, electrical connectors, and accessories. HVR-LS Horizontal Vertical Flame Tester Application Fields The UL94 horizontal and vertical burning tester is widely used in: • Electrical and Electronic Products and Components: Such as lighting equipment, low-voltage electrical appliances, household appliances, etc. • Insulation Materials: For evaluating the fire resistance of materials. • Engineering Plastics: To assess the performance of plastics under different burning conditions. • Other Solid Combustible Materials: Suitable for fire resistance testing across various industries. Equipment Features Multi-functionality: The tester can conduct both horizontal and vertical burning tests, evaluating the combustion performance of materials in different orientations. This versatility makes it suitable for various materials and application scenarios. Simulation of Real Fire Conditions: The device uses a specific gas source and a Bunsen burner of prescribed dimensions to simulate burning conditions in natural fires. This enables more realistic combustion testing, assessing material performance in fire scenarios. High-precision Instruments: Imported high-precision digital display instruments ensure the accuracy of test results. These instruments provide precise burning data, aiding in the accurate assessment of the material’s flame resistance. Structural Design: The device features a stainless steel enclosure with a large observation window for easy test process observation. It is equipped with an integrated intake ignition system, ensuring complete gas combustion and enhancing test stability and reliability. Ease of Operation: Incorporating advantages of similar domestic and international products, the tester offers stable performance and convenient operation. It employs a microcomputer and touchscreen control system along with a high-precision temperature meter independent electrical control system, addressing the analog-to-digital conversion precision issues of PLC systems and improving anti-interference capability. Wide Applicability: Suitable for the research, production, and quality inspection of various electrical and electronic products and components, such as lighting equipment, low-voltage electrical appliances, household appliances, etc. It is also applicable to industries involving insulation materials, engineering plastics, or other solid combustible materials. Safety Protection: The tester includes safety measures such as leakage protection and explosion-proof window protection, ensuring the safety of personnel and equipment. The horizontal and vertical burning tester is widely used in multiple fields, including but not limited to: • Lighting Equipment: Evaluates the flame resistance of lamps and their components to ensure product safety during use. • Low-voltage Electrical Appliances: Tests the flammability of materials in switches, sockets, and other low-voltage electrical devices, enhancing fire safety standards. • Household Appliances: Assesses the burning performance of components in appliances like rice cookers and microwave ovens, ensuring their safety in household environments. • Machine Tool Electrical Devices and Power Tools: Evaluates the flame resistance of materials in machine tools and power tools, ensuring workplace safety. • Electronic Instruments and Electrical Instruments: Tests the burning performance of casings and internal components of electronic and electrical instruments, reducing fire risks. • Information Technology Equipment: Assesses the burning performance of materials in computers, servers, and other IT equipment, ensuring operational safety. • Insulation Materials and Engineering Plastics: Extensively used in the insulation materials and engineering plastics industries to test the flame resistance of materials, improving product quality and safety. The horizontal and vertical burning tester, as a multifunctional and high-precision testing device, provides reliable methods for evaluating the combustion performance of materials across various industries, helping to enhance product safety and quality standards. The horizontal and vertical burning tester is a high-precision testing device specifically designed to evaluate the combustion performance of plastics and other non-metallic materials. By providing accurate combustion performance data, it aids in improving product safety. The device primarily tests the flammability of materials by simulating real fire conditions, assessing the flame resistance of materials to determine their risk of causing a fire in case of accidental ignition. Read the full article

0 notes

Text

Application and Testing Methods of UL94 Horizontal and Vertical Burning Tester

The UL94 horizontal and vertical burning tester is a precision device used to evaluate the combustion performance of materials. It is applicable in research, production, and quality inspection across a wide range of electrical and electronic products and components, including lighting equipment, low-voltage electrical appliances, household appliances, machine tool electrical devices, motors, power tools, electronic instruments, electrical instruments, IT equipment, office electrical equipment, electrical connectors, and accessories. This equipment is also suitable for industries involving insulation materials, engineering plastics, or other solid combustible materials. Main Testing Methods The UL94 horizontal and vertical burning tester supports five primary testing methods: Horizontal Burning Test (HB): The material is placed horizontally, and after burning for a specific duration, the burn rate and flame extinguishing time are measured. It is used to assess the flammability of materials under horizontal burning conditions. Vertical Burning Test (V-0, V-1, V-2): The material is placed vertically, and after burning for a specified time, the flame extinguishing time and dripping behavior are observed. Based on the flame extinguishing time and dripping behavior, materials are classified into V-0, V-1, and V-2 levels. 5V Test: A more stringent vertical burning test assessing the material’s fire resistance under high-temperature conditions. Classified into 5VA and 5VB levels, where 5VA materials do not allow drips, and 5VB materials allow drips but must not ignite cotton. Foamed Plastic Burning Test (HF-1, HF-2, HBF): Specifically for testing the combustion performance of foamed plastic materials. HF-1 and HF-2 levels are based on burning time and dripping behavior, while HBF assesses horizontal burning performance. The UL94 horizontal and vertical burning tester complies with the following standards: • GB4706.1 • GB8898.1 • GB4943.1 • GB7000.1 • GB4793.1 These standards are applicable to the research, production, and quality inspection of electrical and electronic products and components such as lighting equipment, low-voltage electrical appliances, household appliances, machine tool electrical devices, motors, power tools, electronic instruments, electrical instruments, IT equipment, office electrical equipment, electrical connectors, and accessories. HVR-LS Horizontal Vertical Flame Tester Application Fields The UL94 horizontal and vertical burning tester is widely used in: • Electrical and Electronic Products and Components: Such as lighting equipment, low-voltage electrical appliances, household appliances, etc. • Insulation Materials: For evaluating the fire resistance of materials. • Engineering Plastics: To assess the performance of plastics under different burning conditions. • Other Solid Combustible Materials: Suitable for fire resistance testing across various industries. Equipment Features Multi-functionality: The tester can conduct both horizontal and vertical burning tests, evaluating the combustion performance of materials in different orientations. This versatility makes it suitable for various materials and application scenarios. Simulation of Real Fire Conditions: The device uses a specific gas source and a Bunsen burner of prescribed dimensions to simulate burning conditions in natural fires. This enables more realistic combustion testing, assessing material performance in fire scenarios. High-precision Instruments: Imported high-precision digital display instruments ensure the accuracy of test results. These instruments provide precise burning data, aiding in the accurate assessment of the material’s flame resistance. Structural Design: The device features a stainless steel enclosure with a large observation window for easy test process observation. It is equipped with an integrated intake ignition system, ensuring complete gas combustion and enhancing test stability and reliability. Ease of Operation: Incorporating advantages of similar domestic and international products, the tester offers stable performance and convenient operation. It employs a microcomputer and touchscreen control system along with a high-precision temperature meter independent electrical control system, addressing the analog-to-digital conversion precision issues of PLC systems and improving anti-interference capability. Wide Applicability: Suitable for the research, production, and quality inspection of various electrical and electronic products and components, such as lighting equipment, low-voltage electrical appliances, household appliances, etc. It is also applicable to industries involving insulation materials, engineering plastics, or other solid combustible materials. Safety Protection: The tester includes safety measures such as leakage protection and explosion-proof window protection, ensuring the safety of personnel and equipment. The horizontal and vertical burning tester is widely used in multiple fields, including but not limited to: • Lighting Equipment: Evaluates the flame resistance of lamps and their components to ensure product safety during use. • Low-voltage Electrical Appliances: Tests the flammability of materials in switches, sockets, and other low-voltage electrical devices, enhancing fire safety standards. • Household Appliances: Assesses the burning performance of components in appliances like rice cookers and microwave ovens, ensuring their safety in household environments. • Machine Tool Electrical Devices and Power Tools: Evaluates the flame resistance of materials in machine tools and power tools, ensuring workplace safety. • Electronic Instruments and Electrical Instruments: Tests the burning performance of casings and internal components of electronic and electrical instruments, reducing fire risks. • Information Technology Equipment: Assesses the burning performance of materials in computers, servers, and other IT equipment, ensuring operational safety. • Insulation Materials and Engineering Plastics: Extensively used in the insulation materials and engineering plastics industries to test the flame resistance of materials, improving product quality and safety. The horizontal and vertical burning tester, as a multifunctional and high-precision testing device, provides reliable methods for evaluating the combustion performance of materials across various industries, helping to enhance product safety and quality standards. The horizontal and vertical burning tester is a high-precision testing device specifically designed to evaluate the combustion performance of plastics and other non-metallic materials. By providing accurate combustion performance data, it aids in improving product safety. The device primarily tests the flammability of materials by simulating real fire conditions, assessing the flame resistance of materials to determine their risk of causing a fire in case of accidental ignition. Read the full article

0 notes

Text

The DIT-E Series Anti-Vibration Tables are designed to provide comprehensive solutions for managing vibrations in various environments, particularly in laboratories and industrial settings

Dynemech Anti-Vibration Tables from the DIT-E series seem to be an excellent solution for quality laboratories where precise measurements using table instruments like analytical balances, hardness testers, and roughness testers are required, despite the presence of nearby heavy machinery. The use of Double-Layered Dp Elastomeric Sheets for vibration isolation and damping, combined with the granite surface plate with Grade-1 accuracy, makes these vibration isolated tables particularly effective for environments with high vibration levels.

Key Features of DIT-E Series Anti-Vibration Tables:

Vibration Isolation Performance: Achieves 65-70% reduction of passive vibrations from nearby heavy machinery through vibration absorption and damping, which can be further enhanced with additional insulation layers like optical honeycomb.

Double-Layered Dp Elastomeric Sheets: Provides a tailored approach to isolating vibrations based on the needs of the lab, using elastomeric damping.

Granite Surface Plate: The Grade-1 accuracy allows for precise measurement, making the vibration isolated table ideal for laboratories with high precision requirements for table instruments like metrology equipment.

Economical Solution: Offers cost-effective active and passive vibration control, particularly for high-frequency vibrations.

Self-Levelling and Shock Resistant: The floating platform design with pneumatic damping and spring-based damping makes the tables self-levelling and shock resistant.

Applications:

A. Analytical Balances and Galvanometers: Where even minor vibrations can disrupt readings on these precision instruments.

B. Microscopes for Cells Micromanipulation and Embryo Biopsy: Helps stabilize sensitive instruments to provide clear imaging and accurate results for IMSI and ICSI procedures.

C. Spectroscopes and Atomic Absorption Spectrophotometers: Ensures the precise detection of atoms without interference from vibrations.

This anti vibration table could be ideal for quality laboratories located near industrial units or machinery where controlling vibration is critical for instrument accuracy. The precision engineering behind Dynemech's vibration control solutions makes them perfect for high quality vibration control with high energy and the perfect solution for vibration related problems.

To learn more, visit our vibration website:

https://www.vibrationmountsindia.com/products

#Dynemech, #PrecisionEngineering, #AntiVibrationMounts, #AntiVibrationPads,#AntiVibrationTables, #PrecisionEngineering, #VibrationControl, #TestingLabSolutions, #QualityLabEquipment, #GraniteSurfacePlate, #VibrationIsolation, #LabEquipment,

Contact Us: +91-9810760131; +91-9911145131

Email: [email protected]

#Dynemech#PrecisionEngineering#AntiVibrationMounts#AntiVibrationPads#AntiVibrationTables#VibrationControl#TestingLabSolutions#QualityLabEquipment#GraniteSurfacePlate#VibrationIsolation#LabEquipment

0 notes