#fly ash bricks price

Text

Description: Elevate your construction projects with Chhikara Builders, the leading manufacturer of high-quality fly ash bricks in the industry. With our state-of-the-art production process and top-notch materials, we guarantee durable and sustainable solutions for all your building needs.

#FlyAshBricks#ConstructionMaterials#BuildingMaterials#ChhikaraBuilders#QualityBricks#fly ash bricks price near me

0 notes

Text

Buy AAC Block Bricks from local manufacturers suppliers

L&T-SuFin offers the best AAC Block Bricks at reasonable prices in India that are light weight, fire-resistance, thermal insulation, and acoustic insulation properties make them a great choice for any construction project. The blocks are created by mixing silica-rich materials such as, fly ash, Lime, Gypsum and cement, with a foaming agent.

Contact us:

Ph. no. +91 8291 211 421

Location

The Metropolitan, 4th Floor, Plot No. C 26-27, Block E, Bandra Kurla Complex, Bandra East, Mumbai 400051, Maharashtra, India

2 notes

·

View notes

Text

Affordable and High-Quality Interlocking Tiles Making Machines

In today's fast-paced construction industry, efficiency and quality are paramount. At BTM Product, we understand the challenges faced by builders, contractors, and manufacturers in delivering top-notch results while managing costs. That's why we're proud to offer our state-of-the-art interlocking tiles making machines, designed to revolutionize your production process and elevate the standard of your projects.

Our interlocking tiles making machine are the result of years of research, development, and industry experience. We've combined cutting-edge technology with robust engineering to create a solution that not only meets but exceeds the expectations of our clients. Whether you're a small-scale contractor or a large construction firm, our machines are tailored to suit your specific needs and scale of operations.

Why Choose BTM Product's Interlocking Tiles Making Machines?

1. Unmatched Affordability

We believe that high-quality equipment shouldn't break the bank. Our interlocking tiles making machines are priced competitively, offering you the best value for your investment. By choosing BTM Product, you're not just buying a machine; you're making a smart financial decision that will pay dividends in the long run.

2. Superior Quality Output

Quality is at the heart of everything we do. Our machines are engineered to produce interlocking tiles of the highest standard, ensuring consistency, durability, and aesthetic appeal. The precision of our equipment means you can rely on uniform results, batch after batch.

3. Versatility and Adaptability

Our interlocking tiles making machines are designed to handle a wide range of materials, including concrete, cement, and even fly ash. This versatility allows you to experiment with different compositions and create unique products tailored to your clients' needs.

4. Energy Efficiency

In an era where sustainability is crucial, our machines are designed with energy efficiency in mind. By optimizing power consumption, we help you reduce operational costs and minimize your environmental footprint.

5. User-Friendly Operation

We understand that not all operators have extensive technical knowledge. That's why our interlocking tiles making machines feature intuitive controls and user-friendly interfaces, making them accessible to workers of all skill levels.

6. Durability and Low Maintenance

Built to last, our machines are constructed using high-grade materials that withstand the rigors of daily use. This durability translates to less downtime and lower maintenance costs, ensuring your production remains uninterrupted.

7. Customization Options

We recognize that every project is unique. Our interlocking tiles making machines can be customized to meet your specific requirements, whether it's adjusting production capacity or incorporating special features.

8. Comprehensive Support

When you choose BTM Product, you're not just buying a machine; you're gaining a partner. Our team of experts is always ready to provide technical support, maintenance advice, and operational guidance to ensure you get the most out of your investment.

Our Other Machines

paver block making machine

fly ash brick making machine

The Versatility of Our Interlocking Tiles Making Machines

Our interlocking tiles making machines are not limited to a single application. Their versatility extends to various construction materials and products, including:

1. Standard Interlocking Tiles

Perfect for pathways, driveways, and outdoor spaces, our machines produce interlocking tiles that combine strength with aesthetic appeal.

2. Paver Blocks

Create stunning paver blocks for landscaping projects, pedestrian walkways, and commercial spaces.

3. Kerb Stones

Manufacture precise kerb stones for road construction and landscaping applications.

4. Fly Ash Bricks

Our machines are also capable of producing high-quality fly ash bricks, offering an eco-friendly alternative to traditional clay bricks.

The Fly Ash Brick Making Machine: A Game-Changer in Sustainable Construction

As part of our commitment to innovation and sustainability, BTM Product offers a specialized fly ash brick making machine. This cutting-edge equipment allows you to tap into the growing market for eco-friendly construction materials.

Fly ash bricks are gaining popularity due to their numerous advantages:

1. Environmental Benefits: By utilizing fly ash, a byproduct of coal combustion, these bricks help reduce waste and lower the carbon footprint of construction projects.

2. Cost-Effective: The production of fly ash bricks is often more economical than traditional clay bricks, offering savings for both manufacturers and end-users.

3. Superior Properties: Fly ash bricks boast excellent compressive strength, low water absorption, and uniform shape, making them ideal for various construction applications.

4. Versatility: These bricks can be used in both load-bearing and non-load-bearing structures, offering flexibility in design and application.

5. Reduced Energy Consumption: The production process of fly ash bricks requires less energy compared to conventional bricks, further enhancing their eco-friendly profile.

Our fly ash brick making machine is designed to maximize efficiency and quality in the production of these innovative building materials. With precise control over the mixing and molding processes, you can consistently produce fly ash bricks that meet or exceed industry standards.

Streamlining Your Production Process

At BTM Product, we understand that efficiency is key to your success. That's why our interlocking tiles making machines and fly ash brick making machine are designed to streamline your production process:

1. Rapid Production: Our machines boast impressive production rates, allowing you to meet tight deadlines and increase your output.

2. Minimal Waste: Precise material control and efficient molding processes minimize waste, saving you money on raw materials.

3. Quick Setup and Changeover: Easily switch between different product types or sizes with minimal downtime.

4. Automated Features: Many of our machines include automated functions that reduce the need for manual intervention, improving consistency and reducing labor costs.

5. Quality Control Integration: Built-in quality control measures ensure that every tile or brick meets your exacting standards.

Training and Support: Empowering Your Team

When you invest in a BTM Product machine, whether it's our interlocking tiles making machine or fly ash brick making machine, you're not just getting equipment – you're gaining a partner in success. We offer comprehensive training and support to ensure your team can operate the machinery effectively and efficiently:

1. On-Site Training: Our experts provide hands-on training at your facility, ensuring your operators are comfortable with all aspects of the machine's operation.

2. Ongoing Technical Support: Our dedicated support team is always available to answer questions and troubleshoot any issues you may encounter.

3. Maintenance Guidance: We provide detailed maintenance schedules and guides to help you keep your machine in top condition, maximizing its lifespan and performance.

4. Upgrades and Updates: As technology evolves, we offer upgrades and updates to keep your equipment at the cutting edge of efficiency and quality.

Some Blogs

Automatic Fly Ash Brick Making Machine at the Best Price

Get the Best Fly Ash Brick Making Machine in India

Conclusion

In an industry where quality, efficiency, and sustainability are paramount, BTM Product's interlocking tiles making machines and fly ash brick making machine stand out as the clear choice for forward-thinking businesses. By investing in our technology, you're not just purchasing equipment – you're investing in the future of your company and the construction industry as a whole.

Our commitment to affordability doesn't come at the cost of quality. Instead, it's a reflection of our dedication to making advanced technology accessible to businesses of all sizes. With BTM Product's machines, you can compete at the highest level, delivering superior products while maintaining a healthy bottom line.

Whether you're looking to expand your product line, increase your production capacity, or transition to more sustainable building materials, our interlocking tiles making machines and fly ash brick making machine are the tools you need to succeed. Join the ranks of satisfied BTM Product customers who have transformed their operations and elevated their standing in the competitive construction market.

Take the first step towards revolutionizing your production process. Contact BTM Product today to learn more about our affordable and high-quality interlocking tiles making machines and fly ash brick making machine. Let's build a stronger, more efficient, and sustainable future together.

0 notes

Text

Choosing right brick making machine manufacturers in India

Brick making machines are essential in construction especially in the manufacturing of bricks as it makes it possible to have uniform bricks, quality and time effectiveness. Choosing the right brick making machine manufacturer for such machines is an important aspect since the success of construction projects depends on it. In the case of a brick making machine, a quality machine will increase the production, lower the costs, and produce quality bricks, while a low quality machine will result in slow production, high costs, and poor quality bricks that affect building performance.

We will, therefore, focus on what to consider when buying the brick making machine, a comparison of the most popular brick making machine manufacturers in India as well as other invaluable tips to consider. Regardless whether you are a contractor, a builder or a construction company.

Another important aspect is the reliability and quality of manufacturers since their reputation and experience influence their products. Brick making machine manufacturers in India who have been in the business for many years and have been known to produce quality machines should be given preference. The quality of the brick making machine should therefore be evaluated. A quality machine or equipment is usually constructed with reliable and durable materials and technologies to enable efficient functioning.

Brick making machine manufacturers in India and one of the most prominent companies is Brick Machinery. Focused on innovation and reliability, Brick Machinery has become the recognized supplier for construction field specialists all over the country. Brick machinery comprises a variety of brick making machine intended for different construction requirements. Their products include machines that are rugged, fast, and very easy to operate, making them a favorite with the small builder as well as the big construction companies.

Brick Machinery provides a wide variety of products, including manual, semi-automatic, and fully automatic brick making machines. Such choice provides customers with an opportunity to select a particular machine that meets their project needs and financial capabilities. Compared to other manufacturers of such machinery in India, Brick Machinery has a more diversified range of products suitable to various level of operations.

Brick Machinery has a remarkable balance between the quality it delivers and the price it is offered at. Their prices are well set because the features offered by these machines are incredibly powerful and efficient. However, some manufacturers may sell their products at fairly cheap prices but at the same time have lesser quality than others while the others may have high price tag but little added value.

Contact us and start the journey into more effective construction processes with the help of the leading brick making machine manufacturers in India. Come to our website today to discover a range of our brick making machine and to purchase your machine at a better price.

#brick making machine#brick making machine in india#brick making machine manufacturer#brickmachine#brick making machine manufacturers in India

0 notes

Text

Top Brick and Paver Machine Manufacturers in Morbi: Revolutionizing Construction with Advanced Technology

In the bustling hub of Morbi, Gujarat, a revolution in construction technology is taking place. Companies like Lomango Machinery are at the forefront, providing state-of-the-art machines that are transforming the way we build. From brick machines to paver block machines, Lomango Machinery stands out as a leading manufacturer, offering a range of products that cater to various construction needs. In this blog, we'll delve into the details of their offerings, highlighting the key features and benefits of each.

Bricks Machine Manufacturer in Morbi

Lomango Machinery is a prominent bricks machine manufacturer in Morbi. Their machines are designed to produce high-quality bricks that meet industry standards. The advanced technology used in these machines ensures efficient production processes, reducing manual labor and increasing output.

Key Features:

High Efficiency: The machines are designed for high output, ensuring a steady supply of bricks for large construction projects.

Durability: Made from robust materials, these machines are built to last, providing long-term value for money.

User-Friendly: The intuitive design makes them easy to operate, even for those with minimal technical expertise.

Brick Machine Manufacturer in Gujarat

As a brick machine manufacturer in Gujarat, Lomango Machinery caters to a wide market, supplying machines to various regions across the state. Their reputation for quality and reliability has made them a preferred choice among builders and contractors.

Advantages:

Local Support: Being based in Gujarat, they offer excellent customer support and after-sales service to their clients.

Cost-Effective: Their machines are competitively priced, offering excellent value for money.

Fly Ash Brick Making Machine Manufacturer

The fly ash brick making machines from Lomango Machinery are a game-changer in the industry. These machines utilize fly ash, a by-product of coal combustion, making them an eco-friendly option for brick production.

Key Benefits:

Environmental Impact: Using fly ash reduces the need for clay, preserving natural resources and reducing environmental degradation.

Strength and Durability: Fly ash bricks are known for their superior strength and durability compared to traditional clay bricks.

Automatic Fly Ash Brick Making Machine

For those seeking to automate their brick production, Lomango Machinery offers automatic fly ash brick making machines. These machines streamline the production process, reducing the need for manual intervention and increasing efficiency.

Features:

Automation: Fully automated systems ensure consistent quality and high production rates.

Precision: Advanced technology ensures precise brick dimensions and uniformity.

Fly Ash Brick Making Machine Fully Automatic

The fully automatic fly ash brick making machines from Lomango Machinery represent the pinnacle of modern brick manufacturing technology. These machines are designed for large-scale production, making them ideal for big construction projects.

Advantages:

Labor Savings: Automation reduces the need for manual labor, cutting down on labor costs.

Consistency: Ensures consistent quality and uniformity in every batch of bricks produced.

Fly Ash Brick Making Machine Supplier

As a trusted fly ash brick making machine supplier, Lomango Machinery ensures that their clients receive top-quality machines that meet their specific needs. Their commitment to customer satisfaction sets them apart in the industry.

Services:

Customization: They offer customized solutions to meet the unique requirements of their clients.

After-Sales Support: Comprehensive after-sales support ensures that any issues are promptly addressed.

Paver Block Machine Manufacturer in Morbi

In addition to brick machines, Lomango Machinery is also a leading paver block machine manufacturer in Morbi. Their machines are designed to produce high-quality paver blocks that are widely used in landscaping and paving projects.

Features:

Versatility: Capable of producing various shapes and sizes of paver blocks.

Durability: Built to withstand the rigors of continuous use, ensuring long-term reliability.

Paver Making Machine for Sale

Lomango Machinery offers a range of paver making machines for sale, catering to different budgetary and production requirements. Their machines are known for their efficiency and reliability.

Benefits:

Cost-Effective: Competitive pricing makes their machines accessible to a wide range of customers.

High Output: Designed for high production rates, ensuring timely completion of projects.

Paver Block Making Machine Manufacturers

As leading paver block making machine manufacturers, Lomango Machinery's products are trusted by contractors and builders across the region. Their machines are designed to deliver high performance and reliability.

Advantages:

Innovative Technology: Incorporating the latest technology to ensure superior performance.

Customer Satisfaction: A strong focus on customer satisfaction ensures long-term relationships with their clients.

Automatic Paver Block Making Machine

For those looking to streamline their paver block production, Lomango Machinery offers automatic paver block making machines. These machines automate the production process, reducing manual labor and increasing efficiency.

Features:

Automation: Fully automated systems ensure high efficiency and consistent quality.

Ease of Use: Designed for easy operation and maintenance.

In conclusion, Lomango Machinery stands out as a leader in the construction machinery industry. Their range of brick and paver block machines is designed to meet the diverse needs of their clients, offering advanced technology, reliability, and excellent value for money. Whether you're looking for a bricks machine manufacturer in Morbi or a paver block machine manufacturer, Lomango Machinery has you covered. Visit their website at Lomango Machinery to learn more about their products and services.

#Bricks Machine Manufacturer Morbi#brick machine manufacturer in gujarat#fly ash brick making machine manufacturer#automatic fly ash brick making machine#fly ash brick making machine fully automatic#fly ash brick making machine supplier#paver block machine manufacturer morbi#paver making machine for sale#paver block making machine manufacturers#automatic paver block making machine

0 notes

Text

Solid Block Manufacturer in Chennai: Quality and Affordability

Chennai, the thriving capital of Tamil Nadu, is home to numerous construction projects, ranging from residential apartments to commercial buildings. As the city continues to grow, the demand for high-quality building materials like solid blocks has surged. Solid blocks are a preferred choice for builders and contractors due to their durability, strength, and cost-effectiveness. This article delves into the best solid block manufacturer in Chennai and explores the price range of solid blocks in the city.

Top Solid Block Manufacturers in Chennai

ACC Concrete

Overview: ACC Concrete is a leading name in the construction materials industry, offering a range of high-quality solid blocks. Their products are known for their durability and uniformity, making them a top choice for construction projects in Chennai.

Products: Solid blocks, ready-mix concrete, and other construction materials.

Features: High compressive strength, excellent dimensional accuracy, and superior finish.

UltraTech Cement Ltd.

Overview: UltraTech Cement Ltd. is one of India's largest cement producers, also manufacturing solid blocks. Their blocks are designed to provide excellent strength and durability for all types of construction needs.

Products: Solid blocks, concrete blocks, and other building materials.

Features: High load-bearing capacity, resistance to weather conditions, and consistent quality.

Ramco Cement

Overview: Ramco Cement is renowned for its premium quality construction materials. They offer solid blocks that meet stringent quality standards, ensuring longevity and stability in construction.

Products: Solid blocks, cement, and concrete solutions.

Features: Eco-friendly manufacturing process, high strength, and precise dimensions.

NCL Industries Ltd.

Overview: NCL Industries Ltd. is a well-known manufacturer of construction materials, including solid blocks. Their products are widely used in residential, commercial, and industrial projects across Chennai.

Products: Solid blocks, ready-mix concrete, and other construction materials.

Features: High durability, cost-effective, and easy to work with.

Eco Green Products Pvt. Ltd.

Overview: Eco Green Products Pvt. Ltd. specializes in environmentally friendly construction materials. Their solid blocks are made using sustainable methods, ensuring minimal environmental impact.

Products: Solid blocks, fly ash bricks, and pavers.

Features: Eco-friendly, high compressive strength, and excellent thermal insulation.

Solid Block Price in Chennai

The price of solid blocks in Chennai can vary based on factors such as the size of the block, quality, and the manufacturer. Here's a general overview of the pricing:

Standard Solid Blocks (6 inches):

Price Range: ₹30 to ₹50 per block

These blocks are commonly used in wall construction and offer good strength and durability.

Standard Solid Blocks (4 inches):

Price Range: ₹20 to ₹35 per block

Suitable for partition walls and non-load-bearing applications, these blocks are lighter and more economical.

High-Strength Solid Blocks:

Price Range: ₹40 to ₹60 per block

These blocks provide superior strength and are ideal for load-bearing structures and high-rise buildings.

Eco-Friendly Solid Blocks:

Price Range: ₹35 to ₹55 per block

Made from sustainable materials, these blocks are not only durable but also contribute to green building practices.

Conclusion

Choosing the right solid block manufacturer in Chennai is crucial for ensuring the quality and durability of your construction project. The manufacturers listed above are known for their reliable and high-quality products that cater to various construction needs. Additionally, understanding the price range of solid blocks can help you budget effectively and make informed decisions. Whether you are building a residential home or a commercial complex, investing in good quality solid blocks will ensure the longevity and strength of your structure.

0 notes

Text

Harga Concrete Mixer

Concrete mixer is a kind of equipment commonly used in construction sites and concrete mixing plants, usually used to mix various kinds of hard concrete, plastic concrete and fluid concrete. Concrete mixer has the advantages of high mixing efficiency, good mixing quality, easy operation and so on, so it is widely used in engineering construction.

The harga concrete mixer will vary according to the brand, model, specification and function. Generally speaking, the price of an ordinary household twin shaft concrete mixer may range from a few thousand to ten thousand dollars, while the price of a twin shaft concrete mixer for industrial use may be a bit higher. Here are some examples of concrete mixer prices:

Small twin shaft mixers: such as the JS500 model, may cost between a few thousand dollars and $10,000 dollars.

Medium-sized twin shaft mixers: such as the JS1500 model, which may cost between tens and hundreds of thousands of dollars.

Large double horizontal shaft mixer: such as JS3000, the price may reach hundreds of thousands to millions of dollars.

Working Principle of concrete mixer:

Double horizontal shaft concrete mixer adopts the design of two-way rotation of the horizontal shaft, and mixes various raw materials fully through the mixing blades in order to realize the production of uniform and stable quality concrete.

Basic structure of concrete mixer:

It mainly consists of casing, spiral shaft assembly, driving device, piping, cover, chain cover and other components.

The casing is sealed tightly to prevent fly ash from rising and leaking.

Spiral shaft assembly is the main component of double-shaft mixer, including left and right rotating spiral shaft, bearing seat, bearing sleeve, bearing cover, gear, sprocket, oil cup, blade and other parts.

Technical Parameters of concrete mixer:

Capacity: the capacity varies from small JS500 type to large JS4000 type.

Mixing effect: The design of double horizontal shaft enables the material to be fully mixed in a short time, improving the uniformity and quality of concrete.

Stability: the design of mixing blades ensures the stability of materials in the mixer, avoiding the uneven mixing of materials.

Application occasions of concrete mixer:

Widely used in cement, concrete, building and road construction industries, it is one of the important equipments in the field of precast concrete plant, brick making plant, water conservancy project and so on.

Advantage of concrete mixer:

Good mixing effect: double horizontal shaft design greatly improves the uniformity and quality of concrete.

Good stability: ensure the stability of the material in the mixer.

Long service life: made of high-quality materials, with strong durability and wear resistance.

Convenient cleaning: reasonable structure, easy to clean and maintain, reduce dust pollution.

When you buy concrete mixer, it is recommended that you choose famous brand products to ensure quality and after-sales service. In addition, you should choose the right model and specification according to your needs and budget. Before buying, it is better to conduct market research to understand the price, performance and reputation of different brands and models before making a decision.

This resource is from http://www.haomei-machine.com/news/companynews/harga-concrete-mixer.html

Should you be interested in buying our product, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

0 notes

Text

Exploring the Rise of NCL Buildtek Share Price

Introduction

NCL Buildtek Ltd. has recently witnessed a notable increase in NCL Buildtek Share Price, capturing the attention of investors and market analysts. As a prominent player in the construction and building materials industry, the company's impressive performance and strategic initiatives have contributed significantly to this upward trend. This article delves into the factors driving the rise in NCL Buildtek Share Price and explores the company’s future prospects. NCL Buildtek Ltd. ("NCL Buildtek"), formerly known as NCL Alltek & Seccolor Ltd., is a part of the NCL Group. The company specializes in the manufacturing and sale of spray plasters, paints, skim coats, steel profiles, doors, windows (steel, ABS, and uPVC), and fly ash bricks. The group is organized into four divisions:

Coatings (Wall Putties, Paints, and Textures): The group began manufacturing spray plasters in 1992 using technology from M/s. ICP Sweden, becoming the first in India to produce acrylic-based putties (spray plasters). Today, it is the largest manufacturer of spray plasters in the country. The company also produces emulsion paints, textured paints, white cement-based putty, and other cement-based products like tile adhesives, mortars, and plasters.

Windoors: Since 1988, the group has been manufacturing pre-painted steel doors, windows, partitions, and glazing using technology from M/s. Industrie Secco S.P.A. of Italy, marketed under the brand name Seccolor. The group also fabricates uPVC doors, windows, and ABS doors.

Walls: The production of fly ash bricks began in 2016 at Kavuluru, Krishna District, Andhra Pradesh. A second project in Nellore, Andhra Pradesh, with an installed capacity of 500,000 cubic meters, commenced commercial operations in March 2020.

Services: Providing services to buildings and building materials manufacturing units.

The company operates 11 manufacturing units across various states. As the sole licensee in India for ICP plasters, NCL Buildtek has successfully completed numerous prestigious projects. It was the first company in India to manufacture putty (textured paints) and offers a variety of finishes for interior and exterior applications, including plain, granular, textured, and other designer finishes to suit various architectural and design preferences.

Over time, the company's product portfolio has expanded to include AAC blocks, dry-mix mortars, and tile adhesives. The company is planning to establish a steel door unit in Sangareddy district with an investment of over Rs. 10 crores and an AAC block manufacturing unit in Nellore with an investment of Rs. 80 crores.

Founded by Mr. K. Ramachandra Raju in 1986, NCL Buildtek has three decades of experience in providing innovative and alternative building materials.

Company Overview

From NCL Alltek & Seccolor to NCL Buildtek

NCL Buildtek Ltd., formerly known as NCL Alltek & Seccolor Ltd., is a key entity within the NCL Group. The company specializes in the manufacturing and sale of a wide range of construction and building materials. Its product portfolio includes spray plasters, paints, skim coats, steel profiles, doors, windows (steel, ABS, and uPVC), and fly ash bricks. Over the years, NCL Buildtek has established a strong reputation for quality and innovation in the industry.

Diverse Product Range

The company’s diverse product range caters to various segments of the construction market, ensuring a steady demand for its offerings. Some of the key products include:

Spray Plasters: Known for their ease of application and superior finish.

Paints and Skim Coats: Offering durability and aesthetic appeal for various construction projects.

Steel Profiles, Doors, and Windows: Providing robust and reliable solutions for building structures.

Fly Ash Bricks: An eco-friendly alternative to traditional bricks, promoting sustainable construction practices.

Factors Driving Share Price Growth

Strong Financial Performance

NCL Buildtek’s recent financial results have been a significant driver of its rising share price. The company has reported substantial revenue growth and profitability, reflecting its efficient operations and market demand for its products. Consistent earnings and a healthy balance sheet have boosted investor confidence, contributing to the share price surge.

Strategic Expansion and Innovation

The company’s strategic expansion initiatives have played a crucial role in its success. By entering new markets and expanding its product line, NCL Buildtek has managed to capture a larger market share. Additionally, the company’s focus on innovation, including the development of eco-friendly and technologically advanced products, has set it apart from competitors.

Favorable Market Conditions

The construction and building materials industry has experienced favorable market conditions, with increased infrastructure development and housing projects driving demand. NCL Buildtek has capitalized on this trend, positioning itself as a reliable supplier of high-quality materials. The overall bullish sentiment in the stock market has also contributed to the rise in the company’s share price.

Future Prospects

Continued Growth and Expansion

Looking ahead, NCL Buildtek is well-positioned for continued growth. The company’s strategic plans include further expansion into new geographic regions and the introduction of innovative products to meet evolving market needs. By maintaining its focus on quality and customer satisfaction, NCL Buildtek aims to sustain its upward trajectory.

Potential Challenges

Despite the positive outlook, the company faces potential challenges that could impact its future performance. These include regulatory changes in the construction industry, rising raw material costs, and increased competition. However, NCL Buildtek’s robust business model and adaptive strategies are expected to help mitigate these risks.

Conclusion

The rise in NCL Buildtek’s share price is a testament to the company’s strong performance, strategic vision, and ability to capitalize on favorable market conditions. As it continues to innovate and expand, NCL Buildtek remains a compelling investment opportunity in the construction and building materials sector. Investors and stakeholders will be keenly watching the company’s progress as it navigates the dynamic market landscape.

#NCL Buildtek Share Price#NCL Buildtek IPO#NCL Buildtek Pre IPO#NCL Buildtek Unlisted Shares#NCL Buildtek Upcoming IPO

0 notes

Text

Explore Yuken Pv2r Series Vane Pumps With Shriank

When it comes to hydraulic systems, efficiency and reliability are paramount. The Yuken hydraulic pump PV2R Series is a stellar example of high-performance hydraulic pumps that deliver consistent and robust performance. We at ShriAnk offer a comprehensive range of Yuken PV2R Series Vane Pumps that not only match but exceed expectations in various industrial applications.

What Makes Yuken PV2R Series Vane Pumps Stand Out?

The Yuken PV2R Series Vane Pumps are renowned for their durability, high efficiency, and ability to handle high pressures up to 210 BAR (3000 PSI). These pumps are integral to numerous industrial machines, including plastic injection molding machines, hydraulic presses, and tractor backhoe loaders, among others. The versatility and reliability of these pumps make them a preferred choice for industries that demand precise and powerful hydraulic solutions.

A Perfect Replacement Solution

At ShriAnk, under our HYDRANK brand, we specialize in providing one-to-one replacements for Yuken Single Vane Pumps and Double Vane Pumps. Our 12 vane designs are compatible with Yuken’s PVR, PVM, and PV2R Series Pumps, ensuring seamless integration and minimal downtime. Whether you need a replacement for a PV2R 1 pump or a PV2R 34 pump, we have you covered with our HYDRANK equivalents that are always in stock.

Why Choose HYDRANK Pumps?

Direct Compatibility: HYDRANK pumps are designed to directly replace Yuken PV2R Series Vane Pumps. This ensures that there is no need for modifications or adjustments during installation.

High Efficiency: Our pumps maintain the high-efficiency standards set by Yuken, ensuring optimal performance in your hydraulic systems.

Cost-Effective: HYDRANK pumps are competitively priced, providing a cost-effective alternative without compromising on quality or performance.

Minimal Downtime: With a comprehensive stock of pumps and spare parts, we ensure that your operations face the least downtime during replacements.

Types Of Yuken PV2R Series Vane Pumps And Their HYDRANK Equivalents

Yuken Pump PV2R 1

The Yuken Pump PV2R 1 is a versatile and efficient option for various hydraulic applications. Our H-PV2R 1 pump matches its specifications with a maximum pressure of 210 BAR and a speed of 1800 RPM. This pump is particularly suitable for use in plastic injection molding machines and hydraulic presses. The high-pressure tolerance and reliable performance make it a perfect replacement for the Yuken hydraulic pump PV2R 1, ensuring that your machinery operates smoothly without any disruptions.

Yuken Pump PV2R 2

For those using the Yuken Pump PV2R 2 , our H-PV2R 2 pump offers a seamless replacement. It is designed to deliver the same performance standards with easy availability to ensure your machinery remains operational. This pump is ideal for hydraulic bailing presses and fly ash brick-making machines, where consistent pressure and flow are crucial. With our Yuken hydraulic pump PV2R 2, you can expect minimal downtime and sustained efficiency, making it a reliable choice for high-demand applications.

Yuken Pump PV2R 3

The H-PV2R 3 pump is our direct replacement for the Yuken Pump PV2R 3 . It maintains the high efficiency and reliability needed for demanding industrial applications such as hydraulic bending machines and tractor-backhoe loaders. The robust design and precise engineering of the Yuken hydraulic pump PV2R 3 ensures that it can handle intense workloads with ease, providing a cost-effective and efficient solution for your hydraulic systems.

Yuken Pump PV2R 12

Our H-PV2R 12 pump stands in for the Yuken Pump PV2R 12 , ensuring your hydraulic systems operate at their peak with minimal downtime and maximum efficiency. This pump is particularly effective in applications where high performance and reliability are paramount, such as in complex hydraulic press operations. The Yuken hydraulic pump PV2R 12 offers the same high standards of performance, making it an excellent replacement that guarantees seamless integration and continued productivity.

Yuken Pump PV2R 13

With the H-PV2R 13 pump, you get a direct replacement for the Yuken Pump PV2R 13 . It provides the same robustness and performance for your hydraulic needs, making it suitable for a wide range of applications, including heavy machinery and industrial automation systems. Yuken hydraulic pump PV2R 13 is designed to ensure longevity and reliability, helping you maintain consistent operations and reduce maintenance costs.

Yuken Pump PV2R 23

The H-PV2R 23 pump from HYDRANK is designed to replace the Yuken Pump PV2R 23 . It offers high performance and reliability in various industrial applications, including hydraulic presses and injection molding machines. The Yuken hydraulic pump PV2R 23 pump’s ability to handle high pressure and speed ensures that your machinery operates efficiently, providing a dependable solution for your hydraulic systems.

Yuken Pump PV2R 33

For those using the Yuken Pump PV2R 33 , our H-PV2R 33 pump is the ideal replacement. It ensures consistent and efficient operation of your hydraulic systems, making it suitable for use in heavy-duty industrial equipment. The Yuken hydraulic pump PV2R 33 pump’s durability and high performance make it a cost-effective choice, helping you maintain high productivity levels without the need for frequent replacements or repairs.

Yuken Pump PV2R 24

Our H-PV2R 24 pump provides a direct and efficient replacement for the Yuken Pump PV2R 24 . It maintains high standards of performance and durability, making it suitable for demanding applications such as hydraulic bailing presses and fly ash brick-making machines. Yuken hydraulic pump PV2R 24 pump’s robust design ensures that it can withstand high pressures and deliver consistent performance, helping you achieve optimal results in your operations.

Yuken Pump PV2R 34

The H-PV2R 34 pump is our replacement for the Yuken Pump PV2R 34 . It is designed to meet the rigorous demands of your hydraulic systems with ease. This pump is ideal for applications requiring high reliability and efficiency, such as hydraulic presses and bending machines. Yuken hydraulic pump PV2R 34 pump’s advanced design and engineering ensure that it delivers consistent performance, reducing downtime and maintenance costs.

Applications of Yuken PV2R Series Vane Pumps

The Yuken Pumps PV2R Series are highly utilized across a range of industrial machines due to their superior performance and reliability. Here are some of the common applications:

– Plastic Injection Molding Machines: These pumps provide the necessary pressure and flow for precise molding operations.

– Hydraulic Presses: Essential for delivering consistent force in various pressing applications.

– Hydraulic Bailing Presses: Used in recycling and waste management, these pumps ensure efficient baling processes.

– Hydraulic Bending Machines: They enable accurate and powerful bending operations in metalworking.

– Fly Ash Brick-Making Machines: These pumps are critical in ensuring the consistent quality and production rate of bricks.

– Tractor Backhoe Loaders: Providing the hydraulic power needed for efficient digging and loading operations.

Why Partner with ShriAnk for Your Hydraulic Needs?

Partnering with ShriAnk means choosing reliability, efficiency, and a commitment to quality. Our HYDRANK brand pumps are engineered to offer a perfect replacement solution for Yuken PV2R Series Vane Pumps. We ensure that our pumps not only match the specifications of Yuken pumps but also provide additional benefits such as cost savings and reduced downtime.

In conclusion, if you are looking for a reliable, efficient, and cost-effective solution for replacing your Yuken PV2R Series Vane Pumps, look no further than ShriAnk’s HYDRANK brand. Our extensive range of pumps ensures that you can find the perfect match for your hydraulic system needs, maintaining the performance and reliability you expect. Explore our offerings today and experience the difference that HYDRANK can make in your industrial applications.

0 notes

Text

Fly Ash Brick Making Machine Manufacturer and Suppliers in India

The greatest prices on Fly Ash Brick Making Machine can be found at Indian Trade Bird. Fly ash‐lime bricks are generally manufactured by inter‐grinding or blending various raw materials which are then molded into bricks and subjected to curing cycles at different temperatures and pressures. On occasions, as and when required, crushed bottom ash or sand is also used in the composition of the raw material. he bricks are made of the dirt/clay from the place they hold dear to them, mixed with the ashes of the deceased person. The mixture is placed in a simple mould and stamped with the letters of their name. They are fired to make them a hard and durable material.

For More details clicks here - https://www.indiantradebird.com/product/fly-ash-brick-making-machine

0 notes

Text

1000 Bricks Price in India

1000 Bricks Price in India are a quintessential constructing fabric used in building tasks throughout India. Understanding the rate dynamics of bricks is critical for builders, contractors, and house owners alike. In this article, we discover the more than a few kinds of bricks available, elements influencing their prices, modern-day trends, and the place to locate the first-rate offers on bricks in India.

Types of Bricks

Fired Clay Bricks

Fired clay bricks are one of the most common and broadly used kinds of bricks in India. They are made from clay that is molded and then fired in a kiln. These bricks provide desirable sturdiness and thermal insulation properties.

Fly Ash Bricks

Fly ash bricks are a extra sustainable choice to common clay bricks. They are made from a combination of fly ash (a byproduct of coal combustion), cement, and sand. Fly ash bricks are acknowledged for their power and eco-friendly credentials.

Concrete Bricks

Concrete bricks are made from a mixture of cement, sand, and aggregate. They are versatile and regularly used in load-bearing structures. Hyderabad Builders Concrete bricks are long lasting and resistant to weathering.

Factors Affecting Brick Prices

Raw Material Costs

The value of uncooked substances like clay, fly ash, cement, and sand immediately affects brick prices. Fluctuations in these cloth expenses can impact the normal rate of bricks.

Manufacturing Process

The manufacturing process, such as labor costs, electricity consumption, and technological know-how used, performs a tremendous position in figuring out brick prices.

Transportation Costs

Transporting bricks from manufacturing gadgets to building web sites incurs transportation costs, affecting the last price.

Market Demand and Supply

Market dynamics, such as seasonal demand fluctuations and furnish chain disruptions, can lead to fee variations.

Current Trends in Brick Pricing

Price Fluctuations Over Time

Brick expenses in India have proven fluctuations due to altering market conditions, consisting of monetary elements and authorities policies.

Regional Variations

Prices can fluctuate substantially throughout areas primarily based on nearby demand, availability of uncooked materials, and opposition amongst suppliers.

Average Cost of Bricks in India

Cost Comparison Across Types

On average, fired clay bricks vary from ₹4 to ₹6 per brick, whilst fly ash bricks commonly value between ₹3 to ₹5 per brick. Concrete bricks are priced barely higher, ranging from ₹6 to ₹8 per brick.

Cost Variation by using Region

Brick expenses can range by using region. For instance, expenses in city areas have a tendency to be greater in contrast to rural areas due to greater transportation and labor costs.

Tips for Buying Bricks

Quality Considerations

Always prioritize fine over price. Ensure the bricks meet applicable Indian requirements and have exact compressive strength.

Bulk Purchasing Benefits

Buying bricks in bulk frequently leads to discounts. Plan your development initiatives beforehand to gain from bulk purchasing.

Popular Brands and Suppliers

Overview of Leading Suppliers

Some famous brick suppliers in India consist of Red Bricks Industries, Tata Tiscon, and Jindal Mechno Bricks.

Customer Reviews and Feedback

Consider purchaser evaluations and comments when deciding on a brick supplier. Reliable suppliers prioritize nice and purchaser satisfaction.

Future Outlook and Predictions

Forecasted Price Trends

Experts predict a constant upward push in brick costs due to growing demand for building substances and inflationary pressures.

Innovations in Brick Manufacturing

Technological advancements, such as computerized brick-making tactics and the use of recycled materials, may also have an effect on future brick expenditures and sustainability.

Conclusion

Understanding the pricing of bricks in India entails thinking about a number factors, from uncooked fabric prices to market traits and regional variations. By staying knowledgeable and exploring extraordinary sorts of bricks and suppliers, you can make knowledgeable selections for your development projects.

FAQs About Brick Prices in India

What is the common value of one thousand bricks in India?

The common price of a thousand bricks in India varies primarily based on the kind of brick and region. Generally, it tiers from ₹4000 to ₹8000.

How do I select between extraordinary sorts of bricks?

Consider elements such as durability, cost, and environmental impact. Consult with specialists or suppliers to make an knowledgeable choice.

Are there eco-friendly picks to ordinary bricks?

Yes, fly ash bricks and different sustainable alternatives are gaining recognition for their eco-friendly attributes.

Can I negotiate expenses with brick suppliers?

Yes, negotiating expenditures is common, particularly for bulk purchases. Compare charges from exclusive suppliers to get the nice deal.

How can I estimate the volume of bricks wished for a project?

Consult with your architect or contractor to calculate the required range of bricks based totally on the project's dimensions and sketch

0 notes

Text

Discover top-quality fly ash bricks near me for sustainable construction with Chhikara Builders. Our carefully crafted and durable fly ash bricks are made from the by-products of coal combustion, making them an eco-friendly choice for your next building project. Trust in our expertise to provide superior materials that stand the test of time.

#flyashbricksnearme#brick suppliers near me#fly ash bricks price near me#flyaskbrick#fly ash brick manufacturers near me

0 notes

Text

How to Choose the Best Fly Ash Brick Making Machine?

When it comes to sustainable construction practices, fly ash bricks have emerged as a popular alternative to traditional clay bricks. These eco-friendly bricks not only help reduce environmental impact but also offer excellent strength and durability. To meet the growing demand for fly ash bricks, manufacturers need reliable and efficient production equipment. This is where a high-quality fly ash brick making machine becomes essential.

Choosing the right fly ash brick making machine is crucial for ensuring smooth operations, consistent product quality, and optimal productivity. With numerous options available in the market, including those offered by reputable manufacturers like BTM Product, it's important to understand the key factors that influence your decision. This guide will walk you through the essential considerations to help you select the best fly ash brick making machine for your needs.

Production Capacity

One of the first aspects to consider when choosing a fly ash brick making machine is its production capacity. The output of these machines can vary significantly, ranging from small-scale units producing a few thousand bricks per day to large industrial setups capable of manufacturing tens of thousands of bricks daily.

To determine the ideal production capacity for your needs, consider the following:

1. Market demand: Assess the current and projected demand for fly ash bricks in your target market.

2. Available resources: Evaluate your access to raw materials, labor, and storage facilities.

3. Investment budget: Higher capacity machines generally come with a higher price tag.

4. Growth plans: Factor in your business expansion plans to avoid outgrowing your equipment too quickly.

BTM Product offers a range of fly ash brick making machines with varying production capacities to suit different business scales and requirements.

Automation Level

The level of automation in a fly ash brick making machine can significantly impact its efficiency, labor requirements, and overall productivity. Modern machines often incorporate advanced automation features that streamline various stages of the production process.

Consider the following automation aspects:

1. Material feeding: Automated systems for precise measurement and mixing of raw materials.

2. Molding and pressing: Hydraulic or mechanical pressing mechanisms for consistent brick formation.

3. Brick handling: Automated conveyor systems for transferring bricks to curing areas.

4. Quality control: Sensors and monitoring systems to ensure consistent brick quality.

Highly automated fly ash brick making machines, like those offered by BTM Product, can help reduce labor costs, minimize human error, and improve overall production efficiency.

Brick Size and Shape Versatility

The versatility of a fly ash brick making machine in terms of producing different brick sizes and shapes is another crucial factor to consider. While standard brick sizes are commonly used, having the flexibility to manufacture bricks of various dimensions can give you a competitive edge in the market.

Look for machines that offer:

1. Adjustable mold boxes to accommodate different brick sizes.

2. Quick and easy mold change mechanisms.

3. Ability to produce special shapes like hollow bricks or interlocking bricks.

BTM Product's fly ash brick making machines are designed with versatility in mind, allowing manufacturers to cater to diverse customer requirements and market demands.

Raw Material Compatibility

While fly ash is the primary component in fly ash bricks, these bricks often incorporate other materials such as cement, sand, and lime. The ideal fly ash brick making machine should be compatible with a range of raw material compositions to ensure flexibility in production.

Consider machines that can handle:

1. Various fly ash grades and sources

2. Different cement types and proportions

3. Alternative binding materials like gypsum or lime

4. Additives for enhancing brick properties

Ensuring your chosen machine can work with a variety of raw materials will give you greater control over brick quality and production costs.

Energy Efficiency

In today's environmentally conscious world, energy efficiency is a critical factor in choosing industrial equipment. An energy-efficient fly ash brick making machine can help reduce operational costs and minimize your carbon footprint.

Look for features such as:

1. High-efficiency electric motors

2. Optimized hydraulic systems

3. Energy recovery mechanisms

4. Smart power management controls

BTM Product prioritizes energy efficiency in their fly ash brick making machines, helping manufacturers achieve sustainable and cost-effective production.

Our Other Machines

interlocking tiles making machine

paver block making machine

Maintenance and Durability

The longevity and reliability of your fly ash brick making machine depend largely on its build quality and ease of maintenance. A well-constructed machine with durable components can significantly reduce downtime and maintenance costs over its lifetime.

Consider the following aspects:

1. Quality of materials used in machine construction

2. Wear-resistant components in high-stress areas

3. Ease of access for routine maintenance and part replacement

4. Availability of spare parts and after-sales support

BTM Product is known for its robust fly ash brick making machines that are built to withstand the rigors of continuous operation while offering straightforward maintenance procedures.

Technology and Control Systems

Advanced technology and user-friendly control systems can greatly enhance the operation and management of a fly ash brick making machine. Modern machines often incorporate sophisticated control panels and monitoring systems that provide real-time data on production parameters.

Look for features such as:

1. Touch screen interfaces for easy operation

2. Programmable logic controllers (PLCs) for precise process control

3. Remote monitoring and diagnostics capabilities

4. Data logging and reporting functions for production analysis

BTM Product integrates cutting-edge technology into their fly ash brick making machines, ensuring intuitive operation and comprehensive production oversight.

Cost Considerations

While the initial purchase price is an important factor, it's crucial to consider the total cost of ownership when choosing a fly ash brick making machine. This includes factors such as:

1. Installation and commissioning costs

2. Energy consumption and operational expenses

3. Maintenance and spare part costs

4. Potential revenue generation based on production capacity and efficiency

Investing in a high-quality fly ash brick making machine from a reputable manufacturer like BTM Product may have a higher upfront cost but can offer better long-term value through improved efficiency, durability, and product quality.

Safety Features

Ensuring the safety of operators and workers should be a top priority when selecting a fly ash brick making machine. Look for machines that incorporate robust safety features and comply with relevant industry standards.

Key safety considerations include:

1. Emergency stop buttons and safety interlocks

2. Proper guarding of moving parts and pinch points

3. Dust suppression systems to minimize airborne particles

4. Noise reduction measures for operator comfort

BTM Product places a strong emphasis on safety in the design and manufacture of their fly ash brick making machines, helping to create a secure working environment.

Some Blogs

Automatic Fly Ash Brick Making Machine at the Best Price

Get the Best Fly Ash Brick Making Machine in India

After-Sales Support and Training

The level of after-sales support and training provided by the manufacturer can significantly impact the success of your fly ash brick production venture. Consider the following aspects:

1. Availability of on-site installation and commissioning support

2. Comprehensive operator training programs

3. Responsive technical support and troubleshooting assistance

4. Regular maintenance and service packages

BTM Product is known for its commitment to customer success, offering extensive support and training to ensure optimal performance of their fly ash brick making machines.

Conclusion

Choosing the best fly ash brick making machine requires careful consideration of various factors, including production capacity, automation level, versatility, raw material compatibility, energy efficiency, durability, technology, cost, safety, and after-sales support. By evaluating these aspects in relation to your specific needs and business goals, you can make an informed decision that will set the foundation for successful fly ash brick production.

Remember that investing in a high-quality fly ash brick making machine from a reputable manufacturer like BTM Product can offer long-term benefits in terms of productivity, efficiency, and product quality. Take the time to research and compare different options, and don't hesitate to seek expert advice or request demonstrations before making your final decision.

By choosing the right fly ash brick making machine, you'll be well-equipped to meet the growing demand for sustainable construction materials while running a profitable and efficient operation.

0 notes

Text

Brick making machine with modern tech and consistent quality

There is no denying that automation is causing a positive change in the brick manufacturing sector. Construction businesses can now produce bricks more affordably and achieve maximum productivity using brick making machine.

The labor-intensive process of producing bricks by hand is a thing of the past. Now automated brick makers can produce exceptional bricks at fast speeds. Also there are lots of benefits using automatic brick production in your construction sites. These machines boost your productivity by reducing need of manual labors and decrease your making costs.

These machines are also environmentally friendly option because of their lower energy and waste consumption. These machinery can produced high quality output for your construction. Investing in brick making machine ca help your company to get more profit and great success in the market.

One of the main advantage using brick machinery is that they can produce far more bricks per hour than manual methods. Because of this, we can fulfill orders more quickly and produce more.

In the wake of a changing world of the new construction efficiency and Eco-friendly are the determinants. Adopting this value will make your company stand out among the top automatic fly ash brick machine manufacturer in India.

Fly ash brick plant manufacturer tend to contribute to the construction industry by providing pieces of equipment. In the manufacturing process of fly ash bricks, the residue that is released by the burning of coal, known as fly ash. It is used as a major component to the production, thereby generating an alternative method of waste management, which in turn results to less demand for clay bricks.

The realization of manual and semi-automatic machines meant for production of bricks. It has been made possible by brick making machine manufacturers. Small-scale to fully automated high-volume production options with the prices being arranged in different applications and budgets.

There are different types of brick making machine in the market

Manual Brick Making Machine : These machines are operated manually and used for limited production

Semi-Automatic Brick Making Machine : These machines have limited automated parts but they still need some manual effort

Fully Automatic Fly Brick Making Machine: These machines can produce large amount of bricks and required minimum labor

Fly Ash Brick Making Machine: These machines make use of fly ash as one of the primary ingredients. They are environmentally friendly with strong qualities

Hydraulic Brick Making Machine: These machines compressed raw materials and formed bricks using hydraulic pressure

Step by step process of how brick making machine works

The process is start with preparation of raw materials. Then mixing clay, concrete, cement, fly ash or other materials with water

After that the prepared mixture is fed into the brick making machine. Within the machine, the mixture is transferred to a mold or series of molds that shape it into the desired brick size and shape.

A good mixture is poured on the mold. After that the machine is then clamped as it uses pressure to compact the mixture very tightly. The extrusion of the compressed mixture from the molding tool follows this sequence in a continuous column. Afterwards, cut it into each brick of the needed length individually.

Let explore our range of brick machinery at https://www.brickmachinery.in/

#BrickMaingMachine#BrickMaingMachineInIndia#AutomaticFlyBrickMakingMachine#FlyBrickMakingMachine#FlyAshBrickPlantManufacturer#BrickMakingMachineManufacturers#AutomaticFlyAshBrickMachineManufacturerInIndia

0 notes

Text

AAC Bricks: Its application in different sectors

Introduction:

Are you in search of an innovative and sustainable solution for your construction work? Then, bricks made of AAC are the only ideal option! These Autoclaved Aerated Concrete blocks offer a range of advantages over traditional building materials, from energy efficiency to durability. Plus, with versatile applications in various sectors, AAC bricks are becoming increasingly popular among architects and builders alike. In this blog post, We'll discuss the advantages of employing AAC bricks and why they're a wise choice for your upcoming project.

What are AAC Bricks?

AAC, or Autoclaved Aerated Concrete, is a lightweight and eco-friendly building material used in construction projects globally. Natural ingredients including cement, lime, fly ash, water, and an expanding agent that causes bubbles to form in the mixture during curing are used to make AAC bricks.

The resulting product is a strong and durable block that has excellent insulation properties thanks to the entrapped air within its structure. This feature makes it perfect for minimizing temperatures in buildings and enhancing sound insulation.

Another advantage of AAC bricks is their versatility in design. They come in various sizes and shapes to fit any project's needs. Additionally, they're easy to cut and shape on-site without specialized tools.

AAC blocks are environmentally friendly compared to other traditional building materials like concrete blocks or clay bricks because they produce fewer carbon emissions during production due to their lightweight nature.

Contrary to other forms of building materials, AAC blocks are stronger, more resilient, and enable various design options.

Advantages of Using AAC Bricks

Due to their many benefits, Autoclaved Aerated Concrete blocks are rising in popularity in the building sector.

Their many advantages are-

Minimal Expenses : One of the biggest advantages of using AAC bricks is that they are lightweight, making them easier to transport and handle during construction projects. This also means that less structural support is needed, which can save money on building costs.

Resistant to Heat : Another advantage is that AAC bricks have excellent thermal insulation properties, helping to keep buildings cool in hot climates and warm in cold climates. This can reduce energy costs associated with heating and cooling.

Sound Proof : In addition, AAC bricks offer superior sound insulation compared to traditional clay bricks. They absorb more sound waves, leading to a quieter indoor environment for occupants.

Eco-friendly Building Material : AAC bricks are also environmentally friendly as they require much less raw material than traditional clay or concrete blocks. The production process emits fewer pollutants into the air and reduces carbon footprint.

Durable : AAC brick structures tend to last longer as they are highly durable and resistant to fire damage, pests such as termites and mold growth.

It is obvious that using AAC bricks instead of other building materials has several advantages, including lower prices, better energy efficiency, and environmental friendliness.

Application of AAC Blocks in Different Sectors

With their wide uses in various fields, AAC blocks, often referred to as Autoclaved Aerated Bricks, have revolutionized the construction business. These cutting-edge building materials are strong yet lightweight, making them perfect for a variety of tasks.

Due to their versatility and durability, AAC blocks are a great option for a variety of architectural applications. And they are discussed below:

Shopping Complexes : These locations continue to be packed with large crowds almost always. Yet again, they must project an image of more affluent, decorous, and solid. Thus, choosing AAC blocks for such projects works in a perfect way.

How?

AAC blocks feature properties that make them tolerant to both temperature and unwanted noise. Due to the tiny air gaps, it also has great heat insulation potential. In other words, depending on the season, it maintains a cool or warm temperature. Furthermore, visitors are also no longer concerned by the noise from outside.

Residential Sector: AAC blocks can be used to construct homes, apartments, and other small-scale structures. They offer excellent insulation properties, which ensure energy efficiency and reduce energy consumption costs.

Commercial Sector: AAC blocks are commonly used in constructing office buildings, hospitals, schools, and shopping malls. Their lightweight property makes them easy to handle during construction while still providing structural integrity that is necessary for such large buildings.

Industrial Sector: Industrial buildings also benefit from using AAC bricks since they provide thermal insulation when constructing factories or warehouses. This helps regulate temperatures inside these facilities hence making them more comfortable work environments for employees.

Transportation Infrastructure: Transportation frameworks such as bridges and tunnels can also benefit from using AAC blocks due to their strength-to-weight ratio making it easier to transport materials on-site with ease thus reducing transportation costs.

Conclusion:

Hence, there’s no denying that the application of AAC bricks in different sectors has been a game-changer offering cost-effective solutions without compromising on quality. They have revolutionized the construction industry with their numerous applications in different sectors. These innovative building materials are lightweight yet sturdy, making them ideal for a wide range of projects.

In the residential sector, AAC blocks are extensively used for constructing homes due to their thermal insulation properties and energy efficiency. The low-density nature of these bricks allows for cost-effective construction while maintaining structural integrity.

Furthermore, in commercial buildings such as offices and shopping malls, AAC installations provide excellent soundproofing capabilities that enhance the overall comfort and ambiance of the space.

Another significant sector where AAC blocks find application is industrial construction; they are widely utilized in factories and warehouses owing to their fire-resistance properties and durability against harsh environmental conditions.

Moreover, these versatile bricks can be easily cut or shaped according to specific project needs, enabling architects to unleash their creativity while ensuring efficient use of resources. Whether it's creating greenhouses or public infrastructure like schools and hospitals, AAC blocks offer a sustainable solution that combines strength with eco-friendliness.

As technology continues to advance in the realm of building materials, it is clear that AAC blocks have emerged as a game-changer across various sectors by providing exceptional performance characteristics combined with aesthetic appeal.

1 note

·

View note

Text

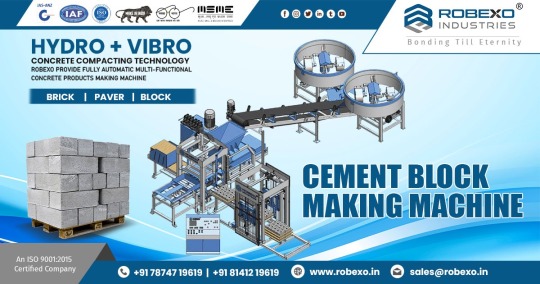

Cement Block Making Machine in Telangana

Company Overview:

Robexo Industries is a manufacturer and supplier specializing in Cement Block Making Machine in Telangana, India.

Robexo Industries is a leading manufacturer of construction machinery established in 2015, based in Ahmedabad, Gujarat, India.

The company specializes in manufacturing a diverse range of machinery including fully automatic/fly ash brick, interlocking brick, paver block, concrete solid/hollow block making machines, vibrating table sets, concrete raw material supply automatic batching plants, and silos.

Robexo Industries is recognized as a prominent engineering consultant, service provider, and manufacturer of automatic, semi-automatic, and manual machines.

We offer the latest technology with distinguishing features of reliability, safety, and rugged construction at an affordable price, understanding the value of money for our customers.

Our focus is on providing multipurpose, low-maintenance, modern designs with new-generation features and complete project solutions, catering to diverse construction needs.

A cement block making machine is a specialized industrial equipment designed to efficiently produce concrete blocks.

These machines automate the process of mixing cement, sand, and other aggregates, compressing them into solid and durable blocks of various sizes and shapes.

Essential in the construction industry, these machines enable cost-effective and consistent manufacturing of building materials used in walls, foundations, and structures.

Key Features of Cement Block Making Machine:

Utilizes Hydro+Vibro German Base System for enhanced performance.

Features a low maintenance compact design for easy operation and upkeep.

Operates on an eco-friendly system, promoting sustainable manufacturing practices.

Geographical Coverage in Telangana:

Robexo Industries offers Cement Block Making Machine in Telangana Including Adilabad, Bhadradri-Kothagudem, Hyderabad,

Jagtial, Jangaon, Jayashankar, Bhoopalpally, Jogulamba-Gadwal, Kamareddy, Karimnagar, Khammam, Komaram Bheem Asifabad, Mahabubabad,

Mahabubnagar, Mancherial, Medchal, Medak, Nagarkurnool, Nalgonda. Nirmal, Nizamabad, Peddapalle, Rajanna Sircilla, Ranga Reddy, Sangareddy, Siddipet, Suryapet, Vikarabad, Wanaparthy, Warangal,Yadadri-Bhuvanagiri.

For detailed information and inquiries, please don't hesitate to contact us.

Read the full article

#Bhadradri-Kothagudem#Bhoopalpally#CementBlockMakingMachine#CementBlockMakingMachineinIndia#CementBlockMakingMachineinTelangana#dilabad#Exporter#Hyderabad#India#Jagtial#Jangaon#Jayashankar#Jogulamba-Gadwal#Kamareddy#Karimnagar#Khammam#KomaramBheemAsifabad#Mahabubabad#Mahabubnagar#Mancherial#Manufacturer#ManufacturerofCementBlockMakingMachine#Medak#Medchal#Nagarkurnool#Nalgonda.Nirmal#Nizamabad#Peddapalle#RajannaSircilla#RangaReddy

0 notes