#extrusion prototyping

Explore tagged Tumblr posts

Text

This is the first entry for my process journal on modeling and printing a 3D figure.

The first thing to note is I have not had any prior experience with 3D modeling or printing before starting this project. My dad, however, has a 3D printer (Ender 3 Pro) that he uses often. He is also somewhat familiar with the 3D modeling program Blender, so that is the program I decided to learn.

Before starting to learn Blender, I drew a simple design of the pose and elements of my figure (image 1). The figure is of a character from a story I am currently writing—he is an angel who wears a cloak and has two sickles as weapons. I had a feeling this would be quite the undertaking for a beginner, but I also didn’t know how quickly I would pick up Blender. If I was going to learn it quickly, I wanted to have enough elements to really challenge myself with.

Once I downloaded Blender, my dad showed me the basics: how to move, scale, and rotate objects; how to add new objects and create meshes; and how to apply modifiers to an object. I also messed around a bit on my own, sculpting a circle to look like a head (image 2). However, I was going to need to learn more in order to create a full figure.

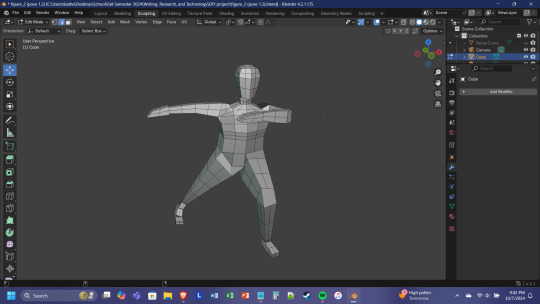

I found this YouTube tutorial by PIXXO 3D which showed me how I could model an entire figure from just a single cube. This video introduced me to mirroring and extrusion, as well as how objects can be altered by selecting and editing a single face. These new techniques allowed me to create first a torso and then limbs and a head by creating new shapes that were attached to preexisting ones. Once I learned how the techniques worked, I used the video as an example but tried to shape the figure on my own (image 3). I did run into some difficulties since the tutorial used an older version of Blender. There were certain ways of morphing an object that didn’t work the way the video showed, and so I had to figure out a different way to achieve the same effect.

After creating a full figure, I then had to pose it. I figured the best way to do so would be to separate the model into pieces that I could rotate and arrange independently of each other (image 4). (You can also see I was messing around with how to create wings—more on that later.) I moved the pieces around, splitting some of them further to achieve the pose that I wanted (image 5). Once the pose was complete, I figured out how to fill in the gaps: by selecting the edges of the gap, I was able to create a new face that joined the pieces together (image 6).

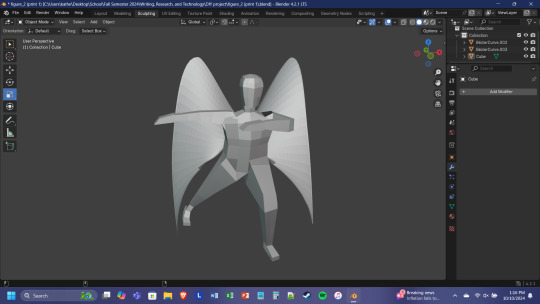

As for the wings, I came up with a technique involving bézier curves. By creating a curve, connecting it in a loop, and then subdividing it with multiple points, I was able to manipulate it into the exact shape I wanted the wing to be. Then I could convert it to a mesh and use grid fill to fill in the shape. I did run into an issue where the fill wasn’t even—there was some weird wrapping going on at the bottom, probably because of how the curve was oriented. But I decided to use it as it was for the moment—I’ll redo the wings later.

I mirrored the wing I’d made and set both of them into the back of the figure (image 7). This was a rough prototype and I wanted to try and print it. I sent my dad the .stl file and he put it into UltiMaker Cura, a program for splicing. Splicing takes a 3D model and figures out what the layers have to be for it to be printed. There were some parts that lacked support because they were hanging in the air (the hands and the wingtips), so my dad showed me how to put supports in that could easily be removed after printing. We scaled the figure to be four inches high and could see the printing would take about three hours.

This was where things got tricky. The first print attempt ended with a big spirally ball of plastic. It seemed the wings were too thin and would need more supports, otherwise the plastic wouldn’t stick to itself and would end up creating a mess. The second print went better, although there were still problems with it—namely, the torso fell out of the body (image 8). The rest of it was in decent shape, but it seems I’ll have to do some work to strengthen the connections. I assume this will involve thickening the objects in Blender so they have more surface area melding them together.

So far, I’ve been able to get the hang of Blender fairly well. This surprised me a bit, although I have had experience with photo-manipulation programs (GIMP) before, so maybe that is helping me more than I thought it would. I am glad the modeling portion is going smoothly, however, since it looks like the printing stage is going to require more finagling than I initially thought.

3 notes

·

View notes

Text

Automotive 3D Printing Market Dynamics - Exploring Growth, Opportunities and Technological Advances Up to 2030

Automotive 3D Printing Marketresearch report by Delvens focuses on primary sections such as – market segments, market outlook, competitive landscape, and company profiles. The segments provide details in terms of various perspectives such as end-use industry, product or service type, and any other relevant segmentation as per the market’s current scenario which includes various aspects to perform further marketing activity, the global Automotive 3D Printing Market size is 2.9 billion USD in 2022 and is projected to reach a CAGR of 22.9% and Forecast to 2030.

Get Free Sample Report: https://www.delvens.com/get-free-sample/automotive-3d-printing-market

3D printing, also referred to as additive manufacturing, comprises printing layer by layer from a 3D CAD model. 3D printing aids in the reduction of lead time as well as cost for prototyping and manufacturing complex parts.

3D printing is used in the automotive sector for applications such as design & concept of communication, prototyping validation, preproduction sampling & tooling, and customization of parts. The materials utilized for automotive 3D printing include several types of polymers, metals, ceramics, and others. The selection of printing material depends on traits expected from printed objects.

Recent Developments

Renishaw launched a new range of RenAM 500 3D printing machinery. The RenAM 500S Flex which is a single laser 3D printing machine and the RenAM 500Q Flex, which is a four-laser 3D printing machine. Both the systems featured a simplified powder handling system, which is suited for research and development (R&D), pre-production or bureau environments.

3D Systems added extrusion technology to its solution portfolio with the acquisition of Titan Additive LLC, a market leader in polymer extrusion technology. This will broaden the range for its customers.

The Prominent Players in the Automotive 3D Printing Market:

3D Systems Corporation

Autodesk, Inc.

Desktop Metal, Inc.

EOS GmbH

General Electric Company

Hoganas AB

Materialise NV

Stratasys, Ltd.

Ultimaker BV

Voxeljet AG and More

North America to Dominate the Market

North America is estimated to hold the largest share of the global 3D printing market; this can be attributed to the continuous technological advancements in this field and hundreds of carmakers in the region.

The major reason for this is the usage of additive manufacturing by leading automotive manufacturers extensively for their R&D, such as prototyping and fixtures. The main factor for using 3D printing in R&D is the cost-effectiveness of the technology. The polymers printed by 3D printers can be recycled for optimum usage.

Automotive 3D Printing Market is segmented into various segments such as application, technology, material, offering, component, vehicle type, and region:

On the basis of application

Prototyping & Tooling

Research, Development & Innovation

Manufacturing Complex Components

Others

On the basis of technology

Stereolithography (SLA)

Selective Laser Sintering (SLS)

Electron Beam Melting (EBM)

Fused Deposition Modeling (FDM)

Laminated Object Manufacturing (LOM)

Three-Dimensional Inject Printing

Others

On the basis of material

Metals

Plastic

Composites and resins

others

On the basis of the offering

Hardware

Software.

On the basis of component

Interior components

Exterior components

On the basis of vehicle type

ICE vehicles

Electric vehicles

On the basis of region

Asia Pacific

North America

Europe

South America

Middle East & Africa

Access Full Report: https://www.delvens.com/report/automotive-3d-printing-market

In addition to the market data for the Automotive 3D Printing Market, Delvens offers client-centric reports customized according to the company’s specific demand and requirements.

Frequently Asked Questions

What are the years considered to study Automotive 3D Printing Market?

What is the compound annual growth rate (CAGR) of the Automotive 3D Printing Market?

Which region holds the largest market share in the Automotive 3D Printing Market?

Which region is the fastest growing region in the Automotive 3D Printing Market?

Who are the major players in the Automotive 3D Printing Market?

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact us:

Unit No. 01, 3rd Floor, Plot No. 56, Block B

Sector 2 Noida, Near Noida Sector 15 Metro Station 201301, IN

+44 20 3290 6466

+0120- 4903958

0 notes

Text

Revolutionizing Wire Manufacturing: The Latest Advancements in Wire Machines

The wire manufacturing industry is undergoing a transformative revolution, driven by cutting-edge technologies that enhance precision, efficiency, and sustainability. From AI-powered automation to advanced material innovations, modern wire machines are reshaping production processes across industries like automotive, telecommunications, aerospace, and energy. This blog explores the latest advancements in wire manufacturing machinery, highlighting how these innovations are setting new standards for quality, speed, and environmental responsibility.

Wire Machine Manufacturers

1. Intelligent Automation and AI Integration

Modern wire machines now leverage Artificial Intelligence (AI) and machine learning to optimize production in real time. Key advancements include:

Predictive Maintenance: AI analyzes sensor data (vibration, temperature, speed) to predict equipment failures, reducing downtime and maintenance costs.

Automated Quality Control: Computer vision detects defects (e.g., uneven winding, surface flaws) with higher accuracy than manual inspections.

Dynamic Tension Control: AI adjusts wire tension in real time, ensuring consistency for delicate materials like fiber optics.

These innovations minimize human error and maximize throughput, making wire production faster and more reliable.

2. High-Speed Precision and Advanced Handling

Next-gen wire machines achieve unprecedented speed and accuracy through:

Laser-Guided Positioning: Ensures precise cutting and welding for intricate designs (e.g., multi-strand power cables).

Servo-Driven Feeding Systems: Reduce wire breaks and improve material handling efficiency.

Multi-Axis Winding: Machines like Showmark’s Multi-Axis Take-Up Systems enable complex winding patterns for aerospace and medical applications.

Such technologies are critical for industries demanding ultra-fine tolerances, such as EV wiring harnesses or high-voltage power grids.

Wire Machinery Manufacturers

3. Sustainable Manufacturing Practices

The push for eco-friendly production has led to:

Energy-Efficient Machines: Regenerative braking systems and smart cooling reduce power consumption.

Material Optimization: Advanced extrusion and drawing techniques minimize scrap (e.g., crosshead extrusion for uniform coatings).

Recycled Materials: Manufacturers increasingly use recycled copper/aluminum and biodegradable insulation.

These steps align with global sustainability goals while cutting operational costs.

4. Smart Manufacturing and IoT Connectivity

Industry 4.0 integration enables:

Real-Time Monitoring: IoT sensors track production metrics (tension, speed) via cloud platforms for remote oversight.

Adaptive Production Lines: AI adjusts settings dynamically to meet custom demands (e.g., rapid switchovers between wire gauges).

AR-Assisted Maintenance: Technicians use augmented reality for troubleshooting and training.

Such interconnected systems enhance agility in responding to market shifts.

5. Customizable and Modular Designs

Flexibility is now a cornerstone of wire machinery:

Modular Systems: Machines like the ARTOS CR.11 allow quick reconfiguration for diverse wire harnesses (automotive, aerospace).

Open Architecture: Supports third-party tool integration for specialized tasks 8.

Programmable Take-Up Units: Enable recipe storage for repeatable precision in medical or fiber-optic wire production.

Wire Machine Manufacturers

The Future Outlook

The wire manufacturing sector is poised for further disruption with trends like:

3D-Printed Cable Components: Rapid prototyping of connectors/spacers.

Smart Cables: Embedded sensors for real-time load/temperature monitoring.

Advanced Robotics: AI-driven robots for complex assembly tasks.

By embracing these innovations, manufacturers can achieve higher productivity, lower costs, and greener operations—ushering in a new era of industrial excellence.

For deeper insights, explore the sources cited or contact industry leaders like Showmark or MSS Machinery.

0 notes

Text

Silicone Rubber Manufacturer for Electronic Vehicles in Malaysia: Enhancing EV Performance & Safety

The demand for electric vehicles (EVs) is rising rapidly, and with it, the need for high-performance materials like silicone rubber. Silicone rubber plays a crucial role in electric vehicle manufacturing, providing thermal stability, electrical insulation, and durability. If you’re looking for a reliable silicone rubber manufacturer for electronic vehicles in Malaysia, you need a partner that ensures high-quality, automotive-grade rubber components.

Why Silicone Rubber is Essential for Electric Vehicles

Silicone rubber is widely used in electric vehicles (EVs) due to its exceptional properties, including:

High Temperature Resistance – Can withstand extreme heat generated by EV batteries and motors.

Excellent Electrical Insulation – Prevents electrical leakage and enhances safety in high-voltage EV systems.

Durability & Flexibility – Ensures long-lasting performance under mechanical stress and environmental exposure.

Weather & Chemical Resistance – Protects EV components from moisture, chemicals, and harsh weather conditions.

Lightweight & Eco-Friendly – Reduces the overall vehicle weight, enhancing efficiency and sustainability.

Silicone Rubber Components for Electric Vehicles

A trusted silicone rubber manufacturer for EVs in Malaysia provides various critical components, such as:

1. Silicone Seals & Gaskets

Battery pack seals & gaskets

Charging port seals

High-voltage electrical enclosure seals

Door & window weather seals

2. Silicone Rubber Insulation & Protective Covers

High-voltage cable insulation

Battery compartment insulation

Motor and powertrain protective covers

Fire-resistant silicone rubber parts

3. Silicone Rubber Hoses & Tubing

Cooling system silicone hoses

Fluid transfer tubes

Ventilation and air duct tubing

Heat-resistant silicone rubber tubing

4. Vibration & Noise Reduction Components

Silicone shock absorbers

Engine and motor mounts

Noise-reducing silicone pads

Vibration-damping bushings

Why Choose a Silicone Rubber Manufacturer in Malaysia for EV Components?

Malaysia has become a leading hub for silicone rubber manufacturing, offering automotive-grade rubber solutions tailored for electric vehicles. Here’s why businesses prefer Malaysian manufacturers:

1. Advanced Silicone Rubber Manufacturing Technology

Top manufacturers utilize cutting-edge silicone molding, extrusion, and compression techniques for precision and consistency.

2. High-Quality & Automotive-Grade Silicone Materials

Leading manufacturers use FDA-approved, RoHS-compliant, and ISO-certified silicone rubber suitable for electric vehicle applications.

3. Custom Silicone Rubber Solutions

Manufacturers provide tailor-made silicone rubber components designed to meet specific EV model requirements.

4. Compliance with Global Automotive Standards

Malaysia-based silicone rubber manufacturers ensure compliance with international automotive and safety regulations, such as ISO 9001, IATF 16949, and UL certification.

5. Cost-Effective & Scalable Production

Malaysian silicone rubber manufacturers offer competitive pricing, efficient supply chain management, and scalable production capabilities.

Choosing the Right Silicone Rubber Manufacturer for EVs

When selecting a silicone rubber manufacturer for electric vehicles in Malaysia, consider these factors:

Experience in the Automotive & EV Industry – Choose a manufacturer with expertise in producing EV-compatible silicone rubber components.

Material Quality & Certifications – Ensure the manufacturer uses premium silicone rubber that meets automotive industry standards.

Customization & Prototyping – Opt for a manufacturer that offers custom designs, prototyping, and rapid production.

Manufacturing Capacity & Efficiency – Verify that they can handle high-volume production while maintaining product quality.

Sustainability & Eco-Friendly Practices – Consider manufacturers that focus on sustainable silicone rubber production.

Trusted Silicone Rubber Manufacturer for EVs in Malaysia – Kennwu

For businesses looking for a leading silicone rubber manufacturer for electronic vehicles in Malaysia, Kennwu is a trusted partner. With years of expertise in automotive silicone rubber manufacturing, Kennwu specializes in high-performance, custom-designed rubber components for electric vehicles.

Kennwu offers:

Premium-Quality EV Silicone Seals, Insulation & Hoses

Advanced Silicone Molding & Manufacturing Techniques

ISO-Certified & Automotive-Grade Silicone Rubber Materials

Custom Engineering & Scalable Production Capabilities

Conclusion

As the electric vehicle industry continues to expand, the demand for high-quality silicone rubber components is increasing. Partnering with an experienced silicone rubber manufacturer for electronic vehicles in Malaysia ensures safety, performance, and durability in EV applications. With expertise in custom silicone rubber manufacturing, Kennwu is the ideal partner for businesses seeking top-tier EV silicone rubber components.

#Silicone Rubber Manufacturer for Electronic Vehicles in Malaysia: Enhancing EV Performance & Safety

0 notes

Text

How to Choose the Best Plastic Fabrication Company for Your Manufacturing Needs

In today's competitive market, finding the right plastic fabrication company is crucial for businesses that require high-quality, durable, and cost-effective plastic components. Whether you need custom plastic parts for industrial applications, retail products, or specialized manufacturing, selecting the right company ensures efficiency, reliability, and long-term success. Here’s a comprehensive guide to help you choose the best plastic fabrication company for your needs.

1. Assess Your Project Requirements

Before searching for a plastic fabrication company, clearly define your project’s needs. Consider the following factors:

The type of plastic materials required (e.g., acrylic, polycarbonate, PVC, HDPE, etc.)

The complexity of the design and required tolerances

Volume and production scale (small batch vs. mass production)

Intended application and environmental considerations (e.g., heat resistance, UV protection, impact strength)

By understanding these specifics, you can narrow down your options to companies that specialize in your required fabrication methods.

2. Evaluate Fabrication Capabilities and Techniques

Different plastic fabrication companies offer a range of manufacturing techniques. It’s essential to choose a company with the right capabilities for your project. Some common fabrication techniques include:

CNC Machining – Ideal for precise and complex parts with tight tolerances.

Thermoforming – Suitable for large plastic sheets molded into specific shapes.

Injection Molding – Best for high-volume production of uniform plastic components.

Extrusion – Used to produce long plastic profiles like tubes and rods.

3D Printing – Beneficial for prototyping and low-volume production.

Ensure that the company you choose has expertise in the method that best suits your needs.

3. Check Industry Experience and Reputation

Experience plays a significant role in the quality and reliability of plastic fabrication services. Look for companies with a proven track record in your industry. Some key indicators of a reputable company include:

Years in business and industry experience

Client testimonials and case studies

Certifications such as ISO 9001 for quality management

Compliance with industry-specific regulations

A company with a strong reputation and experience in handling similar projects is more likely to deliver consistent quality and meet deadlines.

4. Assess Material Quality and Supplier Network

The quality of plastic materials significantly impacts the durability and performance of your final product. Ensure that the company sources high-grade materials from reliable suppliers. Ask about:

Material certifications (e.g., FDA compliance for food-grade plastics, UL ratings for electrical applications)

Recycling and sustainability practices

Availability of specialized materials such as flame-retardant or medical-grade plastics

Working with a company that prioritizes high-quality materials ensures that your products will meet industry standards and customer expectations.

5. Examine Their Quality Control Processes

Quality assurance is a crucial factor in plastic fabrication. The best companies implement strict quality control measures throughout the production process. Some aspects to look for include:

In-house testing and inspection protocols

Use of advanced measurement tools (e.g., CMM, laser scanning)

Compliance with international quality standards

Corrective action policies in case of defects

A company with robust quality control ensures that every part meets the required specifications, reducing the risk of defects and production delays.

6. Consider Customization and Design Support

If your project requires custom parts or unique designs, choose a company that offers design support and prototyping services. Many top-tier plastic fabrication companies provide:

CAD design and engineering assistance

Rapid prototyping for design validation

Tooling and mold-making services

Collaborative problem-solving for complex projects

A company with strong design and customization capabilities will help optimize your product for manufacturability and cost efficiency.

7. Evaluate Production Lead Times and Scalability

Timely production is essential to meet market demands and maintain a smooth supply chain. Ask potential fabrication partners about:

Average lead times for different project sizes

Scalability options for future growth

Their ability to handle urgent or rush orders

Selecting a company that can scale production according to your needs ensures long-term reliability as your business grows.

8. Compare Pricing and Cost Transparency

While cost is an important consideration, it shouldn’t be the sole deciding factor. Look for companies that offer competitive pricing without compromising on quality. Request detailed quotes and compare:

Material costs

Production and labor charges

Tooling and setup fees

Shipping and logistics costs

Ensure the pricing structure is transparent, with no hidden fees or unexpected charges.

9. Check Customer Service and Communication

Effective communication is vital in any business partnership. Choose a plastic fabrication company that is responsive, transparent, and willing to collaborate. Key factors to consider include:

Availability of a dedicated account manager

Clear and timely updates on project progress

Willingness to address concerns and make necessary adjustments

A company with excellent customer service fosters a smooth working relationship and ensures that your expectations are met.

10. Review Sustainability Practices

With increasing emphasis on environmental responsibility, consider working with a company that follows sustainable practices. Ask about:

Use of recycled or eco-friendly materials

Waste reduction and energy-efficient manufacturing processes

Compliance with environmental regulations

Partnering with an eco-conscious company can enhance your brand’s reputation and contribute to sustainability goals.

Choosing the right plastic fabrication company requires careful consideration of various factors, from technical expertise and material quality to pricing and sustainability. By conducting thorough research and assessing potential partners based on these criteria, you can ensure a successful collaboration that meets your manufacturing needs while maintaining high product quality. Take the time to evaluate your options, request samples, and engage in discussions with potential suppliers to make an informed decision. With the right fabrication partner, your business can achieve efficiency, cost savings, and long-term growth.

0 notes

Text

The reliability of rubber extrusion manufacturers depends largely on quality and customization. These manufacturers specialize in creating tailored rubber profiles and seals that meet specific industry needs. Rubber Profile Manufacturers of the highest quality can provide capabilities for gaskets, tubing, and special shapes that guarantee durability and functionality.

Selection of the appropriate materials and profile design are typically included in the process to meet specific parameters. A growing number of manufacturers also provide rapid prototyping services to enable clients to screen samples before undertaking large-scale production. Such versatility is extremely important in automotive and construction fields, which cannot compromise performance.

Among the companies working in this area, Custom Rubber Extrusion stands out (and is also recognized) as a strong adherent to the quality and satisfaction of its customers. Having a long background, they offer a broad set of custom solutions that are adaptable to numerous applications, and each product conforms to the most demanding standards.

0 notes

Text

The Ultimate Guide to UHMW Tubing: Benefits, Applications, and Why It Matters

When it comes to industrial-grade materials, UHMW Tubing is a standout performer. Its durability, chemical resistance, and low friction properties make it a top choice in a range of industries, from food processing to heavy-duty manufacturing. In this blog, we’ll explore what makes UHMW tubing unique, its key advantages, and how it’s used in various applications.

What Is UHMW Tubing?

UHMW (Ultra-High Molecular Weight Polyethylene) tubing is a high-performance thermoplastic known for its exceptional toughness and resistance to wear and abrasion. Its molecular structure creates a highly dense, impact-resistant material with superior longevity.

Top Benefits of UHMW Tubing

Exceptional Durability: UHMW tubing is engineered to withstand extreme impact, making it ideal for high-wear environments. Its long service life reduces maintenance and replacement costs.

Low Friction Surface: The ultra-smooth surface of UHMW tubing prevents materials from sticking, ensuring smooth operation in conveyor systems and other moving applications.

Chemical Resistance: It resists a wide range of chemicals, including acids, solvents, and corrosive substances, ensuring long-term reliability in harsh environments.

FDA Compliance: Certain grades of UHMW tubing are FDA-approved, making them safe for food and beverage processing.

Temperature Tolerance: With excellent performance in both freezing and moderately high temperatures, UHMW tubing works well in demanding industrial settings.

Common Applications of UHMW Tubing

1. Conveyor Systems: UHMW tubing is widely used in conveyor rollers and guides, providing smooth material handling with minimal friction and wear.

2. Food Processing Equipment: FDA-approved UHMW tubing ensures safe transport of food products while maintaining cleanliness and durability.

3. Chemical Processing: Its chemical resistance makes UHMW tubing ideal for handling corrosive substances in chemical plants.

4. Mining and Agriculture: UHMW tubing endures heavy loads and harsh outdoor conditions, making it a favorite in mining and agricultural equipment.

Why Choose Spiratex for UHMW Tubing?

Spiratex is a leading plastic extrusion manufacturer specializing in custom UHMW tubing solutions. Here’s why we’re trusted across industries:

Custom Solutions: We design UHMW tubing to your exact specifications, ensuring optimal performance.

Engineering Expertise: Our experienced team guides you through design, prototyping, and production.

Quality Assurance: We maintain the highest quality standards to guarantee reliable and durable products.

Conclusion: Invest in UHMW Tubing for Long-Term Performance

Whether you need reliable components for conveyor systems, food processing lines, or heavy-duty industrial equipment, UHMW tubing delivers unmatched performance. Its durability, low friction, and chemical resistance make it a smart investment for businesses looking to reduce maintenance and operational costs.

Ready to enhance your production with custom UHMW tubing? Contact Spiratex today to learn more about our custom plastic extrusion services and discover how we can meet your unique needs.

Experience the Spiratex difference—your trusted partner in custom plastic extrusion.

Source Url : - https://gigstergo.com/the-ultimate-guide-to-uhmw-tubing-benefits-applications-and-why-it-matters/

0 notes

Text

From Petrochemicals to Packaging: The Rise of Plastic Manufacturing in KSA

The Kingdom of Saudi Arabia (KSA) has emerged as a leading player in the global plastic industry. With abundant petroleum resources and cutting-edge industrial advancements, the country has successfully transformed its petrochemical sector into a thriving plastic manufacturing hub. From raw material production to high-quality packaging solutions, KSA is home to some of the world’s most innovative plastic manufacturers. This article explores the rapid growth of the Plastic Manufacturing Company in KSA, key industry factors, and the impact of sustainability on the future of the sector.

The Evolution of Plastic Manufacturing in KSA

Plastic manufacturing in KSA has undergone a remarkable transformation, driven by technological advancements and strategic investments. The sector’s growth can be attributed to several key factors:

Abundant Petrochemical Resources: KSA has one of the largest reserves of crude oil and natural gas, making it a major producer of essential raw materials such as polyethylene and polypropylene.

Government Initiatives: The Saudi Vision 2030 plan emphasizes industrial diversification, encouraging investments in non-oil sectors, including plastic manufacturing.

Advanced Infrastructure: World-class industrial zones, specialized manufacturing clusters, and logistics networks have facilitated the industry's expansion.

Increasing Demand: The rising need for plastic products in construction, packaging, healthcare, and automotive industries has fueled the growth of plastic manufacturing companies.

Key Stages of Plastic Production in KSA

1. Petrochemical Processing

The journey from petrochemicals to plastic packaging begins with the extraction and refining of crude oil and natural gas. Saudi Arabia is home to some of the largest petrochemical complexes, producing key polymer resins such as:

Polyethylene (PE) – Used in plastic bags, bottles, and containers.

Polypropylene (PP) – Commonly found in packaging, textiles, and automotive parts.

Polyvinyl Chloride (PVC) – Used in construction materials, pipes, and medical supplies.

2. Plastic Manufacturing

Once raw materials are processed, they undergo various manufacturing techniques to produce plastic products:

Injection Molding – Used for creating plastic containers, toys, and electronic casings.

Blow Molding – Ideal for producing plastic bottles and packaging solutions.

Extrusion Molding – Used in pipe production and sheet materials.

Thermoforming – Employed in food packaging and disposable plastic products.

3. Packaging and Distribution

With global demand for sustainable and high-quality packaging solutions, KSA’s plastic manufacturers have developed innovative packaging techniques such as:

Flexible Packaging – Lightweight, cost-effective, and commonly used for food and beverage industries.

Rigid Packaging – Includes containers, bottles, and industrial storage solutions.

Eco-Friendly Packaging – Biodegradable plastics and recyclable materials are gaining traction as sustainability takes center stage.

Innovation and Technological Advancements in KSA’s Plastic Industry

The Plastic Manufacturing Company in KSA is not only expanding in scale but also embracing cutting-edge technologies to enhance efficiency and product quality. Key innovations include:

Automation and AI Integration – Many manufacturers are adopting robotics and artificial intelligence to streamline production and reduce errors.

Advanced Polymer Development – Research and development efforts are leading to the creation of high-performance plastics with improved durability and recyclability.

3D Printing Applications – The use of additive manufacturing in plastic production is revolutionizing prototyping and custom product designs.

Smart Packaging Solutions – Integration of digital tracking systems and biodegradable materials is enhancing the functionality and sustainability of plastic packaging.

Sustainability and the Future of Plastic Manufacturing in KSA

As environmental concerns grow, KSA’s plastic manufacturing industry is shifting towards sustainable solutions. Major initiatives include:

Biodegradable Plastics – Manufacturers are investing in the development of compostable and eco-friendly plastics.

Recycling Programs – Companies are adopting recycling technologies to reduce plastic waste and promote circular economy practices.

Energy-Efficient Production – Advanced machinery and production techniques are helping reduce carbon footprints.

Government Regulations – Policies encouraging sustainable manufacturing and waste management are being enforced to ensure long-term environmental benefits.

Conclusion

The rise of the Plastic Manufacturing Company in KSA is a testament to the nation’s commitment to industrial growth and sustainability. With a strong petrochemical foundation, cutting-edge manufacturing technologies, and a focus on eco-friendly solutions, KSA continues to position itself as a global leader in the plastic industry. For businesses looking for high-quality plastic products, PDTMC stands out as one of the top plastic manufacturing companies in KSA, offering innovative and sustainable plastic solutions.

As the industry evolves, KSA’s plastic manufacturers will play a crucial role in shaping the future of global packaging and industrial plastic applications. With continued investments in technology and sustainability, the country is well on its way to becoming a global powerhouse in plastic manufacturing.

0 notes

Text

3D Printed Prototypes of Aluminium Extrusions – A Precision Challenge!

This project wasn’t as simple as it might seem!.. read on ...

Typically, creating an extrusion involves importing the profile into CAD and using a simple extrusion process, but for this prototype, the precision required was 0.08mm.

Our solution?

Read more at 3D Printing LEEDS: https://www.3dprintingleeds.co.uk/

0 notes

Text

🌟 Numakers PLA+ 3D Printer Filament – World-Class Quality for Every Maker! 🌟

🔥 Why Choose Numakers PLA+? ✅ Premium Quality: Smooth extrusion, vibrant colors, and high durability. ✅ Beginner-Friendly & Pro-Approved: Easy to print with, no clogs, no warping! ✅ Precision & Strength: Ideal for detailed models, prototypes, and functional prints. ✅ Eco-Friendly & Reliable: Sustainable material with excellent layer adhesion.

💡 Whether you're a hobbyist, designer, or engineer, Numakers PLA+ helps bring your 3D creations to life with flawless prints and unmatched consistency!

📢 Upgrade Your Printing Game – Get Yours Today!

#Numakers #3DPrinting #PLAPlus #Best3DFilament #3DPrinter #MakerCommunity

0 notes

Text

From Prototypes to Production: Services Offered by Expert Plastic Manufacturers in Melbourne

Due to its widespread usage in industry, plastic has a wide range of applications and leading plastic manufacturers in Melbourne offer a number of products as per industrial requirements. The demand for plastic extrusion products is constantly strong, and top plastic producers use state-of-the-art technology to create a range of products, such as flexible edging systems, bumper protection systems, and many other such products. The main advantage of plastic is its extreme strength and resilience and these products are generally not affected much by weather elements. Plastic extrusion technique is widely employed in the production of plastic items in large quantities and it has been quite successful.

In Australia, t-moulding is frequently utilised for flooring, and plastic is used for moulding. There are many uses for plastic, and product prototypes may be made with 3D printing. This method is frequently used to assess a product's quality before it is put into mass production. 3D has advanced significantly in the last several years and most products nowadays are going through 3D printing to test it out.

List of Products and Services Offered by Plastic Industry Brands

Testing Facility: The success of the substance on the market depends on product testing. The Q.U.V. weathering test and several additional tests, such as impact testing, may be conducted by top businesses in this sector.

3D printing: This technology has created a stir in the modern world by simplifying prototyping, allowing for the testing of a product's design and the detection of issues before manufacturing is scaled up.

Colour Matching: Top businesses are able to match the colours of plastic items using computer technology. With proper colour matching one can have products as per their businesses’ requirements

Because of its versatility, durability, and resistance to chemicals, plastic is the material of the future and has established a place in practically every industry. To find out the prices of different items, get in touch with the top companies by phone or online.

Source

0 notes

Text

Inside the World of Cable Machinery: Innovation Driving the Industry Forward

The cable manufacturing industry has come a long way, evolving with cutting-edge technology and advanced machinery to meet the growing global demand for high-quality cables. From power transmission to telecommunications, cables are the backbone of modern infrastructure. But what fuels this industry's progress? Innovation in cable machinery.

Cable Machinery Manufacturers

In this blog, we explore the latest advancements in cable manufacturing machinery, the technologies driving efficiency, and how industry leaders are shaping the future.

1. The Evolution of Cable Machinery

The journey of cable machinery started with basic wire drawing and insulation processes, but modern demands have pushed manufacturers to adopt high-precision, automated, and AI-driven machinery.

Key Developments Over the Years:

Traditional Wire Drawing Machines – Used for reducing the diameter of metal wires.

Extrusion Machines – Developed to coat wires with plastic or rubber insulation.

Stranding Machines – Enabled multiple wires to be twisted together for enhanced strength.

High-Speed Braiding Machines – Improved cable shielding for better conductivity and durability.

Automated Cable Cutting & Winding Systems – Reduced manual labor and improved precision.

The industry has continuously innovated, incorporating smart technologies and automation to enhance production speed, quality, and energy efficiency.

2. Game-Changing Innovations in Cable Machinery

A. Smart Automation & Industry 4.0

One of the biggest transformations in cable manufacturing is automation. Advanced machinery now integrates AI, IoT, and real-time monitoring, enabling: ✅ Predictive Maintenance – Machines detect faults before failure, reducing downtime. ✅ Remote Monitoring – Operators can track performance through mobile apps or dashboards. ✅ Precision Control – Sensors and AI optimize material usage, reducing waste.

Wire Machinery Manufacturers

B. Energy-Efficient Machinery

With a strong focus on sustainability, manufacturers are adopting energy-efficient systems that:

Reduce power consumption using low-friction components.

Optimize heating and cooling in extrusion processes.

Implement regenerative braking systems in wire drawing machines.

C. High-Speed Production Lines

Speed without compromising quality is the goal. New-generation cable manufacturing lines now: 🔹 Operate at higher speeds without overheating. 🔹 Maintain consistent tension control for uniform quality. 🔹 Use laser-guided measuring systems for real-time quality checks.

Cable Machinery Manufacturers

D. 3D Printing & Advanced Materials

3D printing is making its way into cable manufacturing, allowing: ✅ Rapid prototyping of customized cable parts. ✅ Use of lightweight yet durable polymers for insulation. ✅ Cost-effective, small-batch production of specialized cables.

3. The Future of Cable Manufacturing Machinery

As demand for fiber optic cables, high-voltage transmission lines, and eco-friendly materials rises, the future of cable machinery will focus on:

🔹 AI-Powered Quality Control – Using deep learning to detect microscopic defects. 🔹 Eco-Friendly Manufacturing – Biodegradable insulation and recyclable materials. 🔹 Fully Automated Smart Factories – Robotic arms handling end-to-end cable production. 🔹 Nanotechnology Integration – Stronger, more conductive cable materials.

Industry leaders are continuously pushing boundaries to improve efficiency, quality, and sustainability in cable production.

Wire Machinery Manufacturers

Final Thoughts

The cable manufacturing industry is experiencing a technological revolution driven by automation, sustainability, and high-speed innovations. As the demand for better connectivity, power distribution, and data transmission grows, advanced cable machinery will play a crucial role in shaping the future.

Manufacturers investing in cutting-edge technology today will lead the industry tomorrow. Are you ready for the next wave of cable manufacturing innovation? 🚀Would you like more insights on specific cable machinery or manufacturers? Let us know in the comments!

#Wire Machine Manufacturers#Wire Machinery Manufacturers#Cable Machinery Manufacturers#Cable Making Machine Manufacturers#Wire Making Machine Manufacturers

0 notes

Text

Finding the Best Silicone Products Design Company in Malaysia

Silicone products play a crucial role in various industries due to their flexibility, durability, and resistance to extreme conditions. Whether for medical, automotive, electronics, or industrial applications, businesses need a trusted Silicone products design company in Malaysia to develop high-quality, customized solutions. Malaysia is home to several experienced companies specializing in silicone product design and manufacturing, offering cutting-edge solutions for diverse industry needs.

Why Choose Silicone for Product Design?

Silicone is a preferred material due to its unique properties, making it suitable for a wide range of applications. Some key benefits include:

High Durability – Silicone products are resistant to extreme temperatures, chemicals, and moisture.

Flexibility – The material’s elasticity makes it ideal for gaskets, seals, and other flexible components.

Non-Toxic & Safe – Food-grade and medical-grade silicone are widely used in healthcare and food industries.

UV & Aging Resistance – Unlike many other materials, silicone does not degrade quickly, ensuring long-lasting performance.

Excellent Insulation – Its superior electrical insulation properties make it ideal for electronic components.

What Does a Silicone Products Design Company Do?

A silicone products design company specializes in developing innovative silicone-based solutions tailored to specific industry needs. Their services typically include:

Product Concept & Design – Assisting clients in designing unique silicone products from concept to reality.

Material Selection – Choosing the best type of silicone based on the application, such as medical-grade, industrial-grade, or food-grade.

Prototyping & Testing – Creating prototypes and conducting rigorous testing to ensure performance and durability.

Mass Production – Manufacturing silicone products efficiently while maintaining high-quality standards.

Quality Control & Compliance – Ensuring that all products meet international safety and quality standards.

Benefits of Choosing a Malaysian Silicone Products Design Company

Malaysia is known for its advanced silicone product manufacturing capabilities. Here’s why working with a silicone products design company in Malaysia is beneficial:

1. Expertise in Custom Silicone Solutions

Malaysian companies have extensive experience in designing customized silicone products tailored to specific industry requirements.

2. High-Quality Manufacturing Standards

Top manufacturers in Malaysia adhere to strict international standards such as ISO certifications, ensuring that products are durable, safe, and reliable.

3. Cost-Effective Production

Malaysia offers competitive pricing for silicone product design and manufacturing, making it an affordable choice for businesses looking for high-quality solutions.

4. Advanced Technology & Precision Engineering

Many Malaysian companies use state-of-the-art molding, extrusion, and casting techniques to produce precision-engineered silicone components.

5. Sustainable & Eco-Friendly Practices

Many silicone products design companies in Malaysia are committed to sustainability, utilizing eco-friendly materials and minimizing waste.

How to Choose the Right Silicone Products Design Company

When selecting a silicone products design company in Malaysia, consider the following factors:

1. Experience & Industry Expertise

Look for a company with a proven track record in designing and manufacturing silicone products for your specific industry.

2. Material Options

Ensure the company provides a variety of silicone materials suitable for different applications, such as medical, food, or industrial use.

3. Customization Capabilities

A reliable company should offer tailored design services, prototyping, and custom molding to meet your specific needs.

4. Quality Assurance & Compliance

Choose a manufacturer that follows strict quality control measures and meets international safety standards.

5. Production Capacity

Ensure the company can handle your required production volume efficiently, whether for small or large-scale manufacturing.

6. Reputation & Customer Feedback

Check reviews, testimonials, and industry reputation to verify the company’s reliability and service quality.

Trusted Silicone Products Design Company in Malaysia – Kennwu

For businesses seeking a reliable silicone products design company in Malaysia, Kennwu is a trusted provider. With expertise in silicone product design, precision engineering, and manufacturing, Kennwu delivers high-quality silicone solutions for various industries.

Kennwu is known for its commitment to innovation, quality, and customer satisfaction. Whether you need medical-grade silicone components, industrial seals, or customized silicone accessories, Kennwu offers top-tier solutions.

Conclusion

Choosing the right silicone products design company in Malaysia is essential for ensuring high-quality, durable, and cost-effective silicone solutions. By working with an experienced company like Kennwu, businesses can benefit from customized designs, advanced production technologies, and strict quality control.

0 notes

Text

Rapid Prototyping in Prototype

Rapid prototyping refers to one or several prototypes made first according to the product appearance drawings or structure drawings for checking the appearance or structure reasonableness without opening the mould. With the development of technology, the definition and use of the handpiece has expanded, and it is now more often used to test and validate products, optimize product design, and even used directly as a finished product.

Historical Background and Definition Rapid prototyping technology originated in the 1980s, initially to solve the problems in traditional manufacturing methods, such as high cost and long cycle time. With the development of technology, rapid prototyping has gradually matured and has been widely used in various fields. It is not only suitable for product development, but also has a wide range of applications in software applications, architectural design and other fields.

Process Rapid prototyping processes include a variety of technologies such as Stereolithography (SLA), Fusion Deposition Modeling (FDM) and others. SLA technology initiates the polymerisation of photosensitive resins by means of a light source of a specific wavelength to form polymers, while FDM technology involves the extrusion of melted material in layers. In addition, traditional moulding methods such as vacuum infusion, low pressure casting and CNC machining are also widely used in the production of handmade boards. 1.3D printing: Prototypes are created using a 3D printer by adding material layer by layer. This method allows for fast, low-cost prototyping of products with complex structures. 2.CNC machining: Cutting and engraving of materials by means of computer numerically controlled machines, suitable for prototypes requiring high precision and complex shapes. 3.Vacuum casting: Liquid material is injected into the mould using a mould and then cured into shape, suitable for validation prior to mass production. 4.Rapid tooling: Creation of moulds by means of rapid tooling technology, followed by series production. 5.Injection molding: Mass reproduction using injection moulding machines for situations where mass production is required.

Material There is also a wide selection of materials for rapid prototyping, with common ones such as photosensitive resin and nylon. For small batch production, vacuum casting process can be used, using materials such as ABS and PMMA for replication, followed by subsequent processing such as sanding and spraying with oil. For metal parts, the machining services are mostly used.

Advantages 1.Rapid outputs: Compared to traditional manufacturing methods, rapid prototyping can complete prototyping in a short period of time, greatly reducing product development cycles which suitable for low volume manufacturing. 2.Low cost: 3D printing technology, in particular, allows for the low-cost production of complex structural prototypes and small batches. 3.High flexibility: Can be prototyped using a wide range of materials and techniques, adapting to different design needs. 4.High precision: The ability to accurately replicate the structure, detail and texture of a prototype provides a surface quality. 5.Variety of materials: Polyurethane materials with different properties such as rigid, elastic, transparent or various coloured materials can be selected according to requirements.

Applications 1.Manufacturing and Industrial Applications Rapid prototyping technology enables the rapid production of complex and accurate prototypes, helping designers and engineers to validate design concepts, perform functional testing and evaluate appearance. For parts that need to be produced in small quantities, it offers a cost-effective and flexible solution. 2.Automobile industry Automakers use rapid prototyping technology to rapidly develop prototype automotive parts for performance testing and validation.In addition, it enables the manufacture of personalised automotive parts, such as dashboard panels and door handles, and is used for production tooling. 3.Medical field Rapid prototyping technology enables personalized medical devices, implants and prosthetics to be tailored to a patient's body structure, providing better fit and comfort.In the field of bioprinting, it is used for research in tissue engineering and organ transplantation. 4.Others Rapid prototyping also plays an important role in a number of industries, including aerospace, consumer electronics, and artwork creation, and its applications will become more widespread as technology advances and costs are reduced.

Rapid Prototyping is the process of creating a simple model of a product or project in the early stages of development so that it can be used to validate and test design concepts, features and interfaces. It is a method of rapidly building physical prototypes and iterating on a design with few changes to improve the design.

#design#business#prototyping#autos#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#3d printing services#3d printing#metal 3d printing#3d printed#cnc machining service#vacuum casting#rapid tooling#rapid prototype

1 note

·

View note

Text

Custom Extruded Seals: Precision Solutions for Enhanced Durability

In today’s demanding industrial and automotive environments, there is a high demand for quality sealing solutions. These are the custom-extruded seals that provide accuracy and increased durability and are used for a variety of purposes in various industries. In this article,

we’ll explain why custom extruded seals are so important, how and where they are used, and the benefits of advanced extrusion methods, specifically for automotive rubber extrusion, rubber products, rubber tubing, and silicone tubing.

What Are Custom Extruded Seals?

Custom extruded seals are special sealing parts made using the rubber extrusion method. In this process, raw rubber is heated and squeezed through a mold to take a desired form, thus producing a continuous uniform product. These seals can be designed in any size, shape, or material properties consistent with special application requirements.

Benefits of Custom Extruded Seals:

Perfect Fit: These seals are made to exact measurements, thus ensuring that they perfectly fit particular machines or buildings.

Material Versatility: EPDM, silicone, or nitrile materials protect against heat, chemicals, or weather conditions.

Customized Designs: These seals are designed to meet specific applications, ensuring an accurate fit and optimal performance.

Durability and Longevity: Modern techniques and quality materials make the seal resistant to wear, pressure, and environmental issues, making it long-lasting.

Why Automotive Rubber Extrusions Are Essential?

Automotive rubber extrusions play a significant role in enhancing the performance and safety of vehicles. These rubber extrusions form effective seals around doors, windows, and hoods, preventing rain and dust from penetrating the vehicle. These parts also reduce noise and vibrations, which make the car last longer and stay comfortable for passengers, especially in challenging conditions. Here are some of the reasons why automotive rubber extrusions are essential:

Sealing and Protection: These parts make a tight, watertight seal around car doors, windows, and hoods that protect against water, dust, and wind.

Durability in Harsh Conditions: Rubber parts are designed to endure extreme temperatures, UV rays, and oil or chemical exposure for extended periods of service.

Enhanced Safety: These parts keep passengers safe and comfortable by holding the vehicle well-insulated while reducing vibrations, thus keeping noise levels low and making the vehicle strong.

Customization: They can be made to fit a particular vehicle need, such as a unique shape, size, or material, that will allow manufacturers to optimize performance and efficiency.

What Sets Extruded Rubber Products Manufacturers Apart?

Extruded rubber products manufacturers play an integral part in various industries by providing solutions ranging from regular designs to specially engineered forms of shape. Manufacturers mainly specialize in developing seals, gaskets, tubing, and profiles with proper measurement and material qualities such that they function appropriately. They know how to pick the right rubber materials, like EPDM, silicone, or Viton, for situations where the materials need to handle very hot or cold temperatures, chemicals, or wear and tear.

They ensure their products are consistent and durable by using advanced extrusion methods and strict quality checks. In addition, they can easily produce prototypes, meet deadlines, and follow important standards such as FDA or ISO. This blend of technical ability, flexibility, and reliability is what makes the best rubber manufacturers stand out.

Extruded Rubber Tubing: A Key Component Across Applications

Extruded rubber tubing is useful for many applications in various fields, providing flexibility, resistance to extreme conditions, and durability. It is available in a variety of materials to ensure reliable performance in the most critical environments, thereby improving efficiency and safety.

Key Features of Extruded Rubber Tubing:

Silicon, EPDM, nitrile, and neoprene are commonly used because they have some very useful features.

These materials can handle very high or very low temperatures, making them perfect for tough conditions.

Tubing can be made in different sizes of diameter and length to fit particular

Needs.

Uses of Extruded Rubber Tubing:

Healthcare: Used in medical equipment and for moving fluids.

Automotive: Acts as hoses for fluid movement and protects wires.

Food Industry: Guarantees safe movement of liquids and gases in factories.

Extruded Silicone Tubing: Superior Performance and Safety

Extruded Silicone tubing is one of the most popular extruded rubber products because of its excellent resistance to heat and biocompatibility. Its properties make it suitable for critical applications in industries such as healthcare and aerospace.

The benefit of using Extruded Silicone Tubing:

Biocompatibility: Silicone is non-harmful and safe for use in medical situations.

Thermal Stability: Works well in temperatures from -60°C to 200°C.

Flexibility: Very stretchy and hard to bend, making sure liquids flow smoothly.

Applications of Extruded Silicone Tubing:

Pharmaceuticals: Applied for transferring sterile liquids in labs and hospitals.

Food and Beverage: Maintains hygiene in the food processing and serving system.

Aerospace: Provides thermal insulation and protection in harsh conditions.

At Custom Rubber Extrusion, we focus on making high-quality custom seals, rubber items, tubing, and silicone tubing for all kinds of industries. Our custom seals keep things airtight and watertight, while our rubber products are strong and flexible for many uses. We also manufacture heat, chemical, and tough-condition-resistant rubber and silicone tubing. From rubber seals for automotive applications to flexible rubber tubing for use with medical devices, or heat-resistant silicone tubing for food processing, we have all the custom solutions for you. Our extruded products ensure reliability and safety along with efficiency in a wide range of applications while taking into account precision and material perfection.

Discover how our rubber and silicone extruded products can be tailored to fit your needs

perfectly. Our experts are ready to assist you throughout the entire process, from concept to final delivery. Reach out to us via Whatsapp at (647) 294-5240 for more information.

In conclusion, custom-extruded rubber products, such as seals, tubing, and vehicle parts, are important to a variety of industries. They cannot be replaced because of durability and versatility, which enable them to be designed according to specific requirements. Customers can be sure to get the best from the most experienced manufacturers by choosing companies that have the latest technology in extrusion. Extruded silicone tubing for healthcare to rubber extrusions for automobiles-the possibilities are endless, and that is why rubber extrusion will always be a cornerstone of modern innovation.

0 notes