#expirydateprinting

Explore tagged Tumblr posts

Text

The Role of Industrial Coding and Marking: Advancing Product Identification and Traceability

Industrial coding and marking are critical components of modern manufacturing and supply chain processes, providing vital information that ensures product integrity, traceability, regulatory compliance, and brand protection. As industries become more complex and globalized, the demand for accurate and efficient coding systems continues to grow, driving technological innovation and new applications.

This article explores the fundamental principles of industrial coding and marking, its significance across different sectors, the latest technological advancements, and the growing trends that are shaping the future of this industry.

What is Industrial Coding and Marking?

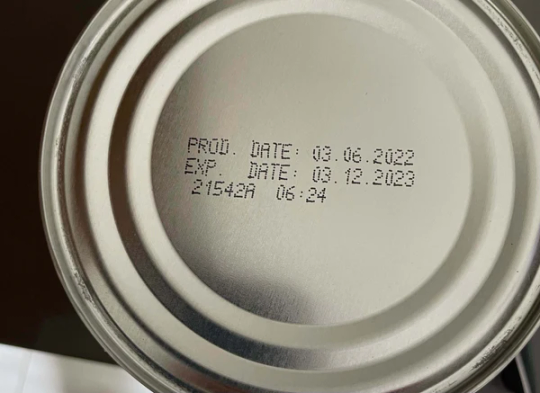

Industrial coding and marking refer to the application of essential information such as barcodes, batch numbers, expiry dates, and product-specific data on goods, components, or packaging. These markings facilitate the identification, tracking, and traceability of products throughout their lifecycle, from manufacturing to consumer delivery.

In high-speed production environments, where millions of items may pass through the assembly line, these markings ensure operational efficiency and help to meet stringent regulatory standards. As the demand for transparency and safety increases, coding and marking solutions play an essential role in reducing errors, protecting consumers, and improving overall supply chain operations.

Why is Coding and Marking Important?

1. Product Traceability

One of the primary reasons for industrial coding and marking is the need for product traceability. Traceability enables manufacturers, distributors, and retailers to track products from the production phase through the supply chain to the end consumer. This process is critical in industries such as pharmaceuticals, food and beverage, and electronics, where product safety, quality, and compliance are of paramount importance.

If a product is found to be defective or hazardous, coding and marking allow for efficient identification of the batch or production lot, enabling swift recalls and corrective action. The ability to trace products quickly and accurately can reduce the scale of recalls, minimize financial losses, and protect the company’s reputation.

2. Regulatory Compliance

Compliance with regulatory standards is another major driver behind the adoption of industrial coding and marking systems. Various industries must adhere to laws and regulations that require accurate and specific labeling on products, especially in sectors where consumer safety is critical. For instance, the European Union’s Food Information to Consumers (FIC) regulation and the U.S. FDA's labeling requirements mandate clear, consistent, and traceable information on food and drug packaging.

In the pharmaceutical sector, regulations such as the U.S. Drug Supply Chain Security Act (DSCSA) and the European Falsified Medicines Directive (FMD) enforce serialization and unique product identifiers to combat counterfeit medications and ensure the integrity of the supply chain.

3. Quality Control

In highly automated manufacturing environments, coding and marking systems help to ensure consistent quality control by providing detailed product information. This data includes information like production time, location, and materials used, enabling manufacturers to monitor their production lines and maintain high standards. Marking systems are often integrated with quality assurance protocols to detect potential defects early, reducing waste and rework.

4. Anti-Counterfeiting

Counterfeiting poses significant challenges to industries such as pharmaceuticals, consumer electronics, and luxury goods. To combat this issue, manufacturers use advanced coding and marking techniques to make it more difficult for counterfeiters to replicate product labels. Techniques such as serialization, secure QR codes, and holographic labeling allow manufacturers to track products and verify their authenticity, providing an extra layer of security and brand protection.

5. Operational Efficiency

Automated coding and marking systems help streamline production processes, especially in high-volume environments. By integrating with existing manufacturing and packaging lines, coding systems can operate at high speeds without sacrificing accuracy. This ensures that even in fast-moving environments, every product is marked clearly and consistently with the necessary information.

Key Technologies in Industrial Coding and Marking

Industrial inkjet printer technologies have evolved to meet the demands of various industries, each with its unique requirements for speed, durability, and versatility. Here are some of the most commonly used technologies:

1. Inkjet Coding

Inkjet technology is one of the most versatile and widely used methods for marking products. Inkjet printers can print on almost any surface—whether porous or non-porous—making them ideal for a variety of industrial applications. Inkjet coding is commonly used for printing batch numbers, dates, and barcodes directly onto packaging or products.

Continuous Inkjet (CIJ): A highly popular method for fast-paced production environments, CIJ involves the continuous flow of ink droplets onto the surface of the product. This technology is suitable for high-speed lines and can be used on different materials such as plastics, glass, metal, and cardboard.

Thermal Inkjet (TIJ): TIJ systems are known for their high-resolution print quality and are typically used for applications that require small, sharp text and codes. TIJ technology is used in industries like pharmaceuticals and electronics where precision is key.

2. Laser Marking

Laser marking technology uses focused beams of light to engrave or etch codes onto the surface of products. Laser systems produce permanent, high-quality marks that are highly resistant to wear, making them ideal for products that undergo harsh conditions or long lifecycles. Laser marking is commonly used in industries such as automotive, aerospace, electronics, and medical devices.

youtube

There are different types of laser technologies used in industrial marking:

Fiber Laser: Suitable for marking metals and plastics, fiber lasers produce high-contrast marks and are commonly used for electronic components, automotive parts, and industrial tools.

CO2 Laser: CO2 lasers are often used to mark non-metal materials such as wood, glass, paper, and leather. They are ideal for applications in packaging, bottling, and the food industry.

UV Laser: UV lasers are used for precision marking on sensitive materials such as glass, silicon, and medical devices. This technology provides high-contrast, durable marks without causing thermal damage to the product.

3. Thermal Transfer Overprinting (TTO)

TTO is a digital printing technology used primarily in packaging applications. It works by applying heat to transfer ink from a ribbon onto the product surface. TTO produces high-resolution text, barcodes, and graphics on flexible packaging materials like plastic films and labels, making it popular in industries like food and beverages, pharmaceuticals, and cosmetics.

4. Dot Peen Marking

Dot peen marking is a mechanical process that creates indented marks on the surface of metal or hard plastic products. This method is often used for marking metal parts in industries such as aerospace, automotive, and heavy machinery. The marks produced are durable and resistant to environmental conditions, making dot peen marking ideal for applications that require permanent identification.

5. Labeling and Print & Apply Systems

In some industries, direct marking may not be feasible due to the nature of the product or packaging material. In such cases, labeling systems are used to print and apply labels to products or packaging. These systems are commonly found in logistics and warehousing, where large volumes of products need to be identified and tracked efficiently.

1 note

·

View note