#electrical and mechanical condition monitoring services

Explore tagged Tumblr posts

Text

Ensuring Reliability and Safety: The Importance of Quality Traction Converters and Connectors in Railways

Introduction

The modern railway industry is evolving at a rapid pace, with advancements in technology playing a crucial role in enhancing efficiency, sustainability, and safety. Among the many components that contribute to the seamless functioning of a railway system, traction converters and connectors stand out as vital elements. This blog explores the significance of quality railway traction converter manufacturer and railway traction connector manufacturer in ensuring the reliability and safety of railway operations, with a specific focus on manufacturers in this domain.

Railway Traction Converters: The Powerhouses of Rail Mobility

Railway traction converters manufacturers play a pivotal role in the electrification of trains. These devices are responsible for converting electrical power from the grid into the appropriate form for the efficient and controlled movement of trains. As the demand for electrified rail systems grows, the role of railway traction converters manufacturers becomes increasingly critical.

Advancements in Traction Converter Technology

Leading manufacturers in the field of railway traction converters are at the forefront of innovation. They constantly strive to develop converters that are not only more efficient but also environmentally friendly. The integration of cutting-edge technologies, such as regenerative braking systems and advanced power electronics, contributes to the reduction of energy consumption and environmental impact.

Reliability Challenges and Solutions

Ensuring the reliability of traction converters is paramount for the uninterrupted operation of rail services. Manufacturers invest significantly in research and development to address challenges related to overheating, voltage fluctuations, and system failures. Robust testing procedures and quality assurance measures are implemented to guarantee the reliability of these critical components.

Railway Traction Connectors: Linking Efficiency and Safety

Railway traction connectors play a crucial role in ensuring the seamless transmission of power between various components of the rail system. These connectors serve as the interface between the traction converter and the train, facilitating the efficient transfer of electrical energy for propulsion.

Key Considerations in Connector Design

Manufacturers specializing in railway traction connectors prioritize several key considerations in their design and production processes. These include factors such as durability, weather resistance, and ease of maintenance. The harsh operating conditions that railways often face, including exposure to extreme weather and mechanical stress, necessitate connectors that can withstand such challenges without compromising performance.

Innovations in Connector Technology

In response to the evolving needs of the railway industry, manufacturers are continually innovating their connector designs. The integration of smart technologies, such as sensor-equipped connectors capable of real-time monitoring, enhances the safety and reliability of railway operations. These innovations contribute to the prevention of malfunctions and enable proactive maintenance measures.

Post Insulator for Railways: Ensuring Electrical Isolation and Safety

Post insulators for railways are critical components in railway electrification systems, providing electrical insulation and preventing current leakage. They play a crucial role in ensuring the safety of both passengers and railway personnel.

Importance of Quality Insulators

Railway electrification systems are subject to high voltage, and the quality of post insulators is paramount in maintaining electrical isolation. High-quality insulators prevent flashovers and electrical breakdowns, reducing the risk of accidents and disruptions. Manufacturers specializing in post insulators for railways adhere to stringent quality standards to meet the safety requirements of modern rail systems.

Challenges in Insulator Performance

The performance of post insulators can be affected by various factors, including environmental conditions, pollution, and mechanical stress. Manufacturers address these challenges through the use of advanced materials and coatings that enhance insulator resistance to environmental factors. Ongoing research and development efforts focus on improving the longevity and reliability of post insulators.

Choosing the Right Manufacturers: A Key to Reliability and Safety

Selecting reliable and experienced manufacturers is crucial for railway operators looking to ensure the longevity and safety of their electrified rail systems. Whether it is traction converters, connectors, or post insulators, the expertise and commitment of manufacturers significantly impact the performance of these components.

Key Criteria for Manufacturer Selection

Railway operators should consider several key criteria when choosing traction converter, connector, and post insulator manufacturers. These include a proven track record, adherence to industry standards, the use of advanced technologies, and a commitment to continuous improvement. Collaborating with reputable manufacturers enhances the likelihood of deploying systems that meet or exceed safety and reliability expectations.

Conclusion

In conclusion, the reliability and safety of railway systems depend heavily on the quality of traction converters, connectors, and post insulators. Manufacturers in these domains play a critical role in advancing technology to meet the evolving needs of the railway industry. As electrification becomes more prevalent, ensuring the highest standards in the design, production, and maintenance of these components is essential for the seamless, efficient, and safe operation of rail networks worldwide.

#Post Insulator For Railways#Railway Traction Converter Manufacturers#India#Railway Traction Connectors Manufacturers#railway#third rail#locomotive#tram#metro#railway engine

7 notes

·

View notes

Text

CONSULTATION SERVICES – TMCS

National Instruments software has been a technical pioneer and leader in virtual instrumentation for than four decades, a groundbreaking notion that has altered the way engineers and scientists in business, government, and academia approach measurement and automation. Everything from prototyping and probability analysis to project management and the integration of third-party software and hardware may be done quickly.

TMCS is a National Instruments, USA Silver Alliance Partner (system integrator/applications expert) capable of handling system design, system integration, and applications engineering utilizing any combination of National Instruments' high-performance software and hardware solutions.

OUR CAPABILITIES INCLUDE

Turn-key Systems Engineering

Software Development for Measurement, Data Acquisition, and Control Applications

System Engineering, Hardware and Software for Sophisticated Networks for Distributed Data Acquisition and Control Systems

Design and Assembly of Complete Control Panels and their Integration

Data Acquisition Systems

Data Acquisition Systems often referred, as the process of digitizing data from the world around us so it can be displayed, analyzed and stored in a computer. DAQ system applications are usually controlled by software programs developed using various programming language such as C, C++, Python, NI LabVIEW.

Data acquisition is a critical component of contemporary test and measurement systems, and National Instruments LabVIEW (short for Laboratory Virtual Instrument Engineering Workbench) is a prominent software tool for this purpose. LabVIEW is a graphical programming language that enables engineers and scientists to rapidly and simply construct unique test and measurement applications.

One typical use for NI LabVIEW is the creation of test benches, which are systems meant to automate the testing of electrical or mechanical components. These test bench may be used to do functional testing, stress testing, and other sorts of testing, and they can considerably increase the efficiency and accuracy of testing operations.

NI 6001 Multifunction I/O- Based System

USB Multifunction I/O Device – 8 AI (14-Bit, 20 KS/s), 2 AO (5 KS/s/Ch), 13 DIO

Description:

Multifunction I/O device

32-bit Counter

Data Logging

Portable Measurements

Data Acquisition system for Verification Validation

NI CDAQ 9185 for Data Acquisition

CompactDAQ Chassis – 4-Slot, TSN-Enabled Ethernet CompactDAQ Chassis

Description:

Controls Timing Synchronization between NI modules and host

Connectivity Options – USB, Ethernet, Wi-Fi

Multiple Hardware timed operations

For limited channel count data acquisitions which needs measurement from multiple networks, signals and sensors, the Compact DAQ is the ideal choice.

NI CDAQ 9181 for Data Acquisition

CompactDAQ Chassis 1 Slot, Ethernet CompactDAQ Chassis

Description:

Created for compact, decentralized sensor measurement systems.

Manages the timing synchronization of NI modules with the host

May be used to produce a mix of analogue, digital, and counter/timer measurements by combining C Series I/O modules.

NI 9234 for Vibration Monitoring system

C Series Sound and Vibration Input Module, 2-Channel, 102.4 KS/s/Ch Simultaneous, ±5 V

Description:

Vibration and Sound Input Module

software-selectable coupling for AC/DC

IEPE short/open detection,

Signal conditioning for IEPE

Signal conditioning for IEPE

Comes with the NI DAQmx driver setup tool.

Supports Python, C++, and NI programming environments.

The system calculates displacement, velocity, and acceleration.

2 notes

·

View notes

Text

4 Things to inspect if Your Porsche Displays ‘Transmission Emergency Run’

Modern cars are installed with certain systems that monitor different activities and warn the user if there is any faults. Warning signs are shown at the dashboard to alert the user. The warning signs are either in form of picture of a particular part or in the form of a message. In this article you will gonna know about a warning message - ‘transmission emergency run’ that comes up at the dashboard and what to inspect.

What do transmission emergency run mean?

When a message ‘transmission emergency run’ comes to the dashboard then there can be many issues in your transmission. Your transmission have either got overheated or making vibrations. Many Porsche owners complain that their transmission slip out from gears while such message comes out. One reason for this message to come can be that your Porsche control module might have stored some trouble codes due to which such error message pops up at the dashboard. Resetting the codes have solved many such problems but if the message still comes, then you may have to diagnose the problem after inspecting the gear box.

What to inspect if the ‘transmission emergency run’ message comes up?

Old battery

Mostly an old and exhausted battery is the culprit to make transmission emergency run message come up. So first you need to inspect if your battery in Porsche in good condition or not. Check the battery terminals, check if there is any leakage from it. At last check the voltage of the battery. If your battery cannot hold charge, they it would have a very less voltage.

Sometimes even a good battery can also die due to over discharge. This happens if some electrical accessories like lights are left on overnight. This would lead to draining out of energy from the battery unnecessarily. If your battery is not much old and also have no damages or leakage, then it may have got discharged. You need to just charge your battery at Porsche service shops.

Temperature sensor

The temperature sensor can also cause the message to come up. The work of the temperature sensor is to detect the temperature of the transmission and informing the control module. If the temperature sensor is faulty then it would not send correct signals and hence lead to illumination of certain warning lights, messages and storing of error codes. Check the temperature sensor to know if it has to be replaces or other fixes like cleaning can solve the problem.

MAF sensor

The MAF or mass air flow sensor is present in the air intake system detects the amount of air to enter into the engine. If the sensor is dirty or faulty then it can lead to transmission emergency run with other error messages regarding the transmission. So a MAF sensor inspection is also needed.

Gear oil

The gear oil or transmission fluid is the vital component of the gear box. It has to be inspected on regular basis and changed if it is old. A bad gear oil can lead to various transmission problems including transmission overheating too. So you need to check the gear oil level and its color.

Battery connections

A battery also makes the transmission to engage. But if the connections to the battery is loosened or damaged at cables, then it has to be fixed by mechanic.

What to do?

Many times, in Porsche, due to error, such messages comes up. So resetting the error can make your car run like before. You can try restarting your car. Just turn off the engine and take out your keys. Wait for some minutes and then turn your car on and start the engine. This method is found to be helpful for many Porsche owners. But if the restarting doesn’t solve the problem, then take an OBD2 scanners to have all the trouble codes checked. Porsche scanners are best for scanning the Porsche cars. So read the trouble codes to know the exact issue that causes the message to come up.

Conclusion

Better get your car fully inspected at a Porsche service center to get a best fix for your car. Porsche are specialized vehicles so require to be scanned by Porsche scanners and get repaired by repair kits provided only by the Porsche service centers.

2 notes

·

View notes

Text

Future of Mega-Line Shock Absorbers: Market Size, Share, and Growth Projections Through 2032

The Mega-Line Shock Absorber Market is experiencing robust growth, driven by increasing applications across automotive, industrial, and transportation sectors. Shock absorbers play a crucial role in mitigating vibrations and enhancing safety, efficiency, and comfort in mechanical systems. With advancements in materials, design, and technology, the mega-line shock absorber market is poised to expand significantly over the coming years, supported by the rising demand for high-performance systems in diverse applications.

Market Overview

Mega-line shock absorbers are designed to handle extreme loads and conditions, offering superior vibration control, enhanced durability, and longer service life. These heavy-duty shock absorbers are widely used in industries such as automotive manufacturing, railways, aerospace, defense, and heavy machinery, where performance and reliability are paramount. The market's growth is fueled by increased adoption in electric vehicles, industrial automation, and infrastructure projects.

Free Sample: https://www.statsandresearch.com/request-sample/39157-global-mega-line-shock-absorber-market

Market Trends

Increasing Adoption in Electric and Hybrid Vehicles The shift toward electric and hybrid vehicles is creating a surge in demand for advanced shock absorbers that can accommodate lightweight designs and regenerative braking systems.

Focus on Industrial Automation The rise of Industry 4.0 has led to increased adoption of mega-line shock absorbers in automated systems to ensure smooth operation and minimize wear and tear on machinery.

Advancements in Materials and Technology Innovations in materials, such as high-performance composites and smart materials, are enhancing the durability, efficiency, and precision of shock absorbers.

Integration of Smart Features Smart shock absorbers with sensors and real-time monitoring capabilities are gaining traction, offering improved diagnostics, predictive maintenance, and operational efficiency.

Expanding Infrastructure Projects The global emphasis on infrastructure development, particularly in emerging economies, is driving demand for shock absorbers in construction and heavy machinery applications.

Market Drivers

Growing Automotive Industry The global automotive industry continues to be a significant driver for the shock absorber market, with increasing demand for passenger and commercial vehicles requiring advanced suspension systems.

Emphasis on Safety and Comfort Rising consumer expectations for safety and comfort in vehicles and machinery are propelling the adoption of high-performance shock absorbers.

Demand for High-Load Capacity Systems Industries such as aerospace, defense, and railways are turning to mega-line shock absorbers for their ability to handle heavy loads and extreme conditions.

Rise in Renewable Energy Projects Wind turbines and other renewable energy systems rely on shock absorbers for vibration control and stability, driving demand in the energy sector.

Global Urbanization and Industrial Growth The rapid pace of urbanization and industrialization, particularly in developing regions, is fueling demand for shock absorbers across multiple sectors.

Request Discount: https://www.statsandresearch.com/check-discount/39157-global-mega-line-shock-absorber-market

Market Challenges

High Initial Costs The development and implementation of advanced mega-line shock absorbers require substantial investment, which can be a barrier for smaller manufacturers and end-users.

Complex Installation and Maintenance Specialized skills and tools are often required for the installation and maintenance of mega-line shock absorbers, which can pose challenges for some industries.

Competition from Alternative Technologies Competing vibration control technologies, such as active suspension systems, may limit the adoption of traditional shock absorbers.

Supply Chain Disruptions The market is vulnerable to fluctuations in raw material availability and global supply chain disruptions, impacting production and pricing.

Market Segmentation

By Type

Hydraulic Shock Absorbers: Widely used for their ability to provide smooth and consistent performance.

Pneumatic Shock Absorbers: Preferred in applications requiring lightweight and energy-efficient designs.

Magnetorheological (MR) Shock Absorbers: Advanced systems offering adjustable damping properties.

By Application

Automotive: Passenger cars, commercial vehicles, and electric vehicles.

Industrial Machinery: Used in manufacturing equipment, robotics, and heavy machinery.

Aerospace and Defense: Aircraft, military vehicles, and missile systems.

Railways: High-speed trains and metro systems.

Energy: Wind turbines and other renewable energy installations.

By End-User

OEMs (Original Equipment Manufacturers)

Aftermarket

By Region

North America: A mature market with high demand in automotive and aerospace sectors.

Europe: Leading in industrial automation and electric vehicle adoption.

Asia-Pacific: Fastest-growing region driven by urbanization, industrialization, and infrastructure projects.

Middle East & Africa: Increasing investments in construction and transportation infrastructure.

Latin America: Expanding automotive and mining industries.

Regional Insights

North America: The presence of leading manufacturers and extensive R&D investments are driving growth. The U.S. remains the largest market in the region.

Europe: Countries like Germany, France, and the UK are at the forefront of adopting advanced shock absorber technologies, particularly in automotive and railway applications.

Asia-Pacific: China and India are key growth markets due to their expanding industrial base, automotive production, and infrastructure development.

Middle East & Africa: Growth is fueled by construction projects and investments in renewable energy systems.

Latin America: Automotive and mining industries are key contributors to market expansion.

Future Outlook

The global mega-line shock absorber market is projected to grow at a steady pace, driven by increasing industrialization, technological advancements, and the push for sustainability across sectors. Emerging markets in Asia-Pacific, the Middle East, and Latin America offer significant growth opportunities for manufacturers and suppliers.

The integration of smart technologies and the development of lightweight, high-performance materials will continue to shape the market's evolution. Additionally, government initiatives promoting infrastructure development and renewable energy adoption are expected to create new avenues for growth.

Full Report: https://www.statsandresearch.com/report/39157-global-mega-line-shock-absorber-market/

0 notes

Text

Crafting an Effective Maintenance Plan: A Detailed Guide

Ensuring the proper upkeep of equipment is critical for extending its service life and maintaining optimal performance. Regular maintenance also minimizes unexpected downtime, making it a vital aspect of any business operation. Developing a robust maintenance plan is key to achieving these goals. This guide provides a step-by-step approach to creating a plan that keeps your equipment in top condition.

To establish a successful maintenance plan, it’s important to grasp the fundamentals of maintenance planning and what constitutes a reliable program. Below, we’ll explore the essential steps for creating an efficient maintenance strategy that can be implemented in your organization.

Defining a Maintenance Plan

A maintenance plan is a structured document outlining the strategies to ensure machinery, equipment, or systems operate efficiently and reliably throughout their lifecycle. This plan specifies routine maintenance activities, schedules, and protocols aimed at preventing unexpected failures and minimizing downtime.

It typically includes information on inspections, condition monitoring, predictive and preventive maintenance, and repair procedures. A well-designed maintenance plan not only enhances performance and safety but also reduces overall operating costs. Such plans are adaptable and can evolve based on data insights, technological advancements, or shifts in operational requirements.

Importance of a Maintenance Plan

While regular maintenance is widely recognized for extending equipment lifespan, some organizations still fail to prioritize it effectively. Ignoring the importance of maintenance can lead to costly downtimes, reduced productivity, and increased repair expenses.

A comprehensive maintenance plan helps ensure that equipment is consistently maintained and operates at peak efficiency. By having a structured approach, businesses can avoid unplanned interruptions and extend the durability of their assets.

Key Areas Requiring Maintenance

Maintenance applies to a wide range of areas, going beyond mere repairs or replacements. It includes preventive measures designed to enhance operational efficiency and extend the lifespan of assets. Below are some critical areas where maintenance plays a significant role:

Civil Maintenance: Focuses on the upkeep of buildings and infrastructure, including tasks like structural repairs, painting, and landscaping. Regular inspections prevent minor issues from escalating into major problems, preserving property value and safety.

Mechanical Maintenance: Involves the care of machinery and equipment, with activities like lubrication, part replacement, and overhauls. This ensures smooth operation, minimizes breakdowns, and extends the life of machinery.

Electrical Maintenance: Covers systems such as transformers, wiring, and lighting. Proper electrical maintenance enhances safety, prevents hazards, and ensures energy efficiency through routine inspections and timely replacements.

IT Maintenance: Deals with maintaining hardware, software, and networks. It includes system updates, cybersecurity measures, and data backups to protect sensitive information and ensure seamless technological operations.

Environmental Maintenance: Includes waste management, pollution control, and green space upkeep. Sustainable practices in this area contribute to a healthier environment and help businesses comply with regulations.

Essential Components of a Maintenance Plan

An effective maintenance plan comprises several critical elements that work together to ensure smooth operations. These include:

Team: Skilled personnel, including technicians and engineers, who perform maintenance tasks and coordinate activities.

Scope: Clearly defines the tasks, equipment, and objectives to streamline efforts.

Work Instructions: Detailed guidelines that provide step-by-step procedures for maintenance tasks.

Schedule: Timelines for routine maintenance, inspections, and planned shutdowns to optimize efficiency.

Tools and Materials: A comprehensive list of resources required for maintenance activities.

Contractors: Guidelines for engaging external experts for specialized tasks or supplemental support.

Steps to Develop an Effective Maintenance Program

Building an efficient maintenance program involves the following steps:

Submit a Maintenance Request: Initiate the process by identifying and reporting maintenance needs.

Evaluate Requests: Assess the urgency and validity of requests to prioritize tasks.

Plan Execution: Devise strategies, allocate resources, and address potential challenges.

Draft a Schedule: Create a timeline that aligns with operational demands and resource availability.

Communicate the Plan: Share the schedule with stakeholders and finalize it collaboratively.

Execute Tasks: Carry out maintenance work as per the plan while adhering to safety protocols.

Tips for Optimizing Maintenance Plans

Regular Updates: Periodically review and revise the plan to reflect changing requirements.

Team Training: Ensure maintenance staff are well-trained and familiar with protocols.

Leverage Technology: Use modern tools to monitor performance and schedule tasks effectively.

Conduct Audits: Regularly evaluate the process to identify areas for improvement.

Promote Continuous Improvement: Encourage feedback and adopt innovative practices to enhance maintenance efficiency.

By following these guidelines, businesses can develop a maintenance plan that ensures the longevity, safety, and reliability of their equipment.

0 notes

Text

Predictive Maintenance Services in Al Jouf

In Al Jouf, a region known for its expanding industrial activities, predictive maintenance is becoming increasingly vital for businesses looking to improve operational efficiency and reduce downtime. By leveraging advanced technologies and data analysis, predictive maintenance anticipates equipment failures before they occur, allowing for proactive repairs and minimizing the risk of costly breakdowns.

What Is Predictive Maintenance?

Predictive maintenance (PdM) involves the use of data analysis tools and techniques to predict the condition of equipment and determine the ideal time for maintenance. Unlike traditional preventive maintenance, which follows a scheduled routine, predictive maintenance is based on actual equipment conditions and performance data, allowing businesses to perform maintenance only when necessary.

Common predictive maintenance techniques include:

Vibration Monitoring: Detects abnormal vibrations to predict failures in rotating equipment.

Thermal Imaging: Identifies overheating or heat buildup, which may signal faults in electrical components or mechanical systems.

Oil Analysis: Monitors the quality of oil and lubricants to detect early signs of wear or contamination.

Ultrasonic Testing: Detects issues like leaks, electrical discharges, or wear in machinery using high-frequency sound waves.

Condition Monitoring: Measures factors like pressure, temperature, and vibration in real-time to evaluate equipment health.

Importance of Predictive Maintenance in Al Jouf

Reduced Downtime: Predictive maintenance helps identify issues before they cause equipment failure, reducing unplanned downtime and ensuring continuous operations.

Cost Savings: By preventing major breakdowns, businesses can save on expensive repairs, parts replacement, and unanticipated labor costs.

Improved Equipment Lifespan: Regular monitoring ensures that equipment is maintained in optimal condition, extending its operational life.

Safety: Early identification of faults reduces the risk of accidents and improves workplace safety by preventing dangerous equipment malfunctions.

Benefits of Predictive Maintenance

Increased Reliability: By catching issues early, predictive maintenance helps ensure that equipment operates reliably and without unexpected disruptions.

Optimized Resource Allocation: Maintenance resources can be focused on equipment that needs attention, rather than performing unnecessary routine checks.

Reduced Maintenance Costs: Maintenance is only performed when required, reducing the overall cost of unnecessary inspections and repairs.

Data-Driven Decisions: Predictive maintenance is powered by data, allowing for informed decision-making and better planning.

Key Applications of Predictive Maintenance in Al Jouf

Predictive maintenance can be applied across various industries in Al Jouf, including:

Manufacturing: Preventing unplanned downtimes in production lines, ensuring machines operate at peak efficiency.

Oil and Gas: Monitoring the condition of pumps, compressors, and other critical equipment to prevent costly failures.

Agriculture: Keeping agricultural machinery like tractors and harvesters in optimal working condition, improving productivity.

Power Generation: Monitoring turbines, generators, and other equipment to avoid power outages and ensure continuous energy supply.

Water Treatment: Preventing failures in pumps, filtration systems, and other infrastructure used in water processing.

How Predictive Maintenance Works

Data Collection: Sensors and monitoring devices collect real-time data on equipment conditions, such as temperature, vibration, and pressure.

Data Analysis: Advanced analytics software processes this data to identify patterns and predict potential failures.

Forecasting and Alerts: The system forecasts the optimal maintenance window and sends alerts to maintenance teams about impending issues.

Actionable Insights: Based on the analysis, maintenance teams can take corrective actions before a failure occurs, such as replacing worn components or recalibrating systems.

Why Choose Predictive Maintenance in Al Jouf?

For industries in Al Jouf, predictive maintenance provides a way to stay ahead of equipment failures and reduce operational disruptions. The benefits of using predictive maintenance include:

Enhanced Efficiency: Minimizes the need for reactive maintenance and reduces the likelihood of unexpected failures.

Advanced Technology: Leveraging modern technologies such as sensors, AI, and machine learning to predict and prevent problems before they affect operations.

Cost-Effective: By targeting maintenance activities based on actual equipment conditions, businesses can cut down on unnecessary labor and part replacement.

Prolonged Equipment Lifespan: Regular, data-driven maintenance helps extend the operational life of critical machinery.

Choosing the Right Predictive Maintenance Provider in Al Jouf

When selecting a predictive maintenance provider in Al Jouf, businesses should look for:

Experience with advanced predictive technologies, including sensors, analytics, and AI.

Expertise in their specific industry and equipment types.

Proactive support, with systems in place for monitoring equipment 24/7.

Customizable maintenance plans that fit the unique needs of the business.

#PredictiveMaintenance#AlJoufIndustries#IndustrialEfficiency#DataDrivenMaintenance#MaintenanceInnovation

0 notes

Text

Explore the World of IPCS

IPCS Global began its journey in 2008 as an Automation Service provider, born from a vision to empower individuals and organizations with cutting-edge technological solutions. Over the years, we have evolved and expanded beyond our loftiest expectations, driven by a single goal: to bridge the gap between technical skills and industry requirements. With growth came larger dreams, and today, IPCS stands as a beacon for job aspirants and recruiters seeking a reliable and comprehensive technological solution.

What truly sets IPCS apart from the rest? The answer lies in one word: Improvisation. This simple yet powerful principle is deeply embedded in our DNA. At IPCS, we understand that staying relevant in a rapidly changing world demands constant evolution. Whether it’s technical training, sales strategies, team management, or student support, we ensure that every aspect of our organization keeps pace with the latest advancements.

OUR COURSES

SEO | SEM | SMM | SMO AFFILIATE SECURITY SYSTEMS | FIRE

MARKETING ALARM | ACCESS CONTROL

SYSTEM

PYTHON | DATA SCIENCE | PLC | SCADA | DCS | CONTROL

ANDROID APP DEVELOPMENT PANEL DESIGN

COURSES DETAILS

SEO (Search Engine Optimization):

Improves website visibility in organic search results.

Focuses on on-page, off-page, and technical optimizations.

SEM (Search Engine Marketing):

Uses paid advertising like Google Ads to drive traffic.

Targets specific keywords for immediate visibility.

SMM (Social Media Marketing):

Promotes products/services on social platforms (Facebook, Instagram, LinkedIn).

Combines organic posts and paid ads for engagement and conversions.

SMO (Social Media Optimization):

Enhances social media profiles and content for better visibility.

Focuses on hashtags, profile optimization, and consistent posting.

Affiliate Marketing:

Performance-based model where affiliates promote products for a commission.

Increases brand reach and sales through partner referrals.

Key Benefits:

Boosts brand visibility and engagement.

Drives targeted traffic and conversions.

Offers measurable ROI and analytics.

Perfect for businesses looking to grow their online presence!

BMS (Building Management System):

Definition: A centralized system that monitors, controls, and manages a building's mechanical, electrical, and environmental systems.

Key Functions:

HVAC (Heating, Ventilation, and Air Conditioning) control.

Lighting and energy management.

Fire safety and alarm systems integration.

Security system management.

Benefits:

Increases energy efficiency.

Enhances building safety and comfort.

Reduces operational costs.

CCTV (Closed-Circuit Television):

Definition: A video surveillance system used for monitoring and recording activities in a specific area.

Key Features:

Live video monitoring.

High-definition recording.

Night vision and motion detection.

Remote access via mobile or computer.

Applications:

Security and crime prevention.

Traffic monitoring.

Employee and workplace monitoring.

Benefits:

Deters unauthorized activities.

Provides evidence in case of incidents.

Ensures safety and surveillance in real-time.

PYTHON & DATA SCIENCE

Python

Definition: A versatile, high-level programming language widely used for various applications like web development, automation, data analysis, and machine learning.

Key Features:

It is easy to understand and use due to its simple syntax.

extensive libraries like as TensorFlow, Matplotlib, Pandas, and NumPy..

Supports multiple paradigms (object-oriented, functional, etc.).

Open-source with a strong developer community.

Applications:

Web and app development.

Data analysis and visualization.

Machine learning and AI.

Data Science

Definition: A multidisciplinary field that uses statistical methods, algorithms, and technology to analyze and interpret complex data.

Key Components:

Data Collection: Gathering data from various sources.

Data Cleaning: Preparing data by removing inaccuracies.

Data Analysis: Identifying patterns and trends.

Machine Learning: Building predictive models.

Data Visualization: Representing data through graphs and dashboards.

Tools and Technologies: Python, R, SQL, Tableau, Hadoop.

Applications:

Business intelligence.

Predictive analytics in healthcare, finance, and marketing.

Fraud detection and risk management.

Let me know if you'd like further details!

Industrial Automation

Definition:using robots, PLCs (Programmable Logic Controllers), computers, and other control technologies to manage industrial machinery and processes with little assistance from humans.

Key Features:

Process Automation: Streamlining repetitive tasks and manufacturing processes.

Robotics: Using robots for precision, efficiency, and safety.

Actuators and sensors: keeping an eye on and managing industrial settings.

SCADA Systems: Supervisory Control and Data Acquisition for real-time monitoring and control.

IoT Integration: Enabling connected devices for smarter decision-making.

Benefits:

Increases productivity and efficiency.

Reduces operational costs and human error.

Enhances quality and precision in production.

Improves workplace safety.

If you want a photograph or further information, let me know!

Comprehensive Placement Assistance

One of the standout features of IPCS is our commitment to placement assistance. We understand that completing a training program is only the first step; the ultimate goal is securing a rewarding career. That’s why we go the extra mile to connect our students with top employers across various industries.

Our placement team works tirelessly to build relationships with recruiters, understanding their needs and matching them with the right candidates. From resume building and interview preparation to job placement, we provide end-to-end support to ensure our students succeed. Many of our alumni have gone on to build successful careers in reputed organizations, a testament to the effectiveness of our training and placement services.

Your Journey Starts Here

IPCS Global is more than just a training institute; it’s a partner in your journey to success. Whether you’re a job aspirant looking to enhance your skills, a professional seeking career growth, or a company aiming to upskill your team, we are here to support you every step of the way.

With IPCS, you are not just enrolling in a training program; you are joining a community dedicated to excellence and innovation. Take the first step today and discover how IPCS can transform your future.

We are thrilled to welcome you to the IPCS community. Together, let's create a world where dreams are realized.

See you soon!

Conclusion for IPCS

IPCS Global stands as a trusted leader in providing innovative technological solutions and industry-focused training. From empowering job aspirants with cutting-edge skills to supporting businesses in upskilling their teams, IPCS is committed to bridging the gap between talent and opportunity. With a strong foundation built on improvisation, practical training, and expert guidance, IPCS ensures that every student and partner achieves their fullest potential.

Whether you aim to transform your career, improve your company’s capabilities, or embrace the latest in technology, IPCS is your ultimate destination. With real-time projects, industry-leading trainers, and top-notch placement assistance, IPCS is dedicated to shaping a brighter and more skilled future for everyone.

Join IPCS today—your journey to excellence starts here!

0 notes

Text

Comprehensive Guide to RO System Service in Chhatarpur by KTECH Water Zone

Introduction

In today’s world, access to clean and safe drinking water is not just a necessity but a priority. With increasing pollution levels and contaminants finding their way into water sources, having a reliable Reverse Osmosis (RO) system in your home or office is essential. However, owning an RO system is only half the solution; maintaining it is equally important to ensure optimal performance. That’s where KTECH Water Zone (RO Service Centre in South Delhi) steps in as your trusted partner for RO system services in Chhatarpur.

Why is RO System Maintenance Crucial?

An RO system is a sophisticated piece of technology designed to remove impurities, toxins, and contaminants from water. Over time, the filters, membranes, and other components can become clogged or inefficient due to prolonged use. Regular maintenance not only extends the lifespan of the RO system but also ensures:

Consistent Water Quality: Regular servicing helps maintain the purity of your drinking water.

Enhanced System Efficiency: Proper upkeep ensures your system operates at peak performance.

Prevention of Major Breakdowns: Timely maintenance can help detect and fix minor issues before they escalate.

Cost Savings: Routine servicing minimizes the need for expensive repairs or replacements.

Common Issues with RO Systems

If your RO system is not functioning as expected, it may be due to one or more of the following problems:

Reduced Water Flow: A clogged filter or membrane could be the culprit.

Odd Taste or Odor: This may indicate a need for filter replacement.

Leakage Issues: Faulty fittings or worn-out components might cause leaks.

Noisy Operation: Air trapped in the system or a malfunctioning pump can lead to noise.

Slow Filtration: This often results from a clogged pre-filter or an exhausted membrane.

Services Offered by KTECH Water Zone in Chhatarpur

KTECH Water Zone specializes in comprehensive RO system services to address all your needs. Here’s what we offer:

Installation and Setup:

Professional installation of new RO systems, ensuring all connections are secure and functioning.

Guidance on system usage and basic troubleshooting tips.

Routine Maintenance:

Periodic filter and membrane replacement.

Cleaning of storage tanks and other components.

Repairs:

Fixing leaks, replacing damaged parts, and resolving water flow issues.

Troubleshooting electrical and mechanical problems.

Upgrades:

Upgrading existing systems to more advanced models or enhancing system capacity.

Water Quality Testing:

Professional testing to ensure your water meets safety standards.

Why Choose KTECH Water Zone?

When it comes to RO system service in Chhatarpur, KTECH Water Zone (RO Service Centre in South Delhi) stands out for several reasons:

Expert Technicians: Our team consists of highly skilled professionals with extensive experience in servicing all major RO brands.

Customer-Centric Approach: We prioritize customer satisfaction by delivering prompt, reliable, and affordable services.

Genuine Parts: We use only authentic replacement parts to ensure the longevity and efficiency of your system.

Comprehensive Solutions: From installation to repairs, we offer end-to-end RO services.

Convenient Location: Situated in South Delhi, we are easily accessible to residents of Chhatarpur and surrounding areas.

Tips to Maintain Your RO System

While professional servicing is essential, there are several steps you can take to keep your RO system in good condition:

Regular Cleaning: Clean the storage tank and exterior of your RO unit to prevent dirt buildup.

Timely Filter Replacement: Replace filters and membranes as per the manufacturer’s recommendations.

Monitor Water Quality: Use a TDS meter to check the Total Dissolved Solids in your water regularly.

Check for Leaks: Periodically inspect the system for any signs of leakage.

Follow Manufacturer’s Guidelines: Adhere to the user manual for best practices and maintenance schedules.

Understanding the RO Filtration Process

To better appreciate the importance of maintaining your RO system, it helps to understand how it works. The RO filtration process typically involves the following stages:

Pre-Filter: Removes large particles and sediment from the water.

Activated Carbon Filter: Eliminates chlorine and organic impurities.

RO Membrane: Filters out dissolved salts, heavy metals, and other contaminants.

Post-Filter: Enhances taste and quality by removing any residual impurities.

Storage Tank: Stores the purified water for use.

Each of these components plays a vital role, and their efficiency directly affects the quality of water you consume.

How Often Should You Service Your RO System?

The frequency of servicing depends on factors like water quality, usage, and the brand of your RO system. As a general guideline:

Pre-filters should be replaced every 6-12 months.

The RO membrane should be replaced every 2-3 years.

A comprehensive service should be conducted annually.

At KTECH Water Zone, we offer customized maintenance plans to suit your specific requirements.

The KTECH Water Zone Experience

Choosing KTECH Water Zone for your RO system service in Chhatarpur guarantees a hassle-free experience. Here’s what you can expect:

Prompt Response: Quick turnaround times for all service requests.

Affordable Pricing: Transparent and competitive pricing with no hidden charges.

Personalized Attention: Tailored solutions based on your system’s needs.

Post-Service Support: Continued assistance for any follow-up queries or issues.

How to Book a Service with KTECH Water Zone

Booking a service with us is easy:

Call our helpline or visit our service centre in South Delhi.

Provide details about your RO system and the issue you’re facing.

Schedule a convenient time for our technician to visit.

Conclusion

Maintaining your RO system is crucial for ensuring the health and safety of your family. With KTECH Water Zone (RO Service Centre in South Delhi), you can rest assured that your system is in expert hands. Our commitment to quality, professionalism, and customer satisfaction makes us the go-to choice for RO system services in Chhatarpur. Whether it’s a routine check-up or an emergency repair, we are here to help.

Contact KTECH Water Zone today and experience unparalleled RO system service in Chhatarpur. Your health deserves nothing less!

Contact Us:

Phone: {080767 47517}

Email: {[email protected]}

Address: {Gate no 1, A 17, Devli Rd, Pocket B, Duggal Colony, Khanpur, New Delhi, Delhi 110062}

Website: {https://ktechwaterzone.in/}

1 note

·

View note

Text

The Importance of Periodic Battery Maintenance: Car Battery in Balmain

A car's battery in Balmain is essential to help your car start off properly and supply power to such necessary appliances as lights and the radio. Regular maintenance can help your battery last a long time and ensure it doesn't break down suddenly. For those in Balmain, checking on their car's battery condition regularly would be a great advantage when having such troubles fixed.

Signs of Wearing out of Your Car Battery

A car battery will gradually wear out if it has been in use for more than three years. Knowing common indicators that show your battery needs to be replaced can help you maintain the performance of your vehicle. Here are a few indicators that might help you know when to replace it:

Slow Engine Cranking: If the engine is cranky and cranks up much slower than it normally should or takes a little more time to start, your battery may be losing its charge or is close to dying. This is often felt in the morning, as the temperature is low, making the battery work a bit harder.

Dimming Headlights: Whenever your lights dim or start blinking when you idle, and more so when you're operating the engine, you know you have a failing battery that is not keeping sufficient charge. Dimmed light bulbs may also mean your alternator is not functioning and that it's unable to charge your car's battery.

Dashboard Warning Lights: Most of today's motor vehicles come equipped with warning lights for the presence of a possible problem with the car systems, including the batteries. When a battery indicator appears on your dashboard, it could mean your battery runs low, is weak, or struggles to hold an electrical charge.

The Necessity for Regular Checks of the Car Battery

Monitoring the car battery's health will depend on its age, which is above three years. Over time, batteries tend to decline due to several factors: aging, weather conditions, and driving habits. The longer you wait, the more you will be stuck with a dead battery and unable to turn your car on or access other electrical appliances.

Car Battery Testing Services in Balmain

Fortunately, Balmain has a few local services that specialize in car battery testing.

They will be able to determine if your battery needs just a recharge or a full replacement.

Testing your battery is one of the quickest and cheapest ways to identify any problems before they leave you stranded.

By having your car battery tested at regular intervals, you ensure that you are not caught off guard by an unexpected failure.

Local mechanics and car service centres in Balmain can test the charge and health of your battery.

Most of these services are also very convenient and may offer to check your battery at the same time you go to them for a repair. You will be aware if you need to change the battery or not in no time after doing the quick diagnostic test.

Little preventative maintenance goes a long way!

Car owners have never had it so important to regularly maintain their Car battery in Balmain. Recognising the signs of wear in a battery, for example, slow engine cranking, dimming headlights, or dashboard warning lights, is what will keep your car reliable. Regular checks and testing, especially for older batteries, can help you avoid unexpected breakdowns. In Balmain, consider using local services that specialise in car battery testing for a smooth ride and avoidance of the inconvenience of a dead battery.

0 notes

Text

Comprehensive Guide to Seakeeper Troubleshooting, Vacuum Service, and Annual Service

Seakeeper systems have revolutionized marine stability, providing unparalleled comfort by virtually eliminating boat roll. However, like any advanced technology, these systems require proper care, routine servicing, and occasional troubleshooting to ensure peak performance. This guide delves into Seakeeper troubleshooting, vacuum service, and annual service, highlighting essential steps and best practices.

Seakeeper Troubleshooting

When your Seakeeper system experiences issues, prompt troubleshooting can prevent more significant problems and costly repairs. Common issues include excessive noise, vibration, and error codes. Here’s how to address them:

Check the Basics: Ensure the Seakeeper is powered on and connected to the vessel’s electrical system. Verify all cables and connectors are secure.

Monitor the Control Panel: The Seakeeper control panel displays error codes. Refer to the Seakeeper manual to identify and resolve specific codes.

Inspect the Gyroscope: Listen for unusual noises or vibrations, which may indicate misalignment or mechanical wear.

Check Cooling Systems: Overheating can occur if the cooling system is compromised. Verify that water and coolant levels are sufficient and that the pump is functioning.

Consult Professionals: If issues persist, seek expert assistance. Trained technicians can diagnose and fix complex problems effectively.

Seakeeper Vacuum Service

The vacuum system is a critical component of the Seakeeper, ensuring the gyroscope operates in a controlled environment. Maintaining this vacuum system is crucial for optimal performance.

When to Service: Vacuum servicing is generally required every two to three years or as recommended by the manufacturer.

Steps Involved:

Vacuum Inspection: Technicians use specialized tools to measure vacuum pressure and identify leaks or degradation.

Seal Replacement: Over time, seals can wear out, compromising the vacuum. Replacing them ensures the system remains airtight.

Vacuum Recharging: Using advanced equipment, the vacuum is re-established to manufacturer specifications, ensuring the gyroscope operates efficiently.

Performance Testing: After servicing, the Seakeeper is tested to confirm stability and reliability.

Seakeeper Annual Service

Annual servicing is vital to maintaining the longevity and functionality of your Seakeeper system. It includes a comprehensive check of all components, ensuring optimal performance throughout the year.

Key Elements of Annual Service:

Lubrication: Proper lubrication of bearings and moving parts reduces wear and prolongs system life.

Software Updates: Technicians update the system’s firmware, ensuring compatibility and improved performance.

Cooling System Maintenance: Inspecting hoses, pumps, and coolant levels prevents overheating.

Hardware Inspection: Bolts, mounts, and gyroscope components are inspected for wear and tear.

System Calibration: Fine-tuning ensures the Seakeeper operates at its maximum potential.

Conclusion

Investing in regular troubleshooting, vacuum servicing, and annual maintenance not only ensures the seamless operation of your Seakeeper system but also enhances the overall boating experience. Collaborate with certified professionals and adhere to the manufacturer’s guidelines to keep your Seakeeper in peak condition for years to come.

#best seakeeper in uae#marine stabilization#seakeeper annual service#seakeeper gyro stabilizers#seakeeper m-series software update#seakeeper software update

0 notes

Text

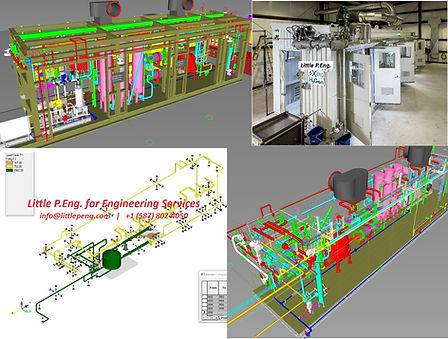

Little P.Eng.: A Leader in Comprehensive Skid Module Design Services

In the ever-evolving industrial landscape, the demand for modular solutions has grown exponentially. Skid modules, also known as packaged units, offer a highly efficient and versatile approach to building process systems. At Little P.Eng., we take pride in delivering end-to-end engineering services for skid module design services, encompassing structural, mechanical (piping stress analysis), and electrical and instrumentation (E&I) engineering.

What Are Skid Modules?

Skid modules are pre-assembled, self-contained units designed to perform specific industrial processes. They are widely used in industries such as oil and gas, petrochemicals, pharmaceuticals, and power generation. These modules integrate multiple engineering disciplines into a compact, transportable frame, ensuring reduced construction time and seamless installation.

Little P.Eng.’s Expertise in Skid Module Design

1. Structural Engineering

Structural integrity is a cornerstone of skid module design. At Little P.Eng., our structural engineering team ensures that skid frames and supports are designed to withstand operational loads, transportation stresses, and environmental factors. Key aspects include:

Finite Element Analysis (FEA) to assess stress distribution.

Design compliance with international standards such as ASCE, AISC, and API.

Material selection for strength, durability, and corrosion resistance.

2. Mechanical Engineering (Piping Stress Analysis)

Piping systems are critical components of skid modules. Our piping stress analysis services ensure that the system operates safely and efficiently under various conditions. Highlights of our approach include:

Analysis of thermal expansion, vibration, and dynamic loading.

Compliance with ASME B31.3, B31.4, and B31.8 codes.

Selection of supports, anchors, and expansion joints to optimize system performance.

Detailed isometric drawings for precise installation.

3. Electrical and Instrumentation (E&I) Engineering

Modern skid modules rely on sophisticated electrical and instrumentation systems for automation and monitoring. Our E&I engineering services cover:

Electrical design, including power distribution, grounding, and lighting.

Selection and integration of instrumentation such as sensors, transmitters, and control systems.

Compliance with IEC, NEC, and CSA standards.

Detailed wiring diagrams and control schematics to ensure seamless operation.

Why Choose Little P.Eng. for Skid Module Design?

Multidisciplinary Expertise: Our team of engineers specializes in structural, mechanical, and E&I disciplines, ensuring a holistic approach to skid module design.

Compliance with Industry Standards: We adhere to global engineering codes and standards, ensuring that your skid modules meet regulatory requirements.

Customization and Innovation: Every project is unique. We collaborate closely with clients to deliver customized solutions that align with their operational needs and constraints.

End-to-End Support: From conceptual design to final documentation, Little P.Eng. provides comprehensive support at every stage of the project.

Applications of Skid Modules Designed by Little P.Eng.

Oil and Gas Processing: Compact units for separation, compression, and refining.

Chemical Plants: Modular solutions for chemical reactions and material handling.

Power Generation: Skids for heat recovery, turbines, and auxiliary systems.

Pharmaceuticals: Hygienic systems for mixing, packaging, and distribution.

Final Thoughts

Skid modules are redefining how industrial processes are implemented, offering flexibility, efficiency, and cost savings. With Little P.Eng., you get a trusted partner that combines engineering expertise with innovative solutions to deliver skid modules tailored to your needs.

Let us help you bring your projects to life. Contact Little P.Eng. today to learn more about our skid module design services!

Tags:

piping stress analysis

Little P.Eng. engineering

structural engineering

finite element analysis

vibration analysis

thermal expansion analysis

mechanical engineering

ASME B31.3 compliance

skid frames

modular process systems

electrical and instrumentation engineering

skid modules for oil and gas

custom skid modules

power generation skids

skid module design

process automation

skid-mounted equipment

instrumentation integration

electrical system design

modular skid units

compact industrial units

skid systems for petrochemicals

modular skid fabrication

industrial automation systems

industrial skid design

modular engineering solutions

E&I engineering

skid-mounted systems

skid-mounted piping systems

packaged process systems

Engineering Services

Structural Engineering Consultancy

Pipe Stress Analysis Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Montréal, Quebec; Houston Texas; Torrance, California; El Segundo, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

0 notes

Text

RO Repairing Services in Safdarjung Development Area by KTECH Water Zone

Introduction

Clean and safe drinking water is a necessity for every household and business. With increasing pollution levels, water purifiers, particularly Reverse Osmosis (RO) systems, have become indispensable. However, like any other appliance, RO systems require regular maintenance and occasional repairs to ensure optimal performance. For residents and businesses in the Safdarjung Development area, KTECH Water Zone (RO service centre in South Delhi) stands as a trusted name in RO repair and maintenance services.

Understanding the Importance of RO Systems

RO systems are designed to remove impurities, harmful chemicals, and contaminants from water. They play a critical role in providing pure and healthy drinking water. Key benefits of using an RO water purifier include:

Elimination of Contaminants: RO systems filter out heavy metals, chlorine, pesticides, and other harmful substances.

Improved Taste and Odor: Removing impurities enhances the water's taste and smell.

Health Benefits: Clean water reduces the risk of waterborne diseases and supports overall health.

Given their importance, maintaining the efficiency of your RO system is crucial.

Common Issues with RO Systems

Despite their reliability, RO systems may encounter issues over time. Some common problems include:

Reduced Water Flow: A clogged filter or membrane can slow down water flow.

Unusual Taste or Odor: This can occur due to expired filters or stagnant water.

Leakages: Loose connections or worn-out parts may cause water leaks.

Noisy Operation: A malfunctioning pump or air trapped in the system can lead to noise.

System Not Working: Electrical or mechanical issues might stop the system from functioning altogether.

Why Choose KTECH Water Zone for RO Repair in Safdarjung Development Area?

KTECH Water Zone is a leading RO service provider in South Delhi, offering comprehensive solutions for all your water purifier needs. Here’s why we are the preferred choice:

Expert Technicians: Our team consists of trained professionals with expertise in diagnosing and fixing RO system issues.

Genuine Spare Parts: We use authentic spare parts to ensure long-lasting repairs.

Quick Response: Our efficient service ensures minimal downtime for your RO system.

Affordable Pricing: We provide quality services at competitive prices.

Customized Maintenance Plans: Regular servicing plans tailored to your specific needs.

Our Range of Services

At KTECH Water Zone, we offer a wide range of services to keep your RO system in top condition:

Installation and Setup: Professional installation of new RO systems.

Filter Replacement: Timely replacement of filters to maintain water quality.

Membrane Cleaning and Replacement: Ensuring the core filtration component functions optimally.

Leakage Repair: Fixing leaks to prevent water wastage.

Annual Maintenance Contracts (AMC): Comprehensive plans for regular maintenance and repairs.

Steps to Avail Our Services

Getting your RO system repaired or serviced by us is a hassle-free process:

Contact Us: Call or visit our service center in the Safdarjung Development area.

Schedule a Visit: Book a convenient time for our technician to visit your location.

Diagnosis and Repair: Our expert will diagnose the issue and perform the necessary repairs.

Post-Service Support: We provide guidance on maintaining your RO system and offer follow-up services if needed.

Tips for Maintaining Your RO System

While professional servicing is essential, regular maintenance can extend the life of your RO system. Here are some tips:

Replace Filters on Time: Follow the manufacturer’s guidelines for filter replacement.

Clean the System Regularly: Prevent sediment buildup by cleaning the system components.

Check for Leaks: Inspect connections and pipes periodically for any leaks.

Monitor Water Quality: Test the water periodically to ensure the system is functioning properly.

Use Authentic Parts: Always use genuine spare parts for replacements.

Customer Testimonials

Our dedication to quality and customer satisfaction has earned us the trust of many in the Safdarjung Development area. Here’s what some of our clients say:

Rohit S.: "KTECH Water Zone provides excellent service. Their technicians are knowledgeable, and my RO system works like new."

Anita M.: "Quick and reliable service at an affordable price. Highly recommended!"

Vivek R.: "I’ve been using their AMC for two years now. They ensure my RO system always runs smoothly."

Why Regular RO Servicing is Crucial

Neglecting RO maintenance can lead to:

Decreased Water Quality: Expired filters fail to remove contaminants effectively.

Higher Energy Consumption: A poorly maintained system consumes more power.

Costly Repairs: Minor issues can escalate if not addressed promptly.

How KTECH Water Zone Ensures Quality

Our commitment to excellence is evident in every aspect of our service. From using advanced tools to employing experienced technicians, we ensure your satisfaction. We also provide transparent pricing and detailed explanations of the work done.

Service Areas

In addition to the Safdarjung Development area, we extend our services to neighboring localities in South Delhi, ensuring no household or business is left without access to pure water.

Contact Us

For reliable and affordable RO repair services, reach out to KTECH Water Zone:

Address: [Gate no 1, A 17, Devli Rd, Pocket B, Duggal Colony, Khanpur, New Delhi, Delhi 110062]

Phone: [080767 47517]

Email: [[email protected]]

Website: [https://ktechwaterzone.in/]

Conclusion

Water is life, and ensuring its purity is a responsibility we take seriously. With KTECH Water Zone, you can rest assured that your RO system is in expert hands. Whether it’s a minor repair or comprehensive maintenance, our team is ready to assist you. Contact us today and experience hassle-free RO servicing in the Safdarjung Development area.

By prioritizing regular maintenance and choosing a trusted service provider like KTECH Water Zone, you can ensure your family’s health and well-being while enjoying uninterrupted access to clean drinking water.

#ROrepair#ROrepairDelhi#LocalROservice#ROrepairservice#DelhiROtechnician#ROservice#WaterPurifierRepair#ROsystem

0 notes

Text

Diesel Dredge Safety: Tips for a Risk-Free Operation

Operating diesel-powered dredge requires a strong focus on safety to prevent accidents and ensure efficient performance. This guide highlights essential safety tips to mitigate risks during dredging operations. From regular equipment inspections and proper maintenance of diesel engines to ensuring adequate ventilation and fire prevention, adherence to safety protocols is critical. It also emphasizes the importance of personal protective equipment (PPE), training for operators, and following emergency procedures. Monitoring fuel systems for leaks, reducing exposure to hazardous emissions, and maintaining a clear communication system on-site are equally vital. By implementing these practices, operators can minimize hazards and maintain a safe, risk-free environment, ensuring both the safety of personnel and the longevity of the equipment.

Introduction to Diesel Dredge: A Vital Tool for Marine Excavation

Diesel dredge are essential machines in the marine and construction industries, widely used for excavating and transporting sediment. Equipped with powerful diesel engines, these dredge offer unmatched efficiency and reliability in challenging aquatic environments. Understanding their purpose and functionality is crucial for industries relying on dredging for land reclamation, harbor deepening, and environmental restoration.

How Diesel Dredge Work: Powering Efficient Sediment Removal

Diesel dredge operate through a robust system powered by diesel engines. The engines provide the energy required to drive pumps, cutters, and suction mechanisms. These components work together to remove underwater sediments, transferring them through pipelines to designated locations. Their high-power output makes them suitable for handling dense and abrasive materials in various water bodies.

Key Features of Diesel Dredge: Durability and Performance

Diesel dredge are designed with features that prioritize durability and performance. The diesel engines are built to withstand heavy-duty operations, while the hulls and components are corrosion-resistant to endure prolonged exposure to water. Advanced control systems and automation enhance operational efficiency, enabling precise dredging even in harsh marine conditions.

Applications of Diesel Dredge: From Harbors to Environmental Restoration

Diesel dredge are versatile, supporting a range of applications:

Port and Harbor Maintenance: Ensuring navigational channels remain clear for vessels.

Land Reclamation: Transforming underwater areas into usable land.

Environmental Projects: Removing pollutants and restoring aquatic ecosystems. Their adaptability makes them invaluable in both commercial and environmental projects.

Advantages of Using Diesel Dredge Over Electric Alternatives

While electric dredge have their place, diesel dredge offer several advantages:

Higher Mobility: Diesel-powered dredge can operate in remote areas without relying on power grids.

Greater Power Output: Diesel engines provide the torque needed for heavy-duty dredging.

Cost-Effectiveness: In regions with limited electricity access, diesel dredge can reduce operational costs.

Maintenance and Challenges of Diesel Dredge

Maintaining diesel dredge involves regular engine servicing, monitoring fuel consumption, and inspecting components for wear. Challenges include high fuel costs, emissions regulations, and the environmental impact of diesel operations. Adopting eco-friendly practices, such as using cleaner fuels or hybrid systems, can mitigate these issues.

Future Trends in Diesel Dredging Technology

As industries strive for sustainability, advancements in diesel dredging technology are emerging. Hybrid diesel-electric systems, low-emission engines, and smart automation are shaping the future of diesel dredge. These innovations aim to enhance efficiency while minimizing environmental footprints, ensuring diesel dredge remain relevant in modern dredging projects.

Conclusion

Diesel dredge are indispensable tools in marine excavation, offering unmatched power and versatility. Their ability to handle complex dredging tasks makes them vital across various industries. However, addressing environmental concerns and embracing technological advancements will be crucial for ensuring their sustainability in the future.

0 notes

Text

Military Connectors: The Backbone of Modern Railway Projects

In the rapidly evolving landscape of railway projects, reliability and efficiency are paramount. Military connectors, often referred to as railway connectors in this context, have emerged as a game-changing solution, offering unparalleled performance in demanding environments. Their robust design, high durability, and superior connectivity make them indispensable in modern railway systems.

Why Military Connectors Are Essential in Railway Projects

Railway systems are subject to extreme conditions, including vibrations, temperature fluctuations, and exposure to moisture and dust. Military connectors are designed to withstand these challenges, ensuring seamless communication and power transmission across various subsystems. Here are key reasons why they are vital:

Durability and Reliability: Built to meet stringent military standards, these railway connectors offer high resistance to wear and tear, ensuring long-term performance.

Environmental Resistance: With IP-rated sealing and corrosion-resistant materials, military connectors are ideal for harsh railway environments.

Versatile Applications: From control systems and signal processing to power distribution, railway connectors are used across multiple components in railway projects.

High-Performance Connectivity: Military connectors ensure stable connections, minimizing disruptions in operations and enhancing overall system efficiency.

Key Features of Military Connectors for Railway Applications

Robust Construction: Designed with rugged materials like stainless steel and aluminum alloys, military connectors can handle mechanical stress and harsh conditions.

Compact and Lightweight Design: Despite their sturdy build, these railway connectors are compact and lightweight, making them suitable for space-constrained railway systems.

Secure Locking Mechanisms: Equipped with advanced locking systems, they prevent accidental disconnections, ensuring uninterrupted service.

High Signal Integrity: These connectors provide superior signal quality, essential for critical communication and control systems.

Applications of Military Connectors in Railway Projects

Military connectors are used in various aspects of railway projects, including:

Train Control Systems: Ensuring accurate signal transmission for automated control and safety systems.

Power Distribution: Reliable power delivery to multiple subsystems, including lighting, HVAC, and propulsion systems.

Communication Systems: Supporting robust data and voice communication between train operators and control centers.

Trackside Equipment: Enhancing the performance of monitoring and signaling devices installed along railway tracks.

Choosing the Right Military Connectors for Your Railway Project

Selecting the right railway connectors can significantly impact the efficiency and reliability of your railway systems. Factors to consider include:

Connector Type: Choose from circular, rectangular, or hybrid connectors based on application needs.

Material Composition: Opt for materials resistant to corrosion, moisture, and temperature extremes.

Electrical Specifications: Ensure the connectors meet the voltage, current, and signal requirements of your systems.

Compliance Standards: Look for connectors that comply with MIL-DTL-5015, MIL-DTL-38999, and other relevant standards.

Partner with Jetronics India for Reliable Military Connectors

At Jetronics India, we specialize in providing top-quality military connectors, also known as railway connectors, tailored for railway applications. Our connectors are designed to meet the highest standards of performance, reliability, and safety. With a proven track record in the industry, we are your trusted partner for all your connector needs.

Visit our Military Connectors for Railway Projects page to explore our comprehensive range of products and solutions. Contact us today to learn how we can support your railway projects with state-of-the-art railway connectors.

0 notes

Text

Medical Device Validation and Verification Market Growth and Opportunities

The global medical device validation and verification market size is expected to reach USD 1.71 billion by 2030, expanding at a CAGR of 8.8% from 2025 to 2030, according to a new report by Grand View Research, Inc.

Increase in demand for advanced and quality medical products and rising complexity with respect to product designing and engineering are anticipated to boost market growth. Rapid innovations in healthcare have increased the need for companies to incorporate new technologies and software applications in their products to meet the demand for validation and verification. Increase in product complexity, availability of newer types of material, and high risk of product failures are some of the key factors increasing the need for validation and verification services.

North America dominated the global medical device validation and verification market, accounting for 44.88% share of the overall revenue in 2019. Rapid growth in manufacturing of medical devices to meet high demand for efficient healthcare services, including validation and verification, is one of the major factors contributing to the regional market growth. In addition, stringent regulatory environment in U.S. is fueling market growth in the region.

Asia Pacific is anticipated to expand at a CAGR of 12.1% during the forecast period. This can be attributed to increased opportunities for players, especially in Japan, China, and India, improved regulatory framework, and increase in the number of medical devices companies.

Medical Device Validation & Verification Market Report Highlights

The oncology segment dominated the market, with a revenue share of 26.5% in 2024, driven by the rising incidence of cancer globally, demanding advanced medical devices for diagnosis, treatment, and monitoring.

The diagnostics segment dominated the market with the largest revenue share of 44.0% in 2024, driven by increasing demand for early disease detection and a shift towards preventive healthcare, emphasizing early diagnosis for better treatment outcomes and lower costs.

The therapeutic segment is projected to grow at a CAGR of 9.0% over the forecast period. It is fueled by the rising prevalence of chronic diseases like diabetes and cardiovascular conditions, demanding validated devices such as drug delivery systems and infusion pumps for effective management.

North America medical device validation & verification market dominated the global market with a revenue share of 45.2% in 2024.

Medical Device Validation & Verification Market Segmentation

Grand View Research has segmented the global medical device validation & verification market on the basis of therapeutic area, application, implants, technology, and region:

Medical Device Validation & Verification Therapeutic Area Outlook (Revenue, USD Billion, 2018 - 2030)

Cardiovascular

Dermatology

Orthopedics

Nephrology

Respiratory

Neurology

Oncology

ENT

Others

Medical Device Validation & Verification Application Outlook (Revenue, USD Billion, 2018 - 2030)

Diagnostics

Therapeutic

Implants

Medical Device Validation & Verification Implants Outlook (Revenue, USD Billion, 2018 - 2030)

Active Implantable Medical Device

Medical Implants