#cstr

Explore tagged Tumblr posts

Text

Hpr cstr

#Hyper coaster#The land of legends#The land of legends hyper coaster#Rollercoaster#Rollercoaster oc#Theme park ocs#Original character#Art#Oc

4 notes

·

View notes

Text

What’s the most effective way to troubleshoot heat transfer issues in a CSTR?

A Continuous Stirred Tank Reactor (CSTR) is a fundamental component in chemical process systems, widely used for liquid-phase reactions in industries such as pharmaceuticals, petrochemicals, and food processing.

While CSTRs offer several operational advantages, they also come with certain limitations. Understanding CSTR advantages and disadvantages is crucial when troubleshooting heat transfer issues, as efficient thermal management is essential for maintaining reaction rates, product quality, and process safety.

Understanding Heat Transfer in a CSTR

Heat transfer in a continuous stirred tank reactor is primarily managed through external or internal heat exchange mechanisms. The efficiency of heat transfer depends on various factors, including the reactor design, agitation efficiency, heat exchanger performance, and process conditions.

Heat Transfer Mechanisms in a CSTR

Jacketed Reactor Systems: In this setup, a heating or cooling jacket surrounds the reactor vessel, allowing heat exchange through conduction and convection.

Internal Coil Systems: Coils placed inside the reactor provide direct heat exchange with the reaction mixture.

External Heat Exchangers: Some CSTRs use external heat exchangers in circulation loops for improved temperature control.

Agitation and Mixing: Proper mixing enhances heat distribution and prevents localized temperature gradients.

Common Heat Transfer Issues in CSTRs

Several problems can hinder heat transfer efficiency in chemical process systems using CSTRs:

Inadequate Heat Exchange: Poor thermal contact between the heat transfer medium and the reactor contents can lead to inefficient temperature control.

Fouling and Scaling: The buildup of reaction byproducts on heat exchanger surfaces reduces heat transfer rates.

Improper Mixing: Insufficient agitation can create hotspots or cold zones within the reactor.

Fluid Maldistribution: Uneven flow of reactants and coolant leads to temperature variations.

Equipment Malfunction: Issues such as pump failures, sensor inaccuracies, and valve blockages can disrupt heat exchange.

Effective Troubleshooting Methods

1. Evaluating Heat Exchanger Performance

Inspect for Fouling: Regularly clean heat exchanger surfaces to remove deposits that reduce heat transfer efficiency.

Check Flow Rates: Ensure that both the heating/cooling medium and reactants flow at optimal rates for efficient heat exchange.

Monitor Heat Transfer Coefficients: Calculate and compare actual values against design specifications to identify degradation in performance.

2. Assessing Agitation and Mixing

Verify Stirrer Design and Speed: Ensure that the impeller type and speed promote uniform mixing.

Examine Baffle Placement: Baffles prevent vortex formation and improve circulation.

Check for Mechanical Wear: Worn-out agitators may not provide sufficient turbulence for effective heat distribution.

3. Temperature Control System Optimization

Calibrate Temperature Sensors: Inaccurate temperature readings can lead to incorrect heat adjustments.

Inspect Valves and Pumps: Faulty control elements can disrupt heat transfer fluid flow.

Implement Advanced Controls: PID controllers or model predictive control (MPC) systems enhance temperature regulation.

4. Managing Process Conditions

Optimize Feed Composition and Flow Rate: Sudden variations in reactant properties can affect heat demand.

Avoid Overloading the Reactor: Exceeding design capacity can cause temperature fluctuations.

Utilize Thermal Insulation: Prevent heat losses by insulating reactor walls and piping.

5. Computational and Experimental Analysis

Conduct Computational Fluid Dynamics (CFD) Simulations: Simulations provide insights into temperature gradients and flow patterns.

Perform Heat Balance Calculations: Comparing theoretical and actual heat loads can reveal inefficiencies.

Use Infrared Thermography: Identify temperature hotspots for targeted troubleshooting.

Conclusion

Efficient heat transfer is critical for optimal chemical process systems using a continuous stirred tank reactor. By understanding CSTR advantages and disadvantages, identifying potential heat transfer issues, and implementing systematic troubleshooting strategies, engineers can maintain stable reactor operation. Regular maintenance, advanced monitoring techniques, and process optimization play key roles in enhancing thermal performance and ensuring process efficiency.

0 notes

Text

Biogas Plant: A Sustainable Solution for Renewable Energy

Introduction

Biogas plants are emerging as a crucial solution in the renewable energy sector, helping to reduce reliance on fossil fuels and manage organic waste efficiently. They utilize biodegradable materials to produce biogas, a clean and sustainable energy source. This article explores the working principle, benefits, and potential of biogas plants in the global energy transition.

What is a Biogas Plant?

A biogas plant is a facility that processes organic waste materials, such as agricultural residues, food waste, and animal manure, through anaerobic digestion. This process produces biogas, primarily composed of methane (CH4) and carbon dioxide (CO2), which can be used for cooking, electricity generation, and vehicle fuel.

How Does a Biogas Plant Work?

The biogas production process consists of several stages:

Collection of Raw Materials: Organic waste is gathered from farms, households, and industries.

Anaerobic Digestion: Microorganisms break down the organic matter in an oxygen-free environment, producing biogas.

Gas Collection and Storage: The generated biogas is stored in gas holders.

Utilization: The biogas is used for energy generation, while the remaining digestate serves as a nutrient-rich fertilizer.

Benefits of Biogas Plants

1. Renewable Energy Source

Biogas is a sustainable alternative to fossil fuels, reducing greenhouse gas emissions and promoting clean energy.

2. Waste Management

Biogas plants help in the effective disposal of organic waste, reducing environmental pollution and landfill use.

3. Reduction in Greenhouse Gas Emissions

By capturing methane from organic waste, biogas plants prevent its release into the atmosphere, mitigating climate change.

4. Cost-Effective Energy Production

With minimal operational costs after installation, biogas plants provide an economical energy solution.

5. Organic Fertilizer Production

The by-product of biogas production, digestate, is a nutrient-rich fertilizer that enhances soil fertility and reduces the need for chemical fertilizers.

Types of Biogas Plants

Fixed-Dome Biogas Plants: A durable design with a dome-shaped gas holder, commonly used in rural areas.

Floating-Drum Biogas Plants: Features a movable drum that rises and falls based on gas production.

Continuous Stirred Tank Reactors (CSTRs): Used for large-scale industrial applications with constant mixing for efficiency.

Future of Biogas Technology

With increasing focus on sustainable energy, biogas technology is gaining traction worldwide. Governments and private entities are investing in biogas infrastructure to promote energy security and environmental sustainability. Innovations in biogas purification and storage are making it a viable alternative to conventional fuels.

Conclusion

Biogas plants represent a promising and sustainable solution to energy needs while addressing waste management challenges. Investing in biogas technology can contribute to environmental conservation, energy independence, and economic growth. As technology advances, biogas is set to play a pivotal role in the global transition to renewable energy.

#biogas generator#biogas plant#biogas power generation#chp combined heat and power#chp plant#cogeneration#combined heat and power#Biogas Treatment Solutions

0 notes

Text

Center Enamel: The Continuous Stirred Tank Reactor (CSTR) Process for Food Waste Biogas Projects

Center Enamel: The Continuous Stirred Tank Reactor (CSTR) Process for Food Waste Biogas Projects

As the world shifts toward more sustainable and circular solutions, food waste management has become an increasingly important challenge. The global food industry generates millions of tons of organic waste every year, much of which is discarded or incinerated, contributing to environmental pollution and waste of valuable resources. However, with the advent of modern waste-to-energy technologies, food waste can be transformed into a valuable resource — biogas.

One of the most efficient and widely used technologies for converting organic waste into biogas is the Continuous Stirred Tank Reactor (CSTR) process. At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we have harnessed this innovative technology to provide reliable, efficient, and environmentally responsible solutions for food waste biogas projects. Our expertise in CSTR systems enables us to help businesses and municipalities turn food waste into clean, renewable energy while reducing their environmental footprint.

What is the Continuous Stirred Tank Reactor (CSTR) Process?

The Continuous Stirred Tank Reactor (CSTR) process is a widely used anaerobic digestion technology in the production of biogas. In simple terms, CSTR is a type of biological reactor where organic materials, such as food waste, are broken down by microorganisms in an oxygen-free (anaerobic) environment. This process occurs in a well-mixed tank, where the organic waste is continuously fed into the system and stirred to ensure uniform contact with the microbial population.

Through the anaerobic digestion process, complex organic matter such as carbohydrates, proteins, and fats are converted into simpler compounds, producing biogas — primarily composed of methane (CH4) and carbon dioxide (CO2). The methane in the biogas can then be used for energy production, such as electricity generation, heating, or even as a fuel for vehicles, making it an excellent renewable energy source.

The CSTR process is ideal for food waste treatment because it can handle a wide range of feedstocks, including high-strength organic waste, and operates efficiently under continuous flow conditions. It is also highly flexible, allowing for the adjustment of operational parameters (such as temperature, pH, and retention time) to optimize the biogas production process.

Why Choose CSTR for Food Waste Biogas Projects?

Efficient Biogas Production: The CSTR process is highly effective at converting organic food waste into biogas. As food waste contains high levels of organic material, it is an ideal feedstock for anaerobic digestion. The continuous mixing and optimized conditions in a CSTR reactor enhance the breakdown of organic compounds, leading to higher biogas yields compared to other treatment methods.

Scalability and Flexibility: CSTR systems are highly scalable, making them suitable for small, medium, and large-scale food waste biogas projects. Whether it's a local food processing plant, a municipal waste facility, or a large-scale agricultural operation, the CSTR process can be tailored to meet the specific needs and capacity of the project. This flexibility makes it an attractive option for various food waste management applications.

Sustainability and Waste Reduction: Food waste is one of the most significant contributors to landfills worldwide, leading to the production of harmful methane gas. By adopting the CSTR process for food waste management, food producers, municipalities, and other stakeholders can significantly reduce the volume of waste sent to landfills. Furthermore, the biogas produced can be used to generate clean energy, reducing reliance on fossil fuels and lowering overall greenhouse gas emissions.

Nutrient-Rich Digestate as a By-Product: One of the key advantages of the CSTR process is the production of digestate, a nutrient-rich by-product that can be used as organic fertilizer. This digestate is an excellent soil conditioner, providing valuable nutrients such as nitrogen, phosphorus, and potassium. By recycling food waste into both biogas and digestate, the CSTR process closes the loop in the waste-to-resource cycle, contributing to a more sustainable and circular economy.

Reduced Environmental Impact: The anaerobic digestion process in a CSTR reactor is highly efficient, with minimal environmental impact. The closed-system design ensures that no harmful pollutants are released into the environment. Additionally, the biogas generated can be used to offset the energy needs of food waste treatment facilities, reducing overall energy consumption and making the entire process more sustainable.

Center Enamel’s Role in Food Waste Biogas Projects

At Center Enamel, we specialize in providing integrated solutions for food waste biogas projects using the CSTR process. Our expertise in designing, manufacturing, and installing advanced biogas systems allows us to offer customized solutions tailored to the specific needs of each project.

We integrate Glass-Fused-to-Steel (GFS) tanks in our biogas systems, which are ideal for use as digesters in the CSTR process. GFS tanks are known for their durability, corrosion resistance, and low maintenance needs, making them the perfect solution for long-term use in anaerobic digestion systems. The tanks provide a secure and reliable environment for the anaerobic digestion process, ensuring optimal performance and minimal downtime.

Key Benefits of Center Enamel’s CSTR-Based Biogas Systems:

Customized Design and Engineering: Our team works closely with clients to design and engineer a solution that meets their specific food waste management goals. We take into account factors such as feedstock type, volume, desired biogas yield, and energy production needs to deliver a highly efficient and cost-effective system.

End-to-End Project Execution: As an experienced EPC (Engineering, Procurement, and Construction) contractor, Center Enamel offers a comprehensive range of services from system design and equipment procurement to construction, installation, and ongoing support. Our full-service approach ensures a seamless project experience from start to finish.

Proven Technology and Expertise: We use cutting-edge technologies and proven processes to deliver high-performance food waste biogas systems. Our experience in anaerobic digestion and biogas production allows us to provide solutions that maximize biogas yields, reduce operating costs, and ensure environmental compliance.

Sustainable Solutions for Food Waste Management: By implementing CSTR-based biogas systems, we help food manufacturers and municipalities turn food waste into valuable renewable energy. This not only supports sustainability goals but also generates economic value by producing biogas for on-site energy use or sale.

Successful Food Waste Biogas Projects by Center Enamel

Center Enamel has successfully implemented a number of food waste biogas projects across various industries, from food processing plants to municipal waste treatment facilities. Our projects have helped clients reduce waste, generate clean energy, and create a more sustainable waste management cycle.

For example, we recently completed a food waste-to-energy project for a large-scale food processing facility in Jiangsu Province. The facility, which processes large quantities of organic waste daily, is now able to convert that waste into biogas using the CSTR process. This project has not only helped the facility meet its sustainability goals but has also significantly reduced its operational costs by providing a reliable, renewable energy source.

Partner with Center Enamel for Your Food Waste Biogas Project

The CSTR process offers an efficient, sustainable, and scalable solution for food waste biogas projects. At Center Enamel, we bring decades of expertise in anaerobic digestion and biogas technology to help clients turn organic food waste into a valuable resource. Whether you are a food processor, municipality, or energy provider, our CSTR-based systems provide the perfect solution for waste-to-energy projects.

Partner with Center Enamel to transform food waste into renewable energy and contribute to a more sustainable future.

Contact us today to learn more about our food waste biogas solutions and how we can help you achieve your sustainability and energy goals.

0 notes

Text

Types of Food Waste Biogas Plants: Which One is Right for You?

With the growing focus on sustainable energy solutions, food waste biogas plants have gained popularity as an eco-friendly way to manage waste and generate renewable energy. These plants convert food waste into biogas, which can be used for cooking, electricity generation, or even as vehicle fuel. However, choosing the right type of food waste biogas plant depends on factors such as scale, budget, and intended use. In this article, we explore different types of food waste biogas plants and help you determine which one suits your needs.

Fixed-Dome Biogas Plants Fixed-dome biogas plants are one of the most common types used for food waste digestion. These plants consist of a digester with a fixed, non-movable dome where biogas is stored. Pros: Long lifespan with minimal maintenance Suitable for domestic and small-scale applications Cost-effective in the long run Cons: Higher initial construction cost Requires skilled labor for installation

Floating-Dome Biogas Plants In a floating-dome system, the gas holder moves up and down depending on the volume of gas produced. This type is often used for small to medium-scale applications. Pros: Easy to monitor gas production Lower risk of gas leakage Simpler to construct than fixed-dome models Cons: Requires regular maintenance More prone to damage due to moving parts

Balloon (Bag) Biogas Plants Balloon or bag biogas plants use a flexible digester made of plastic or rubber, where food waste is decomposed to produce biogas. These plants are often used for temporary or mobile applications. Pros: Low-cost and easy to install Portable and flexible in operation Suitable for small-scale and emergency applications Cons: Shorter lifespan compared to rigid structures Susceptible to damage from environmental factors

Continuous Stirred Tank Reactor (CSTR) Biogas Plants CSTR biogas plants use a mechanized stirring system to ensure uniform mixing of food waste inside the digester, improving efficiency. Pros: High efficiency in gas production Ideal for industrial and large-scale applications Can handle a variety of feedstocks Cons: High initial investment Requires regular maintenance and monitoring

Plug Flow Biogas Plants Plug flow digesters are elongated tanks where waste moves through in a linear manner, reducing the need for mechanical mixing. Pros: Simple design with fewer mechanical parts Suitable for high-solid content food waste Efficient biogas production Cons: Requires constant feeding for optimal performance Not suitable for very liquid waste streams Choosing the Right Biogas Plant for You Selecting the right food waste biogas plant depends on multiple factors: For households and small businesses: Fixed-dome, floating-dome, or balloon biogas plants are cost-effective and easy to manage. For commercial or industrial use: CSTR or plug flow biogas plants offer higher efficiency and better scalability. For temporary or mobile needs: Balloon biogas plants are the best option due to their portability. By understanding the different types of food waste biogas plants, you can choose the one that aligns with your energy needs and waste management goals. Investing in the right biogas system not only helps reduce environmental impact but also provides a sustainable source of energy for the future.

0 notes

Photo

Shepherd Hardware Cup CSTR 1-7 / 8SQ WAL CD4

New in original factory package or box.Box or package may not be in the best condition. Have Question Just Ask?

Listing and template services provided by inkFrog

0 notes

Text

Puzzlement #325

There were 3 responses to Puzzlement #324, only 2 had the correct answer, but the first one, submitted by David Eagle was: 180 feet. Greg McGuire was second.

On to the puzzle:

The two following quotes are from Mark Twain. Both quotes use the same code.

"YX WIN ASOO AZS ACNAZ WIN RIK'A ZTBS AI CSPSPESC TKWAZYKL."

"AZS PTK UZI RISDK'A CSTR LIIR EIIGD ZTD KI TRBTKATLS IBSC AZS PTK UZI FTK'A CSTR AZSP."

To submit an answer, send it to [email protected]

0 notes

Text

Why the Flow Chemistry Market Is Gaining Traction in Pharmaceutical Manufacturing

The global flow chemistry market was valued at USD 1.76 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 11.6% from 2024 to 2030. Several factors are driving this growth, including a rising awareness surrounding sustainable development and the increasing demand from the pharmaceutical and chemical industries. As industries look for more efficient and environmentally friendly production methods, flow chemistry is emerging as a key solution to address these needs. Additionally, advancements in flow chemistry technologies and the growing importance of fine and specialized chemicals are contributing to the market's expansion.

However, the flow chemistry market faced some setbacks during the COVID-19 pandemic. The pandemic led to an oil price collapse, which in turn reduced the cost advantages for chemical companies that depend on feedstocks derived from petroleum. This decline in feedstock availability had a ripple effect, leading to decreased demand for reactors—one of the major drivers of revenue within the chemical industry. The effects were particularly noticeable in the petrochemical and pharmaceutical sectors, where the demand for flow reactors slowed down, negatively impacting overall market growth during this period.

Despite these challenges, the future outlook for the flow chemistry market remains positive, driven by several key factors. The adoption of flow reactors offers numerous benefits, such as smaller equipment sizes, reduced waste generation, lower operational costs, and faster time-to-market for new pharmaceuticals.

Gather more insights about the market drivers, restrains and growth of the Flow Chemistry Market

Reactor Type Insights

The flow chemistry market is segmented by reactor type, with several different types of reactors used in industrial applications. The continuous stirred tank reactor (CSTR) segment led the market in 2023, accounting for over 36.4% of global revenue. CSTRs are widely adopted due to their simple construction, excellent temperature control capabilities, low cost, and adaptability to two-phase runs. These factors make CSTRs ideal for a range of applications, including chemical production, water treatment, and wastewater processing. As industries continue to focus on optimizing their manufacturing processes, the demand for CSTRs is expected to grow, further solidifying their dominant position in the market.

Additionally, CSTRs are increasingly being used in water and wastewater applications, which is expected to boost their adoption in environmental and waste treatment sectors. The ability of CSTRs to efficiently handle continuous flows of reactants makes them particularly well-suited for large-scale chemical production and treatment processes.

Another important reactor type is the plug flow reactor (PFR), also known as a tubular reactor. PFRs are frequently used for gas-phase reactions and are valued for their absence of moving parts, which reduces maintenance requirements and lowers overall production costs. The simple mechanism of PFRs and their ability to deliver a high conversion rate per reactor volume make them an attractive option for chemical manufacturers looking to increase efficiency and reduce operational expenses. Given these advantages, demand for PFRs is expected to grow over the forecast period.

The microreactor segment, which is a newer innovation in flow chemistry, is also expected to experience significant growth in the coming years. Microreactors are valued for their small size, low capital investment requirements, and ability to safely handle highly reactive and hazardous chemicals. These features make microreactors particularly attractive to pharmaceutical companies and fine chemicals producers who need to scale up reactions efficiently while minimizing risk and maintaining safety standards.

Microreactors are increasingly being used for the production of pharmaceuticals, where precise control over reaction conditions is crucial. Their compact size and ability to scale up quickly make them ideal for laboratories and small-scale production runs. As the demand for customized drugs and fine chemicals grows, the adoption of microreactors in pharmaceutical applications is expected to accelerate.

Another innovation in flow chemistry is microwave-assisted organic synthesis (MAOS), which has seen growing attention in recent years. Microwave-assisted reactors provide fast reaction rates, lower byproduct formation, higher product yields, and greater purity. These reactors have been especially useful in academic and laboratory settings, where fast reaction times and ease of scale-up are important. While microwave-assisted continuous reactors are still limited by size constraints, advancements in this area are expected to drive their adoption in more commercial applications in the future.

Order a free sample PDF of the Flow Chemistry Market Intelligence Study, published by Grand View Research.

#Flow Chemistry Market#Flow Chemistry Market Report#Flow Chemistry Market Analysis#Flow Chemistry Industry

0 notes

Text

Flow Chemistry Market Size and Share Analysis: Key Growth Trends and Projections

Global Flow Chemistry Market Report

The Flow Chemistry Market research report offers an in-depth analysis of market dynamics, competitive landscapes, and regional growth patterns. This comprehensive report provides businesses with the strategic insights necessary to identify growth opportunities, manage risks, and develop effective competitive strategies in an ever-evolving market.

According to Straits Research, the global Flow Chemistry Market market size was valued at USD 1.43 Billion in 2021. It is projected to reach from USD XX Billion in 2022 to USD 3.73 Billion by 2030, growing at a CAGR of 11.24% during the forecast period (2022–2030).

Request a Sample Report Today @ https://straitsresearch.com/report/flow-chemistry-market/request-sample

Global Flow Chemistry Market Segmental Analysis

As a result of the Flow Chemistry market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Reactor Type

Continuous Stirred Tank Reactor (CSTR)

Plug Flow Reactor (PFR)

Microreactor

Microwave Systems

Others

By Application

Pharmaceutical

Biotechnology Companies

Chemicals

Academia and Research

Food And Beverage Industries

Petrochemicals

Agriculture And Environmental Sector

Nutraceutical Firms

Analytical Laboratories

Others

By Technology

Gas-Based Flow Chemistry

Photochemistry-Based Flow Chemistry

Microwave Irradiation Based Flow Chemistry

You can check In-depth Segmentation from here:

Why Invest in this Report?

Leverage Data for Strategic Decision-Making: Utilize detailed market data to make informed business decisions and uncover new opportunities for growth and innovation.

Craft Expansion Strategies for Diverse Markets: Develop effective expansion strategies tailored to various market segments, ensuring comprehensive coverage and targeted growth.

Conduct Comprehensive Competitor Analysis: Perform in-depth analyses of competitors to understand their market positioning, strategies, and operational strengths and weaknesses.

Gain Insight into Competitors' Financial Metrics: Acquire detailed insights into competitors' financial performance, including sales, revenue, and profitability metrics.

Benchmark Against Key Competitors: Use benchmarking to compare your business's performance against leading competitors, identifying areas for improvement and potential competitive advantages.

Formulate Region-Specific Growth Strategies: Develop geographically tailored strategies to capitalize on local market conditions and consumer preferences, driving targeted business growth in key regions.

List of Top Leading Players of the Flow Chemistry Market -

Biotage

Lonza

Corning Incorporated

Vapourtec Ltd

Syrris Ltd.

Chemtrix BV

CEM Corporation

Uniqsis Ltd.

Milestone Srl.

Reasons to Purchase This Report:

Access to Comprehensive Information: Gain access to an extensive collection of analysis, research, and data that would be challenging to acquire independently. This report offers valuable insights, saving you considerable time and effort.

Enhanced Decision-Making: Equip yourself with detailed insights into market trends, consumer behavior, and key industry factors. This report provides essential information for strategic planning, including decisions on investments, product development, and marketing strategies.

Achieving Competitive Advantage: Stay ahead in your industry by understanding market dynamics and competitor strategies. This report delivers deep insights into competitor performance and market trends, enabling you to craft effective business strategies and maintain a competitive edge.

Credibility and Reliability: Trust in the expertise of industry professionals and the accuracy of thoroughly researched data. Authored by experts and grounded in rigorous research and analysis, this report enhances credibility and reliability.

Cost-Effective Research: Reduce research expenses by investing in this comprehensive report instead of conducting independent research. It provides a cost-effective means of accessing detailed analysis and insights on a specific topic without requiring extensive resources.

Regional Analysis Flow Chemistry Market

The regional analysis section of the report offers a thorough examination of the global Flow Chemistry market, detailing the sales growth of various regional and country-level markets. It includes precise volume analysis by country and market size analysis by region for both past and future periods. The report provides an in-depth evaluation of the growth trends and other factors impacting the Flow Chemistry market in key countries, such as the United States, Canada, Mexico, Germany, France, the United Kingdom, Russia, Italy, China, Japan, Korea, India, Southeast Asia, Australia, Brazil, and Saudi Arabia. Moreover, it explores the progress of significant regional markets, including North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

To Understand How Covid-19 Impact Is Covered in This Report - https://straitsresearch.com/buy-now/flow-chemistry-market

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Flow Chemistry Market#Flow Chemistry Market Share#Flow Chemistry Market Size#Flow Chemistry Market Research#Flow Chemistry Industry#What is Flow Chemistry?

0 notes

Text

Maximizing Yield and Efficiency: How a CSTR Optimizes Chemical Processes

In the ever-evolving field of chemical engineering, the quest for efficiency and maximum yield is relentless. Among the myriad technologies utilized to achieve these goals, the Continuous Stirred Tank Reactor (CSTR) stands out as a pivotal component of modern chemical process systems. Additionally, the integration of solvent recovery in extraction processes enhances sustainability and cost-effectiveness, making it a cornerstone of industrial chemical practices. This article explores how CSTRs contribute to optimizing chemical processes, delving into their operational principles, advantages, and applications.

Understanding the Continuous Stirred Tank Reactor (CSTR)

A Continuous Stirred Tank Reactor (CSTR) is a type of reactor commonly used in industrial chemical processes. It operates continuously, with reactants entering the reactor and products exiting simultaneously. This ensures a steady-state operation, maintaining consistent conditions for chemical reactions.

Key Features of CSTRs:

Uniform Mixing: The reactor’s stirring mechanism ensures homogenous mixing of reactants, leading to uniform reaction conditions.

Temperature Control: CSTRs often include advanced temperature regulation systems to maintain optimal reaction temperatures.

Continuous Operation: Unlike batch reactors, CSTRs allow for uninterrupted production, increasing throughput.

Scalability: They can be scaled up or down, catering to different production capacities.

The design of a CSTR is particularly advantageous for reactions requiring precise control over temperature, pressure, and mixing. Industries ranging from pharmaceuticals to petrochemicals rely on these reactors to achieve high efficiency and consistent product quality.

The Role of CSTRs in Chemical Process Systems

Chemical process systems encompass a wide range of operations, including reaction, separation, and purification processes. The integration of CSTRs within these systems significantly enhances their performance.

Improved Reaction Kinetics By maintaining uniform mixing and consistent temperature, CSTRs optimize reaction kinetics. This results in higher conversion rates and better yield. For example, in polymerization reactions, where precise control of reaction conditions is crucial, CSTRs ensure the production of polymers with desired molecular weights and properties.

Enhanced Scalability CSTRs are designed to handle varying production scales. Their modular nature allows easy integration into existing chemical process systems, making them a versatile choice for industries.

Integration with Downstream Processes In chemical manufacturing, the products exiting a CSTR often require further processing. CSTRs facilitate seamless integration with downstream operations like distillation, crystallization, and filtration, streamlining the overall process.

Solvent Recovery in Extraction Processes

The concept of solvent recovery in extraction processes is gaining traction as industries prioritize sustainability and cost-efficiency. In chemical production, solvents play a vital role in extracting valuable compounds from raw materials. However, the cost and environmental impact of solvent usage necessitate efficient recovery systems.

How CSTRs Enhance Solvent Recovery:

Efficient Mixing: CSTRs provide thorough mixing, ensuring maximum contact between the solvent and the material being extracted.

Controlled Conditions: By maintaining optimal temperature and pressure, CSTRs improve the efficiency of the extraction process, reducing solvent loss.

Continuous Operation: The continuous nature of CSTRs allows for simultaneous extraction and recovery, minimizing downtime and increasing productivity.

Applications of Solvent Recovery:

Pharmaceutical Industry: Recovery of organic solvents used in drug formulation.

Food Processing: Extraction of flavors and fragrances.

Chemical Manufacturing: Recycling solvents used in synthesis and purification.

Advantages of Using CSTRs

The versatility of CSTRs makes them indispensable in modern chemical engineering. Here are some of their key advantages:

Cost Efficiency: CSTRs reduce operational costs by enabling continuous production, minimizing downtime, and enhancing energy efficiency.

High Yield: By maintaining optimal reaction conditions, CSTRs maximize product yield, ensuring economic viability.

Flexibility: They can accommodate a wide range of reactions, from exothermic to endothermic, making them suitable for diverse industries.

Environmental Benefits: Integration with solvent recovery in extraction processes minimizes waste and promotes recycling, aligning with green chemistry principles.

Challenges and Solutions in CSTR Operation

While CSTRs offer numerous advantages, their operation is not without challenges. Common issues include:

Fouling and Scaling: Over time, the reactor walls may accumulate deposits, affecting heat transfer and mixing efficiency. Regular cleaning and maintenance can mitigate this issue.

Control Complexity: Maintaining consistent reaction conditions requires sophisticated control systems. Advances in automation and real-time monitoring have addressed this challenge.

Energy Consumption: Continuous operation demands significant energy input. However, innovations like heat integration and energy recovery systems have improved the energy efficiency of CSTRs.

Case Studies: Real-World Applications

1. Pharmaceutical Industry: In the production of active pharmaceutical ingredients (APIs), CSTRs enable precise control over reaction conditions, ensuring consistent product quality. Additionally, integrating solvent recovery in extraction processes reduces production costs and environmental impact.

2. Petrochemical Industry: CSTRs are extensively used in refining processes, such as hydrocracking and catalytic reforming. Their ability to handle high-pressure reactions makes them ideal for these applications.

3. Food and Beverage Industry: From flavor extraction to fermentation, CSTRs play a crucial role in enhancing efficiency and product quality. The use of solvent recovery systems further ensures sustainability.

Future Trends in CSTR Technology

The future of Continuous Stirred Tank Reactors lies in innovation and integration with advanced technologies. Emerging trends include:

Smart Reactors: Integration with IoT and AI for real-time monitoring and optimization of reaction conditions.

Advanced Materials: The use of corrosion-resistant and thermally stable materials to enhance reactor longevity and performance.

Hybrid Systems: Combining CSTRs with other reactor types, such as plug flow reactors, to leverage the advantages of both.

Conclusion

The Continuous Stirred Tank Reactor (CSTR) is a cornerstone of modern chemical process systems, offering unparalleled efficiency and versatility. By integrating solvent recovery in extraction processes, industries can achieve sustainable and cost-effective operations. As technology advances, the role of CSTRs in optimizing chemical processes will only grow, paving the way for a more efficient and sustainable future in chemical engineering.

0 notes

Text

Chemical Processing: A Comprehensive Guide

Chemical processing plays a crucial role in various industries, transforming raw materials into valuable products that drive modern society. This comprehensive guide delves into the fundamentals, techniques, equipment, safety measures, and modern advancements in chemical processing, providing a detailed overview for students, professionals, and enthusiasts alike.

Introduction

Chemical processing involves the conversion of raw materials into finished products through chemical reactions, physical changes, or a combination of both. It encompasses a wide range of industries, from pharmaceuticals and petrochemicals to food processing and materials manufacturing. The evolution of chemical processing over the past century has significantly impacted industrial development, contributing to innovations that shape our daily lives.

1. Fundamentals of Chemical Processing

What is Chemical Processing? Chemical processing refers to the application of chemical reactions and physical processes to convert raw materials into useful products. It can involve altering the chemical structure of substances, separating mixtures into their components, or enhancing the properties of materials.

Types of Chemical Processes

Physical Processes: These involve physical changes without altering the chemical composition, such as distillation, filtration, and crystallization.

Chemical Reactions: These involve changing the chemical structure of substances through processes like oxidation, reduction, polymerization, and synthesis.

Chemical Process Industries Chemical processing is integral to industries like oil and gas, pharmaceuticals, agrochemicals, food processing, and materials manufacturing. Each sector has unique requirements and challenges that shape its chemical processing methods.

Chemical Processing Principles

Mass and Energy Balance: A fundamental principle in chemical processing is the conservation of mass and energy, ensuring that the inputs and outputs of a process are accounted for.

Thermodynamics: Understanding energy changes and equilibrium conditions is crucial for designing efficient chemical processes.

Kinetics: Reaction rates and mechanisms guide the design of reactors and influence process efficiency.

2. Key Chemical Processing Techniques

Separation Processes

Distillation: A method used to separate components based on differences in boiling points. Fractional distillation is common in petrochemical industries for refining crude oil.

Filtration: Utilizes physical barriers to separate solids from liquids or gases. Types include gravity filtration, vacuum filtration, and ultrafiltration.

Extraction: Involves transferring a substance from one phase to another, such as liquid-liquid extraction for separating compounds based on solubility.

Chemical Reaction Processes

Catalysis: Catalysts speed up chemical reactions without being consumed. Homogeneous and heterogeneous catalysis are widely used in industrial chemical processes.

Reactors: Vessels designed to carry out chemical reactions efficiently. Batch reactors, continuous stirred-tank reactors (CSTR), and plug flow reactors (PFR) are common types.

Mixing and Blending Proper mixing ensures uniformity in product composition and enhances reaction rates. Industrial mixers range from simple agitators to complex static mixers designed for specific applications.

Heat Transfer Processes Heat transfer is crucial in controlling reaction rates and separation efficiency. Heat exchangers, such as shell-and-tube and plate heat exchangers, facilitate temperature control in chemical processes.

Mass Transfer Processes

Absorption: A gas is dissolved into a liquid, often used for gas purification.

Adsorption: Molecules adhere to a solid surface, useful in applications like water treatment and air purification.

3. Chemical Processing Equipment

Reactors Reactors are the heart of chemical processing. They come in various designs, such as batch reactors for small-scale operations and continuous reactors for large-scale production. Reactor design considers factors like temperature, pressure, mixing, and residence time.

Heat Exchangers Heat exchangers transfer heat between two fluids without mixing them. They are essential for maintaining optimal temperatures in reactors and separation processes.

Distillation Columns These columns separate mixtures based on boiling points through multiple stages of vaporization and condensation. Fractionating columns are commonly used in oil refineries to produce gasoline, diesel, and other products.

Filters and Centrifuges Filters separate solids from liquids or gases, while centrifuges use centrifugal force for rapid separation, essential in industries like pharmaceuticals and food processing.

Mixers and Blenders Mixers ensure uniform distribution of reactants, while blenders are used for homogenizing mixtures. Proper mixing enhances reaction efficiency and product consistency.

Pumps and Compressors Pumps transport liquids, and compressors move gases within processing plants. Their selection depends on fluid properties, flow rates, and system requirements.

4. Process Control and Automation

Importance of Process Control Process control ensures the safety, efficiency, and quality of chemical processing. It involves monitoring and adjusting process variables like temperature, pressure, flow, and concentration.

Automation in Chemical Processing Modern chemical plants use automation to enhance process control. Distributed Control Systems (DCS) and Programmable Logic Controllers (PLCs) automate complex processes, reducing human intervention and errors.

Process Control Strategies

PID Control: Proportional-Integral-Derivative (PID) control is a fundamental strategy for maintaining process variables at desired levels.

Advanced Control: Techniques like model predictive control (MPC) use mathematical models to predict future process behavior, enabling proactive adjustments.

Process Analytical Technology (PAT) PAT involves real-time monitoring and control of processes to ensure consistent product quality. Techniques like spectroscopy and chromatography provide instant feedback for process optimization.

5. Safety in Chemical Processing

Chemical Process Safety Safety is paramount in chemical processing due to the risks of chemical exposure, fires, explosions, and toxic releases. Proper safety measures protect workers, the environment, and the public.

Safety Management Systems

Process Safety Management (PSM): A systematic approach to identifying, evaluating, and controlling process hazards.

Hazard and Operability Study (HAZOP): A structured method for identifying potential hazards and operational issues in chemical processes.

Personal Protective Equipment (PPE) PPE, including gloves, goggles, and respirators, protects workers from chemical hazards. Proper training and adherence to safety protocols are essential.

Emergency Response and Risk Management Emergency response plans address potential incidents like chemical spills, fires, and explosions. Regular safety drills and risk assessments minimize the impact of accidents.

6. Environmental Considerations and Sustainability

Environmental Impact of Chemical Processing Chemical processing can generate waste, emissions, and pollutants. Managing these by-products is crucial to minimizing environmental impact and complying with regulations.

Sustainable Chemical Processing Green chemistry principles focus on reducing the use of hazardous substances, minimizing waste, and improving energy efficiency. Sustainable practices benefit the environment and enhance economic viability.

Waste Treatment and Recycling Waste treatment techniques include neutralization, incineration, and biological treatment. Recycling and reuse of by-products reduce the environmental footprint of chemical processes.

7. Modern Advancements in Chemical Processing

Digital Transformation and Industry 4.0 The integration of IoT, AI, and Big Data enables real-time monitoring, predictive maintenance, and process optimization. Smart sensors and advanced analytics enhance decision-making and efficiency.

Advanced Reactor Technologies Microreactors offer precise control over reaction conditions, enabling safer and more efficient processes. Modular processing units allow flexibility and scalability in chemical production.

Novel Separation Technologies Membrane separation and supercritical fluid extraction provide energy-efficient alternatives to traditional separation methods, improving purity and reducing environmental impact.

Bioprocessing and Biotechnology Bioprocessing uses biological organisms or enzymes to carry out chemical transformations. It has applications in pharmaceuticals, biofuels, and food production.

8. Chemical Processing and Quality Assurance

Quality Control in Chemical Manufacturing Analytical techniques like spectroscopy and chromatography ensure product quality and compliance with specifications. Continuous monitoring detects deviations and maintains consistency.

Regulatory Standards and Compliance Chemical processing must adhere to regulations set by bodies like the FDA, EPA, and OSHA. Compliance ensures product safety, environmental protection, and worker safety.

Quality Assurance Practices

Good Manufacturing Practice (GMP): A set of guidelines ensuring products are consistently produced and controlled to quality standards.

Standard Operating Procedures (SOPs): Detailed instructions for performing tasks to ensure consistency and compliance.

9. Challenges and Future Trends in Chemical Processing

Current Challenges

Process Safety: Preventing accidents and minimizing risks in complex chemical processes.

Environmental Compliance: Reducing emissions and waste to meet regulatory requirements.

Future Trends

Sustainable Processing: Development of green chemical processes that minimize environmental impact.

AI and Machine Learning: Advanced algorithms for process optimization, predictive maintenance, and quality control.

Opportunities for Innovation New catalysts, energy-efficient processes, and alternative feedstocks offer potential for enhancing chemical processing efficiency and sustainability.

10. Case Studies and Applications

Case Study 1: Pharmaceutical Industry Chemical processing in pharmaceuticals involves precise control of reactions and separations to produce high-purity drugs. Continuous manufacturing and PAT enhance product quality and efficiency.

Case Study 2: Petrochemical Industry Crude oil refining uses complex separation and reaction processes to produce fuels, lubricants, and chemicals. Innovations in catalytic cracking and distillation improve yields and reduce environmental impact.

Case Study 3: Food and Beverage Processing Chemical processing in the food industry includes extraction, purification, and preservation of food products. Ensuring safety and compliance with food regulations is paramount.

Conclusion

Chemical processing is a dynamic field that continues to evolve with advancements in technology, safety practices, and sustainability. Its impact on various industries underscores its importance in modern society. By embracing new technologies and sustainable practices, the chemical processing industry can address current challenges and pave the way for a safer and more sustainable future.

0 notes

Text

Livestock Wastewater Treatment Project: Center Enamel’s Sustainable Solutions for a Cleaner Future

Livestock Wastewater Treatment Project: Center Enamel’s Sustainable Solutions for a Cleaner Future

In the face of growing global environmental concerns, effective wastewater management is critical, particularly in the agricultural and livestock sectors. Livestock wastewater, which is often rich in organic matter, nutrients, and pathogens, presents significant challenges in treatment. At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we specialize in providing innovative, sustainable, and cost-effective solutions for livestock wastewater treatment. Our expertise in engineering, procurement, and construction (EPC) ensures that livestock operations can manage wastewater efficiently while reducing their environmental footprint.

The Importance of Livestock Wastewater Treatment

Livestock farming operations produce large volumes of wastewater, often containing harmful organic compounds, nutrients like nitrogen and phosphorus, and high levels of Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD). If left untreated, this wastewater can contaminate local water sources, harm aquatic ecosystems, and contribute to greenhouse gas emissions. In response to this challenge, livestock wastewater treatment becomes essential to protect the environment, ensure compliance with regulations, and recover valuable resources.

At Center Enamel, we offer a range of advanced treatment technologies tailored to meet the unique needs of livestock operations, enabling sustainable wastewater management while minimizing the environmental impact.

Center Enamel’s Comprehensive Livestock Wastewater Treatment Solutions

As a leader in environmental engineering, Center Enamel provides EPC solutions that encompass every aspect of the wastewater treatment process—from engineering design and equipment supply to installation and post-project support. Our turnkey solutions ensure that livestock wastewater is treated efficiently, cost-effectively, and in an environmentally responsible manner.

1. Anaerobic Treatment Systems for Livestock Wastewater

One of the key technologies we employ in livestock wastewater treatment is anaerobic digestion. Anaerobic systems, such as the Upflow Anaerobic Sludge Blanket (UASB) and Continuous Stirred-Tank Reactor (CSTR), provide an efficient means of treating organic waste by using microorganisms to break down organic matter in the absence of oxygen. This process not only removes harmful pollutants but also produces biogas, which can be used for energy generation, contributing to sustainability goals and reducing operational costs.

2. Biogas Recovery for Renewable Energy

A major benefit of anaerobic digestion is biogas recovery. The methane produced during the treatment of livestock wastewater can be harnessed and used for power generation or heating, reducing dependency on traditional fossil fuels and supporting the circular economy. By converting waste into renewable energy, Center Enamel’s solutions not only help livestock farms become more energy-efficient but also lower their overall environmental impact.

3. Modular and Scalable Systems

Every livestock operation is unique, with varying wastewater volumes and treatment needs. Our modular wastewater treatment systems are highly adaptable, allowing us to design scalable solutions that fit any facility size, from small farms to large industrial operations. Whether upgrading an existing system or implementing a new facility, our solutions are flexible and customizable to ensure optimal performance and cost-efficiency.

4. Sustainable Wastewater Treatment Practices

Our EPC solutions focus on sustainable practices, ensuring that livestock wastewater treatment is efficient, eco-friendly, and compliant with local environmental regulations. By incorporating advanced filtration technologies, nutrient removal systems, and sludge management techniques, we help farms reduce the environmental impact of their wastewater and enhance water reuse potential.

5. Comprehensive Support and Maintenance

At Center Enamel, we provide comprehensive after-sales support, including maintenance services, system monitoring, and training programs. Our team ensures that all systems continue to operate efficiently and meet regulatory standards, allowing our clients to focus on their core business operations with peace of mind.

The Benefits of Livestock Wastewater Treatment with Center Enamel

Center Enamel’s livestock wastewater treatment solutions offer a wide range of benefits for the agriculture industry, including:

Improved Environmental Compliance: Our systems help livestock operations meet strict environmental regulations by reducing the pollutants and contaminants in wastewater.

Renewable Energy Production: By converting waste into biogas, our solutions enable livestock farms to produce renewable energy, reducing energy costs and promoting sustainability.

Cost-Effective Waste Management: Our systems minimize the need for external waste disposal, lowering operational expenses and improving the overall financial performance of the facility.

Enhanced Resource Recovery: Beyond wastewater treatment, our solutions provide opportunities to recover valuable resources like compost and biogas, supporting the circular economy.

Scalable and Flexible Solutions: Our customizable designs ensure that wastewater treatment systems are tailored to meet the specific needs of any livestock facility, regardless of size or complexity.

Successful Livestock Wastewater Treatment Projects by Center Enamel

With over 30 years of experience in the field, Center Enamel has successfully completed numerous livestock wastewater treatment projects across China and around the world. Some of our recent projects include:

Large-Scale Dairy Farm Projects: Implementing biogas recovery systems and anaerobic digestion technologies to treat wastewater, produce renewable energy, and reduce environmental impact.

Poultry Farm Wastewater Management: Designing modular treatment systems that effectively treat wastewater while enabling water recycling and biogas recovery.

Hog Farming Operations: Installing advanced anaerobic treatment systems to manage high-strength wastewater and convert organic waste into valuable renewable energy.

Effective livestock wastewater treatment is essential for achieving sustainability, regulatory compliance, and economic efficiency in the agricultural industry. Center Enamel is proud to be a leader in providing EPC solutions for livestock wastewater treatment projects, offering advanced technologies that maximize resource recovery, reduce environmental impact, and support the circular economy.

Our turnkey solutions are designed to help livestock operations improve operational efficiency, generate renewable energy, and contribute to a cleaner, greener future.

Contact Center Enamel Today

Discover how our livestock wastewater treatment solutions can help your operation achieve sustainability goals, reduce costs, and improve resource management. Reach out to our expert team for customized solutions tailored to your specific needs.

0 notes

Text

ES Ranganathan on Biogas: A Paradigm Shift in India's Energy Sector

The Delhi Milk Scheme Biogas Plant serves as a great example. It converts dairy waste into biogas, solving waste disposal issues and cutting energy costs for dairy operations," explained ES Ranganathan. "This plant demonstrates how biogas technology can effectively manage waste and provide energy in urban areas."

"In recent years, biogas plant technology has advanced significantly. New anaerobic digesters like continuous stirred-tank reactors (CSTRs) and plug-flow digesters have boosted biogas production efficiency. These digesters break down organic matter more effectively, yielding more biogas per unit of input."

"Moreover, using pre-treatment techniques such as mechanical sorting and enzymatic hydrolysis has sped up the decomposition process. This makes biogas production more efficient and cost-effective, showing promise in meeting India's energy needs while lessening environmental impact.

Read More

0 notes

Text

Essential Equipment and Technology for Efficient Biogas Plant Operations

Introduction

Biogas plants are integral to advancing sustainable energy solutions, transforming organic waste into renewable energy and reducing environmental impact. At Gruner Renewable, we understand the importance of integrating the right equipment and technology to ensure efficient and effective biogas plant operations. This article explores the crucial components and innovative technologies necessary for running a successful

Setup a Biogas Plant, highlighting our commitment to providing environmentally friendly energy solutions that meet our customers' sustainability goals.

Key Equipment for Biogas Plants

Feedstock Pre-treatment Units

Efficient biogas production starts with effective feedstock preparation. Pre-treatment units such as shredders, mixers, and hydrolysis tanks are essential for breaking down complex organic materials into simpler forms, enhancing the anaerobic digestion process. Gruner Renewable utilizes state-of-the-art pre-treatment technologies to ensure that the feedstock is optimally prepared for maximum biogas yield.

Anaerobic Digesters

The heart of any biogas plant is the anaerobic digester, where the biological process of methane production occurs. These digesters are designed to maintain the ideal conditions for microbial activity, including optimal temperature, pH, and anaerobic conditions. Gruner Renewable offers a range of digester designs, from continuously stirred tank reactors (CSTR) to plug flow digesters, tailored to different types of feedstock and operational scales.

Heating and Mixing Systems

Maintaining a consistent temperature and homogeneous mixture inside the digester is crucial for the efficiency of the biogas process. Gruner Renewable equips its plants with automated heating systems and mechanical or hydraulic mixers that ensure the digestate remains in the optimal state for gas production throughout the digestion cycle.

Advanced Technologies Enhancing Efficiency

Biogas Upgrading Systems

To transform raw biogas into high-quality bio-CNG suitable for commercial use, upgrading systems are necessary. These systems remove impurities such as hydrogen sulfide, moisture, and carbon dioxide. Gruner Renewable incorporates advanced technologies such as water scrubbing, pressure swing adsorption, or membrane separation to produce clean and compressed biogas that meets regulatory standards for various applications.

Gas Storage Solutions

Efficient gas storage is vital for managing the supply and demand of biogas energy. Gruner Renewable utilizes high-pressure cylinders and gas holders designed to safely store bio-CNG until needed, minimizing energy losses and maximizing the utility of produced biogas.

Control and Monitoring Systems

Modern Setup a Biogas Plant are equipped with sophisticated control and monitoring systems that automate many aspects of the operation, from feedstock input to energy output. These systems use sensors and computerized technology to constantly monitor plant performance and adjust processes in real-time, ensuring optimal efficiency. Gruner Renewable integrates IoT technology and smart analytics to provide operators with precise control over every aspect of the plant, enhancing both safety and productivity.

Environmental and Economic Benefits

Waste Treatment and Byproduct Management

In addition to energy production, efficient biogas plants manage waste and byproducts effectively. Systems for digestate separation and treatment allow for the recycling of solid and liquid residues as fertilizers, offering an additional revenue stream and closing the loop in waste management.

Conclusion

The equipment and technology implemented in a biogas plant play a crucial role in determining its efficiency and effectiveness. At Gruner Renewable, we are dedicated to leveraging cutting-edge technologies and high-quality equipment to ensure that our biogas plants are not only efficient but also contribute positively to environmental sustainability and economic viability. Our holistic approach to biogas production reflects our commitment to revolutionizing the future of energy, providing our customers with reliable, sustainable, and cost-effective solutions.

Call to Action

Are you ready to explore the benefits of efficient biogas production? Visit Gruner Renewable to discover how our advanced equipment and technology can help you achieve your sustainability goals. Join us in transforming organic waste into valuable energy and advancing towards a greener future.

SEO Strategy:

- Keyword Optimization: Biogas plant equipment and technology is strategically used throughout the article to enhance search engine visibility.

- Informative and Engaging Content: Provides detailed insights into the equipment and technology necessary for a biogas plant, ensuring reader interest and SEO effectiveness.

- Call to Action: Encourages readers to engage with Gruner Renewable’s solutions, driving website traffic and fostering engagement with the company's sustainable energy technologies.

for more details visit now - https://grunerrenewable.com/

0 notes

Text

Exploring Polystyrene: Manufacturing and Market Trends (2023-2034)

Polystyrene stands as a versatile plastic polymer deeply embedded in various aspects of our daily lives. Its utility extends from packaging and food containers to insulation materials, showcasing a wide range of benefits. Despite its adaptability, polystyrene raises environmental concerns due to its non-biodegradable nature. In this comprehensive examination of polystyrene, we will delve into its unique characteristics, manufacturing processes, diverse applications, and the environmental challenges it presents. We'll explore its lightweight composition, durability, and moldable properties that make it a preferred material for many industries. Furthermore, we'll examine its significant role in sectors such as packaging, food service, and construction. With the global polystyrene market valued at around 11.2 million tons in 2023, it is projected to grow at a Compound Annual Growth Rate (CAGR) of 3.39% until 2034.

Introduction

Polystyrene is a synthetic resin characterized by its robust, rigid, and translucent properties. It is derived from styrene, a liquid hydrocarbon, which acts as the monomer in the polymerization process. Polystyrene's unique attributes, such as its lightweight nature and insulation properties, drive its utilization across various industries. The benefits of polystyrene plastic injection molding encompass its minimal shrinkage, versatility in being utilized in blended and foam states, and its moldability. Polystyrene, like all thermoplastics and can be easily molded, exhibiting minimal shrinkage throughout the injection molding process.

Various forms of polystyrene exist, each tailored for specific applications:

1. Solid Plastic: This category includes General Purpose Polystyrene (GPPS) and High Impact Polystyrene (HIPS), designed for different levels of impact resistance. High-impact grades of polystyrene typically contain 6–12% elastomers, while medium-impact grades have about 2–5%. High impact polystyrene (HIPS) resins are valued for their ease of processing, good dimensional stability, impact strength, and rigidity. These qualities make HIPS suitable for a variety of applications where toughness and durability are required, such as packaging, appliances, and consumer goods.

2. Foam: Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) are foam variants suitable for insulation, packaging, and construction purposes.

3. Films: Oriented Polystyrene (OPS) finds applications in packaging films, offering clarity and stiffness. Oriented Polystyrene (OPS) is processed through orientation techniques to enhance its strength and clarity. Commonly used in clear containers, trays, and lids for food packaging, OPS offers excellent transparency, making it ideal for showcasing food items like salads, desserts, and deli products. OPS stands as a versatile material in the food packaging industry, meeting the demands for both aesthetic appeal and functional performance.

Manufacturing Process

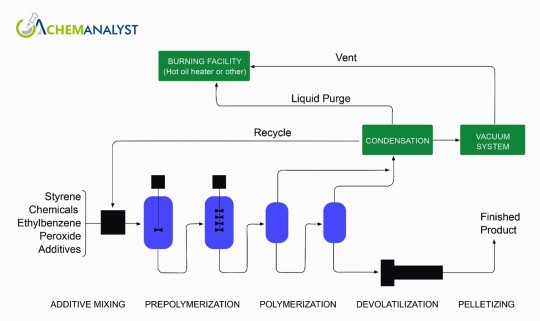

Polystyrene is produced through batch processes that ensure high conversion efficiency, minimizing emissions of unreacted styrene. In the batch bulk polymerization process, styrene monomer, and optionally comonomer, are dissolved in a feed dissolver. The continuous mass peroxide-initiated polymerization of styrene is a multi-stage process designed for efficiency and control. Beginning with the monomer and chemicals into a mixing section, the mass reaction occurs in the presence of a solvent. This mixture then progresses to the polymerization section, typically comprising two continuously stirred tank reactors (CSTRs), where heat generated during the reaction is dissipated by evaporating volatile components. Following the reaction, the polymer solution undergoes devolatilization in two consecutive stages under vacuum conditions, eliminating monomers and low-boiling compounds. The resulting polymer is then transferred to the pelletizing unit, supplied with heat via a thermal oil system.

Polymerization Stage

CSTR reactors facilitate precise control over molecular weight, Alternative configurations, like CSTR combined with plug flow reactors (PFR), offer flexibility to meet diverse process needs.

Devolatilization Stage

The devolatilization section ensures efficient removal of monomers and organic substances, minimizing polymer degradation without additional agents through high rates of heat and mass transfer. This stage consists of a two-step process with low residence periods and high heat and mass transfer rates. Even at very low operating temperatures, the effective removal of monomers and organic compounds is ensured by this special combination.

Expanded polystyrene (EPS), synthesized through suspension polymerization and impregnation with a blowing agent like pentane, and exhibits rigidity, lightweight nature, and low thermal conductivity. Expanded Polystyrene (EPS) foam is derived from expandable polystyrene beads, a rigid cellular plastic containing an expansion agent, typically sourced from oil. The EPS manufacturing process intricately links back to the initial chemical transformation from oil to expandable polystyrene. Now, we delve into the subsequent stages leading to the formation of EPS foam parts. In the first stage of pre-expansion, the raw beads undergo heating in specialized pre-expanders using steam. This process reduces the material density significantly, transforming hard beads into cellular plastic beads with small, closed cells containing air. Following pre-expansion, the beads undergo intermediate maturing and stabilization. As the recently expanded particles cool, they form a vacuum inside, which is compensated for by air diffusion. This enhances mechanical elasticity and expansion capacity, achieved during the material's intermediate maturing in aerated silos or mesh bags, where simultaneous drying occurs. In the final stage of expansion and molding, the stabilized pre-expanded beads are transferred to molds, where they are exposed to steam again to bind together. This results in the formation of large blocks through block molding or products in their final finished shape through shape molding, catering to various applications like boards, panels, and cylinders.

Market Dynamics

The global Polystyrene market is propelled by its distinctive attributes, including its water-resistant nature, making it a preferred choice in the packaging industry. Additionally, its ability to blend seamlessly with other polymers further enhances its versatility and widens its range of applications. Polystyrene's utilization in the manufacturing of automotive components and electronic goods is poised to drive market growth in the coming years, owing to its properties such as insulation and high strength.

Applications of Polystyrene:

1. Construction

Polystyrene is extensively utilized in the construction industry for various purposes. It is a key component in the production of lightweight concrete blocks, which are prized for their ease of handling and installation on construction sites.

2. Appliances

Polystyrene, both in solid and foam forms, is a prevalent material choice for a wide array of appliances, including refrigerators, air conditioners, ovens, microwaves, vacuum cleaners, and blenders.

3. Automotive

Polystyrene serves as a fundamental material in the manufacturing of numerous automotive components.

4. Electronics

Polystyrene is essential for crafting housing and components in televisions, computers, and IT equipment. Its lightweight and moldable nature allow for intricate designs that balance functionality and aesthetics.

5. Food Packaging

Polystyrene foodservice packaging is renowned for its superior insulation properties, which effectively maintain food freshness for extended periods. Compared to alternative packaging materials, polystyrene offers better insulation for hot & cold foods.

Market Outlook:

The global Polystyrene market is anticipated to reach approximately 17.8 million tonnes by 2034. Its affordability, combined with its excellent insulation capabilities, makes polystyrene a preferred choice in various industries, meeting both practical and economic needs effectively. Asia Pacific region is the leading consumer of Polystyrene and with rapid urbanization & construction paired with increasing dispensable income anticipated to remain so in the coming years.

Polystyrene Key Market players

Significant companies in the Global Polystyrene market are Total Petrochemicals, INEOS Styrolution, PS Japan, Jiangsu Laidun Baofu Plastifying, Zhenjiang Chi Mei Chemical, Shanghai Secco Petrochemical, Formosa Plastics, Versalis, Trinseo, Supreme Petrochem Limited, LG Chem, DIC Corporation, and Jiangsu Lyan Qingfeng Newmaterial.

Challenges and Opportunities

While the polystyrene market offers numerous opportunities, it also faces several challenges that impact its growth.

· Environmental Concerns: One of the significant challenges facing the polystyrene market is its environmental impact. Polystyrene is non-biodegradable and can persist in the environment for hundreds of years, contributing to pollution and posing risks to wildlife.

· Shift Towards Alternatives: Growing awareness of environmental and health issues associated with polystyrene has led to a shift towards alternative materials in various industries. Biodegradable and compostable alternatives, as well as recyclable plastics, are gaining popularity as consumers and businesses seek more sustainable options, posing a competitive challenge for the polystyrene market.

Conclusion:

The polystyrene market is diverse and driven by its versatile properties and cost-effectiveness. It finds applications in packaging, construction, automotive, electronics, and more. Polystyrene's advantages include its lightweight nature, thermal insulation properties, and moldability. In packaging, it is known for its resistance to moisture and impact, making it suitable for food packaging and protective materials. High Impact Polystyrene has remarkable dimensional stability alongside easy thermoforming capabilities. Its high impact resistance renders it ideal for various applications such as refrigerator liners, toilet seats, and disposable items, offering both functionality and aesthetic appeal, especially when painted. Additionally, its suitability for food packaging, exemplified by yogurt cups, underscores its versatility. Polystyrene foams leverage their excellent thermal insulation properties for diverse applications in construction and packaging.

0 notes