#corrugated cardboard pallets

Explore tagged Tumblr posts

Text

Corrugated Wooden, Paper Pallets Manufacturers & Exporter

0 notes

Text

youtube

Jude constructs a hot compost bay layered with the perfect ingredients to feed a productive patch.

On a sloping block in the Blue Mountains, Jude has many projects on the go. To keep the garden cranking, Jude’s been learning a lot about compost. “This stuff is gold,” says Jude, “it adds nutrients, water and is the life of the soil.” Here’s how to construct a hot compost bay to feed a productive patch.

The Built Structure:

Jude’s two-bay compost system can house about two cubic metres and was constructed with the help of a mate. They’ve used recycled pallets which are heat treated to make sure the compost is safe to put on edible produce. It has gates at the front, low enough for a wheelbarrow, and is clad with corrugated iron. Jude says the corrugated iron “makes a really good backing when you're digging into the compost, and they also heat it up.” It’s a good idea to install a chicken-wire tube in the centre of the bay for airflow.

Compost is broken down organic matter and is full of nutrients that plants thrive on. Organic matter is anything that was once alive, like plants, animals, and even manures. This material can be broken down slowly by worms in a cool compost system, but in a hot compost system, it’s broken down by millions of micro-organisms and fungi. A big mass of material paired with a lot of microbial action generates a lot of heat. Jude says, “hot compost is a great way to get a lot of compost in a very short amount of time.”

Hot compost needs to be built it all in one go, at least one cubic metre in size. Jude says smaller composts “won't generate the heat required to breakdown the organic matter.” The ideal temperature for hot compost is 60°C, anything higher is way too hot to support the microbes. Regular turning for airflow will help manage the temperature. Jude’s got the perfect ingredients for a healthy hot compost habitat to provide these critters food, air and moisture.

Green & Brown Materials:

Good compost has “a mix of greens and browns,” says Jude. Brown layers are carbon-rich material such as cardboard, sticks, newspaper and straw. These offer energy to the microbes, absorb moisture and improve airflow. Green layers are not always green in colour. Greens are nitrogen-rich materials such as grass clippings, coffee grounds and food scraps. Jude says, “as a general rule of thumb, you want at least twice as much of the carbon-rich material as the nitrogen-rich green stuff.”

Layer #1: Brown:

Cover the base with a carbon layer of sticks and twigs. The rough textures allow excess water to drain, will bulk out the base and help oxygen get into the pile. Jude says, “when I'm adding a layer of carbon, I'm watering it in. I'm aiming for a pile that's moist but not soaking wet.” A layer of wet newspaper on top of the twigs will help create this environment.

Layer #2: Green:

Repurpose your old kitchen scraps and leafy garden waste. Jude says, “avoid meat, bread and dairy” to keep rodents away, and make sure you’re “not adding any weeds with seeds, bulbs or runners.” Break big sections up with a spade to help it breakdown faster. Jude says, “adding diverse nutrients like comfrey will help fire up microbial life.”

Layer #3: Brown:

A thick layer of straw mulch will act as a blanket for all that heating mass underneath. In two weeks, this pile can be lifted and moved into the second bay and turned every few weeks. Check the pile regularly to see if it needs more water or aeration.

You’ll know it's ready when it begins to look like yummy crumbly chocolate cake. Like the one Jude’s brother Charlie was inspired to make - what a team!

#gardening australia#solarpunk#compost#how to#how to make compost#diy#do it yourself#hot compost#hot compost system#Youtube

4 notes

·

View notes

Text

Mariele Neudecker

AFTER LIFE 2016

Mixed materials, Euro-pallet, corrugated cardboard, video on 3 monitors (duration: 42 min, 22 min, 15:10 min), giclée prints on archive paper

2 notes

·

View notes

Text

Ensure Safety of Your Products with Eco Friendly Packaging in Australia

For most businesses, whether they are manufacturing plants, warehouses, godowns, food facilities, or any other type of commercial or industrial establishment, eco friendly packaging in Australia are essential. The leading providers of packaging supplies provide a broad range of products, from vacuum sealers to different types of sticky tapes, and are cognizant of the unique needs of the industry.

Analysing the Different Types of Packaging Products and Their Features

Packaging products come in a wide variety, each designed to meet specific industrial requirements. Foam packaging is important for ensuring that sophisticated items like electronics, etc do not break while in transit. When shipping valuable things on pallets, pallet pads are a crucial commodity since dust, splinters, and other debris can harm the goods. Corrugated cardboard sheets are used to provide protective layers in between items. Cartons and boxes, which are available in a range of sizes and strengths, offer safe packing solutions for products of various shapes and sizes. Corrugated trays and folders are ideal for organising and storing items, particularly in retail and warehouse environments.

Prominent suppliers of packaging products cater to both the industrial and service sectors, which include the hotel and food industries. Some of the goods used to package and distribute food to consumers in a sustainable manner include biodegradable wrap, plates and bowls, mugs of various sorts, and silverware like knives, spoons, forks, etc. Eco-friendly sustainable packaging, such as dispensing cartons, retail rolls, bags, sheets, tubes, wraps, and takeaway bowls, has gained in popularity in recent years as environmental concerns have been more widely recognised.

The best manufacturers of packing materials also meet janitorial concerns, providing a wide choice of things to protect safety and cleanliness in commercial and industrial environments. Workplace hygiene requires supplies like roll-up hand towels, toilet tissue dispensers, and facial tissues. Products such as antibacterial hand cleansers and odour control dispensers keep the toilet or room hygienic and fresh.

Packing machines and dispensers have become essential for providers of items offered online due to the fast expansion of the e-commerce industry in recent decades. Automatic tape dispensers, vacuum sealers, and stretch wrap machines are all designed to handle big loads, boosting productivity and reducing labour costs.

Browse the product sections of the leading packaging product suppliers' websites and buy what you or your company require.

Source: https://paramount-packaging.blogspot.com/2025/01/ensure-safety-of-your-products-with-eco.html

0 notes

Text

Some Protective Packaging Examples

Protective packaging is designed to safeguard products during storage and transportation. Some common examples include:

Bubble Wrap – Air-filled plastic bubbles that cushion items and absorb shock.

Foam Inserts – Custom-cut foamProt pieces that fit around delicate or irregularly shaped products to prevent movement.

Corrugated Boxes – Sturdy cardboard boxes used for shipping; often combined with other materials for added protection.

Peanut Foam (or Packing Peanuts) – Small, lightweight foam pieces that fill empty spaces in boxes, preventing items from shifting.

Air Pillows – Inflatable plastic bags that act as cushioning material, similar to bubble wrap but in larger pieces.

Shrink Wrap – Plastic film that tightly wraps around products, providing both protection and tamper evidence.

Kraft Paper – Crumpled or flat, used to fill voids in boxes and provide cushioning.

Stretch Film – A stretchable plastic film used to wrap pallets of goods, securing them in place.

Cushioning Pads – Thick, soft pads placed between items to protect against impact.

Honeycomb Packaging – A durable, paper-based material used for cushioning, often used for heavier products or in larger volumes.

These protective packaging materials help prevent damage from impacts, vibrations, moisture, and other shipping hazards.

0 notes

Text

Importance of Case Erectors in Modern Packaging Operations

In today's fast-paced industrial world, efficient packaging processes are key to ensuring the timely delivery of goods and maintaining competitive production costs. One critical piece of equipment that has revolutionized packaging lines is case erector. By automating the assembly of cardboard boxes, case erectors streamline operations, increase productivity, and reduce labor costs. But what exactly are case erectors, and why are they essential for businesses that deal with high-volume packaging?

What is a Case Erector?

A case erector is a machine that automates the process of forming, folding, and sealing corrugated boxes or cartons, turning flat, pre-cut cardboard into rigid, ready-to-fill cases. The machine grabs a flat box from a stack, shapes it into a 3D form, and then seals the bottom flaps using adhesive tape or glue. After this, the newly formed boxes are transferred down the packaging line, ready to be filled with products.

Case erectors come in different sizes and configurations, depending on the production speed and the size of the boxes. They can be semi-automatic, where some manual intervention is required, or fully automatic, capable of continuous high-speed operation with minimal human input.

Key Benefits of Using Case Erectors

Increased Efficiency: Automating the box-forming process allows packaging lines to operate faster and more smoothly. Case erectors can handle hundreds of boxes per hour, significantly improving throughput and ensuring that products are packed and shipped without delay.

Reduced Labor Costs: Manually assembling boxes is a time-consuming task, especially in industries that require large volumes. By implementing a case erector, companies can reduce the need for manual labor, freeing workers to focus on more value-added tasks. This reduction in labor can lead to substantial cost savings in the long run.

Consistency and Precision: One of the main advantages of case erectors is their ability to create perfectly formed boxes every time. Human error can lead to poorly folded or sealed boxes, which can compromise product safety during shipping. Case erectors ensure consistent and precise folding, improving the quality and durability of the packaging.

Versatility: Modern case erectors are highly customizable and can be adjusted to form different box sizes and styles. This versatility is particularly beneficial for businesses that package various products with diverse packaging requirements.

Improved Safety: Case erectors reduce the need for repetitive manual tasks that can lead to strain or injury over time. Automation reduces the physical demands on workers, creating a safer workplace environment.

Applications of Case Erectors

Case erectors are widely used across industries, including:

Food and Beverage: Companies in this sector need to package products quickly and securely to ensure freshness and prevent contamination. palletizer machine help meet these high standards while keeping up with the demands of large-scale production.

Consumer Goods: From electronics to personal care items, case erectors enable the rapid packaging of a wide variety of products for retail distribution.

Pharmaceuticals: In this industry, precise packaging is critical for product integrity. Case erectors ensure that boxes are assembled and sealed to exact specifications, minimizing the risk of damage or tampering.

E-commerce: With the growing volume of online orders, e-commerce businesses rely on case erectors to handle high-demand packaging efficiently, ensuring that orders are fulfilled on time.

Factors to Consider When Choosing a Case Erector

When selecting a case erector for your business, several factors should be taken into account:

Production Speed: Evaluate the machine’s speed to ensure it aligns with your production line’s capacity.

Box Size Range: Ensure the erector can handle the box sizes required for your products.

Footprint: Depending on your workspace, the size of the machine may be a deciding factor.

Maintenance: Look for a machine that is easy to maintain and has a track record of reliability.

Integration: Consider how easily the case erector can be integrated into your existing packaging line.

Conclusion

Case erectors are invaluable in today's automated packaging environments, providing speed, accuracy, and cost savings. As businesses continue to seek ways to optimize their operations, investing in a reliable case erector can offer a significant return on investment by enhancing the efficiency and consistency of packaging processes. Whether you’re in food production, consumer goods, pharmaceuticals, or e-commerce, a case erector can be a vital tool in improving your packaging line's performance.

0 notes

Text

The Right Packaging Materials for Automotive Parts 🚗📦: What You Need to Know

In the world of automotive manufacturing, packaging isn’t just about getting parts from Point A to Point B—it’s about protecting those parts, reducing costs, and making sure your supply chain runs smoothly. Whether it’s tiny bolts or heavy-duty engines, choosing the right packaging material is critical.

At Silicon Safepack Pvt. Ltd., as an industrial packaging solutions provider, we help manufacturers select the best materials to keep automotive parts safe and compliant. Here’s a quick guide on the top packaging materials and their applications:

1. Corrugated Cardboard 🛠️

Perfect for lightweight parts like nuts, bolts, and filters. It’s strong, recyclable, and easy to customize for various shapes and sizes.

2. Plastic Pallets & Containers 💪

Need to move heavy components like engines or transmissions? Plastic pallets are durable, reusable, and can withstand moisture, making them ideal for big, bulky items.

3. Foam Inserts & Bubble Wrap 🧩

For delicate items like sensors and electronics, foam inserts and bubble wrap offer the perfect cushioning to prevent damage during transit.

4. Metal Containers 🔒

When maximum protection is required, especially for valuable or oversized parts, metal containers are the way to go. Strong, secure, and built to last.

5. Wooden Crates 🌲

Best for heavy-duty machinery and oversized parts, wooden crates provide the strength needed to keep these components safe during long trips.

No matter the part or packaging need, Silicon Safepack Pvt. Ltd. provides custom industrial packaging solutions that balance cost-efficiency, protection, and sustainability. We ensure that automotive components arrive safely, on time, and in compliance with industry standards

#IndustrialPackaging#AutomotivePackaging#PackagingMaterials#PackagingSolutions#SustainablePackaging#SiliconSafepack#LogisticsSolutions#PackagingInnovation

0 notes

Text

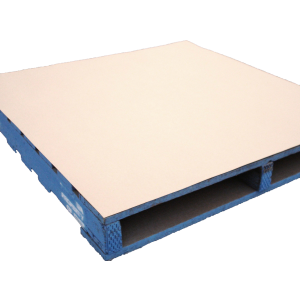

Light Duty Corrugated Tops: The Ultimate Solution for Efficient Packaging

In today's fast-paced industrial environment, the demand for reliable and efficient packaging solutions is greater than ever. Whether you are involved in manufacturing, logistics, or retail, the need for packaging materials that offer durability, cost-effectiveness, and ease of use is crucial. One such solution that has gained significant traction in recent years is the Light Duty Corrugated Top. This versatile packaging material is designed to enhance packaging efficiency, ensuring that your products are securely stored and transported.

In this comprehensive article, we will explore the various aspects of Light-Duty Corrugated Tops, including their benefits, applications, and how they compare to other packaging solutions. By the end, you will have a clear understanding of why Light-Duty Corrugated Tops from Stakall are the go-to choice for businesses looking to optimize their packaging processes.

Understanding Light-Duty Corrugated Tops

Light Duty Corrugated Tops are a type of packaging material made from corrugated cardboard. Unlike traditional cardboard boxes, these tops are specifically designed to be lightweight yet sturdy enough to protect products during shipping and storage. They are typically used as covers for pallets, crates, or boxes, providing an additional layer of protection against dust, moisture, and damage.

Key Features of Light-Duty Corrugated Tops:

Lightweight: As the name suggests, these corrugated tops are light in weight, making them easy to handle and transport. This feature is particularly beneficial for reducing shipping costs and minimizing manual labour during packaging.

Durability: Despite their lightweight nature, Light Duty Corrugated Tops are incredibly durable. They are engineered to withstand external pressures, ensuring that the contents beneath are well-protected.

Eco-Friendly: Made from recyclable materials, corrugated tops are an environmentally friendly option. Businesses that prioritize sustainability can benefit from using them as part of their green initiatives.

Customizable: Light-duty corrugated Tops can be customized to fit various sizes and shapes, making them versatile for different types of packaging needs. This adaptability ensures that your products are securely covered, regardless of their dimensions.

Cost-Effective: Compared to heavier packaging materials, Light Duty Corrugated Tops offer a cost-effective solution without compromising on protection. This makes them an attractive option for businesses looking to optimize their packaging budgets.

The Benefits of Using Light-Duty Corrugated Tops

Enhanced Protection

One of the primary benefits of using Light Duty Corrugated Tops is the enhanced protection they provide. Whether you are shipping fragile items or storing products for an extended period, these tops act as a barrier against environmental factors such as dust, moisture, and physical damage. By adding an extra layer of security, businesses can minimize the risk of product damage, leading to reduced returns and customer complaints.

Improved Efficiency

Efficiency is key in any packaging operation. Light Duty Corrugated Tops contribute to faster packaging times due to their lightweight and easy-to-handle nature. Workers can quickly place these tops on pallets or crates, streamlining the packaging process and increasing overall productivity. Additionally, the lightweight design helps reduce shipping costs, as it contributes less to the overall weight of the packaged goods.

Versatility Across Industries

Another advantage of Light-Duty Corrugated Tops is their versatility. These tops can be used across various industries, including manufacturing, retail, and logistics. Whether you need to protect consumer electronics, food products, or industrial components, Light-Duty Corrugated Tops can be tailored to meet your specific packaging requirements. Their adaptability makes them a valuable asset for businesses with diverse product lines.

Sustainability and Environmental Impact

With increasing awareness of environmental issues, more businesses are seeking sustainable packaging solutions. Light Duty Corrugated Tops are made from recyclable materials, making them an eco-friendly choice. By incorporating these tops into your packaging strategy, you can reduce your carbon footprint and contribute to environmental conservation efforts. This can also enhance your brand's reputation, as consumers are becoming more conscious of the environmental impact of the products they purchase.

Applications of Light-Duty Corrugated Tops

Light Duty Corrugated Tops are widely used in various industries for different applications. Below are some of the common uses:

Pallet Covers

One of the most common applications of Light Duty Corrugated Tops is pallet covers. These tops are placed over products on a pallet to provide a protective barrier against dust and moisture during storage and transportation. They are instrumental in warehouses and distribution centres where products may be stored for extended periods.

Crate and Box Covers

Light Duty Corrugated Tops can also be used as covers for crates and boxes. This application is ideal for businesses that need to protect their products from external elements without using bulky or heavy materials. The tops can be easily placed and removed, providing a convenient and efficient packaging solution.

Layer Pads

In addition to being used as covers, Light Duty Corrugated Tops can also serve as layer pads. These pads are placed between layers of products to prevent shifting during transportation. This helps maintain the integrity of the products and reduces the risk of damage.

Protective Packaging for Fragile Items

For businesses that deal with fragile items such as glassware, electronics, or delicate machinery, Light Duty Corrugated Tops offer an added layer of protection. By placing these tops over the items, businesses can ensure that their products arrive at their destination in pristine condition.

Comparing Light-Duty Corrugated Tops to Other Packaging Solutions

When choosing the proper packaging solution, it's essential to consider the alternatives. Here's how Light Duty Corrugated Tops compare to other packaging materials:

Versus Heavy-Duty Corrugated Tops

While heavy-duty corrugated tops offer superior strength and protection, they are often bulkier and more expensive. For businesses that do not require extreme protection, Light Duty Corrugated Tops offer a more cost-effective and efficient alternative. They provide sufficient protection for most products without the added weight and cost.

Versus Plastic Covers

Plastic covers are another standard packaging solution, but they have several drawbacks. Unlike Light-Duty Corrugated Tops, plastic covers are not as environmentally friendly and can contribute to pollution. Additionally, plastic covers may provide a different level of breathability, leading to potential moisture buildup. In contrast, corrugated tops offer better ventilation and are easier to recycle.

Versus Metal Covers

Metal covers provide robust protection but are often overkill for many packaging needs. They are heavy, expensive, and can be challenging to handle. Light Duty Corrugated Tops offer a lightweight and cost-effective alternative, making them suitable for a wide range of applications.

Why Choose Stakall for Your Light-Duty Corrugated Tops?

When it comes to quality and reliability, Stakall stands out as a leading provider of Light Duty Corrugated Tops. With years of experience in the packaging industry, Stakall is committed to delivering top-notch products that meet the needs of businesses across various sectors.

Unmatched Quality

At Stakall, quality is our top priority. Our Light Duty Corrugated Tops are manufactured using high-grade materials, ensuring durability and long-lasting performance. We adhere to strict quality control standards to ensure that every product meets our customers' expectations.

Custom Solutions

We understand that every business has unique packaging needs. That's why we offer customizable Light Duty Corrugated Tops that can be tailored to your specific requirements. Whether you need a particular size, thickness, or design, Stakall has the expertise to deliver the perfect solution.

Sustainability Focus

As part of our commitment to environmental sustainability, Stakall ensures that all our Light-Duty Corrugated Tops are made from recyclable materials. By choosing our products, you can help reduce waste and promote a greener future.

Exceptional Customer Service

At Stakall, we believe in building long-term relationships with our customers. Our dedicated customer service team is always available to assist you with your inquiries, orders, and after-sales support. We strive to provide a seamless experience from start to finish.

Conclusion

Light Duty Corrugated Tops are a versatile, cost-effective, and eco-friendly packaging solution that can enhance the efficiency of your packaging processes. Whether you need to protect products during storage, transportation, or shipping, these tops offer reliable protection without adding unnecessary weight or cost. By choosing Stakall as your provider, you can rest assured that you are investing in high-quality packaging materials that align with your business goals and sustainability efforts.

Contact Stakall Today!

Ready to optimize your packaging processes with Light Duty Corrugated Tops? Stakall is here to help. Contact us today to learn more about our products and how we can tailor our solutions to meet your specific needs.

0 notes

Text

The Rising Demand for Recycled Packaging in Retail and E-Commerce

High-quality recycled packaging is crucial in the competitive worlds of retail and e-commerce, which is why distributors of high-quality packaging are needed to provide the greatest goods. This type of packaging is becoming more popular as more customers are becoming aware of the harmful impacts of other packaging on environment and consciously choose more environment friendly things. The highest quality products are required by businesses in need of dependable packaging solutions, and there are several product varieties in areas including pallet wrap, adhesive tapes and dispensers, and stretch films, among others.

One of the most often used forms of tape nowadays is eco friendly tape since it not only protects shipments but also presents a distinctive branding opportunity. Because efficient packing is so valuable, businesses must make sure your goods are transported in a stylish and secure manner. Custom-made boxes, custom-printed labels, custom-made signage, and packing tape are just a few of the options available for bespoke packaging items.

A Selection of Products Provided by the Top Packaging Suppliers

Stretch Films and Pallet Wrap: Using the proper stretch films and dispensers is essential for protecting the cargo. Pallets can be manually wrapped with stretch film and stretch film dispensers to provide stability during travel in a quick and straightforward manner. The ideal option for firms to have a pallet wrapping machine combined with machine stretch film for high-volume operations.

Protective Packaging: Leading firms provide solutions like bubble wrap and polyfoam give great cushioning to avoid damage. Protective packaging is necessary to secure items during shipment and handling. Other goods, such as rolls of corrugated cardboard, offer more flexible protection for bigger items, while protective film deters scratching on surfaces.

Adhesive Tapes and Dispensers: These are essential for effectively fastening packages. Machine packaging tape guarantees uniform application in automated procedures, while Forza packaging tape provides strong sealing. Cloth tape's robust stickiness and long-lasting nature make it ideal for demanding operations. Reinforced fiberglass gives filament tape more strength for fastening and bundling big objects.

Get in touch with the top suppliers of the goods needed for packaging different items and purchase in bulk or in accordance with specifications.

Source

0 notes

Link

0 notes

Text

Packing Materials for Businesses: Solutions Available in Dubai

In the bustling business environment of Dubai, efficient packaging is essential for the smooth operation of logistics, shipping, and inventory management. Whether you’re shipping products to clients, managing inventory, or relocating office equipment, selecting the right packing materials is crucial. This blog explores the various packing materials in Dubai that businesses can utilize to enhance their operations and ensure the safe handling of goods.

The Importance of Quality Packing Materials for Businesses

For businesses, the choice of packing materials impacts not only the safety of their products but also their brand image. High-quality packing materials prevent damage during transit, reduce returns due to product damage, and enhance customer satisfaction. Additionally, efficient packaging can lead to cost savings by minimizing waste and optimizing space.

Types of Packing Materials Available in Dubai

Boxes and Cartons:

Cardboard Boxes: Versatile and cost-effective, these are ideal for a wide range of products. They come in various sizes and strengths to accommodate different needs.

Corrugated Boxes: With an additional layer of protection, these boxes are suitable for heavier items or items that require extra cushioning.

Custom Boxes: For businesses looking to enhance branding, custom-printed boxes are available. These can be tailored with your company’s logo and design.

Bubble Wrap:

An essential packing material for protecting fragile items, bubble wrap cushions products against impact and shocks. It is widely used for electronic goods, glassware, and delicate items.

Foam Peanuts and Sheets:

Foam Peanuts: Lightweight and effective at filling voids in boxes, foam peanuts provide cushioning and prevent shifting during transport.

Foam Sheets: Ideal for wrapping and protecting flat or irregularly shaped items, foam sheets are commonly used for electronic devices and machinery.

Stretch Film and Shrink Wrap:

Stretch Film: Used for wrapping pallets and securing items together, stretch film offers protection from dust, moisture, and tampering.

Shrink Wrap: This material provides a tight seal around products, ensuring that they remain intact and protected during shipping and storage.

Packing Paper and Tissue Paper:

Packing Paper: Perfect for wrapping items and filling gaps within boxes, packing paper offers a cost-effective solution for cushioning and protection.

Tissue Paper: Often used for wrapping delicate items or for retail packaging, tissue paper adds a layer of protection and a touch of elegance.

Void Fillers:

Air Pillows: Lightweight and space-efficient, air pillows are used to fill voids in boxes and provide cushioning to prevent items from moving during transit.

Biodegradable Fillers: For environmentally conscious businesses, biodegradable void fillers offer an eco-friendly alternative to traditional materials.

Sealing Tape and Labels:

Packing Tape: High-quality packing tape ensures that boxes remain securely sealed during transit. Options include clear tape, reinforced tape, and branded tape.

Labels: Proper labeling is crucial for tracking and identifying packages. Labels can include shipping information, handling instructions, and barcodes.

Choosing the Right Packing Materials Supplier in Dubai

Selecting a reliable supplier for packing materials in Dubai is essential for ensuring the quality and availability of materials. Here are some tips for choosing the right supplier:

Reputation and Reviews:

Look for suppliers with a good reputation and positive customer reviews. Online reviews, referrals, and testimonials can provide insights into the reliability and quality of the supplier.

Product Range and Customization:

Choose suppliers that offer a wide range of packing materials and customization options. This ensures that you can find the specific materials you need for your business and that they can meet any special requirements.

Pricing and Bulk Discounts:

Compare prices from different suppliers and inquire about bulk discounts. Many suppliers offer competitive pricing for bulk orders, which can be beneficial for businesses with high-volume needs.

Customer Service and Support:

Good customer service is crucial for resolving issues and ensuring timely delivery. Choose suppliers who provide responsive support and are willing to assist with any queries or concerns.

Delivery and Logistics:

Ensure that the supplier can provide timely delivery and efficient logistics. Reliable delivery services are essential for maintaining smooth operations and avoiding delays.

Sustainable Packing Materials in Dubai

As environmental awareness grows, many businesses are seeking sustainable packing materials. Suppliers in Dubai now offer eco-friendly options such as biodegradable fillers, recycled cardboard, and compostable wraps. Opting for sustainable materials not only benefits the environment but also enhances your company’s reputation as a responsible business.

Conclusion

Selecting the right packing materials is vital for the efficient and secure handling of products in Dubai’s dynamic business environment. By understanding the various types of packing materials in Dubai and choosing a reliable supplier, businesses can enhance their logistics operations, reduce costs, and ensure customer satisfaction. Whether you need boxes, bubble wrap, or eco-friendly options, there are numerous solutions available to meet your needs. Prioritize quality, reliability, and sustainability to keep your business running smoothly and efficiently.

0 notes

Text

Get The Top-Quality Pallet Services In Wisconsin

Logical & Packaging Logistics, LLC is your premier logistics and pallet supply in Wisconsin for all your needs. We take pride in top-notch services to assist you with all your packaging and supply chain needs.

We understand how important the role of pallet management is in the transportation and storage of goods. We offer a wide array of pallet services to meet your needs. From new pallets in Brookfield to pallet repair and recycling, we have got you all covered.

Our experienced team is composed of qualified professionals who are trained and have experience with the best tools and techniques to satisfy your pallet needs. From wooden, plastic, and corrugated cardboard pallets, our collection caters to the diversified requirements of industries and businesses.

One of our specialized services is logistic pallet management. Appreciating that individual businesses have varied logistical needs, we try to individualize all our services to meet your needs. Right from pallet storage or inventory management to transportation and delivery, we are known to handle your products safely and store them to optimize your warehouse storage capacity and risk damage during transportation.

Such is our commitment to sustainability that we extend it to the service of pallet recycling and repair. We believe in minimizing our impact on the environment by reusing and repairing as many pallets as possible, rather than manufacturing new ones. Overall, we believe that by repairing damaged pallets and extending their life, we reduce the need for producing many new ones, promoting therefore a greener and more sustainable approach to logistics.

We offer customized pallet solutions. Your business has different packaging requirements, and definitely, one size does not fit all. That is why we work closely to ensure the development of custom pallets for all our clients seeking to meet their exact requirements and yield maximum results at the most economical rates possible.

Want new pallets in Brookfield or need logistics pallet management services? Look no further than Logical & Packaging Logistics, LLC. By our principle of dependable, productive, and cost-effective service, we can help facilitate a lean and mean supply chain operation to ensure success for your business.

Contact us at 262-505-5304 for any logistical help or assistance with pallet needs, and visit our website at https://logicallogistics.org/ let us help you take your business to new heights today.

#Food Grade Pallets Supplier Kentucky#Heat Treated Pallets in Texas#Pallet Distribution Illinois#Pallet Management Wisconsin#Pallet Stamped Heat Treated#Used Pallet Pickup Near Me#New Pallets Brookfield WI

0 notes

Text

Choosing the Right Air Shipment Pallets: A Comprehensive Guide

The use of air for shipment has become a necessity in international trade and more so when it comes to industries that require swift and urgent movement of goods. When choosing air shipment pallets, you need to get the right pallets which are safe, efficient as well as cost-effective for air cargo pallets.

This blog will help you understand various factors involved in selecting air shipment pallets with practical examples and insights tailored for your needs.

Importance Of Air Shipment Pallets

Air shipment pallets, also known as air freight pallets or aircraft cargo pallets are specially designed for maximizing space utilization as well as facilitating secure transport of goods through the airways. The right selection of pallets can significantly minimize transit damage risks, streamline the loading/unloading process and meet all international shipping requirements.

Types of Air Shipment Pallets 1. Wooden Pallet:

ISPM 15 wooden pallets are treated under ISPM No 15 (International Standards for Phytosanitary Measures) to prevent pests from spreading through wooden packaging materials in global trade. These types of pallets are robust, versatile and widely acceptable when it comes to shipping by air.

Example: Pharmaceutical companies based in India use ISPM 15 wooden pallets while sending medicine to Europe ensuring compliance and product safety during transit.

2. Paper Pallets

Crafted from corrugated cardboard or other paper-based materials, paper pallets are lightweight and environmentally friendly, often used for lighter loads. They are a cost-effective solution for companies looking to reduce their carbon footprint.

Example: Indian textile exporters use paper pallets to ship fabrics to neighbouring countries, benefiting from reduced shipping costs and eco-friendly practices.

Considerations When Choosing Air Shipment Pallets

Cargo Weight - Weight is a key factor that can be used in determining the most appropriate type of pallet. Wooden pallets are suitable for shipping heavier goods. There are other options available but are often used for bulky or valuable commodities.

Nature of Goods - In deciding which type of pallet one should use, you must consider what kind of product is being transported. For example, an ISMP 15 wooden pallet may be preferred for transporting pharmaceuticals due to compliance with international hygiene standards and food items.

Regulatory Compliance - Ensure that the pallets comply with international shipping regulations such as ISPM-15 for wooden pallets. Failure to meet this requirement may result in delayed shipment or rejection of goods after inspection at customs points.

Cost Effectiveness - Consider how much you spend on the air shipment pallets in relation to their benefits. Air freight costs can be reduced by having a lightweight material. There are other pallet options available but are expensive compared with ISPM 15 wooden pallets and paper pallets.

Practical Tips On the Use of Air Shipment Pallets

Proper Loading: This will ensure that the pallet is not tilted to one side during transit.

Securing The Cargo: Strapping and wrapping materials should be used in binding the shipments on a pallet.

Regular Inspection: Every once in a while, examine whether there are any damaged pallets and replace them to maintain the safety of the cargo.

Conclusion

The safe and efficient transportation of goods by air depends on the right choice of air shipment pallets. When making a selection, consider features like weight, nature of goods, regulatory compliance, durability and cost-effectiveness.

For premium-grade & high-performance air shipment pallets such as ISPM 15 wooden pallets or paper pallets, Radhesham Wellpack is a good place to start. For more information on choosing the right air shipment pallets and to explore the best options for your air freight needs, visit Radhesham Wellpack (RWPL).

0 notes

Text

The Science Behind Durable and Sturdy packaging material online

Packaging plays a crucial role in the storage, transportation, and presentation of products. The science behind durable and sturdy packaging boxes is multifaceted, involving materials science, engineering, design principles, and environmental considerations. In this comprehensive blog, we will delve order packing materials into the intricacies of packaging, examining the factors that contribute to packing bags online the creation of packing shop robust packing solutions. Whether you are looking for food packing, custom boxes, or seeking the best packaging supply store, this guide will provide valuable insights into packing boxes the world of packaging.

The Role of Packaging in Modern Commerce

Packaging serves multiple purposes: it protects products from damage, provides information, enhances shelf appeal, and facilitates transportation. In modern commerce, effective packaging can make the difference between a successful product and one that fails to reach its market potential. This is packing boxes especially true for online shopping, where the unboxing experience can significantly impact customer satisfaction.

Types of Packaging

Primary Packaging: This is the packaging that comes in direct contact with the product. Examples include bottles for beverages, blister packs for pills, and wrappers for candy bars.

Secondary Packaging: This refers to the packaging that groups primary packages together. It provides additional protection and packing shop makes handling easier. Examples include cardboard boxes and shrink wraps.

Tertiary Packaging: This is used for bulk handling, storage, and packing bags online transportation. Examples include pallets, crates, and large shipping containers.

Materials Used in Packaging

The materials chosen for packaging boxes significantly affect their durability and sturdiness. Let’s explore some common materials and their properties:

Cardboard and Corrugated Board

Cardboard and corrugated board are among the most popular materials for packaging boxes. Their popularity stems from their strength, lightweight nature, and recyclability.

Cardboard: Typically used for smaller, lighter items. It is made from thick sheets of paper pulp and can be easily printed on.

Corrugated Board: Consists of a fluted corrugated sheet sandwiched packing shop between two liners. This structure provides excellent strength and protection, making it ideal for shipping and storage.

Properties of Corrugated Board

Strength: The fluted structure in corrugated board provides rigidity and strength, making it capable of withstanding packing materials near me heavy loads.

Shock Absorption: The air pockets in the flutes act as packing boxes cushions, protecting packing bags online the contents from shocks and vibrations.

Lightweight: Despite its strength, corrugated board is lightweight, which helps reduce shipping costs.

Plastic

Plastic packaging is versatile and widely used across various industries, from food packing to order packing materials electronics.

Types of Plastic: Common plastics packing materials near me used in packaging include order packing materials polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC).

Durability: Plastic is resistant to moisture, chemicals, and packing material online impact, making it ideal for protecting products packaging material online from environmental factors.

Customizability: Plastics can be molded into various shapes and sizes, allowing for custom boxes tailored to specific products.

Environmental Considerations

While plastic offers numerous benefits, its environmental impact is a significant concern. Recycling and the development of biodegradable plastics are key areas of research to mitigate this issue.

Metal

Metal packaging, such as aluminum cans and tin boxes, is primarily used for food and beverages.

Strength and Durability: Metals are highly durable and offer excellent protection against physical damage and contamination.

Barrier Properties: Metal packaging provides a strong barrier against light, oxygen, and moisture, preserving the quality and shelf packing bags online life of products.

Glass

Glass packaging is commonly used for food and beverages, pharmaceuticals, and cosmetics.

Non-reactive: Glass is inert and does not react with the contents, making it suitable for sensitive products.

Transparency: Glass packaging allows order packing materials consumers to see food packing the product, enhancing its appeal.

Design Principles for Sturdy Packaging

Creating durable and sturdy packaging boxes involves more than packing boxes just choosing the right materials. Design principles play a crucial role in ensuring that packaging can withstand the rigors of handling, transportation, and storage.

Structural Integrity

The structural integrity of packaging boxes is paramount. This involves ensuring that the box can maintain its shape and protect its contents under various conditions.

Reinforced Corners and Edges: Adding extra material or using packaging material online stronger materials at the corners and edges can significantly enhance a box's strength.

Interlocking Flaps: Designs that incorporate interlocking flaps provide additional support and prevent the box from collapsing.

Load Distribution

Proper load distribution is essential to prevent damage during transportation.

Even Weight Distribution: Ensuring that the weight is evenly distributed within the box helps prevent deformation and reduces the risk of damage.

Partitioning and Inserts: Using partitions and inserts can help distribute weight more evenly and provide additional support for fragile items.

Ergonomics

Ergonomics in packaging design enhances the user experience and ensures ease of handling.

Handles and Grips: Adding handles or grips can make it easier to carry heavy or bulky boxes.

Easy Opening Mechanisms: Designing boxes that are easy to packing boxes open without compromising their integrity can improve the packing material online user experience.

Innovations in Packaging Materials

Advancements in materials science have led to the development of innovative packaging materials that offer superior strength, durability, and packing materials near me environmental benefits.

Biodegradable and Compostable Materials

With growing environmental concerns, the demand for biodegradable and compostable packaging materials has increased.

Plant-Based Plastics: Plastics made from renewable resources like corn starch or sugarcane are biodegradable and reduce reliance on fossil fuels.

Mushroom Packaging: Made from agricultural waste and mycelium, mushroom packaging is packing bags online biodegradable, compostable, and offers good protective qualities.

Nanomaterials

Nanotechnology has opened new possibilities in packaging, providing packaging material online materials with enhanced properties.

Nano-Coatings: Applying nanocoatings to packaging materials can improve their barrier properties, making them more resistant to moisture, oxygen, and contaminants.

Lightweight Nanocomposites: These materials combine lightweight properties with enhanced strength and durability, reducing material usage without compromising performance.

Packaging for Specific Industries

Different industries have unique packaging requirements, and packing boxes understanding these can help in designing optimal packaging solutions.

Food Packing

Food packing demands materials and designs that preserve freshness, prevent contamination, and comply with safety regulations.

Airtight Seals: Ensuring airtight seals can prevent packing material online spoilage and extend shelf life.

Temperature Control: Insulated packaging can maintain temperature-sensitive products at the desired temperature during transportation.

Electronics

Packaging for electronics must provide protection packing materials near me against physical damage, static electricity, and environmental packing bags online factors.

Anti-Static Materials: Using anti-static materials prevents damage from static electricity.

Cushioning: Foam inserts and cushioning materials protect delicate electronic components from shocks and vibrations.

Pharmaceuticals

Pharmaceutical packaging must ensure product integrity, prevent contamination, and provide tamper-evidence.

Child-Resistant Closures: Ensuring that packaging is difficult order packing materials for children to open helps prevent accidental ingestion.

Tamper-Evident Seals: These seals indicate if a package has been opened, ensuring the product has not been compromised.

Custom Boxes and Their Advantages

Custom boxes offer tailored solutions that meet specific product packaging supply store requirements and enhance brand identity.

Branding and Marketing

Custom boxes provide a canvas for branding and marketing efforts.

Brand Recognition: Unique and attractive packaging helps in building brand recognition and recall.

Product Information: Custom printing allows for the inclusion of detailed product information, enhancing consumer trust.

Protection and Fit

Custom boxes are designed to fit packing materials near me products perfectly, providing better protection and reducing the need for excess packing material.

Reduced Movement: A snug fit prevents the product packing material online from moving around within the box, reducing the risk of damage.

Optimized Space: Custom boxes can be designed to packaging material online maximize space usage, reducing shipping costs.

Packaging Supply Stores and Online Options

Finding the right packaging supply store or ordering packing materials online is crucial for businesses looking to secure high-quality packing solutions.

Packaging Supply Store

Visiting a physical packaging supply store allows businesses to see and feel the materials before purchase.

Expert Advice: Store staff can provide valuable advice on the best materials and designs for specific needs.

Immediate Availability: Products can be purchased and taken away immediately, reducing wait times.

Ordering Packing Materials Online

Ordering packing material online offers convenience and a packing shop wider range of options.

Variety: Online stores often have a broader selection of materials, sizes, and custom options.

Ease of Comparison: Online platforms make it easy to compare prices, read reviews, and make informed decisions.

Sustainable Packaging Practices

Sustainability is a growing concern in the packaging industry, driving innovations and practices aimed at reducing environmental impact.

Reducing Material Usage

Minimizing the amount of material used in packaging without compromising on protection is a key sustainability goal.

Lightweighting: Designing packaging that uses less material while maintaining strength reduces waste and shipping costs.

Efficient Design: Optimizing box designs to fit products packaging material online precisely can eliminate unnecessary material usage.

Recyclable and Reusable Packaging

Promoting the use of recyclable and reusable materials helps in reducing the environmental footprint of packaging.

Recyclable Materials: Using materials that can be easily recycled, such as paper and certain plastics, supports circular packing shop economy practices.

Reusable Packaging: Designing packaging that can be reused multiple times extends its lifecycle and reduces waste.

Conclusion

The science behind durable and sturdy packaging boxes is a complex interplay of materials science, engineering, and design. From selecting the right materials to employing innovative design principles, every aspect packing material online contributes to creating packaging that not only protects but also order packing materials enhances the packing shop product and brand. Whether you're looking for food packing solutions, custom boxes, or sustainable practices, understanding packing materials near me these packaging material online factors will help you make informed decisions and achieve optimal results.

0 notes

Text

Comprehensive Guide to Packaging Supplies in Melbourne: Essential Products for Every Industry

Packaging supplies in Melbourne are vital for the majority of enterprises, whether they be manufacturing facilities, warehouses, godowns, food facilities, or any other kind of commercial or industrial institution. The top suppliers of packaging items are aware of the particular requirements of the sector and provide a wide range of goods, from vacuum sealers to various kinds of sticky tapes.

Examining the Varieties of Packaging Products and Their Characteristics

There are many different types of packaging items, each created to satisfy certain industry standards. Pallet pads are quite an important product when sending important items on pallets as some splinters, dust, etc may damage the products. Sheets of corrugated cardboard are used to create protective layers between goods. Secure packing options for goods of all forms are provided by cartons and boxes, which come in a variety of sizes and strengths. For products’ organisation and storage, corrugated trays and folders are perfect, especially in retail and warehouse settings.

Leading packaging product providers serve not just the industrial sector but also the service industry, including the food and hotel sectors. Biodegradable wrap, plates and bowls, mugs of various kinds, and cutlery such as knives, spoons, forks, etc. are some of the items used to package and deliver food to customers in an appropriate manner. Dispensing cartons, retail rolls, bags, sheets, tubes, wraps, and takeout bowls are examples of eco-friendly sustainable packaging that has become increasingly popular in recent years as people's awareness of environmental issues has grown.

The top providers of packaging materials also address janitorial demands, providing a wide variety of items to preserve safety and cleanliness in commercial and industrial settings. Workplace hygiene requires supplies including roll-up hand towels, toilet tissue dispensers, and face tissues. The room or restroom is kept fresh and clean using products like odour control dispensers and antibacterial hand cleaners.

In recent decades, the e-commerce business has expanded rapidly, and as a result, packing machines and dispensers have become crucial for suppliers of goods sold online. Stretch wrap machines, vacuum sealers, and automatic tape dispensers are all made to handle large quantities of goods, increasing output and lowering labour expenses.

Look through the products area of the websites of top packaging product providers and purchase what you need or what businesses need.

Source: https://paramount-packaging.blogspot.com/2024/11/comprehensive-guide-to-packaging.html

0 notes

Text

Industrial Packaging Market: A Comprehensive Overview

Introduction Effective industrial packaging plays a crucial role in protecting manufactured goods during transportation and storage. With the complexity of modern supply chains that involve multiple touch points, choosing the right packaging solutions becomes all the more important to prevent product damage. This article explores some key considerations for packaging and highlights how incorporating the right practices can boost efficiency. Packaging Materials One of the first steps in industrial packaging market is selecting appropriate materials. Common materials used for packaging include cardboard, plastics like polyethylene (PE), polypropylene (PP), polystyrene (PS), and corrugated fiberboard. Each of these has their strengths - cardboard is cost-effective while plastics provide moisture and impact resistance. It is important to choose materials based on the product type, intended transport and storage conditions. For example, electronics may need anti-static plastics to prevent damage from static electricity. Temperature and humidity sensitive goods require moisture barrier packaging. Fragile items need extra cushioning and protection. Designing for Product Safety Effective packaging design is essential to safeguard products from damage during transportation and warehousing. Packaging needs to be robust yet sustainable. Cushioning needs to absorb impacts without being too bulky. Secure closure and sealing methods prevent items from shifting during transit. Correct labelling with handling instructions ensures careful treatment. Integrated designs for stacking/nesting optimize space. Considerations for unit load capabilities allow consolidation into shipping containers or pallets. Traceability features like barcodes facilitate inventory management. Compliance with regional/global regulations is also important. Streamlining Processes Industrial packaging processes should focus on efficiency and waste reduction. Standardized packaging components allow automating assembly lines. Optimized box/container sizes reduce excess material. Reusable/returnable packaging like IBCs and plastic crates lower total costs. Pull-style kanban or push-style CONWIP systems match demand. Bulk packaging for identical parts improves load consolidation. Robotics automate repetitive tasks. RFID and real-time monitoring enhances visibility. Analytics provide packaging optimization insights. Such streamlining yields cost savings, sustainability gains and scalability for growth. Ensuring Supply Chain Compliance Modern supply chains involve intricate networks encompassing multiple countries, partners, and modes of transport. Non-compliance with packaging, labeling or shipping regulations can disrupt operations. Packaging needs to be designed keeping applicable international regulations in mind whether by air, sea, road or rail. Mandatory information like hazardous material labels, orientation arrows, stacking limits should be clearly displayed. Harmonized System (HS) codes facilitate customs clearance. Certifications prove quality/sustainability. Real-time monitoring maintains temperature/shock control. Compliance minimizes delays, damage claims and builds trust with customers and regulators. Adopting New Technologies Emerging technologies offer huge potential to transform industrial packaging market processes. Internet of Things (IoT) sensors allow real-time monitoring of package conditions, location tracking and predictive maintenance of transport equipment. Blockchain provides tamper-proof provenance information increasing transparency. Augmented/virtual reality aids training and remote troubleshooting. 3D printing customizes designs on demand. Robotics and autonomous vehicles automate material handling and fleet operations. Artificial intelligence recognizes patterns to optimize packaging selection, design defect prediction and demand forecasting. Adopters gain competitive advantages through increased visibility, efficiency and sustainability.

#Industrial Packaging Market Growth#Industrial Packaging Market Size#Industrial Packaging Market Share

0 notes