#biodegradable plastics industry size

Explore tagged Tumblr posts

Text

Bambrew’s range of eco-friendly packaging alternatives

Bambrew, an Indian startup specializing in sustainable packaging, is making strides in the fight against single-use plastics by offering a range of 'eco-friendly' alternatives, says Vaibhav Anant, founder & CEO. The company provides packaging solutions made from renewable, biodegradable materials such as bamboo, seaweed, banana fiber, and agro-waste. According to Anant, these materials are fully compostable and serve as viable alternatives for businesses seeking to reduce their environmental footprint.

“Our solutions are governed by four core principles of sustainability—eco-friendliness, functionality, cost-efficiency, and scalability. These guiding principles enable us to deliver packaging options that are not only environmentally responsible but also commercially viable for businesses of all sizes,” Anant says.

Bambrew offers a range of packaging alternatives, including mailer bags, flexible pouches, rigid boxes, and custom solutions, all designed to meet the functional needs of various sectors while remaining scalable. It has developed solutions for industries such as FMCG, CPG, fresh fruits and vegetables (F&V), food and beverages (F&B), and e-commerce and retail packaging.

Notable clients include Amazon, Nykaa, Hindustan Unilever, Mahindra Logistics, and Tata 1mg.

Material-Agnostic Company

Anant explains that Bambrew is a material-agnostic company, meaning it develops solutions using various materials, all adhering to the four core principles of sustainability as mentioned earlier.

Bambrew prioritizes sustainability not only in its products but throughout the entire product development lifecycle, from sourcing and compounding to conversion processes, says Anant. The company works closely with raw material providers and maintains complete control over production with the latest technology machines for in-house manufacturing. It also operates tech-assisted warehousing and logistics to ensure timely delivery to customers.

“By reducing our reliance on fossil fuels through the use of biofuels and solar energy, we are significantly lowering our carbon footprint. Equally important is the well-being of our workers, and we are committed to maintaining a healthy work-life balance. We adhere to an 8-hour shift structure and offer a range of benefits to ensure a supportive and positive work environment, with a strong emphasis on mental health,” Anant states.

The company has its manufacturing facility in Bangalore and collaborates with several contract manufacturing units across India to expand its reach and capabilities.

Rapid Growth

According to Anant, the company has made big progress over the last 12 months, with growth exceeding 8x.

“This momentum has been incredibly encouraging, and we’re excited to continue building on it in the years to come. As the demand for sustainable solutions grows, we’re committed to scaling responsibly and staying focused on our mission,” he says.

New Offerings

Bambrew is actively working towards the continuous development of advanced meta-materials. It has been extensively researching materials such as Biophil, a home-compostable bioplastic alternative, while also exploring other renewable resources. These materials are designed to offer high performance while being environmentally friendly.

In August of this year, the company introduced a new category of rigid boxes that utilize Kappa boards produced from post-consumer recycled fibers. The product features components like non-animal-based glue, recycled paper cladding, plastic-free Biophil lamination, and plant-based inks. Each element of this product is designed to meet Bambrew's environmental goals and contribute to a fully sustainable manufacturing cycle.

“Additionally, we are actively developing alternative solutions for pharmaceutical packaging, as well as advanced barrier films for food packaging within the FMCG sector. While these are only a few examples, all our efforts are directed towards the broader aim of pushing the envelope of what’s possible within the realm of sustainability and delivering solutions that meet the highest standards of quality while supporting a greener, more sustainable transition into the future,” Anant concludes.

11 notes

·

View notes

Text

Everything You Need to Know About Stickers

Stickers have become a staple in both personal and professional spaces, offering a versatile and creative way to express ideas, promote businesses, and enhance products. They come in a variety of shapes, sizes, and materials, making them suitable for different applications. In this informative guide, we will explore everything you need to know about stickers, including their types, manufacturing processes, and practical uses.

What Are Stickers?

A sticker is an adhesive label with a design or text on one side and a sticky backing on the other. Stickers can be made from different materials such as vinyl, paper, or polyester and can have finishes like glossy, matte, or transparent. Some stickers are designed for permanent applications, while others are removable or reusable.

Types of Stickers

Vinyl Stickers – Known for their durability, vinyl stickers are weatherproof and resistant to water and sunlight. They are ideal for outdoor use, such as car decals and bumper stickers.

Paper Stickers – These are cost-effective and best suited for indoor applications such as packaging, scrapbooking, or labeling.

Die-Cut Stickers – These stickers are precisely cut to the shape of the design, offering a high-end look. Die-cut vinyl stickers are especially popular in branding.

Holographic Stickers ��� With a reflective, multi-color finish, holographic stickers stand out and are often used for decorative purposes.

Clear Stickers – Transparent stickers give a seamless look when applied to surfaces like glass, plastic, or packaging.

Static Cling Stickers – These are non-adhesive stickers that cling to smooth surfaces using static electricity, making them reusable.

Eco-Friendly Stickers – Made from sustainable materials, these stickers are biodegradable and are a great choice for environmentally conscious brands.

Sticker Manufacturing Process

The process of making stickers involves several steps, from design to final production:

Designing – The artwork is created using digital design software.

Printing – The design is printed on sheets or rolls using inkjet, laser, or UV printing techniques.

Cutting – Stickers can be kiss-cut (leaving the backing intact) or die-cut to follow the shape of the design.

Lamination – A protective layer may be added to improve durability and prevent fading.

Packaging – Stickers are then cut into individual pieces or prepared as sticker sheets for distribution.

Common Uses of Stickers

Branding & Marketing – Businesses use custom stickers for logos, promotions, and packaging.

Personal Expression – People decorate laptops, water bottles, and phone cases with stickers to showcase their personality.

Educational & Informational – Schools and organizations use stickers for labeling, instruction, and awareness campaigns.

Event & Political Campaigns – Stickers serve as cost-effective promotional tools for political candidates, advocacy groups, and fundraisers.

Decor & Art – From wall decals to scrapbooking stickers, they add aesthetic appeal to various surfaces.

With the ever-growing demand for personalized and high-quality stickers, the industry continues to innovate with new materials and printing techniques. Whether for business or personal use, stickers remain an affordable and effective medium for creative expression and communication.

2 notes

·

View notes

Text

Effervescent tubes have revolutionised the pharmaceutical and nutraceutical industries, becoming the go-to solution for packaging effervescent tablets. As a prominent name in the sector, NBZ Healthcare, located in Mumbai, stands at the forefront of exceptionally effervescent tube manufacturing, ensuring quality and innovation.

In this article, we delve deep into the manufacturing of effervescent tubes, their applications, benefits, and the unparalleled expertise of NBZ Healthcare in this domain.

Understanding Effervescent Tubes

Effervescent tubes are specialised containers designed to store and preserve effervescent tablets. These tablets, when exposed to moisture or air, tend to lose their potency, necessitating robust, moisture-resistant packaging. Effervescent tubes, often crafted with airtight and tamper-proof caps, provide the ideal solution to ensure the longevity and effectiveness of these tablets.

Importance of Effervescent Tubes

Effervescent tubes are more than just packaging; they play a crucial role in the pharmaceutical and nutraceutical industries by:

1. Protecting Product Integrity:

- Shielding tablets from moisture and air.

- Preventing degradation of active ingredients.

2. Enhancing Consumer Experience:

- Easy to open and reseal.

- Portable and convenient for on-the-go consumption.

3. Ensuring Regulatory Compliance:

- Meeting stringent health and safety standards for pharmaceutical products.

4. Sustainability:

- With increasing focus on eco-friendly materials, many effervescent tubes are now designed to be recyclable or biodegradable.

Effervescent Tube Manufacturing Process

Effervescent tube manufacturing is a precise and technologically driven process. At NBZ Healthcare, we combine state-of-the-art machinery with strict quality control measures to produce exceptional effervescent tubes. Here’s an overview of the key stages:

1. Material Selection

- High-grade plastic materials such as polypropylene (PP) or polyethylene (PE) are used.

- Materials are selected based on moisture resistance, durability, and eco-friendliness.

2. Tube Extrusion

- Plastic granules are melted and extruded into tube-like shapes using extrusion machines.

- The dimensions and thickness are carefully controlled to meet industry standards.

3. Moulding

- Injection moulding is used to form the caps and closures of the tubes.

- Caps are designed to ensure an airtight seal and tamper resistance.

4. Printing and Branding

- Tubes are labelled or printed with product details, branding, and regulatory information.

- Advanced printing techniques ensure durability and clarity.

5. Quality Control

- Rigorous testing for moisture resistance, durability, and compatibility with effervescent tablets.

- Each tube undergoes inspection to ensure zero defects.

NBZ Healthcare: Redefining Effervescent Tube Manufacturing

As a leader in exceptionally effervescent tube manufacturing, NBZ Healthcare sets the benchmark for quality and innovation. Based in Mumbai, our facility is equipped with cutting-edge machinery and a dedicated team of professionals who prioritise precision and excellence.

What Sets NBZ Healthcare Apart?

1. Advanced Manufacturing Capabilities

- NBZ Healthcare utilises the latest extrusion and moulding technologies to produce high-quality tubes.

2. Customisation Options

- We offer custom designs, sizes, and branding options to cater to the unique needs of our clients.

3. Sustainable Practices

- Focused on reducing environmental impact, we incorporate eco-friendly materials and processes wherever possible.

4. Regulatory Compliance

- Our manufacturing processes comply with international standards, including ISO and FDA regulations.

5. Global Reach

- While based in Mumbai, NBZ Healthcare serves clients across India and internationally, ensuring timely delivery and exceptional service.

Applications of Effervescent Tubes

Effervescent tubes find applications in various sectors, including:

1. Pharmaceuticals:

- Storage of vitamins, supplements, and medications in effervescent tablet form.

2. Nutraceuticals:

- Packaging for dietary supplements and health-boosting effervescent tablets.

3. Food and Beverage:

- Containment of flavour-enhancing or health-focused effervescent powders and tablets.

4. Personal Care:

- Packaging for effervescent bath tablets or other similar products.

Innovations in Effervescent Tube Manufacturing

At NBZ Healthcare, innovation is at the heart of our operations. Here are some of the cutting-edge advancements we incorporate:

1. Smart Packaging Solutions

- Tubes embedded with QR codes or NFC tags for enhanced consumer engagement and traceability.

2. Enhanced Moisture Resistance

- Using desiccant-lined caps and advanced sealing technologies to further improve moisture protection.

3. Eco-Friendly Materials

- Transitioning to biodegradable plastics and exploring sustainable alternatives like biopolymers.

4. Automation and AI Integration

- Automated production lines ensure consistency and reduce manufacturing errors.

- AI systems monitor quality in real-time for enhanced accuracy.

Challenges in Effervescent Tube Manufacturing

While effervescent tube manufacturing offers immense potential, it comes with its own set of challenges, such as:

1. Material Costs:

- Balancing quality and affordability when sourcing raw materials.

2. Environmental Concerns:

- Reducing the carbon footprint of manufacturing processes.

3. Regulatory Compliance:

- Adhering to diverse regulatory standards across different markets.

4. Consumer Expectations:

- Meeting the growing demand for sustainable and innovative packaging solutions.

The Future of Effervescent Tube Manufacturing

The demand for effervescent tubes is expected to rise significantly as more consumers turn to effervescent products for their convenience and efficiency. NBZ Healthcare is well-positioned to lead this growth, with a focus on:

1. Sustainability Initiatives

- Introducing greener manufacturing processes and materials.

2. Global Expansion

- Reaching untapped markets to provide high-quality effervescent tubes worldwide.

3. Product Diversification

- Expanding into new applications and industries beyond pharmaceuticals and nutraceuticals.

4. Technological Upgrades

- Adopting emerging technologies to enhance efficiency and product quality.

Why Choose NBZ Healthcare for Effervescent Tubes?

At NBZ Healthcare, we combine years of expertise with a commitment to innovation and customer satisfaction. When you partner with us, you’re choosing:

- Unmatched Quality: Every tube is crafted with precision and care.

- Custom Solutions: Tailored to your product’s specific needs.

- Reliable Service: Consistent and timely delivery of all orders.

- Sustainable Values: Supporting environmentally responsible practices.

Conclusion

Effervescent tubes play a pivotal role in preserving the efficacy and quality of effervescent tablets. With NBZ Healthcare’s expertise in exceptionally effervescent tube manufacturing, businesses can rely on robust, high-quality packaging solutions tailored to their needs.

As a Mumbai-based pioneer in the industry, NBZ Healthcare continues to set the standard for excellence, innovation, and sustainability. Whether you’re in the pharmaceutical, nutraceutical, or any related industry, NBZ Healthcare is your trusted partner for exceptional effervescent tube solutions.

Reach out to us today and experience the difference in quality and service!

2 notes

·

View notes

Text

Why Poly Bags Are Essential for Retail and Industrial Packaging

In the world of packaging, few tools can compare to the versatility and utility of poly bags. From retail businesses to industrial sectors, these unassuming plastic sacks are essential for modern packaging solutions. But beyond their common use, poly bags offer a multitude of benefits across various industries. Whether you’re in retail, manufacturing, food, healthcare, agriculture, or event planning, understanding the importance of poly bags—and why they’re crucial—can optimize your operations and improve your bottom line.

Understanding Poly Bags

Poly bags, short for polyethylene bags, are made from a type of plastic known for its durability and flexibility. They come in various sizes, thicknesses, and designs, including open flat bags, gusseted bags, zipper bags, and more. Their adaptability to different packaging needs makes them an ideal choice for a wide range of applications.

The Benefits of Using Poly Bags

1. Versatility Across Industries

Poly bags cater to diverse needs, making them a staple in industries like retail, food, and healthcare. In retail, they serve as an economical packaging option for clothes, electronics, and hardware. In the food sector, their food-safe properties make them ideal for storing perishables safely. Healthcare sectors utilize them for sterile packaging of medical supplies, ensuring contamination-free storage.

2. Cost-Effective Solution

One of the main advantages of poly bags is their cost-effectiveness. Their lightweight nature reduces shipping costs, while their affordability makes them a budget-friendly option for businesses looking to optimize their packaging expenses without compromising quality.

3. Durability and Protection

Poly bags provide an unsurpassed level of protection for products against dirt, moisture, and damage during transportation and storage. The InfinitePack 1 Mil Clear Plastic Flat Open Poly Bags, for instance, boast extra strength and durability. Their 1 mil thickness ensures that even delicate items remain intact and protected.

4. Customization Options

Businesses can customize poly bags with logos, designs, and branding, offering a unique marketing opportunity. Custom-printed poly bags help reinforce brand identity and enhance the customer experience by adding a professional touch to packaging.

5. Eco-Friendly Options

In response to growing environmental concerns, many manufacturers now offer eco-friendly poly bag options made from biodegradable or recyclable materials. These alternatives allow businesses to maintain their commitment to sustainability while still enjoying the benefits of traditional poly bags.

Applications of Poly Bags in Key Industries

Retail Businesses

Retailers benefit from poly bags' affordability and convenience, using them for packaging clothing, accessories, and other merchandise. Their transparency allows customers to view products easily, enhancing the shopping experience.

Manufacturers and Distributors

For manufacturers and distributors, poly bags streamline the packaging process with their versatile application in bulk storage, transportation, and protection against environmental elements.

Food Industry

Poly bags play a critical role in the food industry, meeting all food safety requirements. The food-grade quality of bags like the InfinitePack ensures safe storage of perishables, snacks, or prepared meals.

Healthcare and Pharmaceutical Industry

In healthcare, sterile packaging is crucial. Poly bags provide a hygienic solution for storing medical instruments, supplies, and pharmaceuticals, reducing the risk of contamination.

Agriculture and Landscaping

Farmers and landscapers use poly bags for seed storage, plant protection, and packaging fertilizers. Their durability withstands the rigors of outdoor conditions, ensuring the integrity of agricultural products.

Event Planners and Marketers

For event planners and marketers, poly bags offer a convenient way to package promotional materials, giveaways, and event supplies. Customizable options also allow for branded packaging that enhances event visibility.

Highlighting InfinitePack 1 Mil Clear Plastic Flat Open Poly Bags

The InfinitePack 1 Mil Clear Plastic Flat Open Poly Bags serve as an excellent example of the versatility and efficiency of poly bags. Here are some key features and benefits:

Exceptional Value & Quality: Made from high-quality materials, providing extra strength and durability.

Stock Up for Any Occasion: Perfect for a variety of uses, from holiday treats to small item storage.

Perfectly Sized & Durable: Measuring 18" x 24" with a sturdy 1 mil thickness, they cater to multiple needs.

Food-Grade & Safe: Certified food-safe to meet all storage requirements, with options for heat sealing or twist tie closure.

Multi-Purpose Utility: Suitable for storing food, organizing supplies, and protecting items from dust and damage.

2 notes

·

View notes

Text

Revolutionizing Packaging: The Importance of Hemp Oil Boxes in the Market

As the wellness industry continues to expand, hemp oil has emerged as a popular product due to its numerous health benefits. This growth in demand has created a significant opportunity for brands to differentiate themselves through innovative packaging solutions. Hemp oil boxes play a crucial role in this endeavor, offering both practical and aesthetic benefits. Companies like Buy Product Boxes are leading the charge in providing high-quality, customized hemp oil packaging that meets the needs of both businesses and consumers. This article explores the importance of hemp oil boxes, current trends, and the innovative solutions offered by Buy Product Boxes.

The Significance of Hemp Oil Packaging

Hemp oil packaging is more than just a container; it serves several critical functions that contribute to the overall success of the product in the market. Here are some key reasons why hemp oil boxes are essential:

Protection and Preservation: Hemp oil boxes is sensitive to light, air, and temperature changes, which can affect its potency and shelf life. Proper packaging provides a barrier against these environmental factors, ensuring that the product remains effective and fresh for longer periods.

Brand Identity and Recognition: Customized packaging allows brands to showcase their unique identity. By incorporating brand colors, logos, and designs, hemp oil boxes can make products instantly recognizable and memorable to consumers.

Consumer Trust and Compliance: High-quality packaging conveys professionalism and reliability, which are crucial in the health and wellness industry. Moreover, compliant packaging that includes necessary information such as dosage instructions, ingredients, and certifications helps build consumer trust and ensures adherence to regulations.

Sustainability: As consumers become more eco-conscious, sustainable packaging options are increasingly important. Hemp oil boxes made from recyclable or biodegradable materials appeal to environmentally aware customers and reflect a brand’s commitment to sustainability.

Functionality and Convenience: Packaging that is easy to open, reseal, and store enhances the user experience. Functional features such as dropper inserts, child-resistant closures, and tamper-evident seals are particularly important for hemp oil products.

Trends in Hemp Oil Packaging

Several trends are shaping the landscape of hemp oil packaging. These trends reflect both consumer preferences and advancements in packaging technology.

1. Eco-Friendly Materials

Sustainability is a major trend in the packaging industry. Consumers are increasingly seeking products that minimize environmental impact. Hemp oil boxes made from eco-friendly materials, such as recycled paper, biodegradable plastics, and sustainable inks, are gaining popularity. Buy Product Boxes offers a range of sustainable packaging options that help brands reduce their carbon footprint and appeal to eco-conscious consumers.

2. Minimalist Design

The trend towards minimalist design is prominent in the hemp oil market. Clean, simple, and elegant packaging designs convey a sense of purity and quality. This approach often involves the use of natural colors, straightforward typography, and minimal graphics, which align well with the health-focused nature of hemp oil products.

3. Customization and Personalization

Customization allows brands to create unique packaging that stands out on the shelves. Personalized packaging, which can include custom shapes, sizes, and designs, helps brands differentiate themselves from competitors. Advances in digital printing technology have made it easier and more cost-effective to produce customized packaging, even for smaller batches.

4. Smart Packaging

The integration of smart technology into packaging is an emerging trend. Features such as QR codes, NFC tags, and augmented reality can provide consumers with additional information about the product, enhance the user experience, and offer interactive elements. Smart packaging not only adds value to the product but also helps brands engage with their customers in innovative ways.

5. Functional Features

Functionality is key to consumer satisfaction. Hemp oil packaging with practical features such as child-resistant caps, tamper-evident seals, and easy-to-use dropper inserts enhances the user experience. These features are particularly important for ensuring the safety and convenience of the product.

Buy Product Boxes: Leading the Way in Hemp Oil Packaging

Buy Product Boxes has established itself as a leader in the customized packaging industry, offering a wide array of solutions tailored to the needs of hemp oil brands. Their commitment to quality, innovation, and sustainability makes them a preferred partner for businesses looking to elevate their packaging.

Innovative Design Solutions

Buy Product Boxes provides a comprehensive range of design options, allowing brands to create packaging that perfectly aligns with their identity. Whether it’s through vibrant colors, unique shapes, or interactive elements, their design team collaborates closely with clients to bring their vision to life. This collaborative approach ensures that the final product not only looks great but also resonates with the target audience.

Advanced Printing Technology

Leveraging the latest in printing technology, Buy Product Boxes offers high-quality, precise, and vibrant printing options. This capability is crucial for creating detailed and eye-catching designs that stand out on the shelves. Their digital printing technology supports short runs and rapid prototyping, allowing brands to test new designs quickly and cost-effectively.

Sustainable Packaging Solutions

Sustainability is a core focus for Buy Product Boxes. They offer a variety of eco-friendly materials, including recycled paper, biodegradable plastics, and compostable films. Additionally, they are committed to minimizing waste in their production processes and ensuring that their packaging solutions are as environmentally friendly as possible.

Customization at Scale

One of the standout features of Buy Product Boxes is their ability to deliver customized packaging at scale. Whether a brand needs a few hundred units or several million, Buy Product Boxes can accommodate their needs without compromising on quality or turnaround time. This scalability is particularly beneficial for growing brands that need to quickly adapt to changing market demands.

Exceptional Customer Service

Buy Product Boxes prides itself on providing exceptional customer service. From the initial consultation to the final delivery, their team is dedicated to ensuring a seamless and satisfactory experience for their clients. This commitment to service is reflected in their high customer retention rates and positive testimonials.

The Future of Hemp Oil Packaging

As the hemp oil market continues to grow, the role of packaging will become increasingly important. Here are some predictions for the future of hemp oil packaging:

Increased Personalization

The demand for personalized experiences will drive further advancements in customization technology. We can expect to see more sophisticated and affordable options for creating individualized packaging, including mass personalization capabilities that allow for unique designs on a large scale.

Greater Emphasis on Sustainability

Sustainability will remain a critical focus, with continued innovation in eco-friendly materials and processes. Brands will seek out packaging solutions that not only meet but exceed environmental standards, and companies like Buy Product Boxes will play a crucial role in developing these solutions.

Enhanced Consumer Interaction

Interactive packaging will become more prevalent, with augmented reality (AR) and virtual reality (VR) features providing immersive and engaging experiences. These technologies will offer new ways for brands to connect with consumers, providing added value beyond the product itself.

Integration of Smart Technologies

Smart packaging will become more integrated, offering features such as freshness indicators, temperature controls, and real-time tracking. These advancements will improve product safety and quality, while also providing valuable data for both consumers and brands.

Evolution of Design Aesthetics

Design trends will continue to evolve, with a focus on simplicity, functionality, and authenticity. Brands will seek to create packaging that not only looks good but also tells a story and reflects their values. Minimalist designs, coupled with high-quality materials and finishes, will remain popular.

Conclusion

Hemp oil box packaging is a vital component of product success, offering protection, branding, compliance, and sustainability. Companies like Buy Product Boxes are leading the way in providing innovative, high-quality, and customized packaging solutions that meet the diverse needs of the market. As consumer preferences continue to evolve, the importance of hemp oil boxes will only grow, offering exciting opportunities for brands to connect with their audience in meaningful and memorable ways.

By investing in high-quality, customized hemp oil packaging, brands can enhance their identity, improve consumer satisfaction, and ultimately drive business success. The future of hemp oil packaging is bright, and with the right partner, the possibilities are endless.

2 notes

·

View notes

Text

History of poultry cartons in Todays era ?

Poultry cartons, also known as egg cartons or egg crates, have a rich history dating back to the early 20th century. These containers have evolved over the years, reflecting changes in the poultry industry, consumer preferences, and environmental concerns. In today's era, poultry cartons have undergone several significant developments.

Early History: The use of containers to transport and sell eggs can be traced back to ancient civilizations. However, the modern egg carton as we know it began to emerge in the early 20th century. In 1911, a Canadian newspaper editor named Joseph Coyle patented a paperboard egg carton, which was designed to protect eggs during transportation and storage.

Evolution of Materials: In the mid-20th century, as plastics gained popularity, some egg cartons transitioned from paperboard to plastic. However, this shift was often met with resistance from consumers and environmentalists concerned about plastic waste. As a result, many producers returned to using paper-based cartons in response to consumer demand for more eco-friendly packaging.

Environmental Considerations: In recent years, there has been a growing emphasis on sustainability and environmental responsibility. Poultry cartons have adapted to this trend by becoming more eco-friendly. Many cartons are now made from recycled paper or other sustainable materials. Some are even biodegradable or compostable, addressing concerns about plastic pollution.

Labeling and Information: In today's era, poultry cartons often include detailed information beyond just protecting eggs. They may feature branding, nutritional information, and certifications such as "cage-free," "organic," or "free-range." This transparency allows consumers to make informed choices about the eggs they purchase.

Variety of Sizes and Styles: Poultry cartons come in various sizes and styles to accommodate different quantities of eggs, from half-dozen cartons to bulk containers for commercial use. Some cartons have clear plastic windows, allowing consumers to see the eggs inside. These variations cater to a wide range of consumer needs and preferences.

Technological Advancements: Modern technology has also influenced the poultry industry and its packaging. Automated machinery is often used to fill and seal cartons efficiently, ensuring that eggs are handled with care and precision. Additionally, advancements in printing technology have made it easier to create colorful and informative packaging.

E-commerce and Direct Sales: The rise of e-commerce and direct-to-consumer sales has impacted poultry cartons as well. Farms and small-scale producers can now sell eggs directly to consumers, often in personalized or artisanal packaging, allowing them to stand out in a competitive market.

In conclusion, poultry cartons have a long and evolving history, adapting to changes in the poultry industry, consumer preferences, and environmental concerns. In today's era, they reflect a growing emphasis on sustainability, information transparency, and technological advancements. As consumer demands and industry practices continue to evolve, so too will the design and function of poultry cartons.

https://poultrycartons.com/about/

2 notes

·

View notes

Text

Explore Top Sustainable Packaging Trends in 2023

Introduction:

Sustainable packaging has become a significant concern for businesses and consumers alike, as the world continues to prioritize environmental consciousness.

With the increasing focus on sustainability, it’s crucial to explore the top sustainable packaging trends that will shape the packaging industry in 2023. This article delves into the various sustainable packaging trends that are expected to make a significant impact in the coming year.

Importance of Sustainable Packaging:

Sustainable packaging plays a prime role in minimizing waste, conserving resources, and minimizing environmental impact.This doesn’t only prioritize eco-conscious consumers but also is very beneficial for businesses in the long run.

Sustainable packaging can enhance brand reputation, attract environmentally conscious customers, and lead to cost savings through optimized material usage and streamlined logistics.

Sustainable Packaging Trends:

Read below to know more about the top Sustainable Packaging Trends that are shaping the future of packaging industry.

Eco-Friendly Packaging Materials:

To achieve sustainable packaging goals, businesses are increasingly turning to eco-friendly materials that have minimal impact on the environment. Three prominent options are:

Biodegradable Packaging: Biodegradable packaging materials are designed to decompose naturally over time, minimizing the piling of waste in landfills. They are formed from plant-based polymers, such as PLA (polylactic acid), which can break down into harmless elements with the help of microorganisms.

Compostable Packaging: Compostable packaging goes a step further by not only breaking down but also providing valuable nutrients to the soil during the composting process. These materials are made from organic matter, such as cornstarch or bagasse, and contribute to a circular economy by turning into compost that can enrich agricultural lands.

Recyclable Packaging: Recyclable packaging materials includes cardboard, glass, and certain types of plastics, can be gathered, refined, and reused to create new packaging or other products. Recycling preserves resources, reduces usage of energy, and minimizes the demand for virgin materials.

Minimalistic Packaging:

One of the emerging sustainable packaging trends is minimalistic design. This approach focuses on eliminating excess packaging and using the bare minimum required to protect and present the product.

Minimalistic packaging not only reduces waste but also enhances the product’s visual appeal, creating a sleek and modern aesthetic.

Packaging Reduction and Lightweighting:

To further minimize the impact of packaging on the environment, companies are vigorously. seeking ways to minimize the amount of material used. Packaging reduction involves optimizing the size and dimensions of packaging to minimize waste, transportation costs, and storage requirements.

Lightweight, on the other hand, aims to decrease the weight of packaging materials without compromising their integrity, leading to energy savings and reduced emissions during transportation.

Smart Packaging Solutions:

Advancements in technology have paved the way for smart packaging solutions that offer enhanced functionality while remaining environmentally friendly. Two notable examples are:

Intelligent Labels: Intelligent labels comprise of RFID (Radio Frequency Identification) or NFC (Near Field Communication) technology to impart real-time insights about the product, such as its origin, ingredients, and expiration date. By enabling consumers to make informed choices, intelligent labels promote transparency and minimize food waste.

Active Packaging: Active packaging involves the integration of active substances or components into the packaging material to extend the shelf life of the product. Oxygen absorbers, moisture control packets, and antimicrobial films are examples of active packaging solutions that help maintain product freshness, reduce spoilage, and minimize food waste.

Plant-Based and Renewable Packaging:

As the demand for sustainable packaging grows, there is a rising focus on plant-based and renewable materials. Packaging created from renewable resources, such as bamboo, sugarcane, or hemp, offers a viable substitute to traditional petroleum-based plastics.

These materials are not only biodegradable or dispensable but also have a lower carbon footprint during production.

Packaging Innovations:

In addition to the aforementioned sustainable packaging trends, packaging innovations continue to drive sustainable practices. Three noteworthy innovations include:

Edible Packaging: Edible packaging materials, often made from natural polymers like seaweed or starch, can be consumed along with the product. This eliminates the need for additional waste and offers a unique, eco-friendly packaging experience.

Water-Soluble Packaging: Water-soluble packaging is created to dissolve when it comes into contact with water, minimizing the amount of waste produced. This type of packaging is particularly applicable for single-use items like detergent pods or dishwasher tablets.

Mushroom Packaging: Mushroom packaging is also known as mycelium packaging, it makes use of the root structure of mushrooms to create a biodegradable and compostable material. It offers a sustainable alternative to foam-based packaging materials, minimizing reliance on non-biodegradable options.

Packaging for E-commerce:

With the emergence of e-commerce, sustainable packaging solutions are crucial to minimizing the environmental impact of shipping and handling.

Sustainable Packaging Trends in the Food Industry:

The food industry is actively adapting to sustainable packaging practices to address the challenges of food waste and environmental impact.

From compostable food containers to eco-friendly food wraps, innovative packaging solutions are being developed to ensure the freshness and safety of food products while reducing the ecological footprint.

Sustainable Packaging Trends in the Beauty and Personal Care Industry:

Sustainable Packaging Trends in the Fashion Industry:

Sustainable Packaging is gaining popularity in the Fashion Industry, as various brands realize the need to minimize environmental impact of products.

Packaging that is created using recycled materials, biodegradable garment bags and innovative ideas such as seaweed-based packaging is becoming increasingly popular.

Sustainable Packaging Trends in the Electronics Industry:

The electronics industry is notorious for its excessive packaging and e-waste. However, manufacturers are now adopting to sustainable packaging trends such as corrugated cardboard, molded pulp, and plant-based plastics to minimize waste generation and improve recycling rates.

Collaboration for Sustainable Packaging:

Collaboration between stakeholders is crucial to drive sustainable packaging initiatives forward. Brands, packaging manufacturers, consumers, and policymakers need to work in harmony to develop and implement effective strategies that boost sustainable practices throughout the supply chain.

Conclusion – Sustainable Packaging Trends:

In conclusion, the packaging industry is witnessing a shift towards sustainability, driven by the growing awareness of environmental issues and consumer preferences.

In 2023, the top sustainable packaging trends will revolve around eco-friendly materials, minimalistic design, packaging reduction, smart solutions, plant-based alternatives, and innovative packaging options.

By adapting to these sustainable packaging trends, businesses can align with consumer values, minimize their carbon footprint, and contribute to a more sustainable future.

FAQs:

Why is sustainable packaging important?

Sustainable packaging is crucial as it helps to minimize waste, preserve resources, and minimize environmental impact. It also improves brand reputation and attracts eco-conscious consumers.

What are some eco-friendly packaging materials?

Eco-friendly packaging materials such as biodegradable packaging, compostable packaging, and recyclable packaging. These materials have minimal impact on the environment and promote a circular economy.

How can minimalistic packaging benefit businesses?

Minimalistic packaging not only reduces waste but also enhances the visual appeal of products, creating a sleek and modern aesthetic. It can attract consumers and differentiate brands in the market.

What are some packaging innovations in sustainability?

Some packaging innovations in sustainability include edible packaging, water-soluble packaging, and mushroom packaging. These innovations offer biodegradable or compostable alternatives to traditional packaging materials.

How can collaboration drive sustainable packaging initiatives?

Collaboration between brands, packaging manufacturers, consumers, and policymakers is crucial to develop and implement effective strategies for sustainable packaging. By working together, stakeholders can drive positive change throughout the supply chain.

2 notes

·

View notes

Text

And here��s the thing — you CAN make stabilized resinous plastic that conforms like leather out of wood, or any plant containing cellulose. It’s called celluloid or Parkesine. It was discovered in the mid 1800’s. There’s a VERY good reason we don’t use it anymore.

It’s SO flammable that it will unpredictably spontaneously combust at temperatures above 100 degrees F.

Celluloid caused more house fires in the 1800’s than almost anything else did. It was very popular for ornamental pieces and was woven into textiles for upholstery to stiffen it. It IS in fact a type of plastic, very similar to polyester. But the fact it’s so ridiculously flammable makes it unusable in modern times, where most cloth is required to be demonstrably intolerant of spontaneous combustion. (The irony that PVC is still so ubiquitous doesn’t elude me — it’s not unto itself very flammable, true, but it does turn into acid and releases some very sketchy fumes when it’s heated above 140F.. But I digress.)

It’s the main reason I look at faux leather with great suspicion, especially vegan leather’s manufactured in countries where they don’t test for fire safety and may use celluloid inclusions, which is dirt cheap to produce as its fundamental components come from pitch, a byproduct of making burnable charcoal.

Bio-plastics are something you treat with extreme caution. Many of them are even more dangerous than oil plastics, either because they’re flammable, or because they’re irritating if not outright toxic to your skin. (Many seaweed/algae plastics are like this, which is why you typically don’t see them marketed for textiles, and if you do, then I suggest you second guess the notion, lest you rush to the ER in anaphylactic distress).

Yes they’re biodegradable, but SO IS LEATHER. And leather, treated right, is nearly fireproof, waterproof, And it’s warm.

Honestly I get the sentiment — many fur farms still have a ways to come in terms of humane treatment. And some furs and hides just aren’t sustainable. Rabbits seem like they’d be great fur animals, but their hide is where almost all their minimal fat is stored, (as an oil, no less) leaving it very porous and thin. It’s got its place in decorative clothing but it’s pretty useless otherwise. You can line a coat with rabbit fur, but it’s so hard to maintain it’s not cost effective.

Foxes are better, and fox fur is among the warmest on earth, (and most cost effective for the size of the animal) but foxes are carnivorous, territorial, and only get on with each other in small groups, so to farm them ethically requires a lot of space and many many separate cages. I’ve seen good fox farms, and they’re HUGE, because each fox needs at least 18 square feet to itself, and there’s 3-5 in a group, times 250 foxes. It adds up. The startup loans for that take half a lifetime to repay and that’s assuming the market value stays where it’s at now, with 40-200 dollars a pelt.

Of course this would be easier if those farms got subsidies for making renewables, but nobody wants to have that conversation.

Then there’s cows. Bullhide and steer hide are actually quite cheap, because cows are very numerous, for places that sell the hide, but nobody wants to pay extra to have their cows skinned to par, because cattle farmers have a hard enough time as it is, and that’s with all the subsidies they already get.

Mind, yes, cows are already skinned prior to processing, and many of the hides DO go to making leather goods, but the current industrial process ruins most of the hide in the name of doing it as fast as possible, meaning that you can’t make anything more than small items out of it because too much of the whole hide has holes or has been over-stretched. Plus nobody is actually maintaining the cows for hide like they used to. It’s why branding is done on the back end of a cow, where the hide is not as likely to be good, because any rancher worth his salt kept his cows as clean and undamaged as possible to get the best money from their hide, which maybe didn’t sell for much, but it was a nice bonus.

Point is, COW leather is quite easy to turn into a nice, renewable material, provided industry takes a few minutes more to skin the cow properly, (which requires humans to do — machines haven’t yet developed to the point of being able to clean skin something as big and variable as a cow, which is half of the problem.) it just takes incentive to do it.

Other leathers get more tricky, I.e the fox example above. But cows are a good place to start.

ALSO I’d like to point out that bio leather IS NOT ENVIRONMENTALLY FRIENDLY. The amount of power, water, chemicals and machinery it takes to produce it FAR outstrips its usefulness as a biodegradable plastic product, not when you have animal hides that are already there in abundance, being mutililated for the sake of efficiency. It’s creating problems by trying to solve them, without actually addressing the problem.

Now, give it another 30 years and some conspiratorial Dutch scientists will come up with a way to streamline the process and actually turn it into an arguably better alternative.

But the way those plastics and leather are produced now? Nah. Go with real leather. It’s far nicer to both the animal, whose life is going to be done away with anyway, no matter the reason, and it’s more environmentally friendly, assuming the leather is tanned properly. Yes there are chemicals used these days like Lye, but lye is ridiculously easy to make, easy to dispose of, and isn’t actually very toxic to waterways at large. And it’s much more hygienic than using ammonium from urine or highly toxic saltpeter. The only other chemicals you need to cure and tan leather all come from natural and renewable sources, provided it’s not softened with mineral oil (which sometimes it is, for dyeing purposes, but that’s not much of a stretch to fix, just switch to a different low viscosity oil. People have been making leather LONG before mineral spirits and oil were a thing.)

Leather is your friend for environmental protection and actually recycling wastes.

28K notes

·

View notes

Text

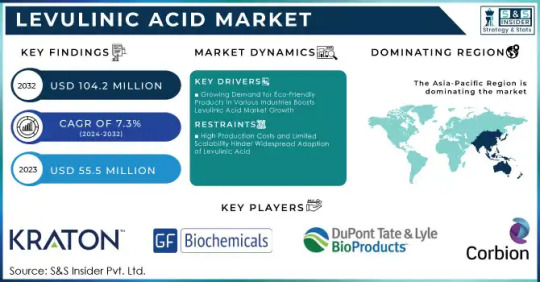

Bio-Based Chemicals Drive Growth in the Levulinic Acid Market

Growing Demand for Bio-Based Chemicals and Sustainable Industrial Solutions Drives Growth in the Levulinic Acid Market.

The Levulinic Acid Market Size was valued at USD 55.5 Million in 2023 and is expected to reach USD 104.2 Million by 2032 and grow at a CAGR of 7.3% over the forecast period 2024-2032.

The Levulinic Acid Market is driven by increasing global interest in bio-based and renewable chemicals. Levulinic acid, derived from biomass such as cellulose and sugars, serves as a versatile platform chemical used in the production of resins, plasticizers, solvents, pharmaceuticals, and fuel additives. With growing environmental concerns and the shift away from fossil-based feedstocks, levulinic acid is emerging as a key ingredient in green chemistry solutions across various industries.

Key Players

Beijing Sino-High Technology

BioChem

Corbion

Dupont Tate & Lyle Bio Products

GFBiochemicals

Kraton Polymers

Nexant Inc.

Renewable Energy Group, Inc.

Segetis, Inc.

Shanxi Lihua Bio-Technology Co., Ltd.

Future Scope & Emerging Trends

The future of the levulinic acid market looks promising, bolstered by increasing R&D investment in bio-refineries and rising adoption of sustainable manufacturing practices. Key emerging trends include the use of levulinic acid in biodegradable plasticizers, agrochemicals, and green solvents, along with its growing role as a platform chemical in the synthesis of biofuels and specialty polymers. As regulatory bodies worldwide push for reduced environmental impact and carbon footprint, industries are transitioning to renewable alternatives—positioning levulinic acid as a vital contributor to the global green chemical economy. The Asia-Pacific region is expected to witness the fastest growth due to increasing demand from pharmaceuticals, agriculture, and cosmetics sectors.

Key Points

Derived from renewable biomass; key ingredient in green chemistry

Used in pharmaceuticals, agrochemicals, plasticizers, and fuel additives

Strong push from environmental regulations favoring bio-based chemicals

R&D driving innovation in levulinic acid-derived polymers and solvents

Asia-Pacific leading market growth due to industrial demand and sustainability goals

Conclusion

The Levulinic Acid Market is set for long-term expansion as industries and governments prioritize sustainability and the transition to a circular bioeconomy. With its wide application range and eco-friendly profile, levulinic acid is becoming a cornerstone in the development of next-generation bio-based products.

Read Full Report: https://www.snsinsider.com/reports/levulinic-acid-market-4917

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Levulinic Acid Market#Levulinic Acid Market Size#Levulinic Acid Market Share#Levulinic Acid Market Report#Levulinic Acid Market Forecast

0 notes

Text

Wooden Spoons Manufacturer in Ahmedabad - Unitech Cutlery

Wooden Spoons Manufacturer in Ahmedabad - Unitech Cutlery

In today’s environmentally conscious world, the demand for sustainable kitchenware is higher than ever. As more individuals and businesses turn toward eco-friendly alternatives, wooden spoons manufacturer brands are gaining significant attention. Among them, Unitech Wooden Cutlery, based in Ahmedabad, stands out as a trusted name for high-quality, disposable wooden spoons.

Unitech Wooden Cutlery specializes in manufacturing wooden spoons in Ahmedabad, offering a wide variety of options suitable for both personal and commercial use. From catering businesses and food stalls to home kitchens, our spoons are crafted to deliver durability, functionality, and sustainability. If you’ve ever searched for "wooden spoons near me" in hopes of finding a reliable supplier, Unitech is your answer.

Eco-Friendly and Sustainable Approach

We live in an era where plastic pollution is a growing threat. Single-use plastic cutlery contributes immensely to environmental damage. That’s why switching to biodegradable alternatives like wooden spoons is no longer a luxury—it's a necessity. At Unitech Wooden Cutlery, we produce spoons using natural wood sourced from sustainable forests. These spoons are completely biodegradable and compostable, making them the perfect alternative to plastic.

As a leading wooden spoons manufacturer in India, our process includes selecting premium wood that maintains its strength and smooth finish. Our production methods emphasize hygiene, safety, and precision, so every spoon that leaves our facility is clean, sturdy, and food-safe. Whether you’re using them to stir hot soups or serve delicious desserts, our spoons never disappoint.

Versatile and Durable Wooden Spoons

Our product range is designed to cater to a variety of needs. Unitech Wooden Cutlery manufactures disposable wooden spoons that are ideal for every occasion—from small get-togethers to large-scale catering services. Available in various sizes and shapes, they add a rustic, aesthetic appeal to your table setting while also being completely functional.

Being a responsible wooden spoons manufacturer, we go the extra mile to offer customization options. If your restaurant, café, or event business is looking for custom-branded spoons, Unitech can deliver. Our wooden spoons are not only strong and splinter-free but also elegant enough to elevate your food presentation.

When people search for wooden spoons near me, they’re often looking for availability and reliability. At Unitech, we stock a large quantity of products to meet bulk demands without compromising on quality. Our nationwide delivery network ensures that your order reaches you quickly and efficiently.

Competitive Pricing and Bulk Orders

Being a well-established wooden spoons manufacturer in India, we understand the importance of offering products at competitive prices. Our cost-effective manufacturing process allows us to offer the best prices in the market. Whether you are buying in small quantities or placing a bulk order, you will always get great value for money.

Our packaging is designed to maintain product integrity while making storage and distribution convenient for retailers and end users. Each set of wooden spoons is carefully packed, sealed, and labeled for easy handling. If you're a distributor or wholesaler, our team is ready to assist you with pricing, logistics, and after-sales support.

Why Choose Us

Unitech Wooden Cutlery is more than just a wooden spoons manufacturer. We are a brand committed to sustainability, quality, and customer satisfaction. Our spoons are crafted from premium-grade wood, undergo strict quality checks, and are produced in a hygienic environment. What sets us apart is our dedication to excellence and the ability to serve a wide range of industries across India. We understand our clients' needs and work hard to build lasting relationships through dependable service and timely deliveries. Our reputation as a top wooden spoons manufacturer in Ahmedabad has been built on trust, innovation, and our relentless focus on customer satisfaction.

Conclusion

Unitech Wooden Cutlery is your go-to wooden spoons manufacturer in India, known for producing eco-friendly, high-quality, and affordable wooden spoons. Whether you are a business owner, caterer, or just someone who prefers sustainable living, our spoons offer the perfect blend of utility and environmental responsibility. With our manufacturing unit based in Ahmedabad, you can count on us for reliable supply, excellent craftsmanship, and unmatched service. So, the next time you search for "wooden spoons near me," remember that Unitech Wooden Cutlery is just a call or click away. Choose a better future, choose Unitech.

For more information about these blogs, please call us at +91-812-832-1196 or mail us at [email protected]. Let us help you switch to a greener tomorrow with Unitech Wooden Cutlery!

For More Information

+91-812-832-1196

+91-990-941-9148

20, Raghukul Industrial Estate, Aadarsh Estate -2, Odhav, Ahmedabad, Gujarat 382415

0 notes

Text

Europe Bioplastics Market Trends, Size, Demand, Competition, Challenge and Future Opportunities 2034: SPER Market Research

Bioplastics are materials made from sustainable biological sources that provide an alternative to typical petrochemical-based plastics. They are made from natural resources including plants, animals, and microorganisms, making them more sustainable and eco-friendly. Bioplastics can be biodegradable, breaking down naturally over time, or non-biodegradable, providing durability comparable to traditional plastics. Bioplastics are being developed and adopted in order to minimize reliance on fossil fuels, reduce greenhouse gas emissions, and alleviate plastic pollution. Bioplastic technologies have advanced, resulting in increased performance qualities that make them more competitive with regular plastics. However, problems persist, such as rising production costs, restricted raw material supply, and the requirement for adequate waste treatment infrastructure.

According to SPER Market Research, ‘Europe Bioplastics Market Size- By Product Type, By Application - Regional Outlook, Competitive Strategies and Segment Forecast to 2034’ states that the Europe Bioplastics Market is estimated to reach USD XX billion by 2034 with a CAGR of 15.37%.

A number of important reasons are propelling the bioplastics market in Europe to tremendous growth. The growing need for environmentally friendly and sustainable materials across a range of sectors, such as packaging, automotive, and agricultural, is one of the main motivators. This change is being driven by stricter laws intended to cut down on plastic waste and carbon emissions, as well as increased environmental consciousness. For example, in order to promote the use of bioplastics, the European Commission has put laws into place to control the use of polymers in food packaging applications. Improvements in bioplastic technologies have also resulted in better performance attributes, increasing their competitiveness with conventional polymers.

The European bioplastics market faces a number of challenges that may limit its growth and adoption. A major concern is that bioplastics have higher production costs than conventional plastics, which can reduce their competitiveness in price-sensitive industries. Furthermore, the scarcity of raw materials suitable for bioplastic production creates a supply chain challenge that may limit the scalability of bioplastic manufacturing. Another issue is the lack of standardized definitions and certifications for bioplastics, which causes consumer confusion and skepticism about their environmental benefits. Furthermore, industrial composting infrastructure is lacking in many areas, limiting end-of-life options for bioplastic products and potentially increasing waste.

Germany dominates the European bioplastics market due to its large production base and commitment to sustainable methods.Some of the key players are:- Arkema, BASF SE, Braskem, Corbion, Danimer Scientific.

Request a Free Sample Report: https://www.sperresearch.com/report-store/europe-bioplastics-market.aspx?sample=1

Europe Bioplastics Market Segmentation:

By Product Type: Based on the Product Type, Europe Bioplastics Market is segmented as; Bio-based Biodegradables, Bio-based Non-biodegradables.

By Application: Based on the Application, Europe Bioplastics Market is segmented as; Flexible Pakaging, Rigid Packaging, Automotive and Assembly Operations, Agriculture and Horticulture, Construction, Textiles, Electrical and Electronics, Others.

By Region: This research also includes data for Germany, Australia, Switzerland, France, Great Britain, Spain, Italy.

For More Information, refer to below link: –

Europe Bioplastics Market Growth

Related Reports:

Saudi Arabia Biodegradable Polymers Market Growth, Size, Trends Analysis- By Material Type, By Application - Regional Outlook, Competitive Strategies and Segment Forecast to 2033

Middle East & Africa Oilfield Chemicals Market Growth, Size, Trends Analysis - By Product, By Application - Regional Outlook, Competitive Strategies and Segment Forecast to 2033

Follow Us –

LinkedIn | Instagram | Facebook | Twitter

Contact Us:

Sara Lopes, Business Consultant — USA

SPER Market Research

+1–347–460–2899

#Europe Bioplastics Market#Bioplastics Market#Europe Bioplastics Market Growth#Europe Bioplastics Market Trends#Europe Bioplastics Market Size#Europe Bioplastics Market Share#Europe Bioplastics Market Revenue#Europe Bioplastics Market Demand#Europe Bioplastics Market Forecast#Europe Bioplastics Market Competition#Europe Bioplastics Market Report#Europe Bioplastics Market Future Outlook#Europe Bioplastics Market Segmentation#Europe Bioplastics Market Challenges

0 notes

Text

The Ultimate Guide to Twisted Handle Paper Bags: Stylish, Sustainable, and Smart for Carrying Your Papers

In today’s eco-conscious world, finding practical and sustainable alternatives to single-use plastics is more important than ever. Whether you're organising documents, gifting items, or packaging retail products, twisted handle paper bags are fast becoming the go-to solution for businesses and individuals alike. If you’re looking for a sturdy and eco-friendly bag for papers, or planning to stock up for your business, look no further than Thepaperbagstore – a trusted name in providing high-quality paper packaging solutions in the UK.

Why Choose a Paper Bag for Papers?

Storing and carrying paperwork might seem like a simple task, but anyone who’s ever dealt with disorganised sheets, dog-eared folders, or bulky plastic wallets knows how frustrating it can be. That’s where a bag for papers truly shines.

Paper bags offer:

Structure and support – Unlike plastic carriers that crumple under weight, paper bags with reinforced bases and sides keep documents flat and protected.

Eco-appeal – Paper bags are recyclable, compostable, and biodegradable, aligning with sustainable lifestyle choices.

Professional look – A kraft paper bag exudes sophistication and responsibility, making it perfect for events, presentations, or office errands.

For instance, when attending a job interview or business meeting, handing over a proposal or brochure in a smart, twisted handle paper bag gives an immediate impression of care and professionalism.

What Makes Twisted Handle Paper Bags Stand Out?

Among the wide variety of paper bags available, twisted handle paper bags are a standout for several reasons:

1. Durability

These bags are built to handle weight. The handles are crafted by twisting strong paper into a rope-like texture and securely attaching them to the bag. This makes them strong enough to carry not only papers, but small gifts, merchandise, and promotional items too.

2. Comfort and Convenience

The twisted paper handles are comfortable to grip and easy on the fingers, even when the bag is full. Compared to die-cut handles or string options, twisted handles balance practicality and comfort perfectly.

3. Reusable and Recyclable

Made from kraft paper or recycled paperboard, these bags are eco-friendly through and through. Most are uncoated, which enhances recyclability, and many can be reused multiple times before showing signs of wear.

4. Aesthetic Appeal

Available in various colours and finishes, these bags are ideal for both personal and commercial use. Whether plain brown kraft or vibrant hues, they provide a neat canvas for branding, labelling, or custom messages.

Thepaperbagstore – Your One-Stop Paper Bag Solution

When it comes to quality and variety, Thepaperbagstore is a leader in the paper bag industry in the UK. Catering to individuals, small businesses, and large retailers, the store specialises in all kinds of paper bags – with a special focus on twisted handle paper bags.

Why Shop at Thepaperbagstore?

Wide Selection – Choose from a diverse range of sizes, colours, and styles.

Eco-Focused – Most bags are made from recycled materials and are fully recyclable.

Competitive Pricing – Great value for bulk orders, ideal for retail and promotional events.

Fast UK Delivery – Reliable and quick shipping across the United Kingdom.

From small lunch-bag sized options to A3-sized bags for papers, their catalogue ensures you’ll find the right fit for your needs.

Creative Uses for Twisted Handle Paper Bags

Twisted handle paper bags are more versatile than they might appear. Let’s explore how you can use them creatively:

● Business Branding

Small boutiques and artisan stores often use branded paper bags to enhance customer experience. Thepaperbagstore offers plain bags ideal for stamping or custom printing, allowing you to add your logo or design for a personalised touch.

● Event Giveaways

Organising a seminar, workshop, or corporate event? Pack information brochures, catalogues, pens, and notebooks into a neat bag for papers with twisted handles. They’re practical, presentable, and reusable.

● Gift Packaging

Ditch the plastic gift bags. A twisted handle bag made of coloured or kraft paper, dressed up with tissue paper and a ribbon, is a stylish and sustainable alternative for birthdays, weddings, and other celebrations.

● Document Organisation

Need a neat way to separate and carry project papers or student assignments? Use medium-sized paper bags for papers with labels. It’s a tidy and eco-friendly system to manage your paperwork.

Choosing the Right Bag for Your Needs

With so many options out there, how do you select the perfect bag for papers? Here are a few tips:

Consider Size

Make sure the bag is large enough to accommodate standard document sizes (A4, A3, etc.) without folding. If you plan to carry folders, choose a size that allows a bit of extra space.

Handle Strength

For heavier loads or thicker documents, go for twisted handle paper bags that are reinforced and rated for extra weight.

Appearance

For business or formal use, stick to neutral tones like brown, white, or black. For parties or creative events, you can go bold with colours or patterns.

Supplier Trust

Buy from reputable sellers like Thepaperbagstore. Their experience in the industry ensures consistent quality and a wide range of choices.

Environmental Impact of Twisted Handle Paper Bags

Let’s not forget one of the biggest benefits of switching to paper bags: their minimal impact on the planet. Unlike plastic bags that can take hundreds of years to decompose, paper bags break down quickly and naturally. Plus, the manufacturing process of paper bags – especially when recycled materials are used – consumes fewer resources and results in less pollution.

Thepaperbagstore supports sustainable practices by offering products that are:

Made from recycled paper

Manufactured using water-based inks

Fully recyclable and compostable

By using twisted handle paper bags, you’re not just choosing a more practical bag for papers – you're contributing to a cleaner, greener environment.

Final Thoughts

In the growing world of sustainable alternatives, twisted handle paper bags prove that style, strength, and environmental responsibility can go hand-in-hand. Whether you need a reliable bag for papers, are looking for eco-friendly packaging, or want to add a branded touch to your retail space, these paper bags deliver across all fronts.

Choosing high-quality bags from Thepaperbagstore ensures you’re investing in products that are not only functional but also align with today’s values of sustainability and minimalism. So next time you need to carry paperwork or package products, think beyond plastic – think twisted handle paper bags.

0 notes

Text

Thermoformed Trays Market: Trends, Growth Drivers, and Future Outlook

The Thermoformed Trays Market is experiencing substantial growth as industries across the globe continue to recognize the advantages of thermoformed packaging. With their lightweight design, cost-effectiveness, and versatility, thermoformed trays have become a popular choice in sectors like food packaging, electronics, and pharmaceuticals. This blog delves into the current trends driving the thermoformed trays market and offers insights into future growth prospects.

Key Trends Shaping the Thermoformed Trays Market

The demand for thermoformed trays is being driven by several key trends that reflect the evolving needs of industries worldwide.

1. Sustainability Initiatives

As sustainability becomes a critical focus for manufacturers, thermoformed trays made from recyclable materials are gaining popularity. Consumers and businesses alike are increasingly prioritizing eco-friendly packaging options to reduce waste and carbon footprints. Thermoformed trays made from PET (polyethylene terephthalate), which is highly recyclable, are particularly in demand. Companies are investing in sustainable materials, such as biodegradable plastics and recycled content, to meet both regulatory requirements and customer preferences.

2. Customization and Consumer Preferences

Another trend in the Thermoformed Trays Market is the growing demand for customization. Manufacturers are adopting flexible thermoforming technologies to create trays in various shapes, sizes, and colors, catering to specific consumer needs. This customization is especially important in the food and beverage sector, where companies are seeking packaging solutions that offer convenience, branding opportunities, and extended shelf life for their products.

3. Technological Advancements

The continued advancement in thermoforming technology is another factor contributing to the market’s growth. Automation and the use of more sophisticated machinery are improving the efficiency and precision of thermoforming processes. These innovations allow manufacturers to produce complex, high-quality trays at lower costs, making them an attractive option for businesses looking to improve their packaging operations.

Growth Drivers in the Thermoformed Trays Market

Several factors are contributing to the growth of the Thermoformed Trays Market and are expected to continue driving demand in the coming years.

1. Food and Beverage Industry

The food and beverage sector is one of the largest consumers of thermoformed trays. These trays offer an efficient and cost-effective solution for packaging fresh produce, ready-to-eat meals, snacks, and baked goods. With an increasing global population and rising demand for packaged food, the market for thermoformed trays in this industry is expected to grow significantly.

Thermoformed trays provide benefits such as convenience, product protection, and easy handling for consumers. Additionally, these trays often feature features like tamper-evident seals, making them suitable for preserving the integrity of food products during transportation and storage.

2. Healthcare and Pharmaceuticals

Thermoformed trays are also gaining traction in the healthcare and pharmaceutical sectors. These trays are used for packaging medical devices, surgical instruments, and pharmaceutical products. Their ability to be molded into intricate shapes makes them ideal for protecting delicate items during shipping and handling.

As the global healthcare industry continues to expand, particularly in emerging markets, the demand for thermoformed trays in medical packaging is expected to increase. Moreover, the trend toward home healthcare solutions, which require smaller, more personalized packaging, further boosts the demand for thermoformed trays.

3. E-commerce and Logistics

The surge in e-commerce and online shopping is another driver behind the growth of the thermoformed trays market. As online retailers continue to experience significant growth, the need for efficient, protective packaging solutions becomes more critical. Thermoformed trays, with their ability to offer product protection while being lightweight, are a natural fit for e-commerce packaging.

The logistics sector is also benefitting from thermoformed trays due to their durability and ability to streamline packaging operations. They help reduce the risk of product damage during transit, ensuring that items arrive at their destination in excellent condition.

Challenges and Opportunities

While the Thermoformed Trays Market is experiencing strong growth, there are some challenges to consider.

1. Cost Fluctuations in Raw Materials

The cost of raw materials, such as plastics, can fluctuate significantly due to global supply chain disruptions and economic conditions. This volatility could impact the pricing structure of thermoformed trays, posing a challenge to manufacturers and consumers alike. However, this also presents an opportunity for innovation in material sourcing and development of cost-effective alternatives.

2. Regulatory Constraints

Stringent regulations regarding plastic packaging and waste management are forcing companies to adopt eco-friendly materials. While this shift is beneficial for the environment, it also presents challenges for manufacturers who need to comply with various national and international regulations. The development of biodegradable or recyclable thermoformed trays will play a key role in addressing these challenges.

Future Outlook for the Thermoformed Trays Market

The Thermoformed Trays Market is expected to continue its growth trajectory, driven by advancements in technology, increasing demand for sustainable packaging, and the expansion of industries like food packaging, healthcare, and e-commerce. As manufacturers invest in innovative solutions to meet the evolving demands of consumers and businesses, the market will likely see new opportunities emerge, particularly in the realm of eco-friendly and customized packaging.

In conclusion, the thermoformed trays market is poised for a bright future as companies across multiple industries increasingly recognize the benefits of thermoformed packaging. For businesses looking to stay ahead of the curve, investing in sustainable materials and advanced manufacturing techniques will be key to capitalizing on the growing demand for thermoformed trays.

For a deeper understanding of the market trends and growth prospects, explore our Thermoformed Trays Market report.

0 notes

Text

Rotomolded Containers Market Future Trends Highlight Asia-Pacific as the Fastest Growing Regional Consumer and Producer

Rotomolded containers, known for their durability, cost-effectiveness, and versatility, have emerged as a crucial component across a variety of industries such as agriculture, chemicals, pharmaceuticals, food & beverage, and logistics. As global supply chains evolve and environmental sustainability becomes a dominant theme, the rotomolded containers market is poised for significant growth and transformation in the coming years.

1. Increasing Demand Across Key Sectors

One of the most notable trends shaping the future of the rotomolded containers market is the rising demand in industries such as pharmaceuticals, food processing, and e-commerce logistics. These containers offer superior protection for sensitive goods and are particularly favored in cold chain logistics, where temperature control and hygiene are critical. Their seamless construction and resistance to impact, corrosion, and harsh environmental conditions make them ideal for both storage and transport applications.

The agricultural sector also continues to adopt rotomolded containers for transporting produce, seeds, and fertilizers. Their ability to withstand rugged conditions and repeated use without structural compromise makes them a cost-efficient long-term investment.

2. Eco-Friendly Manufacturing and Recyclability

Sustainability is no longer optional—it’s a global mandate. Manufacturers of rotomolded containers are increasingly integrating eco-friendly materials into their production processes. With greater emphasis on circular economies and reducing plastic waste, many companies are focusing on using recyclable and biodegradable raw materials.

Furthermore, the energy-efficient nature of rotational molding compared to other plastic manufacturing methods (like injection molding) aligns well with the market's shift toward green production technologies. These advancements will help businesses meet their environmental compliance requirements while also catering to environmentally conscious consumers.

3. Technological Innovations Driving Customization

Customization has become a key differentiator in today’s competitive industrial landscape. As a result, technological innovations in the rotomolding process now allow for the development of highly specialized and tailored container solutions. Whether it’s custom sizing, built-in compartments, RFID tracking capabilities, or enhanced insulation for thermal-sensitive goods—customers expect solutions that meet their exact needs.